2026 Buyers’ Guide

DTABC Boat Cruise Recap

Creating the Canadian Association of Dental Technology (CADT)

The Art of Porcelain Microlayering

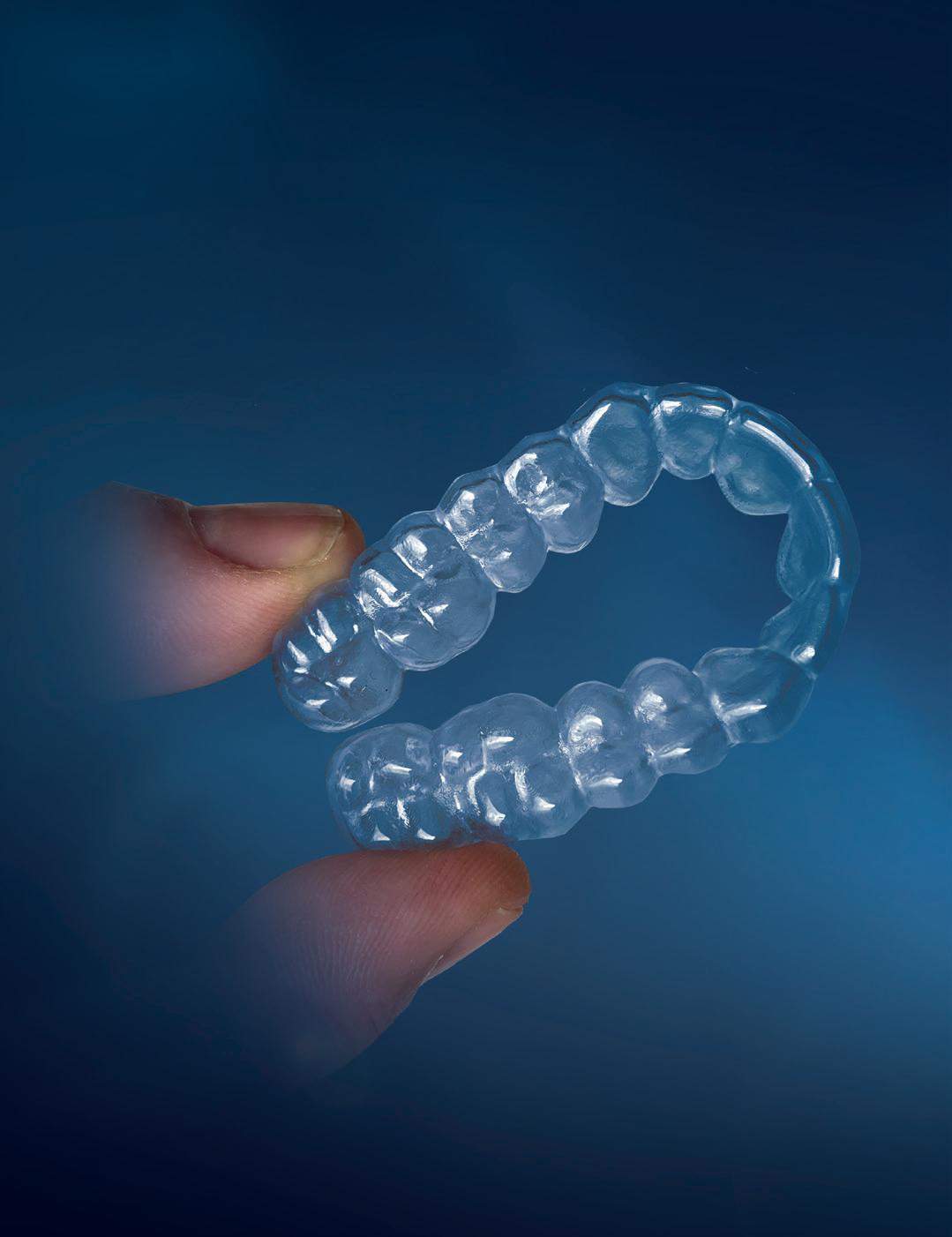

V-Print splint comfort

510k-Cleared, Thermo-flexible

3D Printing Splint Resin from VOCO

Comfortable and Effective for Them –Speed and Simplicity for You

A THERMO-FLEXIBLE, COMFORTABLE SOLUTION TO 3D PRINTED SPLINTS

High flexural strength and excellent wear resistance allow for devices as thin as 1 mm

Thermo-flexibility, biocompatibility, odorless and neutral flavor increases patient acceptance

Extremely fracture resistant and durable

Clear-transparent, easy to polish and color stable for excellent esthetics

No sedimentation – therefore, no shaking or “rolling” prior to use

V-Print splint comfort – bottle 1000 g clear – [9399275]

Also available from VOCO’s Digital Dentistry Line:

• FDA 510k Cleared

• CE Marked

• ISO Certified NO MIXING REQUIRED

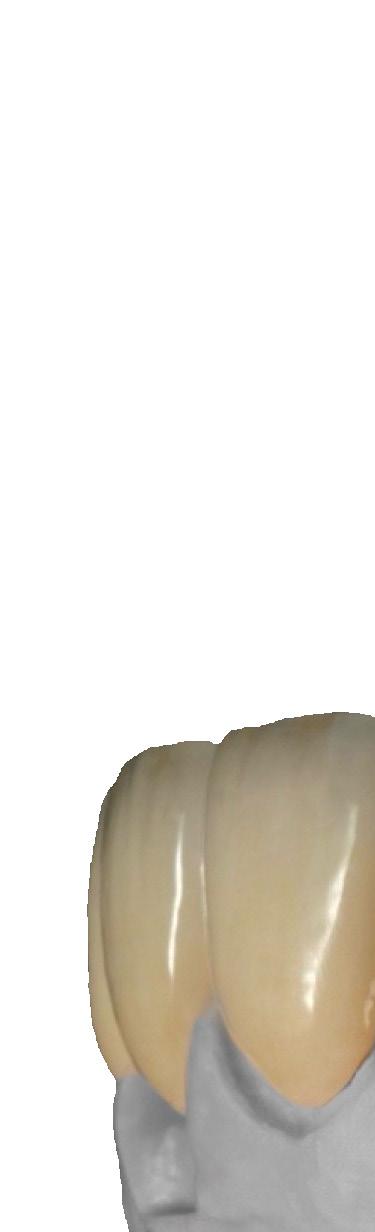

MultiColor

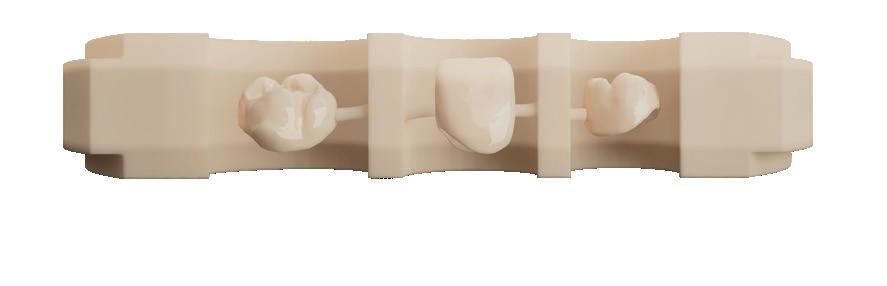

Nano-ceramic hybrid CAD/CAM disc with Invisible Layer Technology for Enhanced Esthetics

V-Print® splint · V-Print® c&b temp

V-Print® SG · V-Print® dentbase

V-Print® DT · V-Print® Try-In

V-Print® model 2.0

V-Print® tray · V-Print® cast

Validated for 3D printers from trusted partners like Asiga®, Ackuretta® and other fine 3D Printer Manufacturers

Asiga and Ackuretta are not registered trademarks of

NANO-CERAMIC HYBRID CAD/CAM DISC

86% filled for enhanced strength and excellent wear resistance

Toothlike elasticity and thermal expansion allows for thinner crown margins

Natural esthetics with enhanced color stability and polish retention

No firing required for true one-appointment dentistry

Easy intraoral polishability, characterization and repair

Available in 11 Vita shades, 2 transparencies and 6 MultiColor variations for enhanced, natural esthetics

98.4 mm × 15 mm size capable of up to 30 restorations per disc

Grandio disc MultiColor, most popular shade (A2) –[9992903]

Grandio disc MultiColor available in five other shades. Grandio disc available in 11 shades and two translucencies.

Incisal layer

Cervical layer

Basic tooth shade

SCAN TO LEARN MORE

SCAN TO LEARN MORE

WINTER 2025

90C Centurian Drive, Unit 211

Markham, ON L3R 8C5

Toll Free: 877-788-ADTO (2386) (within Ontario)

Telephone: 416-742-ADTO (2386)

Fax: 416-798-2613

www.adto.ca

12100 Riverside Way, MB #273 Richmond, BC V6W 1K5

Ashley Opitz, Office Administrator

Telephone: 604-278-6279

www.dtabc.ca

©2025 Craig Kelman & Associates Ltd.

All rights reserved. The contents of this publication may not be reproduced by any means, in whole or in part, without prior written consent from the publisher.

Published by:

DTABC 2025 Boat Cruise Recap

The annual DTABC boat cruise brought colleagues together to celebrate connection, craftsmanship, and the people who make our profession thrive.

3rd Floor, 2020 Portage Avenue

Winnipeg, MB R3J 0K4

Tel: 204-985-9780

Fax: 204-985-9795

Email: anna@kelman.ca www.kelman.ca

Managing Editor: Anna Savard

Design/Layout: Tabitha Robin

Marketing Manager: Chad Morrison

Advertising Coordinator: Sabrina Simmonds

Return undeliverable Canadian addresses to:

Craig Kelman & Associates

3C-2020 Portage Avenue

Winnipeg, MB R3J 0K4

Publication Mail Agreement: PM#40065075

In recent years, the dental technology profession in Canada has faced evolving challenges and unprecedented opportunities. The collaboration between the Association of Dental Technologists of Ontario (ADTO) and the Dental Technicians Association of British Columbia (DTABC) to form the Canadian Association of Dental Technology (CADT) marks a pivotal moment for the industry.

Dani Krivorot, a RDT Dental Technician and published author from Toronto, Canada, explores the art of porcelain microlayering using VITA YZ Multi Translucent.

The 15th annual Buyers’ Guide contains a list of industry products and services by alphabetical order and by category.

Box 397, 101-1001 West Broadway

Vancouver, BC V6H 4E4

90C Centurian Drive, Unit 211 Markham, ON L3R 8C5

Ashley Opitz, Administrative Assistant Toll Free: 1-888-495-4566

Toll Free: 1-877-788-ADTO (2386) (within Ontario)

Telephone: 604-278-6279

www.dentaltechniciansofbc.com

Telephone: 416-742-ADTO (2386)

Fax: 416-798-2613

www.adto.ca

ADTO PRESIDENT’S MESSAGE

Karim Sahil, MDT, RDT, President, Association of Dental Technologists of Ontario

Embracing AI: A New Era for Dental Technology

Dear ADTO Members,

DTABC BOARD OF DIRECTORS

ADTO EXECUTIVE BOARD OF DIRECTORS

As we welcome the winter season and reflect on the past year, our profession stands at the crossroads of tradition and innovation, and it is my privilege to address you during this transformative time.

PRESIDENT

PRESIDENT

Hal Hamilton, RDT

Karim Sahil, MDT, RDT

Embracing Artificial Intelligence in Dental Technology

VICE PRESIDENT

VICE-PRESIDENT

Shabana Mirza, RDT

Chris Opitz, RDT

TREASURER

John Eggeling, RDT

Nadja Jakobi, RDT

Aura Szigiato, RDT

Greg Tamkin, RDT

SECRETARY

Stuart Thomson

Sunny Cai, RDT

MANAGEMENT STAFF

EDUCATION

Malcolm Ashford Executive Director

Tiffany Lee, DD, RDT

Debra Orozco Blanco, RDT

MEMBER BENEFITS

DIRECTOR OF COMMUNICATIONS AND MEMBER SERVICES

Chris Ji, RDT

Zhe Lin, RDT

Renata Cecconi 604-940-2995

PAST PRESIDENTS

2016-2020 - Franklin Parada

2010-2016 - Jason Robson

2007-2010 - Gabriel Ghazal

2004-2007 - Stephen DeLuca

2003 - Michael Hrabowsky

2001-2002 - Al McOrmond

2000 - David Kochberg

1999 - Thomas Kitsos

1998 - Feliks Dawidowicz

1997 - Wilhard Barth

1996 - Bob Huybrechts

1994-1995 - Andre Theberge

1992-1993 - Michael Hrabowsky

1990-1991 - Jamie Matera

1989 - Joe Nagy

One of the most significant changes shaping our industry is the rapid advancement of artificial intelligence (AI). AI is no longer a distant concept – it is actively reshaping how we design, fabricate, and deliver dental prosthetics and appliances. From AI-driven CAD/CAM systems that enhance precision and efficiency, to machine learning algorithms that predict treatment outcomes and streamline workflows, these technologies are revolutionizing our daily practice.

While some may view these changes with apprehension, I encourage you to see AI as a powerful tool that can elevate our profession. By embracing AI, we can reduce repetitive tasks, minimize errors, and focus our expertise on the artistry and patient-centered aspects of dental technology.

Collaboration with DTABC: Building a National Voice

This year, I am excited to highlight our ongoing collaboration with the Dental Technicians Association of British Columbia (DTABC). Together, we are laying the groundwork for the creation of the Canadian Association of Dental Technology – a unified national body that will represent and advocate for dental technologists from coast to coast.

This partnership is more than a strategic alliance; it is a testament to our shared vision for the profession. By joining forces, we can amplify our voice on regulatory matters, promote best practices, and foster a sense of community among dental technologists/ technicians nationwide. The Canadian Association of Dental Technology will serve as a platform for knowledge exchange, professional development, and advocacy, ensuring that our interests are represented at the highest levels. I urge you to stay informed and engaged as this initiative progresses. Your input and participation are vital to shaping the future of our profession on a national scale.

Looking Ahead: The Future of Dental Technology

The future of dental technology is bright, but it will require us to be proactive, innovative, and united. I encourage each of you to seek out opportunities for professional growth – whether through advanced training, networking, or involvement in ADTO committees and events. Let us also remember the importance of mentorship and supporting the next generation of dental technologists. By sharing our knowledge and passion, we can inspire others to pursue excellence and uphold the highest standards of care.

Warm regards,

MDT, RDT

Karim Sahil, MDT, RDT President Association of Dental Technologists of Ontario

“AI is no longer a distant concept – it is actively reshaping how we design, fabricate, and deliver dental prosthetics and appliances.”

MB #273 - 12100 Riverside Way Richmond, BC V6W 1K5

Ashley Opitz, Office Administrator Telephone: 604-278-6279 office@dtabc.ca www.dtabc.ca

DTABC BOARD OF DIRECTORS

PRESIDENT

Will N. Varda, RDT, Anvarda Dental Services Ltd.

VICE-PRESIDENT

Calvin Moon, RDT, Moon Dental Technology Solutions

BOARD DIRECTORS

Mohammad Lashgary, RDT, Kinetic Dental Laboratory

Olaf Lutz, RDT, Okanagan Dental Lab Inc.

Chris Opitz, RDT, Shanto Dental Ceramics Ltd.

Justin Ku, RDT, D&R Dental Ceramics Ltd.

MANAGEMENT STAFF

Lih Fen Young, RDT Executive Director lih@dtabc.ca

Ashley Opitz Office Administrator office@dtabc.ca

PAST PRESIDENT

James Neuber, RDT, Ocean Ceramics Ltd.

Sachiyo Tsunemi

Will Varda, RDT, President Dental Technicians Association of BC

A Night on the Water, A Vision for the Year Ahead

Hello everyone!

I’m already looking back fondly on our inaugural DTABC boat cruise this past September. The event went even better than I could have imagined! It was a bit of a risk launching it, but everyone showed up with full support.

Our sponsors – Ivoclar, Roland, Central Dental, Zahn Canada, and Nobel Biocare – were incredibly generous and stepped up without hesitation. Not only did we completely break even, but thanks to Roland’s auction, we were also able to donate $2,500 to the BC Children’s Hospital.

Attendees from both DTABC and DABC arrived in great spirits and brought such positive energy, making it a truly fun and memorable day.

I’d like to once again thank all of our sponsors, and especially Lih, our Executive Director, for handling the event logistics. Knowing that our community is strong enough to make events like this possible means a lot to me. A special shout-out as well to Karim and ADTO for inspiring the idea of the boat cruise.

Just a quick reminder – membership renewals opened on November 1, so don’t delay! Your membership helps bring our community together for events like this

and gives you access to free lectures and conferences such as the PDC.

Finally, DTABC and ADTO are joining a newly formed national association to bring the voice of dental technicians to the federal level. This is an important opportunity to have our interests heard in a stronger, more unified way than ever before. As in-office milling becomes more prevalent –and increasingly influenced by AI and offshore design services – it’s vital that we demonstrate how irreplaceable our expertise is as healthcare professionals, and ensure that the standards and scope of practice maintained by RDTs across Canada continue to be respected. More details on the national association will emerge as we move further through its formation.

For now, may your milling tools not hit anything unexpected, your porcelain not crack, your software not crash, your difficult patients become satisfied, and your sintering program run all night long!

Cheers,

Will Varda, RDT President Dental Technicians Association of BC

Top 5 Mistakes That Cost Labs Their Best Accounts

Janice Wheeler, Senior Practice Analyst – Northbound Consulting Inc.

Losing a client is never fun, but when it’s one of your best accounts, the impact can be devastating. For dental labs, where relationships are everything, a single lost dentist can represent tens of thousands of dollars in lost revenue each year. The good news? Most labs don’t lose accounts because of their workmanship alone. More often, it’s preventable missteps in communication, service, or professionalism that send a great client looking elsewhere.

Here are the top five mistakes that cost labs their best accounts and how you can avoid them.

Mistake #1: Ignoring Communication

Dentists and their teams want updates, not radio silence. If a case is delayed, they need to know. If you receive a poor impression, they want a heads-up and a solution, not a lastminute scramble when the patient is already in the chair.

Why it costs you accounts: Silence erodes trust. Even a great product can’t make up for the stress of being left in the dark.

What to do instead: Communicate proactively. A quick call or email update reassures clients that you’re on top of things. Position your lab as a partner, not just a vendor, by always keeping the dentist’s schedule and patients in mind.

Mistake #2: Inconsistent

Quality

One crown looks beautiful, but the next needs a remake. Margins vary, shades don’t always match, and suddenly the dentist is doing extra work chairside to make things fit.

Why it costs you accounts: Dentists depend on consistency to run smooth appointments. Unreliable quality forces them to lose chair time, frustrates patients, and makes them question whether your lab is worth the risk.

What to do instead: Implement strict quality control. Standardize your processes and double-check each case before it leaves the lab. Consistency is as valuable as artistry, and it’s what keeps dentists coming back.

Mistake #3: Failing to Respect Timelines

Few things irritate dentists more than late cases. Even a technically perfect restoration isn’t worth much if it doesn’t arrive when promised. Why it costs you accounts: A late case disrupts schedules, upsets patients, and puts the dentist in the awkward position of apologizing for something outside their control. Eventually, they’ll look for a lab that delivers on time.

What to do instead: Be realistic about turnaround times and stick to them. Build in buffer space for rush requests and emergencies. And if a case truly can’t be finished on time, notify the office immediately with a proposed solution. Reliability often trumps speed.

Mistake #4: Overpromising and Underdelivering

In an effort to please, some labs say “yes” to everything: rush jobs, complex designs, impossible deadlines. But when they can’t deliver, the goodwill quickly turns sour. Why it costs you accounts: Broken promises feel like broken trust. Dentists don’t forget when they’ve rearranged a patient’s schedule only to have a lab miss the mark.

What to do instead: Be honest about your capabilities. If a request isn’t possible, explain why and suggest alternatives. Surprisingly, dentists often respect a lab more when it sets boundaries, as long as you deliver exactly what you do commit to.

Mistake #5: Treating the Relationship as Transactional

It’s easy to slip into seeing cases as numbers: impressions in, restorations out. But dentists want more than a product. They want a partner who helps them succeed, reduces their stress, and understands their preferences. Why it costs you accounts: If you treat the relationship as purely transactional, you leave the door wide open for another lab to come in offering more personal attention.

“The best labs don’t just make crowns and bridges, they make life easier for dentists and their teams.”

What to do instead: Invest in the relationship. Learn each dentist’s preferences and quirks. Send quick notes when cases go particularly well. Offer continuing education, share helpful tips, or even drop by with coffee once in a while. These small touches build loyalty that competitors can’t easily replace.

Final Thought

The best labs don’t just make crowns and bridges, they make life easier for dentists and their teams. Avoiding these five mistakes is less about changing your artistry and more about strengthening your professionalism and reliability.

When dentists see you as a partner who communicates clearly, delivers consistent quality, respects deadlines, sets honest expectations, and invests in the relationship, they have no reason to look elsewhere. In fact, they’ll go out of their way to keep sending cases to the lab they know they can trust … yours. And maybe, just maybe, they’ll refer their colleagues to you as well!

Janice Wheeler is the Senior Practice Analyst for Northbound Consulting Inc, a practice management company dedicated to helping professionals reach their full potential. For more information call 416-694-5005, email janicewheeler@northboundconsulting.ca, or go to www.northboundconsulting.ca.

Engineered for Precision. Designed for Ef ciency.

The Zirlux® brand has been a global leader in digital materials for years, trusted by dental labs worldwide for their esthetics, performance, and reliability.

The Zirlux® 3D Print Resins are the latest products to enter the Zirlux Digital Portfolio and are designed to integrate seamlessly into your existing work ow.

Whether you’re printing models, surgical guides, nightguards, or gingival masks, Zirlux® resins deliver the quality and reliability your lab depends on.

Model Print Resin Ivory (921-0034)

Model Print Resin Light Grey (921-0035)

Nightguard & Splint Print Resin Flexible (921-0037)

Nightguard & Splint Print Resin

(921-0036)

(921-0032)

Zirlux

Rigid

Zirlux Surgical Guide Print Resin (921-0033)

Zirlux

Zirlux

Zirlux

Zirlux Gingiva Mask Print Resin

Boat Cruise 2025 2025

Photo credit: Kayjaye Studios

Photo credit: Kayjaye Studios

Photo credit: Kayjaye Studios

Photo credit: Kayjaye Studios

Photo credit: Kayjaye Studios

Uniting for a National Voice:

The Collaboration of ADTO and DTABC in Creating the Canadian Association of Dental Technology (CADT)

STRENGTHENING THE FUTURE OF DENTAL TECHNOLOGY THROUGH COLLABORATION AND COLLECTIVE ADVOCACY

Introduction

In recent years, the dental technology profession in Canada has faced evolving challenges and unprecedented opportunities. The collaboration between the Association of Dental Technologists of Ontario (ADTO) and the Dental Technicians Association of British Columbia (DTABC) to form the Canadian Association of Dental Technology (CADT) marks a pivotal moment for the industry. This unified approach aims to give dental technologists and technicians a strong, national voice, fostering innovation, advocacy, and professional growth across all provinces. In this essay, we will explore the significance of this collaboration, the necessity of a national voice, and the critical importance of unifying the profession in today’s rapidly changing landscape.

The Need for a National Voice in Dental Technology

Canada’s dental technology sector, while highly skilled and innovative, has historically been fragmented, with each province operating under its own regulatory frameworks and professional standards. This fragmentation has often led to inconsistencies in practice, limited influence on national policy, and missed opportunities for collective advancement. By establishing CADT, ADTO and DTABC are addressing these challenges head-on, paving the way

for a unified voice that can advocate for the profession’s interests at the federal level.

A national association like CADT is crucial for several reasons. First, it enables dental technologists and technicians to speak with one voice on matters affecting the profession, such as education standards, regulatory changes, and technological advancements. Secondly, it positions the profession to better engage with government agencies, educational institutions, and other stakeholders in shaping the future of oral healthcare in Canada. Finally, it fosters a sense of unity and shared purpose among professionals, promoting best practices and elevating the industry’s reputation nationwide.

The Importance of Collaboration:

ADTO and DTABC Leading the Way

Collaboration between provincial associations is not merely an option – it is a necessity in today’s interconnected world. The decision by ADTO and DTABC to join forces stems from a recognition that the challenges facing dental technologists and technicians are too complex and far-reaching to be addressed by individual provinces alone. Issues such as technological innovation, workforce development, regulatory harmonization, and public awareness require coordinated action and shared resources.

ADTO and DTABC bring unique strengths to this partnership. ADTO, representing the largest province by population, has extensive experience in regulatory affairs, public outreach, and continuing education. DTABC, with its innovative approach and strong ties to the Pacific region’s dental community, offers valuable perspectives on emerging trends and technological adoption. By combining their expertise, resources, and networks, these organizations are setting a powerful example of what can be achieved through collaboration.

Unifying the Provinces: Building a Collective Voice for Dental Technology

The creation of CADT is about more than merging organizations – it is about forging a new identity for dental technology professionals across Canada. Unifying all provinces under one association enables members to share knowledge, advocate for common interests, and develop consistent standards of practice. This collective voice is essential for influencing policy decisions, securing funding for research and education, and ensuring that dental technologists/ technicians remain at the forefront of change in oral healthcare.

Provincial differences in licensing, education, and practice standards have historically created barriers to mobility

and collaboration. CADT aims to break down these barriers, facilitating dialogue among provinces and promoting harmonization of standards. This not only benefits practitioners by making it easier to move and work across the country but also improves patient outcomes by ensuring high-quality care regardless of location.

Why Collaboration Is More Critical Than Ever

The dental technology profession is undergoing rapid transformation, driven by advances in digital dentistry, 3D printing, biomaterials, and artificial intelligence. These innovations present both opportunities and challenges, requiring practitioners to adapt quickly and continually update their skills. In this environment, collaboration is more important than ever. By working together, ADTO and DTABC – and soon, other provincial associations – can pool resources to provide robust professional development, share research, and ensure access to cuttingedge technologies for all members.

Furthermore, the healthcare landscape in Canada is evolving, with increasing emphasis on interdisciplinary collaboration and

patient-centred care. Dental technologists and technicians must ensure their voices are heard in these discussions to protect their scope of practice and advocate for the profession’s unique contributions. CADT’s unified approach strengthens the profession’s position in these conversations, ensuring that changes in dental technology are shaped by those with the expertise to understand their implications.

Commitment to Professional Advocacy and Change

ADTO and DTABC’s commitment to forming CADT is a testament to their dedication to the profession and its future. The guiding principle behind this initiative is clear: changes in dental technology must reflect the needs and perspectives of dental technologists and technicians. Only through a strong, unified voice can the profession ensure that its interests are protected and advanced.

CADT will prioritize advocacy, education, and ethical practice, working tirelessly to ensure that dental technologists/technicians are recognized as essential members of the oral healthcare team. The association will actively engage with policymakers,

educators, and industry leaders, promoting policies that support innovation, patient safety, and professional growth. Above all, CADT will maintain an unwavering commitment to representing the profession’s interests, ensuring that its voice remains central in shaping the future of dental technology in Canada.

Conclusion

The collaboration between ADTO and DTABC to create the Canadian Association of Dental Technology represents a transformative step forward for the profession. By uniting under a single, national association, dental technologists and technicians are better equipped to navigate the challenges and seize the opportunities of a rapidly changing industry. The importance of a national voice cannot be overstated, nor can the need for ongoing collaboration among provinces. CADT promises to be a catalyst for positive change, empowering dental technology professionals to lead the way in shaping the future of oral healthcare in Canada. Through unity, advocacy, and collective action, we will ensure that the profession’s voice remains strong and its contributions recognized for years to come.

Restoring Smiles, Reviving

The Art of Porcelain

Microlayering

Dani Krivorot

Porcelain

“As a dental technician, I understand that most patients don’t know how to evaluate or communicate their expectations. That’s why I ask guiding questions: Do you like the current length? What about the shade – brighter or more natural? Do you have a photo reference?”

Consultation

Meet patient ‘D.’

Patient D restored her upper anterior teeth twenty years ago and has disliked her smile ever since.

Now, more than two decades later, she returned with a fractured central incisor that required an implant. She ultimately chose to replace both her central and lateral incisors, keeping the old restorations on her canines intact. When I was called in for a brief consultation and shade selection, I found myself at a loss – not because she was difficult or demanding, but because she couldn’t articulate what she did or didn’t like about her old crowns.

As a dental technician, I understand that most patients don’t know how to evaluate or communicate their expectations. That’s why I ask guiding questions: Do you like the current length? What about the shade –brighter or more natural? Do you have a photo reference?

Patient D had only one response: “I don’t know.”

She explained that she hadn’t smiled properly in a very long time, constantly anxious about how her teeth looked. I felt deeply empathetic. This woman had spent a significant amount of money on something she unfortunately regretted. While I believe in self-advocacy, I also recognize that not everyone is outspoken by nature. Her inability to pinpoint what bothered her made it difficult for me to determine the best approach (Figures 1 and 2).

She mentioned that she liked her flipper, which was shorter and slightly brighter than her original crowns. Her natural lower teeth were heavily stained, so I disregarded them entirely during the consultation. The dentist and I showed her a few shades from the VITA Universal and 3D-Master shade guides. She didn’t like the bright bleached shades (0M1–0M3) but gravitated toward a more natural white. We settled on 2M1, but the rest was left up to me (Figure 3).

Back at the lab, I analyzed this case and drew several conclusions. First, her teeth were too bulky facially. They pushed her lip out in an unnatural way. Flattening them slightly and curving the incisal edges inward would help correct this issue. Second, the crowns were too long. One canine was longer than the other, and the original crowns matched the length of the longer one. I decided to shorten the centrals for better balance, making them slightly shorter than her shortest canine to avoid a ‘vampiric’ look. I also considered her preference for the flipper’s shorter length. I liked the feminine curvature of her original crowns, so I wanted to keep the overall shape but make it more refined, with added texture on the facial surface. Finally, while her original crowns were close to a low-value 2M1, I aimed to make the new ones slightly brighter, while still maintaining a natural, ‘age-appropriate’ shade. Her crowned canines had a harsh transition between the gingival and middle thirds (2M3 abruptly to 2M1). I opted for a softer, more natural gradient to eliminate this abrupt colour change. Once I had a plan in mind, I started on the case.

Digital Designing

The first step was covering the titanium abutment with a zirconia one. Since I needed to flatten the crowns to reduce bulkiness, I didn’t want the patient’s stump shade or the titanium implant to shine through and alter the zirconia’s colour. By designing a zirconia abutment to be cemented onto the titanium one, I eliminated the risk of a grey zirconia core. I also opaqued the intaglio of the crowns pre-sinter with a white opaque liquid. This helped mask the underlying stump shade and gave me a clean, white base to work with.

Before sintering, I used a small amount of pre-sinter stain on the zirconia abutment to bring warmth into the implant restoration –

a decision I later regretted (Figure 4). Even the tiny bit of stain I applied ended up shining through the zirconia crown, slightly altering the shade. This wasn’t a major issue, as I later needed to stain the remaining zirconia crowns before porcelain application, to achieve a warmer basal colour.

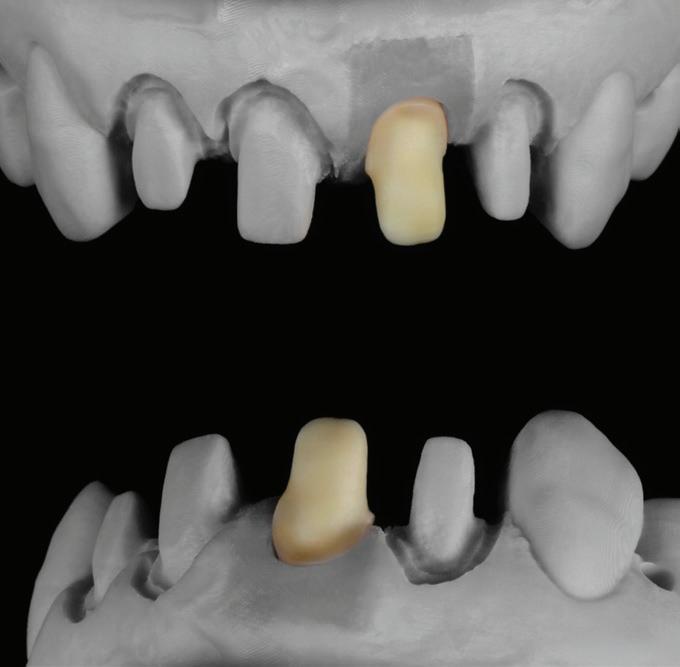

Microlayering is one of my favourite techniques when the case allows for it. Patient D had a significant overbite, so I wanted to ensure the porcelain was protected during excursive movement. When designing this case, I flattened the facial surface and left ample room to apply porcelain – especially at the gingival third (where chroma is established) and the incisal third (where translucency and age characteristics are shown).

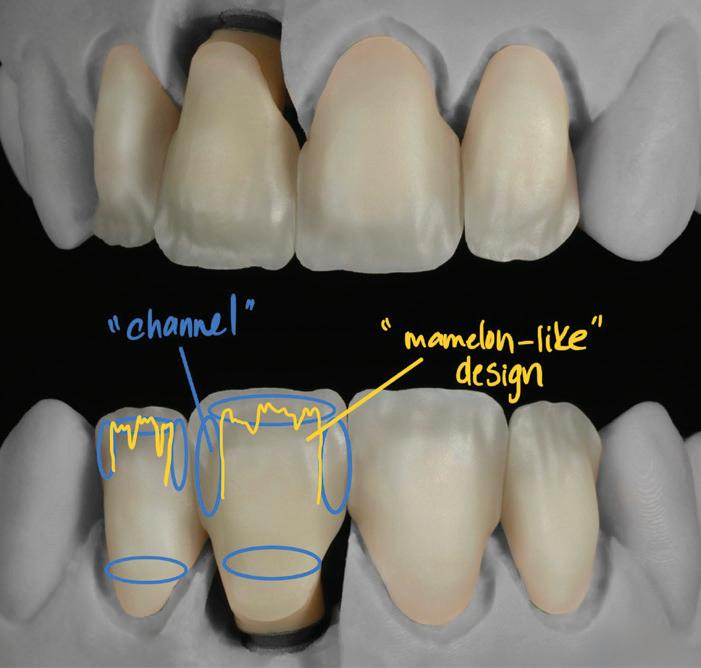

To achieve this, I reduced the zirconia to about 0.6 mm thickness at the gingival and middle third and created a ‘channel’ right below the incisal edge. This gave me the necessary space to internally stain and stack porcelain. I designed mamelon-like structures in the incisal third to break up the surface and create uneven light reflection. I say ‘mamelon-like’ because, at Patient D’s age, true mamelons should likely not be present, and incisal translucency should be minimal (Figure 5).

Every patient is different, which is why consultations, high-quality dental photography, and strong lab–clinic communication is all essential in esthetic anterior cases.

Internal Stain

For this case, I decided to use VITA’s new YZ MT zirconia. I’m already familiar with the YZ ST (Super Translucent) Multicolor, a polychromatic 4Y zirconia with 46% translucency, and the YZ XT (Extra Translucent) Monocolor, a monochromatic 5Y zirconia with 50% translucency. Recently, VITA introduced the MT – a ‘MultiTranslucent’, multi-layered, multi-gradient 4Y–5Y zirconia with 46%–50% translucency, available in a wide range of shades perfectly matched to the VITA shade guides.

For this case, I selected an A2 shade and positioned it higher in the puck to achieve more translucency and less chroma, resulting in a slightly lower value. This choice complemented her grey-tinged crowned canines, likely caused by the underlying lithium disilicate substructure combined with a thick layer of translucent enamel porcelain.

I prefer choosing slightly more chromatic shades – whether it be in internal staining, dentin layering, or zirconia selection – because the addition of enamels and translucent layers predictably lightens the final restoration.

When internally staining a micro-layered restoration, I begin by lightly glazing the porcelain-bearing surface to fill microporosities and break surface tension, ensuring smoother stain application. The glaze must not be too wet, or stains will run and mix together.

Next, I establish the body shade. For this case, I went slightly darker to offset the lighter

porcelains and enamels planned for later. I applied ES04 (yellow) at the gingival third and feathered it into the middle third, creating a soft gradient. Because we aimed for a 2M1 shade with minimal details, I skipped adding dark stains at the neck or interproximals.

In the incisal third, I avoided pronounced mamelons and excessive translucency to keep the look age-appropriate. I applied ES11 (blue) to the crown’s incisal corners and down the line angles. To mimic deeper translucency, I mixed ES13 (light grey) with ES14 (black) to create a dark grey and placed it in small sections beneath the incisal edge, in the trough-like cavity I had designed earlier. Beside these dark grey areas, I applied ES07 (green-yellow) for contrast.

The underlying prep shape created a harsh outline in the zirconia, so I ‘floated’ ES02 (cream) upward to break it up. Finally, I added ES02 along the incisal edge to form a subtle halo effect (Figure 6).

Once satisfied with the staining, I sprinkled Effect Liner 2 over the surface to enhance fluorescence, then baked it using VITA VM9’s preinstalled ‘First Dentine Bake’ program.

TIP: Avoid having the stained surface come out shiny or glossy, as this indicates high temperature and will result in a loss of surface roughness for mechanical porcelain adhesion. The ideal surface remains slightly rough in texture and underbaked in appearance.

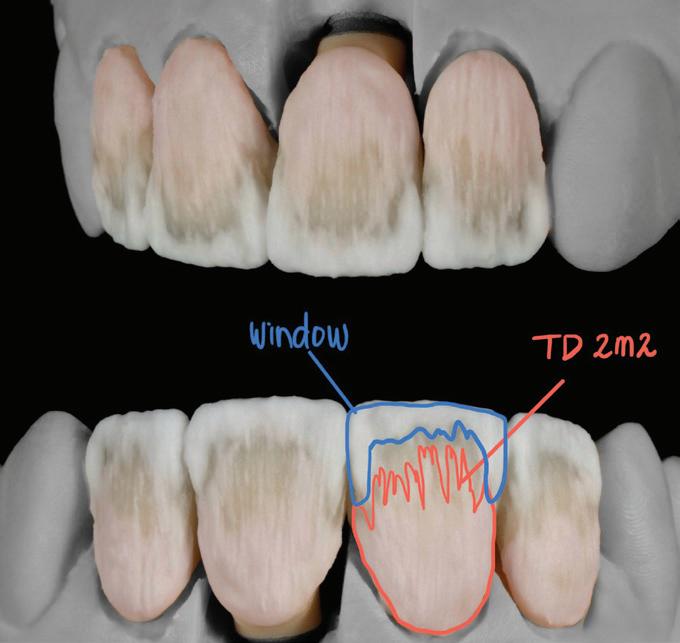

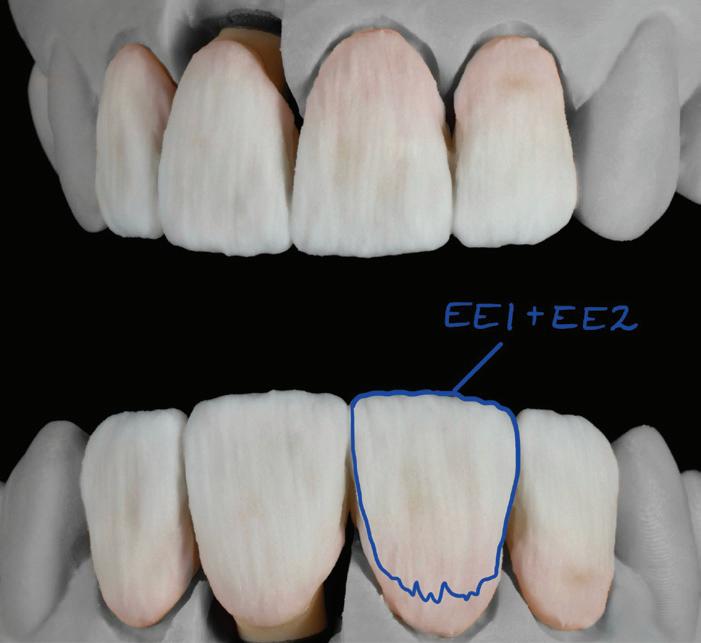

Figure 1 Pre-operative picture from patient D. Figure 2 Temporary crown. Figure 3 Shade selection for Patient D’s new crowns. Figure 4 Zirconia abutment.

Figure 5 Design markings. Figure 6 Internal stain map.

Sprinkling porcelain can be considered controversial – some see it as unnecessary, others swear by it. I find it adds an extra bonding layer between the first and second porcelain applications, in addition to sandblasting before staining. Both methods create surface texture for mechanical retention and irregular light reflection. Choosing a highly fluorescent powder also brightens the restoration from within, though the layer itself needs to be thick enough to actually make a significantly noticeable difference. All that to say, results and personal experience will vary, so I encourage you to experiment for yourself.

Stacking Porcelain – First Bake

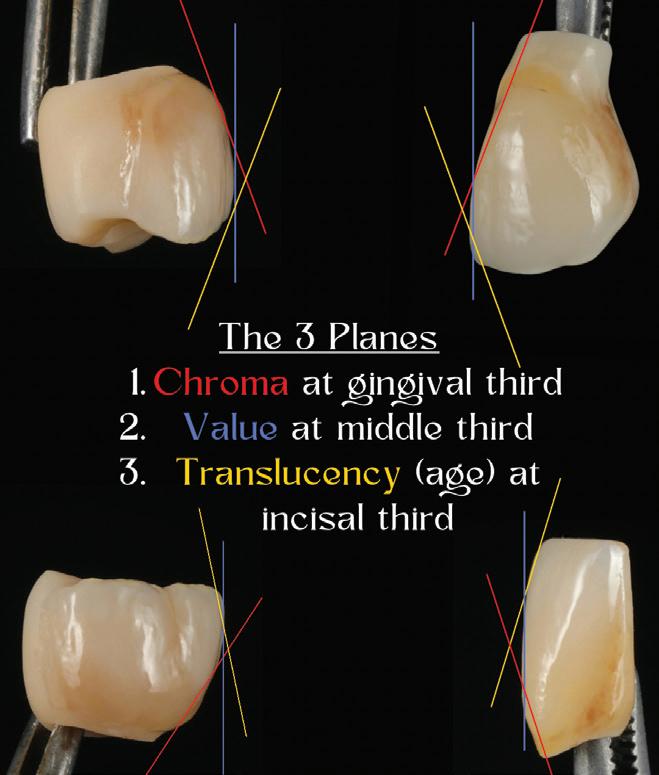

I find that, after over a decade of stacking porcelain, I do so intuitively. How and where I start layering porcelain depends on my circumstances. If the zirconia substructure is too light, I start by adding chroma in the gingival third. If my substructure is too bright, I might begin in the middle third and focus on adjusting the value before moving on to less important details. If I’m happy with my base – as I was in this case – I’ll turn my attention to ‘protecting’ (or securing) the illusion of incisal translucency I painted on in the previous layer and then focus on highlighting the three planes of an anterior tooth: the gingival (chroma), middle (value), and incisal (translucency or age) thirds – a concept I learned from Peter Pizzi (Figure 7).

In the past, I found that much of my internal stain or buildup would go to waste once I began layering dentine and enamel porcelains overtop. This was likely due to them being covered with more opacious and/or chromatic materials that masked the

“Every patient is different, which is why consultations, high-quality dental photography, and strong lab–clinic communication is all essential in esthetic anterior cases.”

intricate details I painted underneath. To avoid this, I started covering the stained incisal edge with a thick layer of Window (AKA Clear) porcelain, working my way slightly down onto the ridges, where I stained them ES11 (blue) previously (Figure 8).

TIP: As a rule of thumb, the more translucent a porcelain, the lower the value it will appear. I’ve found that when I use too much clear ceramic, it can substantially lower the value of the restoration as a whole. However, value is typically lower around the incisal third, as that is where a tooth generally exhibits the most translucency. I’ll later add enamel porcelains overtop the clear layer, but since it will be a thinner coating – just to shape the incisal edge of the crown – it won’t be thick enough to cover the staining work done beneath.

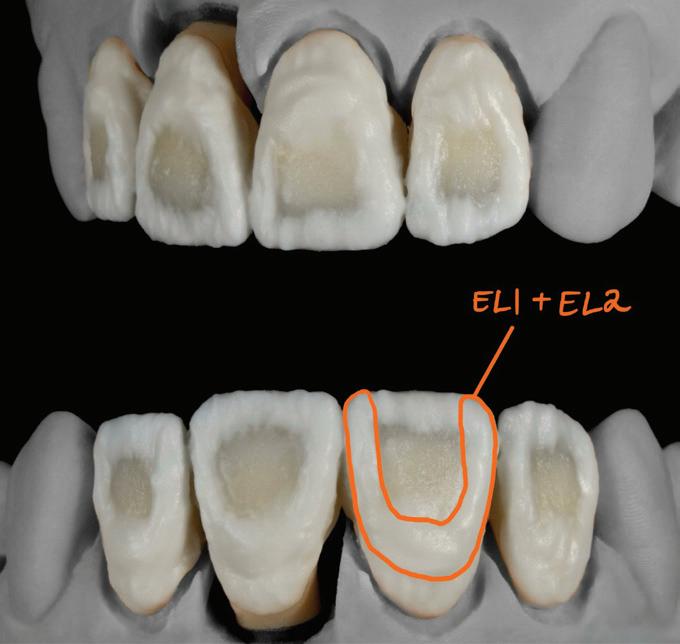

Once I’ve secured the incisal stains with the Window porcelain, I move on to establishing chroma in the gingival third. For this, I used Effect Chroma – specifically, a mix of EC1 and EC2 – which I placed above the margin in a wedge-like shape (Figure 9).

Next, I work on highlighting the convex areas, since they are the most light-reflective. I do this by placing Effect Liner material –specifically, EL1 mixed with EL2 – which together enhance light reflection while complementing the 2M1 final shade. I typically apply Liner material on the ridges and the height of contour, both of which are the most convex areas of a tooth and which, with added fluorescence from the Liner material, imitate natural light reflection (Figure 10).

Finally, for this first porcelain build-up bake, I placed 2M1 Base Dentine in the middle third of the crown to establish both the base color and value of the finished restoration. Base Dentine helps establish the foundation of the shade and is slightly more opaque and chromatic compared to Transpa Dentine. I place a layer in the middle third, above the Liner, and feather it upward – thinning out the layer as I approach the incisal third. The feathering helps avoid any harsh transition lines. I’m lucky to have both the Universal and 3D-Master ceramic shades in the lab, because it takes a lot of the guesswork out of converting shades from one guide to another (Figure 11).

Once I finished this step, I baked the crowns using the same ‘First Dentine Bake’ program that was used for the stain and sprinkle layer. In theory, each bake should be a few degrees lower than the one before it – but this also depends on how thick the subsequent porcelain layer is and how many crowns are being baked at one time, since heat disperses. In this case, I used the same parameters as the First Dentine Bake program.

Stacking Porcelain – Second Bake

Since the first bake’s primary focus was to establish chroma, value, and translucency, and is severely under-contoured, there’s not much to trim at this point. After removing the crowns from the furnace, I evaluated the bake. Comparing the first bake to the shade guide helps determine my next steps – whether that’s another thin layer of stain or a mix of ceramic powders to correct or adjust the chroma and value (Figure 12).

7 Figure 7 The three planes of a tooth.

Figure 8 Placement of Window porcelain. Figure 9 Placement of Effect Chroma.

For the second bake, I started by layering 2M2 Transpa Dentine in a wedge-like shape in the gingival third to deepen the chroma in that area. I also added another thin layer of Window (clear) porcelain in the incisal third, to build up the thickness in that region before layering enamel overtop (Figure 13).

Next, I used 2M1 Transpa Dentine and placed it on and slightly above the 2M2 Transpa Dentine, feathering it up into the middle and incisal thirds. This helped achieve a more natural gradient and break up any harsh lines.

Finally, I applied a 1:1 mixture of Effect Enamel 1 and Effect Enamel 2 to create a custom blend of enamel. I layered it over the entire tooth, concentrating the bulk of the material in the middle third and thinning it toward the gingival third. In natural dentition, the thickest enamel is typically found in the middle third, which often results in slightly lower value in that area. Conversely, the gingival third has more dentin, resulting in increased chroma and decreased translucency. I try to replicate this esthetic by mimicking natural layering patterns (Figure 14).

I baked these crowns using the ‘Second Dentine Bake’ program on the VITA furnace, which runs about 10 degrees cooler than the previous bake.

“I prefer using powder stains because I feel they offer more control over both consistency and colour. I always stain and glaze separately to prevent slumping, running, or mixing of the stains.”

Stacking Porcelain – Third Bake

After removing the restorations from the furnace and adjusting the contacts, I re-evaluated the crowns. The basic shape, shade, and value were now established, but a few things stood out to my trained eye (Figure 15).

First, I noticed I hadn’t feathered the dentine far enough into the incisal third, resulting in more translucency than I wanted for this patient. Second, I wanted to give the teeth a more pronounced, feminine morphology by introducing curvier line angles. I also felt the facial surface, after trimming, looked a bit too flat and twodimensional. Finally, while I didn’t want to match the grey tone of her existing canines, I also didn’t want the crowns I was building to appear too bright in comparison.

To correct these issues, I placed 2M1 Transpa Dentine in mamelon-like shapes between the middle and incisal thirds,

stretching the shade farther into the incisal area to reduce the excessive translucency. I also took some ENL (Enamel) porcelain and applied a thin layer across the entire surface of the crown, building and reshaping the line angles and height of contour as I went. Both of these porcelains were mixed with VITA AKZENT PLUS Powder Glaze Liquid – NOT build-up liquid (Figure 16).

After refining the contour and line angles, I finished the stack with a small amount of 2M1 Transpa Dentine right along the incisal edge, enhancing the morphological character of the crown and deepening the ‘halo’ we had earlier stained with a Cream shade (Figure 17).

TIP: Glaze liquid has a higher glycerin content than build-up liquid, giving it a thicker, slightly sticky consistency. When mixed with ceramic, it gives the porcelain a tacky feel, making it easier to pick up with

Figure 10 Placement of Effect Liner porcelains. Figure 11 Placement of Base Dentine porcelain. Figure 12 The result after the first porcelain bake. Figure 13 Placement of Transpa Dentine. Figure 14 Enamel Effect placement. Figure 15 The result of the second bake.

just the tip of your brush and place precisely where needed. This is a great technique when building mamelons or other internal effects with porcelain, as you can stack completely different powders side by side –or even on top of each other – without them running or blending together. The only catch? You’ll need to add an extra minute of dry time to your bake. A fair trade, if you ask me!

External Stain

Once the final correction layer is baked and trimmed, I finish the restoration with external stain and glaze. I prefer using powder stains because I feel they offer more control over both consistency and colour. I always stain and glaze separately to prevent slumping, running, or mixing of the stains.

Patient D wanted clean, natural-looking teeth that resembled the crowns she already had, so heavy staining wasn’t necessary. Although simple, the build-up layers had already done much of the work for me.

I reapplied ES02 (Cream) along the incisal edge, pulling the color down slightly with the tip of my brush to create fine crack lines and break up an otherwise solid halo. Finally, to give the restoration a slightly warmer look, I added a touch of ES04 in the gingival third – right at the margin and in the interproximals. This not only created a warmer, more natural gradient, but also gave the restoration some depth in those tight areas. Even a slight darkening in the interproximals creates the illusion of shadow, visually separating the teeth.

I baked the crowns on a ‘Fixation’ program – a quick bake at a low temperature without vacuum – meant to adhere the stains to the surface. Once dry, I mixed Powder Glaze to a thick, honey-like consistency and applied a thin layer to break surface tension. I do this roughly, allowing it to fill in any micro-porosities (Figure 18).

TIP: I like working with a thicker glaze consistency because it behaves like

porcelain, staying exactly where it’s placed. You can easily tighten contacts, sharpen incisal corners, and even add length – especially when mixed with a bit of porcelain. Most of my texture work is additive, whether I’m using porcelain or glaze. I can create perikymata and more aggressive surface textures in the concave areas of the tooth, while keeping the convex areas smoother and more light-reflective. All of this is made easier by being able to control the consistency – something much more flexible with powders than with pastes.

After making corrections and applying texture with a thin brush and Powder Glaze, I bake the crowns one final time using the ‘Powder Glaze’ setting. This is slightly higher in temperature than the Fixation Bake, but significantly cooler than any of the porcelain bakes, to prevent the porcelain from slumping.

Once the bake is complete, I high-polish the lingual surfaces of the crowns and the tissue-bearing surfaces of the zirconia abutment to promote tissue growth and adaptation. Finally, I cement the crown onto the zirconia abutment and – voilà! –a new smile.

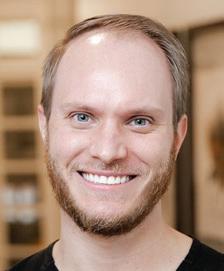

Patient D was thrilled with the result. Although she couldn’t articulate exactly what she didn’t like about her original crowns, she knew what she liked when she saw it. The dentist delivered the case to a happy patient – one who now has twenty years of smiling to make up for (Figures 19-22).

(Krivorot D. Restoring Smiles, Reviving Confidence. Inside Dent Tech. 2025 Oct;16(8):13-18. Copyright © 2025 to Conexiant LLC. All rights reserved. Used with permission of the publisher.).

Figure 16 Placement of TD 2M1 and ENL. Figure 17 Final layering prior to last bake. Figure 18 External stain and glaze results.

Figure 19 Picture prior to restoration. Figure 20 Picture before and after restoration. Figures 21-22 After intraoral results.

2026 Buyers’ Guide

Welcome to the 15th annual Dental Technology Today Buyers’ Guide. When making purchasing decisions about products and services in the dental technology industry throughout British Columbia and Ontario, please support the companies whose advertising makes Dental Technology Today possible.

This Buyers’ Guide consists of two sections: a categorical listing of products and services, including a list of companies that provide them, and an alphabetical listing of all the companies appearing in the Guide. This alphabetical listing includes the company’s name, contact information, and website.

Categorical Listing

EQUIPMENT

3D PRINTERS

Argen Canada

Roland DGA

Unique Dental Supply Inc.

Zirkonzahn

AIR ABRASION UNITS

Zahn Canada, A Division of Henry Schein Canada

AIR PURIFIERS

Argen Canada

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

ARTICULATORS AND ACCESSORIES

Argen Canada

Ivoclar Vivadent Inc.

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

Zirkonzahn

AUTOCLAVES

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

BURNERS, ELECTRIC AND GAS

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

BURNOUT TRAYS

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

CAD/CAM

Argen Canada

Ivoclar Vivadent Inc.

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

Zirkonzahn

CALIPERS

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

CASTING, MACHINES AND ACCESSORIES

BEGO Canada Inc.

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

Zirkonzahn

CLEANERS, AIR, AIR/WATER, STEAM, ULTRASONIC

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

COMPUTER, HARDWARE, SOFTWARE

Argen Canada

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

Zirkonzahn

CURING UNITS, LIGHT, WATER PRESSURE AND HEAT, VACUUM

Argen Canada

BEGO Canada Inc.

Unique Dental Supply Inc.

VOCO Canada

Zahn Canada, A Division of Henry Schein Canada

DENTAL MILLING MACHINES

Argen Canada

Roland DGA

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

Zirkonzahn

DENTURES, ACRYLIC PROCESSORS, FLASKS, INJECTION MOLDING, PRESSES

Ivoclar Vivadent Inc.

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

DUST COLLECTORS AND CABINETS

Argen Canada

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

ELECTROFORMING AND ELECTROPLATING EQUIPMENT AND ACCESSORIES

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

FACEBOWS

Ivoclar Vivadent Inc.

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

FURNACES, BURNOUT, PORCELAIN, PRESSABLE, VACUUM

Argen Canada

BEGO Canada Inc.

Ivoclar Vivadent Inc.

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

Zirkonzahn

FURNITURE

BEGO Canada Inc.

Zahn Canada, A Division of Henry Schein Canada

GAUGES AND CALIPERS

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

HANDPIECES, ELETRIC, BELT, AIR-DRIVEN, MICROMOTORS

BEGO Canada Inc.

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

INVESTING UNITS AND ACCESSORIES

BEGO Canada Inc.

Ivoclar Vivadent Inc.

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

KNIVES

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

LAMPS AND LIGHTING

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

MAGNIFYING EQUIPMENT

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

MILLING MACHINES AND INSTRUMENTS

Argen Canada

Ivoclar Vivadent Inc.

Roland DGA

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

Zirkonzahn

MIXERS, VACUUM AND INVESTING

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

PALETTES, PORCELAIN

Ivoclar Vivadent Inc.

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

PIN SETTING SYSTEMS AND ACCESSORIES

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

PLASTER, BINS, NIPPERS, TRAPS, SPATULAS

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

POLISHERS AND GRINDERS

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

Zirkonzahn

POSTS

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

PRESSURE POTS

BEGO Canada Inc.

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

PUMPS, VACUUM

Ivoclar Vivadent Inc.

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

SAFETY EQUIPMENT

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

SANDBLASTERS AND ACCESSORIES

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

SAWS AND ACCESSORIES

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

SHADE GUIDES

Argen Canada

Ivoclar Vivadent Inc.

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

Zirkonzahn

SOLDERING EQUIPMENT AND ACCESSORIES

BEGO Canada Inc.

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

SPLASH HOODS

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

STUDY MODELS

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

SUCTION DRAWERS

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

TORCHES

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

TRIMMERS, MODEL AND ACCESSORIES

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

VIBRATORS

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

WATER BATHS

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

WAXING EQUIPMENT AND ACCESSORIES

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

MATERIALS

ACRYLICS

Argen Canada

Ivoclar Vivadent Inc.

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

ADHESIVES, BONDING AGENTS, CEMENTS

Ivoclar Vivadent Inc.

Unique Dental Supply Inc.

VOCO Canada

Zahn Canada, A Division of Henry Schein Canada

ALGINATES

Ivoclar Vivadent Inc.

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

ALLOYS, CERAMIC, CROWN & BRIDGE, IMPLANT, DENTURE, TITANIUM

Argen Canada

BEGO Canada Inc.

Ivoclar Vivadent Inc.

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

Zirkonzahn

CASTING, FLUX, SOLDER

Argen Canada

BEGO Canada Inc.

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

CEMENTATION

Ivoclar Vivadent Inc.

VOCO Canada

Zahn Canada, A Division of Henry Schein Canada

CERAMICS

Argen Canada

Ivoclar Vivadent Inc.

Zahn Canada, A Division of Henry Schein Canada

Zirkonzahn

COMPOSITE RESINS

Argen Canada

Ivoclar Vivadent Inc.

VOCO Canada

Zahn Canada, A Division of Henry Schein Canada

DENTURE CARE

VOCO Canada

Zahn Canada, A Division of Henry Schein Canada

Zirkonzahn

DENTURES, FULL AND PARTIAL

Argen Canada

BEGO Canada Inc.

Ivoclar Vivadent Inc.

VOCO Canada

Zahn Canada, A Division of Henry Schein Canada

Zirkonzahn

DUPLICATING MATERIALS

BEGO Canada Inc.

Ivoclar Vivadent Inc.

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

ETCHING, GELS AND LIQUIDS

BEGO Canada Inc.

Ivoclar Vivadent Inc.

Unique Dental Supply Inc.

VOCO Canada

Zahn Canada, A Division of Henry Schein Canada

Zirkonzahn

IMPLANTS,

ATTACHMENTS AND SYSTEMS

Argen Canada

BEGO Canada Inc.

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

IMPRESSION MATERIAL

Ivoclar Vivadent Inc.

Unique Dental Supply Inc.

VOCO Canada

Zahn Canada, A Division of Henry Schein Canada

INVESTING, CROWN & BRIDGE, HIGH AND LOW HEAT

BEGO Canada Inc.

Ivoclar Vivadent Inc.

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

MODELLING LIQUID

BEGO Canada Inc.

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

MOUTHGUARD MATERIAL

Argen Canada

Unique Dental Supply Inc.

VOCO Canada

Zahn Canada, A Division of Henry Schein Canada

NIGHT GUARD AND SPLINT MATERIALS

Argen Canada

BEGO Canada Inc.

Unique Dental Supply Inc.

VOCO Canada

Zahn Canada, A Division of Henry Schein Canada

Zirkonzahn

OPAQUERS, ACRYLIC, PORCELAIN, SPRAY OPAQUERS

Ivoclar Vivadent Inc.

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

Zirkonzahn

ORTHODONTIC, MATERIALS AND ACCESSORIES

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

POLISHING COMPOUNDS AND PASTES

Argen Canada

BEGO Canada Inc.

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

PORCELAIN SYSTEMS AND KITS

Ivoclar Vivadent Inc.

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

Zirkonzahn

SEALERS AND SEPARATORS

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

SOLDERING MATERIALS

BEGO Canada Inc.

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

TEMPORARY MATERIALS, CROWN AND BRIDGE

Argen Canada

Ivoclar Vivadent Inc.

Unique Dental Supply Inc.

VOCO Canada

Zahn Canada, A Division of Henry Schein Canada

Zirkonzahn

VACUUM FORMING MATERIALS

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

WAX

Argen Canada

BEGO Canada Inc.

Ivoclar Vivadent Inc.

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

Zirkonzahn

ZIRCONIA

Argen Canada

Ivoclar Vivadent Inc.

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

Zirkonzahn

SUPPLIES

ABRASIVE, DISCS, SLEEVES, CAPS, POINTS

BEGO Canada Inc.

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

ARTICULATING, FILM, PASTE, PAPER, LIQUIDS

BEGO Canada Inc.

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

BLASTING COMPOUND

BEGO Canada Inc.

Ivoclar Vivadent Inc.

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

BOIL-OUT SOLVENT

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

BRUSHES, CERAMIC

Ivoclar Vivadent Inc.

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

Zirkonzahn

BURS AND ACCESSORIES

Argen Canada

BEGO Canada Inc.

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

Zirkonzahn

CASTING RINGS

BEGO Canada Inc.

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

CLOTHING

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

DEBUBBLIZERS

BEGO Canada Inc.

Ivoclar Vivadent Inc.

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

DIAMONDS, DISCS AND WHEELS

Argen Canada

BEGO Canada Inc.

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

Zirkonzahn

DOWEL PINS AND ACCESSORIES

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

EPOXY, DIE

BEGO Canada Inc.

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

EYEWEAR, PROTECTIVE

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

FELTS, POLISHING

BEGO Canada Inc.

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

FIRING PEGS AND TRAYS

Ivoclar Vivadent Inc.

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

FOIL

Argen Canada

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

FORMERS, MODEL

BEGO Canada Inc.

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

GLASS BEADS

BEGO Canada Inc

Ivoclar Vivadent Inc.

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

GYPSUM, DIE

BEGO Canada Inc.

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

INFECTION CONTROL

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

LABELS, BIOHAZARD, BUSINESS, IMPRINTS

Argen Canada

LUBRICANT, MODEL AND DIE

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

MIXING BOWLS

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

MODEL, HARDENER, GLOSS, SPACERS, GLAZE

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

MODELS AND MOLDS, ANATOMICAL, EDUCATIONAL

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

MOLDS FOR WAX PATTERNS

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

OCCLUSAL INDICATORS AND SPACERS

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

ORTHODONTIC SUPPLIERS

Zahn Canada, A Division of Henry Schein Canada

PATTERNS, WAX, BAR, PLASTIC, CLASP

BEGO Canada Inc.

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

PLASTER

BEGO Canada Inc.

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

PRESCRIPTION FORMS

Unique Dental Supply Inc.

PUMICE

BEGO Canada Inc.

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

SILICONE SPRAY

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

SOAPS, HAND

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

SOLVENTS, ACRYLIC, METAL, CERAMIC

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

SPRUCES, PLASTIC

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

STONE, MODEL

BEGO Canada Inc.

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

STRIPPING AGENT

Zahn Canada, A Division of Henry Schein Canada

ULTRASONIC SOLUTIONS

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

WIRE

Argen Canada

BEGO Canada Inc.

Unique Dental Supply Inc.

Zahn Canada, A Division of Henry Schein Canada

Argen Canada 877-527-8535 sales@argencanada.com www.argen.ca

BEGO Canada Inc.

800-463-2680 info@begocanada.com www.begocanada.com

Ivoclar Vivadent Inc. 800-263-8182 www.ivoclarvivadent.com

Roland DGA 800-542-2307 dental@rolanddga.com www.rolanddga.com/dental

Unique Dental Supply Inc. 905-532-0554 orders@udscanada.com www.udscanada.com

VOCO Canada 888-658-2584 infousa@voco.com www.voco.com

Zahn Canada, A Division of Henry Schein Canada 905-646-1711 800-496-9500 info@zahncanada.ca www.zahncanada.ca

Zirkonzahn +39 474066824 isabella.foy@zirkonzahn.com www.zirkonzahn.com/ca/products/ millable-materials/multistratumflexible/multistratum-flexibleprodukte

Three days of varied and contemporary

Fantastic line-up of speakers / topics to choose from in open sessions and hands-on workshops, as well as the Live Dentistry Stage in the Exhibit Hall

Spacious PDC Exhibit Hall with all your favourite exhibiting companies looking forward to connect with you

Lunches & Exhibit Hall Receptions (Thurs/Fri) included in the registration fee

Manny Padda Brian Lindke Lincoln Fantaski

Will Varda Ashtyn Hoffer William Liang

Karim Sahil Michelle Glover-DaCosta

Devaughn Fraser

Ria Mozhina

BRITISH COLUMBIA Career Opportunities

Experienced Denture Technician, Experienced Ortho Technician and Junior Denture Technician

Vancouver

We are seeking a high-quality dental technician for our state-of-the-art dental laboratory in Vancouver, BC. Experienced Denture Technician, Ortho Technician and a Junior Denture Technician – 3 positions. Full time.

Junior Denture Technician: You’ll be working in the wet lab pouring models, investing, making custom trays, bite blocks and loading/unloading 3D printers, as well as being trained on the digital workflows depending on your work experience and knowledge.

Experience Denture Technician: Abilities/skills should include being able to pour and/or print models, investing, relines, repairs, experience with setting teeth and finishing dentures (complete/partial/ implant). You will have the opportunity to work and train with our experienced digital denture technicians to learn our digital denture workflow. Previous digital skills are a plus, or at least some computer skills.

Orthodontic Technician: You will be fabricating orthodontic appliances, both removable retainers and fixed appliances, pouring models and loading/unloading 3D printers, as well as being trained on the digital workflows depending on your work experience and knowledge.

For all positions:

• A positive attitude and personality are a must. You need to be able to work

as a team player and independently when necessary.

• Fluency in English is required.

• Compensation will be based on experience, skill, problem-solving, and the quality of work. Pay ranges from $20-$35 an hour with benefits after a 6-month probation period.

• No working on weekends, as we are only open M-F during regular business hours.

• Close to a SkyTrain station and transit Contact person: Fannie or Soyoung Phone: 604-872-6656, Email: digital@integraldentallab.com.

Looking for a Denture Technician and/or Night Guard Technician

Burnaby

Contact: Frank Lando. Phone: 604-294-2881. Email: landofrank@yahoo.ca.

ONTARIO

Career Opportunities

Certified Lab Technician Needed

Haileybury

Immediate opening for a Certified Dental Lab technician for a newly constructed state of the art in-house Laboratory located in Haileybury Ontario. Must have a minimum 5 years experience and be willing to relocate. A rare opportunity for a person with drive and the business acumen to deliver results. Ownership is being offered as part of a superior remuneration package that will include a comprehensive benefit plan. You will be rewarded for attainting the production targets we will set together. Please your resume to firstline_dental@hotmail.ca attention: Henry Quinn.

Experienced Registered Dental Technologist (RDT)

Toronto

We are an established and growing dental laboratory in Toronto seeking an experienced Registered Dental Technologist (RDT) to join our team. The ideal candidate will have strong technical expertise along with the ability to supervise, manage workflow, and ensure top-quality standards for all daily cases. Key Responsibilities: oversee and manage daily operations within the dental laboratory, help supervisors and support staff to ensure efficient workflow and timely case completion, perform and maintain high standards of quality control for all cases before dispatch, ensure adherence to lab protocols, safety guidelines, and regulatory requirements, collaborate with different departments to resolve technical concerns and improve efficiency. Requirements: must be a Registered Dental Technologist (RDT) in Ontario, proven experience in supervising or managing dental laboratory operations, strong attention to detail and commitment to highquality craftsmanship, ability to guide, mentor, and support lab technicians, excellent communication and problemsolving skills. What We Offer: competitive/ good pay based on experience, opportunity to work in a fully equipped dental lab, supportive team environment. Urgent hiring – immediate start preferred. Contact at: 416-469-4121 or mirjana@pro-artdentallab.com

CLASSIFIEDS

Denture Technician

Whitby

Pay: CA$25.00 – CA$32.00 per hour. Denture Dental Technician needed in our busy and growing Denture Department. The candidate will: setup and wax-up Complete Dentures, Partial Dentures and Flippers, trim and polish dentures, repairs and Relines. maintain, organize and clean lab equipment, supplies and work areas. As a Dental Technician, you will be essential in creating high-quality dental prosthetics and appliances. Reporting to the department supervisor you will utilize your core skills in dental terminology and laboratory experience to ensure precision in the Denture Departments work. Qualifications: Proficient in dental terminology and laboratory practices. Strong attention to detail and precision in work. Ability to collaborate effectively with dental professionals Job Type: full-time.

INDUSTRY NEWS

Benefits: casual dress, flexible schedule, on-site parking, paid time off. Education: secondary school (preferred). Experience: Dental technician: 3 years (required). Work Location: in person. Contact: 905-668-8000 or wesley@glasscanvasds.com.

Denture Technician

Burlington

We are seeking skilled Denture Tech to join our team. Ideal candidate need to able to finish denture, Night-guard, Essex retainer and other removable appliances. This position for full time. Fabricate dentures, partials, and other dental prosthetics using various materials and techniques. Perform adjustments and repairs on existing dentures. Keep a clean and organized laboratory environment, following to safety rules. Contact at 289-707-1025 or shafiq_mojaddedi@hotmail.com.

In-House Lab Technician Required

Kitchener

ISO CDTO certified dental lab technician for an in-house lab. No experience required, but registration with CDTO is essential. Wage is negotiable. Open to full or part time position. drdeborahoreilly@gmail.com.

For Sale Owner

Timmins

Well established dental lab in business for over 35 years. Crown & bridge, dentures and splints. Contact owner for details. 705-288-5734 timminsdental@gmail.com.

Space for Lease

Mississauga

Office space for lease, ideal to set up a new lab in Mississauga. Closed to LRT, ample parking and in ground floor. Please email jnrosewood@gmail.com.

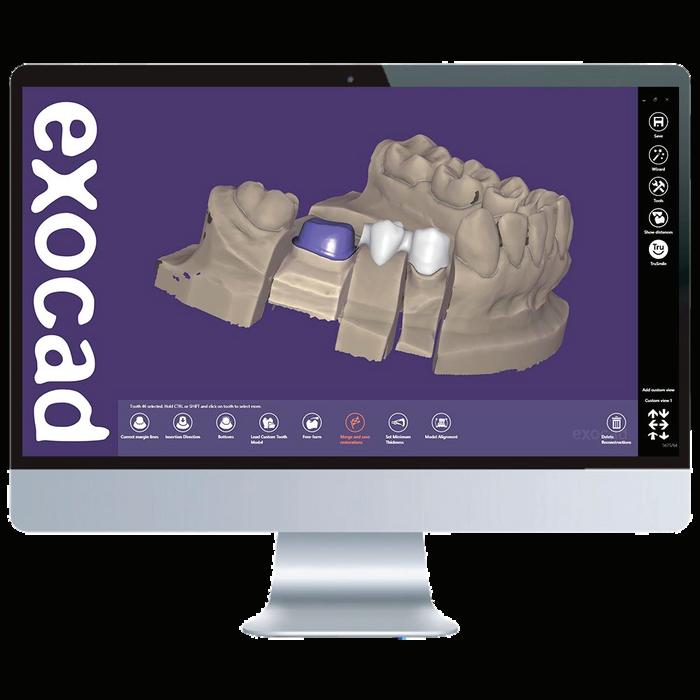

DentalCAD 3.3 Chemnitz — Smarter, Faster, and More Enjoyable Digital Dentistry

This new release from exocad brings intelligent automation, seamless workflows, and better AI assistance to everyday dental design.

What’s new & what it means for you

• Implant Module Upgrade: Smarter, auto-optimized abutment proposals, easier editing, reusable presets, and 3D component previews.

• Split-Denture Workflow: Design All-on-X and bar + suprastructure cases in one process — perfectly fitting, with minimal adjustment.

• AI-Enabled Multi-Unit Design: AI assists with up to three crowns or bridges for faster, more precise outcomes.

• Enhanced Smile Design: Improved TruSmile™ Photo & Video, automatic lip-line detection, and better 3D alignment for realistic patient previews.

• Workflow Refinements: Faster morphing, improved model creation, mesh editing, support for 20 articulators, plus new Inspira™ teeth and KaVo PROTARevo 7.

• Open System: Full compatibility with scanners, printers, mills, and materials — no vendor lock-in.

Why this matters?

DentalCAD 3.3 Chemnitz saves time on repetitive tasks and streamlines every workflow, letting you focus on creativity and precision. It improves patient communication through more realistic visualizations and scales easily for labs or clinics of any size. With its open, upgradeable design, it’s built to evolve with you.

If you’re in digital dentistry and you’re aiming to stay ahead in a rapidly evolving field, DentalCAD 3.3 Chemnitz presents a meaningful advance. Whether it’s smarter abutment design, AI-assisted multi-unit workflows, or enhanced visualization tools, this release is built to help you get your best results—faster, easier, and with greater joy.

For more information on this amazing product please contact Unique Dental Supply Inc. at 1.888.532.0554 , visit us on the web: www.udscanada.com or email us at orders@udscanada.com

ADVERTISER PRODUCT & SERVICE CENTRE

Dental Technology Today would not be possible without the advertising support of these companies and organizations. Please think of them when you require a product or service. We have tried to make it easier for you to contact these suppliers by including their telephone numbers and websites. You can also go the electronic version at www.adto.ca or www.dtabc.ca and access direct links to any of these companies.

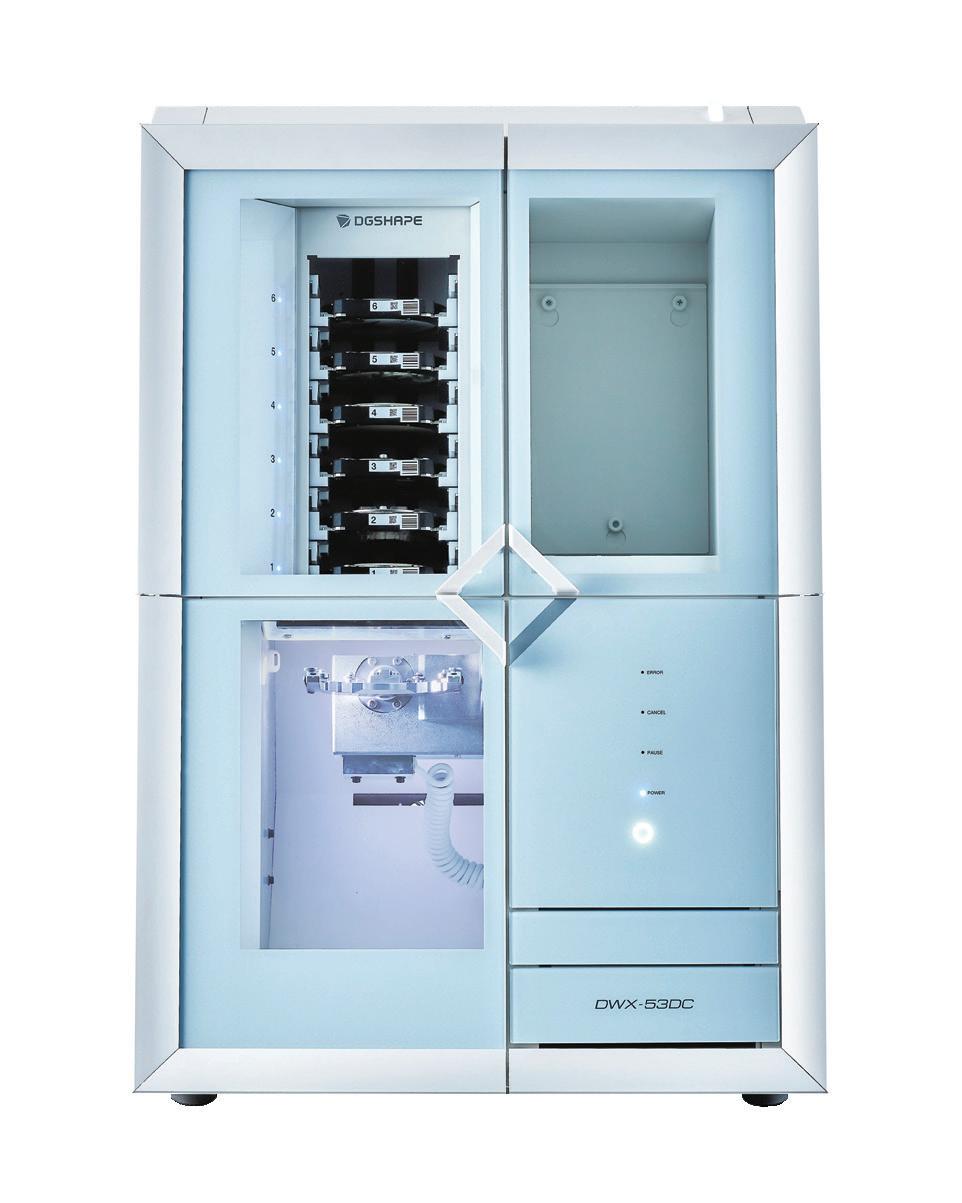

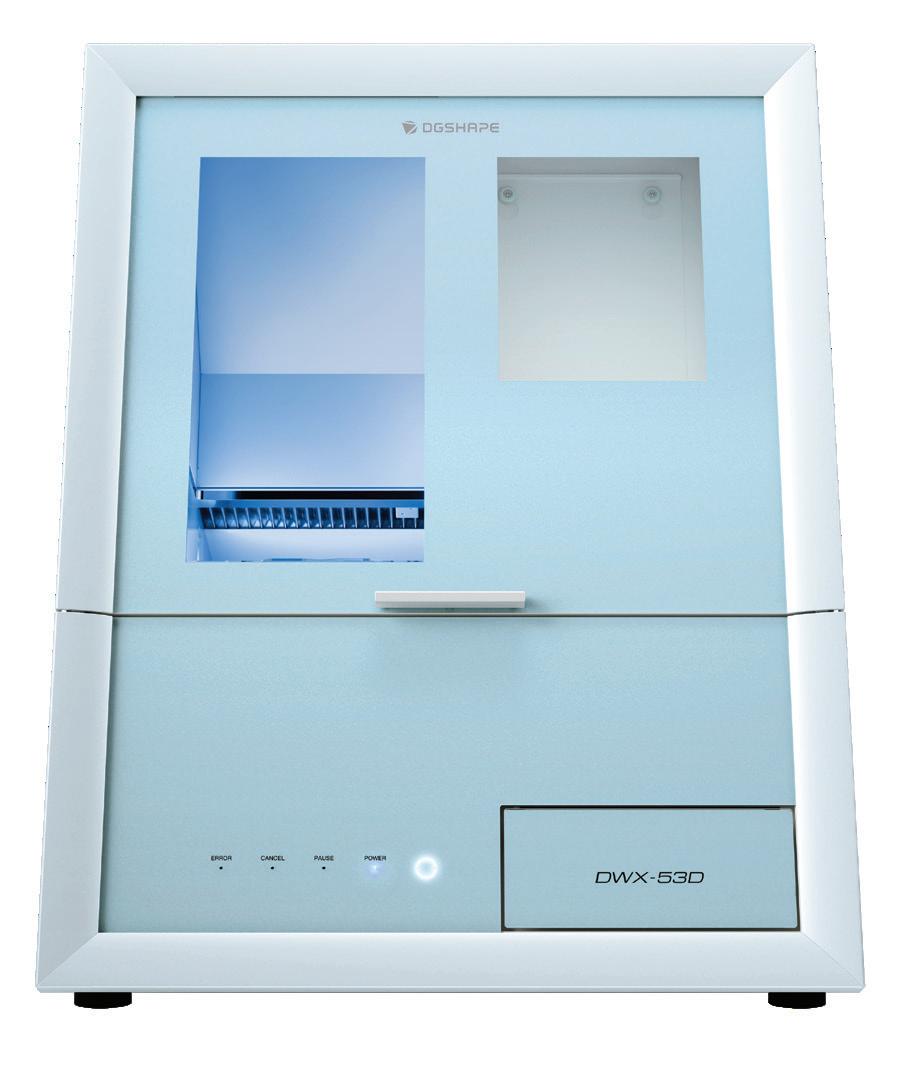

DGSHAPE Digital Workflows can save valuable time and money by streamlining the process of creating dental restorations and providing greater precision and accuracy resulting in better outcomes. Roland DGA’s DGSHAPE DWX-53DC and DWX-53D are the Dry Milling powerhouse solutions built for All-On-X implant-supported applications.

DGSHAPE’s DWX-53D Series is the bold next step in that evolution for your dental business.

• A built-in camera, linking you seamlessly to DGSHAPE CLOUD — control, monitor, and troubleshoot from anywhere.

• Faster PMMA roughing, automated cleaning, and greater gripping force gives you reliability when it matters most.

• Features an open architecture ecosystem. This makes it easy to work with your choice of CAD/CAM software, scanners and restorative materials to achieve maximum production of high-esthetic, precise restorations.

• Advanced milling capabilities with the included open-edge adapter enable production of 100% of the case design.

All materials, all you need. *

PrograMill® PM7

The ability to mill over 300 Ivoclar materials.

Powerful and versatile with outstanding results, the PrograMill® PM7 excels in both wet and dry milling. Advanced 5-axis precision delivers exceptional accuracy, efficiency, and surface quality across the entire line of Ivoclar CAD/CAM materials.

The complete line of Ivoclar CAD/CAM materials: