International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 02 | Feb 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 02 | Feb 2025 www.irjet.net p-ISSN: 2395-0072

Dr.S.Parthasarathy 1, R.Thangasankaran2, T.J.A.Saravana Kumar3, S.Santhosh 4 , E.H.VishnuKumar5

1 Prof/EEE, Department of Electrical & Electronics Engineering, K.L.N. College of Engineering, Tamil Nadu, India

2Assistant Professor/EEE, Department of Electrical & Electronics Engineering, K.L.N. College of Engineering, Tamil Nadu, India

3,4,5 UG Scholar, Department of Electrical & Electronics Engineering, K.L.N. College of Engineering, Tamil Nadu, India ***

Abstract - In an effort to improve dependability and productivity inindustrialenvironments,thisresearchproposes a real-time monitoring and visualization system for motor health management. The system gives a thorough picture of motor performance by continuouslymonitoringcritical motor characteristics like vibration, temperature, speed, and electrical metrics. To increase accuracy, key metrics such as power loss, output power, and efficiency are computed with corrections for temperature- induced resistance variations. Consistent tracking and analysis are made possible by the regular logging of data and its storage in an Excel sheet. By visualizing patterns in parameters, automated graphs let operators understandmotorstatusanddecideonpreventative maintenance. In order to minimize unplanned downtime and promote predictive maintenance, our system provides realtime insights into motorbehavioranalysis.Earlyfindingsshow improved monitoring capabilities that provide cost savings and increased operational efficiency. This method offers a workable and effective way to control motor health, which enhances industrial performance

Key Words: Industrial efficiency, predictive maintenance, performance visualization, real-time motor monitoring, and motor health management

Motor health has a direct impact on system efficiency, dependability, and operating costs in industrial systems, where they are essential tooperations.Unexpectedmotor failures can result in a large amount of downtime and expensive repairs, which emphasizes how crucial ongoing monitoring is to preserving peak performance. The use of reactivemaintenancetechniquesandsporadicinspections, whichmaymisssmall flawsorslowchangesthatcouldcause biggerproblems,isacommonlimitationoftraditionalmotor monitoringsystems.

The objective to continually monitor and visualize importantmotorparameters,thisprojectintroducesaRealTime Monitoring and Visualization System for Motor

Parameter Health Management. In order to provide a multifacetedpictureofmotorhealth,thesystemusessensors to monitor electrical properties, temperature, speed, and vibration. The system allows precise tracking of motor performance by computing important performance parameterslikepowerloss,outputpower,andefficiencyand adjusting in real-time for temperature-induced resistance fluctuations.

Dataisrecordedatregularintervals,storedinanExcel sheet,andvisualizedinrealtimethroughautomatedgraphs, allowing for immediate insights into motor behavior. This approach supports predictive maintenance, enabling operators to identify potential faults early and make proactive decisions. The system offers an efficient, costeffectivesolutiontomotorhealthmanagement,promoting enhancedoperationalreliabilityandminimizingunexpected downtime.

This paper provides a real-time motor monitoring and visualization system uses a multi- sensor technique to continuouslytrackimportantdataandevaluatethehealthof themotors.Tomeasureimportantmotorcharacteristics,the systemhasanumberofsensors.

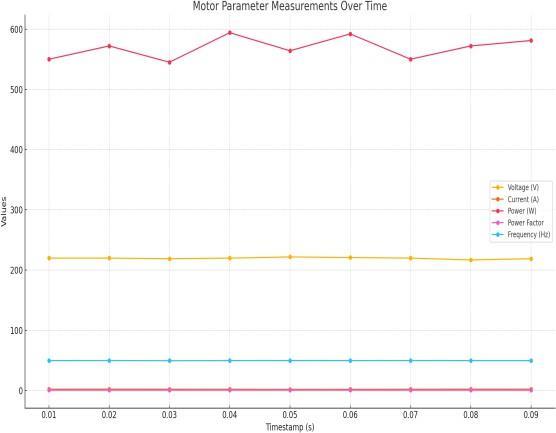

These include a PZEM-004T module for electrical parameters (voltage, current, power, power factor, and frequency),anon-contactMLX90614infraredtemperature sensor for motor surface temperature, a Hall Proximity Switch sensor for rotational speed (RPM), and a 3-axis accelerometer for vibration recording in three different directions.

Data is processed and stored in an Excel sheet at oneminute intervals when each sensor sends data via GPIO connectionstoacentral processingunit.

The technology uses real-time temperature data to dynamically calculate resistance in order to improve the analysis.InordertoaccuratelycalculatepowerlossusingI2

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 02 | Feb 2025 www.irjet.net p-ISSN: 2395-0072

R, where I is the current supplied by the PZEM- 004T, the user first enters a baseline resistance value R0 and temperature T0. As the motor heats, the resistance T is recalculatedwithatemperaturecoefficient.

Efficiency is measured as the ratio of output to input power,whichisobtainedfromthespeeddatausingtorque andcomputedasafunctionofinputpowerandpowerloss

Byprovidinginformationonmotorvibration,the3-axis accelerometer can identify imbalances or alignment problems that could compromise the motor's mechanical stability.Operatorsmayeasilyexaminepatternslike power loss, efficiency, temperature, and vibration thanks to the automaticgraphsthatarecreatedfromthesereal-timedata points,whicharerecordedinExcel.

Early fault detection and effective implementation of predictivemaintenancetechniquesaremadepossiblebythe system'sabilitytosimplifydatadisplaywithouttheneedfor artificialintelligence.Thismethodoffersaworkablewayto preserve motor health, minimize downtime, and enhance industrialefficiency

Toguaranteethehealthofthemotorandfacilitate predictive maintenance, the Motor Management System's methodology focuses on real-time monitoring and data visualizationofcriticalmotorparameters.

Thesystem incorporatesanumberofsensors,such asa3- axisaccelerometerforvibrationmeasurement,aHall ProximitySwitchforspeed(RPM)detection,anMLX90614 infraredtemperaturesensorformotor surfacetemperature monitoring, and aPZEM-004Tmoduleforvoltage,current, power,powerfactor,andfrequencymeasurement.Through GPIOconnectionstoaRaspberryPi,whichactsasthecentral computing unit, these sensors are set upandcalibrated to deliverprecise,real-timedata

TheRaspberryPireceivescontinuousdatafromeach sensorandappliespreprocessingandfilteringtoguarantee dataquality.

Thisentailsdynamicallycalculatingresistancebased ontemperaturechanges,filteringnoisefromvibrationdata, and confirming sensor readings to withstand abrupt fluctuations.

Inordertocreateconsistenttime-seriesrecordsand facilitatelong-termtrendresearch,thedataisloggedintoan Excelsheetatone-minuteintervals.

The data is used to compute key metrics, such as output power (determined using speed and torque data), efficiency.TheExceldataisautomaticallytransformedinto visualizations that highlight important trends, such as temperature increases, efficiency shifts, and vibration patterns, to assist operators in quickly evaluating the conditionoftheirmotors.

3.PROTOTYPE DESIGN DESCRIPTION AND IMPLEMENTATION

The "Real-Time Monitoring and Visualization of Motor Parameters for Its Health Management System" prototype design seeks to develop an effective, real-time system that continuously tracks important motor health indicators, including electrical characteristics, vibration, temperature,andspeed.Earlyidentificationofperformance irregularities that might indicate motor wear, possible failures,ormaintenancerequirementsismadepossibleby this configuration. The system collects these parameters usingavarietyofsensors,interpretsthedata,anddisplaysit forreal-timemonitoringandanalysisusingaRaspberryPias thecentralcomputingunit.

Setting up the Raspberry Pi to serve as the main controller and data processor is the first step in the prototype'shardwareconfiguration.InstallingRaspbianOS (formerlyknownasRaspberryPiOS)ontheRaspberryPiis the first step. This creates a compatible environment for Python programs and other required libraries to operate. LibrariesenablingGPIOaccesstoconnecttodifferentsensors andlibrariesforinteractingwiththeI2CandUARTprotocols areessential.FollowingOSsetup,youwillconfiguredistinct GPIOpinsontheRaspberryPiforeachsensorconnection:

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 02 | Feb 2025 www.irjet.net p-ISSN: 2395-0072

theHallProximitySensorandAccelerometerwillconnectvia general-purpose GPIO pins, the PZEM-004T power monitoring module will connect via UART, and the MLX90614 infrared temperature sensor will use the I2C protocol.

AllofthesensorsareconnectedtotheRaspberryPi inaccordancewiththeir connectivityneeds.ThePZEM-004T moduleconnectsviatheTXandRXUARTpinsforserialdata exchange,whereastheMLX90614temperaturesensoruses I2CandneedsparticularSDAandSCLconnections.Boththe analog-outputaccelerometerandtheHallProximitySensor areconnectedtoGPIOpins;however,becausetheRaspberry Piitselfonlyaccepts digitalinputs,theaccelerometerneeds an Analog- to-Digital Converter (ADC). The ADC ensures precisevibrationmeasurementandforreal-timemonitoring of the motor's mechanical condition by converting the accelerometer's analog vibration data into a digital signal thattheRaspberryPicanhandle.Everysensorissetupto collectdataatthepropertimes,deliveringaconstantflowof dataforanalysisanddisplayinrealtime.

Thisproject'ssoftwaredevelopmententailswriting a number of dependable and effective Python scripts to control dataprocessing,gathering,andvisualization.Each sensor needs a script that is specific to its protocol (for example,I2CforthetemperaturesensorandUARTforthe powermodule)inordertocollectdatainreal-timewiththe least amount of delay. To handle any disconnections or communicationproblemsthatmayoccurandguaranteethe system stays responsive and stable, these scripts must include strong error handling. Processing procedures are usedtocalibrateeachsensorduringinitialsetupfollowing data capture, guaranteeing precise baseline values. Additionalfilteringmethods,suchaslow-passfiltering,are used to the accelerometer to eliminate noise and highfrequency fluctuations and create a clean data stream for trustworthy analysis. Finally, the visualization dashboard, which was created with LiberOffice libraries, shows realtimedatainaneasy-to-understandmanner,makingitsimple to spot irregularities and track trends. A LiberOffice, is installed on the Raspberry Pi for further versatility. This allowsuserstomonitormotorcharacteristicsremotelyviaa network from any compatible device nearby. Real-time monitoring and insights are supported by this integrated softwarearchitecture,whichguaranteesasmoothtransition fromdatacollectiontovisualization

Tracking vital factors including voltage, current, power, temperature, speed, and vibration, the Motor ManagementSystemprototypeisafullyfunctional,scaleddownversionofthereal-timemotormonitoringandhealth managementsystem.Simulatingthefunctionalityofafullscalemotorhealthmonitoringsystem,thisprototype,which is based on the Raspberry Pi platform, incorporates a numberofsensorsthatcommunicatewiththecentralCPUto collectandinterpretdatainrealtime

The Raspberry Pi, the primary processing and controlunitatthecenterofthesystem,gathersdatafroma variety of sensors. By directly measuring the motor's electrical health, the PZEM-004T module records crucial electrical data like voltage, current, and power factor. In ordertoevaluatethermalbehaviorandavoidoverheating, theMLX90614Infrared TemperatureSensordeliversnoncontact temperature readings to monitor motor temperature. A three-axis accelerometer provides information about mechanical stability and alignment by sensing motor vibration across several axes, while a Hall ProximitySwitch sensormeasuresmotorspeedbydetecting rotational pulses. A smooth data acquisition network is createdbyeachofthesepartsinteractingdirectlywiththe RaspberryPiviaGPIOconnectors.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 02 | Feb 2025 www.irjet.net p-ISSN: 2395-0072

The key elements utilized in the Motor Management Systemprojectaredepictedinthefigure.Theseconsistofa TTL to USB module for serial data connection with the Raspberry Pi, a PZEM-004T module to monitor voltage, current,power,andfrequency,andanMCB(MiniatureCircuit Breaker) to guard against electrical overloads. A vibration sensor records 3-axis vibration data to show mechanical stability,whileaHallproximitysensorgaugesmotorspeed. TheprimaryprocessingunitistheRaspberryPi4,whichalso stores data and interfaces with sensors. Motor surface temperature is measured using an infrared non-contact temperature sensor, and data visualization and real-time monitoringarefacilitatedbya7-inchdisplay.Comprehensive motor parameter monitoring is made possible by this configuration for predictive maintenance and health management

To ensure that the system is accurate and responsiveingatheringmotorhealthdata,pilottestingwas doneontheprototypeconfiguration.Accuratecalculations wereensuredbycalibratingthesensorsandsettingstarting baselinevalues.Afterseveralhoursofmotoroperation,the Raspberry Pi successfully connected to each sensor and recorded data in real time. The MLX90614 temperature sensor identified temperature increases during prolonged operation, the Hall Proximity Switch recorded RPM for output power calculations, and the PZEM-004T module precisely monitored electrical parameters. By recording vibrationdata,the3-axisaccelerometerwasabletodetect imbalances at higher speeds. Data visualization made it simple to identify patterns and possible problems by displaying power, efficiency, temperature, and vibration trends. After a successful pilot test, the system's dependability for real-time motor health monitoring was validated,allowingforadditionalindustrialimprovement.

An essential instrument for tracking motor efficiencyandhealthisthePZEM-004Tmodule.Inorderto comprehend the motor's operation and spot possible problems, it measures vital electrical characteristics like voltage, current, power, power factor, and frequency. The module's responsibilities in the project include efficiency

calculation testing, power factor analysis under various loads, voltage fluctuation response testing, temperaturerelatedpowerlosstesting,baselinetesting in an idlestate, and load testing to assesspowerconsumption.

⮚ Baselinetestingatidlestate

⮚ Loadtestingtomeasurepowerconsumption

⮚ Voltagefluctuationresponsetesting

⮚ Temperature-relatedpowerlosstesting

⮚ Efficiencycalculationtest

⮚ Powerfactoranalysisunderdifferentloads.

Baseline testing captures stable voltageandlowcurrent draw,whileloadtestingobserveshowpowerconsumption andcurrentdrawchangewithincreasingload.

Voltage fluctuation response testing ensures the motor operates within safe limits, while temperaturerelated power loss testing observes the correlation between motortemperatureriseandpowerloss.

Efficiency calculation test calculates motor efficiency under real operating conditions, while power factor analysis observes changes in power factor under differentloads.

The PZEM-004T module's ability to provide accurate electricaldataformonitoringmotorhealthallowsforearly identification of potential issues, ensuring efficient motor operationandenhancingpredictivemaintenanceefforts.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 02 | Feb 2025 www.irjet.net p-ISSN: 2395-0072

Basedonthecollecteddatathestablestatewassetbelow the75thpercentile,thewarningstaterangewasdefined betweenthe75thand95thpercentiles.

4.2.

An essential part of motor systems, the vibration sensorrecognizesandevaluatesvibrationpatterns.

The sensor's response to variations in motor load is tested,abaselinefortypicalmotorvibrationisestablished, andthesensor'scapacitytoidentifymechanicalproblemsis confirmed.

Temperature-relatedvibrationteststrackhowthermal variables or material expansion impact vibration as temperaturesvary.testingforfrequencyresponsemakesure thesensordetectsvibrationchangesprecisely,whiletesting forexternalinterferencemakesurethesensorsuccessfully separatesmotorvibration.

Theseexperiments confirm that the sensor can identify the vibration sensor is an essential part of motor system.

⮚ Baselinecalibration

⮚ loadtesting,faultsimulation

⮚ Temperaturerelatedvibrationtest

⮚ frequencyresponsetest

These tests make sure the sensor can identify mechanical problems, test how the sensor-these experimentsconfirmthatthesensorcanenablepredictive maintenanceplansandidentifymotorhealthmetricsinreal time.

Table 2: VIBRATION SENSOR

In order to test the functionality of the vibration alarm program and configure the alarm thresholds, vibrationmagnitudedata associatedwiththetwomotors were collected three times respectively under stable operatingconditions.

Normalworkingconditions,loadconditions, continuousoperation,rapid temperaturechanges,accuracy verificationusinganexternalreference,andenvironmental conditions are all used to assess the accuracy of the MLX90614temperaturesensor.Temperaturereadingsare takenperiodicallywhenthesensorisrunningatitsnormal pacewithoutanyload.

After that, it is loaded to varying degrees and its temperatureistracked.

❖ BaselineMeasurementTest

❖ LoadConditionTest

❖ ContinuousOperationTest

❖ RapidTemperatureChangeTest

❖ AmbientConditionTest

Long-term evaluation of the sensor's performance guarantees precision and reliability. Additionally, it may identify rapid temperature fluctuations brought on by abruptadjustmentstomotoroperation.Bycontrastingthe sensor witha trustworthy temperaturemeasuring device, the accuracy of the sensor is confirmed.

Real-time motor monitoring, power loss calculations, and efficiencyalldependonthesensor'sperformance.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 02 | Feb 2025 www.irjet.net p-ISSN: 2395-0072

The accuracy of the speed sensor is evaluatedinthefollowingscenarios:noload, loadvariation, continuousoperation,abruptspeedchanges,errordetection andnoisereduction,andRaspberryPiintegration.

Thesensor'saccuracyinmeasuringthemotor'sRPM isguaranteedbythebaselinespeedtest.Theloadvariation test evaluates how well the sensor can identify speed variations when the motor's load is raised. The sensor's accuracyismaintainedthroughoutextendedusethanksto thecontinuousoperationtest.

Thesensor'sresponsivenesstoabrupt changesin motorspeedisverifiedbythesuddenspeedchangetest.The test for error detection and noise reduction finds outside influences on the sensor's findings. Lastly, the integration testverifiesthatthesensorandRaspberryPiintegratedata seamlessly.

Small changes in motor performance are indicated by the linegraph'ssmallfluctuations.Thisinformationisessential for tracking motor health and making sure it functions within safe bounds to avert possible problems. For applications needing dependable speed regulation, the constanttrendinRPMindicatesstableperformance.

Thispaperpresentedthedesignanddevelopmentofareal time condition monitoring and maintenance management system for low voltage industrial motors using IoT. The device monitors the temperatureand vibration frequency levelofindustrialmotors,wirelesslytransmitsthedatatoa logging station and sends a push notification in case of a spike, or once the temperature or vibrations exceed predefinedparameters.Thefunctionalityandaccuracyofthe deviceweretestedontwodifferentmotorsandpilottesting resultswereanalyzedandpresented.

This paper presented the design and development of a realtime condition monitoring and maintenance managementsystemforlowvoltageindustrialmotorsusing IoT.

The device monitors the temperature and vibration frequencylevelofindustrialmotors,wirelesslytransmitsthe datatoaloggingstationandsendsapushnotificationincase of a spike, or once the temperature or vibrations exceed predefinedparameters.

Thefunctionalityandaccuracyofthedeviceweretestedon twodifferentmotorsandpilottestingresultswereanalyzed and presented. It will be anticipated before expensive failures.

In order to decrease breakdowns and increase motor longevity, the system will evaluate motor efficiency, alert operators of anomalies in real time, and provide maintenanceregimensthatareoptimum.

[1] T. Dunne, "Plant age and technology use in US manufacturing industries," The RAND Journal of Economics,pp.488-499,1994.

[2] V.E.Lambson,"Industryevolutionwithsunkcostsand uncertainmarketconditions,"InternationalJournalof Industrial Organization, vol. 9, no. 2, pp. 171-196, 1991.

[3] W. G. Garrison, "One hundred largest losses-A Thirtyyear review of property damage losses in the hydrocarbon-chemical industries," M&M Protection Consultant,Chicago,1988.

[4] P. A. Carson and C. J. Mumford, "An analysis of incidents involving major hazards in the chemical industry.,"JournalofHazardousmaterials,vol.3,no.2, pp.149-165,1979.

[5] S. A. McInerny and Y. Dai, "Basic vibration signal processing for bearing fault detection," IEEE Transactionsoneducation,pp.149-156,2003.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 02 | Feb 2025 www.irjet.net p-ISSN: 2395-0072

[6] S.Nandi,H.A.ToliyatandX.Li,"Conditionmonitoring and fault diagnosis of electrical motors A review," IEEEtransactionsonenergyconversion,pp.719-729, 2005.

[7] L.M.Bergasa,J.Nuevo,M.A.Sotelo,R.BareaandM.E. Lopez, "Real-time system for monitoring driver vigilance," IEEE Transactions on Intelligent TransportationSystems,pp.63-77,2006.

[8] W.Yang,P.J.Tavner,C.J.CrabtreeandM.Wilkinson, "Cost-effective condition monitoring for wind turbines,"IEEETransactionson industrialelectronics, pp.263-271,2009.

[9] V. J. Hodge, S. O' Keefe, M. Weeks and A. Moulds, "Wirelesssensornetworksforconditionmonitoringin therailwayindustry:Asurvey,"IEEETransactionson Intelligent Transportation Systems, pp. 1088-1106, 2014.

[10]D.Goyal,A.Chaudhary,R.K.Dang,B.S.PablaandS.S. Dhami,"ConditionMonitoringofRotatingMachines:A review,"WoldScientificNews,pp.98-108,2018.

[11]B. K. N. Rao, Handbook of Condition monitoring, Elsevier,1996.

[12]S. D. T. Kelly, N. K. Suryadevara and S. C. Mukhopadhyay,"TowardstheimplementationofIoT for environmental condition monitoring in homes," IEEEsensors journal,vol.13,no.10,pp.3846-3853, 2013.

[13]Angelopoulou,K.Mykoniatis,K.CarlsonandS.J.Kim, "UCFSmartMailbox:ReinforcingCommunicationsin theNeighborhoods.In,"inInternationalConferenceon Human-ComputerInteraction,2014.

[14]P.Asghari,A.M.RahmaniandH.H.S.Javadi,"Internet of Things applications: A systematic review," ComputerNetworks,vol. 148,pp.241-261,2019.

[15]J. Manyika, M. Chui, P. Bisson, J. Woetzel,J.R.Dobbs and B. a. D. Aharon, "Unlocking the potential of the Internet of Things," McKinsey Global Institute, New York,2011.

[16]E.Condes, "Fast Fourier Transform for Arduino,"[Online].Available:https://github.com/kosme /arduinoFFT.[Accessed2019].

[17]T. J. Barnish, M. R. Muller and D. J. Kasten, "Motor Maintenance:ASurveyofTechniquesandResults,"in Proceedings of the 1997 ACEEE Summer Study on EnergyEfficiencyinIndustry.AmericanCouncilforan Energy-EfficientEconomy,Washington,DC,1997.

[18]E. Cowern, "Motor Temperature Ratings," Baldor Basics:Motors,no.317,pp.42-47, March2017.

[19]R.J.Lawerie,"Commoncausesof vibration,"EC&M: ElectricalConstructionandMaintenance,vol.3,no.92, 1994.

[20]Y.R.PatniandM.Ansari,"ReviewpaperonStatorand RotorFaultDiagnosis Of3-PhaseInductionMotors," International Research Journal of Engineering and Technology,vol.5,no.4,pp.180-185,2018.

[21]PK,I.Diah,B.Y.DewantaraandW.M.Utomo,"Healthy MonitoringandFaultDetectionOuterRaceBearingin InductionMotorUsingStatorCurrent,"International Journalof IntegratedEngineering,vol.11,no.3,2019.

[22]D. S. Matteson and N. A. James, "A nonparametric approach for multiple change point analysis of multivariate data," Journal of theAmerican StatisticalAssociation,vol.109,no.505,pp.334-335, 2014.

[23]Gandy, "Sequential implementation of Monte Carlo tests with uniformly bounded resampling risk," Journal of the American Statistical Association, vol. 104,no.488,pp.1504-1511,2009.

[24]Cheng, Mengyu, Xing Zhao, Mahmoud Dhimish, Wangde Qiu, and Shuangxia Niu. "AReview of Datadriven Surrogate Models for Design Optimization of ElectricMotors."IEEE Transactionson Transportation Electrification(2024).

[25]Manuel, Nelson Luis, Nihat İnanç, and Murat Lüy. "Control and performance analyses of a DC motor using optimized PIDs and fuzzy logic controller." Results in Control and Optimization 13 (2023): 100306.

[26]Omar,Mohamed,EhabSayed,MohamedAbdalmagid, Berker Bilgin, Mohamed H. Bakr, and Ali Emadi. "Review of machine learning applications to the modeling and design optimization of switched reluctancemotors."IEEEAccess10(2022):130444130468