International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 01 | Jan 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 01 | Jan 2025 www.irjet.net p-ISSN: 2395-0072

Sanyami Chaudhary1 , Maithili Choudhary2

1,2 B. Tech Student, Department of Mechanical Engineering, St. Vincent Pallotti College of Engineering and Technology, Nagpur, Maharashtra, India ***

Abstract - Improvement of productivity is crucial for manufacturing industries to remain competitive and achieve breakthroughs. Work study serves as a powerful tool to identify and eliminate non-value-added (NVA) activities, thereby improving overall productivity. In this case study, the timestudyisconductedusing processmappingtoevaluatethe work activities of manual operators in the casting industry. It aims to maintain the same output while minimizing input resources, particularly labor, to streamline operations effectively. The study aims to identify NVA activities, record cycle and idle time, assess workforce utilization, and provide recommendations for manpower planning. By analyzing and mapping the work processes, the research highlights areas of redundant activities and proposes changes to optimize labor efficiency, reduce workplace stress, and ensure better workload distribution. Theresults ofthisstudyareexpectedto contribute to both time and cost optimization within the company.

Key Words: Productivity Improvement, Time Study, NVA, WorkforceAllocation,LaborOptimization

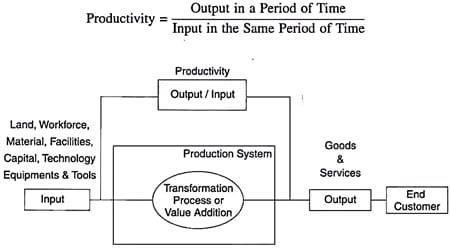

1.1 Productivity

Productivityisacriticalmeasureofefficiencythatreflectsthe relationship between outputs and inputs in a production process.Itcanbedefinedastheamountofoutputproduced perunitofinputused,whichmayincludelabor,materials, andcapital.

Inmathematicalterms,productivitycanbeexpressedas:

Productivity=Output/Input

This concept is fundamental in both economic theory and practical business applications, as it directly impacts profitabilityandcompetitiveness.Highproductivityindicates that an organization is effectively utilizing its resources to generategoodsorservices,whilelowproductivitysuggests inefficienciesthatneedtobeaddressed.

Productivitycanbeincreasedby:

I.Generatingmoreoutputsfromthesamelevelofinputs.

II. Producing the same level of outputs with a reduced levelofinputs.

III.Acombinationofboth.

Work study is a systematic approach aimed at improving productivity through the analysis of work processes. The objectiveofworkstudyistoidentifythemostefficientways ofperformingtaskswhileminimizingwasteandoptimizing resourceuse.

The International Labor Organization (ILO) defines work studyas:"Atermusedtoembracethetechniquesofmethod studyandworkmeasurementwhichareemployedtoensure the best possible use of human and material resources in carryingoutaspecifiedactivity."

Work study comprises two areas of study: Method study (motionstudy)andTimestudy(workmeasurement). Timestudyservesasacrucialtooltoevaluateandimprove workprocesseswhilemaintainingqualitystandards.Ithelps in determining accurate labor requirements, optimizing resource utilization, and establishing realistic production schedules.

Thiscasestudyisbasedonasmall-scalecastingindustryin theMaharashtraregion Thecastingindustryisacornerstone of manufacturing, enabling the production of intricate and durable metal components across diverse sectors such as automotive,aerospace,andconstruction.Thisindustryrelies ontheprocessofpouringmoltenmetalintomoldstoachieve precise shapes, making it essential for high-performance applications.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 01 | Jan 2025 www.irjet.net

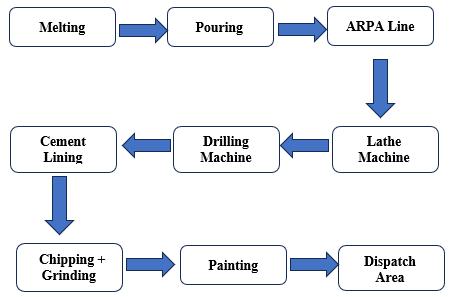

Theindustryprocesschartbelowillustratesthesequenceof operationsandkeystagesinvolvedintheworkflow

Fig -2:ProcessChart

1.4 Problem Statement

Improvementofproductivitytoincreaseoverallprofitability bymaintainingthesamelevelofoutputwhilereducingthe inputsrequired.

1.5 Objectives

a) Optimizeresourceutilization

b) Efficiencyenhancement

c) Costreduction

2. RESEARCH METHODOLOGY Fig -3:ResearchMethodology

Datawascollectedfromtheindustryusingvideographyto capturethemeltingandpouringprocesses.Fouriterations oftheprocesswereobserved,anddetailedtimestudydata sheetswerecreatedbasedontherecordedfootage.

Table -1: TimeStudyObservationSheet

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 01 | Jan 2025 www.irjet.net p-ISSN: 2395-0072

Melting + Pouring:

The process begins with two crucibles, each having a capacityof1.5tons,usedformeltingrawmaterials.Ittakes approximately60minutestomeltthemetalstotheirmolten stateatacontrolledtemperature.

Ttotal =Totaltimeforthemeltingprocess=3302seconds

Ttouch =Timewhenworkerswerenotidle=1785seconds

Tidle=Timewhenworkerswereidle=1517seconds

Time without worker involvement = 1286 seconds (Only meltinginprocess)

Nworkers =Totalnumberofworkersinvolved=9

The ideal time for the pouring process is 7 minutes = 420 seconds

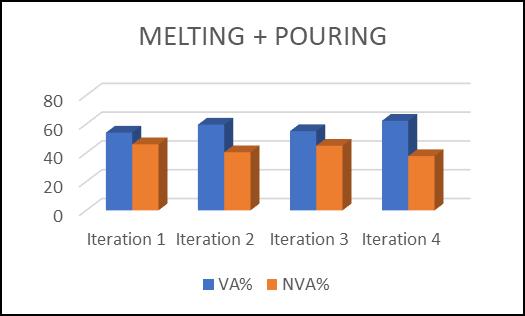

VA%=TouchTime/TotalTime*100 =1785/3302*100 =54.06%

NVA%=IdleTime/TotalTime*100 =1517/3302*100 =45.94%

Theabovedatacorrespondstomeltingandpouringprocess ofIteration1.

Similar data collection and calculations have been carried outfortheotherthreesubsequentiterations

Chart -1: VA and NVA Comparison

TheabovegraphreflectsthescopeofreducingNVAactivities and enhancing overall productivity in the melting and pouringoperation.

Datawascollectedinafoundry,includingtouchtime,idle time, and total time, to analyze the efficiency of activities. ThisdatawasusedtocalculatetheValue-Added(VA)and Non-Value-Added (NVA) percentages of operations. Observations revealed significant NVA activities, during whichseveralworkerswereunutilized.Toaddressthis,the workforceallocationwasoptimizedbyreducingthenumber ofworkersinvolvedinNVAtasks.Basedonthisanalysis,a revisedworkforceplanmayensurebetterutilizationoflabor andimprovedproductivity.

Table -2: WorkforceComparison

Existingworkforce: Engineer-1

GeneralWorkers–9

-Melting-5

-Pouring-4

Recommendedworkforce: Engineer-1

GeneralWorkers–4 -Melting-2

-Pouring-2

Thedata indicates thatcertaintaskscanbereallocatedor streamlinedtooptimizetheexistingworkforce,eliminating inefficiencies and maximizing the utilization of current resources.

Insights from VA% and NVA% can guide us to eliminate bottlenecks, highlighting areas where reductions in nonvalue-addedactivitiesarenecessarytoimproveefficiency.

This productivity improvement research highlights the criticalimportanceofbalancingValue-Added(VA)andNonValue-Added(NVA)activitiesinasmall-scaleindustry. Toimproveproductivity,thenumberofworkershasbeen suggestedtobereducedsothateachoneremainsoccupied withatask,withsomebuffertimeavailable.Thisapproach minimizesidletimeandresultsinhigheroverallutilization. Thelaborthatwaspreviouslyreducedcanbereassignedto other tasks during idle periods to optimize resource utilization.

Bystreamliningtasksandoptimizingtheexistingworkforce, theindustrycanenhanceproductivitywithouttheneedfor additionallabor.Implementingthesechangesleadstobetter utilizationofresourcesandmoreefficientoperations.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 01 | Jan 2025 www.irjet.net p-ISSN: 2395-0072

Thefuturescopeofthisprojectliesinfurtheroptimizingthe productivity of small-scale industries by extending the findings to other processes and departments. By refining laborallocationthroughdata-driveninsights,industriescan standardizeoperationsandreducedependencyonexcessive manpower, leading to cost savings. Advanced techniques such as automation and lean manufacturing could be exploredforlabor-intensive tasks.Additionally,thisstudy can serve as a foundation for implementing ergonomic improvements and enhancing workplace safety. The methodology could also be applied to similar industries, helping them achieve higher efficiency. With continued analysis,theindustrycanadapttochangingdemandswhile maintaining consistent output, ensuring long-term sustainabilityandcompetitivenessinthemarket.

Wewishtoexpressoursincerethanksandsenseofgratitude to our mentor for his guidance, constant motivation, and continuous support throughout the tenure. We sincerely thank the industry professionals for their support and for allowing us to conduct this research within their organization.Wethankourcolleagueswhoprovidedtheir insightsinthestudy.

[1] VatsalSingh,SharwariNalawade,AshishDhongde,and Saumdeep Bera: “Productivity Improvement by Time StudyAnalysisModerateScaleIndustry–Manufacturing of Cutting Tools”, International Research Journal of EngineeringandTechnology(IRJET),Volume06,Issue 04,2019.

[2] Ateeq ur Rehman, Muhammad Babar Ramzan, Muhammad Shafiq, Abher Rasheeda, Muhammad SalmanNaeemaandMatteoMarioSavino:“Productivity Improvement Through Time Study Approach: A Case Study from An Apparel Manufacturing Industry of Pakistan”,ScienceDirect,2019.

[3] Shantanu Ravindra Kale: “Improving Productivity by Reducing the Assembly Time of Rotary Tillers in A Manufacturing Industry in Maharashtra, India”, International Research Journal of Engineering and Technology(IRJET),Volume08,Issue09,2021.

[4] AfrazRajiwate,HuzefaMirza,SamiKaziandMohd.Moiz Momin:“ProductivityImprovementbyTimeStudyand Motion Study”, International Research Journal of EngineeringandTechnology(IRJET),Volume07,Issue 03,2020

[5] RavikumarKambleandVinayakKulkarni:“Productivity Improvement at Assembly Station Using Word Study Techniques”, International Journal of Research in EngineeringandTechnology(IRJET),Volume03,Issue 09,2014.