International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

B V Mathew1 , Kripa K M2 , Shifana K3 , Viswetha V4, Binu K U5, Geethu G

1 Head of the Dept., Dept. of Civil Engineering, Ahalia School of Engineering and Technology, Kerala, India.

2Assistant Professor, Dept. of Civil Engineering, Ahalia School of Engineering and Technology, Kerala, India.

3UG Scholar, Dept. of Civil Engineering, Ahalia School of Engineering and Technology, Kerala, India.

4UG Scholar, Dept. of Civil Engineering, Ahalia School of Engineering and Technology, Kerala, India.

5UG Scholar, Dept. of Civil Engineering, Ahalia School of Engineering and Technology, Kerala, India.

6UG Scholar, Dept. of Civil Engineering, Ahalia School of Engineering and Technology, Kerala, India.

Abstract

The study on the Parametric Analysis of Engineered Cementitious Composite (ECC) and Ultra-HighPerformanceConcrete(UHPC)FilledDoubleSteelTubular Composite Columns explores the structural performance of these advanced composite columns under axial compression and varying parametric conditions. Double steel tubular composite columns, widely used in high-rise and heavy-load structures, exhibit superior strength and durabilitywhenfilledwithECCandUHPCduetotheirhigh ductility, impact resistance, and crack control properties. Thisresearchemploysfiniteelementmodellingtoanalyse theeffectsofkeyparameterssuch assteel tubethickness, steel tube diameter, slenderness ratio, and material properties on load-bearing capacity, deformation behaviour,andenergyabsorption.

Additionally, the study incorporates stiffeners vertical, circular, and diagonal within the composite columns to enhance strength, prevent local buckling, and improve load-carryingefficiency.Stiffenerscontributetoincreased stability, reduced deformation, and efficient load transfer, reinforcing the structural integrity of the columns. A detailedfailuremechanismanalysisisconductedtoassess the impact of these reinforcements under varying conditions. The research findings provide valuable insights into optimizing design parameters for improved structural resilience, weight efficiency, and service life, offering engineers data-driven guidelines for safer and more efficient high-rise buildings and large-scale infrastructureprojects.

Key Words: ECC, UHPC, Double Steel Tubular Composite Columns, Axial Compression, Finite Element Modelling, Stiffeners, Load-Bearing Capacity, Deformation, Local Buckling, Structural Integrity.

1. INTRODUCTION

The parametric analysis of Engineered Cementitious Composites (ECC) and Ultra-High-Performance Concrete (UHPC)filleddoublesteeltubularcompositecolumnsisa

crucial research area in structural engineering. These columns, consisting of inner and outer steel tubes filled with ECC between the steel tubes and UHPC in the core, offer superior load-bearing capacity, ductility, and durability, making them ideal for high-rise buildings, bridges, and heavy-load structures. The unique material combination of ECC and UHPC enhances the column's overall performance by providing high compressive strength,crackresistance,andenergyabsorption.

In this study, stiffeners are introduced to further improve structural stability. These stiffeners are incorporated within the double steel tubular columns to prevent local buckling, enhance load transfer, and optimize overall strength. The research involves a detailed parametric analysis using finite element modelling, investigating variablessuchassteeltubethickness,steeltubediameter, slenderness ratio, stiffener configurations, and material properties to optimize the structural behaviour under axialandeccentricloadingconditions.

Engineered Cementitious Composite (ECC), often referred to as "bendable concrete," is a fibre-reinforced cementitious material known for its high ductility, crack control, and energy absorption properties. Unlike conventional concrete, which is brittle and prone to cracking, ECC forms multiple micro-cracks under stress, allowingittomaintainstructuralintegrityeveninextreme conditions.

ECCiscomposedofcement,sand,water,chemicaladditives and microfibres that improve its tensile properties. These microfibres help bridge cracks and distribute stress efficiently, making ECC ideal for earthquake resistant structures, bridge decks, pavements, and high-durability infrastructure.Thematerial'ssuperiorflexibilityandlongterm durability reduce maintenance costs and enhance sustainabilityinmodernconstruction.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

Ultra-High-Performance Concrete (UHPC) is an advanced form of concrete that provides exceptional mechanical strength and durability, significantly surpassing conventional concrete. With compressive strength exceeding 120 MPa, UHPC is widely used in critical infrastructureprojectssuchasbridges,high-risebuildings, andmilitarystructures.

UHPC consists of fine aggregates, high-quality cement, silica fume, superplasticizers, and steel fibres, which create a dense microstructure resistant to abrasion, chemical attacks, and freeze-thaw cycles. The inclusion of steel fibres enhances tensile strength and toughness, preventingbrittlefailureunderhigh-stressconditions.

Additionally,UHPCexhibitsself-healingproperties,where micro-cracks seal over time, further extending the material’s service life. Despite challenges such as high initial cost and complex mix design, ongoing research is making UHPC a more accessible and efficient solution for long-lastingandsustainableconstruction.

Mild steel (FE250) is widely used in structural applications due to its balanced strength, ductility, and cost-effectiveness. Classified under IS 2062 standards, FE250 has a minimum yield strength of 250 MPa, making it suitable for medium-load structures such as beams, columns,andframesinbuildingsandbridges.

Its low carbon content enhances weldability, formability, and ductility, allowing for easy fabrication and stress absorption without fracturing. Although it does not provide the high tensile strength of alloyed steels, FE250 compensates with affordability and versatility. It is also corrosion-resistant when treated or coated, expanding its usabilityinvariousenvironmentalconditions.

Toenhancethestructuralintegrityofdoublesteeltubular composite columns, stiffeners are incorporated in different configurations. These stiffeners help in preventing local buckling, improving stress distribution, and increasing overall load-bearing capacity. The followingtypesofstiffenersareintroducedinthisstudy:

1.4.1 Vertical Stiffeners

Placedalongtheheightofthecolumn.

Provide additional axial strength and reduce deformation.

Enhance buckling resistance under axial and lateralloads.

Positionedatregularintervalsinsidethecolumn.

Improve confinement effect by distributing loads moreevenly.

Increase local stability and prevent distortion of theinnerandoutersteeltubes.

Placed at an angle between the inner and outer tubes.

Enhanceshearresistanceandenergyabsorption.

Improve load transfer efficiency, especially in seismicconditions.

By integrating these stiffeners with ECC and UHPC, the columns achieve higher strength, stability, and resilience, making them more efficient for modern structural applications.

Thisstudyfocusesonthe parametric analysis of ECC and UHPC-filled double steel tubular (EUFDST) composite columns under axial compression using finite element modelling in ANSYS. It examines the influence of key design parameters, including steel tube thickness, steel tube diameter, slenderness ratio, and stiffener configurations (vertical, circular, and diagonal) on the structural performance of EUFDST columns. The research aims to optimize these parameters for improved loadbearing capacity, deformation behaviour, and energy absorption, making the findings applicable to highrise buildings, bridges, and heavy-load infrastructure.

To conduct a parametric analysis of ECC and UHPC-filled double steel tubular composite columnsunderaxialloading.

To evaluate the effect of key dimensional parameters on the structural performance of the columns,including:

L/D ratio and its impact on buckling behaviour.

Steel tubediameteranditsinfluenceonloadbearingcapacity.

Steel tube thickness and its role in confinementefficiencyandductility.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

To analyse the contribution of different stiffener configurations in enhancing column strength and stability,specifically:

Vertical stiffeners for controlling local buckling.

Circular stiffeners for improving confinementandloaddistribution.

Diagonal stiffeners for increasing shear resistanceandoverallstructuralintegrity.

To compare the ultimate load-carrying capacity and deflection of composite columns with different material infill (ECC and UHPC) and stiffenerarrangements.

To optimize the design of double steel tubular composite columns by identifying the most effective combination of material properties, dimensional parameters, and stiffener configurations for improved structural performance.

The Finite Element Method (FEM) is a numerical analysis technique used to approximate engineering solutions by dividingstructuresintosmallerfiniteelements,assembled at nodes. It employs shape functions to approximate displacement, strain, and stress, while the virtual displacement principle is used to derive equilibrium equations.

ANSYS 2024 R2 Workbenchisutilizedfornonlinearstatic analysistoevaluatethestructuralperformanceofEUFDST compositecolumns Advanced featureslikesub-modelling, random vibration, and design optimization enhance accuracyinsimulations.

Thestudyinvolves25models,including13withstiffeners (vertical, circular, and diagonal), analysed under axial compression and eccentric loading conditions. Key output parameters include load capacity, deflection, stress distribution, and failure modes, which help assess the structuralperformanceofthecompositecolumns.

Forfiniteelementmodelling,SOLID65isusedforconcrete, simulating cracking and crushing effects, while SOLID186, a higher-order 3D element, ensures precise stress calculations. CONTA174 and TARGE170 handle contact interactionsbetweenstructuralcomponents.

Material modelling in Finite Element Analysis (FEA) includes nonlinear material models for concrete and steel. The concrete model incorporates cracking, crushing, and

plasticity, whereas the steel model considers yielding, strainhardening,andductilitytoensurerealisticstructural behaviour.

ThisFEM-basedstudyprovidesinsightsintothestructural behaviour, load resistance, and failure mechanisms of EUFDST composite columns. The inclusion of stiffeners further enhances stability and strength, contributing to optimizedstructuraldesignandperformanceprediction.

Table -1: ParametricData

Table -2: ParametersofReferenceModel

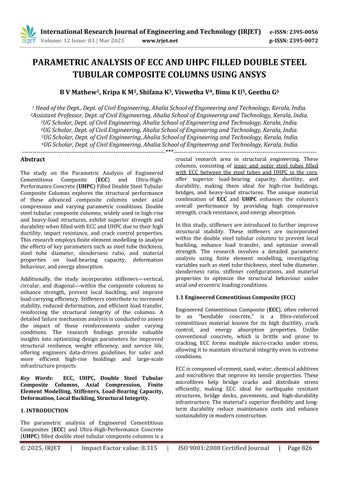

Table -3: ParametersofVerticalStiffeners

Table -4: ParametersofCircularStiffeners

Table -5: ParametersofDiagonalStiffeners

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

4.1 EUFDST Composite Column parameters

4.2 Axial and Eccentric loading boundary conditions

4.3 Arrangements of different types of Stiffeners

4.3.1 Vertical stiffeners M3-2-AIO-16S

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

M3-2-AIO-8S

M3-2-AIO-4S

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072 © 2025, IRJET | Impact Factor value: 8.315 | ISO 9001:2008 Certified Journal | Page830

M3-2-AI-8S

M3-2-AI-4S

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

M3-2-AO-8S

M3-2-AO-4S

4.3.2 Circular stiffeners

CIRCULAR-16S

CIRCULAR-8S

© 2025, IRJET | Impact Factor value: 8.315 | ISO 9001:2008 Certified Journal | Page831

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

4.3.3 Diagonal stiffeners

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072 © 2025, IRJET | Impact Factor value: 8.315 | ISO 9001:2008 Certified

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

5.1 Results and Discussions of EUFDST Composite Columns

:M3-1-Axial(InnertubeDia=168.3mm)

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

:M6-1-Axial(InnertubeDia=168.3mm)

Fig-6:M6-1-Eccentric(InnertubeDia=168.3mm)

Fig-7:M6-2-Axial(InnertubeDia=60.3mm)

Fig-8:M6-2-Eccentric(InnertubeDia=60.3mm)

Fig-9:M9-1-Axial(InnertubeDia=168.3mm)

Fig-10:M9-1-Eccentric(InnertubeDia=168.3mm)

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

Fig-11:M9-2-Axial(InnertubeDia=60.3mm)

Fig-12:M9-2-Eccentric(InnertubeDia=60.3mm)

Fig-13:Load-DeflectioncurveunderAxialLoading

Fig-14:Load-DeflectioncurveunderEccentricLoading

Fig-15:DeformationComparisonchartunderAxial Loading

Fig-16:DeformationComparisonchartunderEccentric Loading

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

Fig-17:LoadComparisonchartunderAxialLoading

Fig-18:LoadComparisonchartunderEccentricLoading

5.2 Results and Discussions of EUFDST Composite Columns with Stiffeners

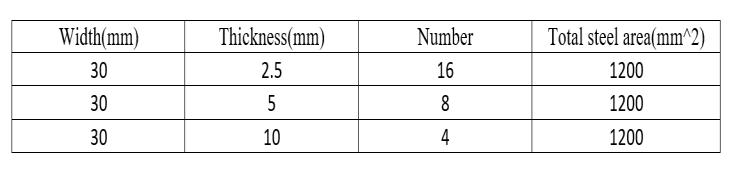

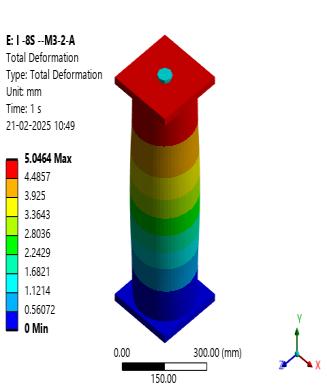

5.2.1 Vertical Stiffeners

Fig-19:M3-2AEUFDSTCCwith16InnerandOuterVertical Stiffeners

Fig-20: M3-2AEUFDSTCCwith8InnerandOuterVertical Stiffener

Fig-21: M3-2AEUFDSTCCwith4InnerandOuterVertical Stiffeners

Fig-22:M3-2AEUFDSTCCwith8InnerVerticalStiffeners

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Fig-23:M3-2AEUFDSTCCwith4InnerVerticalStiffeners

Fig-24:M3-2AEUFDSTCCwith8OuterVerticalStiffeners

Fig-25:M3-2AEUFDSTCCwith4OuterVerticalStiffeners

Fig-26: LoadvsDeflectioncurve

Fig-27: Deformationcomparisonchart

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072 © 2025, IRJET | Impact Factor value: 8.315 | ISO 9001:2008

Fig-28: Loadcomparisonchart

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Fig-29: %IncreaseinLoadchart

5.2.2 Circular Stiffeners

Fig-30:M3-2AEUFDSTCCwith16CircularStiffeners

Fig-31:M3-2AEUFDSTCCwith8CircularStiffeners

Fig-32:M3-2AEUFDSTCCwith4CircularStiffeners

Fig-33: LoadvsDeflectioncurve

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072 © 2025, IRJET | Impact Factor value: 8.315 | ISO 9001:2008

Fig-34: Deformationcomparisonchart

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Fig-35: Loadcomparisonchart

Fig-36: %IncreaseinLoadchart

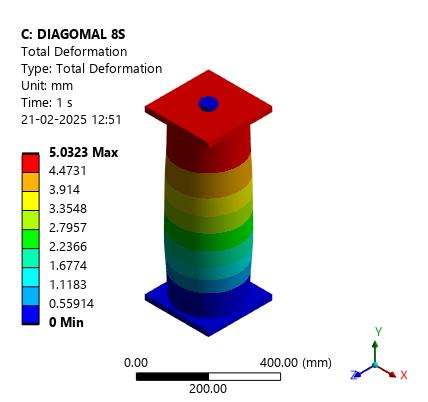

5.2.3 Diagonal Stiffeners

Fig-37:M3-2AEUFDSTCCwith16DiagonalStiffeners

Fig-38:M3-2AEUFDSTCCwith8DiagonalStiffeners

Fig-39: M3-2AEUFDSTCCwith4DiagonalStiffeners

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072 © 2025, IRJET | Impact Factor value: 8.315 |

Fig-40: LoadvsDeflectioncurve

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

Fig-41: Deformationcomparisonchart

Fig-42: Loadcomparisonchart

Fig-43: %IncreaseinLoadchart

6.1 From the axial loading case

TheanalysisontheperformanceofAxiallyloadedEUFDST composite columns, it is determined that column models with larger inner tube diameter (d=168.3mm)(Models: M3-1-A,M6-1-A,M9-1-A)showsbetterperformancewhen compared with column models with smaller inner tube diameter (d=60.3mm)(Models: M3-2-A, M6-2-A, M9-2-A), increasing the inner tube Diameter and it's thickness contributes more steel area and more volume of UHPC which performs the better axial strength and enough volumeofECCtowithstandthetensilestress.

6.2 From the eccentric loading case

The analysis on the performance of Eccentrically loaded EUFDST composite columns, it is determined that column models with larger inner tube diameter (d=168.3mm)(Models: M3-1-E, M6-1-E, M9-1-E) shows better performance when compared with column models with smaller inner tube diameter (d=60.3mm)(Models: M3-2-E, M6-2-E, M9-2-E), increasing the inner tube Diameter and it's thickness contributes more steel area and more volume of UHPC which performs the better column strength and enough volume of ECC to withstand thetensilestress.

As the set of column models with λ=3 shows better performance than other models, the model M3-2-A has been taken as the representative model to incorporate stiffeners as its inner steel tube diameter is smaller and the space between two steel tubes facilitates the phenomenon.

Vertical

The analysis on the performance of EUFDST composite columns with Vertical Stiffeners, it is determined that column IO-16S-M3-2A model shows better structural performancewhencomparedwiththeothercombinations of vertical stiffeners- IO-8S-M3-2A, IO-4S-M3-2A, I-8S-M32A,I-4S-M3-2A,O-8S-M3-2A,O-4S-M3-2Amodels,itshows lessdeformationandhighloadcarryingcapacitywithmore confinement property of 16 number of inner and outer stiffenersinsidethecolumnimprovestheoverallstructural performance.

The analysis on the performance of EUFDST composite columns with Circular Stiffeners, it is determined that column CIRCULAR-4S model shows better structural performancewhencomparedwiththeothercombinations

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

of circular stiffeners- CIRCULAR - 16S, CIRCULAR - 8S models, it shows less deformation and high load carrying capacity with more confinement property of 4 number of stiffeners inside the column enhances overall structural performance

Since the behaviour of CIRCULAR 16-S and CIRCULAR 4-S models are same, both options have the same total crosssectionalareaof1200mm²,meaningthematerialusageis identical.

However,economyalsodependsonfactorslikefabrication, welding,andstructuralefficiency:

16 stiffeners of 2.5 mm thickness might involve more cutting, handling, and welding, increasing labourcosts.

4 stiffeners of 10 mm thickness requires fewer stiffeners, meaning less welding and fabrication time, making it more economical in practical terms.

HenceCIRCULAR-4Smodelislikelymoreeconomicaldue toreducedlabourandfabricationefforts.

The analysis on the performance of EUFDST composite columns with Diagonal Stiffeners, it is determined that column DIAGONAL 16S model shows better structural performancewhencomparedwiththeothercombinations of diagonal stiffeners- DIAGONAL 8S, DIAGONAL 4S models, it shows less deformation and high load carrying capacitywithmoreconfinementpropertyof16numberof stiffeners inside the column increases overall structural performance

The analysis on the ECC and UHPC Filled Double Steel Tubular Composite Columns with (Vertical, Circular and Diagonal) Stiffeners, the column with Vertical stiffeners shows better performance than other models.

[1] Pagoulatou, M., et al. ”Finite element analysis on the capacity of circular concrete filled double-skin steel tubular (CFDST) stub columns.” Engineering Structures72(2014):102-112.

[2] Han, Lin-Hai, Hong Huang, and Xiao-Ling Zhao. ” Analytical behaviour of concrete-filled double skin steel tubular (CFDST) beam-columns under cyclic loading.” Thin-walled structures 47.6-7 (2009): 668680.

[3] Huang, Hong, et al.”Analytical behaviour of concretefilled double skin steel tubular (CFDST) stub

columns.” Journal of Constructional Steel Research 66.4(2010):542-555.

[4] Tao, Zhong, and Lin-Hai Han. ”Behaviour of concretefilled double skin rectangular steel tubular beam–columns.” Journal of Constructional Steel Research 62.7(2006):631-646.

[5] Li, Wei, et al.”Behaviour of tapered concrete-filled double skin steel tubular (CFDST) stub columns.” Thin-walledstructures57(2012):37-48.

[6] Ekmekyapar, Talha, and Hussein Ghanim Hasan. ”The influence of the inner steel tube on the compression behaviouroftheconcretefilleddoubleskinsteeltube (CFDST)columns.”MarineStructures66(2019):197212.

[7] Hsiao, Po-Chien, et al.”Investigation of concrete-filled double-skin steel tubular columns with ultrahighstrengthsteel.”Journalofstructuralengineering141.7 (2015):04014166.

[8] Li, Wei, Lin-Hai Han, and Xiao-Ling Zhao. ”Axial strength of concrete-filled double skin steel tubular (CFDST) columns with preload on steel tubes.” Thinwalledstructures56(2012):9-20.

[9] Deng, Ran, et al.”Compressive behaviour of tapered concrete-filled double skin steel tubular stub columns.” Journal of Constructional Steel Research 184(2021):106771.

[10] Ayough,Pouria,NHRamliSulong,andZainahIbrahim. ”Analysis and review of concrete-filled double skin steel tubes under compression.” Thin-Walled Structures148(2020):106495.

[11] Jiang,Liangqin,etal."BearingBehaviorofEngineered Cementitious Composite and Ultra-High-Performance Concrete Filled-In Double Steel Tubular Composite Columns Subjected to Eccentrical Load." Buildings 14.5(2024):1487

[12] Zhang,Zaiyu,etal."Experimentalinvestigationonthe seismic performance of square concrete/ECC filled stiffened high-strength steel tubular columns." EngineeringStructures314(2024):118341.

[13] Du, Panwei, You-Xin Ma, and Kang Hai Tan. "Experimental study of ultra-high-performance fiberreinforced concrete (UHPFRC)-encased CFST short columns under axial and eccentric compression." EngineeringStructures316(2024):118452.

[14] Jiang,Liangqin,etal."BearingBehaviorofEngineered Cementitious Composite and Ultra-High-Performance Concrete Filled-In Double Steel Tubular Composite

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 03 | Mar 2025 www.irjet.net p-ISSN: 2395-0072

Columns Subjected to Eccentrical Load." Buildings 14.5(2024):1487.

[15] Yuan,Fang,HongHuang,andMengchengChen."Effect of stiffeners on the eccentric compression behaviour ofsquareconcrete-filledsteeltubularcolumns."ThinWalledStructures135(2019):196-209.

[16] Bahrami, Alireza, Wan Hamidon Wan Badaruzzaman, andSitiAminahOsman."Numericalstudyofconcretefilled steel composite (CFSC) stub columns with steel stiffeners." Latin American Journal of Solids and Structures11(2014):683-703.

[17] Liu, Jiepeng, et al. "Seismic behavior of thin-walled square CFST columns with diagonal rib/circular liner stiffeners." Journal of Constructional Steel Research 179(2021):106519.

[18] Ghannam, Mohamed, and Ibrahim M. Metwally. "Numericalinvestigationforthebehaviourofstiffened circular concrete filled double tube columns." Structures.Vol.25.Elsevier,2020.

[19] Yuan,Fang,HongHuang,andMengchengChen."Effect of stiffeners on the eccentric compression behaviour ofsquareconcrete-filledsteeltubularcolumns."ThinWalledStructures135(2019):196-209.

[20] Zheng,Ming,XinNie,andRanDing."Experimentaland numerical research on the uniaxial behaviour of the stiffened circular concrete-filled steel tube stub columns." Engineering Structures 306 (2024): 117785.