International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 01 | Jan 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 01 | Jan 2025 www.irjet.net p-ISSN: 2395-0072

Bhagyashri Jadhavar1 , Dr.Digambar Date2 , Dr.V.V.Mane3

1M.Tech Student Dept. of Mechanical Engg. College of Engineering Dharashiv, Maharashtra, India

2H.O.D. Dept. of Mechanical Engg. College of Engineering Dharashiv, Maharashtra, India

2Principal College of Engineering Dharashiv, Maharashtra, India

Abstract – This project work is based on the LS-DYNA code which captures the impact phenomenon on a given target material of ceramic, steel/ceramic and ceramic/FRP and projectile system. In this project investigation of projectile mass, the residual velocity of the projectile, plate orientation means their material, properties, width, stress, structure etc., kinetic energy, and sliding energy. To do finite element (FE) simulation to capture impact phenomenon on a given armour plate and projectile system. To develop a high-quality composite sandwich for ballisticprotection fortargetmaterial from the impact of a high-velocity projectile system. This simulation is based on the Johnson-Holmquist model and Johnson-cook model. The ceramic (Alumina 99.5%) and the Fibre-reinforced plastic (FRP) are used. The obtained result is in the form of residual velocity and the energy conversation.

Key Words: LS Dyna, Bullet Impact, Composite Material etc.

Composite armors include numerous fabric layers normally made from metals, composite, ceramics, and different materials intently bonded together. Composite armor has spearheaded a vast innovation within the industry, and although there have been some remarkable milestones,theadvancementinballistictechnologyrequires the need for armor systems with extra extraordinary mechanicalandimpactperformance,decreasedweight,and betterformability,abletoresisting excessivethreats. This topic of interest has pioneered the study of advanced sandwich-typecompositearmors,whicharecomposedofa cocktail of functional materials, consisting of ceramics, metals,andcomposites,purposefullyselectedandcombined for their impactor tip erosion functionality, energy dissipation properties, light-weight nature, high stiffness, ductility, and higher protective advantage over the conventional protective bulletproof vest, which is usually madefromasinglelayeroffabric,mostlyaramid.Theaimof this project work is to recognize the design of current sandwicharmorsandusethefindingstocreateasandwich composite armor with higher qualities. Since higher and continuous affect resistance are the focus of armor manufacturers,segmentedarmorsareafantasticmannerto improvemodern-dayarmordesigns.Thisstudiesistargeted ondevelopingsegmentedsandwicharmorwithagradient coremid-section.Thegradientcoredesignistomakesure

thatthelightweightarmorsystemisstillcapabletobetter ballisticresistance.

1.1 Theoretical background

1. Methods to solve any engineering problem-

A. Analytical method

Applicableonlyforsimpleproblemslikecantilever &simplysupportedbeamsetc.completeinitself

B. Numerical method

1. Finite element method (FEM)-

It is a computational tool for performing engineeringanalysis.Itishelpfulformeshbuilding.It is used for solving a numerical problem most of the times. Application – thermal, linear &non-linear, fatigueanddynamicanalysis.

2. Boundary Element Method (BEM) –

BEM is an efficient technique to solve Noise, vibration, and harshness (NVH) and acoustics problems. This method considers the only outer boundaryofthedomainisconsideredintheproblem ofvolumeandfortheareaproblem,itconsidersonly the outer periphery which helps to reduce dimensionalityandsolveaproblemfaster.

3. Finite volume method (FVM)-

FVM assist to solve parabolic, elliptic, or hyperbolicpartialdifferentialequationswithinsidethe shapeofalgebraicequations. Thecomputationalfluid dynamics software is based on the finite volume method (FVM). The FVM is based on Navier- stokes equations;itisEnergyandMomentumconservation equilibriumequations.

4. Finite Difference method (FDM)-

This method Taylor’s series is used to solve the differential equation which is converted into algebraic equations. In this conversation, the higher valve is neglected.

C. Explicit method

a.InthismethodtheABAQUSRADIOSS,MS-DYTRANis thecommonlyusedsoftware.

b. Thecomputationalspeedisveryfastasthereis nomatrix.

c. Thefilteringofthefrequenciesasnosignificant

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 01 | Jan 2025 www.irjet.net p-ISSN: 2395-0072

effectobserved.

d. Thestepsaretoosmallerinorderof1xe-6sec. formeshsizeof5mm.

1.2 Need of armour technique-

SampleWarandcriminalactivityarepartofsociety.All different types of weapons are used to harm the opponent.That’swhythereisalwaysbeentheneedfor protection from enemies. Nowadays weapons are developed to able to increase injury capabilities, improvingtheaccuracyofattackandattackfromalarger distance. For those reasons an armour technology is introducedwhichareopposedtoimpactforcefromthe weapons.

Militaryvehicleswhichwithstandtheimpactof missiles or shells, shrapnel and bullets protecting the personnelinsidefromenemyfire,suchvehiclesinclude armouredfightingvehiclesliketanks,shipsandaircraft.

1.3 Objective

Theobjectiveoftheprojectworkhasbeenstatedas:

To implement a suitable material model and to validate and simulate ceramic armour materialsinanexplicitdynamicFEMtool.

To carry out a depth research review of bullet impactonceramic-Steelarmour.

To carry out a depth research review of bullet impactonceramic-FRParmour.

To analysis the impact of projectile (bullets) on armouratadifferentspeed.

Modifythedifferenttypesofarmour.

1.4 Problem Statement

The aim of the problem is to do finite element (FE) simulation to capture impact phenomenon on a given armour plate and projectile system. Armour plate has beendesignedusingaluminaceramicandfiberreinforced plastic materials. The armour plate is of sandwich construction.Thefrontalpartisceramic.Thebackingof thearmourisprovidedbyglassfiberreinforcedplastic plates. The report has been made to give details of an impactproblemfordoingFEsimulationusingLS-DYNA software.

The types of material including ceramics, composite laminatesandbondingagentsthistypeofmaterialisusedin targetmaterialforarmourapplications.

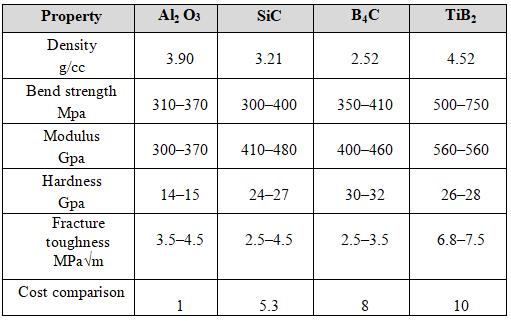

The ceramic is divided into oxide and non-oxide the selectionofceramicforarmourapplicationisprimarilybased on flexural strength, density, hardness and compressive strength.

Aluminaisthefirstandextensivelyusedoxideceramic materialtodateduetoitsreadyavailability,relativelylow cost,andeasytomanufacture.Thestablephaseofaluminais called corundum or α-Al2O3 with the hexagonal crystal structure.Bauxiteistheprimarysourceofaluminaandthe aluminiumhydroxides,andtheseareseparatedthroughthe Bayer process which is further calcined to get alumina. Aluminaforarmourapplicationsiscommonlyprocessedvia way of means of dry pressing or slip casting technique followedbypressurelesssintering.

Thesecond-generationceramicthat'sgettingusedas light-weightceramicarmourincomparisontoaluminafor lots vehicular applications is silicon carbide (SiC). This material has got lower density and better mechanical properties as compared to alumina. It can give higher ballisticmassefficiency.Therefore,Siliconcarbidehasbeen usedinmanyarmoursystemsfordefeatingmoretenacious threats.

Boron carbide is the third hardest material next to diamondandcubicboronnitride.Thecompositionofboron carbide is assigned between B4.3C and B10.4C, but the commercial composition is close to B4C. Boron carbide powderisproducedonacommercialscalebycarbothermic reductionofhydrobromicacidorboronoxidewithgraphite, petroleumcoke,starch,etc.at1500–2500Cusingelectrical resistance or an arc furnace. Even though B4C has got excellentpropertieslikehighhardnessandlowdensity, it suffers from the reduction of shear strength at high pressuresduetoshock-inducedamorphization.

Composite laminates are utilized in both add-on armour or stand-alone armour applications. As the name itselfexplainsadd-on,thearmourislocatedoveranexisting structure.

Thepredominantfunctionoffibrereinforcedplastic inthelaminateistoabsorbbulletkineticenergyeitherby undergoing fracture or elastic plastic deformation and arrest the perforation of the projectile. Glass, ultrahigh molecularweightpolyethylene(UHMWPE)andaramidare the main type of FRP Armour made of these fibres could provide protection against soft bullets such as mild steel, leadandfragments.Here,aramidfibreisuseditisfibreare ofclassheatresistantandstrongsyntheticfibres.Theyare usedinmlitaryapplication,aerospace,etc

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 01 | Jan 2025 www.irjet.net p-ISSN: 2395-0072

Itwasdecidedthatsomuchceramic usedforballistic protectionistobeselectedforfurtherwork.Thecriteriaused forselectingceramicwereasfollows: Select materialsthat-

Lowweightperarea.

Highhardness.

HighEmodulus.

Highfractureresistance.

Bythemanufacturing,automobile,construction, aerospace,military,andbioengineeringindustries.

3.1

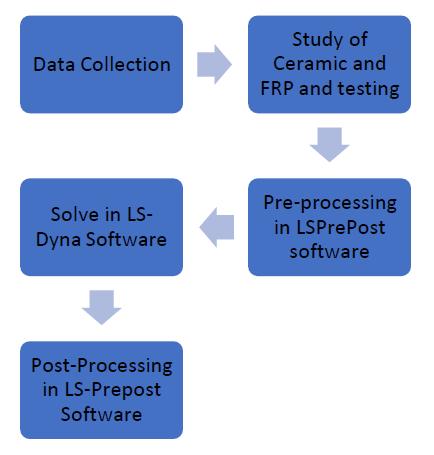

ThesoftwareisusedforsimulationisLS-DYNA.LSDYNAisageneral-purposefiniteelementprogramcapableof simulatingcomplexreal-worldproblemsinday-to-daylife. LS- DYNA is for solving problems in manufacturing, automobile,construction,aerospace,militaryetc.

The armour design is usually done in two phases specially First phase of armor design is the selection of optimumcombinationofmaterialstobeusedandthesecond phaseincludessimulationandtestingofthestructureforthe ballistic resistance of the material being used in the designing of the bullet proof armor and to check the total efficiencyofthearmor.

The bullet proof Armor was designed using several materialslikeceramic,steelcompositemateriallikeFRP& GFRP.

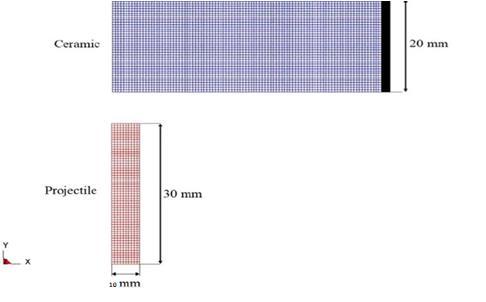

Thebulletismadeaccordingtothedimensionsof10mm in dia and 30mm length. A material tungston alloy is assignedtobulletmodelandisreadyfortheanalysispart.

ThesoftwareisusedforsimulationisLS-DYNA.First,the geometry of both the bullet and the armor has been modelledwithLSPrePostModeler,andthensimulationof the projectile against each sample stacked up in unidirectionallayuphasbeendone.

LS Dyna has been used to solve the model and generate modellingresults.

Case 1-ArmorMaterial-Ceramic(Alumina99.5%)

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 01 | Jan 2025 www.irjet.net p-ISSN: 2395-0072

Result

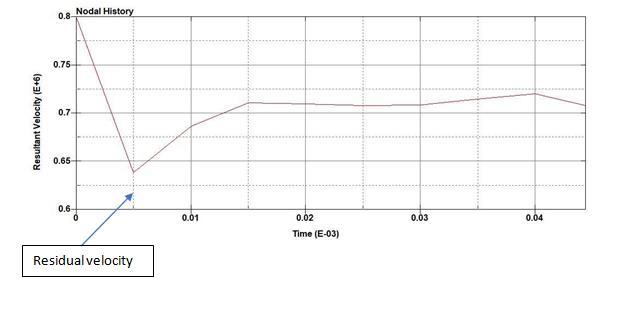

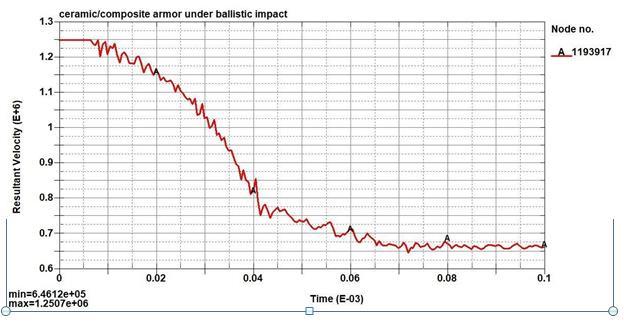

Fig -3: Residualvelocityplotofprojectile

TheresultisDamageoftargetplatewithrespecttotime. Theprojectileitas initialvelocityis800mm/stoResidual velocityis638mm/s

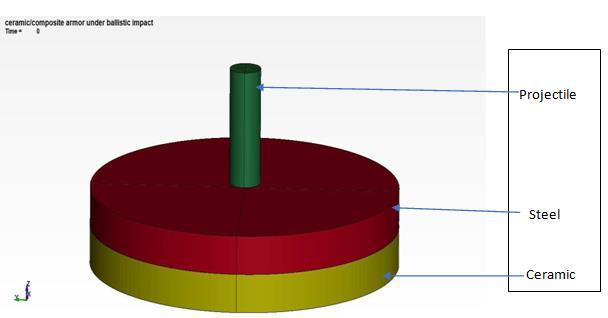

Case 2- ArmorMaterial- CeramicandSteel

Fig -4:TheFEsimulationmodelofprojectileand steel/Ceramictargetmaterial

Result

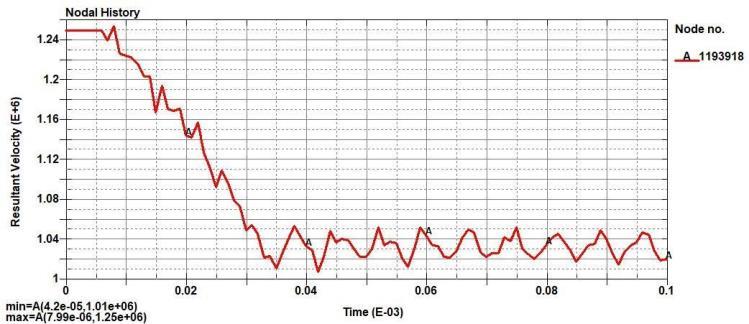

Fig -5:Residualvelocityplotofprojectileforceramic/steel targetmaterial

ItisanFESimulationmodelfortheimpactsimulation problems. In fig 5 a two-layer of the target material the CeramicisAlumina99.5%withitsdensity3700Kg/m3and steelofdensity8050Kg/m3.

Theinitialvelocityoftheprojectileis1250m/s,and theresidualvelocityis1010m/s.

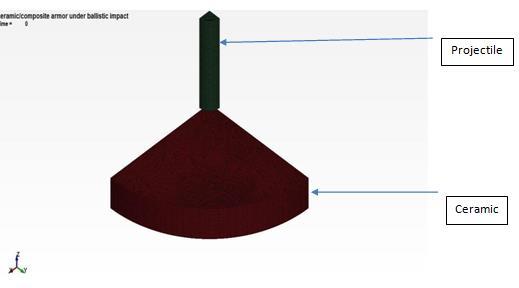

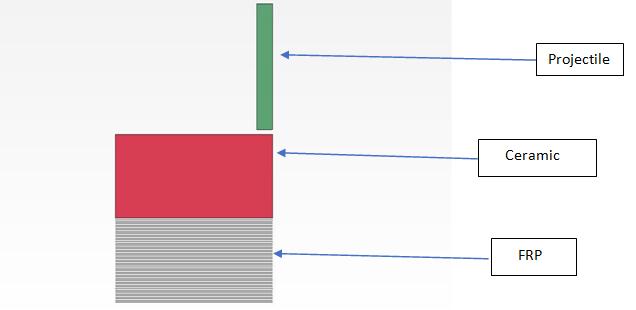

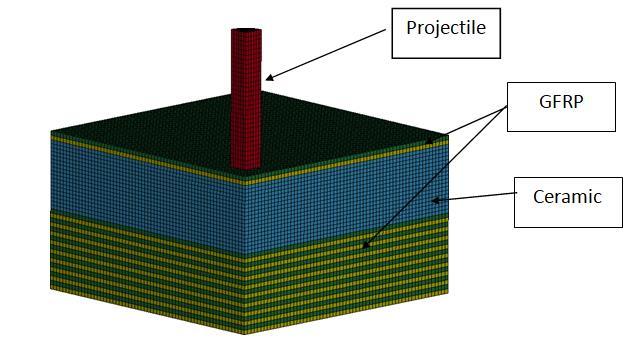

Case 3- Ceramic/compositetargetmaterial

Fig -6: TheFEsimulationmodelof projectileandceramicandCompositetarget material

Result

Fig -7: Residualvelocityplotofprojectile forCeramicandFRPasTargetMaterial

ThedecelerationinKineticEnergyismaineffectonvelocity ofprojectile.Thereis frictionbetweenprojectileandtarget materialofceramicand FRPtheslidingenergyisincreased. The initial velocity of projectile is 1250 m/s, and the residualvelocityis 64 m/s.

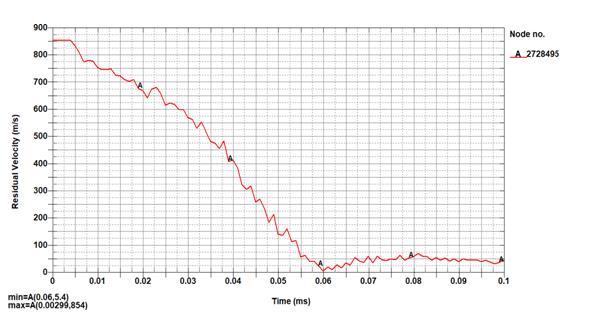

Case 4- Ceramicandcompositesandwichtargetmaterial

Fig -8: FEsimulationmodelofprojectileandceramic andCompositesandwichtargetmaterial

There is friction between projectile and target material of ceramicandFRPtheslidingenergyisincreased. Theinitialvelocityofprojectileis850m/s,andtheresidual velocityis5.4m/s.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 01 | Jan 2025 www.irjet.net p-ISSN: 2395-0072

Fig -9:Residualvelocityplotofprojectileforceramic/ Compositesandwich

Table 5.1: Differencesbetweenceramic targetmaterialapproachandceramic/steel targetmaterialapproach

Particulars Ceramic target material Ceramic / steel

Shape of the specimen Cylindrical Cylindrical

Target Material ceramic Ceramic and steel

Initial velocity

Residual velocity

Safe No No

On basis of this approaches the ceramic as well as ceramic/steeltheresidualvelocitynotbecomezero.Infig5the kinetic energy is get decreased because of steel and ceramic propertiesbutnotwithinlimitsoitnotbecomessafearmour material.

Table 5.1: Impactanalysisofcorrugatedplateofdifferent material

Table9.1.ItcanbeobservedfromtheTable thatceramic& Composite sandwich structure which is softer than other materialscanundergomoresevereplasticdeformationand absorbenergy.

1. Thevarioustypeofmaterialisusedformakingarmour. The armour should have high hardness; high fracture resistance and low weight per area that bases the ceramiccompositearmourisintroduced.

2. Thevarioustypesofceramicareexplained.Thearmour modelsofceramic,ceramic/steel,Ceramic/composite, Ceramic/composite sandwich are discussed on their material specification, layers, involving the ballistic impactonit.

3. Theceramicisreducingtheprojectilespeedupto20% approx. The ceramic with composite sandwich is introduced.

4. IntheceramiccompositesandwichFEsimulationmodel the initial velocity of projectile is 850 m/s it gets reduced up to 5.4 m/s. The projectile depth of penetrationis12.30mm.

5. The reduction in velocity of projectile in ceramic composite sandwich target material is up to 98 % of initialvelocity.

[1] D.Vit.ShanelandMiroslavSpaniel(2013) Procedia Engineering- Ballistic impact experiments and modelling of sandwich armor for numerical simulations.

[2] Z. Rosenberg, E. Dekel, (2012) Terminal ballistics Ch 04 Plate Perforation,Springer,NewYork.

[3] K. Krishnan, S. Sockalingam, S. Bansal, S.D. Rajan (2010)Composites-Numericalsimulationofceramic compositearmorsubjectedtoballisticimpact.

[4] S. Feli, M.R. Asgari (2011) Composites - Finite element simulation of ceramic/compositearmour underballisticimpact.

[5] I. Chocron Benloulo,J. Rodriguez and V. Shchez Galvez(1997) C3, Supplement au Journal de PhysiqueI11d'aoiit-ASimpleAnalyticalModelfor BallisticImpactinComposites

[6] JanardhanaReddyJ,SaivardanN,BhanuPrasadVV. IndigenousdevelopmentaofTitaniumdiborideand other ceramics for armour applications. DMRL TechnicalreportNo.DRDO-DMRL-CCG-085-2015

[7] http://www.np-aerospace.co.uk. Accessed on 28 Apr 2021

Table 5.1 shows the exit velocities for various input velocities.Higherthevelocity,lesseristhetimefortheplate to absorb the kinetic energy. analysis is carried out on Ceramic,Steel&ceramic,andceramic&compositematerials fortheprojectileatdifferentvelocity.Resultsaretabulatedin

[8] G.R. Johnson, T.J. Holmquist, and S.R. Beissel. Response of aluminum nitride (including phase change)tolargestrains,highstrainratesandhigh pressures.J.Appl.Phys.,94(3):1639-1646,2003.