International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 02 | Feb 2025 www.irjet.net p-ISSN:2395-0072

OPTIMIZATION OF ELECTRO-COAGULATION FOR PRIMARY WASTEWATER TREATMENT IN THE SUGAR INDUSTRY

1Abhishek Dattatray Mangalekar, Master of Technology, Environmental Science and Technology, Department of Technology, Shivaji University Kolhapur, Maharashtra, India.

2Shrikant. M. Bhosale, Assistant Professor, Environmental Science and Technology, Department of Technology, Shivaji University Kolhapur, Maharashtra, India

Abstract: This research explores the optimization of electro-coagulation (EC) for treating wastewater from the sugar industry. By evaluating the impact of different electrode materials (Aluminum, Iron, and Copper), current densities, flow rates, and polyelectrolyte dosages, the study aims to enhance the removal efficiencies of Chemical Oxygen Demand (COD), Biochemical Oxygen Demand (BOD), turbidity, and color intensity. The findings indicate that Aluminum electrodes are superior in performance, with optimal conditions identified as current densities of 30-40 A/m², flow rates of 1.0-1.5 L/min, and polyelectrolyte dosages of 10-20 mg/L. The study highlights the effectiveness of electro-coagulation to traditional methods, demonstrating reduced operational costs and improved environmental benefits.

Keywords: Electro-coagulation, Wastewater Treatment, Aluminum Electrodes, Flow Rates, Current Densities, Polyelectrolyte

1. Introduction

Electro-coagulation (EC) has emerged as a promising technology for wastewater treatment, particularly in industries like the sugar sector where high organic and particulate loads are common. Traditional treatment methods such as sedimentation and chemical coagulation often encounter challenges including inefficiencies, high chemical consumption, and significantenvironmentalimpacts.Thisresearchfocuses onoptimizingtheECprocessbysystematicallyanalyzing the effects of various parameters on treatment performance. The primary objectives are to determine the optimal electrode materials, current densities, flow rates, and polyelectrolyte dosages for maximizing the removalefficienciesofkeycontaminants.

The significance of this study lies in its potential to improve wastewater treatment processes in the sugar industry, which is critical for meeting environmental regulations and sustainability goals. The study focuses on optimizing electrocoagulation (EC) parameters to develop a more cost-efficient and eco-friendlier alternativetoconventionaltreatmentmethods.

2. Analysis

2.1.

Experimental Setup

The experimental setup for this study includes a batch electro-coagulation reactor designed to test various combinations of electrode materials, current densities, flow rates, and polyelectrolyte dosages. The reactor is equippedwithAluminum,Iron,andCopperelectrodesto compare their effectiveness in treating sugar industry wastewater.

Electrode Materials: Aluminum, Iron, and Copper electrodes were selected for their different electrochemical properties. Aluminum electrodes are known for their high reactivity and efficiency in removingcontaminants,whileIronandCopperoffer varyingdegreesofperformance.

Current Densities: Current densities ranging from 10to50A/m²weretestedtodeterminetheirimpact on treatment efficiency. The range includes low, moderate, and high current densities to evaluate performanceacrossdifferentoperationalconditions.

Flow Rates: Flow rates from 0.5 to 2.0 L/min were varied to assess how the rate of wastewater flow through the reactor affects removal efficiencies. Flow rates were selected to represent typical operationalconditionsinindustrialsettings.

Polyelectrolyte Dosages:

Polyelectrolyte dosages ranging from 5 to 20 mg/L were used to evaluate their impact on the coagulation process. Polyelectrolytes enhance the coagulationprocessbyimprovingtheflocculationof suspendedparticles.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 02 | Feb 2025 www.irjet.net p-ISSN:2395-0072

2.2. Statistical Analysis

The data collected from the experiments were analyzed using statistical methods to determine mean removal efficiencies and standard deviations. The analysis helps to identify the optimal conditions for each parameter and compare the performance of different electrode materials.

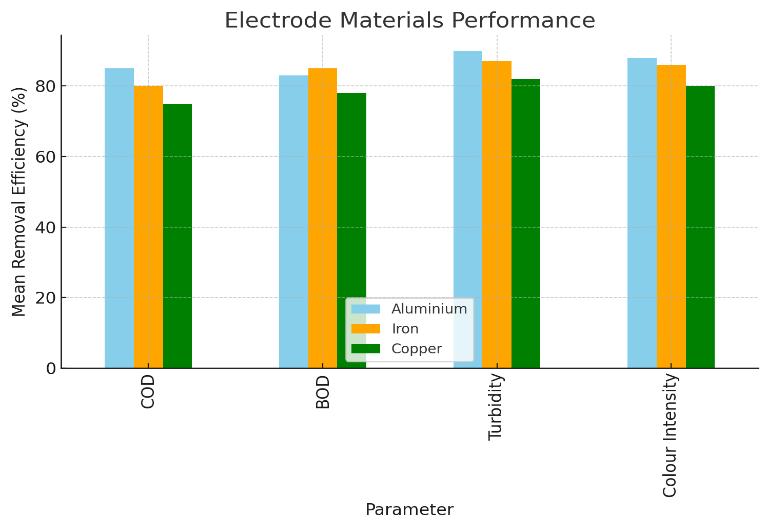

2.2.1. Electrode Materials

Table 1. Statistical Analysis of Electrode Materials Performance

The results indicate that Aluminum electrodes achieved thehighestmeanremovalefficienciesforallparameters, followed by Iron and Copper electrodes. Aluminum electrodesexcelledinremovingCOD,BOD,turbidity,and colorintensity,makingthemthepreferredchoiceforEC processesinwastewatertreatment.

2.2.2. Current Density

Table 2. Statistical Analysis of Current Density's Effect on Performance

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 02 | Feb 2025 www.irjet.net p-ISSN:2395-0072

The data shows that higher current densities generally improve removal efficiencies, with the optimal range identified as 30-40 A/m². Beyond this range, the efficiency improvements become marginal, suggesting that excessively high current densities may not be beneficial.

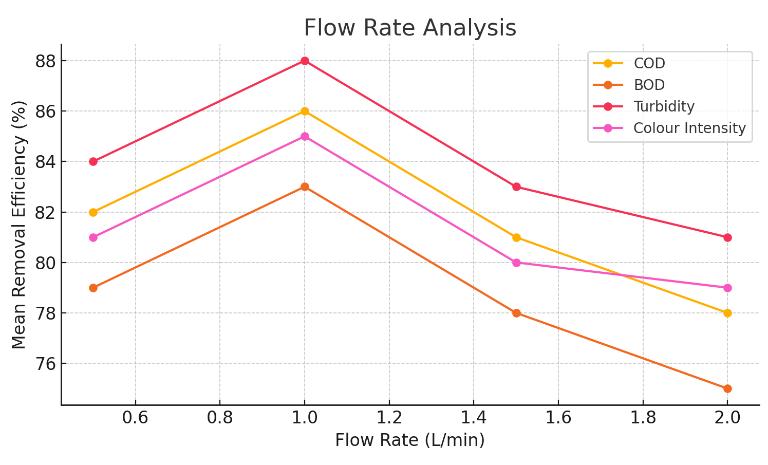

2.2.3.

Flow Rate

Table 3. Statistical Analysis of Flow Rate's Effect on Performance

The results reveal that lower flow rates generally yield higher removal efficiencies, with the optimal flow rate identified as 1.0-1.5 L/min. increased flow rates tend to dilute the effectiveness of the coagulation process, highlighting the importance of maintaining appropriate flowconditions.

2.2.4. Polyelectrolyte Dosage

Table 4. Statistical Analysis of Polyelectrolyte Addition's Effect on Performance

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 02 | Feb 2025 www.irjet.net p-ISSN:2395-0072

Thedatasuggeststhatincreasingpolyelectrolytedosage improvesremovalefficienciesuptoacertainpoint,with thehighestefficienciesobservedat15-20mg/L.Beyond thisdosage,theremovalefficienciesplateau,indicatinga threshold beyond which additional polyelectrolyte does notsignificantlyenhanceperformance.

3. Results

3.1. Electrode Materials

Aluminum electrodes demonstrated superior performanceacrossallparameterscomparedtoIronand Copper electrodes. The mean removal efficiencies for Aluminum electrodes were consistently higher, indicating their effectiveness in electro-coagulation processesforsugarindustrywastewater.

3.2. Current Density

The optimal current density range for effective electrocoagulation was identified as 30-40 A/m². This range provided the best balance between treatment efficiency and operational cost. Higher current densities beyond thisrangedidnotsignificantlyimproveperformanceand couldpotentiallyincreaseenergyconsumption.

3.3. Flow Rate

TheoptimalflowratefortheECprocesswasfoundtobe 1.0-1.5 L/min. This range ensured that the treatment efficiency wasmaximized whilemaintainingoperational feasibility. Flow rates above this range resulted in reduced removal efficiencies due to decreased contact timebetweenthewastewaterandelectrodes.

3.4.

Polyelectrolyte Dosage

The study found that the addition of polyelectrolytes improved removal efficiencies, with the most effective dosage being 15-20 mg/L. Higher dosages did not provide additional benefits, indicating that excessive polyelectrolyte usage may not be necessary and could

lead to increased costs without corresponding improvementsinperformance.

4. Discussion

4.1. Comparison with Traditional Methods

Electro-coagulation presents a significant improvement over traditional wastewater treatment methods. Traditional methods, such as chemical coagulation and sedimentation,oftenrequiresubstantialchemicalinputs and longer processing times to achieve comparable results. Electro-coagulation, with its high removal efficienciesandreducedchemical requirements,offersa more sustainable and cost-effective solution. The use of Aluminum electrodes in particular highlights the potential of EC to outperform traditional methods, making it a viable alternative for treating high-load industrialwastewater.

4.2. Practical Implications

The findings suggest that Aluminum electrodes are optimal for electro-coagulation in the sugar industry. The identified optimal parameters for current density, flowrate,andpolyelectrolytedosageprovideaguideline forimplementingeffectiveECsystems.Thetechnology’s scalability and flexibility make it suitable for various industrial applications, contributing to environmental sustainability and regulatory compliance. The study underscores the potential for EC technology to be integrated into existing wastewater treatment infrastructure, offering a path towards more efficient andeco-friendlyoperations.

4.3. Limitations and Future Research

While the study provides valuable insights into the optimizationofelectro-coagulation,therearelimitations to consider. The experiments were conducted under controlled laboratory conditions, which may not fully represent the complexities of real-world industrial applications. Future research should focus on exploring different electrode materials, varying operational conditions, and testing the technology in actual industrial settings. Additionally, long-term studies are neededtoevaluatethedurabilityandperformanceofEC systemsoverextendedperiodsofoperation.

5. Conclusions

This study demonstrates that electro-coagulation, particularlywithAluminumelectrodes,offerssignificant advantages for wastewater treatment in the sugar industry. The optimal parameters for current density, flow rate, and polyelectrolyte dosage identified in this research enhance treatment efficiency and align with sustainability goals. The technology shows promise as a

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 02 | Feb 2025 www.irjet.net p-ISSN:2395-0072

viable alternative to traditional treatment methods, providing reduced operational costs and improved environmentalbenefits.Furtherresearchandreal-world testing are necessary to fully assess the potential of electro-coagulation technology in diverse industrial applications.

6. References

• Chakrabarti, T., & Mohanty, A. (2021). Electrocoagulation: A sustainable approach for wastewater treatment in the sugar industry. In A. K. Mishra,S.Mohanty,&S.C.K.Mohapatra(Eds.),Advances in water treatment and pollution prevention (pp. 215234).Springer.

•El-Ashtoukhy,E.S.Z.,&Amin,N.K.(2009).Removalof pollutants from sugar industry wastewater using electrocoagulation. Journal of Hazardous Materials, 167(1-3), 10-17. https://doi.org/10.1016/j.jhazmat.2008.12.048

• Holt, P. K., Barton, G. W., Mitchell, C. A., & Ross, B. (2005). Electrocoagulation as a treatment process for wastewater: A review. Water Research, 39(6),13631376.https://doi.org/10.1016/j.watres.2005.01.009

• Khandegar, V., & Saroha, A. K. (2013). Electrocoagulation for treatment of wastewater from the sugar industry: A comprehensive review. Journal of Environmental Management, 128,949-963. https://doi.org/10.1016/j.jenvman.2013.06.040

• Rashidi, A., Bonakdarpour, B., & Farasati, M. (2010). Electrocoagulationprocessinwatertreatment:Areview of electrocoagulation technology, efficiency, and recovery mechanisms. Journal of Applied Sciences, 10(20), 2473-2484. https://doi.org/10.3923/jas.2010.2473.2484

• Sahu, O., Mazumdar, B., & Sharma, V. (2019). Electrocoagulation: A sustainable technique for wastewater treatment in industries. In R. Srivastava, A. Kumar, & S. Singh (Eds.), Advances in environmental biotechnology (pp. 311-332). Springer. https://doi.org/10.1007/978-981-13-1878-2_13

• Ghosh, D., and Medhi, C. R. (2015). Electrocoagulation process for treatment of wastewater a review. Environmental Science and Pollution Research, 22(2), 1311-1330.

•Kumar,V.,andChopra,A.K.(2017).Electrocoagulation treatment of industrial wastewater: a review on recent trends. Journal of Environmental Chemical Engineering, 5(5),4793-4807.

•Suresh,S.,andBalasubramanian,N.(2011).Treatment of tannery wastewater by electrocoagulation using iron and Aluminium electrodes. Journal of Hazardous Materials,186(1),540-548.

• Indian Standard IS 10500:2012. Drinking Water Specification (Second Revision). Bureau of Indian Standards,NewDelhi.

2025, IRJET | Impact Factor value: 8.315 | ISO 9001:2008