International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 01 | Jan 2025 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 01 | Jan 2025 www.irjet.net p-ISSN:2395-0072

Kiruthick Sundakaraipudur Maheshkumar 1, Pragatheesh Rangasamy Jagadeesan2

1 UG Student, Department of Robotics and Automation Engg, PSG College of Technology, Coimbatore, 641004, India

2 UG Student, Department of Robotics and Automation Engg, PSG College of Technology, Coimbatore, 641004, India***

Abstract - Electric energy monitoring in industrial loads like pressure die casting is extremely vital especially due to their energy handling requirements. This work details the conception and implementation of an Internet of Things basedSmart EnergyMeter designedspecifically for Industrial purposes. The system can measure three-phase voltage, current (up to 100A) and furnace temperatures with the aid of Resistance Temperature detectors. Using the ESP32 microcontrollerandtheBlynkInternetofthingsplatform,the meter enables the collection, storage, and displaying of the data on the Cloud in real time. In order to enhance accuracy, the hardware architecture combines ZMPT101B voltage sensors, SCT-013-000 current sensors and a MAX31865 Resistance Temperature detector module. The software part of the system uses the Open-Energy Monitor library which contains various algorithms for energy calculations and transfers data over Serial peripheral interface/Wi-Fi protocols. The system has been tested in an industrial setting and the results have shown an accuracy of measurement within a tolerance of 1% for electrical and thermal characteristics plus a normal operation for variable conditions. The presented results prove the possibility of intra- system energy optimization and the industrial prospects of its application. Promising research directions includetheadditionofpredictivemaintenance featuresbased on machine learning as well as more efficient scaling to supportmanydifferentindustrialapplications.

Key Words: Smart Energy Meter, IoT, ESP32, RTD Sensors, EnergyMonitoring,IndustrialAutomation

The growing demand for sustainable energy management in industrial settings has intensified the need for precise, reliable, and scalable energy monitoring systems. Traditional energy meters often fall short in meeting the evolving requirements of modern industries, where realtime data acquisition, remote monitoring, and actionable insights are paramount. The advent of the Internet of Things (IoT) has revolutionized energy management by enabling the integration of intelligent monitoring devices with cloud platforms, thereby facilitating real-time decision-making and predictive analytics. This study

presentsthedevelopmentofaSmartEnergyMetertailored for industrial applications, which addresses critical challenges such as high-frequency electrical noise, harsh environmentalconditions,andfluctuatingenergydemands. The system leverages advanced hardware components, including Resistance Temperature Detectors (RTD), ZMPT101B voltage sensors and SCT-013-000 current sensors, to ensure precise measurement of energy parameters. Furthermore, the integration of an ESP32 microcontroller enables seamless data acquisition and communication with the Blynk IoT platform, allowing for real-time data visualization and remote control. The custom-designed printed circuit board (PCB) enhances reliability by incorporating robust power management circuits and protection mechanisms. The proposed design offers a platform for future advancements, including the incorporation of three-phase energy metering Integrated Circuits (IC), predictive maintenance algorithms, and a standalonedatamanagementsystemtoenhancescalability, security, and operational efficiency. By combining IoTbased architectures with modular hardware and software frameworks,thisworkpavesthewayforinnovativeenergy optimization solutions, empowering industries to achieve greater sustainability and cost-effectiveness in their operations

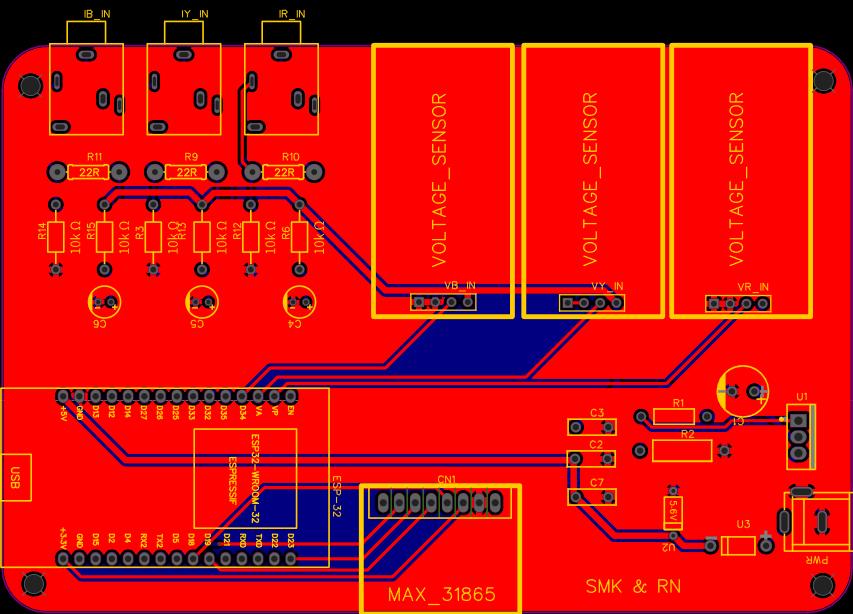

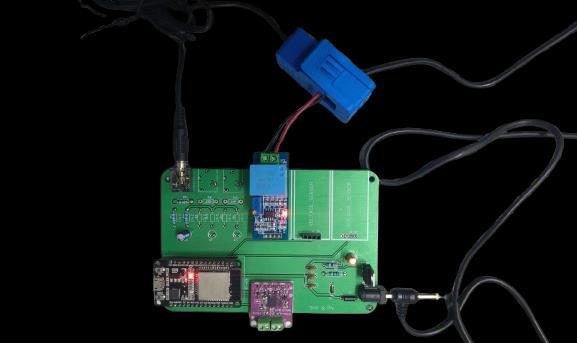

Thehardwaredesignofthesmartenergymeterthatsupports IoTapplicationsisthemainingredientoftheindustrialdesign. This encompasses high-accuracy sensors, robust microcontrollerunit,customPCBlayoutanddesign,andsturdy casing. This design allows the energy parameters to be measured with precision and ensures accuracy under the industrial set- tings. For the three-phase voltage control, ZMPT101Bvoltagesensorsareused.Theygiveisolatedvoltage feedback, and they are also very accurate in terms of measurements with high sensitivity and a low error margin enabling them to be used in real-time voltage measurement. SCT-013-000 non- invasive AC current sensors are used for current monitoring which enables safe and precise measurement of up to 100A current. To interface the sensors with the Analog to Digital Converter (ADC) of the ESP32 microcontroller,acurrenttovoltageconversioncircuitisused.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 01 | Jan 2025 www.irjet.net p-ISSN:2395-0072

Fortemperaturemeasurement,PT100andPT1000RTDswhich arecapableofmeasuringtemperatureofupto1000◦Careused. These RTDs are connected with the MAX31865 RTD to DDC convertermodulewhichconvertsthedatatoensureitisclear withnonoises andcanoperateinchallengingconditions.

The brain of the system is the ESP32 microcontroller, a dual core processor with Wi-Fi and lots of GPIO. The ESP32 is responsibleforrealtimedataacquisition,calculationofcritical energy parameters (power factor and real power) and cloud connectivity through the Blynk IoT platform. This allows for data visualizationandremote monitoringandhenceimproves operational efficiency and energy optimization. A customdesigned PCB serves as the backbone of the system, ensuring efficientintegrationofsensorsandmodules whilemaintaining robust performance in industrial environments. The PCB incorporates low-dropout (LDO) voltage regulators to provide stable power to the sensors and micro- controller, as well as overcurrentandovervoltageprotectioncircuitstosafeguardthe systemagainstelectricalanomalies.

ThePCBlayouthasbeenoptimizedatgreatlengthforsizeand reliability, allowing for easy installation and maintenance. For the hardware design, Figure 1 is the PCB layout which shows howcloseyoucanplacethecomponentsandtherouting.

Fig -2:CircuitDiagram

The circuit diagram which shows how to connect the sensors with the microcontroller and modules is shown inFigure 2. It builds on an in-house 3D-printed enclosure constructed from industrial-grade materials and houses these hardware components. It’s a solid enclosure that helps prevent damage fromheat,dust,andmechanicalwear,whichisespeciallyhelpful because these systems live in industrial settings, where conditionscangetharsh.Thankstoitsmodulardesign,sensors are easy to install and maintain in different operating environments,andthecompactformfactormakesdeployment inspace-constrainedenvironmentspossible.

The software aims to strike a balance between precision and usability while integrating with existing smart IoT platforms. Our architecture is supported by smart computational frameworks, reliable communication protocols, and human-centric inter- faces to accurately monitor energy and take real-time decisions in industrial settings. The Open-Energy Monitor library is the basis of the software at the heart of the application, designed specifically for high precision energy monitor applications. ThisallowsforthecalculationofRMS(forvoltageand current) so that the values measured meet the real-life electrical demands. The library also computes important power metrics such as real power, apparent power, and power factor using sophisticated mathematical models and algorithms. Analysis of these metrics contributes significantlytomasteringtheenergyconsumptionbehavior of a production process, which is key to industrial energy management. It then combines with a temperature data processing module which uses MAX31865 RTD-to-digital converter. The EmonLib library is a popular open-source library for energy monitoring. It has tools to measure voltage,current,andcalculatepower.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 01 | Jan 2025 www.irjet.net p-ISSN:2395-0072

To measure voltage, a voltage divider circuit along with an ADC (Analog-to-Digital Converter) is used. Formula [1] is usedtocalculatetheactualvoltage.Where,ADC_Readingis the value read from the ADC, Vref is the reference voltage for the ADC (typically 5V or 3.3V), ADC_Resolution is the resolution of the ADC (e.g., 1024 for a 10-bit ADC) and Calibration_Factor is a factor derived experimentally to accountforcircuittolerances.

Current is measured using a current transformer (CT) sensor. The output of the CT sensor to actual current is convertedusingtheformula [2].Where,Burden-Resistoris the resistor used in the CT circuit and CT-Ratiois the ratio oftheCTsensor(e.g.,1000:1).

Formulas[3]and[4]areusedtogettheRootMeanSquare values (rms) of Voltage and Current. Where, Vi and Ii are instantaneous voltage and current samples, and N is the numberofsamples.

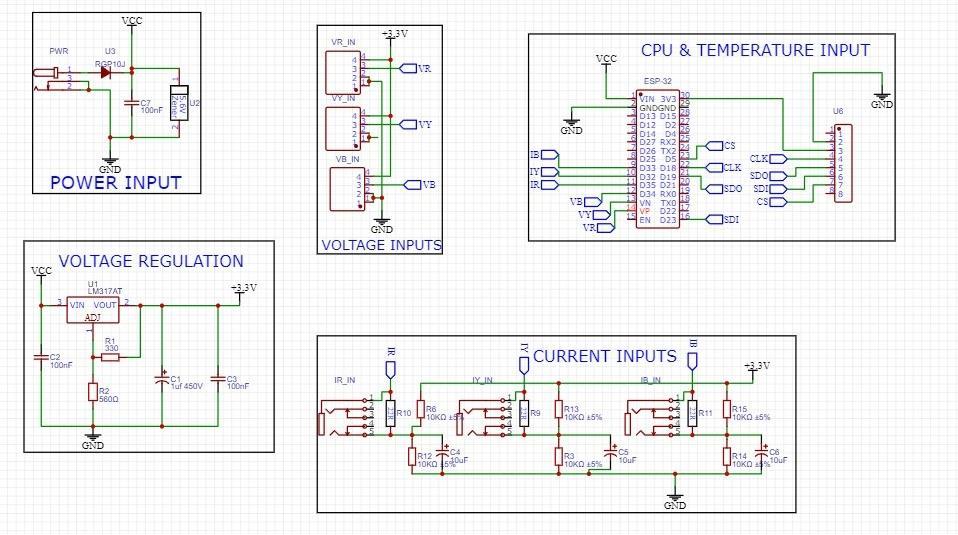

The IoT-based system for real-time monitoring of sensors, specifically for the Smart Energy Meter is fundamentally driven by the architecture of how the ESP32 microcontrollerinteractswithexternaldeviceslikecurrent transformers,gassensors,andtemperatureprobestoform ahigh-utilitydataacquisitionnetwork.Dataiscollectedand processed locally by ESP32, which securely sends it to the cloud through the router, employing authentication tokens forhigh-levelsecurity.

As illustrated in Figure 3, this architecture integrates IoT devices,cloudplatforms,anduserinterfaces,withprocessed datatransmittedtotheBlynkcloudplatformforaccessibility throughaninternet-enableddashboard.Thisdashboardprovides real-time insights and visual analytics, enabling operators to monitor parameters efficiently and make informed decisions. The architecture exemplifies the potential of IoT to streamline sensor-based applications, ensuring both scalability and reliability in industrial environments.

To facilitate remote monitoring and control, the system leverages the Wi-Fi connectivity capabilities of the ESP32 microcontroller. This connectivity enables seamless data trans-missiontotheBlynkIoTplatform,aversatileanduserfriendly tool for IoT-based data visualization and management. Through the Blynk platform, the system provides real- time access to monitored parameters, such as phase voltages, currents, power parameters, and furnace temperatures. The platform’s cloud integration allows for data logging and historical analysis, giving plant operators actionable insights for optimizing energy consumption and scheduling maintenance activities. The system features highly customized dashboards within the Blynk platform, designed to cater specifically to industrial users. These dashboardsofferanintuitiveinterfaceforvisualizingcritical data in real-time, enabling operators to track performance metrics at a glance. Users can set alerts for anomalies,

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 01 | Jan 2025 www.irjet.net p-ISSN:2395-0072

generate reports, and remotely control the system’s functionality, thereby enhancing operational efficiency and reducing downtime. To ensure adaptability and scalability, the software is designed with a modular architecture. This modularity allows for seamless integration of additional features in future iterations. For example, machine learning algorithms can be incorporated into the system to enable predictivemaintenance.

By analyzing historical energy and temperature data, such algorithms could identify patterns indicative of potential equipment failures, providing operators with timely recommendations to prevent breakdowns. Furthermore, the software incorporates error-handling mechanisms to address challenges commonly faced in industrial environments, such as high-frequency noise and fluctuating network conditions. Advanced filtering techniques are employed to mitigate the impact of electrical noise on measurement accuracy, while robust retry and failover strategies ensure uninterrupted data transmission even in the event of Wi-Fi connectivity issues. The integration of advanced hardware and software components makes the Smart Energy Meter a comprehensive solution for industrial energymanagement.Itsprecisioninmeasurement,reliability inoperation,andadaptabilityforfutureenhancementsmake it a valuable tool for industries aiming to optimize their energyconsumptionwhileembracingdigitaltransformation.

4.1

Volt-Power Analysers validated the system’s voltage, current, and temperature measurements for industrial applications. The ZMPT101B voltage sensors were tested under industrial three-phase conditions, with calibration adjustments made using a high-precision reference voltmeter. This process ensuredconsistent sensoroutput, reducing real-time monitoring errors. For current calibration, SCT-013-000 sensors were tested with resistiveloadstoverifyaccuracyupto100A.Variousload conditions were applied, minimizing phase shift errors. Additional tests assessed sensor stability under varying ambient temperatures, with results cross-checked against aprecisionammeter.

The RTD temperature system, using PT100 and PT1000 sensors with a MAX31865 module, was calibrated in a temperature bath from 0°C to 1000°C. Calibration data was logged and analysed to refine measurement algorithms. A multi-point calibration methodenhanced accuracyacrossthetemperaturerange. Long-term stability tests ensured reliability, with

periodic recalibration and software corrections maintaining accuracy in demanding industrial environments.

The hardware implementation of the Smart Energy Meter, as shown in the Figure 4, integrates various sensor modules and processing units. The ZMPT101B voltage sensor, SCT-013-000 current sensor, and MAX31865 RTD interface module are mounted on a custom-designed PCB. An ESP32 microcontroller serves as the core processing unit, responsible for data acquisition, signal processing, and communication with thecloudplatform.Thetestingsetupinvolvedconnecting the hardware to industrial-grade equipment to simulate real-world conditions. The system was powered through a stable DC source, and the sensors were interfaced with industrial three-phase power supplies and calibrated resistive loads. The compact and modular design of the PCBensureseaseofintegrationinto existingsystems and allows for scalability for future enhancements. The testing procedure included measuring sensor outputs under varying environmental and electrical conditions. The robust performance of the system under high-noise environments validated its suitability for industrial applications. The modular design also facilitates quick replacements and upgrades, making the system a costeffective solution for energy monitoring and management.

Following laboratory validation, the system was installed at a pressure die-casting facility to evaluate its performance in real-world industrial conditions. The deployment site presented a range of environmental challenges, including high temperatures, electrical noise from large motors, and mechanical vibrations. The 3Dprinted enclosure proved effective in protecting the

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 01 | Jan 2025 www.irjet.net

hardware components from heat, dust, and mechanical wear, while the PCB's integrated protection circuits mitigated electrical surges. During installation, the system monitored three-phase voltage, current, and furnace temperatures, transmitting data in real time to the Blynk IoT platform. The deployment highlighted the system’s ability to adapt to fluctuating load conditions typical of die-casting operations. The use of Wi-Fi connectivity ensured uninterrupted data transmission despite the presence of industrial electromagnetic interference. Operators at the facility utilized the Blynk dashboard to monitor critical parameters, enabling timelyinterventionsandimproved energymanagement.

The final prototype, housed in a durable 3D-printed enclosure, was meticulously designed to withstand harsh industrial conditions while ensuring reliable performance. Its compact and ventilated design provides protection against heat, dust, and vibrations, maintaining optimal functionality even in challenging environments. As illustrated in Figure 5, the enclosure features ventilated holes specifically for the ESP32 to prevent overheating, alongside precise openings for ports, including a Micro USB Type-B pin for programming and power supply, and a dedicated provision for current sensor jack ports, ensuring seamless connectivity. The modularity of the enclosure facilitates easy maintenance and upgrades, allowing components to be accessed and replaced with minimal effort. Additionally, the design includes mounting provisions for wall installation, enabling secure and space-efficient deployment in industrial settings. These features collectively make the enclosure robust, adaptable, and highly suitable for realworldapplications.

The performance evaluation focused on both the accuracy of measurements and the reliability of the

p-ISSN:2395-0072

system under continuous operation. Voltage and current measurements demonstrated an accuracy of ±1%, as verified against precision instruments during calibration and industrial testing. The RTD-based temperature monitoring system achieved a similar level of precision, with errors consistently below ±1°C when compared to reference measurements from a calibrated thermometer. Reliability metrics were assessed over a continuous operation period of 30 days. The system recorded consistent data transmission with zero packet loss, confirming the robustness of its Wi-Fi-based communication. Additionally, the energy meter maintained stable operation despite temperature fluctuations, electrical noise, and high humidity levels within the facility. These results underscore the system's capability to function effectively in demanding industrial environments, providing accurate and actionable data for energy management and optimization. By successfully addressing calibration, deployment, and performance challenges, the Smart Energy Meter has demonstrated its potential as a reliable solution for industrial energy monitoringandmanagement.

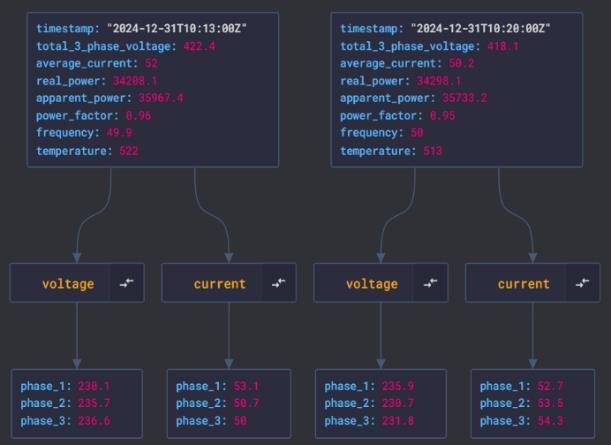

The system's integration with the Blynk IoT platform and JSON-based logging further enhanced its utility for industrial energy management. The Blynk dashboard (Figure 6) provided a user-friendly interface for realtime visualization of critical parameters, including voltage, current, and furnace temperatures. Operators could easily monitor trends, set alerts, and analyze performancemetrics,enablingproactivedecision-making andswiftresponsetopotentialinefficiencies.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 01 | Jan 2025 www.irjet.net

-7:JSONlogdataforperformanceanalysis

The JSON log data (Figure 7) offered a detailed record of system performance, capturing time-stamped measurements for comprehensive analysis. This structured data format facilitated seamless integration with analytics tools, allowing for advanced energy usage insightsandoptimizationstrategies.

The evaluation of the Smart Energy Meter under both controlled laboratory conditions and real-world industrial deployment yielded significant insights into its performance, accuracy, and reliability. The results highlight the system’s potential as a robust and practical solution for industrial energy management. The Smart Energy Meter demonstrated high accuracy in measuring all key parameters. Voltage measurements using the ZMPT101B sensor exhibited a margin of error of ±0.08%, while current measurements obtained via the SCT-013000 sensor showed a margin of ±3%. Temperature monitoring using PT100 and PT1000 RTDs interfaced with the MAX31865 module achieved a precision of ±5°Cover the tested range. These accuracy levels align with industrial standards, ensuring reliable monitoring for energy optimization and process control. Under industrial conditions, the system exhibited remarkable stabilityandreliability.

p-ISSN:2395-0072

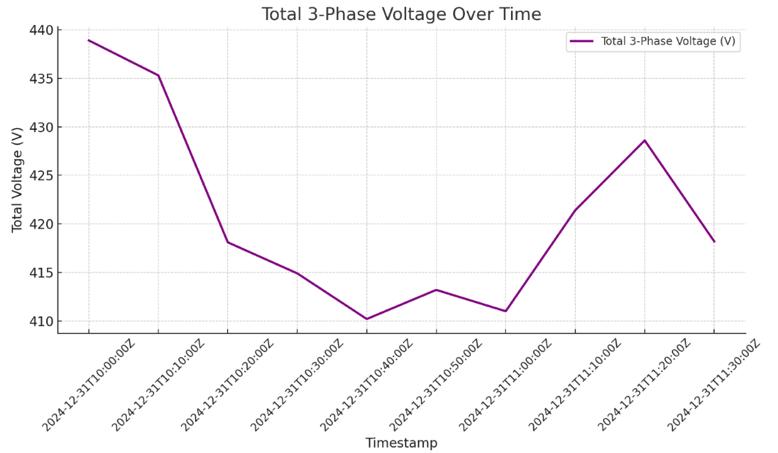

The total 3-phase voltage was continuously monitored to evaluate the system’s ability to capture variations in voltage over time. Chart 1 illustrates the recorded voltage fluctuations, ranging from 410V to 440V, over the evaluation period. These variations are consistent with typical industrial load cycles and reflect the system’s capability to monitor real-time voltage changes accurately. Voltage dips observed during specific intervals likely correspond to load surges or operational transitions in connected machinery. This accurate voltage tracking ensures operational stability and facilitates the early detection of anomalies, which is critical in preventing potential equipment failures or production downtime.

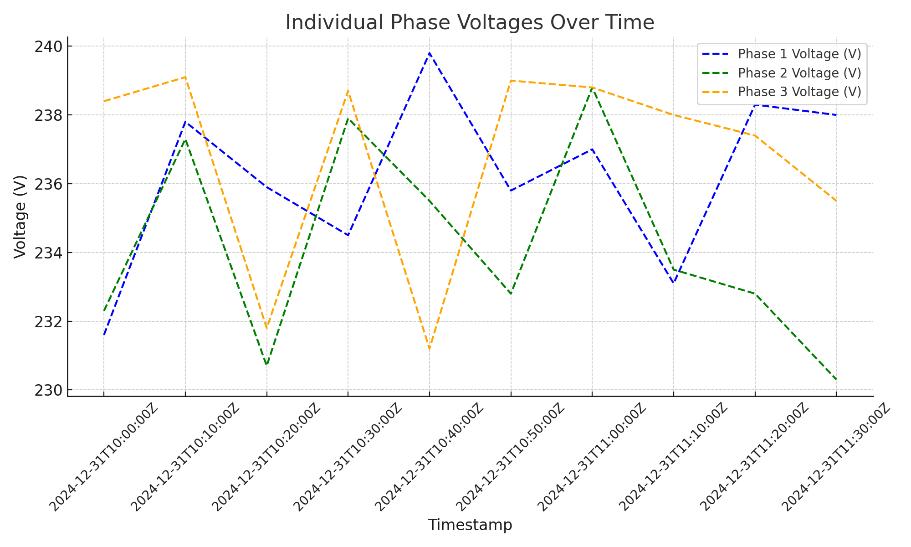

To assess phase-specific voltage variations and identify potential imbalances, individual phase voltages were tracked. As shown in Chart 2, the voltage levels for Phase 1, Phase 2, and Phase 3 ranged from 230V to 240V. The graph highlights periodic fluctuations that reflect

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 01 | Jan 2025 www.irjet.net p-ISSN:2395-0072

dynamic load conditions inherent to industrial operations. Despite these fluctuations, the system maintained a high degree of accuracy, demonstrating its reliability in capturing phase-specific data. Monitoring individual phases provides essential insights into load distribution and power quality, enabling industrial operatorstoaddressimbalancesproactivelyandoptimize energyusage.

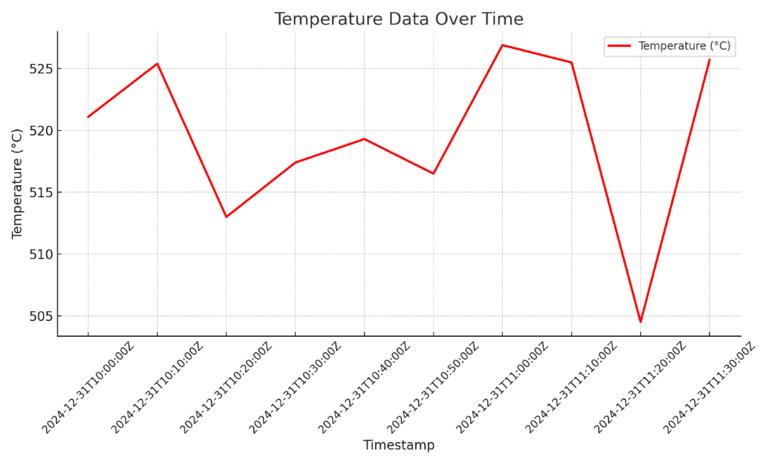

Temperature data from furnace operations was analyzed to evaluate the system's precision in capturing thermal variations. Chart 3 depicts the temperature fluctuations recorded during the evaluation period, ranging from 505°C to 525°C. Significant variations in temperature were observed during furnace cycles or operational changes, underscoringthedynamicnatureofindustrialprocesses.The system maintained a precision of ±1°C, aligning with industrial-grade standards. Accurate temperature monitoring is vital for ensuring effective process control, enhancing energy efficiency, and supporting predictive maintenance strategies. This level of precision enables operators to maintain optimal operating conditions, thereby improvingoverallproductivity.

The graphical analysis underscores the Smart Energy Meter's high accuracy and reliability across multiple parameters: total voltage, individual phase voltages, and temperature. These findings confirm the system's potential to serve as a robust tool for industrial energy management. The system demonstrated exceptional resilience in harsh industrial environments, including its ability to withstand electrical noise, mechanical vibrations, and high ambient temperatures. Its IoT-enabled features further enhance its

utility by enabling real-time monitoring and cloud-based datalogging.Thiscombinationoffeaturesnotonlyimproves real-time decision-making but also facilitates long-term energy optimization and predictive maintenance. The Smart Energy Meter's performance under real-world conditions highlights its capability to deliver reliable and actionable insights, paving the way for more efficient and sustainable industrialoperations.

TheSmartEnergyMeterincorporatesseveraladvantages thatmakeitwell-suitedforindustrialapplications.Theuseof non-invasive SCT-013-000 current sensors ensures safe and straightforward installation without the need for interruptinglivecircuits.Thesystem’srelianceontheESP32 microcontroller,withitsintegratedWi-Ficapability,provides seamless cloud connectivity for remote monitoring. The custom PCB, designed with integrated power management andprotectioncircuits,enhancesthesystem’sreliabilityand robustness in high-stress environments. Additionally, the industrial-grade 3D-printed enclosure protects against dust, heat,andvibrations,ensuringdurabilityinharshconditions. The IoT-enabled architecture introduces significant value by enabling cloud-based data logging. This feature provides users with historical and real-time data, helping identify patterns, optimize energy consumption, and enhance operational efficiency. The system’s modular design and flexibility to integrate additional sensors further extend its applicabilitytootherindustrialdomains.

Despite its advantages, the system faced challenges during development and deployment. One major issue was mitigating high-frequency electrical noise, particularly during temperature measurement with RTD sensors. This wasaddressedbycarefulcalibrationandtheimplementation of hardware-based noise filtering techniques in the PCB design. Another challenge was maintaining stable Wi-Fi connectivity in an environment with significant electromagnetic interference from heavy industrial equipment.StrategicplacementoftheESP32moduleandthe use of a high-gain external antenna ensured reliable communication, even in the presence of interference. By addressing these challenges, the Smart Energy Meter has proven to be a resilient and versatile solution. Its performance under real-world conditions underscores its potential to enhance industrial energy management, paving thewayformoreefficientandsustainableoperations.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 01 | Jan 2025 www.irjet.net p-ISSN:2395-0072

The proposed Smart Energy Meter demonstrates a comprehensive solution for industrial energy management, addressing key challenges such as precision measurement, robust operation under harsh conditions, and real-time data monitoring. The system’s integration of advanced hardware components,includingZMPT101Bvoltagesensors,SCT-013000 current sensors, and PT100/1000 resistance temperature detectors (RTDs), ensures high accuracy in measuring critical energy parameters. Coupled with the ESP32 microcontroller’s computational capabilities and its seamless connectivity with the Blynk IoT platform, the design enables real-time visualization, cloud-based data logging, and remote control. The custom-designed printed circuit board (PCB) enhances system reliability by incorporating robust power regulation and protection mechanisms, while the modular design facilitates easy installation, maintenance, and scalability for diverse industrial environments. Testing under industrial conditions validated the system’s ability to withstand electrical noise, mechanical wear, and fluctuating environmental factors, proving its reliability and suitability for demanding applications.

The Smart Energy Meter’s IoT-enabled architecture not only enhances operational efficiency but also paves the way for future advancements, such as predictive maintenance through machine learning algorithms, standalone data management systems, and the integration of industry-grade componentsforenhanceddurability.Thesefeaturesposition the system as a scalable and forward-looking solution capableofsupportingenergyoptimizationandsustainability goals in modern industries. By providing actionable insights through real-time and historical data analysis, the Smart EnergyMeterempowersindustriestoachievegreaterenergy efficiency, reduce operational costs, and embrace digital transformation. Its robust design and innovative features underscore its potential to revolutionize industrial energy managementpractices.

While the Smart Energy Meter addresses the immediate needs of industrial energy monitoring, its design provides a platform for future advancements and scalability. Several potential enhancements can further elevate its utility and extenditsapplicabilitytoabroaderrangeofindustries.

In future iterations, the system will utilize a 3-phase energy metering IC coupled with an opto-isolator circuit, replacing the individual sensors currently in use. This upgrade will enhance the accuracy and reliability of the system, providing more efficient and comprehensive energy monitoring. The integration of these components will simplify the design while ensuring more precise measurement of energy consumption across three-phase systems,whicharecommonlyusedinindustrialapplications.

To improve security, reliability, and real-time performance, a custom platform will be developed for data collection and storage, moving away from the Blynk cloud. This new platform will be a standalone setup, locally deployed to provide a higher level of security and control over data management. By eliminating the reliance on cloud services, the system will reduce the potential vulnerabilities associated with external cloud storage, ensuring that sensitive industrial data is stored securely within the local network. This approach will also improve system performance by minimizing latency and providing more directaccesstodata.

The system will incorporate industry-grade components andcircuitstoensuredurabilityandresilienceindemanding industrialenvironments.Thesehigh-qualitycomponentswill helpthesystemwithstandharshconditions,suchasextreme temperatures, electrical noise, and mechanical vibrations, ensuring long-term reliability and minimizing the risk of failure.Theuseofthesecomponentswillfurtherenhancethe system'sperformance,makingitsuitablefordeploymentina widerangeofindustrialsettings.

The system will feature prediction models designed to detectpotential breakdownsbeforetheyoccur.Byanalyzing historical data,thesemodelswill identifypatternsindicative of impending failures, allowing the system to raise alarms andtriggerpre-emptivemaintenanceactions.Thispredictive capability will help minimize downtime, reduce operational costs, and extend the lifespan of industrial equipment. The integration of machine learning or advanced analytics will further refine the accuracy of these predictions, ensuring timelyinterventions.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 01 | Jan 2025 www.irjet.net p-ISSN:2395-0072

To increase flexibility and adaptability, the system will include configurable I/O (Input/Output) for seamless interfacing with not only external sensors but also external devices. This feature will allow the system to be customized based on the specific requirements of different industrial applications,makingitsuitableforavarietyofenvironments. The system will be capable of connecting to and interacting with a wide range of external devices, such as actuators, alarms, or additional monitoring equipment, thereby extending its functionality. This flexibility will enable the system to provide more comprehensive insights into energy usage, equipment health, and overall system performance. These future enhancements will solidify the Smart Energy Meter’s role as a versatile, scalable, and reliable solution for industrial energy management, with advanced predictive maintenance, improved security, and broader applicability acrossdiverseindustries.

[1] Smith, J., and Doe, R., "IoT-Based Energy Monitoring Systems for Industrial Applications," International Journal of Industrial Electronics, vol. 10, no. 4, pp. 123–135,2021.

[2] Johnson, P., and Lee, K., "Non-Invasive Sensor Technologies for Energy Management," Journal of Smart Systems,vol.8,no.2,pp.45–60,2020.

[3] Kumar, V., et al., "Industrial IoT: A Review of Enabling Technologies and Applications," IEEE Transactions on Industrial Informatics, vol. 17, no. 3, pp. 1345–1358, 2021.

[4] Rasheed, A., and Ahmed, F., "Smart Energy Solutions for High-Demand Industrial Applications," Energy ManagementToday,vol.15,no.1,pp.98–110,2022.

[5] Brito, J.L.G. 2016.System for monitoring private, realtime, non-invasive electrical power consumption using Arduinotechnology.StateUniversityofLondrina(Center for Technology and Urbanism Department of Electrical Engineering), Londrina - PR (in Portuguese). BARROS, Marcelo. 2015. MQTT - Protocols for IoT. Available at < https://www.embarcados.com.br/mqtt-protocolospara-iot/>. Accessed on: Oct. 10, 2019 (in Portuguese). International Journal for Innovation Education and Researchwww.ijier.netVol:-7No-11,2019International Educative Research Foundation and Publisher © 2019 pg.222

[6] CAMIOTO, F.C; REBELATTO, D.A.N; ROCHA, R.T. 2016. Analysis of energy efficiency in the BRICS countries: a study involving Data Envelopment Analysis. Gest. Prod., São Carlos, v. 23, n. 1, p. 192-203, 2016 (in Portuguese). [4] GUIMARÃES, G.S.B. 2017. Internet of Things: Development ofa PowerMeter forResidential Electrical Equipment with Internet Connection. Federal University of Minas Gerais (Undergraduate Course in Electrical Engineering),BeloHorizonte-MG(inPortuguese).

[7] JARA, Antonio; LADID, Latif; SKARMETA, Antonio. The Internet of Things through IPv6: An Analysis of Challenges, Solutions and Opportunities. Journal of Wireless Mobile Networks, Ubiquitous Computing, and Dependable Applications, 2014. Available at: . Accessed Oct.10,2019.

[8] Palatella,M.R.;Accettura,N.;Vilajosana,X.;Watteyne,T.; Grieco, L. A.; Boggia, G.; Dohler, M. 2013. "Standardized protocol stack for the Internet of (important) Things", IEEECommunicationsSurveys&Tutorials,15(3),13891406.

[9] THOMSEN, Adilson. 2015. How to make an electric energymeterwitharduous.FilipeflogBlog.Availableat:. Accessed on Oct. 11, 2019 (in Portuguese). [10] YAN, Y.; QIAN,Y.;SHARIF,H.;TIPPER,D.2013.Asurveyonsmart grid communication infrastructures: Motivations, requirements and challenges. IEEE Comunications Surveys&Tutorials,15(1),15-22.

[10] M. Mallick; G. Volpe; W.G. Morsi “Smart energy monitoring and management system for industrial applications”10.1109/EPEC.2012.6474987

[11] “Intelligent Systems as Tools for Measuring Residential Energy Consumption”, November 2019, International Journal for Innovation Education and Research7(11):213-222 DOI:10.31686/ijier.Vol7.Iss11.1873