Volume: 12 Issue: 02 | Feb 2025 www.irjet.net p-ISSN:2395-0072

Volume: 12 Issue: 02 | Feb 2025 www.irjet.net p-ISSN:2395-0072

Sangeetha Kalivarapu1, Dr.B.Mahesh Babu2,G.V.N.S.Rama Krishna3

1Student,Dept.of Civil Engineering, Seshadri Rao Gudlavalleru Engineering College, Gudlavalleru,Andhra Pradesh, India.

2Assistant Professor, Dept.of EEE, Seshadri Rao Gudlavalleru Engineering College, Gudlavalleru, Andhra Pradesh, India.

3Assistant Professor, Dept.of Civil Engineering,V.K.R,V.N.B&A.G.K College of Engineering, , Gudivada, Andhra Pradesh,India.

Abstract - In this work, the stabilizing properties of sisal fibre for expansive black cotton soil are assessed in a controlled laboratory setting. Numerous tests were carried out using Sisal Fibre additions of 0%, 0.25%, 0.5%, 0.75%, and 1%, including Heavy Compaction, California Bearing Ratio (CBR), Unconfined Compressive Strength (UCS), and Consolidation. The fibers were 10–15 mm long. The CBR tests in both drenched and un soaked circumstances were conducted after the modified Proctor test was used to determine the Optimum Moisture Content (OMC), with the greatest value recorded at 0.75% fibre. For extended curing times, 0.5% fibre had the highest strength in UCS tests, which were carried out at 0, 3, 7, 14, and 28 days. According to consolidation experiments, sisal fibre enhanced the soil's consolidation properties.

Key Words: Black-Cotton Soil, Soil stabilization, Expansive Soil, Sisal Fibre, Engineering Properties, Compressibility, BearingCapacity.

1.INTRODUCTION

Acohesivesoil,blackcottonsoilisusuallydarkGreyor black in hue. It causes structural problems since it swells during the rainy season and contracts during the summer[1]&[2]. While shrinkage causes cracks in walls, slabs, and floors, swelling causes uplift pressure that affectsplinthbeams,foundations,androadsurfaces.Even for constructions with light loads, its extreme compressibility and low bearing capacity make construction challenging[3]. Nonetheless, particularly in central and southern India, it is extremely fertile and produces crops like cotton, paddy, and sugarcane. Construction on Black Cotton Soil need mat foundations, deep foundations, or under-reamed piles for stability becauseofitslimitedbearingcapacity[4].

2.LITERATURE

S.Bharathi [1]:-This study examines how Black Cotton Soil can be enhanced by the addition of polypropylenefibreinvaryingconcentrations(0%,0.25%,

0.5%, 0.75%, and 1%). Significant soil properties were measuredandcomparedtoacontrolsample,includingthe California Bearing Ratio (CBR) and Unconfined Compressive Strength (UCS). The results indicated strongersoilsinceahigherfiberconcentrationraisedUCS. The results show that stabilizing Black Cotton Soil with polypropylene fiber is a good way to enhance its engineeringproperties.

KiranKumarM.S[2]:-Accordingtoresearch,adding jutefiberstosoilgraduallyimprovesitsCaliforniaBearing Ratio (CBR) and unconfined compressive strength (UCS). Jute fibers have been added to soil in different amounts, improvingpropertiesincludingmaximumdrydensityand idealmoisturecontent.Accordingtoexperimentalfindings, addingjutefiberssignificantlyincreasesthesoil'sstrength, makingitmoreappropriateforbuilding.Accordingtoour research, the ideal percentage of jute fiber content to get theoptimumstrengthandstabilityoutcomeswas4%.

S.Andavan [3]:-Fibers are essential for stabilizing soil because they increase the soil's compressive and shear strengths. The purpose of this study was to assess the impact of fibers on stability and strength by adding them to the soil in varying amounts (0%, 5%, 10%, 15%, and20%).Thepurposeofaddingfiberstoredsoilwasto increaseitsload-bearingcapacityandstructural integrity. The results show that fiber reinforcing greatly increases the strength of the soil, which makes it more appropriate forbuilding.

R.Gopala Krishna [4]:-This study explores the improvement of expansive soil characteristics by adding differentamountsofcoirpith.Thestudyfocusesonadding coir pith to expansive soil to chemically stabilize it. The addition of coir pith improves the soil’s strength and boostsitsbearingcapacity,makingitmoreappropriatefor foundationapplications.

Rajashekhar Rathod [5]:- This project's goal is to improve the qualities of black cotton soil by figuring out the right amount of lime and how to combine it with bamboofiber.Ithasbeendeterminedthatstabilizingblack International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

International Research Journal of Engineering and Technology (IRJET)

Volume: 12 Issue: 02 | Feb 2025 www.irjet.net

cotton soil with 6% lime is an effective way to make it suitable for road construction. In this study, different amounts of bamboo fiber (2%, 4%, 6%, and 8%) are combined with black cotton soil and 6% lime to evaluate theimpactonsoilparameters.

Gopu Ganesh Naidu [6]:-By adding stabilizing materials, this study seeks to improve the strength properties of weak soil, making it more appropriate for sustaining tall buildings. The study focuses on using soil stabilization techniques to improve key technical attributes like strength, compressibility, and bearing capacity. It specifically investigates how well glass fibers and lime work to fortify black cotton soil. In order to improvestabilityandload-bearingcapability,theeffectsof varying ratios of lime and glass fibers on soil parameters areexamined.

Prabakaran Ellappan [7]:-In order to improve the engineering qualities of black cotton soil, this study looks into stabilizing it using natural fibers. In different amounts 0.2%, 0.4%, and 0.6% by the dry weight of the soil the study adds sisal, banana, and jute fibers. With the greatest California Bearing Ratio (CBR) of 21.55% obtained utilizing a mixture of 0.4% banana fiber, 0.6% sisal fiber, and 0.6% jute fiber, the resultsshowa notable improvement in soil strength. With this combination, the Optimum Moisture Content (OMC) also rose to 20%. The results show that adding fibers that are dispersed at random improves the strength properties of black cotton soil.

Thecharacteristicsofsisalfiberandblackcottonsoil, which are used in this study, are covered in the sections thatfollow.

3.1.Black

The properties of soils can be classified into two categories:

EngineeringProperties:

Permeability, compressibility, and shear strength thethreeprimaryengineeringcharacteristicsofsoils are crucial for civil engineering projects, but they necessitate complex and drawn-out experiments involving undisturbedsoilsamples.Suchsamplesarechallengingto collect, which further increases the time needed. Indicativepropertiescanbeutilizedforsmallerprojectsto estimate soil behavior more quickly, but these tests are requiredforhigh-budgetprojects.

IndexProperties:

Index properties are those aspects of soil that suggest engineering characteristics but are not of main importancetoGeotechnicalengineers.

For testing, the Black Cotton Soil used in this investigation was air-dried after being collected from a depth of 1 to 1.5 meters. Preliminary testing revealed its characteristics,whicharelistedinTable1.

3.2.Sisal

The natural fiber known as sisal fiber is obtained from the sisal plant. A fiber producing facility in Cherakupalli village, Guntur district, Andhra Pradesh, India, called Sri Lakshmi Groups provided the sisal fiber usedinthisstudy.Thefirer'saveragelengthwasbetween 10 and 15 mm, and its average diameter was 0.2 mm. In Fig. 1, the sisal fibre utilized in this investigation is depicted.

3.3.Methodology

Cotton in black During the two stages of the experiment, soil was allowed to air dry. Preliminary tests such as specific gravity, liquid limit, plastic limit, and differentialfreeswellwerepartofphase1.SisalFibrewas added at 0%, 0.25%, 0.50%, 0.75%, and 1% in Phase 2, resulting in five samples, as indicated in Table 2. Sisal fiber's impact on the soil's engineering qualities was assessed using modified compaction, CBR, UCS, and consolidationtests.Thetypesofsamplesandthenotations usedinthegraphsarelistedinTable-2.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 02 | Feb 2025 www.irjet.net p-ISSN:2395-0072

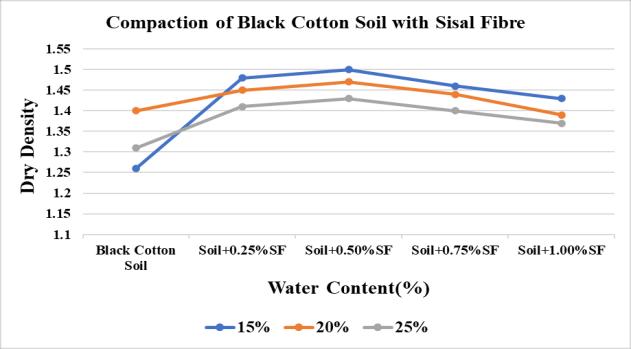

g/cc. Fig. 2 illustrates how adding sisal fiber raised OMC andloweredMDD.

S.No SamplePrepared Notation

1 BlackCottonSoil(BC) S0 2 BC+025%Sisalfibre S025 3

BC+050%Sisalfibre S050 4

BC+075%Sisalfibre S075

5 BC+1.00%Sisalfibre S1.00

The samples in Table 1 underwent several tests to evaluate the effect of sisal fiber on black cotton soil. The following sections provide a description of the testing techniques.

a. The following IS standards were used to test the indexproperties:DFS,LiquidLimit,PlasticLimit,and SpecificGravity: IS: 2720-Part5 (1985) for limits, IS: 2720-Part 3 (1980) for specific gravity, and IS 2720Part11(1977)forDFS.

b. The Modified Compaction technique (IS: 2720 – Part 8,1983)wasusedtoevaluatecompactionproperties, with an emphasis on the OMC and MDD connection foreverysample.

c. In accordance with IS: 2720 – Part 16 (1979), CBR values were calculated using samples that were soakedfor96hours.

d. Consolidation tests were performed at pressures between 0.1 and 1.6 kg/cm² in accordance with IS: 2720 – Part 15 (1986). The impact of Lime and Sisal Fiber on Black Cotton Soil was evaluated by calculating the Coefficient of Compressibility (av), Compression Index (cc), and Coefficient of Volume Change(mv).

4.RESULTS AND DISCUSSIONS

A. Index Properties

ThesoilhasbeenclassifiedasCHbasedonitsLiquid Limitof52%,PlasticLimitof25.15%,andPlasticityIndex of 26.85%. With a Differential Free Swell of 50% and a specific gravity of 2.67, it is classified as High Expansive Soil.

B. Compaction Characteristics

According to the Modified Compaction test, untreated soil had a n OMC of 20% and an MDD of 1.50

-1:

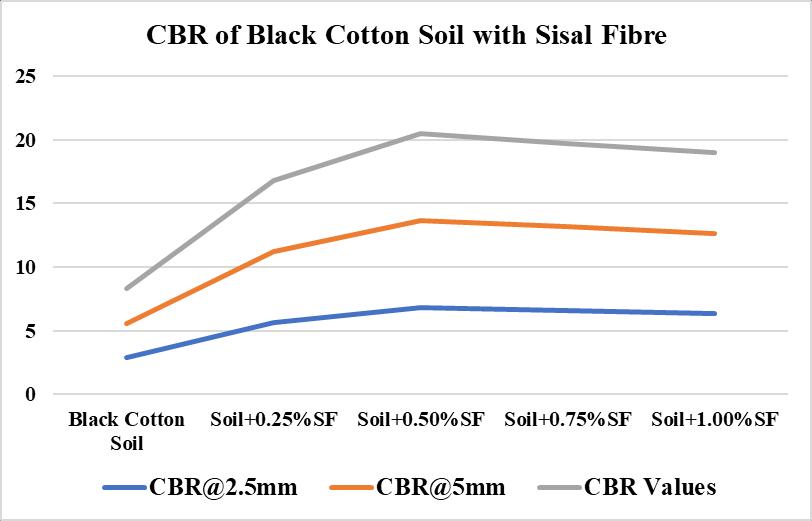

C.California Bearing Ratio

Blackcottonsoilloadversuspenetrationfiguresare shown for both drenched and unsoaked circumstances withvaryingpercentagesofsisalfibre.

Table-3:CBRTestResults

Chart -2:CBRofBlackCottonSoilwithSisalFibre

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 02 | Feb 2025 www.irjet.net p-ISSN:2395-0072

The experimental study of the sisal fiber-reinforced black cotton soil's strength parameters produced a number of important findings. At 0.5% sisal fiber concentration, the soil's California Bearing Ratio (CBR) reached its highest value. The Maximum Dry Density (MDD) rose at 0.5% sisal fiber, however the Optimum Moisture Content (OMC) fell at the same amount. A lower specific gravity and a lower liquid limit were also observed in the sisal-fiber-reinforced soil as compared to theuntreatedBlackCottonSoil.Theseresultsdemonstrate howsisalfiberimprovestheengineeringqualitiesofblack cottonsoil.

a. DifferentlengthsofSisalfibersareused.

b. Varioustypesoffiberswillbeusedasadditivestothe soil.

c. Different soil stabilization techniques will be applicableattainbetterstrength.

[1].Amrutha Mathew et.al – “Effect on strength characteristics of expansive soil using sisal fiber and waste materials”, - International Journal of Science andResearch(IJSR)ISSN:2319-7064(2015).

[2].IS: 2720, part 3 (1980), Sect/2 “Determination of specific gravity of fine, medium and coarse grained soil, Indian Standard Methods of Test for Soils”, BureauofIndianStandards,NewDelhi.

[3].IS: 2720, part 5 (1985), “Determination of Liquid and Plastic Limit, Indian Standard Methods of Test for Soils”,BureauofIndianStandards,NewDelhi.

[4].IS:2720, part 8 (1983), “Determination of Water Content – Dry Density Relation using Heavy Compaction, Indian Standard Methods of Test for Soils”,BureauofIndianStandards,NewDelhi.

[5].Santhi Krishna k et.al (2009) – “Behavior of black cotton soil reinforced with sisal fiber”, 10th National Conference on Technological Trends (NCTT09)67Nov2009

[6].ShrithiSBadami–“StabilizationofBlackcottonsoilby randominclusionofsisalfiber”,-InternationalJournal of Innovative Research in Science, Engineering and Technology.Volume6,Issue2,Feb2017.

[7].Mr.Kilabanur promod et.al(2017) – “A Comparative study on Engineering properties of expansive soil

treated with sisal fiber in addition to cement”,IJRTI,Volume2,Issue7,ISSN:2456-3315.

[8].SoilMechanicsandFoundationEngineeringByArora.

[9].Highway,Rail way,Airport and Harbour Engineering by K.P.Subramanian.

[10].IS:2720(Part-16) -1987 Methods of test for soil part16,laboratorydeterminationofCBR.

[11].Bose, B. (2012), “Geo-engineering Properties of Expansive Soil Stabilized with Fly Ash”, Electronic Journal of Geo technical Engineering, Vol. 17,pp. 1339-1353.

[12].P.K.Pradhan,R.K.Kar,and A.Naik, “Effect of random inclusion of polypropylene fibers on strength characteristics of cohesive soil,”Geotechnical and GeologicalEngineering,vol.30,no.1,pp.15-25,2012.

[13].K.K.Santhi and M.K.Sayida, “Behavior of black cotton soil reinforced with sisal fiber,” in Proceedings of the10thNationalConferenceonTechnologicalTrends (NCTT’09),Kerala,India,2009.

[14].IS: 2720, part 10 (1991), “Determination of Unconfined Compressive Strength,Indian Standard MethodsofTestforSoils”,BureauofIndianStandards, NewDelhi.

[15].IS: 2720, part 11 (1977), “Determination of Free SwellIndexofSoils,IndianStandardMethodsofTest forSoils”,BureauofIndianStandards,NewDelhi.

[16].IS: 2720, part 15 (1986), “Determination of ConsolidationProperties,IndianStandardMethodsof TestforSoils”,BureauofIndianStandards,NewDelhi

[17]. IS: 2720, part 16 (1979), “California Bearing Ratio Test of Soils, Indian Standard Methods of Test for Soils”,BureauofIndianStandards,NewDelhi.