International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 01 | Jan 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 01 | Jan 2025 www.irjet.net p-ISSN: 2395-0072

Nasir Alam1 , Ankit Goyal1 , Gaurav Goswami1

1Department of Mechanical Engineering, Technocrats Institute of Technology and Science Anand Nagar, BHEL Opposite Hathaikheda Dam, Bhopal, Madhya Pradesh 462021

Abstract - Jet impingement cooling is a well-researched method used to achieve high heat transfer rates, with applications in areas like electronics cooling, turbine blades, and nuclear reactors. The addition of nanofluids, especially TiO₂-water nanofluids, has proven to significantly improve heat transfer efficiency by enhancing convective heat transfer and promoting better thermal conductivity. This review investigates the performance of nanofluids of TiO₂ and water in cooling systems that use jet impingement., considering the main factors that influenceheattransfer.Italsoexaminesthelatestadvancements in research and discusses the potential future developments in this area.Theanalysis highlights theimportanceofparameterssuchas nanoparticle concentration, flow conditions, and surface characteristics in optimizing the advantages of heat transfer in nanofluids. It also describes the obstacles and possibilities for additional refinement and incorporation of TiO₂-water nanofluids intousefuljetimpingementcoolingapplications.

Key Words: Nano fluid, Heat Transfer, TiO₂-water nanofluids

Withinthermalengineering,heattransferisacrucialfield that focusses on the production, use, transformation, and interchange of thermal energy, or heat, between various systems. It is divided into a number of mechanisms, such as radiation, convection, thermal conduction, and energy transfer during phase transitions. Energy conservation, material sustainability, thermal regulation, and system compactness all depend on effective heat transport. The need for more efficient heat exchange systems has grown due to technological advancements and the optimisation of industrial processes. Microelectronics, power electronics, nuclear energy, air conditioning, transportation, aerospace, renewable energy, chemical engineering, and other industrial processes are just a few of the many industries that use heat transfer. Three main strategies are employed to increase heat transfer rates: passive,active,andcombinationstrategies.

By adding inserts or other devices, the passive technique typically modifies the channel's flow geometrically or on thesurface.For instance,addfluidadditives,coiledtubes, surface tension devices, extended surfaces, displacement augmentation devices, treated surfaces, rough surfaces, swirl flow devices, and additional components. The active

approach increases heat transmission by requiring some external power input. Some examples of active methods includefluidvibration,surfacevibration,jetimpingement, suction or injection, mechanical assistance, and induced pulsation by cams and reciprocating plungers. The enhancement is achieved through utilizing an external power source or activator. The compound method, which includesroughsurfaceswithtwistedtapes,fluidvibration, and a swirl flow device, is a combination of passive and aggressivetechniques.

Fluids should have low viscosity, high volumetric heat capacity, and high thermal conductivity for optimal heat transferperformance.Theymustalsobesafe,economical, non-corrosive,andenvironmentallyfriendly. Thefactthat energy-efficient heat transfer fluids, which are essential for high-performance cooling, are intrinsically less heatconductive than conventional coolants like water, oil, and EG, is one of the primary challenges in developing them. The coefficient that quantifies the speed at which heat movesfromtheheattransfermediumtotheheattransfer surface is referred to as the heat transfer coefficient is significantly impacted by the thermal conductivity of conventional coolants, making them inherently poor heat transfer fluids. In recent years, numerous methods have beendevelopedtosuspendnanoparticlesinthesefluidsto improvetheirthermalconductivity,whichareliquidswith typical diameters less than 100 nm. These liquids are referred to as "nanofluids." In addition to lowering emissions,thegreenhousegaseffect,andthepotentialfor global warming, the usage of nanofluid will save energy. The stability of nanofluids, which is correlated with the appropriate dispersion of nanoparticles, determines their performance.Sodiumdodecylsulphate(SDS),asurfactant, is added to a nanofluid to lower surface tension, keep nanoparticles from clumping in a base fluid, and keep the base fluid in which the nanoparticles are suspended stable.

Conventional heat transfer fluids such as air, water, lubricating oil, and ethylene glycol have much lower thermal conductivities than metals and metal oxides. In order to improve the special qualities of liquid coolants, thisrestrictionisfrequentlyovercomebyaddingadditives

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 01 | Jan 2025 www.irjet.net p-ISSN: 2395-0072

[2]. Additives are nanoparticles composed of a variety of elements, including metals, semiconductors, carbon nanotubes, oxide ceramics, nitride ceramics, carbide ceramics, and composite materials [1]. A base fluid containinguniformlyandsteadilydispersednanoparticles (1–100 nm) makes up a novel kind of heat transfer medium called a nanofluid. Metal or metal oxide are frequently the dispersed nanoparticles, significantly improve the nanofluid's thermal conductivity by raising theconductionandconvectioncoefficients,whichpermits greater heat transfer [3]. Because so many atoms are occupied on the borders, a higher surface area to volume ratio is found in nanoparticles than micrometer-sized particles, making them extremely stable in suspensions. Nanofluids have improved effective thermal properties because the qualities of nano-sized materials, such as thermal conductivity, are usually several times greater thanthoseofbasefluids.Becauseoftheirsmallersize,the dispersednanoparticlescanactinasuspensionlikeabase fluid molecule, which helps us avoid issues like sedimentation and particle clogging that arise with microparticlesuspensions.

Greater heat conduction is made possible by the nanoparticles'vastsurfacearea.Theyaremobileandhave the potential to cause micro convection because of their smallsize.Theaforementionedfactorsareresponsiblefor the unusual rise in the nanofluid's thermal conductivity.

Stability: There is less chance of sedimentation because the particles are smaller and weigh less, solving the sedimentation problem. One of the main disadvantages of suspensions can be addressed with less sedimentation. Decreased likelihood of erosion: Because nanoparticles are so tiny, their impact on a solid wall is minimal. As a result, the materials they come into contact with erode less.

Pumping power reduction: Increasing heat transfer in a conventional fluid by a factor of two requires a tenfold increaseinpumpingpower. Unlesstheviscosityincreases dramatically, a very modest increase in pumping power willbeneededinthecaseofnanofluid[4].

Fluids with dispersed nanoscale particles are referred to as "nanofluids". Ethanol, Water, oil, EG and refrigerants can all contain carbon materials (like graphite, carbon nanotubes, and diamond) suspended in them, as well as singleelements(likeAg,Fe,andCu),singleelement-based oxides(likeTiO2, Al2O3 Cu2O,andCuO),alloys(likeAg-Cu, Fe-Ni, and Cu-Zn), multi-element based oxides (like ZnFe2O4, NiFe2O4 and CuZnFe4O4,), metal based carbides (likeZrC,B4CandSiC),metalbasednitrides(likeAiN,TiN, and SiN), and carbon based materials (like diamond,

carbon-nanotubes, and graphite) blended in refrigerants, ethanol, and water. Two main categories into which they canbeseparatedaresingle material nanofluidandhybrid nanofluid[5].Nanofluidofasinglematerial.Itisregarded asthestandardformofnanofluid,inwhichasuspensionis created using a single kind of nanoparticles and several research methods Several authors have discovered that these nanofluids outperform their base fluids due to their notably superior thermo-physical properties. hybrid nanofluid. Comprising different types of nanoparticlessuspendedinabasefluid,hybridnanofluids areacomplexkindofnanofluid.

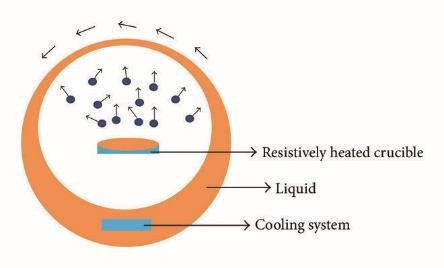

Not merely solid-liquid mixtures, nanofluids are made by solid particles dispersed at the nanoscale without clumpingtogetherinbaseliquidslikeethyleneglycol(EG), water, oils, and so on. One-step and two-step approaches are the two techniques utilised to prepare nanofluid. As seen in fig. 1[6], Producing nanoparticles and dispersingtheminthebasefluidaredoneinasinglestep usingtheone-stepmethod.Lowproductioncapacitiesand leftoverreactantsfromanincompletechemicalreactionin thenanofluidarethemethod'sdrawbacks.

Nanoparticles are created using the two-step technique and then distributed throughout the base fluids. When it comestoproducingnanofluidinlargequantities,thetwostepmethodisbeneficial.Thereisadrawbacktothetwostep method while the nanofluid is being prepared, the nanoparticles cluster together without being properly dispersed. Ultrasonic equipment is typically used to decrease clumping and distribute the particles intensely. Other methods, such adjusting the base fluid's pH or adding surface-active agents (surfactants), are employed inadditiontotheuseofultrasonicwaves.

Numerousindustrialapplicationsemployjetimpingement heattransfer,anactivetechniquethatbooststhesystem's heat transfer efficiency by using external power. An increase in the convective heat transfer coefficient is the resultofahigh-speedfluidjetthatmixesthefluidnearthe surface and breaks up the boundary layer. When jets hit the corresponding dish, it is known that the area

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 01 | Jan 2025 www.irjet.net p-ISSN: 2395-0072

surrounding the stagnation zone has a high heat transfer coefficient.

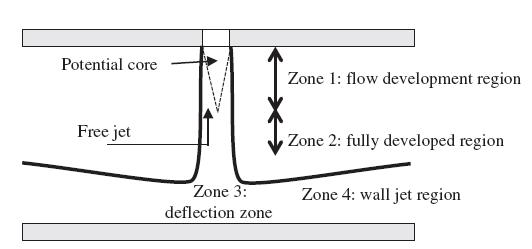

2 Arrangement of Single jet based impingement [6].

1. The flow development region is Zone 1. It consists of a core zone and a free jet zone The core zone's speed is almost similar as the bulk speed of the nozzle exit. At 95 percent of the nozzle exit speed, the center of the jet's velocity marks the end of the core region. Shear contact with the surrounding fluid causes the free jet zone to enlargewithincreasingdistancefromthenozzle. Therate offlowofthefluidinthefreejetarea lessensbecausethe surroundingfluidgetsincorporatedintothejet.

2.Atthe endof thecore isthefullydeveloped area (Zone 2). As one gets farther away from the nozzle, the axial jet velocitydrops.

3.Theareaclosetothewall(Zone3)isdistinguishedbya steep drop in axial velocity and an increase in static pressure. The deflection zone is the name given to this area.Thepointofstagnationislocatedinthecenterofthe deflectionzone.

4. After reaching its maximum, the transverse velocity in the wall jet zone (Zone 4) gradually falls. Since the stabilizing influence of the acceleration diminishes, the flow becomes turbulent because of the deceleration. Becauseofthischangefrom laminartotheturbulentshift inthe flow,heattransmissionisimprovedanda resulting peak appears on the Nusselt number change at low separationdistancevalues.Therefore,anumberoffactors influence the heat transmission coefficient. The most important ones include velocity profiles, heat flux, jet Reynolds number, turbulence intensity, nozzle shape, and nozzle-to-plate distance. According to a key finding of single jet studies, heat transmission is strong at the collision zone but quickly drops away from it. Using numerous jets, as shown below, is one way to get around thisissue.

With the aid of the jet impingement cooling technique, numerousheattransferissuescanberesolvedbypushing fluid onto a heated surface. The jet impingement cooling

methodiswidelyusedin manyindustrial areas,including the production of metal sheets, the drying of textiles, paper, and wood, the cooling of high-temperature glass, andthecoolingofinternalcombustionenginepistons,due to its greater heat and mass transfer rates and ability to thin the boundary layer of the heated surface [7]. Use of nanofluid to accelerate heat transfer is known as the jet impingementtechniquehasdrawntheattentionofseveral researchersoverthelastthreedecades.Inthepresentday, this kind of technique is widely employed in numerous industrial applications. To date, many researchers have conducted experimental, numerical, and theoretical studies.Theirprimarygoalwastomanipulateanumberof variables, including the Reynolds number, the distance between the target jet and the plate, the concentration of nanoparticles inside the base fluid, the angle at which the jet is projected, and others, in order to improve the coefficient of heat transfer of the nanofluid. Jizu Lv et al. [7] carried out an experimental study with nanofluid of SiO2-waterforthefollowingparameters:jettotargetplate distance 2–5; jet impingement angle 30-90 degrees; Reynolds number 8000–13000; and volume fraction 1-3 percent. They found that the SiO2-water nanofluid with a volume fraction of 3–0 percent nanoparticles had the largest increase in heat transfer coefficients, by 40 percent, when compared to pure water. An Al2O3-water nanofluid with a volume fraction ranging from 0 to 5 to 2 percentwasusedintheexperiment.JizuLvetal.[8]found that the nanofluid's convective heat transfer coefficient reduces as the impact angle increases and rises with the volume fraction and Reynolds number. Performance in heat transfer is optimal when H/D=4. For Al2O3-water nanofluids with a volume proportion of 2 and 0 percent nanoparticles impinging vertically, the heat transfer coefficients were 61 and 4 percent higher, respectively, than pure water under Re=12,000 comparison. Using varying particle volume fractions results in a similar tendency for the heat transmission coefficient, which decreases radially. Bin Sun et. al. sconducted a study to assess the heat transfer efficiency of a heat exchanger using an experimental Cu-water nanofluid. They discovered that the optimal heat transfer occurs with a circular nozzle spaced 3 mm from the target plate, and thattheheattransferriseswithincreasingjetangle.Using an Al2O3-water nanofluid, Jaware V.B. et al. [10] conducted an experiment in which they examined a number of parameters, including the volume fraction between0.1-0.5%,intermsofnozzlediameterratio(H/D) andtargettoplatedistance,therangesare2to18mmand 2 to 4 lpm, respectively. Maximum heat transfer required an H/D ratio of 2 to 8 and the heat transfer coefficient increasedfrom 24to44 percent for volume fractionsof 0 to 1 to 5 percent, respectively. The experimental study that Qiang Li et al. [11] conducted, showed that using a copper-water nanofluid for submerged jet impingement improves the heat transfer coefficient. for nanoparticle dimensions of 25 nanometers compared to 100

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 01 | Jan 2025 www.irjet.net p-ISSN: 2395-0072

nanometers. Using an Al2O3-water nanofluid, both experimental and numerical research werecarriedout by Mohamed A. Teamah et al. [12]. At Reynolds number 24000, they discovered that the heat transfer coefficient rises to 62 percent as both Reynolds number and volume concentration rise. TiO2 has the lowest heat transfer rate, while CuO has the highest, according to their comparison ofthethreenanofluids'heattransferrates(TiO2,CuO,and Al2O3). Santosh K. Nayak et al. [13] evaluated the heat transfer performance using TiO2-water and Al2O3-water nanofluids by incorporating a jet impingement experiment.Asthedistancebetweenthejetandthetarget plateincreases,theheattransfercoefficientdecreases,and it rises to a certain point as the concentration of nanoparticles increases, the results show that Al2O3 outperforms TiO2 and water. For nanoparticle concentration, the maximum heat Nusselt number measured was 2 points 0 percent, and the twisted tape ratio was 6. In an experimental investigation, K. Wongcharee et. al. [14] delved into the characteristics of swirling impingement jets, utilizing a TiO2-water nanofluid as the test substance. D. Lee, H. [15] conducted the study, in order to investigate heat transfer, used the following parameters: twisted tape ratio (Y/W) 4-7, volume fraction 0.5-2.5 percent, Reynolds number 500020000,andjettotargetspaceratio(H/D)1-4.

2. CONCLUSIONS

Because of their enhanced thermal characteristics and increased turbulence at the target surface, TiO₂-water nanofluids greatly improve heat transfer in jet impingement systems. Improvements in jet system designs and nanofluid synthesis hold the potential of overcoming obstacles like viscosity and stability. It is anticipated that future developments will expand the potential uses of this exciting technology and further optimize performance. A higher Reynolds number, more nanoparticles in the base fluid, and a greater distance between the heated surface and the nozzle all contribute tothenanofluid'sconvectiveheattransfercoefficient.

[1] Godson, Lazarus, B. Raja, D. Mohan Lal, and S. Wongwises. "Enhancement of heat transfer using nanofluids anoverview."Renewableandsustainable energyreviews14,no.2(2010):629-641.

[2]Raja,M.,R.Vijayan,P.Dineshkumar,andM.Venkatesan. "Review on nanofluids characterization, heat transfer characteristics and applications." Renewable and sustainableenergyreviews64(2016):163-173.

[3] P. Sivashanmugam. “Application of Nanofluids in Heat Transfer”.

[4] Sanjyot Varade*, Chinmay Patil and S. P. Wadkar. "A StudyofHeatTransferwithNanofluids.”International JournalofCurrentEngineeringandTechnology.

[5]Ali, Naser, Joao A. Teixeira, and Abdulmajid Addali. "A review on nanofluids: fabrication, stability, and thermophysical properties." Journal of Nanomaterials 2018(2018).

[6] Ali N, Teixeira JA, Addali A. A review on nanofluids: fabrication, stability, and thermophysical properties. JournalofNanomaterials.2018;2018(1):6978130.

[7] Lv, Jizu, Chengzhi Hu, Minli Bai, Ke Zeng, Shengnan Chang,andDongdongGao."Experimentalinvestigation of free single jet impingement using SiO2-water nanofluid."ExperimentalThermalandFluidScience84 (2017):39-46.

[8]Lv, Jizu, Shengnan Chang, Chengzhi Hu, Minli Bai, Peng Wang,andKeZeng."Experimentalinvestigationoffree single jet impingement using Al2O3-water nanofluid." International Communications in Heat and Mass Transfer88(2017):126-135.

[9]Sun, Bin, Yi Qu, and Di Yang. "Heat transfer of single impinging jet with Cu nanofluids." Applied Thermal Engineering102(2016):701-707.

[10]JawareV.B.,BhagatG.B.“HeatTransferEnhancement By Using Nanofluid Jet Impingement”. International Journal of Engineering Technology, Management and AppliedSciences3(2015).

[11]Li, Qiang, Yimin Xuan, and Feng Yu. "Experimental investigation of submerged single jet impingement using Cu–water nanofluid." Applied Thermal Engineering36(2012):426-433.

[12]Teamah, Mohamed A., Mohamed M. Khairat Dawood, and Ali Shehata. "Numerical and experimental investigation of flow structure and behavior of nanofluids flow impingement on horizontal flat plate." Experimental Thermal and Fluid Science 74 (2016):235-246.

[13]Nayak, Santosh Kumar, Purna Chandra Mishra, and S. K. S. Parashar. "Enhancement of heat transfer by water–Al2O3 and water–TiO2 nanofluids jet impingement in cooling hot steel surface." Journal of Experimental Nanoscience 11, no. 16 (2016): 12531273.

[14]Wongcharee,K.,V.Chuwattanakul,andS.Eiamsa-Ard. "Heat transfer of swirling impinging jets with TiO2water nanofluids." Chemical Engineering and Processing:ProcessIntensification114(2017):16-23.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 01 | Jan 2025 www.irjet.net p-ISSN: 2395-0072

[15]Lee, D., and Nur Irmawati. "Investigation on Fluid Flow and Heat Transfer Characteristics in Spray Cooling Systems Using Nanofluids." dynamics 9, no. 8 (2015):1409-1413.

© 2025, IRJET | Impact Factor value: 8.315 | ISO 9001:2008 Certified Journal | Page480