International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 02 | Feb 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 02 | Feb 2025 www.irjet.net p-ISSN: 2395-0072

Hiren Sonaiya1, Shashwat Yadu2, Swapnil Shelke3

1Hiren Sonaiya, Project Manager, Tata Technologies, 2Shashwat Yadu, Sr. Technical lead, Tata Technologies, 3Swapnil Shelke, Team lead, Tata Technologies,

Abstract - The automotive industry is continually evolving to meet increasingly stringent regulatory standards and consumer demands for improved efficiency and performance. The cold end exhaust system of a vehicle plays a crucial role in managing emissions, optimizing performance, andenhancing fuel efficiency. For flex fuel vehicles (FFVs), which can operate on a range of ethanol-blended fuels, unique challengesarisein the design of the cold end exhaust system due to the varying chemical properties and combustion characteristics of the different fuel types. This paper explores key design considerations for cold end exhaust systems in FFVs, focusing on factors such as material selection,corrosionresistance,and thermal management systems. The study highlights the importance of adapting the exhaust system to accommodate the increased ethanol content in the fuel, which can lead to higher exhaust temperatures and more aggressive chemical environments. By addressing these considerations, manufacturers can ensure that FFVs maintain optimal performance,durability,andenvironmentalcomplianceovera wide range of operating conditions.

Key Words: Automotive, Exhaust System, flex fuel vehicles (FFVs)

The automotive industry has undergone a transformative shiftinrecentyears,drivenbyaconfluenceoffactorssuchas tightening emission regulations, increasing consumer demandforfuelefficiency,andadvancementsinmaterials and manufacturing technologies. As a result, automotive engineersanddesignersarefacingtheintricatechallengeof developing innovative solutions that not only meet these demandingrequirements butalsoenhanceoverall vehicle performanceanddrivingexperience.

Flexfuelvehicles(FFVs)havebecomeincreasinglypopular duetotheirabilitytooperateonavarietyofethanol-blended fuels,offeringgreaterflexibilityandreducingdependencyon traditionalgasoline.However,thisadaptabilityintroduces unique challenges in vehicle design, particularly when it comestotheexhaustsystem.Thecoldendexhaustsystem, whichincludescomponents suchastheexhaustmanifold, catalyticconverter,andexhaustpipe,playsapivotalrolein managingemissionsandmaintainingengineperformance.In FFVs,thecoldendexhaustsystemmustbeabletohandlea

range of fuel compositions, including higher ethanol concentrations, which can significantly alter exhaust characteristics, including temperature, chemical composition,andcorrosivetendencies.

Designing a cold end exhaust system for FFVs requires careful consideration of several factors to ensure both optimal performance and long-term durability. Ethanolblendedfuelstendtoproducehigherexhausttemperatures compared to conventional gasoline, which can impact the longevityandefficiencyoftheexhaustsystemcomponents. Furthermore,thehigheroxygencontentinethanolfuelscan result in more aggressive chemical reactions within the exhaust system, necessitating advanced materials and coatings to mitigate corrosion. Additionally, the cold end systemmustworkintandemwithothervehiclecomponents, suchasthefuelmanagementandaftertreatmentsystems,to effectivelymeetemissionstandardswhileaccommodating thevaryingcombustioncharacteristicsofflexfuels.

Paper by S.T.Coelho, José Goldemberg, inEncyclopedia of Energy, 2004 Alternative Transportation Fuels: Contemporary Case Studies suggest Alternative transportationfuelsarebecomingincreasinglyimportantas the world seeks to reduce greenhouse gas emissions, improveairquality,anddecreasedependenceonfossilfuels. Variousinnovativefueloptionsarecurrentlybeingexplored anddeployedinreal-worldscenarios.

PaperbyGurusamyA,B.Ashok-Criticalreviewonrecent progressof ethanol fuelled flex‐fuel enginecharacteristics suggests-Ethanol-fuelledflex-fuelengines(FFEs)haveseen significantdevelopmentandadoptioninrecentyears,driven by the increasing need for alternative fuels to reduce greenhousegasemissions,lowerdependencyonfossilfuels, and promote renewable energy. Flex-fuel engines are designed to run on a mixture of ethanol and gasoline (in varying proportions), offering flexibility in fuel choice dependingonavailabilityandcost

This paper aims to address the primary design considerations for cold end exhaust systems in flex fuel vehicles. It explores key challenges such as material selection, heat management, corrosion resistance, and integration with other vehicle systems. By understanding these factors, manufacturers can design more efficient,

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 10 Issue: 03 | Mar 2024 www.irjet.net p-ISSN: 2395-0072

durable,andenvironmentally-friendlyexhaustsystemsthat aretailoredtothespecificneedsofflexfuelvehicles.

M/sTataTechnologiessuggestsDesignConsiderationsfor ColdEndExhaustSystemsinFlexFuelVehicles

Anexhaustsystemforflexfuelvehicles(FFVs)isdesignedto handletheuniquecharacteristicsoffuelslikeethanol(E85), whichiscommonlyblendedwithgasolinetocreateamore eco-friendlyfuelmix.Flexfuelvehiclesarebuilttorunona widerangeofethanol-gasolineblends,frompuregasolineto up to 85% ethanol, giving them flexibility in fuel choice dependingonavailability.

Thekeyconsiderationsforanexhaustsysteminaflexfuel vehicleinclude:

2.1.Corrosion Resistance: Ethanol has higher corrosive properties compared to gasoline, so exhaust systems must be constructed from materialsthatresistrustanddegradation.Stainless steel or other corrosion-resistant alloys are typicallyused.

2.2.Temperature Management:Ethanolburnsata highertemperaturethangasoline,whichcanresult in higher exhaust temperatures. The exhaust systemmustbedesignedtohandletheseelevated temperatureswithoutdegradingorcausingdamage tocomponentslikethecatalyticconverter.

2.3.Emissions Control:Flexfuelvehiclesaresubject to the same emissions regulations as traditional gasoline-poweredvehicles.Therefore,theexhaust systemmustintegrateeffectiveemissionscontrol devices,includingacatalyticconverter,toensure compliancewithenvironmentalstandards.Ethanol generally produces fewer pollutants like carbon monoxide (CO) and hydrocarbons (HC), but the systemstillneedstooptimizeforemissionsacross differentfuelmixtures.

2.4.Compatibility with Different Fuels: The exhaust system must accommodate the varying combustioncharacteristicsofdifferentfuelblends. This includes differences in exhaust gas volume, temperature,andthepresenceofcombustionbyproducts,allofwhichaffecthowtheexhaustgases areprocessed.

2.5.Fuel Efficiency:Awell-designedexhaustsystem canhelpimproveoverallfuelefficiencybyenabling betterengineperformance,reducingbackpressure, andensuringtheefficientflowofexhaustgases.

Overall, an exhaust system tailored for flex fuel vehicles ensures that the vehicle operates efficiently and meets emissionsstandards,regardlessofwhetheritisrunningon higherethanolblendsorregulargasoline.

3. Material Selection

Materialselectionforanexhaustsysteminflexfuelvehicles (FFVs)iscrucialbecauseoftheuniquechallengesposedby ethanol and other biofuels used in flex fuels. These fuels exhibit different combustion properties compared to traditional gasoline, such as higher corrosiveness, higher exhaust temperatures, and the potential for varying fuel blends.Theexhaustsystemmustbedesignedtowithstand thesechallengeswhileensuringdurability,performance,and compliancewithemissionsstandards.

KeyMaterialSelectionConsiderations:

3.1. Corrosion Resistance:

Ethanolandotheralcohol-basedfuelscanbemorecorrosive thangasoline,especiallyathigherconcentrations,whichisa keyconcernfortheexhaustsystem.Materialsusedmustbe resistant to ethanol's hygroscopic nature (its ability to absorbmoisture)andothercorrosiveby-productsproduced duringcombustion.

3.2. Materials:

StainlessSteel(304,441,316L):Thesearecommonlyused for exhaust systems due to their corrosion resistance and abilitytowithstandhightemperatures.Stainlesssteelalloys, especially 316L, provide excellent resistance to corrosion fromethanolandmoisture.

Aluminized Steel: A less expensive alternative to stainless steel,aluminizedsteeliscoatedwithalayerofaluminumto offerprotectionagainstcorrosion,thoughitmaynotbeas durable in very high-temperature environments or under extendedexposuretocorrosivefuels.

Titanium:Insomehigh-performanceapplications,titanium ischosenforitsexcellentresistancetocorrosionandhigh temperatures,thoughitcomesatahighercost.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 10 Issue: 03 | Mar 2024 www.irjet.net p-ISSN: 2395-0072

Flex fuel vehicles may experience higher exhaust temperatures, especially when running on higher ethanol blendslikeE85.Materialsmustbeabletowithstandthese elevatedtemperatureswithoutdegradingovertime.

Materials:

Stainless Steel Alloys (e.g., 441, 304): These alloys are particularlychosenfortheirhigh-temperatureendurance. 441 stainless steel, for instance, is often used in exhaust manifoldsduetoitsresistancetoheat.

StrengthandDurability:

Exhaustsystemsneedtobedurableenoughtoendurethe mechanicalstresses,vibration,andthermalcycling(heating andcooling)encounteredduringoperation.

Materials:

StainlessSteel(e.g.,441,304):Thesealloysareknownfor theirstrength,ductility,andabilitytoretaintheirintegrity undervaryingoperationalconditions.

Mild Steel: While less resistant to corrosion, mild steel is sometimesusedinexhaustcomponentswherelowercostis apriority,thoughitwouldneedtobecoatedtoprovidesome protectionagainstcorrosion.

ResistancetoOxidationandSulfurContamination:

HigherethanolblendslikeE85mayleadtoincreasedsulfur orothercontaminantlevelsintheexhaustgases,whichcan accelerateoxidationincertainmaterials.Thisisimportant forcomponentslikecatalyticconvertersandmufflers,which needtofunctionproperlyundervariousfuelconditions.

Materials:

High-GradeStainlessSteel:Stainlesssteel ischosenfor its ability to resist oxidation over long-term use, especially whenexposedtosulfurcompoundsintheexhaustgases.

Inconel: This high-performance alloy is used in extreme applicationsbecauseofitsresistancetooxidation,especially inareasexposedtoveryhightemperatures.

Cost-Effectiveness:

While higher-end materials like titanium offer excellent performance,theyarecostly.Formostflexfuelvehicles,a balancebetweenperformanceandcostisessential.

Materials:

Stainless Steel (304, 441): Offers a good balance of cost, corrosionresistance,andtemperatureendurance,makingit themostcommonlyusedmaterialinFFVexhaustsystems.

MildSteelwithCoatings:Usedinsomenon-criticalareasor forbudget-consciousapplications.

EmissionsControlCompatibility:

Flexfuelvehicles,especiallythoserunningonhigherethanol blends, need exhaust materials that are compatible with emissions control technologies, like catalytic converters. Theseconvertersmustbeabletoeffectivelytreatdifferent exhaust compositions to reduce pollutants such as hydrocarbons (HC), carbon monoxide (CO), and nitrogen oxides(NOx).

Compared to Conventional Petrol, flex fuel is hygroscopic duetopresenceofethanol.Besideswater,flexfuelalsohave Chloride, Aldehyde and Acid. An increasing percentage of ethanol blendinginflexfuel isproneto causingcorrosion andwateraccumulationinexhaustparts.

Due to the low ethanol content in E20 fuel, it behaves similarly to conventional petrol; therefore, no special materialchangesarerequiredintheexhaustsystemforE20.

However,forethanolblendshigherthanE20,higher-grade stainless steel materials are required compared to conventionalmaterials.

Fuel type Exhaust Component Material

Petrol&E20 Pipes&Sheets

SS441 EndPlateSheet&Tailpipe

>E20, E85, E100 Allpipes&Sheets

SS439/SS441

SS439/SS441

Table -1:-ExhaustSystemMaterialSelection

Provision

Inanexhaustsystem,especiallyatthecoldend(theportion ofthesystemfarthestfromtheengine),wateraccumulation can be a common issue due to the condensation of water vapor in the exhaust gases. This water is a byproduct of combustion, particularly when ethanol or alcohol-based fuels (common in flex fuel vehicles) are used. It can accumulate and potentially cause corrosion or freezing duringcolderweather,leadingtosystemdamageorreduced efficiency. Therefore, effective drainage provisions are essentialtopreventtheseissuesandensurethelongevityof theexhaustsystem.

ProvisionforAccumulatedWaterDrainageintheCold-End ExhaustSystem:

DrainageHoles/Ports:

One of the most common solutions is to include small drainageholesorportsatthelowestpointsofthecold-end

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 10 Issue: 03 | Mar 2024 www.irjet.net p-ISSN: 2395-0072

exhaust system. These holes allow water to drain out naturallyasitaccumulates.

Placement: The holes should be placed at the rear-most sections of the exhaust system, such as in the muffler or tailpipe,wherewaterismostlikelytocollectduetogravity.

Size and Design: The holes should be small enough to preventlargedebris(suchasroadsaltordirt)fromentering butlargeenoughtoallowwatertoescapeeasily.

TailpipeDesign(SlopedTailpipe):

Thedesignofthetailpipecanbemodifiedsothatitslopes downward,encouragingwatertoflowoutbygravity.This helps in preventing water from accumulating in low-lying sectionsoftheexhaustsystem.

ModifiedExitGeometry:Thetailpipecouldalsohaveaslight upwardangletowardsthevehicle’srear bumpertodirect moisture away from critical exhaust components and preventthere-entryofrainorsnowintothesystem.

CondensateTraps:

Some exhaust systems include condensate traps or reservoirs designed to collect and then drain away any accumulated water. These traps are typically located in sections like the muffler or resonator, where water accumulationismostlikely.

Drain Valve: A small valve can be installed in these condensatetrapstomanuallyorautomaticallyreleasethe waterasneeded.

VentilationandMoistureReleaseValves:

Incorporatingsmallventilationvalvesintheexhaustsystem, especially at the cold end, can allow for the release of moistureinacontrolledmanner.

Automatic Release: Some systems are designed to automatically release moisture after the vehicle has been running for a short time and the exhaust has heated up, evaporatingmostofthecondensation.

Preventing Freeze-ups: In regions where freezing temperaturesarecommon,thesevalvescanpreventwater from freezing in the exhaust system, reducing the risk of damage.

Corrosion-ResistantMaterialsinWaterCollectionAreas:

Tomitigatethepotentialdamagecausedbylong-termwater accumulation,partsofthecold-endexhaustsystem,suchas the muffler and tailpipe, should be made from corrosionresistantmaterialslikestainlesssteeloraluminizedsteel.

DrainagePathswithProtectiveCoatings:Areaswherewater tends to accumulate should have additional protective coatingstoreducetheriskofcorrosion.

PeriodicMaintenance:

Somevehicles,particularlythoseoperatingincoldclimates, mayrequireperiodiccheckstoensurethatdrainageholes, vents, and other water management features are clear of debris.Thisensuresthatwatercanflowoutfreelyandthe systemdoesn'tgetclogged.

Benefits of Proper Water Drainage in Cold-End Exhaust Systems:

PreventsCorrosion:Byallowingaccumulatedwatertodrain, the system is less likely to rust or corrode over time, especiallywhenusingethanol-richfuelslikeE85,whichmay increasemoisturelevels.

Improves Exhaust Performance: Proper drainage ensures that water doesn't pool and hinder the smooth flow of exhaust gases, potentially leading to back pressure or blockages.

ExtendsExhaustSystemLifespan:Minimizingtheeffectsof wateraccumulationhelpspreservethestructuralintegrityof theexhaustsystem,reducingtheriskofrust,holes,orother damage.

ReducesFreezingRisks:Incolderclimates,efficientdrainage reduces the risk of water freezing in the exhaust system, which could block the flow of exhaust gases or cause damage.

Ethanolburnsmorecleanlythanconventionalgasoline,but itstillproduceswatervaporasabyproduct.Thisvaporcan condense in the exhaust system, especially under cooler conditions.

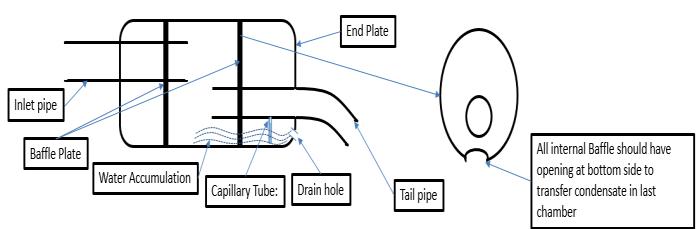

Belowaresomeprovisionsforwaterdrainagefrommuffler:

Drainage Holes & Sloped Design: Incorporatestrategically placeddrainageholesatthelowestpointsofthemufflerto allowaccumulatedwatertoescape.

Designthemufflerwithaslightslopetowardsthedrainage pointstofacilitatethenaturalflowofwater.

Capillary Tube: The capillary tube takes advantage of capillaryaction,whichhelpsdrawwateroutofthemuffler evenifthewaterlevelislow.Thisisparticularlyusefulin maintainingadryexhaustsystem.

Fig -2:ExhaustSystemCapillaryTubeScheme

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 10 Issue: 03 | Mar 2024 www.irjet.net p-ISSN: 2395-0072

Provisionsforaccumulatedwaterdrainageinthecold-end exhaust system are essential for maintaining the system's efficiency,preventingcorrosion,andextendingitslifespan. Methodssuchasdrainageholes,slopedtailpipes,condensate traps,and moisture release valveshelp manage thewater produced by combustion gases, particularly in flex fuel vehiclesusingethanol-basedfuels.Properdrainageiscritical notonlyforfunctionalitybutalsoforensuringthevehicle complies with emissions standards and operates safely in variousenvironmentalconditions.

Thematerialsselectedforaflexfuelvehicleexhaustsystem must balance corrosion resistance, strength, temperature endurance,andcost.Stainlesssteelisthepreferredmaterial duetoitswell-roundedproperties,whilehigh-performance alloys such as titanium may be used in more demanding applications.Additionally,ceramiccoatingsandthecareful integrationofemissionscontroltechnologieshelpoptimize theperformanceandlongevityoftheexhaustsystem.

[1] S.T.Coelho,JoséGoldemberg,inEncyclopediaofEnergy, 2004AlternativeTransportationFuels:Contemporary CaseStudies

[2] Gurusamy A, B. Ashok - Critical review on recent progress of ethanol fueled flex‐fuel engine characteristics - International Journal of Energy Research,January202246(110)-DOI:10.1002/er.7610

BIOGRAPHIES

Hiren Sonaiya, Project Manager, TataTechnologies, ShashwatYadu,Sr.Technicallead, TataTechnologies,

Swapnil Shelke, Team lead, Tata Technologies