International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 01 | Jan 2025 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 01 | Jan 2025 www.irjet.net p-ISSN:2395-0072

P Marikannan1, M Kiruthika2 , A C Mariappan3, G Peter packiaraj4

1,2 Final Year B.E Marine Cadets, PSN CET, Tirunelveli, Tamil Nadu

3,4 Assistant Professor, Department of Marine Engineering, PSN CET, Tirunelveli, Tamil Nadu***

The automatic anchor system is a pivotal advancement in maritime technology, designed to enhance the safety, precision, and efficiency of the anchoring process in modern ships. This system automates the deployment and retrieval of anchors, significantly reducing the need for manual intervention. By incorporating advanced sensors, real-time monitoring, and remote operation capabilities, automatic anchor systems mitigate risks associated with traditional anchoring methods, such as anchor dragging andchainslippage.

This paper examines the technological components of these systems, their integration with other navigational tools, and their impact on operational efficiency. As shipping demands evolve, the automatic anchor system represents a critical innovation in ensuring safe and reliablemaritimeoperations.

An automatic anchor system is designed to automate the anchoring process for vessels, ensuring safe and efficient operation without the need for manual intervention. The system typically integrates sensors, motors, and control units to detect the appropriate depth, seabed conditions, and environmental factors. Upon receiving the command, the system lowers or raises the anchor automatically, adjusting based on real-time data to secure the vessel in place.

Advanced versions may include GPS integration for dynamic positioning, enabling the vessel to maintain its location despite changes in tides or currents. This technology improves operational safety, minimizes human error, and enhances the ease of anchoring in complex marineconditions.

Keyword: Automatic anchor, AI technology, suitable for allvessels,automationmethod,safestoperation.

The anchoring process is a fundamental aspect of maritime operations, crucial for the safe and secure mooring of vessels. Traditionally, anchoring has relied heavilyonmanuallabour,withcrewmembersphysically handling the anchor and its chain. This process, while effective, presents several challenges, including the risk

of human error, physical strain on the crew, and inefficiencies,particularlyinadverseweatherconditions orcomplexdockingenvironments.

In response to these challenges, the maritime industry has seen the development and widespread adoption of automatic anchor systems. These systems revolutionize the anchoring process by integrating automation and advanced control technologies, allowing for precise, efficient,andsafeanchorhandling.Theautomaticanchor system operates by automating the deployment, monitoring, and retrieval of the anchor, significantly reducing the need for manual intervention and enhancingtheoverallsafetyoftheoperation.

Modern automatic anchor systems are equipped with a range of features, including real-time monitoring, tension control, and integration with the ship's navigation and dynamic positioning systems. These features ensure that the anchor is deployed and retrieved with optimal accuracy, reducing the risk of anchor dragging or fouling. Additionally, the ability to control the anchoring process remotely from the bridge furtherenhancesoperationalsafetyandefficiency.

This paper explores the technological advancements in automaticanchorsystems,theirintegrationintomodern shipdesign,andtheirimpactontheefficiencyandsafety ofmaritimeoperations.Byunderstandingthesesystems' capabilities and limitations, we can better appreciate their role in the evolving landscape of maritime technology.

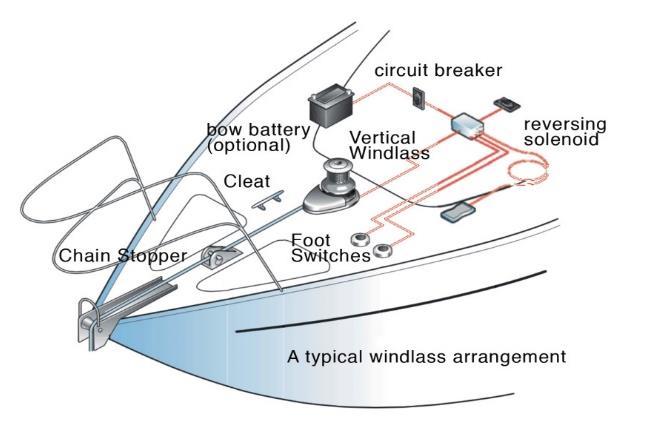

The automatic anchor system uses a combination of Electric or hydraulic motors, Gearboxes and winches, Chain wheels and gypsy wheels, Sensors (position, speed,direction,tension, andseabed), Control units and software, Power supply and backup systems. This integrated system ensures precise and efficient anchor handling, reducing the risk of accidents and improving overallsafety.

Sensorsmonitortheship'sposition,speed,anddirection, aswellastheanchor'sstatusandseabedconditions.The control unit processes data from sensors and executes commands based on pre-programmed algorithms and

Volume: 12 Issue: 01 | Jan 2025 www.irjet.net p-ISSN:2395-0072

operator input. The system deploys the anchor at the designated location, controlling the speed and direction oftheanchorchain.

The system uses GPS or other location-detecting technologiestomonitorthevessel’spositionandidentify the optimal time for anchoring based on predefined parameters like depth, seabed conditions, and environmentalfactors.

AutomaticDeployment:Uponcommandfromthecaptain oraspartofapre-setprogram,thesystemautomatically begins lowering the anchor. Sensors monitor the depth and rate at which the anchor chain or rope is released. The anchor is dropped at a controlled speed to prevent damageortangling.

AnchorLocking:Oncetheanchorreachestheseabed,the system continues to monitor the tension and position. If necessary,itadjuststhelengthofthechaintoensurethe anchorissecurelylodgedintheseabed.Thesystemmay perform automatic "dragging checks" by pulling slightly totestthegrip.

Position Maintenance: Advanced systems can integrate withGPSordynamicpositioningsystemstomaintainthe vessel’s location, compensating for drift due to tides, winds, or currents by automatically adjusting the chain lengthorreactivatingtheanchoringprocessifthevessel shiftsfromitssetposition.

AutomaticRetrieval:Whenthevesselneedstomove,the system will automatically retrieve the anchor by reversing the motorized mechanism, pulling the anchor chain back onboard while monitoring for potential obstaclesortangling.

Modern systems are equipped with alarms or alerts to notify the operator in case of any malfunction, unexpected slippage, or environmental changes that couldaffectanchoringsafety

The safety of an automatic anchor system in a ship is ensured by Redundant systems and backup power sources. Advanced sensors and monitoring systems for real-time feedback. Automated emergency release and retrievalsystems.

The system continuously monitors the anchor's status andadjuststhechain'slengthandtensionasneededthe system retrieves the anchor, controlling the speed and direction of the chain. The system stows the anchor and chaininthedesignatedstoragearea.

Regular maintenance and inspection schedules. Crew training and familiarization programs. Compliance with international safety standards and regulations. Fail-safe

defaults to prevent accidental deployment or release. Secure and reliable communication between system components. Protection against cyber threats and hacking.

Continuous software updates and performance enhancements. Integration with other safety systems, suchaspropulsionandnavigation.Emergencyshutdown andmanualoverridecapabilities

Anchorlockpreventers

Chainstoppers

Brakesystems

Emergencyreleasesystems

Alarmandwarningsystems

Redundantcontrolsystems

Regularsystemtestingandcertification.

Anchor winch: Electricorhydraulicwinchfordeploying andretrievingtheanchor.

Anchor chain locker: Storage space for the anchor chain.

Chain wheel and gypsy: Guidestheanchorchainduring deploymentandretrieval.

Anchor control unit: Houses the control system, sensors,andactuators.

Sensors: Monitor anchor position, chain tension, and seabedconditions.

Actuators: Control the anchor winch, chain wheel, and gypsy.

Power supply: Electric or hydraulic power source for thesystem.

Control panel: User interface for monitoring and controllingthesystem.

Anchor deployment and retrieval system: Automatic systemfordeployingandretrievingtheanchor.

Mooring system: Integrates with the automatic anchor systemforsecuremooring.

Navigation system: Provides data for accurate anchor positioning.

Alarm and warning system: Alerts crew to system statusandpotentialissues.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 01 | Jan 2025 www.irjet.net p-ISSN:2395-0072

These arrangement enables automated anchoring operations, improving safety, efficiency, and reducing crewworkload.Thespecificcomponentsandlayoutmay vary depending on the ship's size, type, and operational requirements.

Improved Safety: Reducedriskofaccidentsandinjuries duringanchoringoperations.

Increased Efficiency: Faster and more precise anchoring,savingtimeandfuel.

Reduced Workload: Automated anchoring reduces physicaldemandsoncrewmembers.

Enhanced Accuracy: Precise control over anchor deploymentandretrieval.

Better Monitoring: Real-time monitoring of anchor statusandseabedconditions.

Reduced Damage: Minimizedriskofdamagetotheship, anchor,andsurroundingenvironment.

Environmental Benefits: Reduced risk of damage to marineecosystemsandhabitats.

Cost Savings: Reduced fuel consumption, lower maintenancecosts,andminimizeddamage.

Improved Reliability: Automated system reduces humanerrorandensuresconsistentperformance.

Enhanced Situational Awareness: Real-time data and alertsforimproveddecision-making.

Reduced Anchor Loss: Automated retrieval and securingoftheanchorreduceslossrisk.

Compliance with Regulations: Meets and exceeds internationalsafetyandenvironmentalregulations.

Increased Crew Productivity: Automation allows crew tofocusonothercriticaltasks.

Improved Ship Stability: Precise anchoring ensures stableshippositioning.

Reduced Weather-Related Risks: Automated system adaptstochangingweatherconditions.

These advantages make automatic anchor systems a valuable investment for shipowners and operators, enhancing safety, efficiency, and productivity while reducingcostsandenvironmentalimpact.

Improvedsafetyandreducedriskofaccidents

Increasedefficiencyandreducedanchoringtime

Reduced workload and physical demands on crewmembers

Bettermonitoringandreal-timedataanalysis

Reduced damage to the ship, anchor, and surroundingenvironment

Cost savings through reduced fuel consumption andmaintenance.

[1] "AutomaticAnchoringSystemforShips"byS.K. Leeetal.publishedintheJournalofNavigation, 2018, Design and Development of an Automatic AnchoringSystemforShipsbyY.S.Kimetal.

[2] International Organization Maritime (IMO) MSC.1/Circ.1463 Guidelines for the design. and operationofautomaticanchoringsystems.

International Research Journal of Engineering and Technology (IRJET)

Volume: 12 Issue: 01 | Jan 2025 www.irjet.net

[3] Anchoring and Mooring by The Nautical Institute,2019.

[4] ShipHandlingandSafetybyD.J.House,2020.

BIOGRAPHIES

I am pursuing B.E final year Marine Engineering cadet at PSN College of Engineering & Technology,Tirunelveli,Tamil Nadu

I am pursuing B.E final year Marine Engineering cadet at PSN College of Engineering & Technology,Tirunelveli, Tamil Nadu

Project guide com assistant professor PSN College of Engineering and Technology, tamil Nadu. Also having 15 years experience in Oil and Gas industries Specialization in NDT and worked varies GulfCountries.

Project Guide cum Assistant Professor PSN College of Engineering & Technology, Tirunelveli, Tamil Nadu. MEO Class-IV Marine Engineer and workedvariesCountries.