International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 01 | Jan 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 01 | Jan 2025 www.irjet.net p-ISSN: 2395-0072

Sneha R. Badole1 , R. M. Swamy2

1M.E. Student, Dept. of Civil Engineering, SSJCET college, Asangaon, Maharashtra, India

2 Professor, Dept. of Civil Engineering, SSJCET college, Asangaon, Maharashtra, India

Abstract - This research explores the challenges and opportunities related to the adoption of innovative technologies and effective equipment management practices within the construction industry. A survey conducted among 97constructionprofessionalsaimedtoevaluatemanagement training tools, identify key issues in managing construction equipment, assess the effectiveness of management practices, and determine the success rate of current equipment management processes. The findings reveal a significant gap between awareness and actual adoption of advanced technologies, such as Building Information Modeling (BIM) and3D printing, with barriers includinghigh costs anda lack of skilled labor. Additionally, critical issues in equipment management, such as inadequate maintenance practices and reliance on outdated machinery, were identified as factors negatively impacting overall project productivity. The study demonstratesastrongpositivecorrelationbetweenstructured project management methodologies and enhanced productivity levels. Furthermore, the assessment of current equipment management processes highlights both strengths andweaknesses,withmanyfirmsfacingchallengesrelatedto maintenance scheduling and operator training. The research emphasizes the necessity for construction firms to invest in comprehensive training programs, implement systematic maintenance practices, and foster a culture of innovation to overcome barriers to technology adoption. Overall, this study contributes valuable insights into how effective management and innovative technologies can enhance productivity in the constructionindustry,providingactionablerecommendations for practitioners to improve project outcomes and competitiveness.

Key Words: Construction Industry, Equipment Management, Survey, Data collection, Barriers to Adoption, Productivity construction

Theconstructionindustryisavitalsectorthatsignificantly contributes to economic development and infrastructure growthworldwide.However,itfacesnumerouschallenges, including low productivity, high operational costs, and a pressing need for innovation. As the industry evolves, the integration of advanced technologies such as Building Information Modeling (BIM), 3D printing, drones, and robotics has emerged as a potential solution to enhance

efficiencyandproductivity.Despitetherecognizedbenefits of these technologies, their adoption remains limited, primarilyduetobarrierssuchashighcosts,alackofskilled labor,andresistancetochange.

Effective management practices play a crucial role in navigating these challenges and facilitating the successful implementation of innovative technologies. Management training tools are essential for equipping construction professionals with the necessary skills to adapt to new methodologiesandtechnologies.However,theeffectiveness ofthesetrainingprogramsandtheirimpactonproductivity and equipment management practices have not been thoroughlyexamined.

Effectiveequipmentmanagementmethodsnotmerelyboost productiontimeandequipmentaccessibility,butadditionally capitalize on the business benefit by decreasing many expenseslikeallthosefrompriceydowntime.Nevertheless, investigations in the area of equipment control practice, especiallyinthebuildingcontext,arealreadyunusual.

The buildingequipmentapplied toan enterprisehasa life cycle.Itstartsoffwiththerecognitionofapossibility,then simplyadvancestoapprovalandfeasibility.Iftheconceptis foundbeneficialacompleteselection,equipmentisbought, setupandplaceintooperation.Thevastbulkofthelifecycle isitsoperationwhichcarriesonuntiltheplace&equipment areinevitablydecommissionedanddisposed,Source,audit reportofIndianconstructionequipmentlifecycle.

1. Future studies should explore other influencing factorsaffectingconstructionproductivityatallstagesofthe procurementprocess.

2. Contractingcompanieshavetoconductproductivity studyattheactivity/operationlevelsuchasstudyingfactors affectinglabourproductivity.

3. The productivity and materials waste data can be usedtoprepareestimatesforfutureprojects.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 01 | Jan 2025 www.irjet.net p-ISSN: 2395-0072

1. Toevaluatetheprimarytoolsmanagementtrainingand managing experience within the target business in the buildingsector.

2. Torecognizethemainissuesofmanagingconstruction equipment.

3. In order to look at the effectiveness and productivity regardtomanagement.

4. Inordertoassessthesuccessrateofthelatestbuilding equipment management process of the enterprise understudyandalsoinordertodeterminetheweakness.

1.4 Problem statement

The construction industry is vital to India, making workforce efficiency crucial for productivity. Effective resource management ensures timely, cost-effective, and qualityprojectdelivery,keytosuccess.Laborproductivity directlyimpactsprojectoutcomes,emphasizingtheneedfor performanceimprovement.Enhancingworkforceefficiency isessentialforachievingconstructiongoals.

The performance of excavating equipment in construction depends on factors like utilization, maintenance, operator skill, site conditions, and project management. Efficient scheduling, regular maintenance, and skilled operators enhance productivity and minimize downtime. Advanced technologies,optimizeequipmentmanagement,improving efficiencyandsafetywhilereducingcosts.

[1] “Integrated agent- based construction equipment management:conceptualdesign”

Effectiveequipmentmanagementiscrucialforconstruction firms to minimize financial losses and improve efficiency. Existingsystemsoftenlackintegrationandrelyonsubjective decisions, leading to errors. The proposed agent-based equipmentmanagementsystem(ABEMS)leveragesreal-time data,ERPintegration,andautonomousdecision-makingto optimize operations, reduce human interference, and enhanceoverallperformance.

[2]“ManagementofEquipment&MachineryinConstruction”

Thepaperemphasizestheimportanceofeffectiveequipment management in construction to enhance productivity, efficiency,andprojectsuccess.Ithighlightskeyaspectssuch asequipmentselection,maintenance,andskilledoperation whileaddressingchallengeslikehighcostsanddowntime. Theauthorsadvocateleveragingadvancedtechnologiesand systematic practices to optimize resource utilization and improvedecision-making.

[3]“SystematicReviewofTheLiteratureonConstruction& Productivity”

Theauthorsreviewresearchonconstructionproductivity, identifyingkeythemeslikeprojectmanagement,workforce skills,technology,andeconomicfactors.Theyemphasizethe need for both quantitative and qualitative approaches to understand productivity challenges. Future researchareas includedigitaltechnologies,collaboration,andsustainability. Thepaperaimstoguideimprovementsforefficientproject delivery.

[4] “Implementation of technologies in the construction industry:asystematicreview”

This paper reviews technologies like BIM, automation, robotics,anddigitaltoolsinconstruction,highlightingtheir potential to boost efficiency, safety, and productivity. It examineschallengessuchasresistancetochange,highcosts, and the need for skilled labor. The authors stress the importanceofmanagementsupportandcallforresearchon bestpracticesfortechnologyintegration.

[5] “Control Chartsasa ProductivityImprovement Tool in Construction”

The author discusses using control charts to enhance constructionproductivitybymonitoringprocessvariations and enabling early corrective actions. Ault highlights their value in identifying trends, stabilizing processes, and optimizingresources.Casestudiesdemonstratetheirsuccess, and the paper calls for broader adoption, research, and training to integrate control charts into construction management.

[6]“FactorsAffectingPerformance of Excavating Equipment:AnOverview”

Theauthorsanalyzefactorsaffectingexcavatorperformance, including design, operations, maintenance, and environmental conditions. They stress the importance of training, maintenance, and best practices to optimize efficiency. Addressing these factors minimizes downtime, reduces costs, and enhances project outcomes in construction

[7]“Innovationinconstructionequipmentanditsflowinto theconstructionindustry”

Theauthorsexaminedriversofinnovationliketechnology, market demands, and competition, emphasizing collaborationbetweenmanufacturersandconstructionfirms. Theyaddresschallengessuchasresistancetochangeandthe needfortraining.Thepaperunderscorestheimportanceof fosteringinnovationtoboostproductivity,safety,andproject outcomes.

This research used survey methods, favoring web-based questionnaires for cost-effectiveness and respondent conveniencedespitelowerresponseratesthaninterviews. Data sources included literature reviews and focus interviews, followed by a structured plan for field data

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 01 | Jan 2025 www.irjet.net p-ISSN: 2395-0072

collection.Clearcommunicationwasemphasizedtoensure respondentsunderstooddefinitionsandprocedures.

4. DISCUSSIONS & FINDINGS

Thequestionnairewasdistributedto97participantswith constructionexperience,andtheirfeedbackwasanalyzed.It includedYes/No,scaled,andcontingencyquestionstogather detailedinsights.

youusedor seeninconstruction

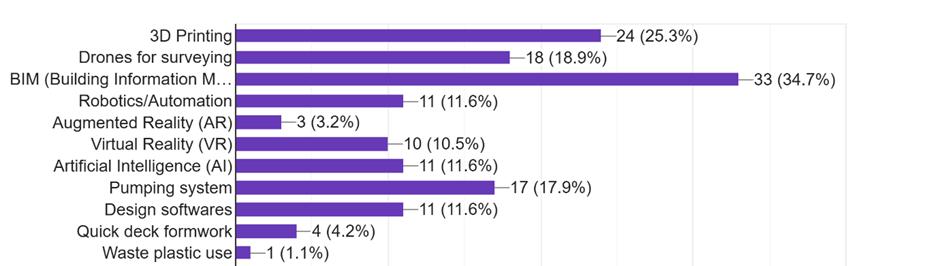

BIM (34.7%) and 3D printing (25.3%) are the most commonlyusedtechnologiesreportedbyrespondents.

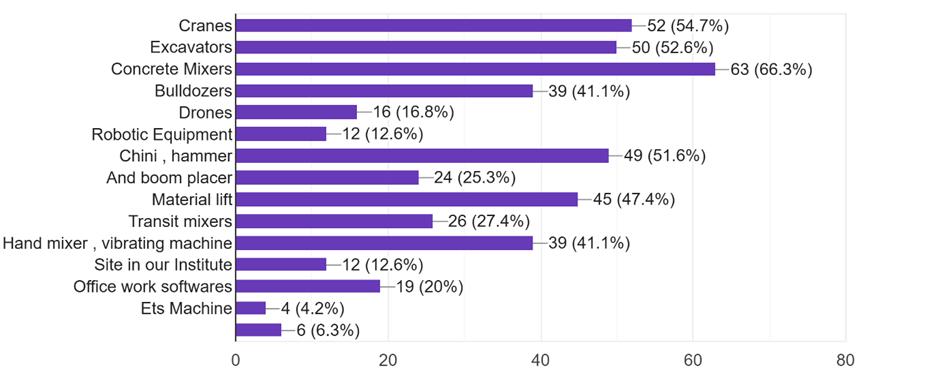

Concrete Mixers (66.3%) are the most widely used, followed by Cranes (54.7%) and Excavators (52.6%), with advanced technologies like Drones (16.8%) and Robotics (12.6%)beinglessadopted.TraditionalequipmentlikeChini andHammers(51.6%)andMaterialLifts(47.4%)aremore commonthannewertoolslikeOfficeWorkSoftware(12.6%) andETSMachines(4.2%).

Table -01: Innovativetechnologiesinconstruction

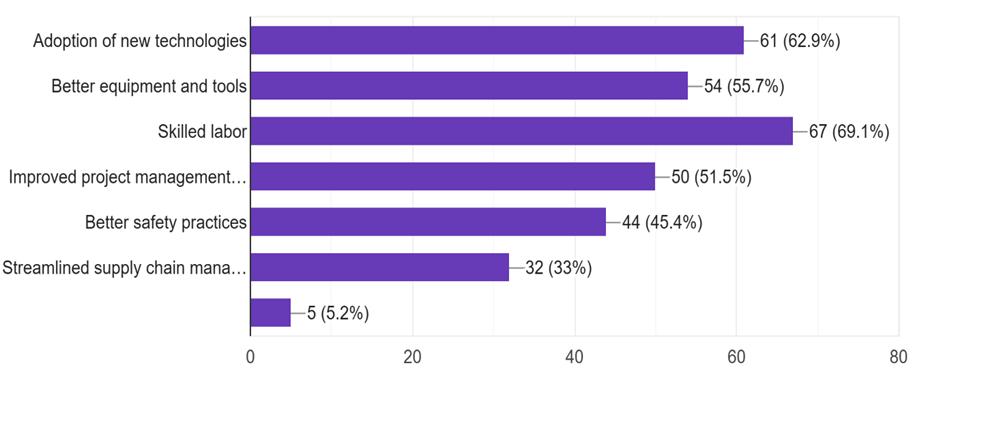

No. 05 Factorsdoyoubelievearemostcriticalin improvingproductivityonconstructionprojects

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 01 | Jan 2025 www.irjet.net p-ISSN: 2395-0072

Theevaluationemphasizesadoptingadvancedtechnologies like BIM, AI, and automation to improve construction efficiency,withdata-drivenstrategiesenhancingequipment managementanddecision-making.

Survey Question

Key Findings

Innovative TechnologiesUsedin Construction BIM(34.7%),3DPrinting (25.3%)

BarriertoAdopting Innovative Technologies

Construction EquipmentRegularly Used

HighCosts(40.2%),Lackof SkilledLabor(30.9%), InsufficientTraining(11.3%)

ConcreteMixers(66.3%),Cranes (54.7%),Excavators(52.6%)

Frequencyof EquipmentUpgrade 2-3Years(30.9%),4-5Years (27.8%),Annually(18.6%)

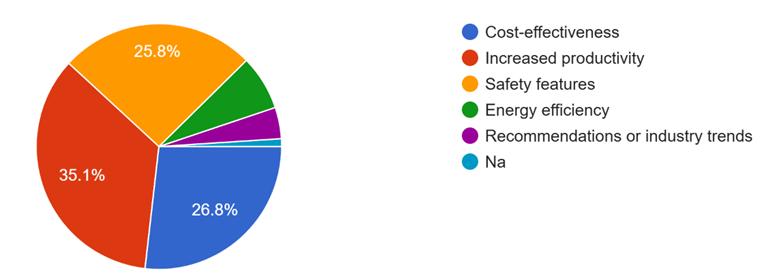

FactorsInfluencing EquipmentAdoption

Challengesin AdoptingNew Technologies

CriticalFactorsfor Improving Productivity

IncreasedProductivity(35.1%), Cost-Effectiveness(26.8%), SafetyFeatures(25.8%)

HighCosts(58.3%),Lackof SkilledWorkers(59.4%), MaintenanceIssues(33.3%), LimitedTechnologyAvailability (34.4%)

SkilledLabor(69.1%),New Technologies(62.9%),Better Equipment(55.7%),Improved ProjectManagement(51.5%)

The survey results provide valuable insights into construction technology adoption and its impact on productivity.Traditionalequipmentlikecranes,excavators, and concrete mixers remains dominant, yet innovative technologies such as BIM and 3D printing are gaining interest.However,theiradoptionremainslimited,withonly 34.7%usingBIMand25.3%using3Dprinting,mainlydueto financialconstraintsandtheneedforspecializedskills.This indicatesthatwhileinnovationholdspotential,overcoming thesebarriersisessentialforbroaderadoption.

Financialcosts(40.2%)andthelackofskilledlabor(30.9%) aresignificantchallengeshinderingtheadoptionofadvanced technologies. Despite a relatively low percentage of respondents citing resistance to change (5.2%), the data showsthattheconstructionindustrymustaddressworkforce readiness and the financial feasibility of new technologies. Theneedforabalancebetweentechnologicaladvancement and cost-effective, skilled labor solutions is crucial.

Additionally,equipmentupgradingpracticesvary,withsome firms hesitant to invest in newer machinery, potentially affectingproductivityandsafetyinthelongterm.

1. Omer Tatari and Mirosław Skibniewski, Integrated agent-based construction equipment management: conceptual design, Journal of Civil Engineering and Management,VolumeXII3,231–236,2006.

2. Prajeesh. V. P and Mr. N. Sakthivel, Management of Equipment&MachineryinConstruction,ISET-International JournalofInnovativeScience,Volume52016.

3. Asitha Rathnayake and Campbell Middleton, Ph.D., Systematic Review of The Literature on Construction & Productivity, Journal of Construction Engineering and Management · March 2023 DOI: 10.1061/JCEMD4.COENG13045

4. Xichen Chen and Alice Yan Chang-Richards, Implementationoftechnologiesintheconstructionindustry: a systematic review, Engineering Construction & ArchitecturalManagement·July2021DOI:10.1108/ECAM02-2021-0172

5. JospehHubertAult,ControlChartsasaProductivity Improvement Tool in Construction, 2013, College of TechnologyMastersTheses,Paper79.

6. DushyantA.DeshmukhandParagS.Mahatme,Factors Affecting Performance of Excavating Equipment: An Overview, International Journal of Science and Research (IJSR),ISSN:2319064,Volume5,2016.

7. David Arditi, Serdar Kale and Martino Tangkar, InnovationinConstructionEquipmentandItsFlowintoThe ConstructionIndustry,JournalofConstructionEngineering andManagement,ASCE,Volume123,Issue4123:371-378, 1997.

8. AnnaDuboisandLars-ErikGadde,TheConstruction Industry as a Loosely Coupled System Implications for productivity and innovativity, Paper for the 17th IMP Conference,9th-11thSeptember2001,Oslo,Norway.

9. NarimanGhodrati,TakWingYiu,SuzanneWilkinson, Unintended consequences of management strategies for improving labour productivity in construction industry, JournalofSafetyResearch,2018.