International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 02 | Feb 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 02 | Feb 2025 www.irjet.net p-ISSN: 2395-0072

Prajakta Jadhav1 , Aariya Vora2 , Lecturer Ms.Suparna Naik3

1Student, Dept. of Computer Technology, Bharati Vidyapeeth’s Jawaharlal Nehru Institute of Technology(poly.), Pune, India

2Student, Dept. of Computer Technology, Bharati Vidyapeeth’s Jawaharlal Nehru Institute of Technology(poly.), Pune, India

3Lecturer, Dept. of Computer Technology, Bharati Vidyapeeth’s Jawaharlal Nehru Institute of Technology(poly.), Pune, India

Abstract - 3D printing, additionally called additive production, is a generation that has revolutionized diverse industries in recent years. Unlike conventional subtractive manufacturing, which entails cutting or drilling a metal to create an item, 3-D printing constructs gadgets layer by layer. First of all, we introduce the essential principles of additive production that promotes using digital modeling which can be executed using software programs like Autodesk 3ds Max, Maya, AutoCAD, andso forth and makes use of a 3-D printer to construct the object by means of depositingsubstances, along with plastics,resins,ormetals, layer upon layer. The generation has opened doorways to an entire new realm of possibilities, from creating problematic clinical implants andprosthetics to producing complicated architectural fashions and precise artwork pieces. We tested its technique on imparting exceptional flexibility and customization. Next we delve into its wide ranging programs that make 3D printing one of these recreation-changers. From speedy prototyping to the manufacturingofcomplex geometriesandcustomdesigned products, these technologies have observed software in aerospace, automobile, healthcare and customer items sectors. With 3-D printing, complicated designs and prototypes may be created at a fragment of the time and value compared to standard strategies. Additionally, 3D printing permits for on-demand and decentralized production, permitting merchandisetobe madetowardthe factor of intake, searching in advance to take a look at additionally explores onthe improvementsandtremendous benefits and limitations this era brings.

Consisting of the drastic lessen in waste technology, most effectiveactualamount ofsubstances are used to construct anitemandthe amazingpotential ofadditiveproductionin enhancing efficiency, customization, and sustainability. Their increasingtalents, transformativeability,demanding situations, material barriers andregulatory hurdles andso forth within their respective area.

Key Words: rapid prototyping, digital modeling, customizedproducts,transformativepotential,cutting traditional methods

3D printing, additionally called additive production, revolutionizes traditional production techniques via constructinggadgetslayervialayerfromdigitaldesigns. Unlikesubtractivestrategies,whichputoffmaterialfroma solidblock,3-Dprintingprovidesmaterialexactlyinwhich it is wanted, offering unheard of design freedom and customization.Thismoderngenerationspansnumerous industries,fromaerospaceandautomobiletohealthcare andstyle,allowingfastprototyping,on-callforproduction, andfee-powerfulproductionofcomplicatedgeometries. Itsenvironmentaladvantagesconsistofreducedwasteand power consumption as compared to conventional manufacturing.

As 3-D printing continues to increase, its capability to reshape production paradigms, foster innovation, and democratize production underscores its significance withinthecontemporaryindustriallandscape.

1.1.1

We know-how 3D printing involves its additive manufacturingmethod,whereinobjectsarebuiltlayerby the way of layer from digital designs. The system starts with a 3-D version created for the usage of Computeraideddesign(CAD)softwareorobtainedvia3-Dscanning. This version is then sliced into skinny horizontal layers usingcuttingsoftware, whichgeneratesinstructionsfor the3-Dprinter.Theprintertranslatesthoseinstructions and deposits material layer by layer, which could vary from plastics and metals to ceramics and even food components,relyingonthekindofprinterandmaterial used. Each layer fuses with the preceding one, progressivelybuildinguptheverylastitem.

1.1.2

3Dprintingrevolutionizesindustrieswithitscapacity tofacilitatefastprototyping,price-powerfulproductionof elaborative designs, and on-demand manufacturing. It streamlines procedures, reduces material waste, and

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 02 | Feb 2025 www.irjet.net p-ISSN: 2395-0072

empowers innovation, fostering agility and competitiveness. With its versatility and capability for customizationitsvarietyisinfluencedfromaerospaceto healthcare, 3-D printing reshapes conventional manufacturing, offering remarkable opportunities for advancement.Average,3-Dprintingofferstransformative opportunitiesforindustriestostreamlinemanufacturing processes,innovateproductdesigns,andreplyeffectively tomarketneeds.

Givenbeneathareanumberofcaseresearchstudies. These deliver a short review over additive production. One compelling the Covid-19 repose with the medical supplies used to deal with the sufferers, other having NASA'sinitiativetodesign3DprintinghabitatandIndia’s 1stadditivelyprocessedpostoffice.

1.2.1 Covid-19 response

Inresponse to the COVID-19 pandemic, 3-D printing emergedasaimportanttoolfortheproductionofscientific supplies.Hospitalsfacingshortagesturnedovertoadditive production,toproduceventilatoradditives,faceshields, and nasopharyngeal swabs swiftly. Communities worldwidecollaborated tolayout, percentage,and print importantobjects,leveragingthetechnology'sflexibility and accessibility. This grassroots attempt tested 3-D printing'sagilityinaddressingdeliverychaindisruptions, showcasingitscapacitytoassisthealthcaresystemsinthe courseofemergencies.

1.2.2 NASA 3D printed habitat challenge

● NASA's 3-D printed Habitat venture aimed to design and construct sustainable habitats for deep space exploration using additive production. Teamscompetedtocreatehabitats which were able to withstand harsh extraterrestrialenvironments.

● Theundertakingfosteredinnovationinsubstances and creation techniques is paving the way for destinyofspacemissions.

● It showcased the capacity of 3-D printing to revolutionize area of exploration by permitting theon-websiteproductionofhabitatsandtheuse ofnearbyassets.

1.2.3 India’s

TheSiliconValleyofIndia-Bangalorehasreceiveditsfirst 3D-printed publishing office. Union Minister of Communications,Electronicsandstatistics era, Ashwini Vaishnaw inaugurated to put up an office which was constructedinonlyforty-fivedaysusingaroboticprinter thatworkson3Dprintinggeneration.

Withdecreasedproductiontimeandfees,aswellasmore advantageous layout flexibility, it sets a precedent for destiny urban improvement projects, emphasizing performance, sturdiness, and eco-friendliness in productionpractices.

Design optimization in 3D printing includes maximizing theelementperformanceandatthesametimeminimizing the fabric intake and manufacturing time. Through iterative processes and specialized software, engineers createcomplicatedgeometrieslikelightweightlatticesand complicated internal systems, unlocking unparalleled performance, customization, and innovation across industries.Righthereareafewoptimizationstrategieslike topology,heuristicsetofrules,STL,multi-practicalaspect, andmanyothers

Topology optimization in 3D printing entails the use of superior algorithms to determine the ideal cloth distributioninsideagivenlayoutspace.Throughanalyzing elements like pressure, stress, and cargo requirements, this technique generates organic, high- performance structureswithminimalmaterialusage.

Leveraging additive manufacturing's abilities, topology optimization permits the introduction of light-weight, complex geometries that decorate the part strength, reduce weight, and optimize functionality in various programs.

Heading to Heuristic algorithms in 3D printing, first optimize the printing technique through iteratively refining parameters to acquire desired effects. Those algorithms utilize rules of thumb or approximations to successfully explore massive answer spaces, enhancing print niche, velocity, and cloth utilization. Examples encompasses layer-by-layer optimization to minimize supportmaterial,pathplanningalgorithmsforgreentool path generation, and adaptive reducing strategies for superiorsurfacefinish.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 02 | Feb 2025 www.irjet.net p-ISSN: 2395-0072

Through leveraging heuristic algorithms, 3-D printing workflows grow to be extra streamlined and effective, advancingthegeneration'scompetenciesacrossindustries.

2.3 STL (stereo-lithography) design Optimization

STL layout optimization is a file format which is a 3-D printing generation that builds parts bypolymerizing a liquidphotopolymerresinwithaUVlaseronelayerata time.Thishelpsindisposingofundesirabledetails,faster reducingandensuresreliableprinting.Forinstance,STL isextensivelyusedforrapidprototyping,3-Dprintingand computer-aided

2.4Multifunctional component Design

Multifunctional element layout is performed with a 4aspect printer that permits tri-bo-filaments to be mixed with up to 3 different filaments. Considering placement about the filament, routing how the filament will run through to print the object, and coupling strategies to acquire unique necessities for the printed item. As an example, plane indoor components, replacement componentsforautomobiles,andsoforth.

3.1 Alloy and Metal Development

Oneofthemostresearchedregionsin3Dprintingisalloy development,inparticularforbiomedicalpackages.

Titanium, asturdyandcorrosion-resistant material, has obstacleswhileutilizedinhumanboneandtissueimplants sotoimprovethedownside,researchersaregrowingnew alloysespeciallyfor3-Dprintingmetalslikechromesteel andcobaltchromealloy.Thosealloyscanbecustomizedfor preciseprograms,offeringimprovedoverallperformance andreducedhazard.

With all this we can use superior materials along with Polymers,Nano-debris,Ceramics,Graphenecomposites. Those materials enable each traditional and advanced electronics package, leveraging the power of additive productionsystems.

3.2 Data driven material development

Data-drivenstatisticsmaterialimprovement,aidedbyusing systemlearning,optimizesclothresidencesforparticular applications.

MITandotheruniversitiesareemployingmachinelearning toenhancetheirlookatthesubstances.

However,whyblendmachinelearningwith3-Dprinting?

Byanalyzingtheserecords,wewillcreatematerialswith precisetraits(e.g.,electricity,corrosionresistance).This approach complements product satisfaction and

functionality, which will also cut down the fee of experimentingforphotographingidealgadgets.

This development in material selection is predicted to advance additive manufacturing into diverse fields, significantly biomedical applications, in which issues consist of printing pace, mobile increase feasibility, and complex form of fabrication for medical gadgets and implants.

Researchersareexploringthecapabilityof3-Dprintingin growingpatient-specificimplants,drugtransportsystems, andevenorganreplicasforpre-surgicalmakingplans.

Furthermore, the expansion of 3-D printing in biomedicineopensdoorwaystopersonalizedmedicinal drugs, in which treatments may be tailored to personal patients primarily based on their particular anatomical traits.

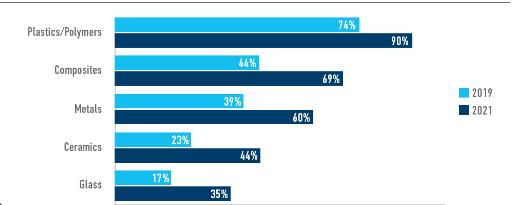

Fig 2. Shows how there was improvement in the 3-D printingmaterialsamongtheyears2019-2021.Andthe substances that are used to its maximum potential are plastics/polymer, composites and metal. This graph additionally suggests the popularity of additive manufacturing(3-Dprinting)insidethemarketplace.

Future developments in 3-D printing are poised to revolutionizeproductionthroughoutnumeroussectors,yet theycomewiththeirsetofchallenges.Onedistinguished fashion is the expansion of substances past plastics and metals. Researchers are exploring bio-compatible materialsforscientificprograms/options,orevensuitable foreatingmaterialsformealsprinting.Thisbroadeningof fabric options enhances customization and capability, howevernecessitatesstringentprotectionandregulatory concerns.

Moreover, improvements in multi-cloth and hybrid printingtechniquesenablethefabricationofcomplicated systemswithvaryingresidencesinasingleprintrun.But thiscomplexityintroduceschallengesinprintsatisfactory management, material compatibility, and publishprocessing.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 02 | Feb 2025 www.irjet.net p-ISSN: 2395-0072

Anothermassivefashionistheintegrationof3Dprinting with different technology like robotics, artificial intelligence, and the net of factors (IoT). Collaborative robots, as an example, can assist in printing huge-scale structures or carry out complex responsibilities like elementinspectionandmeeting.Evenaspromising,this convergence needs interdisciplinary understanding and posesdemandingsituationsininteroperabilityandsafety. Thisintegrationwillrevolutionizethemannerproductsare manufactured and customized, leading to remarkable performanceandinnovation.

Similarly,themostcrucialcharacteristicof3-Dprintingis sustainabilityandneighborhoodproductionconverge as additiveproduction.Withthepotentialtoapplysubstances anddecreasewaste,3Dprintingispavingthewayforan extra environmentally aware production process. This minimizes clothwasteand transportation emissions via producinggoodson-webpageorclose tocustomers,3-D printing reduces reliance on worldwide supply chains, promoting practices and supporting neighborhood economies.

Furthermore,thedemocratizationof3Dprintingthrough inexpensivedesktopprintersandopen-source platforms empowers individuals and small businesses to innovate andprototypeswiftly.

In the end, the destiny of 3-D printing holds massive capacity for excessive pace, technological convergence, sustainability,andlocalproduction,shapingagreenerand panoramaforindustriesworldwide.

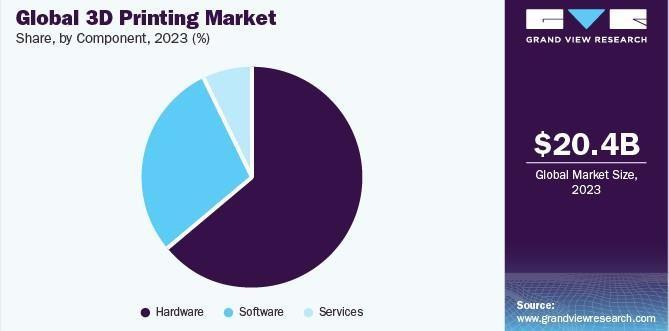

Fig.3.Indicatesadifferent viewoftheapplied3Dprinting marketglobally.Theinformationconstitutesinformation ratenetwellworthof12months2023

5. CHALLENGES AND CONSIDERATIONS

Demandingsituationsandconsiderations,oneofthekey aspectstobearinmindarethetechnologybarriersfound in3-Dprinting,thatcouldaffectthecomplexityandlength ofgadgetsthatcanbeefficientlyprinted.Fabricissuesplay agood-sizedfunction,becausethetypeoffabricusedcan greatly affect the high-quality and sturdiness of the

printed item, making cloth selection is therefore an essentialpartwithintheprintingprocedure.

Furthermore, the dearth of requirements and design suggestions inside the 3-Dprinting enterprise canpose challenges for designers and producers, mainly due to inconsistencies in print-exceptional or compatibility problems.

It's crucial for people to evolve in 3-D printing and be knowledgeable about the brand-new tendencies in substances and technologies, for you to navigate those challengesefficientlyanddevelopprints.

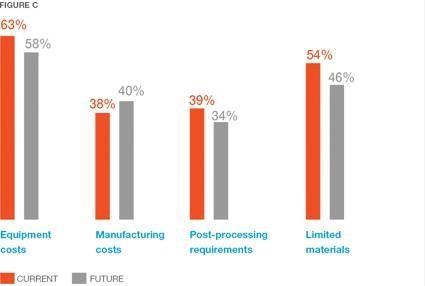

Fig.4.Representstwoofthetopfourchallengesthatare financially-based,indicatingcostremainsanotablebarrier toimplementation.Butsurprisinglylackofsoftwareand legalimplicationsdidn’trisetothetopasbelieved

Fig4.Topchallengesarewidespreadin3Dprinting

Addressing these challenges requires concerted efforts from researchers, policymakers, and industry stakeholders. Regulation must keep pace with technologicaladvancementstoensuresafety,quality,and ethical use of 3D printing. Collaboration between academia,governmentagencies,andindustryiscrucialfor advancingresearch,developingstandards,andfostering innovation.Ultimately,overcomingthesechallengeswill unlockthefullpotentialof3Dprintingtodrivesustainable, personalized, and accessible manufacturing solutions in thefuture.

In Conclusion, 3D printing and additive manufacturing have basically changed the world approach to design, prototyping, and production in a way that is unprecedented.

This technology opens up new scopes of customization, efficiency,andsustainability,therebyredefiningtraditional boundaries of manufacturing. Concepts ranging from healthcare to aerospaceand consumer goodsare being changedduetotheversatilityandpotentialof3Dprinting.

With advancements improving material abilities, speed, and cost-effectiveness, additive manufacturing will

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 02 | Feb 2025 www.irjet.net p-ISSN: 2395-0072

undeniably play a grand role in the future of manufacturing.Therefore,itwillbeusedtobringideasinto realitywithunprecedentedaccuracyandimagination.

Wewouldliketoextendoursinceregratitudetoallthose who contributed to the completion of this paper presentation on 3D printing. Special thanks to our mentors and advisors for their guidance and support throughout the research process. Additionally, we appreciatetheassistanceofourcolleaguesandpeerswho offeredtheirfeedbackandsuggestions.

[1] "3Dprintingscalesup". The Economist.5September 2013.

[2] Excell, Jon (23 May 2010). "The rise of additive manufacturing". The Engineer. Archived from the originalon19September2015.Retrieved30October 2013.

[3] 3D Printing: All You Need To Know” explainedideas.com. Archived from the original on 20 August 2022. Retrieved 11 August 2022.

[4] "Most used 3D printing technologies 2017–2018 Statistic”.Statista.Retrieved2December2018.

[5] "Pratt&WhitneytoDeliverFirstEntryIntoService EnginePartsUsingAdditiveManufacturing".Additive Manufacturing.6April2015.Retrieved20December 2020..