2025 Corporate Profiles

Learn about the companies and technologies shaping the future of Industrial Ethernet, the IIoT and Industry 4.0.

Learn about the companies and technologies shaping the future of Industrial Ethernet, the IIoT and Industry 4.0.

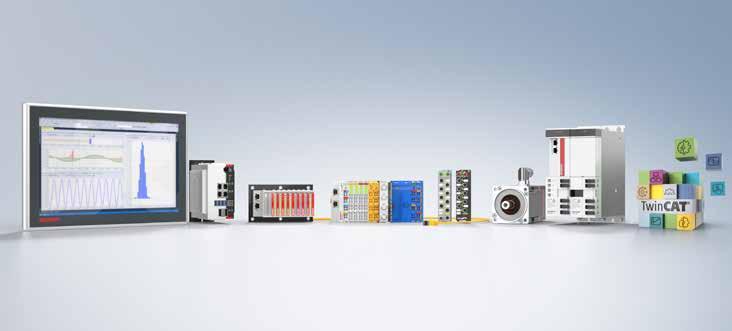

Beckhoff implements open automation systems using proven PC-based control technology. The main areas that the product range covers are industrial PCs, I/O and fieldbus components, drive technology, automation software, control cabinet-free automation, and hardware for machine vision.

PRODUCT RANGES THAT CAN BE USED AS separate components or integrated into a complete and mutually compatible control system are available for all sectors from Beckhoff Automation. New Automation Technology stands for universal and industryindependent control and automation solutions that are used worldwide in a large variety of different applications, ranging from CNC-controlled machine tools to intelligent building control.

Since Beckhoff’s foundation in 1980, the development of innovative products and solutions on the basis of PC-based control technology has been the foundation of the company's continued success. We recognized many standards in automation technology that are taken for granted today at an early stage and successfully introduced to the market as innovations. Beckhoff’s philosophy of PC-based control as well as the invention of the Lightbus system and TwinCAT automation software are milestones in automation technology and have proven themselves as powerful alternatives to traditional control technology. EtherCAT, the real-time Ethernet solution, provides a powerful and future-oriented technology for a new generation of control concepts.

The corporate headquarters of Beckhoff Automation GmbH & Co. KG in Verl, Germany, is the site of the central departments such as development, production, administration, sales, marketing, support and service. Beckhoff’s presence in the international market is guaranteed by its subsidiaries. Beckhoff is represented in more than 75 countries by worldwide cooperation partners.

Selecting the communication technology is important: it determines whether the control performance will reach the field and which devices can be used. EtherCAT, the Industrial Ethernet technology invented by Beckhoff, makes machines and systems faster, simpler and more cost-effective. EtherCAT is regarded as the "Ethernet fieldbus" because it combines the advantages of Ethernet with the simplicity of classic fieldbus systems and avoids the complexity of IT technologies. The EtherCAT Technology Group (ETG), founded in 2003, makes it accessible to everyone. With over 8,000 member companies from 72 countries (as of February 2025), the ETG is the world's largest fieldbus user organization.

EtherCAT is an international IEC standard that not only stands for openness, but also for stability: until today, the specifications

have never been changed, but only extended compatibly. This means that current devices can be used in existing systems without any problems and without having to consider different versions. The extensions include Safety over EtherCAT for machine and personnel safety in the same network, and EtherCAT P for communication and supply voltage (2 x 24 V) on the same 4-wire cable. And also EtherCAT G/G10, which introduces higher transfer rates, while the existing EtherCAT equipment variety is integrated via the so called branch concept: even here there is no technology break.

Beckhoff Automation at a glance

• 2024 global sales: €1.17 billion

• Headquarters: Verl, Germany

• Managing owner: Hans Beckhoff

• Employees worldwide: 5,300 (FTE, March 2025)

• Engineers: 2,000

• Subsidiaries/representative offices worldwide: 41

• Sales offices in Germany: 23

• Representatives worldwide: >75

Beckhoff Automation GmbH & Co. KG info@beckhoff.com Phone: +49 5246 963-0

Visit Website

Moxa offers scalable, secure and reliable solutions that help enterprises strengthen their digital operations, drive IT/OT convergence and build future-proof industrial organizations.

WITH OVER 35 YEARS OF INDUSTRY EXPERIENCE , Moxa is a global leader in edge connectivity, industrial computing, and network infrastructure solutions that empower the Industrial Internet of Things (IIoT). The company has connected more than 111 million devices worldwide and serves customers in over 91 countries, delivering reliable networking solutions and unparalleled customer service.

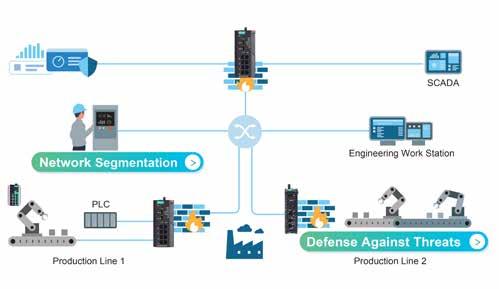

Moxa introduced the world’s first IEC 62443 certified network appliance in the OT market and continues to advance OT security as a CVE Numbering Authority while helping customers respond to NIS2 requirements. Moxa’s approach integrates robust industrial networking with cuttingedge OT cybersecurity: security-hardened devices that meet IEC 62443-4-2, advanced network segmentation with proactive threat prevention, and customized OT deep packet inspection for effective industrial IPS.

Industrial control systems face rising cyber risk as connectivity grows. Moxa aligns product design and lifecycle practices with IEC 62443 to help operators apply multilayer protection across devices, cells, and sites. This secure-by-design foundation supports real-time visibility, segmentation, and rapid recovery to keep operations reliable.

Create zones and conduits that reflect how operations run. Moxa’s EDR-G9010 Series industrial secure routers and EDS-4000/G4000 Series industrial managed Ethernet switches enable segmentation at Layer 2 and Layer 3 using VLANs, ACLs, and routing. Administrators can restrict access by VLAN ID or MAC address and control traffic by IP and ports. Policy firewalls and NAT establish conduits between zones and help shield internal addressing. OT DPI validates industrial traffic, so only approved content moves between production cells. The result is a reduced blast radius, clearer responsibilities, and simpler control across plants and sites.

Effective management is essential for resilience. MXview One provides unified monitoring, diagnostics, and change control across wired, wireless, and IEC 61850 substation networks. Role-based access, topology views, baselines, and log collection give lean OT teams the context to act early and support audit readiness for programs such as NIS2.

Moxa empowers industries with secure and reliable networking solutions that support continuous operations. By combining ruggedized hardware, software with long-term support, and proven cybersecurity practices, Moxa helps businesses stay competitive, secure, and ready for the future.

Moxa GmbH

Website: moxa-europe.com/solutions/ ot-cybersecurity Email: europe@moxa.com Visit Website

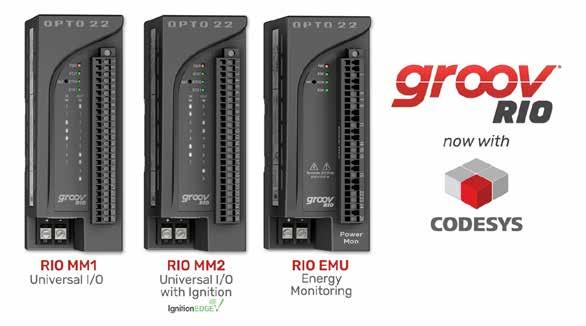

READY TO CONNECT AUTOMATION, ENTERPRISE, and cloud data? Opto 22’s groov family of industrial edge controllers and I/O gives you the integrated control, connectivity, and cybersecurity tools to do it.

With groov EPIC and groov RIO, you can bring brownfield systems into the next generation of industrial automation.

Create cohesive OT data systems from multi-vendor networks with OPC UA, MQTT, and more.

Secure PLC, I/O, and equipment data with built-in cybersecurity features like encryption, mandatory user authentication, and configurable device firewalls.

And you can collect, process, and publish OT data where it’s needed, into on-premises and cloud-based applications like databases, CMMS, SCADA, and ERP.

Control and I/O options at the edge For groov EPIC, develop real-time control programs in a language you know: ladder logic, function block diagram, flowcharts, Python, C/C++, and more. Build HMI screens for embedded or external touchscreens, PCs, and mobile devices. Run Inductive Automation’s Ignition Edge on the EPIC programmable industrial controller.

groov RIO edge I/O combines security,

software-configurable I/O, embedded software, and even CODESYS control programming in a single compact edge device.

Why choose groov?

Built on Opto 22’s over 50 years of experience, groov products are backed by lifetime guarantees on solidstate I/O, UL Hazardous Locations approval, ATEX compliance, and a wide -20 to 70°C operating temperature range.

Count on free pre-sales engineering help and product support as well. All Opto 22 products are developed, manufactured, and supported in the U.S.A.

Contact our engineers today, and let’s talk about what you want to do.

Providing innovative and reliable solutions to the industrial automation industry for more than 50 years, Contemporary Controls has been a leader in innovative solutions for industrial automation.

WITH MORE THAN 50 YEARS OF experience, Contemporary Controls has been a leader in innovative solutions for industrial automation. Contemporary Controls’ CTRLink products are designed for unattended operation in environments not conducive to office-grade equipment.

The products provide convenient DIN-rail mounting in control panels, 24 VAC/DC power, UL 508, improved EMC compliance and reliability. Contemporary Controls’ repeating hub, switches, media converters and IP routers adhere to IEEE 802.3 standards and more. Specialty regulatory needs are addressed in selected models.

Whatever the Ethernet infrastructure need, a solution is available from CTRLink products. For simple systems, plug-and-play unmanaged switches provide a cost-effective method for expanding Ethernet networks. Most models include features such as auto-MDIX and autonegotiation. For demanding applications, managed switches provide features such as VLANs, SNMP, Quality of Service, port security, port mirroring, alarming and cable redundancy.

For troubleshooting, diagnostic switches allows a network sniffer to attach to an unused port on a switch and observe all traffic on the network.

Contemporary Controls’ Skorpion series of IP routers ease the integration of new machines into the existing network. Each machine consisting of multiple IP devices

SOURCE: CONTEMPORARY CONTROLS

SOURCE: CONTEMPORARY CONTROLS

connects to the LAN side while keeping the same IP settings for the devices and the application, lowering installation cost and eliminating trouble shooting.

The IP address for the WAN port on the IP router is the only setting that requires modification allowing multiple machines to reuse the same configuration on the LAN side. Skorpion routers have been successfully used in Robotics, Automated Guided Vehicles (AGVs), Packaging and Scientific Equipment.

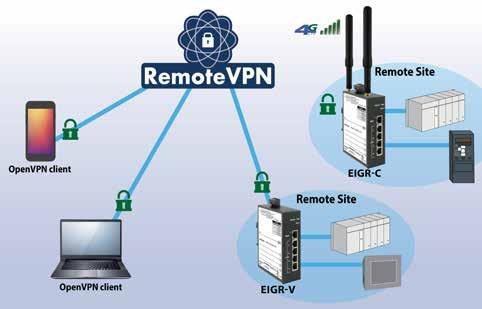

Utilizing the EIPR/EIGR series VPN routers, Contemporary Controls offers three VPN solutions that deliver secure, remote access—RemoteVPN subscription service, and Self-HostedVPN and BridgeVPN solutions. Hosted on the Internet and maintained by Contemporary Controls, RemoteVPN provides secure communication and the convenience of remote access without having to maintain a VPN server.

Contemporary Controls’ Self-HostedVPN and BridgeVPN solutions allow users to set up and maintain their own secure remote access without subscription fees and without the need for a cloud-based VPN server.

With automation systems, applications vary and can require a special product or need. Contemporary Controls has worked with OEMs in obtaining UL 864 compliance with some CTRLink switches and can help in other areas such as private-labeling, unique packaging or extreme environmental design.

Contemporary Controls’ customers are systems integrators, contractors and OEMs seeking simple, reliable networking and control products from a dependable source. With headquarters based in the US, Contemporary Controls also has operations in the UK, Germany and China and is well suited to fulfil your application needs.

Contemporary Controls www.ccontrols.com

Visit Website

SOFTING INDUSTRIAL IS A LEADING PROVIDER of advanced and easy-to-use products and solutions for the digitalization and networking of industrial systems and processes. Our mission is to deliver secure, flexible, and scalable connectivity that helps customers unlock the full potential of their data. With Softing, manufacturers can increase production efficiency, integrate operations across OT and IT, and seamlessly connect to edge and cloud platforms.

Our controller connectivity products simplify access to automation equipment from leading manufacturers, making it easier to scale projects and reduce operating costs. They provide a robust bridge between OT and IT, enabling industrial IoT applications for both brownfield and greenfield environments.

Softing’s software and hardware gateways provide direct access to HART, PROFIBUS, and other field device data. By integrating this information into Plant Asset Management applications, users can streamline commissioning, enhance maintenance efficiency, and improve diagnostics.

We help customers implement a single source of truth through the OPC UA Unified Name Space

(UNS). This ensures consistent and structured data across the enterprise, making it readily available for SCADA, MES, ERP, and other higher-level applications.

Our CNC solutions provide secure data access without altering machine configurations. This enables manufacturers to connect legacy and modern CNC assets to IoT and cloud applications quickly and reliably.

Softing supports device manufacturers in embedding Industrial Ethernet and Ethernet-APL into their systems. We provide proven solutions for real-time Ethernet protocols, ensuring reliable and future-proof communication. Our flexible software stacks and integration services help accelerate development cycles and maintain market competitiveness.

By implementing Ethernet-APL, we enable process automation networks to extend Ethernet connectivity right down to the field level, supporting faster data access, simplified architectures, and greater transparency in harsh environments.

With Softing Industrial, you gain a trusted partner committed to advancing your connectivity strategy. Our solutions enable:

• Optimized data exchange

• Seamless OT/IT integration

• Resilient and scalable industrial networks Empowering your digital transformation and preparing your operations for the future.

Email: info.automation@softing.com

For more than 40 years, W&T has been designing networking & automation components that make people’s work easier - so they can focus on what really matters.

HEADQUARTERED IN WUPPERTAL, GERMANY, Wiesemann & Theis offers a wide range of components for industrial ethernet communication.They stand out through German precision engineering and manufacturing as well as the most dedicated and proficient customer support.

What is most disruptive in any kind of process, may it be industrial automation, building technology or IT/OT security? When something does not work and needs to be fixed. Therefore, our primary goal is to offer components that are durable, robust, and always functional. We achieve this goal through highly qualified designing, precise manufacturing, high testing requirements and the continuous development of our products in close cooperation with our customers.

W&T reliable hardware comes with all necessary industry standards, from classical Ethernet to Single Pair Ethernet, from MQTT to OPC UA, Modbus/TCP, and other common protocols.Thanks to simple commissioning and integration as well as user-friendly interfaces, components are quickly ready for their, literally, lifelong use.

Our aim is to enable reliable access, secure data transfer, and flexible network integration — optimized for use cases in energy management, access control, traffic infrastructure, mechanical engineering and any IIoT application. As different as they may be from each other, all of these industries

W&T components include IO and sensor modules, serial and USB device servers and edge computing platforms.

have in common that they require secure and seamless data communication and often enough very individual, customized solutions.

W&T did not start out with IIoT components like web sensors and IO modules. In the beginning there were simple, yet revolutionary printer interfaces and switches. These made it possible to use document printers simultaneously from multiple workstations and allowed printers to be integrated into commercial networks regardless of

SOURCE: WIESEMANN & THEIS

manufacturer or built-in interface. What seems completely natural today, was quite progressive at the time and made W&T the market leader for printer interfaces in the 1980s.

To this day, W&T has remained true to its basic idea of offering devices and services that make customers' work a little easier: with W&T, devices, machines, and systems can be supplemented, networked, and modernized in a way that is simple, flexible, and sustainable.

One of our key technologies has always been industrial retrofitting, which for example with the help of serial device servers catapults wellestablished, powerful machines into the age of the Industrie 4.0. Our Com Servers remain among the most popular products because they prevent older production machines and other devices from having to be replaced at a great expense.

Besides the wide range of IoT components, including the first Single Pair Ethernet components, a growing focus is on development services for both software and hardware in the areas of automation, switching, reporting and connecting all kinds of data points.

Wiesemann & Theis

www.wut.de

Email: info@wut.de

Phone: +49 202 26 80 0

Visit Website

Moore Industries is a world leader in the design and manufacture of exceptionally rugged, reliable and highquality field and DIN rail-mounted instrumentation for the process monitoring and control industries.

MOORE INDUSTRIES WORLDWIDE SALES AND support offices provide first rate customer service and solutions for the chemical, petrochemical, utilities, petroleum extraction, refining, pulp and paper, food and beverage, mining and metal refining, pharmaceuticals, and biotechnology industries.

HART and MODBUS industrial communication protocols have dramatically increased access to device and process information that allows you to make more effective operational process decisions. Our Remote I/O systems, including the NCS Net concentrator System® and HART gateways and converters such as the HES HART to Ethernet Gateway System with HART Tunneling and the HCS HART to MODBUS Converter, help integrate valuable data into your monitoring and control system strategy.

Moore Industries can specify, procure, and assemble your multi-vendor electronic and pneumatic instrumentation/hardware into custom-built instrument panels, systems and enclosures. We will provide complete documentation, expert technical assistance, and the assurance that complete and thorough testing has been performed.

Moore Industries Universal PC-Programmable, Smart HART® Temperature Transmitters convert and send RTD or thermocouple signals ready for

direct interface with an indicator, recorder, PLC, DCS, or SCADA system. Temperature assemblies and measurement components include the WORM® flexible RTD and thermocouple sensors, connection heads and enclosures, thermowells and fittings. Our TCS Temperature Concentrator System now enables highdensity temperature monitoring over Ethernet, supporting more connections while providing precision measurements via HART, MODBUS RTU, MODBUS/TCP, and HART-IP, significantly reducing hardware, wiring, and installation costs.

Provide on/off control, warn of trouble, or provide emergency shutdown with one or more programmable alarm (relay) outputs when a monitored process signal falls outside

SOURCE: MOORE INDUSTRIES

of a selected high and/or low limit. Our SLA Multiloop and Multifunctional Safety Logic Solver and Alarm bridges the gap between single-loop logic solvers and costly safety PLCs. With up to 16 alarms and eight physical alarm outputs, simple and complex alarming strategies can be implemented. The SLA is SIL 3-capable, simple to program, and offers costeffective protection by reducing installation and engineering time.

Our spectrum of SIL 2 and SIL 3 capable FS Functional Safety Series instruments include signal isolators and splitters, single and multi-loop alarm trips and logic solvers, temperature transmitters and more. Every instrument is built and approved for use in Safety Instrument Systems and is third-party certified by exida to IEC 61508 standards.

Moore Industries has been proudly serving the process instrumentation needs of global manufacturers and automation companies since 1968. Designing, building and supporting more than 170 products across 14 product lines with unmatched systems, support and services expertise.

Moore Industries-International www.miinet.com Email: info@miinet.com

Visit Website

With a focus on reliability, scalability, and security, HiveMQ helps organizations get their data AI-ready— enabling advanced analytics, predictive maintenance and digital transformation.

SOURCE:

HiveMQ Swarm tests the reliability and scalability of deployments.

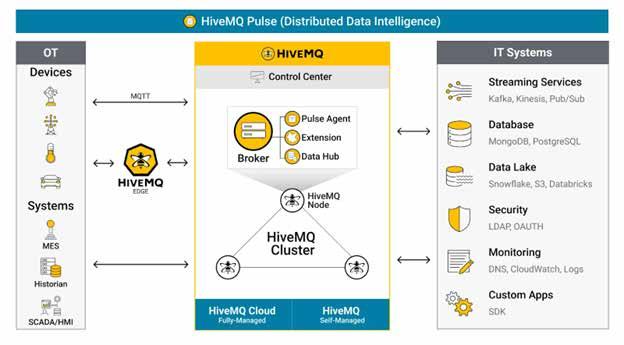

HiveMQ prepares industrial data for analytics, industrial automation, predictive maintenance, and AI/ML applications by ensuring high-quality, governed, and secure data streaming from edge to cloud. HiveMQ Pulse Distributed Data Intelligence Platform helps standardize and govern data streams through Unified Namespace (UNS), so data becomes more reliable and AI-ready.

HiveMQ

HIVEMQ EMPOWERS BUSINESSES TO UNLOCK the full potential of their data with the most trusted edge-to-cloud IoT data streaming platform.

Built on MQTT’s publish/subscribe architecture for seamless and flexible integration across operational technology (OT) assets and information technology (IT) applications, HiveMQ ensures businesses can efficiently connect, stream, and govern their data in real-time. With a focus on reliability, scalability, and security, HiveMQ helps organizations get their data AI-ready—enabling advanced analytics, predictive maintenance, and digital transformation.

With HiveMQ, individual customers have achieved:

• $35M annual savings from a 20% reduction in energy usage

• $83M in savings by cutting production downtime by 40%

• $2M in savings through a 25% boost in workforce efficiency

with HiveMQ

Securely collect, stream, and govern industrial data in real-time, from edge to cloud, for smarter decision-making.

Power seamless connectivity across your enterprise with HiveMQ’s trusted MQTT platform. Easily connect any device using our open-source MQTT client libraries, bridge legacy industrial protocols to MQTT with HiveMQ Edge, and extend functionality with HiveMQ Extensions to integrate data into existing streaming services, databases, and IT systems.

Leverage HiveMQ MQTT Broker, the eventdriven messaging platform designed for fast, efficient, and reliable data movement between IoT devices and enterprise systems. 100% MQTT-compliant, it enables instant, bi-directional communication, ensuring seamless, real-time data exchange for automation, analytics, and AI-driven insights.

Take control of your IoT data with advanced data management tools. The HiveMQ Control Center monitors the health of the system, while HiveMQ enterprise security features ensure robust protection. HiveMQ Data Hub enables validation, enforcement, and transformation of data in motion, and

Smart Manufacturing: Enables real-time data flow between OT and IT systems to reduce downtime, improve efficiency, and drive data-driven decisions.

Automotive: Powers connected car platforms and automotive manufacturing with reliable, secure data streaming to enhance connected vehicle experiences and optimize production.

Transportation & Logistics: Provides real-time fleet and supply chain visibility to streamline fleet management, improve service, and reduce costs.

Energy: Connects remote assets, optimizes operations, and supports energy transition initiatives through real-time insights.

Trusted by industry leaders like Audi, BMW, Liberty Global, Mercedes-Benz, Siemens, and Eli Lilly, HiveMQ helps organizations modernize operations, accelerate innovation, and deliver smarter, datadriven experiences.

HiveMQ GmbH Website: www.hivemq.com Visit Website

The only publication worldwide dedicated to Industrial Ethernet Networking and the IIoT. Visit iebmedia.com for latest updates.

New website offers deepest, richest archive of Industrial Ethernet and IIoT content on the web.

View and/or download latest issue of Industrial Ethernet Book and past issues.

Search our database for in-depth technical articles on industrial networking.

Learn what's trending from 5G and TSN, to Single Pair Ethernet and more.

Keep up-to-date with new product introductions and industry news.