Speaktoour EVExperts

Speaktoour EVExperts

Publisher

Jerry Ramsdale jerry@torque-expo.com

Editor Jonathon Harker jonathon@torque-expo.com

Deputy Editor Simon Yuen simon@torque-expo.com

Sales Manager – UK Claire Warman claire@torque-expo.co.uk

Sales Manager – International Harry Whyte harry.whyte@torque-expo.com

UK Sales Manager – Tools

Lloyd Ramsdale lloyd@torque-expo.com

Circulation

Tracy Howell tracy@torque-expo.com

Head of Production

Luke Wikner production@torque-expo.com

Designers

Dan Bennett

Victoria Arellano

Published by Stag Publications Ltd 18 Alban Park Hatfield Road

St Albans Herts AL4 0JJ

tel: +44 (0)1727 739160 fax: +44 (0)1727 739169

Email: info@torque-expo.com Web: www.torque-expo.com

Disclaimer

Although the utmost care is taken to ensure that information contained herein is accurate and up to date, the Publisher cannot be held responsible or in any way liable for errors or omissions during input or printing of any material supplied or contained herein. The Publisher also cannot be held liable for any claims made by advertisers or in contributions from individuals or companies submitted for inclusion within this publication. The opinions

06 NEWS

12 WOMEN IN FASTENERS > CORINNE JOUX, CEO OF DEGOMETAL

14 COVER PROFILE > AMBROVIT LOOKS BACK ON A YEAR OF GROWTH AND INNOVATION

16 FOCUS > C-PARTS, LOGISTICS AND KANBAN

22 FOCUS > BATTERY TECHNOLOGY & SMART TOOLS

26 OPINION > THE OPPORTUNITY IN ONLINE MARKETPLACES

28 FOCUS > PRODUCTION LINE TOOLS

30 SPOTLIGHT > HEAMAR

40 ROUNDTABLE > JAPANESE SUPPLIERS TALK FASTENERS

44 FOCUS > AUTOMOTIVE FASTENERS & TOOLS

48 BUILDING & CONSTRUCTION > ADHESIVES, TAPES, SEALANTS & FILLERS

52 2025 WRAP UP > INDUSTRY AND TRADE ASSOCIATIONS TAKE STOCK

60 SPOTLIGHT > SKS

62 SHOW ROUND-UP > IFE 2025, DACH + HOLZ & TITE X IHT

To subscribe to Torque Magazine visit: torque-expo.com/subscribe/ or scan this QR code... As part of our commitment to the environment,

With the lion’s share of the year done and dusted, we’ve got a pretty good idea of how 2025 was. Having sat in on a few association meetings and chatted with plenty of industry faces on and off the record throughout the year, it feels like the consensus was that 2025 was far from ‘barnstorming’. And that’s putting it politely.

On a fastener industry level, there’s been a few spinning plates to contend with. CBAM, price inflation, developing share in a flat market, antidumping changes and more.

However, the fastener sector is, maybe more than most, inextricably linked to other sectors –be they automotive, construction, industry, white goods, aerospace… all of those tend to be impacted by the general economy. And you don’t need me to tell you that the general economy, in many of the nations this magazine reaches, hasn’t exactly been barnstorming either.

But, as wiser heads than mine say, this isn’t the first lull in the economy that fastener businesses have had to persevere through. Readers of this magazine and our weekly email newsletter will have read many examples of investment and organisation by businesses who are making plans and changes despite (or perhaps because of) the tough market.

Likewise, when things inevitably pick up, it won’t magically solve the longer-term challenges facing the fastener and related markets. Sustainability, diversity, recruitment… Luckily there are a number of fine associations and actors working on some of those common themes to help the industry overcome them. For more comment on that and the year that was, turn to page 52. Thanks for reading.

Jonathon Harker Editor jonathon@torque-expo.com

NE Fasteners and online arm Screwshop.co.uk – the home of own brands Rhino and Turboqwik screws – are celebrating 40 years in the trade.

Nigel Elliott set up N E Fasteners in his garage in 1985, and his first customers and suppliers still work with the firm. Nigel’s son Matt joined him in 2001, and the company now employs almost 20 people, including on a very popular kitting and packaging line with new automated machinery running in early 2025.

The firm said: “It’s a testament to hard work, dedication from our staff, and shows loyalty and consistency in a constantly evolving sector. Our familyrun business provides essential components for the construction, manufacturing and DIY project and has built a strong reputation locally and nationally.”

The year of celebrations has been filled with memorabilia recognising the journey N E Fasteners has taken within the crucial industry and the commitment from its team. Each team member was presented with a special 40year gift box, personalised cupcakes and a relaxed afternoon off work.

Looking to the future, N E Fasteners aims to continue delivering value and building trusted relationships with its customers and suppliers and constantly having a strong customer led focus in person or with its ecommerce presence (Screwshop) to improve customers’ buying experience online.

screwshop.co.uk

nefasteners.co.uk

J

CP Construction Products, the specialist fixing division of OwlettJaton, is a leading supplier of high

quality construction fixings exclusively to the distributor.

Reacting to market feedback, JCP has introduced a comprehensive range of ETA approved Option 1 hexagon flange head Ankerbolts in a bright zinc plate (BZP) finish. A selftapping anchor for use in a variety of base materials, the selftapping action produces a positive anchorage. Applications can include Concrete C20/25 to C50/60, cracked concrete, and noncracked concrete, and offer a fireresistance loading.

Spanning 27 sizes over six diameters and 10 unique lengths, they complement the existing range of Ankerbolts, as well as ETA affiliated products. ETAs provide designers and contractors. Each product undergoes a rigorous and independent verification process to confirm its quality, performance and reliability.

www.jcpfixings.co.uk

www.owlett-jaton.com

Operating 50 advanced machines across three dedicated manufacturing sites.

Manufacturing standard fasteners and bespoke components in all material grades that are often not available “off the shelf”.

“Doing what we say, when we say”.

Distribution Centre Unit 2

Stour

Lye

Lesjöfors has appointed Oscar Fredell as CEO. Fredell brings extensive experience from leading and developing industrial companies with decentralised business models. The company said Fredell boasts experience in strategy, acquisitions and longterm value creation, which are areas central to the Beijer Alma group’s ambition to build a leading group of independent, entrepreneurial industrial companies. Lesjöfors is a subsidiary of the Beijer Alma Group. www.lesjoforsab.com

OwlettJaton has welcomed back two longstanding colleagues: Paul Johnstone, OwlettJaton’s Area Sales Manager (ASM) for Scotland, and Reza Jafari, Technical Strategy & Development Lead for JCP Fixings.

Paul joined OwlettJaton six years ago as ASM for Scotland. In that time, he developed and maintained good working relationships with customers, successfully increasing sales year on year. Earlier in 2025, Paul decided to leave OwlettJaton, but after a few months away, he is back and picking up where he left off.

Reza previously spent six successful years at JCP Fixings as Technical Manager, before leaving approximately two years ago to broaden his career in the construction sector. In his new role, Reza has returned as JCP’s Technical Strategy & Development Lead. www.owlett-jaton.com

Packer Fastener has advanced its AI capabilities to streamline internal processes and improve customer experience through its participation in the TitletownTech and Microsoft AI CoInnovation Lab. It worked with technical experts to develop an AIpowered quoting and ordering tool, which extracts key data from customer requests and matches it directly with internal stockkeeping units to streamline the quoting process. The new software is expected to automate up to 75% of quote transactions, saving about 40 hours per month.

FASTENER SOLUTIONS EXPANDS OPERATIONS WITH ACQUISITION >

Fastener Solutions has acquired RJ Fasteners, a distributor based in Hatfield, Pennsylvania. As part of the integration, RJ Fasteners’ facility will undergo a full modernisation of operations, including upgraded technology, streamlined processes and increased inventory. Fastener Solutions said the upgrade will allow for faster delivery times, greater product availability and a more efficient ordering experience for customers. It will also “strengthen its position” in the Northeastern US and enhance its ability to serve both new and existing customers.

WEDGE GROUP GALVANIZING OPENS NORTH EAST FACILITY >

Wedge Group Galvanizing has opened a new site to offer galvanising services and local support to customers in North East England. Based in Durham, the site officially opened on 28 October. The new location enables customers to continue enjoying fast and reliable service while gaining the convenience of dropping off and collecting work onsite. They will also benefit from the support of nearby facilities, including the closest Metaltreat Galvanizers plant in Bradford.

ANOCHROME GROUP’S ANOTEC GAINS RISQS APPROVAL >

The Anochrome Group’s Anotec has been verified by the Railway Industry Supplier Qualification Scheme (RISQS). The company said the certification marks a significant step forward in its engagement with the rail industry and reinforces its position as a trusted supplier to one of the sector’s most demanding markets. Anotec gained recognition following a comprehensive audit covering its production and management systems, including environmental practices and operational control.

RIVIT AWARDED AT BLECHEXPO 2025 FOR CONTROLRIV GEN3 >

Rivit has won an award for its fastening control system, CONTROLRIV Gen3, at Blechexpo 2025. The company took third place in the Best Award 2025 in the Separating, Joining and Connecting Technologies category, with its CONTROLRIV Gen3 impressing the jury with its technical capabilities designed to enhance efficiency and quality in industrial assembly processes.

To subscribe to Torque Magazine and receive the newsletter visit: www.torque-expo.com/subscribe/ or scan this QR code...

SOUTHCO ASIA OPENS MANUFACTURING SITE IN CHINA >

Southco Asia has opened a new manufacturing facility in Foshan, Guangdong Province, China. The site spans 13,000 square meters and is home to over 400 skilled professionals. The company said Foshan's strategic location provides advantages in logistics and supply chain management, enabling Southco to achieve faster turnaround times and deliver enhanced customer service.

FISCHER SMASHES WORLD RECORD >

fischer has achieved a Guinness World Record for the most holes drilled by a semiautonomous robot within 24 hours. The company’s fastening robot, Baubot, drilled 3,717 holes during the certified record attempt on 10 and 11 September at its test centre in Traiskirchen, Austria. Each drill hole met the specified requirements, including a minimum diameter of 10 mm and a depth of 50 mm, with no overlaps allowed.

VOSSLOH WINS €20M CONTRACT FOR NEW HIGH-SPEED RAIL LINE IN CHINA >

German rail technology specialist Vossloh has secured a contract for a new highspeed rail line in China. The company’s subsidiary, Vossloh Fastening Systems China, will deliver fastening systems for the new line connecting Xining, in northwestern China, with Chengdu, in southwestern China, by 2027. It added that the total value of the contract is under €20 million.

Corinne Joux, CEO of Degometal, has spent decades in the fastener industry, witnessing its evolution through digitalisation, automation and rising quality standards. Yet, she believes the most significant transformation has been cultural, with strides in diversity reflected in the growing presence of women across technical roles, R&D and management…

How did you get into the industry?

At the time, the Sales Director happened to be my neighbour. I had just finished my studies and had no professional experience. He was looking to expand export sales and was interested in my language skills.

Very quickly, I began working closely with the company’s Managing Director who later became my partner for more than 20 years. He recognised my adaptability and strong work ethic, which helped me progress quickly within the organisation and take an active role in shaping its strategy.

To this day, one of my greatest strengths remains my deep understanding of the operational side of our business.

What does your day-to-day job involve?

As CEO, my responsibilities go far beyond daytoday management. I oversee strategic vision, ensure the continuity of our industrial expertise and promote ongoing innovation, while staying closely connected to what’s happening on the ground.

I work to grow the company, support our teams and strengthen Degometal’s position in a highly technical and demanding market.

I also place great importance on passing on both skills and values, not only to men but increasingly to women, whose collaborative and crossdisciplinary perspectives bring real value to the sector.

Degometal’s products are supplied to renowned industrial groups in various sectors including the automotive industry, electrotechnics and electrical appliances.

What are the biggest changes you have seen in the industry and company since you started?

Over 40 years ago, the fastening industry was almost entirely male and often resistant to atypical profiles. Productivity was the main focus.

Today, the industry has been transformed: digitalisation, automation, quality standards and environmental impact are all front and centre. However, the biggest change is about the culture in the industry as attitudes are shifting. Diversity, especially gender diversity, is now seen as a strength. Women are increasingly present in technical roles, R&D and management. At our company, we’ve actively supported this evolution by bringing more women into the business.

Moreover, amid global industrial competition, I’m proud to be fighting every day to maintain production in France.

Can you share some of your career highlights and milestones so far?

My path has been shaped by continuous challenges. I worked my way up through different roles before becoming CEO. One of my proudest achievements is helping transform a familyrun business into a respected player in the fastening sector without losing our human values.

A defining moment was the death of my husband in 2001. That’s when I truly took over the company, in a context that was personally painful and professionally demanding. I had to act fast, reassure the teams and stay the course.

That experience revealed a strength within me I didn’t know I had. I realised that leadership isn’t just about knowledge, it's about embodying a vision and values, protecting and sharing them, especially with your teams. That ordeal shaped me and reinforced my belief that resilience is a key skill, particularly for women in industry.

What is your favourite thing about the fastener industry?

Its apparent simplicity hides remarkable complexity. A rivet may seem insignificant, yet it can be a crucial component for safety and reliability.

I love the combination of technical precision and the quiet, realworld impact our work has on major projects.

It’s also an industry built on transmission of knowhow, experience and trust. I’m proud that our group, Degometal, with its two French production sites, 4F and TPI, provides an environment where people can grow and learn, including young women just starting out.

Unfortunately, attracting new candidates remains one of our biggest challenges today.

What do you think needs to be done to encourage more women to get involved in the fastener industry?

We need to break down stereotypes as the industry, and fastening in particular, is not just for men. It’s equally important to highlight female role models, because visibility inspires confidence.

We should also promote technical and industrial careers from secondary school onwards, showing that these paths are open and rewarding for everyone.

At our company, we regularly welcome apprentices and interns, giving them a chance to imagine themselves in an industrial future. Ultimately, it comes down to supporting and recognising talent whatever the gender.

If you could, what piece of advice would you give your younger self as you started working in the fastener industry?

Believe in yourself. Build your credibility through your work, your skills and your personality.

Stay curious and disciplined. Learn from others but never lose sight of who you are.

And above all, don’t wait for doors to open. Sometimes you have to push them or build them yourself.

Any final thoughts?

The fastening industry is evolving for the better. It’s becoming more advanced, cleaner and more inclusive. But this momentum must continue and women are key to that progress. I hope we’ll soon stop talking about “women in industry” as something unusual, and simply see it as normal. I’m proud to have played a part in this shift, and even prouder to see it carried forward by a new generation of talented and committed women.

www.degometal.com

// I hope we’ll soon stop talking about “women in industry” as something unusual, and simply see it as normal. I’m proud to have played a part in this shift, and even prouder to see it carried forward by a new generation of talented and committed women //

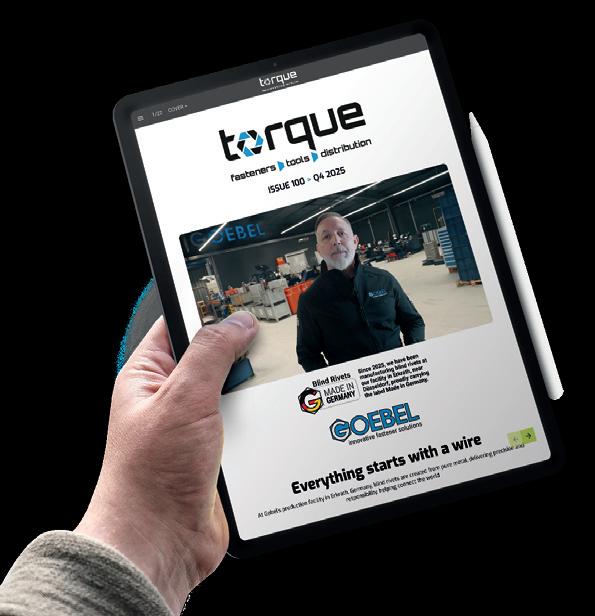

The automated Proxima warehouse –now fully operational – and a revamped digital storefront are among the latest key developments at Ambrovit

As 2025 draws to a close, major international fastening system provider Ambrovit looks back on a year marked by growth and innovation, reviewing two of its more significant milestones…

Ambrovit is based in Garlasco, Italy, and is continuing to invest in cuttingedge technologies and targeted strategies to make its business offering increasingly competitive and sustainable, with an eye toward international markets.

Its most significant milestones in recent years include two key projects: the new digital catalogue and the Proxima automated warehouse, which both represent the synthesis of digitisation, logistical efficiency and environmental responsibility.

A digital catalogue for a smoother and smarter experience

In a world where speed and ease of use are paramount, Ambrovit has completely revamped its digital storefront with a smart and intuitive online catalog designed to guide all professionals in the choice of screws, bolts and fastening systems.

From the home page, a smart search bar allows users to

// Using advanced automation technologies, the warehouse ensures faster, more efficient and sustainable processes, reducing energy consumption and environmental impact //

quickly locate items by typing in a code, description or category. To make the catalogue search even more accessible, a dedicated colourcoded system distinguishes the different product families, simplifying navigation and reinforcing the visual identity of each range.

The new digital catalogue is not merely a technical update, but also a real work tool: a modern, accessible and contentrich platform that enhances the completeness and quality of Ambrovit’s product offering. It is an environment designed to meet the needs of those who seek precision, reliability and speed in industrial supplies every day.

Proxima: sustainable automation in the service of quality

Alongside Ambrovit’s digital transformation, Proxima, the automated warehouse that aims to revolutionise business logistics, is now fully operational. Proxima represents a decisive step in the brand's pursuit of innovation, as an infrastructure designed to optimise management time and further improve quality control.

Using advanced automation technologies, the warehouse ensures faster, more efficient and sustainable processes, reducing energy consumption and environmental impact. This is an investment that reflects Ambrovit’s philosophy: combining the power of mechanics and technology with responsibility toward the planet.

International growth and established relationships

In parallel with its technological evolution, Ambrovit continues its journey of commercial expansion, consolidating relationships with longstanding partners and embarking on new

collaborations in international markets. Its consistent endeavour to listen and be present has enabled the company to strengthen its distribution network and position itself as a global benchmark in its industry. Behind each new partnership is the same philosophy that has guided Ambrovit for 30 years: quality, reliability and a focus on people.

The rebranding journey undertaken in recent years continues to evolve, redefining Ambrovit’s image in a modern and consistent way.

From its revamped visual identity to more direct and dynamic language, through to the improved digital experience, each element tells a story of a solid, contemporary and forwardlooking company.

Ambrovit closes the year with a clear and concrete vision: to innovate in order to simplify, to grow in order to get even closer to its customers and build value every day, with the same passion and precision it has always been known for.

Würth Industrie Service ensures continuous material availability, optimised inventory levels and more responsive supply chains.

Würth Industrie Service is aiming to revolutionise intralogistics with its RFID Kanban systems, combining automation and intelligent technology to ensure efficient, reliable material supply…

Würth Industrie Service’s RFID Kanban systems are aiming to transform intralogistics by ensuring materials are always available, inventories optimised and supply chains responsive. By combining intelligent systems with automated solutions, the company is making efficient, forwardlooking logistics a reality for manufacturing.

RFID, originally Radio Frequency Identification, is a firmly established system for managing production material in the manufacturing industry and is a central component within an efficient value chain. Within industrial Kanban systems, Würth Industrie Service has made use of this technology for lean inventory management, automated mapping of repeat orders and identification of fluctuations in demand at an early stage.

So, the systems in Würth Industrie Service’s CPS®RFID (short for CProductService with Radio Frequency Identification) family deliver an even higher level of supply security than conventional Kanban processes.

The concept is simple yet powerful: each Kanban bin is equipped with an RFID tag containing a unique ID for secure data handling. Readers and transmitters capture this information and communicate directly with the specially developed Kanban Management System (KMS) of Würth Industrie Service,

triggering replenishment without any manual intervention.

Alongside the batteryoperated iPLACER®, which uses RFID technology for both ordering and inventory management, the digital rack label iDISPLAY also enhances efficiency. iDISPLAY provides realtime information on items, quantities, availability, storage locations and upcoming replenishments directly at the point of use, ensuring maximum productivity.

When combined with the newly developed iTERMINAL, which serves as a central digital point of interaction, the Kanban rack becomes fully digitalised. This enables picking and searching processes to be streamlined and optimised for maximum efficiency.

With iSCALE, an almost autonomous warehouse management system for Cparts becomes possible. The sensorcontrolled scale is directly connected to the Kanban bin and automatically detects material requirements based on weight, ensuring timely replenishment of production materials and small parts.

Currently, around 7,000 customers worldwide rely on Würth Industrie Service’s RFID Kanban systems, with more than 15,500 installations currently in operation.

www.wuerth.com

The compact, battery-powered iPLACER® features an integrated reader and transmitter and can be installed almost anywhere.

// RFID Kanban systems from Würth Industrie Service are trusted by around 7,000 customers worldwide, with more than 15,500 systems currently in use //

WASI combines digital Kanban systems, automated processes and a robust eCommerce platform to ensure reliable supply security...

WASI GmbH continues to strengthen its logistics and digital capabilities, ensuring a reliable and efficient supply chain for its global customers. The company’s ongoing investments in automation and AI reflects its commitment to turning Cparts, often considered minor components, into a major competitive advantage.

By combining digital Kanban systems, automated processes and a robust eCommerce platform, WASI transforms Cparts logistics into a strategic asset for its partners. Its automated warehouse, short lead times and tailored Kanban concepts guarantee maximum supply security while keeping capital expenditure low.

A major milestone in WASI’s digitalisation journey has been the implementation of AI tools to optimise internal processes. From demand forecasting and warehouse management to automated quotation generation, AI is now driving higher efficiency and faster response times.

“Because Cparts are not minor details: they are the backbone of production efficiency. Companies that master their Cparts logistics gain time, cost savings, and reliability,” the company says. “WASI delivers exactly that: smart, digital, and sustainable supply solutions.”

In addition, WASI will present its latest innovations at Solar Solutions Düsseldorf over 3–4 December 2025. Visitors can expect to see advanced solar substructures for pitched and flat roofs, designed with both efficiency and durability in mind. The event provides an ideal platform for WASI to showcase its expertise in stainless steel connections and solar technology.

Headquartered in Wuppertal, Germany, WASI offers a portfolio of over 21,000 products from screws and nuts to bespoke parts and solar components. In July 2025, the company appointed Sascha Kloda as CEO, whose expertise in supply chain management is expected to accelerate WASI’s digital transformation and strengthen its strategic purchasing initiatives.

www.wasi.de

// The company’s ongoing investments in automation and AI reflects its commitment to turning C-parts, often considered minor components, into a major competitive advantage //

A wood screw excelling in sustainability!

We believe in sustainability! The Hapax wood screw with 4Top coating is designed with the environment in mind. The coating not only protects the screws but also guarantees a long lifespan, meaning they need to be replaced less often and contribute to a greener, more sustainable approach to construction.

• Free bit in every box.

• The impressions for screw diameters 3.5, 4.0, 4.5, and 5.0 are combined into a Tx20 stick-fit impression.

• The 4Top coating is new and offers very high resistance to atmospheric corrosion and aggressive substances that may be present in the wood.

At pgb-Europe, our daily goal is to provide our customers with quality products and the right service. For almost 70 years, we’ve been an established supplier and manufacturer of fasteners. It’s been in our DNA for three generations.

Dresselhaus’ latest dispensing systems can be used in multiple scenarios, including industrial production, manufacturing and construction…

Dresselhaus has expanded its portfolio of modern dispensing systems with the new DIREKTallround and DIREKTausgabe RFID machines.

The DIREKTallround provides storage across 12 levels, offering up to 432 compartments depending on the configuration, while the DIREKTausgabe features up to 30 fillable compartments that can be divided as needed. Both models share standard dimensions of 183 x 75 x 71 cm and weigh around 200 kg, aligning with the size of other premium dispensing units on the market. They are designed for use across industrial production, manufacturing, construction, logistics and warehousing environments.

Equipped with RFID functionality, the new units can be integrated into the Dresselhaus DIREKT RFID Kanban system. Access is controlled via electronic ID cards, company chips or similar methods, and users can navigate the interface easily through an intuitive onscreen menu. Usage data is recorded in real time, with consumption fully traceable and replenishment orders generated automatically. Customers can also restock the machines themselves.

// Equipped with RFID functionality, the new units can be integrated into the Dresselhaus DIREKT RFID Kanban system //

Aside from these two systems, Dresselhaus has also intro

duced a new hazardous materials cabinet, developed specifi

cally for the safe storage of flammable liquids.

The cabinet meets Type 90 safety standards and carries all relevant certifications, including GScertified Z1A 012906 0520 and TÜV Südcertified Z2 012906 0513, in line with DIN EN 144701 and DIN EN 16121/16122 requirements. These approvals confirm its compliance with the latest industrial safety regulations.

Materials can be issued either by authorised warehouse staff or through a selfservice system, with each transaction recorded via barcode scanning. Depending on customer needs, the cabinet can also be upgraded with RFID technology and access control, such as ID card authentication.

Designed for demanding industrial environments, the new cabinet is ideal for sectors such as automotive and mechanical engineering.

“With the new DIREKT vending machines and the hazardous materials cabinet, we are responding to our customers' desire to have an easytouse dispensing system on site,” says Stephan Pertschy, Chief Sales & Marketing Officer at Dresselhaus. “Demand is high and users appreciate being able to quickly obtain specific goods from our tool & technology and DIN and standard parts ranges themselves.”

www.dresselhaus.de

The DIREKTausgabe features up to 30 fillable compartments that can be subdivided as required, boasting standard dimensions of 183 × 75 × 71 cm and weighs around 200 kg.

More than 130,000 items in stock to ensure highest availability

Flexible kanban supply

Customised packing solutions

High-level e-business solutions

REYHER test laboratory for reliable product quality

The evolving battery technology world sees this key player bring out additions to the M18 charging range, designed to make the life easier of professionals…

MILWAUKEE has launched the new M18™ TOPOFF Mini Charger, a compact charger with the ability to charge M18 batteries and any USBC compatible devices.

Crucially, this latest addition to the M18 charging range is a bidirectional CHARGER; so users can charge and discharge through the 100 W USBC port. When utilising both ports users can charge two personal devices/MILWAUKEE personal lights, or ONE PERSONAL device/Light and the M18 battery simultaneously.

The M18 TOPOFF Mini Charger features two USBC ports; one 100 W bidirectional charging and discharging port and one 15 W charging port. They allow users to either charge two USBC devices simultaneously or charge the M18™ battery whilst charging a personal device. The 100 W bidirectional port enables users to extend the power and run time of the M18 battery whilst charging a personal device. The compact size of the M18 TOPOFF Mini Charger allows it to be stored in small spaces or easily carried around. It minimises the need to carry bulkier chargers around the job site.

Specs – M18™ TOP-OFF Mini Charger

• Battery System: M18

• Charge Rate: 2.5 A/h

• Charging Ports: 1 x M18

- 1 x USB-C 100 W Charging and Discharging Port

- 1 x USB-C 15 W Discharging Port

• Power Source: AC, USB-C

• Weight: 0.371 kg

Charging cluster: the new M18 TOP-OFF Mini Charger can charge multiple devices at once

LED lights on the top of the charger illustrate the state of charge of the connected M18 battery while charging.

MILWAUKEE said it is “committed to improving productivity by providing performancedriven and tradefocused solutions so users can perform an entire day's work on one battery system”.

The M18™ TOPOFF Mini Charger is fully compatible with the entire M18™ line, now offering more than 315 solutions.

Hot on its heels is the 100 W USBC Wall Adaptor (TCUSBC100). The 120 W wall adaptor features two USBC ports: one 100 W primary port and one 20 W secondary port. Users can charge an M18 battery with the M18 TOPOFF Mini Charger (100 W port) and add a personal light or device on the secondary port (20 W).

Recharging the M18 5.0 Ah battery takes place in 75 minutes in combination with the M18 TOPOFF Mini Charger, says the brand. It offers simultaneous charging of two USBC compatible products, such as personal lights, mobile phones, tablets or laptops.

www.milwaukeetool.eu

THE STANDARD DIN 912 | DIN 931 | DIN 933

HEXAGON HEAD DIN 6921 | ISO 4014 | ISO 4017 | DIN 960 | DIN 961

HEXAGON SOCKET HEAD DIN 7991 | ISO 10642 | DIN 6912 | DIN 7984 | ISO 7380 -1 & -2

THREADED SCREWS WITH HEXALOBULAR SOCKET ISO 14579 | ISO 14580 | ISO 14581 | ISO 14583

HEXAGON SOCKET SET SCREWS DIN 913/ISO 4026 | DIN 914/ISO 4027 | DIN 915/ISO 4028 | DIN 916/ISO 4029

THREAD ROLLING SCREWS DIN 7500 Form CE | DIN 7500 Form M

TAPPING AND DRILLING SCREWS DIN 7504 Form K | DIN 7981 | DIN 7982 | ISO 14585 |

HEXAGON NUTS DIN 934 | DIN 985 | DIN 980 | DIN 439 | DIN 6923 | ISO 4032 | ISO 7042

WASHERS DIN 125 | ISO 7089

PARALLEL PINS ISO 8734 | DIN 7979 Form D Achilles Seiber t GmbH | Philipp-Reis-Straße 3 | D-24558 Henstedt-Ulzburg Phone +49 (0) 41 93 89 55 | sales@achill-fasteners.com

|

|

Helping to bridge a national skills gap that is challenging manufacturers, Atlas Copco Tools and Industrial Assembly Solutions is actively supporting a brandnew training initiative for advanced battery manufacturing, which is the UK’s first fully accredited and industrybacked programme.

Launched by University College Birmingham, in partnership with City & Guilds and Innovate UK, the Battery Manufacturing Skills Pathway (BMSP) is the first of its kind to be developed with direct involvement of industry, to tackle a critical skills deficit in UK battery manufacturing.

Setting a national benchmark for electrification skills and creating a talent pipeline that will sustain the nation’s battery supply chain, for SMEs and gigafactories alike, the programme aims to deliver a structured, workforceready pathway, that aligns with employer needs and the UK’s Net Zero ambitions.

Through advanced immersive learning using AR/VR, as well as realworld simulations and cuttingedge technology, supplied and codesigned by industry partners including Atlas Copco, the BMSP provides a dynamic, comprehensive skills ecosystem, which has been developed to adapt and scale, in response to the evolving electrification transition.

From day one, BMSP students interact with live production equipment used in gigafactories and the broader supply chain, building their capabilities, confidence and workforce readiness. This ‘learning factory’ model echoes the government's

Industrial Strategy call for employerdriven technical provision that directly supports industrial scaleup.

The new programme is also closely aligned with the Electrification Skills Network (ESN), a UKwide coalition of employers, training providers and sector leaders, working together to deliver the skills required for battery production, power electronics, motors and drives (PEMD).

www.atlascopco.com

Austrian fastener and tool company BECK has joined the Cordless Alliance System (CAS). Three devices are part of the first tranche: the BECK Cordless Brad Nailer 55 mm, the BECK Cordless Narrow Crown Stapler 40 mm and the BECK Cordless Framing Nailer 33°, 90 mm.

The company said that joining the CAS is a “strategic step that meets the requirements of modern craft and industrial businesses”, and the CAS system is “open, compatible and available internationally”.

Christian Beck, CEO of BECK, says: “The CAS battery, which powers BECK nailers and staplers, also fits into cordless screwdrivers from Metabo, saws from Mafell, extraction solutions from Starmix and lighting from Scangrip, for example. The CAS system therefore reduces tool inventory costs while setting the highest quality standards. We see this as a clear competitive advantage.”

BECK is a fourthgeneration family business that has been developing and producing fastening solutions for professional applications since 1904. The product portfolio includes collated nails, staples, pins and the innovative SCRAIL® nail screw fasteners, as well as the matching BECK pneumatic tools. With the LIGNOLOC® system, the familyowned company BECK also offers the world’s first shootable wood nail, enabling metalfree and sustainable construction.

"Our alliance benefits from strong international partners

such as the familyowned company BECK, allowing us to offer users worldwide an everincreasing variety of products,” said Thomas Zeller, Head of the CAS Partner Programme at Metabo.

“In the particularly strong woodworking and metalworking trades, our CAS partners cover the majority of applications on the construction site with a wide range of professional cordless power tools. This simplifies tool management and avoids the costs of purchasing different systems.”

www.beck-fastening.com

Intrigued about the marketplace sales channel? These portals suit specific areas of the market and there’s potential there, however it’s not necessarily as easy as it looks, writes the Daley Hub for Torque Magazine…

Alongside DIY and building products in general, tools and fixings came relatively late to the ‘marketplace’ party and the channel consequently remains hot news for our sector. While there is no doubt of the opportunity, today’s marketplace proliferation means that they are no longer all the same, and it is therefore worth taking time to understand which ones are most suitable for a product range or strategic plan.

And equally crucial, what it takes to make each different marketplace work effectively – which can require a not to be underestimated investment of time. At Daley Hub, we have built up considerable experience in the field and with Nils Kernchen, the former platform developer for the original DIY and garden marketplace, ManoMano joining the team, we are a perfect source of advice and partnership. Nils is also a freelance associate of specialist marketplace agency, ChannelMojo.

As a platform, marketplaces are now easier to build than ever before and the marketplace format – now around 62%is predicted to be as much as 80% of all ecommerce sales in the nottoodistant future. They have also gained traction and trust amongst both buyers and sellers, with more and more traditional brands on board, alongside the startups and the

incomers who were often the earlier adopters.

Popular with shoppers for convenience and price comparison, online marketplaces appeal to suppliers as a flexible business opportunity with relatively low startup costs enabling the sale of goods without the need for an online store. The four largest global marketplace leaders of today are Amazon, Alibaba, Pinduoduo and JD.com. In the UK, the largest are again Amazon as well as eBay UK, ASOS, Argos, John Lewis, Currys PC World, Zalando, Notonthehighstreet, Boohoo, and Very. DIY.com is also surprising the sector with the pace of its growth and participation. But there are many other international names worth considering and a continuous stream of new or imminent entrants including Bauhaus, Hornbach, Zalando, Leroy Merlin, Conrad and more.

Advantages – including the cross-border opportunity

For sellers the attractions are an additional route to market with apparently lower marketing costs than other sales channels. The online marketplace’s own brand may well provide a level of additional trust in the seller’s brand and the impartial reviews can be a real win in marketing terms. From an operational perspective the supplier can enjoy round the clock trad

ing with availability, prices, and stock levels transparent and accessible in an open environment. Plus, it can be a great way to overcome export barriers – and this alone may make marketplace trading worthwhile. So far, so very good.

But there are also disadvantages. Marketplaces can charge commission on every sale and fees can vary. There may be restrictive terms, conditions about how to communicate with customers, and limitations as to how a seller’s online presence can be branded.

Don’t underestimate the work involved

Marketplaces today are all different – in their suitability and requirements for success. It is no longer just about appropriate titles, descriptions, images for the category. Each marketplace is different anyway, and then again by territory. Set ups and onboarding procedures all vary accordingly. Some marketplaces are in effect ‘closed’ to newcomers. For those that are ‘open’, there are different brand systems, marketplace inhouse systems, key words, advertising and invoicing procedures, licenses. And that’s just the online part. There are also different product requirements – size, weight. Too small in which case represent product bundles as ‘kits’; perceived as ‘dangerous’ such as batteries and bladed items. It's not only getting everything right at the start. Sellers will need to undertake continuous monitoring of their own and competitor activity. Surveying every aspect is fulltime daily work.

Nils Kernchen (left) is the former platform developer for the original DIY and garden marketplace ManoMano, and now part of the Daley Hub team, which was co-founded by Clive Daley (right)

Get some expertise

At Daley Hub, we are fans of the marketplace phenomenon, but real success is not as easy as it may at first seem. To make a go of what is certainly a great opportunity, then tools and fixings suppliers need to budget for quality research, knowledgeable recommendations, and ongoing commitment – well above and beyond winning initial listings. Daley Hub can help.

www.daleyhub.com/contact-us

BESSEY will launch its own enhanced version of the one-hand assembly tool BEYCEPS through the license agreement with VIKING ARM…

VIKING ARM has signed a licence agreement with BESSEY Tool GmbH. The agreement allows BESSEY to launch its own enhanced version of the onehand assembly tool, BEYCEPS, for which a patent application has already been filed. Both companies, known for their innovation in the hand tool industry, say they are delighted with the new collaboration. The goal is to introduce even more professional users and DIY enthusiasts to the benefits of a onehand assembly tool. Launched in 2019, the VIKING ARM tool is now sold in 36 countries. “With an ingenious idea, VIKING ARM has set a real milestone in the field of hand

Carsten Spang, CEO, BESSEY

tools,” says Carsten Spang, CEO of BESSEY. “It is a tool that is not only powerful, but also carries the BESSEY DNA – innovative, precise and unique. We are proud of this strong partnership with VIKING ARM and are very much looking forward to what we will achieve together in the future.”

Ulf Atle Hansen, CEO of VIKING ARM, added: “Our vision is ‘Viking Arm shall be recognised for its innovation, quality and speed to the market’. This agreement is a testament to that vision coming to life.”

www.vikingarm.com

// IT IS A TOOL THAT IS NOT ONLY POWERFUL, BUT ALSO CARRIES THE BESSEY DNA –INNOVATIVE, PRECISE AND UNIQUE //

BESSEY launches its own enhanced version of the one hand assembly tool BEYCEPS (right) after signing a license agreement with VIKING ARM.

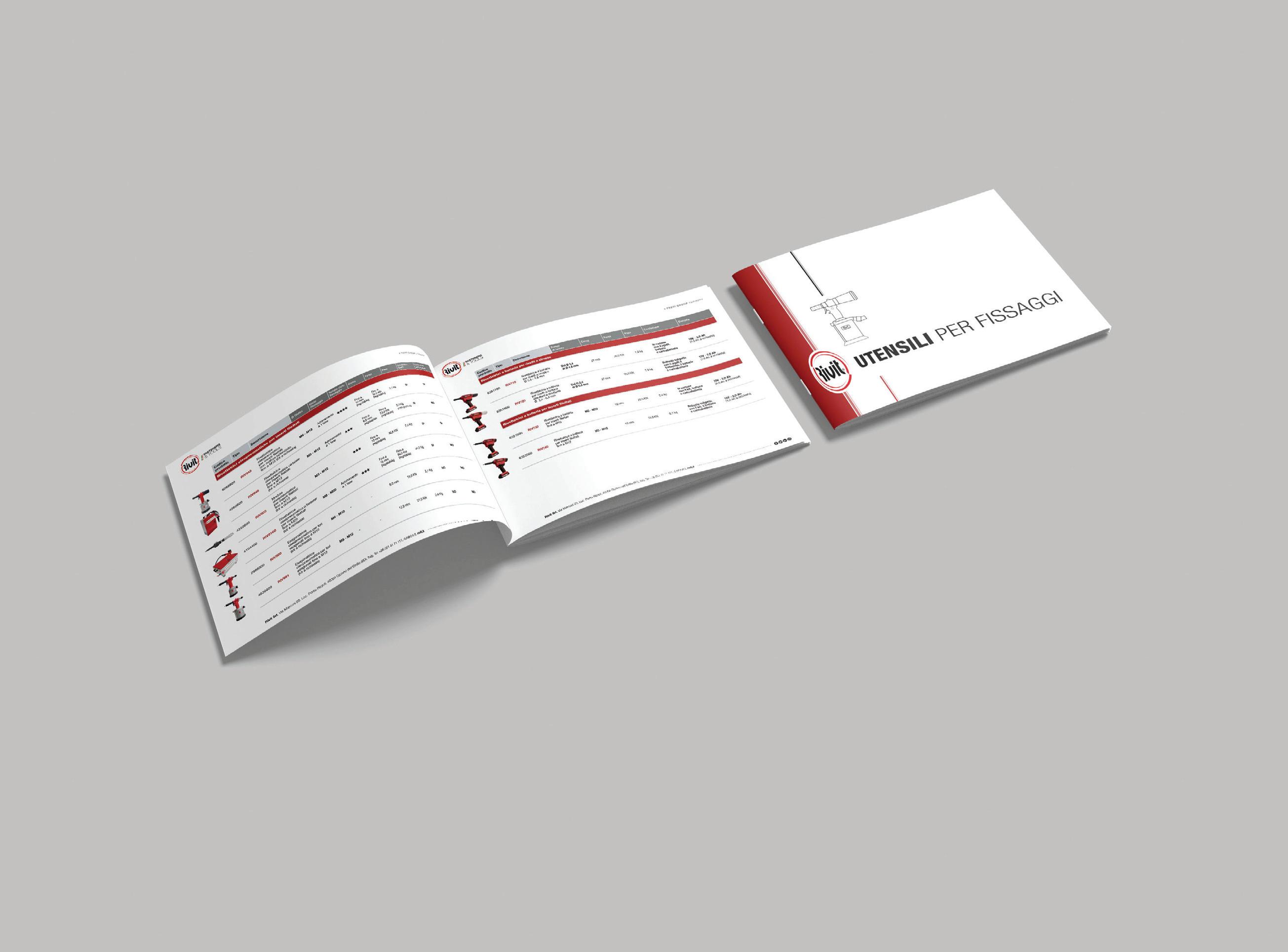

All products featured in the brochure are in stock for immediate delivery and available at promotional prices until the end of 2025…

Rivit has launched a new brochure featuring more than 30 models of riveting tools.

The range includes hydropneumatic and batterypowered riveting tools, automatic systems, automatic feeding systems for blind rivets and rivet nuts and process control solutions. All products are available for immediate delivery and are on promotion until the end of 2025.

The guide compares tools for blind rivets and threaded rivet nuts using clear and intuitive diagrams, offering a complete overview that helps users identify

the most suitable solution for their operational needs in just a few steps.

Available in both print and digital formats, the brochure is designed to simplify machine selection. Many models are ready for immediate use, held in stock and available at a promotional price.

With this new publication, Rivit aims to provide effective, uptodate resources to improve the purchasing experience and support customers, drawing on more than 50 years of expertise in the sector.

www.rivit.it

As a full-service provider, we offer customised shot blasting solutions – from application technology and machine design to after-sales service.

A breakthrough from Heamar delivers greater assurance and consistency through intelligent tooling, for ever smarter fastening…

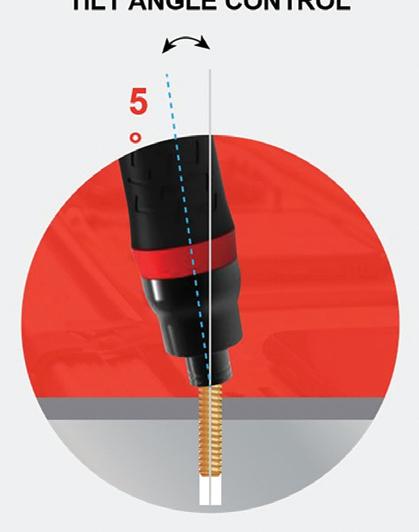

In the current manufacturing landscape, accuracy and validation during the fastening process are more important than ever. Whether assembling vehicles, building infrastructure or producing complex machinery, a single incorrectly fastened joint can affect performance, reliability and safety. Even small deviations in tool angle or torque can cause crossthreading, inconsistent clamping or damaged components, all of which lead to costly rework or failure in the field.

Heamar has long supplied advanced tooling solutions designed to help engineers and manufacturers tackle these challenges headon. One of the most innovative examples is the Ingersoll Rand IQi Series Tranducerised Screwdrivers, a smart fastening controller that redefines what’s possible in precision assembly.

Traditional fastening systems focus primarily on torque and angle control. While these remain essential, they don’t always capture the full picture. A joint can appear correctly tightened according to torque readings but still be misaligned if the tool was not held at the correct angle. This misalignment can compromise the joint’s strength, lead to uneven load distribution and reduce product quality.

The IQi series addresses this issue through a breakthrough feature, tilt angle accuracy. This worldfirst capability allows the controller to continuously monitor and validate the tool’s orientation during fastening. By ensuring that bolts are tightened at the proper angle relative to the joint surface, the IQi provides a level of assurance and consistency previously unattainable with standard torqueangle systems, explains Heamar.

Although originally developed with highreliability sectors in mind, the benefits of intelligent fastening extend across a wide range of industries, from aerospace and defence, to renewables and automotive. In any application where a fastener must perform under stress, ensuring accuracy at every stage of tightening is essential.

Torque alone can be misleading. Operators may achieve a target torque value but still create an incomplete or overtightened joint if the angle is incorrect. The IQi series eliminates this uncertainty by integrating torque, angle and tilt data into a single intelligent control system. The result is a threedimen

sional understanding of joint quality, a major advantage wherever product integrity and traceability are priorities.

Heamar partners with leading manufacturers such as Ingersoll Rand to deliver tools that not only meet engineering specifications but elevate production standards. With the IQi series, users benefit from:

• Tilt angle validation – Guarantees correct tool positioning and consistent joint quality.

• Advanced traceability – Automatically records every fastening action for full auditability and quality assurance.

• Intelligent control – Offers realtime feedback and adaptive adjustments to prevent errors before they happen.

Heamar says no other controller combines this level of precision, insight and reliability, making it ideal for organisations aiming to reduce rework, improve efficiency and strengthen their quality control processes.

At Heamar, the focus is on empowering engineers and manufacturers to achieve smarter, safer and more consistent assemblies. By providing nextgeneration fastening technology like the IQi series, Heamar ensures that production teams have the right tools for the job, tools that improve accuracy, enhance traceability, and ultimately deliver better products to market.

To learn more or book a demonstration, contact one of Heamar’s tooling consultants today.

sales@heamar.co.uk

Now holding applicator licences for DÖRKEN MKS, MAGNI and GEOMET, CETIN CIVATA is focused on continuing to expand and evolve its coating abilities and capabilities…

As regular readers will know, CETIN CIVATA recently obtained the GEOMET surface coating licence from NOF METAL COATINGS EUROPE and is now a certified member of the GEOMET global licensee network of NOF METAL COATINGS for Geomet coatings in part maker applicator class for BULK / DIP SPIN application process.

That GEOMET licence, obtained earlier this year, joins other key licences held by CETIN CIVATA, including applicator licence of German DÖRKEN MKS brand (2019) and the applicator license of the MAGNI brand (2016).

Not only is CETIN CIVATA now supplying Geomet coated products, finished inhouse in its coating plant in Istanbul, but its coating offering is continuing to develop as 2025 draws to a close.

CETIN CIVATA has newly implemented GEOMET PLUS VL/VLh coating, which provides superior results, especially for fasteners requiring high performance, thanks to its high corrosion resistance, environmentally friendly composition (Cr(VI)free), improved heat resistance and full compliance with automotive industry standards. It also provides standardised coefficient of friction (914) values and the

possibility of production in compliance with OEMapproved processes.

The firm says: “Within the scope of our continuous improvement and customer satisfactionfocused efforts, we hope this new coating system will contribute to our valued business partners.”

CETIN CIVATA will also start implementing Zinc Nickel Silver + Zink Flake organic topcoat to coat the surface of bolts and screws for delivery to its clients in the wind turbine industry to secure very high corrosion protection over 1500 hours Salt Spray Test hours.

The automotive market, in Europe and the US, is one of the key sectors where the wideranging coating capabilities of CETIN CIVATA are beneficial. For years, the three coating brands’ Zinc Flake applications have been recognised and officially allowed by nearly all global automotive producers in their official technical specifications.

“The importance of offering and supplying coated/plated fasteners to those market segments is getting more critical for us. OEM and parts maker customers prefer to have finished parts supplied directly to their production lines, either direct from us or via our FSP business partners.”

Besides the automotive industry, CETIN CIVATA sees rising demand – especially in Zinc Flake coated parts – in renewable energy, agricultural equipment and even for countryside construction fields in some markets. The share of coated parts’ sales in CETIN CIVATA’s total turnover has climbed from 80% to 95% in three years. The Group’s coating capacity can easily fulfil this demand.

The firm explains: “It is obvious that all automotive related markets will continue to increase their demand for Zinc Flake Coated Fasteners rather than other high corrosion protection coating types such as Zinc Nickel or Alkali Zinc platings.

“We expect in some fields of construction and agriculture and machinery industries also to shift their demands to Zinc Flake coated fasteners in the midterm. Generally speaking, in our export markets (80% Europe and 20% USA), we can say that the last two year average coating types’ segmentation was 30% Zinc Flake, 30% Acidic Zinc and Alkali Zinc, 16% Zinc Nickel, 14% Hot Dip Galvanised, 10% noncoated blank products; however recently the share of Zinc Flake Coatings is rapidly growing to 3840% within our coating share level breakdown from the previous 30% level. That’s due to our growing furnace and dip spin capacities for Zinc Flake coatings and also our newly obtained GEOMET licence – and because of our fast growing new markets and new market segments such as USA construction consumer segment and automotive manufacturing plants in Turkey.”

The majority of the coated parts CETIN CIVATA supplies to automotive, machine, agriculture and other main industries are used in critical and vital equipment in its customers’ products, playing a big role in the safety and functionality of the relevant products of industry clients. Find out more at the official site.

www.cetin.com.tr

Anew highperformance, anticorrosion coating is being tested on motorway barriers.

Fasteners used on motorway barriers are traditionally galvanised to protect against moisture, road salts and fluctuating temperatures.

The galvanisation process involves submerging a part in molten zinc at a high temperature to form a protective layer.

Keen to find a more sustainable way to protect the millions of nuts and bolts used on barriers, surface coatings provider Anotec partnered with fastener manufacturers to test a new onecoat, C5compliant system.

The advanced zinc flake finish is applied via spray application, ensuring uniform coverage while maintaining a thin coating thickness of ≤ 20 microns. This process is more environmentally friendly than the galvanising alternative – and also completely eliminates the risk of hydrogen embrittlement.

Mark Smith, Assistant General Manager at Anotec, says: “Galvanising offers excellent corrosion protection but we believe we have a solution that is equally as effective and more sustainable, while being completely C4 and C5 compliant. Both the

process to apply the finish and the product itself is more environmentallyfriendly, making it a better option all round.”

Thousands of fasteners have been trialled on motorway barriers so far.

The spray application of the zinc flake technology eliminates the risk of thread blocking on large screws and bolts, a common issue with thicker, multilayered coatings. Switching from traditional galvanising to zinc flake coatings also completely eliminates the risk of hydrogen embrittlement.

Hydrogen atoms can be introduced into the metal substrate during galvanising, which can cause hydrogen embrittlement. This can lead to the material becoming brittle and susceptible to sudden, catastrophic failure under stress.

No hydrogen is generated or absorbed when using zinc flake coatings, increasing the structural integrity of the parts, making them safer and more reliable.

Anotec’s onebase, onetopcoat zinc flake system, results in lower costs and improved efficiency and is also effective in the wind energy, oil and gas, marine and rail sectors.

www.anochrome.com

The new Rivit catalogue has arrived number 11 !

More than 4500 products, including blind rivets, rivet nuts, lockbolts, tools for fasteners and many other service references, to fulfil even better all requirements.

Increasingly effective and efficient sales support tool, essential for choosing and browsing our comprehensive product range.

A significant purchase will boost staff count by 250 and push combined revenue north of €230 million…

Mödling, Austriaheadquartered AICHELIN Group, has finalised the acquisition of the NTS & UPC business units from NITREX Inc., a portfolio company of Novacap, a leading North American private equity investor. The HTS division of NITREX is not part of the transaction.

AICHELIN is one of the world’s leading providers of heat treatment solution and – through the acquisition – is expanding with around 250 new employees in the USA, Poland, Germany, France, and China.

In total the AICHELIN Group will expand to more than 1,350 employees in total, generating combined revenues of approximately €230 million. This represents the largest acquisition in the company’s history and marks another milestone in the implementation of its Strategy 2030.

The purchase expands AICHELIN Group’s technology portfolio with leading expertise in nitriding furnaces and strengthens its presence in key industrial regions. The integration of the NITREX sites will take place step by step, in close coordination with the respective local leadership teams.

// In total the AICHELIN Group will expand to more than 1,350 employees in total, generating combined revenues of approximately €230 million //

Christian Grosspointner, CEO of the AICHELIN Group

“This acquisition is an important step in the execution of our strategy,” said Christian Grosspointner, CEO of the AICHELIN Group. “We want to grow meaningfully, with a strong foundation, local proximity, and technological excellence. Together with NITREX, we are combining knowhow and regional strengths for the benefit of our customers, employees, and all stakeholders.”

With its Strategy 2030, the AICHELIN Group has laid out a roadmap for sustainable growth and technological advancement. The focus is on diversification into new industries and applications, driven both by inhouse development initiatives and targeted acquisitions. Under the motto “think global, act local”, the emphasis lies on tailoring products, services, and structures to regional market requirements in order to strengthen customer proximity and responsiveness.

With the integration of NITREX, the Group is consistently executing this strategy: the portfolio is being expanded with leading nitriding technologies, while at the same time strengthening its presence in the Americas, Europe and Asia with additional sites.

www.aichelin.com

There are as many screws as grains of sand on a beach. But not every screw can handle the sea and sand.

The specifications in the application areas of stainless steel are growing more and more –the used products have to withstand all extremes, the selected material and quality must be just right. It’s a huge responsibility for human and material.

We take this responsibility seriously. It is not without reason that TOBSTEEL is listed in the general building inspectorate approval Z.30.3-6 as a specialist for stainless steel fasteners. With a comprehensive range in grades A2, A4, A5, D6, A8 – and now, newly added, D8 – ready for immediate delivery, we provide the right solution for every stainless steel application.

TOBSTEEL GmbH Rudolf-Diesel-Straße 8 | D-74613 Öhringen T: +49 7941 6073-0 | F: +49 7941 6073-500 | info@tobsteel.com | www.tobsteel.com

We are the specialist in high-quality fasteners made from stainless highgrade steel and special materials and stock the right material for all five corrosion resistance classes (CRC)!

TOGE offers protection for screws against the elements

Screw coatings are crucial for the durability and reliability of fasteners – especially in demanding environments. TOGE has developed coating solutions that last –even when things get tough…

TOGE concrete screws are not only strong in their anchoring, but also optimally protected against corrosion –thanks to modern zinc flake coatings. TOGE offers a graduated portfolio of highquality coatings that provide optimum protection against corrosion and are suitable for a wide range of applications. With the TOGE ZFC, TOGE ZFC Solid and TOGE KORR variants, the company offer coordinated solutions for different environmental conditions.

The offering from TOGE can be separated into four materials and main coatings with the following properties and advantages:

Steel, galvanized – the standard for dry indoor areas (C1).

TOGE ZFC – the basic coating for applications in corrosive indoor areas (C3-medium).

TOGE ZFC Solid – ideal for increased requirements in humid or industrial atmospheres (C4-high).

TOGE KORR – high-end protection with an impressive protection period of up to 50 years – for projects where long-term reliability is required.

The classification into corrosivity categories is based on extensive tests. This gives you a reliable assessment of the duration of protection under real operating conditions. The coatings are in accordance with DIN EN ISO 12944.

TYPICAL AREAS OF APPLICATION:

Corrosion class C1:

Heated buildings with a neutral atmosphere.

Corrosion class C3:

Urban and industrial atmosphere with moderate sulphur dioxide pollution.

Corrosion class C4:

Industrial atmosphere and coastal atmosphere with moderate salt exposure.

Corrosion class C5:

Industrial areas with high humidity and aggressive atmosphere. Coastal atmosphere with high salt contamination.

TOGE coatings provide reliable corrosion protection for a wide range of applications that are quality tested to international standards and the company’s own reports, as well as having a long protection period for sustainable connections.

toge.de

// TOGE offers a graduated portfolio of high-quality coatings that provide optimum protection against corrosion and are suitable for a wide range of applications //

In the summer of 2025, SUNCO INDUSTRIES CO., LTD held a roundtable discussion with four of its suppliers, centered around the theme: “Discussing the Present and Future of Overseas Business.”Participants shared their insights on the current state and outlook of global expansion in the fastener industry…

COULD EACH OF YOU BRIEFLY INTRODUCE YOUR COMPANY?

Mr. Ando: ANSCO CO.,LTD. specialises in manufacturing slim socket screws. We have facilities in Aichi, Saga, Japan, and Thailand. Most of our clients are in the machine tool and automotive industries. Compared to last year, demand from machine tool manufacturers has been relatively strong and the automotive sector remains steady.

Mr. Taniguchi: NAKAUMI INDUSTRIES CO.,LTD. is a manufacturer specialising in fully threaded rods. We produce products from 3mm to 64mm, mainly in steel and stainless steel. We have four factories in Japan and one in Vietnam. Recently, the construction market has been a bit sluggish, but our business in Europe has been relatively strong and our Vietnam facility has been quite busy.

Mr. Hashimoto: UNYTITE CORPORATION was founded in 1946 and manufactures highstrength bolts, grade 10.9 bolts, nuts and other related products for a variety of industries. Our headquarters is in Kobe, and we have overseas offices in the US and China. While the construction and civil engineering sectors are slowing down, the shipbuilding market is still performing fairly well. Due to the high proportion of automotive clients in China, business there is weaker than in Japan, but our US operations remain solid.

Mr. Murakami: NIPPON FASTENER CORPORATION manufactures CHQ steel wires, hightension bolts, hex socket bolts and more. We operate factories in Tsurumi (Osaka) and Shiga. Unlike the others here today, we haven't yet expanded overseas. Our current customer base is mainly domestic, but we’re beginning to look toward international markets for future growth.

AS YOU’VE ENGAGED IN GLOBAL BUSINESS, WHAT STRENGTHS HAVE YOU IDENTIFIED IN YOUR COMPANY OR IN JAPANESE FIRMS MORE BROADLY?

Mr. Ando: I’d say Japan’s technical expertise. One moment that stood out to me was when we showed our overseas partners screws in the 1mm range – they were genuinely amazed. Something that feels routine to us can have a huge impact

abroad. I also think our reputation for reliability is a strength. We provide aftersales service, which contributes to the trust our clients place in us.

Mr. Taniguchi: When we try to sell our products overseas, the first thing we often hear is, “Japanese products must be expensive, right?” It’s clear that Japanese goods are perceived that way. On the other hand, when dealing with things like export/import documentation – especially in Europe – we’re sometimes trusted more because we’re a Japanese company.

Mr. Hashimoto: I agree with the previous points. The high quality of Japanese products is a major strength. Also, Japanese companies are generally seen as reliable partners. In international business, issues like payment and trust are crucial, and I feel Japanese firms are highly rated in those areas. However, one drawback is the slow decisionmaking process within many Japanese companies.

Mr. Murakami: I’ve noticed differences in manufacturing approaches. Overseas, the attitude tends to be that it’s fine to sort out defects during final inspections, even if the production process isn’t perfect. In contrast, Japanese manufacturers aim to prevent defects right from the production stage. That results in a higher level of quality overall. While marketability is another issue entirely, Japan excels in its accumulated knowhow and skilled human capital.

Mr. Takada: I believe one of our strengths at SUNCO is the breadth of our product lineup. Thanks to the support of our suppliers, we can ship quickly after receiving an order, which is a big advantage for overseas customers and one reason they choose us. We also get positive feedback on our fast response times and we now receive inquiries from overseas almost every day.

Mr. Taniguchi: Speaking from the perspective of fully threaded rods, price is still a key factor. It's difficult to massproduce inexpensively in Japan, so our overseas facility focuses on highvolume production. The more we produce, the more costeffective it becomes, which helps us stay competitive globally.

ANSCO CO.,LTD.

President: Mr Hidefumi Ando

UNYTITE CORPORATION

President: Mr Atsushi Hashimoto

NAKAUMI INDUSTRIES CO.,LTD.

President: Mr Yoshifumi Taniguchi

NIPPON FASTENER CORPORATION

Fastening Division Deputy

General Manager: Mr Tateo Murakami

Mr. Hashimoto: Japanese raw materials are indeed expensive by global standards. But with the yen so weak right now, I question whether price is the only issue. There are also challenges related to standards – many companies can handle JIS specifications, but not ISO. That limits us. In the U.S., tackling niche markets could yield big opportunities – even enough to start a new company. We once had a product imitated right after letting a U.S. patent expire. So besides strong development capabilities, we need to bolster our sales strategies too. I still see a lot of potential in Japanese fasteners.

Mr. Murakami: Expanding sales channels is a major challenge for manufacturers like us, so we rely heavily on trading companies like SUNCO

Ms. Hiraoka: We don’t have overseas branches, so it’s tough to actively visit and sell globally like we do within Japan. That’s why we put our energy into promotional activities – raising awareness that there are so many unique fastener companies in Japan and that Japanese products can be competitive. We hope our magazine, SOCKET BOY, helps us reach a wider audience. Our efforts in promotion rely heavily on the technological capabilities of our suppliers.

Mr. Murakami: In other words, you're arming the trading company with the right “weapons.”

Ms. Hiraoka: Exactly. While we specialize in JISstandard products, we don’t yet offer enough variety in other international standards. Sometimes we can’t respond well to customer requests, but we always aim to be better prepared next time. That said, it’s hard to decide how far to expand our range.

Mr. Taniguchi: So even for different standards like DIN, you try to be ready to respond next time?

Mr. Takada: Yes, as much as possible. We can’t handle everything, of course, but when a customer takes the time to inquire, we want to meet their expectations. Even if we can't carry all sizes, we’d like to stock at least some, so they’ll come back to us. Talking with everyone today has made me realize just how important “awareness” is. There are so many amazing Japanese manufacturers, but overseas buyers don’t know them. Many assume Japan is too far and too expensive. But once they do know us, they often take an interest – so spreading awareness is vital.

Mr. Ando: I agree. First, we need to get users to know who we are. Then we need to build systems that let them get our products quickly when they need them. I think Sunco’s Socket Boy magazine is a very effective strategy in that regard. Going forward, strong collaboration between manufacturers and trading companies will be key. By leveraging each other’s strengths, we can boost Japan’s competitiveness globally and sell more fasteners.

SUNCO INDUSTRIES CO., LTD.

General Manager, Purchasing Department: Ms Miki Hiraoka

SUNCO INDUSTRIES CO., LTD.

Purchasing Department, International Trade Section, Section Chief: Mr Tomokazu Takada

Mr. Hashimoto: Many Japanese firms assume they can’t compete on price, but maybe they’re just not promoting themselves enough. Despite the large number of fastener manufacturers in Japan, many midcareer and younger overseas professionals don’t know they exist. There’s also a common misconception that Japan only makes automotive fasteners, when in fact, we produce a wide variety of industrial products too. I think it’s partly due to lack of overseas experience and knowhow in selfpromotion. That’s why, as Mr. Ando mentioned, collaboration between manufacturers and trading firms to build an overseas strategy is so promising.

Mr. Taniguchi: That’s true. Not many people associate Japan with fasteners. I once visited a company in Italy that I thought was just a trading firm, but they were also manufacturing. It’s the same as how we don't usually associate Italy with fasteners – they’re known for fashion. It goes both ways.

Mr. Murakami: Even something as simple as our website is an issue – we only have it in Japanese. If your messaging is only in Japanese, it’s naturally hard to reach an international audience. We definitely need to adapt to more global languages.

AS YOU EXPAND INTERNATIONALLY, COULD YOU SHARE THE CHALLENGES YOU’VE ENCOUNTERED WHEN DOING BUSINESS WITH OVERSEAS COMPANIES AND THE ISSUES YOU FORESEE GOING FORWARD?

Mr. Ando: I feel that “people” are a key challenge. Overseas, cultural and customary differences can make communication difficult, which in turn can hinder smooth business operations. Another issue is securing domestic talent who are eager to engage in international business.

Mr. Taniguchi: In Vietnam, navigating local laws and tax regulations is extremely challenging. Recently, anticorruption efforts there have slowed administrative decisionmaking. That means we often have to make judgments ourselves regarding legal and tax issues. While these challenges are numerous, we see them not as problems but as opportunities for growth – and we’re committed to tackling them proactively.

Mr. Hashimoto: For our overseas operations, a significant issue is placing local leaders at the top – having management run by local nationals to drive business in their own country. That means investing in training and developing our people on the ground is critical.

Mr. Murakami: Launching exports marks our next challenge, but it’s essential to monitor political risks. In the past, we operated a nail manufacturing subsidiary in South Korea that exported mainly to the U.S. – our only foray abroad. But when

By Ikumi Shinomiya SOCKET BOY magazine Editor in Chief

SUNCO INDUSTRIES CO.,LTD export@sunco.co.jp www.socketboy.com

South Korea’s political system changed, local law required local nationals to own the company, forcing us to withdraw. That experience showed us the importance of staying watchful about political developments.

Mr. Takada: Our greatest challenge was engaging team members, who had only domestic experience, to think internationally. Our company has more than 70 years of history in Japan, but our export business is only in its fourth year, which initially caused confusion among staff. To help, we built systems minimizing the gap between domestic sales and exports and worked hard to raise internal awareness of the export business. As a result, exporting is becoming embedded in our culture, and staff attitudes are shifting positively. We’re now even targeting exports to contribute to 1 % of total revenue. A future challenge is handling security and compliance – managing risks carefully even as we expand export operations.

Mr. Hashimoto: Even in my own company, it's not easy to instill an international mindset across domestic teams. From experience, I know some departments feel – because they have little overseas contact – that “this doesn’t concern me.” That makes me appreciate Mr. Takada’s accomplishments even more. To increase global visibility among employees, we’ve adopted fully overseas manufactured forging machines. That way, employees naturally interact with overseas vendors in English, raising their awareness of international operations.

FINALLY, COULD YOU SHARE YOUR THOUGHTS ON “JAPAN AS SEEN BY THE WORLD, THE WORLD AS SEEN FROM JAPAN, AND THE CHALLENGES THE FASTENER INDUSTRY WILL FACE GOING FORWARD”?

Mr. Hashimoto: I hate to sound pessimistic, but Japan’s geographic isolation seems to have driven a tendency to complete business domestically – even in the fastener sector. As Japan’s population continues to age and shrink, the market will likely contract, driving consolidation through M&A – and potentially opening the door for foreign companies to enter Japan seriously. I think that isn’t an unlikely scenario.

Mr. Ando: The challenges facing Japan’s fastener industry mirror those confronting SMEs in Japanese manufacturing –aging, labor shortages, and so on. That means recruiting and securing strong distribution channels are key. As the market shrinks, recruitment will become even harder. That makes it vital to communicate a shared vision and operate with colleagues united around common goals.

Mr. Takada: Reflecting on ideas like Peter Clarke’s Law, changes in industry structure, an aging population, a shrinking domestic market, and potential overseas players entering Japan could reshape the fastener industry's makeup. Looking

ahead, adapting means strengthening marketing, expanding into new markets, and emphasizing Japan’s remarkably high craftsmanship on the global stage. Viewed positively, this is the moment for us to unite and showcase our manufacturing excellence to the world.

Ms. Hiraoka: To adapt to industrial shifts, it's crucial to offer customers strong added value. One example is our ability to ship screws individually or in mixed configurations – ”BARA.” By adding value to products supplied by domestic manufacturers, we can give Japanese fasteners a compelling competitive edge – and I believe that will become increasingly important.

Mr. Takada: We’re seeing more and more inquiries from abroad that fall outside what we can handle alone – things like specific standards or tight delivery timelines. We’d greatly appreciate your support in those areas. At the same time, we plan to continue ramping up our promotion to overseas markets to generate more inquiries – creating mutual benefits for us and our suppliers. Also, just as overseas manufacturers build facilities using Japanese screws, there are projects in Japan using nonJapanese fasteners. We’d like to win more orders in those areas. In fact, some foreign firms have already asked us to help with product substitutions. We’d like to share such information with our suppliers so we can boost both our sales together.

This is an edited version of the Roundtable. Find the full version on www.torque-expo.com (search for Sunco Roundtable).

This article was provided by Socket Boy magazine, with editorial support from KINSAN FASTENER NEWS

SOCKET BOY magazine is a free publication issued by SUNCO. Since its launch in 2024, it has consistently delivered a wide range of content, including the latest news about the fastener industry, interviews with suppliers, and the culture and history of HigashiOsaka City, Japan's manufacturing hub.

Furthermore, SUNCO plans to launch the SOCKET BOY magazine website in autumn 2025. In addition to the magazine PDF, exclusive articles only available online will be posted. This content will be shared globally, targeting industry professionals, manufacturing enthusiasts and anyone with a curious spirit.

Apex Stainless Fasteners’ products meet the rigorous material demands of the electric and hybrid vehicle sectors, offering long service life and exceptional durability that help reduce waste…

Established in 1991, Apex Stainless Fasteners is one of the major suppliers of stainless steel fasteners in Europe. As EV adoption gains traction, the company aims to tap into the opportunities driven by the automotive sector’s growing focus on sustainability.

Across the automotive industry, stainless steel fasteners have long been used in legacy applications due to their inherent ability to perform effectively in environments requiring excellent heat resistance, withstanding temperatures of up to 800°C.

The company primarily supplies customers in the automotive components sector, particularly those manufacturing turbochargers and fuel systems. Turbochargers operate under extremely

demanding conditions, with temperature cycles that can exceed 1,000°C in a matter of seconds. As a result, reliable, highstrength fasteners that are lightweight, corrosionresistant and capable of withstanding extreme temperatures are essential.

Apex Stainless Fasteners is now seeing new growth opportunities from distribution and engineering customers in the electric and hybrid vehicle sectors. These vehicles are designed and built with a greater emphasis on components such as thermal management systems, wiring harnesses and battery packs, all of which demand fasteners that are exceptionally durable and capable of withstanding high temperatures and continuous vibration. Apex’s stainless grades, including A2/304 and

As PFAS can contaminate soil and water, is testing PFAS-free coating systems to help support safer manufacturing…