www.ies.org.sg

www.ies.org.sg

DECEMBER 2025 MDDI (P) 002/03/2025

ENERGY ENGINEERING: New initiatives to bolster the power grid’s reliability through flexible electricity demand

SOLAR PANEL RECYCLING: Redux launches advanced automated solar panel recycling facility

MAINTENANCE ENGINEERING: Turbomachinery risks rise as expertise runs dry

04 Bridging theory and practice: key insights from the IES Young Engineers Forum 2025

WiSER-IES Christmas Party 2025: a festive celebration of fellowship & community

05 IES Members Networking Night 2025: a celebratory evening of connection

06 ECM Networking Night 2025: a resounding success!

08 Universal Vapor Jet Corporation unveils global headquarters and R&D centre in Singapore

10 The development of new rhodium material for probe pins

11 GE Vernova and Seatrium secure a major contract to connect North Sea wind power to Germany’s grid

12 CAAS sets up company to centrally procure sustainable aviation fuel

14 Aster and Aether Fuels partner on the first next generation commercial sustainable aviation fuel plant in Singapore

16 Singapore Airshow 2026 marks 10th edition with new frontiers in aviation and space

17 ST Engineering and Safran forge stronger alliance

18 Blending nature and heritage with stormwater management in Bidadari Park

President Er. Chan Ewe Jin

Chief Editor T Bhaskaran t_b_n8@yahoo.com

Ms Jasmine Foo

Dr Chandra Segaran

Dr Ang Keng Been

Dr Aaron Sham

Mr Jaime Vega Bautista Jr

24 New initiatives to bolster the power grid’s reliability through flexible electricity demand

25 Sembcorp unveils landmark clean energy initiatives on Jurong Island

26 AHR Expo announces 2026 Innovation Awards Winners

28 Redux launches advanced automated solar panel recycling facility

32 Turbomachinery risks rise as expertise runs dry

CYBERSECURITY

34 Responsible innovation in the age of intelligent automation

36 Robot and elevator work together seamlessly in pilot project

38 Belgium’s ETCS Level 2 rollout completed

40 Aerotech’s new drives make high-performance hexapod control more accessible

The Singapore Engineer is published monthly by The Institution of Engineers, Singapore (IES). The publication is distributed free-of-charge to IES members and affiliates. Views expressed in this publication do not necessarily reflect those of the Editor or IES. All rights reserved. No part of this magazine shall be reproduced, mechanically or electronically, without the prior consent of IES. Whilst every care is taken to ensure accuracy of the content at press time, IES will not be liable for any discrepancies. Unsolicited contributions are welcome but their inclusion in the magazine is at the discretion of the Editor. www.ies.org.sg

The IES Young Engineers Committee (YEC) successfully convened the Young Engineers Forum 2025 on 29 November, at PSB Academy City Campus, uniting young engineers and students from various Institutes of Higher Learning (IHLs).

Centred on the theme ‘The Future of Young Engineers’, the forum featured an insightful panel discussion with industry leaders Mr Mervyn Sirisena (IES Deputy President), Er. David Ng

(IES Honorary Treasurer) and Dr Lim Chong Lye (Assistant Director, PSB Academy). The session was expertly moderated by Er. Victor Tan (Deputy Chair, YEC and Chair, IES Student Chapters Committee).

Participants actively explored the transition from academia to practice, discussing practical strategies to apply theoretical knowledge to real-world engineering challenges. This dialogue continued through an

engaging Q&A session, fostering a vibrant exchange of ideas.

The event concluded with an informal networking lunch, providing a valuable opportunity for students and young engineers to connect directly with IES Council Members, sharing insights and building professional relationships.

We extend our sincere gratitude to all panellists, participants and PSB Academy, for contributing to a truly meaningful and inspiring forum.

The IES Women in Science, Engineering & Research (WiSER) Committee successfully hosted its year-end WiSER–IES Christmas Party 2025 on 19 December at IES@Bukit Tinggi.

The festive gathering brought together IES members, Council representatives and guests, for an evening of warm celebration and camaraderie. Tasteful holiday decorations created a cheerful and inviting atmosphere, perfect for relaxed networking and fellowship.

Attendees enjoyed a delightful selection of food and drinks while reconnecting with colleagues and forging new connections across generations and engineering disciplines. The presence of

IES Council Members helped strengthen the dialogue between the Institution’s leadership and its members, highlighting the closeknit and supportive nature of the IES community.

The WiSER Committee extends its sincere gratitude to all members and guests for their participation and support, and looks forward to further enriching engagements in the coming year.

The IES Members Networking Night 2025 was successfully held on 10 December 2025, at the Raffles Room, Tanglin Club. The event brought together current and new IES members, Council representatives and merchant partners, for an uplifting evening of connection, celebration and professional camaraderie.

The evening commenced with a warm and inspiring welcome address by IES President, Er. Chan Ewe Jin.

In his remarks, he emphasised

the importance of strengthening the engineering community, fostering meaningful engagement and celebrating the collective achievements of IES members over the past year.

A notable highlight was the active participation of IES merchant partners.

They presented special, exclusive membership benefits and privileges, engaging directly with members to better understand their needs. This interaction showcased how their services and

partnerships enhance the overall membership experience, adding tremendous value to the night and reinforcing IES’ commitment to delivering meaningful benefits.

IES extends its sincere appreciation to all members and merchant partners who attended and contributed to the energy and success of the evening. We look forward to hosting more opportunities in 2026, for our community to connect, collaborate and continue shaping the future of engineering together.

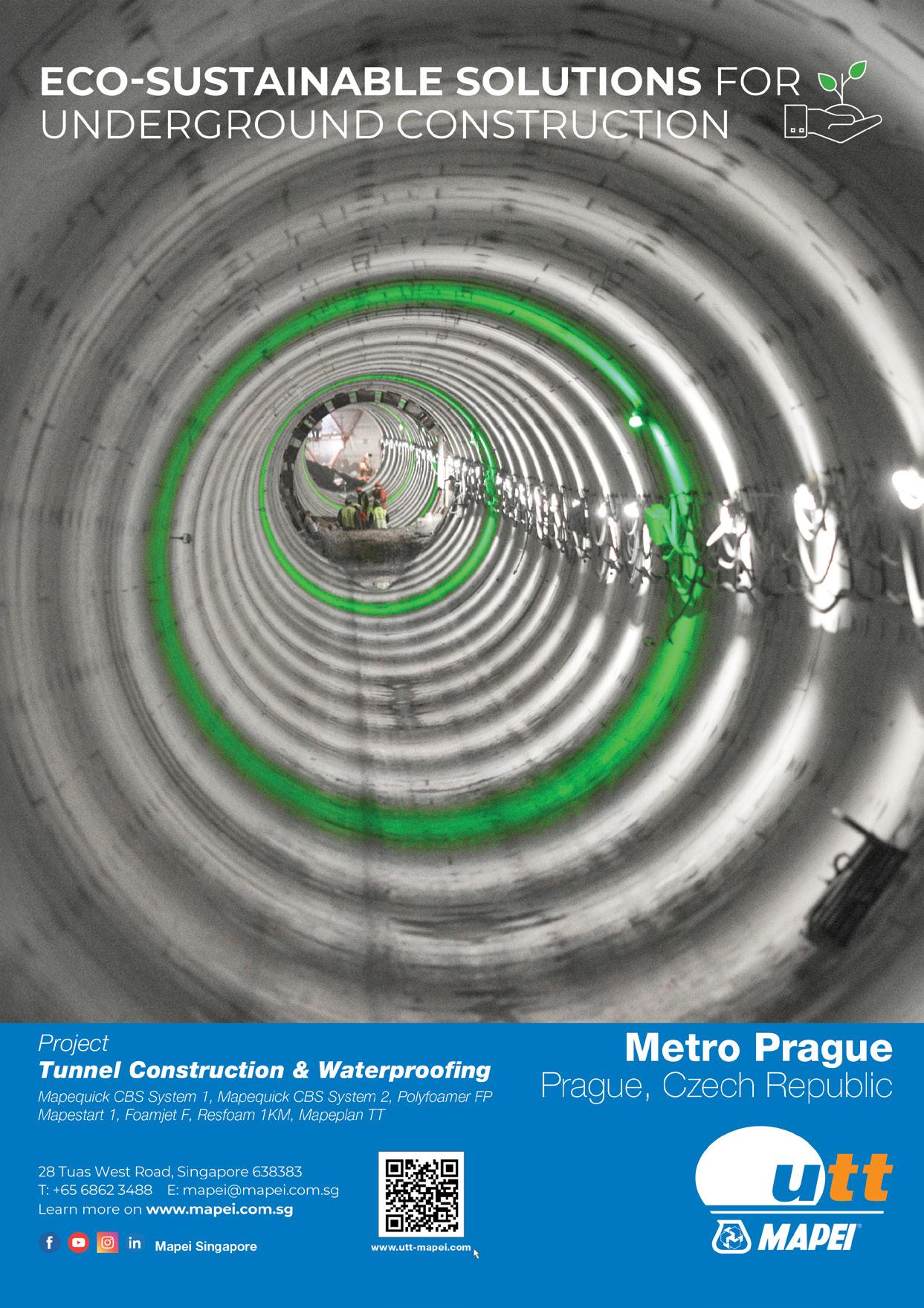

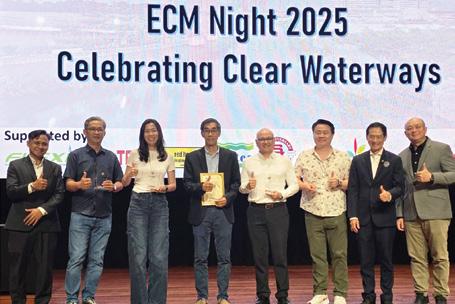

More than 300 professionals from the QECP and ECMO communities converged at ITE College Central on 11 December, for an evening of meaningful connection and cuttingedge knowledge sharing on Earth Control Measures.

A heartfelt thank you to IES President, Er. Chan Ewe Jin, for his opening address on protecting our waterways and building a sustainable future. The highlight was the honouring of 16 outstanding individuals, with the ECMO Exemplary Award for their dedication to the profession.

Deep Dive Insights: our industry experts delivered powerhouse sessions. The topics covered by the respective speakers were:

• SWD Code amendments by Ms Brenda (PUB, Singapore’s National Water Agency)

• IoT-driven Ultrafiltration by Mr Kumaraguru (Biofuel Industries)

• Concrete Canvas applications by Mr Michael Chong (Wall Tag)

• GFRP innovations by Ms Rita (Oneberry Technologies)

A huge shout-out to our sponsors and exhibitors for showcasing the latest solutions! The energy in the room was a testament to our vibrant, collaborative community.

Universal Vapor Jet Corporation (UVJC), a wholly-owned subsidiary of Universal Display Corporation (UDC)), recently announced the launch of its global headquarters and R&D centre in Mapletree Hi-Tech Park @ Kallang Way, Singapore.

The 8,000 ft2 facility includes the company’s global headquarters, its state-of-the-art research and development (R&D) centre, laboratory and prototype manufacturing space, to support innovation and commercialisation of its proprietary Universal Vapor Jet Printing (UVJP) technology.

Over the next five years, UVJC plans to invest SGD 50 million in tools, equipment and talent to accelerate the research and commercialisation of UVJP.

UVJC’s new Singapore headquarters will create high-value jobs across strategy, technology and advanced engineering. With support from the Singapore Economic Development Board (EDB), UVJC is building a multidisciplinary workforce that anchors nextgeneration R&D and manufacturing capabilities in Singapore, with process and product engineers and software, electronics and mechanical specialists. These roles not only strengthen the local deep-tech talent base but also help position Singapore as a global hub for precision manufacturing innovation.

Revolutionising thin-film printing and deposition with UVJP

UVJP is a transformative dry, solvent-free printing and deposition technology designed to meet the growing demands of precision additive manufacturing while offering greater efficiency and sustainability. By revolutionising thin-film jet printing technology, UVJC believes its platform could open the door to creating

devices and materials that are not achievable with traditional techniques, while implementing cleaner, faster and more intelligent manufacturing.

“At UVJC, we’re not just building equipment, we are building the foundation for the next generation of clean manufacturing. Our platform can print materials with micro precision, without solvents or masks, and is poised to open new possibilities across semiconductors, displays, life sciences and clean energy,” said Chandran Nair, CEO, UVJC.

“We chose Singapore as our headquarters because of its thriving manufacturing and innovation ecosystem, along with its skilled talent base. With institutional partners like the EDB and A*STAR, we are ready to serve global innovation and manufacturing markets, while anchoring the next phase of growth,” he added.

With over 26 years of global leadership experience, Nair brings deep operational expertise across

Asia, Europe and the United States, positioning UVJC to redefine advanced manufacturing.

“We welcome UVJC’s decision to establish its global headquarters and R&D centre in Singapore. This investment will not only create new job opportunities in advanced printing and manufacturing technologies, but will also deepen Singapore’s research capabilities in semiconductors, healthcare and materials science, through collaboration with local partners like A*STAR,” said Marcus Dass, Senior Vice President and Head, Global Enterprises, Singapore Economic Development Board.

Enabling the future of advanced manufacturing in Singapore Through partnerships with local research institutions, universities and global industry players, UVJC plans to co-develop tailored solutions and intellectual property (IP) that support greener, faster and more precise production.

UVJC will be exploring collaborations

with several A*STAR Research Institutes, including the Institute of Microelectronics (IME), the Institute of Materials Research and Engineering (IMRE), and the Singapore Institute of Manufacturing Technology (SIMTech), in areas such as advanced manufacturing, semiconductors and healthcare technologies. Researchers from both organisations will also be facilitating the joint development of advanced technologies, materials and processes, that have strong potential for commercialisation.

“UVJC’s establishment of its global headquarters and R&D centre in Singapore underscores the importance of deep-tech partnerships in advancing sustainable manufacturing. A*STAR looks forward to building deep partnerships with companies like UVJC, that are committed to invest and grow in Singapore, combining our complementary strengths to deliver industry and societal impact,” said Beh Kian Teik, Chief Executive Officer, Agency for Science, Technology and Research (A*STAR).

From OLED to universal applications

UVJP evolved from Organic Vapor Jet Printing (OVJP), a proprietary process manufacturing platform developed by Universal Display Corporation for OLED (Organic Light Emitting Diode) displays. OVJP offers solvent-free, mask-free deposition of organic molecules, that overcomes challenges faced by current deposition methods in manufacturing large OLED displays, while also providing a cleaner, more efficient and more precise alternative to older methods.

UVJC is now extending the technology’s potential into new application areas and industries, to create tools that will help bridge the gap between laboratory research and industrial-scale applications. Opportunities include cleaner semiconductor chip packaging and, in the long run, innovative pharmaceutical smart dosing appliances, as well as more

efficient production of solid-state battery electrolytes and organic photovoltaics for renewable energy systems.

UVJC’s focus is first to demonstrate real-world use cases with industrial-scale adoption to follow as processes are validated.

“UVJC is extending our novel dry printing and precision additive manufacturing platform into exciting new application areas with transformative potential. UVJC’s

grand opening marks a pivotal step in the evolution of Universal Vapor Jet Printing – advancing toward more efficient, costeffective manufacturing across a range of industries,” said Steven V Abramson, President and CEO of Universal Display Corporation.

“Under Chandran’s leadership, the team has built a world-class operation. Singapore’s vibrant advanced manufacturing ecosystem and renowned research institutions

make it a well-positioned base for turning cutting-edge science into market-ready solutions. At UDC, our mission is to envision possibilities and innovate to make them a commercial reality. We are proud to support Chandran and the UVJC team as they drive this groundbreaking technology forward to serve customers and industries around the world,” he added.

Universal Vapor Jet Corporation

Universal Vapor Jet Corporation (UVJC), a wholly-owned subsidiary of Universal Display Corporation (UDC), is at the forefront of developing cutting-edge tools and processes that bridge the gap between laboratory research and industrial-scale applications.

UVJC leverages its proprietary Universal Vapor Jet Printing (UVJP) technology to offer scalable,

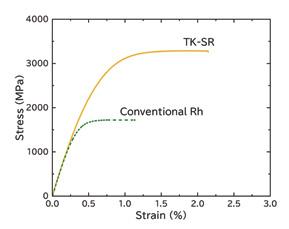

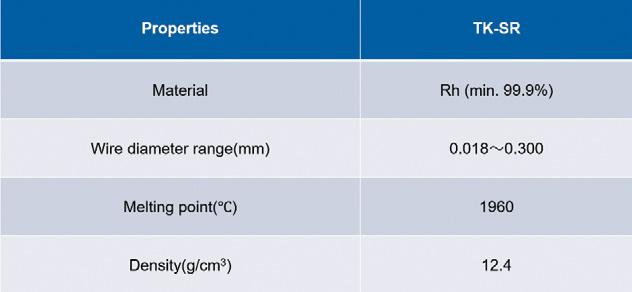

TANAKA PRECIOUS METAL TECHNOLOGIES Co Ltd (TANAKA), an industrial precious metals organisation, has announced the development of TK-SR, a rhodium (Rh) material for probe pins used in probe cards during the frontend processes of semiconductor package manufacturing.

TANAKA manufactures and supplies various precious metal probe pin materials for the inspection equipment used in the front- and back-end processes of semiconductor manufacturing.

TANAKA is said to be the first company in the world to successfully develop a rhodium probe pin material that simultaneously offers high strength, elasticity, hardness and electrical conductivity, that will extend the lifespan of probe cards and lower their costs.

TK-SR is available in widths as narrow as 18 μm, enabling precision inspection for today’s increasingly compact, narrowpitch semiconductor packages. TANAKA plans to ship twice as many of these products as conventional products, by 2030.

Probe cards play a critical role in current-carrying tests on silicon wafers during frontend semiconductor processes, using thousands or sometimes tens of thousands of precision probe pins. These pins endure extremely light loads applied hundreds of thousands, or even

millions, of times.

If a single probe pin bends or breaks, it must be replaced, and in some cases, the entire probe card. That’s why durability is essential. TANAKA’s high-strength, highelastic limit TK-SR significantly reduces the risk of deformation and breakage, minimising replacement frequency and improving overall reliability.

Since its foundation in 1885, TANAKA has built a portfolio of products to support a diversified range of business uses focused on precious metals. TANAKA is a leader in Japan, based on the the volume of precious metals it handles. Over many years, TANAKA has manufactured and sold precious metal products for industry and provided precious metals in such forms as jewellery and assets. As precious metals specialists, all group companies in

solvent-less and mask-less thinfilm print and deposition solutions across a spectrum of industries, including semiconductors, electronics, life sciences and renewable energy. The innovative technology is designed to meet the growing demands of precision manufacturing, while offering greater efficiency and sustainability.

UVJC was established in 2024 and is headquartered in Singapore.

Japan and worldwide collaborate on manufacturing, sales and technology development, to offer a full range of products and services.

GE Vernova and Seatrium recently announced that their consortium has been awarded a contract by TenneT to deliver a major part of BalWin5, a new 2.2-gigawatt (GW) offshore high-voltage direct current (HVDC) grid connection designed to transmit electricity from offshore wind farms in the German North Sea to the onshore transmission network in Germany.

Once operational, BalWin5 is expected to provide enough renewable electricity to power approximately 2.75 million households. BalWin5 is one of TenneT’s 2 GW projects. This new generation of powerful offshore grid connection systems is set to speed up the integration of large-scale offshore wind energy into the German grid, thereby supporting the country’s energy transition and climate goals.

This contract is the fourth project awarded to the GE VernovaSeatrium consortium under the five-year Framework Cooperation Agreement with TenneT announced in March 2023. It is also the consortium’s first win concerning TenneT’s German 2 GW projects. BalWin5 marks an important step in strengthening Germany’s electricity infrastructure and supporting the country’s long-term goals for energy security and decarbonisation.

GE Vernova-Seatrium consortium’s scope

As part of the contract, GE Vernova’s Electrification Systems business is expected to deliver the onshore and offshore converter stations and the complete HVDC technology, including the advanced control and protection systems that help maintain stable and secure operation across the transmission network. HVDC links are designed to support the high-capacity, longdistance transmission of offshore

wind power, helping to reduce transmission losses and improve overall system performance.

Seatrium is responsible for the design and construction of the offshore converter platform and will manage transportation and installation in the German North Sea. Works are scheduled to commence on 1 January 2026, with the majority of platform fabrication taking place at Seatrium’s yards in Singapore and Batam.

“BalWin5 reflects the scale and ambition of Germany’s energy transition, and we are proud to support TenneT in this important programme. Our Electrification Systems business brings decades of innovation in HVDC technology, helping deliver solutions that are designed for efficiency, affordability, and long-term energy security,” said Philippe Piron, CEO, GE Vernova’s Electrification Systems business.

“Working alongside Seatrium, we are confident in our ability to deliver a high-quality system that strengthens the offshore grid and supports Europe’s move toward a more resilient and sustainable electricity infrastructure,” he added.

“We are proud to extend our partnership with TenneT and GE Vernova to deliver this transformative offshore wind solution as we collectively push boundaries to accelerate energy transition goals and innovation,” said Samuel Wong, Executive Vice President of Seatrium

Energy (Fixed Platforms).

“Leveraging the proven design and experience gained from the first three platforms we are building for TenneT, we are confident in delivering an equally high-quality product safer and more efficiently through our series-build strategy, underpinned by the collective power harnessed from our One Seatrium Global Delivery Model,” he added.

BalWin5

BalWin5 is one of TenneT’s major new projects to bring more electricity from North Sea wind farms into Germany’s power grid.

The connection is being designed to carry up to 2.2 gigawatts of wind power to homes and businesses, allowing Germany to make better use of the large offshore wind farms operating in the North Sea.

The additional 200 MW above the standard 2 GW design come from building the system with enough technical headroom to transport more power when wind conditions allow. This means more renewable electricity can be delivered without needing extra infrastructure or added cost.

The system will include an offshore converter station in the North Sea, an onshore converter station at Bremen-Werderland, and a combined 325 km sea and land cable system.

Commissioning is planned for 2032.

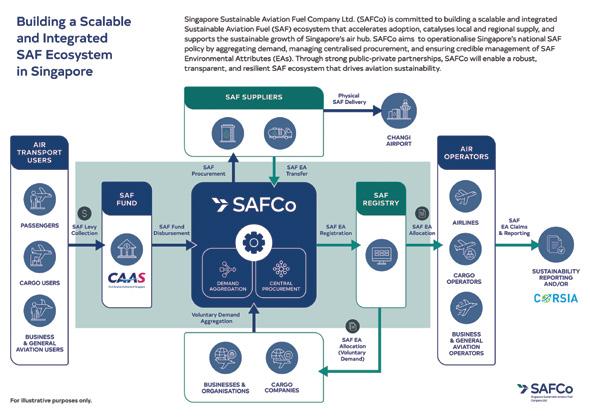

The Civil Aviation Authority of Singapore (CAAS) has set up the Singapore Sustainable Aviation Fuel Company Ltd (SAFCo) to centrally procure sustainable aviation fuel (SAF) for the Singapore air hub and support the implementation of Singapore’s national SAF policy.

SAFCo is set up as a non-profit Company Limited by Guarantee, wholly owned by CAAS. Mr Han Kok Juan, Director-General of CAAS, will chair SAFCo’s Board. Ms Tan Seow Hui, a seasoned leader in the energy and aviation industries, has been appointed as its founding Chief Executive Officer.

The setting up of SAFCo follows the passing of the Civil Aviation Authority of Singapore (Amendment) Bill in Parliament on 14 October 2025, which allows for the implementation of SAF policies for air transport in Singapore and empowers CAAS to collect a SAF Levy, to set up a SAF Fund and to procure, manage and allocate SAF and SAF environmental attributes (EAs) or to establish and appoint a central procurement entity to carry out these functions.

SAF environmental attributes is a value representing the difference between the amount of carbon dioxide (CO2) emissions of SAF throughout its life cycle and that from the same quantity of conventional aviation fuel throughout its life cycle.

SAF environmental attributes may be used by a person to meet offsetting requirements applicable to that person under the Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA) developed by the International Civil Aviation Organization or other similar programmes, or reported by a person as carbon emissions reduction from the use of SAF under any scheme applicable to, or adopted by, that person for the reporting of environmental sustainability efforts undertaken

by that person to stakeholders or investors of that person or regulators of the business of that person.

Through SAFCo, CAAS seeks to build a transparent and integrated SAF demand market that brings together airlines, corporate buyers of SAF, fuel producers, carbon market platforms and stakeholders across the aviation fuel chain in Singapore to aggregate demand, stimulate investment and accelerate the use of SAF.

Carbon market platforms are digital marketplaces that facilitate the trading of carbon, SAF or other sustainability credits.

SAFCo will centrally procure SAF, using the SAF Fund to achieve the 1% SAF target in 2026, for flights departing Singapore. The amount of SAF procured by SAFCo will increase accordingly when the SAF target is raised to 3% to 5% by 2030, subject to global developments and the wider availability and adoption of SAF.

SAF and SAF EAs will be sourced through a transparent competitive tender process from SAF suppliers that meet international sustainability standards like CORSIA. With predictable cashflows from the SAF Levy, SAFCo will be able to go into longer-term, competitive price agreements to secure a more stable and affordable SAF supply.

Beyond the regulated demand from the SAF Levy, SAFCo will also aggregate voluntary SAF demand from organisations seeking to purchase SAF to reduce their air travel or supply chain carbon footprint credibly and costeffectively. The demand from the SAF Levy forms a scalable baseload, enabling SAFCo to negotiate attractive pricing for SAF and SAF EAs, and to anchor long-term supply agreements.

Businesses that participate in

SAFCo’s voluntary SAF purchases can leverage this baseload to unlock economies of scale. They can also gain access to competitively priced and verified SAF and SAF EAs through SAFCo and avoid the need to set up their own procurement systems.

As a new entity, SAFCo’s immediate priorities will be to establish robust governance and procurement frameworks, set up levy collection systems and processes, and build manpower and procurement capability, while engaging stakeholders on the implementation, ahead of the first SAF procurement in 2026.

SAFCo will also build a scalable voluntary demand programme for SAF and SAF EAs as a complement to the SAF Levy. SAFCo will reach out to businesses and airlines to encourage them to partner SAFCo and use its central procurement mechanism for voluntary SAF purchases.

SAFCo will also support the development of the SAF supply ecosystem in Singapore and the region. With predictable and stable cashflows, SAFCo can sign longer and larger contracts with SAF suppliers, providing demand certainty in a still nascent SAF market. This approach aims to encourage investment in SAF production capacity and the development of SAF-related carbon markets in Singapore and the region.

Mr Han Kok Juan, DirectorGeneral, CAAS and Chairman of SAFCo said, “Singapore is taking a pragmatic, balanced and actionoriented approach to advancing sustainability in the aviation sector. The setting up of SAFCo is another concrete step forward. Through SAFCo, we want to get the best value for the SAF Levy collected and activate a SAF ecosystem which will help advance sustainable

aviation and create new economic opportunities for Singapore and beyond.”

Ms Tan Seow Hui, Chief Executive Officer of SAFCo said, “I am honoured to lead SAFCo at this pivotal stage. My priority will be to put in place, credible and scalable frameworks, partnerships and processes to ensure that SAFCo delivers on its mandate to aggregate demand, procure SAF efficiently, and manage SAF EAs transparently. By working closely with airlines, businesses and suppliers, we aim to facilitate greater SAF adoption in the region and contribute to the decarbonisation of aviation.”

In early September 2025, the Civil Aviation Authority of Singapore (CAAS) unveiled Singapore’s National Aviation Safety Plan (2025-27) to strengthen aviation safety as Singapore’s air passenger volume hits record levels and is expected to grow strongly in the coming years.

National Aviation Safety Plan (2025-27) identifies the safety challenges in Singapore’s aviation sector, particularly operational safety risks, for example, on runways; emerging risks, for example, those associated with manpower constraints and Global Navigation Satellite System Radio Frequency Interference; and the integration of new and emerging technologies into the aviation eco-system.

To address these challenges, the National Aviation Safety Plan sets out 45 actions the sector will take along four priority areas:

• To holistically improve operational safety, through infrastructure improvements, systems integration, and proactive risk management.

• To review and develop new policies and rules to support industry growth and innovation

without compromising safety.

• To strengthen safety management and culture, through closer tripartite partnership and stronger safety management systems.

• To develop human capital, to ensure and sustain safe operations.

As Singapore’s aviation safety regulator, CAAS oversees over 200 aviation companies, 220 aircraft and 25,000 aviation professionals, including pilots, air traffic controllers and engineers, involved in aviation operations in Singapore and around the world.

Through the National Aviation Safety Plan, CAAS works with other government agencies, international partners, aviation companies and personnel, to review the operating environment and identify safety risks and develop coordinated actions to address them.

The first National Aviation Safety Plan was released in 2022 with 50 action items. Its focus then was on the smooth and safe ramp-up of aviation manpower and operations post-COVID.

Of the 50 action items, 75%

have been implemented. The remaining items will take more time to complete. The Singapore aviation sector has since achieved a strong and full recovery, while maintaining a low number of safety occurrences.

In 2022, Singapore was audited by the International Civil Aviation Organization (ICAO) for its aviation safety management under ICAO’s Universal Safety Oversight Audit Programme (USOAP). Singapore achieved zero findings and an Effective Implementation score of 99.7%, the highest score amongst states in the world, above the global average of 67.5% at the time.

Mr Han Kok Juan, DirectorGeneral of CAAS, said, “Singapore has today one of the strongest aviation safety regimes in the world. Notwithstanding this, the recent spate of serious aviation safety incidents around the world is a timely reminder that we must stay vigilant and not take safety for granted. The National Aviation Safety Plan is a call to action, for the Singapore aviation sector to work together, to ensure aviation safety as we position ourselves for growth.”

Aster, a leading provider of energy and chemical solutions in Southeast Asia and Aether Fuels (Aether), a sustainable aviation fuels (SAF) producer, recently signed an agreement to develop the first next-generation, commercial-scale SAF production facility in Southeast Asia, at Aster Pulau Bukom in Singapore.

Combining Aether’s breakthrough technology with Aster’s deep expertise at its fully integrated refining and chemical hub in Singapore, this facility will position Singapore at the forefront of energy transformation and decarbonisation, reinforcing its role as the region’s leading centre for sustainable industrial innovation.

Project Beacon, Aether’s commercial demonstration facility, will utilise the company’s Aurora technology to produce up to 50 barrels of fuel per day (2,000 tons of fuel per year). It will convert industrial waste gas and biomethane into CORSIAcertified SAF, achieving more than 70% reduction in greenhouse gas (GHG) emissions, compared to conventional jet fuel, making it the first commercial facility of its kind.

Project Beacon is expected to commence construction in 2026 and begin commercial operations in 2028.

Locating the plant on Pulau Bukom underscores Aster’s commitment to fostering breakthrough innovation within its asset ecosystem. Aster will provide renewable power, waste carbon feedstock, utilities and site support, to accelerate the development and commercialisation of Aether’s scalable solution.

Erwin Ciputra, Group CEO of Aster, said, “Today marks an important step forward in reducing carbon intensity and advancing

new energy pathways. By bringing together Aether’s technology with the expertise of our Bukom facility, we are demonstrating how partnerships between established industrial leaders and agile innovators can catalyse the introduction of disruptive solutions on a commercial scale.”

“This reflects Aster’s broader sustainability agenda and through Aster Ventures, we will invest in transformative technologies and next-generation energy solutions – working closely with innovators to strengthen Singapore’s role as the region’s hub for industrial renewable energy,” he added.

Conor Madigan, Founder and CEO of Aether Fuels, said, “Singapore is a natural location for this breakthrough facility, with its world-class talent, strong innovation ecosystem, and steady support from the Economic Development Board (EDB). It is also where Aether began as a venturebuild at Xora Innovation, a global deep tech venture firm backed by Temasek, making this project especially meaningful.

“We are particularly impressed by the expertise, openness and innovation-focus of Aster and other regional partners, such as the Singapore Airlines Group and Sembcorp, with whom we aim to advance Singapore’s SAF industry. By building Project Beacon within Aster’s world-scale refinery, we can accelerate deployment of our Aurora solution and help position Southeast Asia as a global hub for sustainable fuels,” he added.

Png Cheong Boon, Chairman of the Singapore Economic Board (EDB), said, “This new Sustainable Aviation Fuel (SAF) facility strengthens Singapore’s competitiveness as a hub for sustainable products and

demonstrates how companies here can seamlessly collaborate to scale breakthrough innovations. We welcome more companies to partner with us in advancing sustainable solutions and lowcarbon technologies, to shape the next chapter of growth for Singapore and the region.”

Project Beacon will be able to use a range of waste carbon feedstock, which is a critical enabler of nextgeneration SAF. While the HEFA (hydro-processed esters and fatty acids) process ignited the first wave of SAF production, feedstock limitations such as the lack of used cooking oil make it challenging to support future demand.

Aether Aurora overcomes these constraints by converting a variety of abundant waste carbon feedstocks into fuel with high yields and low capital costs, making it a sustainable and scalable approach to drive the next SAF production wave.

Aether Fuels is a climate technology company revolutionising sustainable fuel production to help hard-to-abate industries like aviation and ocean shipping achieve their decarbonisation goals. The company’s breakthrough Aether Aurora technology converts waste carbon into drop-in liquid fuels with near-ideal carbon conversion efficiency.

The scalable solution addresses the core requirements of nextgeneration sustainable fuels by increasing production yields and reducing capital costs, while utilising a diverse range of feedstocks.

Founded in 2022 and backed by global investors and partners, Aether Fuels maintains principal offices in the US and Singapore.

Aster

Aster is a leading provider of energy, chemical and infrastructure solutions in Southeast Asia, supplying products and services to various manufacturing industries in both domestic and international markets.

It is a Chandra Asri-led joint venture with Glencore. Since Chandra Asri Group’s establishment in 1992, the group has grown from strength to strength, to build its reputation as a reliable growth partner, with strategically wellpositioned assets in Indonesia and Singapore.

The group’s total asset base includes a refinery with a capacity of more than 300,000 barrels per day with ongoing asset rejuvenation, alongside a 1.1 million metric ton naphtha cracker on Bukom Island, 2.5 million metric tons of downstream chemical assets on Jurong Island, and a 0.9 million metric ton naphtha cracker in Cilegon. The company’s business is supported by core infrastructure assets, including energy, electricity, water, jetty and tank farm facilities.

Singapore Airshow 2026, the international aerospace and defence exhibition, will be held from 3 to 8 February 2026, at the Changi Exhibition Centre.

Marking two decades of defining the future of flight, the biennial event will once again bring together global industry leaders, government and military delegations, innovators and investors, to exchange ideas, forge partnerships and chart the next era of aerospace and defence.

Since its debut in 2008, the show has grown into one of the world’s leading platforms for aviation and defence, serving as a critical gateway to Asia Pacific’s dynamic markets. The 2026 edition will unveil new perspectives, fresh participants and expanded opportunities for an industry in transformation.

Trade attendees can expect more than 1,000 participating companies from more than 50 countries and regions. In addition to returning exhibitors such as Airbus, AVIC, Bell, Boeing, COMAC, GE Aerospace, Gulfstream, Leonardo, Lockheed Martin, MBDA, Rolls Royce, RTX, Saab, SIA Engineering, ST Engineering and Thales, attendees can also look out for the presence of next-generation defence technology companies like Helsing, Quantum and Shield AI.

Country pavilions expected at the event include those by Australia, Canada, Czech Republic, France, Germany, Japan, Korea, Malaysia, the Philippines, Singapore, Switzerland, the United Kingdom and the United States, with expanded presence from both the Italian Trade Agency Pavilion and the China Pavilion.

“Reaching our 10th edition is a significant milestone for Singapore Airshow. Over the past two decades, the Airshow has evolved alongside the industry, serving as a key global meeting platform for

stakeholders across the aviation and defence ecosystem,” said Mr Leck Chet Lam, Managing Director of Experia Events, organiser of Singapore Airshow.

“In 2026, we are proud to expand our horizons further with new features and partnerships that reflect the industry’s transformation. This edition underscores our continued commitment to supporting the region’s growth and fostering meaningful collaboration,” he added.

Introducing Space Summit 2026 Singapore Airshow 2026 will introduce a brand-new feature –Space Summit 2026, to be held from 2 to 3 February 2026, at the Sands Expo and Convention Centre, Marina Bay Sands, marking a key expansion of the show’s scope from air to the frontiers of space.

Officially endorsed by Singapore’s Office for Space Technology & Industry (OSTIn) and the Economic Development Board (EDB), the summit positions Singapore as the hub for space dialogue and collaboration in Asia-Pacific.

Themed ‘New Frontiers: Shaping a Responsible and Inclusive Space Future’, it will convene global policymakers, space agencies, investors and innovators, to discuss topics such as infrastructure, sustainability, investment and the in-space economy – a sector projected by McKinsey to reach USD 1.8 trillion by 2035. By bringing the space agenda into the Airshow, the Space Summit underscores Singapore’s growing role as a collaborative hub for the expanding space economy and encourages cross-sector engagement across aviation, connectivity and emerging technologies.

Collaborating towards a sustainable future Sustainability continues to anchor

the Singapore Airshow’s vision for the industry. The 2026 edition will place sustainable aviation fuel (SAF) and net-zero initiatives in the spotlight, showcasing real-world applications and technologies that move aviation closer to decarbonisation.

Neste, the global leader in renewable fuels, joins as the Sustainable Aviation Partner to share insights at AeroForum on SAF adoption, supply chain transformation and enabling greener aviation operations.

Through a series of forums, showcases and sustainability partnerships, Singapore Airshow 2026 will continue to drive conversations and collaborations that accelerate the transition towards a cleaner, more resilient and sustainable aviation ecosystem.

Nurturing innovation and emerging technologies

Innovation remains at the heart of the Singapore Airshow. What’s Next, the show’s startup showcase will return with a sharper focus on emerging and dual-use technologies across aerospace and defence. The 2026 edition will also feature expanded exhibition zones spotlighting digital aviation, sustainable propulsion and future defence technologies, fostering connections between global original equipment manufacturers (OEMs), small and medium-sized enterprises (SMEs) and technology start-ups.

These platforms will reinforce Singapore Airshow’s role as the nexus for collaboration between established industry players and the next generation of innovators shaping the aerospace landscape.

A platform for high-level exchange and collaboration

Beyond the exhibition, the Singapore Airshow continues to

serve as a vital networking hub through its exclusive trade days and strategic forums.

The AeroForum at Singapore Airshow 2026 will feature a comprehensive programme, spotlighting the industry’s most pressing priorities, including market and budget outlooks, autonomy and human machine teaming, cybersecurity, sustainable aviation pathways, advanced air mobility, workforce transformation and the global race to commercialise next generation technologies. These sessions will bring together thought leaders and technical experts to share insights across both civil and military domains.

AeroCampus will also return as

a dedicated platform to inspire and nurture the next generation of aerospace talent. Bringing together educational institutions, training organisations and industry partners, AeroCampus will offer students and young professionals, first-hand exposure to career pathways, emerging skillsets and innovations shaping the future of aviation.

The Changi Aviation Summit brings together senior government officials and industry leaders to exchange views on key issues faced by the civil aviation industry. Organised by the Singapore Ministry of Transport and the Civil

Safran Electronics & Defense and ST Engineering have expanded their global cooperation into the defence domain through the signing of a Memorandum of Understanding (MoU). With the growth in the global defence market, the MoU will strengthen both partners’ cooperation across several areas including joint business development, technology integration, lifecycle support and sustainment services, in order to meet customers’ operational requirements.

This expanded partnership brings together complementary capabilities to deliver integrated and mission-critical solutions in the land, air, sea and space domains in Asia Pacific and worldwide.

A key focus will be the integration of Safran’s core expertise in optronics, avionics and PNT (Positioning, Navigation and Timing) electronics with ST Engineering’s domain expertise in integrated defence solutions to deliver high-performance solutions that address the global demand for technology-driven defence modernisation.

“As ST Engineering grows its

Aviation Authority of Singapore, this year’s summit will explore how the aviation sector can capture opportunities, navigate challenges and build new partnerships to drive competitiveness and sustainable growth, even as passenger traffic reaches new heights.

The summit will host a series of focused panel discussions on 2 February, which will bring together leaders and experts across the sector, including airlines, airports, regulators and international organisations, to discuss how the industry is building networks, reinventing business models and designing airports for the future.

Singapore Airshow is organised and managed by Experia Events Pte Ltd.

international defence business, strengthening partnerships with international counterparts is aligned with our commitment to deliver advanced, missionready solutions to our customers. Such partnerships reinforce our position as a trusted partner of choice in the global defence industry,” said Mervyn Tan, President, Defence & Public Security, ST Engineering.

“This MoU with Safran builds upon the strength of our existing collaboration and leverages the complementary technical expertise that both sides will bring to drive innovation and excellence across multiple domains,” he added.

“ST Engineering and Safran Electronics & Defense have established a robust and reliable partnership in the worldwide aviation market. This MoU marks a significant expansion of this collaboration into the defence sector, demonstrating our strong commitment to mutual growth in this field,” said Alexandre Ziegler, Head of Defence Global Business Unit, Safran Electronics & Defense.

By combining our technological and industrial capabilities, we will jointly enhance innovation, operational readiness and lifecycle support thereby creating greater value and long-term capability for our customers,” he added.

Opened on 3 September 2024, Bidadari Park is a recent addition to the network of parks that adorns Singapore and make it a City in Nature. Nestled at the heart of the Bidadari estate and spanning approximately 13 hectares, the park is a tranquil urban oasis.

Featuring the picturesque Alkaff Lake, a first-of-its-kind, multifunctional drainage infrastructure, the park offers both the community and birdwatchers a place to relax and appreciate nature.

In 2013, the Housing & Development Board (HDB) unveiled the vision for Bidadari as ‘A Community in a Garden’, a concept that embraces the area’s natural landscape and heritage. This initiative led to a multi-agency collaboration involving HDB, National Parks Board (NParks), National Water Agency PUB, National Heritage Board (NHB) and a diverse team of building consultants. CPG Consultants served as the lead consultant for the main Bidadari Park area which

covered 12 ha.

The late Mr Anthony Gabriel, who was Senior Vice President of Architecture, CPG Consultants and Project Director of the Bidadari Park project, had stated, “The team’s design philosophy for Bidadari Park is to respect, transform and beautify. Through the thoughtful transformation of the space, we want to create multifunctional areas that meet the community's diverse needs while honouring the heritage of the original location and inspiring a connection with nature and promoting biodiversity.”

This vision is rooted in a bluegreen masterplan conceived in collaboration with industry partners, for which a Request for Proposal was won in 2019. The outcome is a rustic and wooded park, inspired by the Hundred Acre Wood from the classic children’s tale, Winnie-the-Pooh.

A key attraction of Bidadari Park

is the 1.8 hectare Alkaff Lake, inspired by the legacy of the site’s former identity as Alkaff Gardens. This multi-functional drainage infrastructure is a first-of-its-kind.

In dry weather, Alkaff Lake resembles a regular lake, forming part of the public’s recreational and aesthetic space. Visitors can enjoy panoramic views of the cascades and lake, from the nest shelter or the large viewing deck extending over the water.

During heavy rainfall, Alkaff Lake plays a vital role as a retention pond that regulates stormwater runoff, with the capacity to hold up to 40,000 m3 of water – the equivalent of 16 Olympic-sized swimming pools. The design and engineering strategy prioritises the creation of floodplains that effectively manage water runoff to the downstream drainage system.

“Designing and constructing Alkaff Lake presented a rewarding yet complex challenge. To effectively preserve existing features and integrate flood control measures

with landscape elements requires a thoughtful blend of engineering, application of nature-based solutions and creative ingenuity,” said Dr Chi Bui, Vice President and Technical Lead of the Climate Resilience Studio at CPG Consultants.

The landscaped lake is bordered by cascading wetlands and a meandering stream, culminating in an island featuring the iconic Samanea Saman (Rain Tree) which remains a landmark.

“To preserve the mature Rain Tree with its naturally umbrellashaped canopy, an island was created around the tree as part of an integrated multifunctional floodplain within Alkaff Lake, balancing tree preservation with flood-storage requirements and water-quality management,” Dr Chi explained.

Steps, platforms, and boardwalks are integrated within the upper and lower marshlands, providing diverse experiences along the water’s edge. The marshlands, planted with aquatic species, support natural filtration and contribute to improved water quality.

During wet weather, rainwater is collected at the upper marshland, flows through the lower marshland into a swale known as the Ficus Stream, and eventually cascades into Alkaff Lake, where a dedicated water filtration and circulation system further enhances water quality.

This innovative approach, which integrates the park’s natural topography into the design, not only supports sustainable water management but also transforms the water system into a selfoperating, nature-driven network.

To bring the client’s vision of ‘A Community in a Garden’ to life and to make Bidadari Park a haven for biodiversity, the team also conceptualised a marshland experience where a wide variety of wildlife can make their home.

A marshland, divided into upper and lower sections, has been created within the woodland.

Both the Upper Marshland and Lower Marshland are designed with different water depths to nurture a wide array of biodiversity throughout the year. This natural habitat is particularly conducive for a diverse range of birds to potentially nest and to perch on trees.

Winding through the marshland,

the Marshland Boardwalk provides visitors with excellent vantage points to spot dragonflies. Along the way, an observation deck and pavilion – designed to resemble a bird’s nest – offer tranquil rest spots where guests can take a break, while immersing themselves in the beauty of aquatic flora

and fauna. These thoughtfully integrated structures enhance the experience of being surrounded by nature.

The marshlands also serve as a nature-based solution during heavy rainfall by absorbing and storing excess rainwater, slowing down surface runoff and allowing water to seep into the ground to increase groundwater. The plants in the marshland also filter pollutants, helping to improve the water quality.

A land bridge was designed to link the main area of Bidadari Park to the hillock across the road. The land bridge is mostly planted with carefully curated species of plants and trees. Its footpath is flanked on both sides by lush greenery. Not only does this improve accessibility for estate residents and visitors to the park, but the land bridge

also acts as a conducive route for butterflies and birds to travel across.

This ‘linking green to the green’ concept creates a continuous habitat corridor, supporting both the local ecosystem and the park’s role as a sanctuary for biodiversity.

Located between the Adventure Playwoods and Alkaff Lake in Bidadari Park is the Heritage Walk. In reimagining a section of the Heritage Walk, which includes the former Upper Aljunied Road, the team proposed an alternative approach.

Rather than demolishing the older stretch, the team decided to integrate it into the new park development. By pedestrianising the former road and transforming it into, what is now known as, the Sang Nila Utama Boulevard, residents can walk and exercise along wide pathways flanked by

majestic Rain Trees which provide much-needed relief from the sun. Along the boulevard, natural solutions such as upcycled logs and stumpery create habitats for various species of insects and amphibians.

All images by Finbarr Fallon, unless otherwise stated

PROJECT CREDITS

Project Bidadari Park

Client

Housing & Development Board (HDB)

National Heritage Board (NHB)

National Parks Board (NParks)

National Water Agency PUB

Lead Consultant in Multidisciplinary Team

CPG Consultants

Architecture

CPG Consultants

Civil & Structural Engineering

CPG Consultants

Environmental Engineering and ABC Waters Professional Engineering

CPG Consultants

Landscape Architecture

Henning Larsen

Water Sensitive Urban Design

Ramboll Waters and Henning Larsen

Main Contractor

Expand-Landscape

Engineering Joint Venture

Mechanical & Electrical

Engineering

CPG Consultants and BECA

Project Management

CPG Consultants

Quantity Surveyor

AECOM

Signage and Wayfinding

CPG Consultants and Henning Larsen

Site Supervisory Team

Construction Professional

Dr Chi Bui, Vice President and Technical Lead of the Climate Resilience Studio at CPG Consultants elaborates on the highlights of the Bidadari Park project.

The Singapore Engineer (TSE): Could you summarise the design philosophy of the Bidadari Park project?

Dr Chi Bui (CB): The park’s design philosophy is rooted in integrating nature, respecting heritage and enhancing the landscape. Once a cemetery and home to the iconic Alkaff Gardens, the site carries deep historical significance.

The challenge for the project team was to honour this legacy, while transforming the area into a vibrant, climate-resilient park within the tight footprint of an urban estate. The result is a network of multifunctional spaces designed to serve people, support biodiversity and manage storm water sustainably.

This design philosophy guided the integration of numerous nature-based solutions to enhance biodiversity and create a natural environment for birdwatchers and nature lovers. The park functions as living infrastructure, while remaining a welcoming, peoplecentred green space.

Bidadari Park is not just a community space – it is an example of Singapore’s efforts in adapting to climate change. The project supports the Singapore Green Plan 2030 by expanding green spaces, strengthening flood resilience and enriching biodiversity.

TSE: What are the main design and functional highlights of the project?

CB: A key attraction of Bidadari Park is the picturesque 1.8-hectare Alkaff Lake. Serving a dual role, it is both a serene centrepiece for the community and a first-of-its-

kind, multifunctional drainage infrastructure.

Engineered as a high-capacity stormwater retention system, Alkaff Lake manages urban runoff from a 43.5 hectare catchment, releasing it gradually through controlled outlets to mitigate flash floods in downstream areas. In doing so, it also restores the site’s natural hydrology, honouring the legacy of the original Alkaff Gardens.

In dry weather, Alkaff Lake is a tranquil space that contributes to the community’s recreational and aesthetic environment. During heavy rain, it transforms into a robust stormwater retention pond capable of holding up to 40,000 m3 of water – the equivalent of 16 Olympic-sized swimming pools.

By capturing and retaining the stormwater from nearby areas, the lake regulates and slows down the amount of runoff that flows into the downstream drainage system which cannot be widened further due to space constraints. This significantly reduces downstream flood risks.

Designed to follow the site’s natural terrain, the lake incorporates a hybrid, engineered wetland ecosystem, seamlessly integrated with its edge. This enhances biodiversity while naturally filtering water – improving water quality and enriching the park’s ecological character by supporting habitats for birds, fish and aquatic plants.

Engineered safety is embedded in the project team’s design. Transiently floodable areas serve as open parkland on normal days but transform into water-holding zones during storms. Clear signages, safe pathways, warning lights, elevation markers and a clear broadcast

system ensure visitors remain within safe areas when water levels rise.

Backed by the multidisciplinary expertise of the project team, the engineering strategy turns wetlands, transiently floodable areas and controlled outlets into a living infrastructure. Alkaff Lake becomes a space that respects its heritage and offers the community a place of beauty and resilience in the face of climate change.

To make Bidadari Park a haven for biodiversity, the team conceptualised a marshland experience to provide habitats for a wide variety of biodiversity. Within the woodland, a marshland has been created and divided into upper and lower sections. Each is designed with different water depths to support diverse species throughout the year. This natural habitat is especially conducive for a range of bird species, offering nesting opportunities and perches among the trees.

The Upper and Lower Marshlands are engineered as an integrated pre-treatment system to improve water quality, before it enters the main lake. Beyond being biodiversity hotspots, these marshlands operate at different water levels, enabling a staged treatment process. They also serve as a nature-based solution by absorbing and storing excess rainwater, slowing surface runoff and allowing water to seep into the ground.

In the Upper Marshland, water first slows down, allowing natural settling of suspended particles. This gradual process transforms the water’s appearance from brownish to becoming clearer as finer particles settle. The Lower Marshland continues this treatment,

with water passing through aquatic vegetation that further filters it before discharge into the lake.

A natural weir between the marshlands maintains water at optimal levels, extending retention time to enhance settling and biological uptake while preventing stagnation.

In addition to improving water quality, the marshlands serve as a valuable habitat for fish and other aquatic life, creating a thriving ecological zone that supports both environmental and recreational objectives.

Green connectivity is achieved through a land bridge which links Bidadari Park to the hillock and provides a safe passage for visitors and biodiversity across Bidadari Park Drive.

The 19 m wide, 100 m long Bidadari land bridge merges ecology with engineering, connecting the hillock and main park across Bidadari Park Drive. About three-quarters of the deck has been planted up with a carefully curated planting palette, creating a continuous canopy for birds and butterflies, while offering visitors a shaded, pleasant crossing buffered from traffic noise and glare.

From an engineering perspective, the bridge is unique in supporting substantial soil depth, irrigation and drainage within its deck, to sustain a full canopy. Its sculpted, curved edges give the underside a seamless, flowing form that blends into the surrounding landscape, allowing visitors to experience the bridge as part of the park rather than merely a crossing over the road.

Constructing over a live roadway posed major challenges. Engineers adopted prestressed beams and a precision launching operation during overnight road closures to minimise disruption. Massive girders were lifted into place with rigorous centre of gravity and rigging analyses to counter unbalanced forces introduced by the curved profile. Temporary bracing and carefully sequenced lifts ensured safety and stability

throughout.

The result is a structurally efficient land bridge that appears as a single, continuous form from below, while functioning above as a vital ecological corridor. By marrying architectural vision with engineering precision, the project demonstrates how infrastructure can strengthen both biodiversity and community connectivity.

TSE: Please outline the contributions of CPG Consultants in this project.

CB: CPG Consultants served as lead consultant for this multiagency initiative, bringing together expertise in Architecture, Environmental Engineering, Civil and Structural Engineering, Mechanical and Electrical engineering, Master Planning,

and Project Management. The team’s role spanned the entire project lifecycle – from concept to completion – ensuring that every design decision aligned with both community needs and technical requirements.

CPG’s specialists addressed a range of complex challenges:

• Architectural and Engineering integrated solutions for heritage preservation.

• Environmental Engineering to develop nature-based flood management and water treatment systems.

• Civil and Structural Engineering for robust hydraulic design and safe infrastructure, including the underground service reservoir.

• Project Management to facilitate coordination among HDB, NParks, PUB, NHB, and private contractors.

The Chartered Engineering Registry aims to provide professional recognition to qualified Engineers, Technologists and Technicians across all sectors.

Being registered as a Chartered Engineering Professional will be an external validation of your experience, expertise and practising competence; and is a quality mark to differentiate your professional standing in the following sectors of engineering:

Harnessing a larger pool of resources.

The Energy Market Authority (EMA) has launched Singapore’s DemandSide Flexibility Roadmap and outlined new initiatives for demand side resources to support the needs of Singapore’s power system. Demand flexibility describes the ability of electricity users to adjust their electricity use in response to the needs of the power system, helping to balance electricity supply and demand.

The electricity fuel mix, which is predominantly made up of natural gas today, will see the entry of more solar energy and electricity imports. With consumers adopting more distributed energy resources such as smart electric vehicle (EV) chargers and battery energy storage systems (BESS), EMA envisages that Singapore could develop and tap on a larger pool of demand-side flexibility resources to contribute to the evolving needs of the power system. EMA’s Demand-Side Flexibility Roadmap charts the vision and plans to harness these resources.

Under EMA’s Interruptible Load (IL) Programme, business consumers can adjust their electricity demand to address imbalances in electricity demand and supply, when called upon by the power system operator and, by so doing, help support a more reliable grid. To provide participants with greater certainty over their obligations during such contingency events, EMA plans to reduce each IL activation period to 30 minutes and will update the industry, once the implementation details are finalised.

The current pool of IL resources is opportunistic, reducing their offtake

only when their schedules allow. This is largely due to the operational constraints of IL participants – these are mainly factories or production lines, whose primary focus is to keep their core operations running smoothly, and who are unable to offer IL capacity consistently, for prolonged periods.

There are some electricity users who may deploy distributed energy resources such as BESS and backup generators to support their operations and provide backup power. These resources are typically maintained on standby, placing them in a state of readiness that enables activation with short notice. Their capability to sustain load curtailment over extended periods suggests they could be wellpositioned to provide ancillary services alongside their primary operational role. In addition, there may be some loads with higher or similar availability than conventional IL resources that can be curtailed to address the needs of the power system.

Collectively, these distributed energy resources and highavailability loads represent a potentially dependable and scalable means of contributing to system reserves, with the possibility of enhancing overall grid reliability. Hence, EMA will be publishing a Request for Information to explore the feasibility and design of a programme that can incentivise these distributed energy resources and loads that are highly available to support system reliability on a nearcontinuous basis.

EMA’s Demand Response (DR) programme allows business consumers to reduce their electricity demand when wholesale electricity

prices are high. Recognising the potential of DR to bring benefits to the power system, EMA expanded the DR programme to allow EV charging stations and BESS with nameplate rating below 10 megawatts (MW) to participate in the programme.

EV charging regulatory sandbox

EMA is collaborating with ComfortDelGro on a 13-month regulatory sandbox to pilot the participation of EV charging stations and Environmental Control Systems of the SBS Transit Rail network in the DR programme. ComfortDelGro will leverage its EV Aggregation Platform and intelligent sensing system to automatically adjust energy consumption in response to power system needs.

BESS participation

With BESS being incorporated into a facility’s energy management system, participating business consumers can tap on power stored in their BESS during peak demand periods to reduce their electricity demand from the grid, without affecting day-to-day operations. This gives the system more flexible resources to draw on when needed. EMA currently expects around 15 MW of BESS capacity to enter the DR programme, when ready.

ENERGY MARKET AUTHORITY

The Energy Market Authority (EMA) is a statutory board under the Singapore Ministry of Trade and Industry. Through its work, EMA seeks to build a clean energy future that is resilient, sustainable and competitive. EMA aims to ensure a reliable and secure energy supply, promote effective competition in the energy market and develop a dynamic energy sector in Singapore.

Battery stacking solution and the largest ground-mounted solar project.

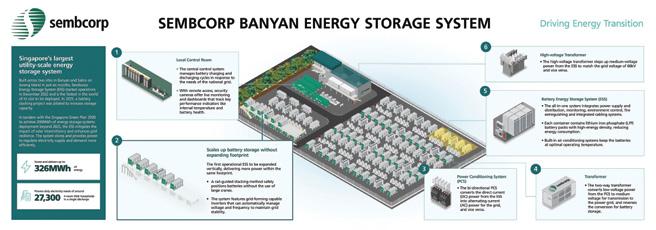

Sembcorp Industries (Sembcorp), Singapore’s leading energy and urban solutions provider, recently unveiled two clean energy projects on Jurong Island.

Scaling up Singapore’s largest utility-scale energy storage system

Sembcorp has successfully piloted a battery stacking solution on land at its existing Jurong Island energy storage system (ESS) facility. This is the first vertical expansion of an operational ESS on the same land area, enabling additional capacity without increasing physical footprint.

Through Sembcorp’s engineering capabilities in scaling infrastructure and leveraging innovative solutions, the company’s ESS capacity has since increased from 285 MWh to 326 MWh.

Building on this success, Sembcorp is exploring further opportunities to deploy battery stacking across other sections of its Jurong Island ESS, reinforcing its leadership in advanced energy storage solutions.

Following the completion of the stacked ESS units, Sembcorp will also partner the Energy Market Authority (EMA) to assess the ESS’s ability to provide inertia. Inertia plays a key role in maintaining grid stability by slowing down sudden changes in electricity frequency during disruptions. While traditionally provided by rotating thermal generators such as combined cycle or open cycle gas turbines, Singapore is now turning to advanced ESS to deliver this stable and responsive alternative, as the nation increases its reliance on solar and electricity imports.

Mr Puah Kok Keong, Chief Executive of EMA, said, “Energy storage plays an important role in enabling Singapore’s energy

transition. In particular, battery energy storage systems (BESS) have the potential to provide a wide range of energy services, including frequency regulation for the power grid. Our collaboration with Sembcorp will allow us to test and understand these new BESS capabilities better. The knowledge and experienced gained will help EMA plan for a grid that is cleaner, smarter and more resilient.”

Singapore’s largest groundmounted solar project

The Sembcorp Jurong Island Solar Farm, with an installed capacity of 118 MWp, is Singapore’s largest ground-mounted solar project to date. Spanning six interim vacant land parcels in an industrial zone, the solar farm generates clean energy, sufficient to power approximately 33,200 four-room HDB flats annually. This project demonstrates

Sembcorp’s ability to leverage the use of vacant land in Singapore, unlocking greater renewable energy potential in support of the Singapore Green Plan 2030.

Mr Koh Chiap Khiong, President & CEO, Gas and Related Services, and CEO, Singapore, Sembcorp Industries, said, “Jurong Island is a cornerstone of Singapore’s industrial ecosystem, and Sembcorp has been a long-standing partner in delivering essential energy solutions here.

As Singapore’s energy landscape evolves, we remain fully committed to supporting the nation’s energy needs. These initiatives demonstrate our ability to integrate and scale clean energy generation and storage technologies, reinforcing a resilient and future-ready energy ecosystem.”

Sembcorp Industries

Sembcorp Industries (Sembcorp) is headquartered in Singapore.

The winning products and technology will be presented at the 2026 AHR Expo which will be held in Las Vegas, in February 2026.

AHR Expo (International AirConditioning, Heating, Refrigerating Exposition) recently announced the winners of the 2026 AHR Expo Innovation Awards.

Winners in 10 industry categories are chosen annually to represent the most innovative products and technologies in the market today.

“The achievement of an Innovation Award winner is a meaningful distinction in HVACR. We are proud to showcase the commitment and recognise the hard work of these manufacturers and their collective teams who are putting in the work, to bring new and inventive solutions to market,” said Show Manager, Mark Stevens.

“The Innovation Awards not only highlight these accomplishments, but also act as a benchmark for excellence, honouring the creativity and dedication shaping our industry's future,” he added.

Each year, the Innovation Awards receive hundreds of submissions from manufacturers putting forward their breakthrough designs for new and ‘never before seen’ solutions or improvements upon existing products and technologies.

Entries are then closely reviewed by a panel of third-party judges, made up of distinguished ASHRAE members. Evaluations are based on overall innovative design, creativity of the product or service offered, product or technology in realworld application, as well as overall potential market impact.

“It is a positive indicator that each year we see more and more manufacturers meeting industry challenges with creativity and innovation. The winning products, along with all the finalists,

demonstrate HVACR’s preparedness to respond to critical demands and challenges, with innovative performance,” continued Stevens.

An exciting added benefit of flourishing innovation driving entries to the Innovation Awards is the ability to strengthen the industry through funding attributed to the AHR Expo Workforce Development programme. The programme, celebrating its fourth year in Vegas, aims to trigger industry growth through experiences geared to inspire future members of the HVACR community.

Funds collected from the entry fees are donated to programming at the student level, including field trips to the show, curated introductions to professionals and manufacturers, equipment for hands-on learning in school laboratories and monetary donations to student programmes in the hosting city.

Winner: Honeywell

Innovation: Honeywell Connected Solutions

Honeywell’s Connected Solutions suite empowers building owners and service providers with cloudbased tools for remote monitoring, predictive maintenance, energy optimisation and asset lifecycle management. These applications streamline operations, reduce costs and enhance sustainability, all through a unified, intuitive platform that transforms traditional building management into a connected, data-driven experience.

Winner: Daikin Applied Americas Inc

Innovation: Magnitude WME-C Quad

Magnitude WME-C Quad is the first dual circuit series counterflow chiller that delivers up to 3,000 tons of capacity using Daikin’s magnetic bearing compressor technology. With four compressors, Daikin’s proven WME oil-free, magnetic bearing technology and missioncritical features like RideThrough and RapidRestore, offer unmatched part-load efficiency, reliability and uptime.

Winner: Copeland

Innovation: Copeland heatingoptimized modulating vapor injection portfolio

The Copeland heating-optimized modulating vapor injection portfolio combines innovative two-stage, tandem and variablespeed compression platforms with enhanced vapour injection (EVI) technologies to deliver maximum flexibility, scalability and performance, in achieving the capacity and efficiency requirements of next-generation commercial heat pumps for hot air and water applications.

INDOOR AIR QUALITY

Winner: Sharp Corporation

Innovation: Airest

Airest is the world's first minisplit heat pump with built-in MERV 14 certified filters. It captures over 99.9% of dust before it enters the unit. With an airflow reach of 43 feet, Airest cools, heats and purifies the air simultaneously, all made possible by its uniquely engineered internal structure.

Winner: IDC Fluid Control

Innovation: LeakStop III

LeakStop III is a fully automated, water leak detection system for homes and small commercial buildings. The system is built to activate an alarm, in the event of a leak detection. When the water flow is continuous and exceeds a preset and programmable maximum value, the system automatically shuts down.

Winner: Copeland

Innovation: Copeland transcritical CO2 scroll compressor with dynamic vapor injection technology

The Copeland transcritical CO2 scroll compressor marks a new era of simplicity, scalability and sustainability for small-footprint, distributed CO2 refrigeration. Featuring dynamic vapour injection (DVI) technology, which enhances efficiency and simplifies design, the transcritical-rated compressor revolutionises CO2 refrigeration system designs and applications in North America.

Winner: Rebar

Innovation: Rebar

Rebar is the first AI-powered takeoff platform built for HVAC. It reads construction plans, identifies mechanical pages, marks equipment and generates accurate takeoffs in minutes - cutting hours of manual work. Purpose-built by industry experts, Rebar helps reps move faster, win more jobs and streamline the entire sales process.

Winner: Blue Frontier

Innovation: BF-DOAS

Blue Frontier’s technology to cool & dehumidify is an evolution away from refrigerants and the vapour compression cycle. It is 300% more efficient than current technologies, contains a dispatchable thermal storage battery and can independently control db and dp, providing superior comfort. The hotter it gets, the more efficient it becomes.

Winner: CSG Compressors (Houston & American Hermetics)

Innovation: SAMMi

SAMMi is an AI-powered HVAC monitoring and dispatch system that detects issues before they cause breakdowns. It autonomously alerts and dispatches technicians, saving time, money and product loss. Easy to install and scalable, SAMMi turns reactive maintenance into smart, seamless prevention.

Winner: ABB Motors and Drives

Innovation: ACH580 Variable Frequency Drives

The ACH580 drive enables seamless control of up to six EC Titanium motors, optimising energy efficiency, reducing installation complexity and lowering total cost of ownership. This intelligent fan array solution delivers high performance and simplified permanent magnet motor management for advanced HVAC applications.

At the show in February, one overall 2026 Product of the Year winner will be announced. This prestigious honour, selected from the 10 category winners, is awarded based on exceptional leadership in HVACR innovation.

“As the industry continues to face workforce challenges alongside rising equipment demand, everchanging regulations and the

need for more innovative solutions, the AHR Expo Innovation Awards will continue to play a critical role in showcasing the pulse of industry advancement. Participation in the Awards – and the distinction of being awarded a win – is a key indicator to the wider industry that your company is leading the way for the future of HVACR,” said Kim Pires, AHR Expo.

AHR Expo is the world’s premier HVACR event, attracting the most comprehensive gathering of industry professionals from around the globe each year. The show provides a unique forum where manufacturers of all sizes and specialities, whether major industry brand or innovative start-up, can come together to share ideas and showcase the future of HVACR technology under one roof.

Since 1930, AHR Expo has remained the industry’s best place for OEMs, engineers, contractors, facility operators, architects, educators and other industry professionals, to explore the latest trends and applications and to cultivate mutually beneficial business relationships.

The 2026 AHR Expo, cosponsored by ASHRAE and AHRI, will be held from 2 to 4 February 2026, in Las Vegas, Nevada, USA. The show will be held concurrently with ASHRAE’s Winter Conference.

AHR Expo is produced and managed by International Exposition Company Inc.

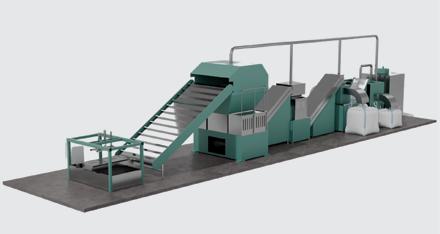

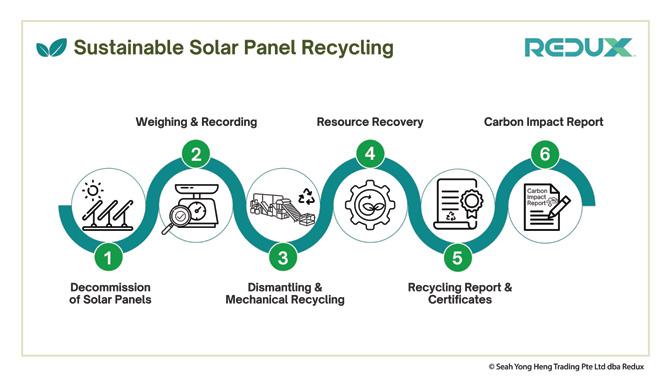

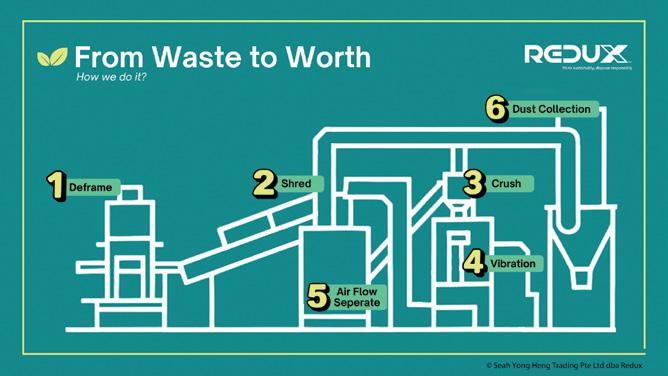

Redux, a Singapore-based recycling company specialising in ewaste, has announced the unveiling of an advanced automated solar panel recycling facility and integrated partnership approach, in anticipation of Singapore’s expected increase in photovoltaic (PV) waste over the next decade.

Redux estimates the percentage of solar panels supplied, that will be decommissioned over the next two years, nationwide, to grow from 138,522 to 143,000 panels a year, which highlights the importance of circular economy solutions in the renewable energy sector.

Globally, solar panels are known to have an efficiency reduction of up to 80%, after around the 25-year mark [1]. However, due to the unavailability of solar panel maintenance services in Singapore, panels here experience efficiency degradation as early as after the 7-year mark. They are then replaced and the old solar panels disposed of, creating a significant disposal market in Singapore and a landfill risk if unmanaged. Other countries continue maintaining their panels for as long as 30 years.

“This is a fledgling industry for Singapore, with gaps in services to ensure truly sustainable solar panel maintenance and

management,” said Jeff Seah, Founder and Business Development Director of Redux.

“As our nation continues to increase our reliance on solar power, we also generate more solar e-waste. As an advocate for sustainability and better e-waste management, Redux sought out solutions to manage this waste holistically. Together with two other local companies, Project SolaREV was created. We envision that this marks the beginning of broader solutions for our industry,” he added.

Project SolaREV is an advanced technology solar e-waste facility and partnership system that aims

to recover, recycle and reuse as much as 96% of each solar panel, significantly reducing PV waste, as opposed to conventional solar panel decommissioning methods.