Full Moscow show preview

P LU S :

• L a t e s t f ro m t h e I W M A

• C o m p a n y a n d p ro d u c t n e w s

• N e w I W M A c o m m i t t e e m e m b e r S t e v e S m i t h

LAST time I was half-way between visits to the wire China and wire India fairs, and this time I’m the half-way man again, putting away the business chats and memories of that wire India event and looking forward to wire Russia in Moscow.

I’m greatly fond of the wire India event: the industry there is full of energy and growth and I always come away from it thinking things are looking forward and upward. At the same time, the warm nights and nation of friendly, sociable people means good times are had by all. I still recall the dancing and making a fool of myself at our Bollywood night at the 2016 wire India (and I’m probably not alone). This year our social event was just as colourful and fun, but I managed to remember I’m not that good a dancer!

Since then we have enjoyed our latest CabWire iteration at Southampton University. And I say “latest iteration” advisedly: this was a rather different event than in previous years, at which engineers and scientists have presented their latest research to likeminded engineers. This one was sponsored by the IWMA Educational Trust and aimed at newcomers to the industry and those wanting a bit of a refresher – I hesitate to add “like me” – on the latest science and technology of cable and wire.

Our report on the successful first CabWire Fundamentals Training event at Southampton University in April. 20

Read the latest news and product developments from member companies. 4 & 22

8

Everything you need to know about this year’s event. Who’s exhibiting? Who’s attending?

A look back at the IWMA’s visit to wire India in Mumbai in the autumn.

We talk to new IWMA committee member Steve Smith about how he sees his new role.

At a series of short, fascinating workshops, some of the leaders of the industry took us through the fundamentals and processes in their particular field, the whole event serving as an introduction to the modern wire and cable industry. It was deliberately kept to around 80 or so delegates and there were very enjoyable visits to the university’s high voltage lab and the wonderful Beaulieu Motor Museum too. The whole thing was a great success. It won’t be our last CabWire of its kind.

And so to Russia: the magnificence of Moscow aside, wire Russia offers some real opportunities to those keen to break into the massive Russian market. As our introduction (page eight) suggests, it hasn’t been easy trading in Russia in past years, but business there is on the rise and wire Russia brings together all the right people. See you there...

Dates for your diary. Our list of the leading industry events coming up. 25

More dates for your diary. The IWMA runs a full calendar of social, educational and networking events throughout the year. Make sure you don’t miss out.

Martin Van Der Zwan Chairman, International Wire & Machinery Association

Through its educational trust fund and travel award scheme, the association actively promotes the learning of new skills and the gaining of greater experience for tomorrow’s talent.

Welcome new members and discover the many benefits of joining is the world's largest and most influential corporate association for the wire and cable industry.

Editorial deadline for next issue: 29 July 2019

All text and illustrations in WCN are copyright protected. Copying contents by any means is forbidden without the publisher’s written consent. The publisher, agents, printers and contributors are not responsible for the accuracy of claims printed or implied in the editorial or advertisements published in this, previous or subsequent editions. The publication in this newsletter of brand names, trade names and trade marks and similar does not imply that these may be used elsewhere. WCN reserves the right to edit, reword and sub-edit all editorial submissions in accordance with editorial policy. Al l matters relating to this disclaimer are governed by English law.

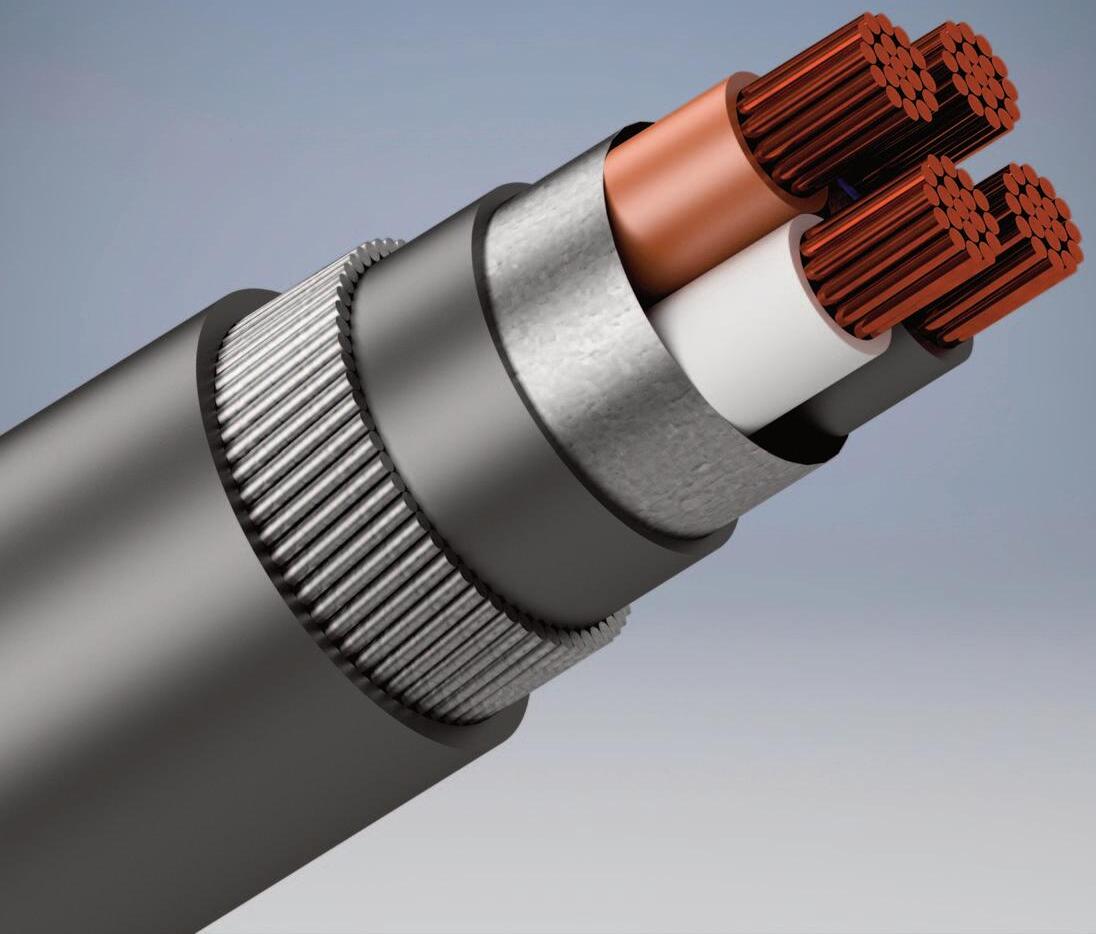

THE introduction of a fully-integrated 3D CAD tool within Cimteq’s CableBuilder environment goes one step further in streamlining the cable design and manufacture process.

Powered by Autodesk Inventor, CableBuilder3D generates 3D models on demand, so teams other than draftsmen can work with the images. CableBuilder3D integrates seamlessly with the CableBuilder design, quotation and manufacturing module, which manages the complete cycle of design, quotation, ordering, production, quality assurance and ERP.

The flexible design environment of CableBuilder3D allows fewer physical and more virtual product iterations, reducing cost and waste.

Switching the drawing of cable to a virtual process frees engineer time to work on activities that have a greater impact on company performance. Three-dimensional models can also quickly be included in production notes, simplifying production team operations.

CableBuilder3D also gives access to a continually up-to-date image library fully within your control, allowing the production of professional marketing imagery. Presentations of 3D designs also give potential customers the ideal view of innovative design, short of physical prototypes.

CableBuilder 3D images can be integrated easily into a company website.

www.cimteq.com

CABLE industry authority and global testing and certification institution BASEC has launched a certification scheme to standardise quality for control cable product ranges – known as YY, SY, CY.

Control cables are found in many industrial and everyday applications across a huge range of industries.

The products in question are flexible, interconnecting and used to measure, control or regulate equipment on assembly or production lines, as well as supporting associated computer units and processes. Until now there has been no agreed standard for such products – making quality standards a hotly-debated topic.

The new BASEC scheme comes from direct demand by manufacturers and

users and offers the industry improved safety levels throughout the supply chain. The scheme is made up of six BASEC specifications: BA1411, BA1413 and BA1415 for PVC composition, and BA1412, BA1414 and BA1416 for LSHF composition.

The scheme is relevant to cable products up to 300/500V, with a maximum conductor operating temperature of 70°C. Standards EN 50525-1 and EN 50565-2, where applicable, will be referenced in conjunction with the control cable scheme document.

BASEC is known within the industry for rigorous certification, factory auditing and testing schemes that improve cable quality and safety.

The new certification offers an all-

inclusive testing programme for this widely-used and barely-regulated range of products.

A rigorous testing regime is undertaken for each product, including electrical tests, construction and dimensional accuracy, material and mechanical insulation and sheath tests and a vertical flame-propagation check.

In 2016, a BASEC specification, BA1200 for single-core, fire-resistant cables was incorporated as a BS standard, BS8592. The company’s long-standing reputation as a leading test and certification provider and technical authority suggests the new standard has similar potential to become a universal marker for such products.

www.basec.org.uk

AJEX & Turner India has produced a range of high-quality trapezoidal wire drawing dies and sector-shaped conductor dies. The company is also willing to modify products with special tooling, to produce dies for shapes such as trolley, oval, trapezoidal, rectangular, square, triangle and other cross sections, plus sector-shaped compacting dies for bunching and stranding lines.

The new dies will be most useful to the wire design and cable manufacturing industries

Dies are made from polycrystalline diamond (PCD), A&J’s vitrified nanocrystalline technology (VNT Nano), tungsten carbide and steel and as with other VNT dies, remain 100% accurate throughout their service life and require no repolishing or recutting, offering reliability, corrosion resistance and longer life

www.ajexturner.com

ATRIO of quality accreditations has helped Alloy Wire International to win £150,000 worth of sales. The employee-owned manufacturer of high-performance nickel alloys, which has bases in Brierley Hill and Yorkshire, UK, has won contracts with customers in the aerospace and oil & gas sectors.

The company claims its recent reapproval to the Aerospace & Defence standard AS9100 (revision D) and the ISO 14001 environmental standard is the chief reason for the contracts, as is being one of the first UK companies to achieve ISO 45001 – a new international health and safety accreditation.

“It’s been a very busy few months, with all the team working hard to make sure we passed audits so we could continue to supply the aerospace sector, and manufacture with as little impact on the environment as possible,” said AWI quality executive Kevin Guest.

AWI’s quality team has been strengthened with the appointment of a new technical specialist to work in testing and final inspection. Gary Whitehouse will help to underpin the company’s quality standards and to offer additional support for increasingly technical customer enquiries.

www.alloywire.com.

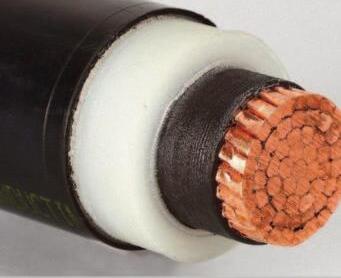

LEADING supplier AEI Cables is highlighting the need for the highest-quality cabling in sprinkler systems in new buildings.

This follows a call in March this year from the Royal Institute of Chartered Surveyors (RICS), the Royal Institute of British Architects (RIBA) and the Chartered Institute of Building (CIOB).

They wanted the British Government to make the installation of sprinklers mandatory in all residential buildings, hotels, hospitals, schools and care homes over 11m tall, as well as when refurbishing such buildings wherever possible.

The call came partly as a result of the tragic Grenfell Tower fire in London in 2017, in which 71 people died.

Graham Turner of AEI said providing continuous power to sprinkler systems is a key component of the issues involved in

improving fire safety: “Buildings such as tower blocks, hospitals and schools, and those areas with large numbers of people moving around, need cabling that will continue to operate in a fire for the highest fire protection of 120 minutes,” he said.

“This ensures fire and rescue services can safely evacuate people and that sprinklers will continue to operate during a fire.”

The Hackitt Review into the Grenfell disaster set out proposals to make tower blocks safer to live in, but stopped short of recommending the mandatory fitting of sprinklers.

New-generation AEI Total Fire Solutions cables ensure critical circuits can continue to

operate for 30min up to two hours, and have BASEC and LPCB approvals covering design, manufacture and supply.

AEI also holds approvals from organisations including Lloyds, the Ministry of Defence and Network Rail and works to international standards worldwide.

www.aeicables.co.uk

MANY Turkish companies have become partners with Russian enterprises, and these make a significant contribution to economic ties between two countries.

One is Turkish company Gurfil, which has made significant advances since it was founded in 1981 – taking it from a small lamination workshop to a modern, hightech supplier of materials and equipment for the manufacture of cable and wire products around the world.

The Russian market is a Gurfil priority, offering high growth potential.

Gurfil’s machines are easy to operate and reliable and work with an expanded range of materials, including aluminium and PET films. Advanced models offer working speeds with spools (cross-wound winding) up to 2,500 rpm and can work with the tape wound in pads or spools.

Machines come with various options, meaning buyers can tailor products according to needs and budget.

www.gurfil.com

LEADING lubricant manufacturer Metalube has seen significant growth for its Rope-Tek™ WRD range of wire rope lubricants in South East Asia. The 50% leap follows the recent use of Rope-Tek WRD in the tethering and towing equipment of an oil rig support vessel in advance of its leaving port for a six-month tour of duty.

Steel wire ropes are complex and subject to tough conditions. Loading and unloading the rope, bending and flexing over sheaves and pulleys creates high-load points where wires and strands cross over each other, sometimes resulting in wear and corrosion and reducing rope life.

Formulated from high-performance base oils and thickeners, Rope-Tek WRD contains an advanced additive system that minimises friction and delivers strong corrosion protection. Metalube global product manager Matthew Buffin said: “We’re delighted by how well our wire rope lubricants have been received in this region. A 50% growth within the offshore industry is a significant achievement. The Thai shipyards is a very exciting project for Metalube.”

l Metalube is also doing wood panel makers some good. Manufacturers complained that the grease used on bearings used on continuous presses would eventually run-off and stain the panelling. Metalube formulated Metalife™, a fully-synthetic lubricant designed to work without degradation at temperatures of around 280 degrees C while also being resistant to acids, alkalis, solvents and other chemicals used in the industry.

INDUCTOTHERM Heating & Welding

Limited has won an Indian order for one of its industry-leading Radyne spring wire lines.

Working with a global wire manufacturer towards a start date in late 2019, the induction-tempered, water-cooled line will process 7mm-14mm spring wire, predominantly for hardened and tempered automotive springs, at around two tonnes an hour.

The line for India – one of 18 currently in use around the world – will offer efficient induction heating and clean waterquenching systems and new induction hardening and tempering lines that will

offer greater specification consistency than the traditional oil-tempered process. Induction offers non-contact instant heating, with no fluidised bed and low maintenance. The instant nature of the heat means no furnace to warm up and cool down, while quenching with water is also more efficient, with no special oils nor fire hazard, and no need to dispose of waste liquid.

Other benefits of the new line include only minor decarburisation – due to the extremely short heating time, minimal grain-growth, the ability to heat-treat exotic alloy steels needing higher temperatures, and in some cases higher tensile

strength, while maintaining full ductility. The heat treatment stage involves heating the wire to around 700°C, then up to the desired hardening temperature before water-quenching at a controlled rate to obtain the correct austenitic structure. Once hardened, the material is tempered back to its final martensitic specification by heating to the correct temperature. The wire is again water-cooled before take-up. The wire finally passes through a product protection stage that applies a protective coating, while a hydraulic shear removes the weld.

www.inductothermhw.com

THE global supply chain for steel, copper and aluminium products is set to gather in Johannesburg for the inaugural Africa Wire, Cable & Tube Conference in November. Wire, cable, tube and pipe products are crucial to many African industries, from mining and power supply to construction.

This first conference, organised by IWMA member CRU, will bring together local stakeholders and international experts to discuss production and trade in these products throughout the continent.

The inaugural conference will be held on 11-13 November 2019 at the Emperor’s Palace, Johannesburg, with Messe Düsseldorf as lead sponsors, and hopes to bring African companies and institutions and international suppliers together. Nicola Coslett, CEO of CRU Events explained: “CRU is a leading authority in wire and cable markets. This important inaugural event is being launched in response to the interest in these rapidly-changing markets.”

Frank Aletter, Deputy CEO of The Southern Africa-German Chamber of Commerce and Industry added: “We are excited to be coorganising this new conference, which will benefit local enterprise as well as establishing a dialogue with international investors. We look forward to helping to build long-lasting rela-

tionships between South African SMEs and their new partners.”

The conference will explore the main impacts on global steel, copper and aluminium wire, cable and tube markets and what this means for Africa. Delegates will also be brought up to date on consumption trends within Africa for these products.

Attendees will also gain insights into the political and investment climate from local experts and international organisations, while investors will also have the chance to assess greenfield and brownfield projects.

In other sessions, industry experts will discuss the latest global technological advances in wire, cable, tube and pipe manufacturing, and how this can be applied to African operations.

www.crugroup.com

BY ANY standard, Russia’s economy is a strange and wonderful thing. The Russian Federation, part of the nine-country Commonwealth of Independent States, covers the world’s largest land mass and is generally believed to have the planet’s greatest oil, gas and gold reserves – not forgetting massive tranches of other muchin-demand minerals.

Russia is also very much at the centre of things globally, a link between Europe and Asia both politically and for trade.

Russia is a full, modern economic nation of over 143 million people, the sixth-largest economy on the planet –but one that has been, by any measure, economically unbalanced.

Almost two-thirds of its annual exports were of fuel and ore, and a large percentage of the rest was of arms and aerospace products.

As a result the economy since Communism suffered less in the worst times,

and more in better times. When the crash came in 2008, Russia’s natural reserves allowed it to weather the financial storms reasonably well, but as the world gradually recovered, Russia roller-coasted along, ironically affected by the lacklustre oil and gas prices on which so much of its economy rests. Russia is currently enjoying a production peak, reflecting the improving price of oil, and unlike many industrial nations, has a small positive balance of trade.

Lack of investment over the decades saw Russia fall to a place in global competitiveness behind India and China. The country’s reliance on commodities led industrial output to decline and industry – the life blood of many European and Asian nations –made up a relatively small percentage of the total Russian economy. Knowing these things, and also that no country as large as Russia can be well run without taking care of the entire nation (rather than just the large cities,

Continued on page 10

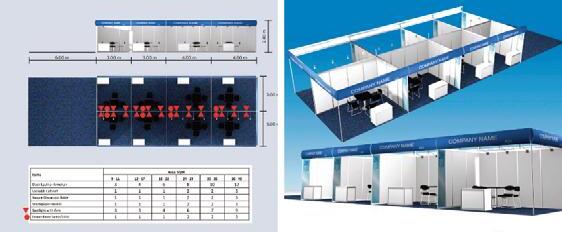

RUSSIA is moving forward. The country is developing and investing heavily. The consumer climate is a guarantee for good business. Trade fairs in Moscow and at other locations in Russia are in greater demand than ever before.

A 20% increase in the size of area rented, over 43,000 exhibitors (one in five of whom are from abroad), two million visitors; figures showing the development of the Russian trade fair market are impressive.

With our trade fairs, Messe sets the tone and shakes up markets. We combine supply and demand in important growth markets – with leading trade fairs that

Continued from page eight

mainly in the west and south) the Russian government embarked on a massive project to improve its national infrastructure and industry, to help reduce poverty and boost economic output. Expectations remain high: government and private partnerships are reckoned to be investing around a trillion dollars by 2030. While railways – for decades the main way across this vast country – still rank highly on the international scale, roads, ports, air transport and electricity supply have all been in need of significant investment and are only now set to receive it, with many projects currently underway and more to come.

Effectively halfway through the investment period, things have already improved greatly. The average wage is up, industrial output is up and GDP is improving steadily, as is private spending on cars and consumer goods.

and international companies have headquarters here, and this is also the location of the Moscow Expocentre, in which wire Russia is held.

As the Russian government gradually replaces its decades-old bureaucratic stranglehold on business with better oversight and project support, there are many openings for companies both domestic and foreign, and virtually every field of infrastructure development, from transport to power transmission to electronics, requires vast quantities of cable and wire.

Expectations remain high: government and private partnerships are reckoned to be investing around a trillion dollars by 2030.

Economic improvement, consumption and government and regional support now make Russia an attractive target for companies who want to make the most of market opportunities.

Our main picture here, for example, shows not the familiar tourist pictures of Moscow – the Kremlin, Red Square and St Basil’s Cathedral –but the modern Moscow a few kilometres away. “Moscow City”, as it is known, is where modern Russian business, financial services and industry are centred. The biggest Russian corporations

The cable and wire industry in Russia has had a better run than most since the 2008 crash. In the readjustment that took place internationally, many European companies won contracts for projects in Russia, and with them went their preferred choice of cable and wire products –though Russia’s biggest producer, Uncomtech, has reasserted its dominance in some areas.

Regardless of this domestic competition, the market for European companies in power transmission, automotive wiring and general usage is potentially very large.

For example, Russia makes only 1.6 million vehicles a year, and has only around 11 cars per thousand of population. The UK, in comparison, has over 40 vehicles per 1,000, for not much more than half Russia's population. So Russia still has a long way to go.

successfully developed on the Rhine. We react to developments in society and have provided specialist trade fairs such as ‘Integration. Life. Society.’, which is focused on the requirements of disabled people, and have brought the fascinating ideas of international fashion designers to Moscow.

Many facets, one aim: to successfully establish the basis for business in the Russian trade fair market. For consumers and companies who are open to innovations from all over the world, for providers who want to take advantage of the opportunities offered to them in the Russian market and for all those seeking continuity and reliability.

Though most companies doing business in Russia tend to look for a local partner to help smooth obstacles, in the past decade Russia has still seen more foreign investment than acknowledged fast-movers India and Brazil. As any student of modern history knows, the USSR loved its five-year economic plans. These days the country works on a longer timescale. Up to 2030, railways are receiving the lion's share of investment, for they remain the easiest way for the majority of people to get around and the cheapest way to move bulk materials in and out.

Highways are the second-greatest investment area – encouraging greater car ownership –while power and utilities have the greatest number of projects.

All this activity will naturally – if the experience of other nations is anything to go by – lead to greater foreign investment and competition with local companies, lower production costs, increased national output and Russian economic progress.

Next year is the 100th anniversary of the first plan for the electrification of the Soviet Union, and we will be at the mid-point of the current, wide-ranging infrastructure plan – which for Russia, and companies doing business with this vast country, can only be a good thing for international trade and industry.

We’re here for you

WHEN you’re at wire Russia, don’t forget the IWMA stand a great place to do business and enjoy refreshments amid the hustle of the event. There are meeting rooms for private meetings with contacts and potential customers, and we’ll have a translator on hand to make conversation easier.

Our other services include free wifi, promotional activity for member companies, business services such as printing and copying, a cloakroom and even credit card facilities. Make sure you visit our stand. We look forward to seeing you in Russia.

Stand: A30 www.iwma.org

ABZ(Shanghai) Smart Technology is based alongside the Huangpu river in Shanghai and manufactures cable-making machinery, principally drawing, bunching, stranding, twisting and rod breakdown machines.

Stand: D19

en.abz-sh.com

The Italian Wire Machinery Manufacturers Association

ACIMAF will be at the show to offer advice and answer questions. The non-profit voluntary association promotes marketing activity aimed at penetrating markets in more profitable geographical regions.

Stand: C51 www.acimaf.com

For over 40 years AESA Cortaillod has pioneeed develoments such as the first balunless automatic measuring equipment for patch cords, connectors and LAN cables and the only instrument capable of performing linear resistance measurement directly on a production line. The company offers full systems covering hardware and software.

Stand: B34

www.aesa-cortaillod.com

August Strecker butt-welding equipment is sold in over 110 countries worldwide. The exhibition team will show visitors how customers are helped through the buying process from choosing the right product to final delivery and commissioning.

Stand: D57 www.strecker-limburg.de

Aymak Makine Mühendislik Hizmetleri San ve Tic

Aymak Makine is one of the biggest cable machinery producers in Turkey.

Certified to ISO EN9001:2008, Aymak

12: Wire & Cable

BWE LTD will be available to discuss new developments in its Conform™, Conklad™ and SheathEx™ technologies at this year’s wire Russia.

Conform and Conklad are well established continuous extrusion technologies in the non-ferrous, cable and tube industries. SheathEx is a new alternative to the ‘seamless’ aluminium sheathing of medium-high voltage cables.

The first SheathEx 400 line will be installed and commissioned later this year.

A new Conklad machine joins the range, enabling small and delicate cores to be sheathed from one alu-

maintains strict control from design to operation and constantly aims to enhance and improve customer satisfaction.

Stand: B31 www.aymakmakine.com

German company Bongard Machines

GmbH & Co KG is a second-generation family business with 58 years of expertise in new machine manufacturing, plus decades of experience in the purchase and sale of used machines.

This includes the design and production of custom machines, the combining of new and used machines and the reconditioning of used machines.

Stand: C31

www.bongard.de

Precision Ltd

CANADIAN company Calmec Precision Ltd has launched the CT2 dual-strip armouring machine (pictured right) for circuit size building wire cables. The CT2 is a double-pad compact machine with 12in traverse-wound strip coils at each end, and will save money on mate-

minium feedstock rod instead of two. The machine will reduce capital and running costs for applications such as AS wire, OPGW, sheathed composite cores, reinforced aluminium wire and solid aluminium conductor.

BWE’s development department continues to offer proving trials and demonstrations for new applications at its headquarters in Ashford, Kent, UK.

A complete range of cold welders and dies for a fast, cost-effective and reliable solution to welding non-ferrous materials from fine wire to round rod will be available to order at the show.

Stand: A47 www.bwe.co.uk

rial and labour costs while doubling production speed to 70 feet per minute. Unlike the larger four-pad, two inch and five inch CT2 machines, the new model doesn’t require a strip rewinding process. The machine is equipped with a four–motor spindle drive synchronous transmission without mechanical gear reducers

or variators. The dual-synchronised tooling assemblies guarantee a centrally-produced cable.

The CT2 is also supplied with a newlydeveloped recipe storage system and a patent-pending slitting tool, which easily removes armour ends from the cable.

Stand: D58 www.calmec.biz

Carl Bechem GmbH

As the oldest German manufacturer of industrial lubricants, Bechem is today one of the leading producers of high-quality special lubricants and metalworking fluids

Meet the Bechem team on the company stand to find out more about the latest range.

Stand: D44 www.bechem.com

Condat Lubrifiants SAS

Condat lubricants work with all materials and offer solutions suited to each surface preparation: phosphated, galvanised and coppered wires, and products with internationally recognised names, such as Vicafil and Steelskin.

Stand: A38

www.condat-lubricants.com

CSM Metalurji Imalat Sanayi

Ve Mühendislik Ltd sti

As well as manufacturing machinery, CSM Metalurji designs and produces machines and process equipment for the steel wire industry, designing high efficiency plants, providing services from production to installation and commissioning to marketing finished products.

Stand: B26

www.csmmetal.com.tr

Sandelin AB will be a co-exhibitor with Maschinenfabrik Niehoff. The company will be promoting its latest lead extruder, which is horizontal, floor-standing and fully automatic, enabling continuous operation for weeks with little or no variation in temperatures and wall thickness or concentricity. The lead wall thickness can be kept to a minimum with corresponding savings in lead. Die blocks cover a range from 6mm-190mm (over lead), and melting pots are available with 10, -18, -35 and 60-tonne capacities. Visitors can also get information on Sandelin’s other equipment, including its cable repair and recovery systemCRRS - which can remove individual layers (such as the outer jacket, lead sheath or triple layer XLPE insulation), without causing any damage to the layer below.

Sandelin also provides upgrades, extensive after-sales service, expertise, experienced technicians and parts.

Stand: D58

www.hfsab.com

With over 60 years of experience, Eder is a worldwide specialist and leader in advanced drawing die-tools, die-processing technology and equipment.

The company’s products encompass wire-drawing dies made from tungsten carbide, natural diamond and synthetic PCD; die-tool processing machines for the repair or production of die tools, and die workshop ancillary equipment.

Stand: C29 www.eder-eng.com

For more than 35 years, EJP Maschinen GmbH has been a partner for tailor-made production systems for the production of

(list correct on 27 May 2019)

wire, bar, tube and profiles. The company will showcase its many installations around the world.

Stand: D51 www.ejpmachines.com

Eurotek manufactures and distributes components for industrial and electronic automation.

The company will be promoting its broad range of products, application knowledge and professional technological services,

Stand: D17

www.eurotek-italy.it

FIB Belgium is a world leader in heat-processing lines for patenting, galvanising, oil tempering and annealing, and bell and pit furnaces. With more than 35 lines in operation in Russia & CIS countries, FIB Belgium is a leading supplier in this market and has an experienced, Russian-speaking staff.

Stand: C65 www.fib.be

The Gauder group will have a team at wire Russia with information on ita hundreds of available machines.

Worldwide leaders in rotating machines for the cable industry, French companies Pourtier and Setic are leaders in their field, offering a wide range of cable twisting and stranding solutions. Chinese group member Daloo makes mediumcost machinery based on European standards. Services companies C2S and Bow Technology, and used-machine dealer Gauder, complete the group.

Stand: B28

www.gaudergroup.com

I.C.E.is a world leader in the design, manufacture and supply of production equipment to the wire Industry.

Continued on page 16

A Karpat Ltd Canada

ABZ (Shanghai) Smart Tech Co Ltd China

ACIMAF Italy

ACOTEQ GmbH Germany

Acuity Products Ltd UK

AESA Cortaillod Switzerland

AFH-Antriebstechnik GmbH Germany

Ajex & Turner Wire Dies Co India

Aleados del Cobre SA Spain

Aliaj Fanar Omid Industrial Co Iran

Alloy Wire International UK

Ambrell Group Netherlands

Anglia Metal Ltd UK

Anushka Wire India

Arcelor Mittal Luxembourg

Associated Engineers & Industrials Ltd India

August Strecker GmbH & Co KG Germany

Australasian Wire Industry Association Australia

Aversion Technologies Europe SL Spain

Aymak Makine Mühendislik Hizmetleri San ve Tic Turkey

Badger Wire Australia

Balloffet SA France

Bar Products & Services Ltd UK

BASEC (British Approvals Service for Cables) UK

BB Spring Technologies SRL Italy

Bonakdar Ind & Com Group Iran

Bongard Machines GmbH & Co KG Germany

Bridon International Ltd UK

British Diamond Wire Die Co Ltd UK

BWE Ltd UK

Cable Tapes UK Ltd UK

Calmec Precision Ltd Canada

Cape Gate (PTY) Ltd South Africa

Carl Bechem GmbH Germany

Ceeco Bartell - Bartell Machinery Systems USA

Cemanco LC USA

Central Wire Industries UK Ltd UK

CeramTec GmbH Germany

Chaplin Bros (Birmingham) Ltd UK

Chemetall Ltd UK

Cimteq Ltd UK

Commission Brokers Inc USA

Condat Ltd France

Consultex SP Zo o Poland

Control and Power Engineering Ltd UK

Copperweld Bimetallics UK Ltd UK

CRU Events UK

CSM Metalurji Imalat Sanayi Ve Muhendislik Ltd STI Turkey

Danross Engineering UK

De Montfort University UK

Deutsches Kupferinstitut Berufsverband EV Germany

DLB Draht und Litzen GmbH Germany

Dongguan XinMei Precision Mold Co Ltd China

Drahtwerk Waidhaus GmbH Germany

DRT Impianti SRL Italy

DSE Test Solutions AS Denmark

Ducab UAE

E Braude (London) Ltd UK

Eder Engineering GmbH Austria

EFD Induction AS Norway

EJP Maschinen GmbH Germany

Er-Bakir Elektrolitik Bakir Mamulleri AS Turkey

Eurobend GmbH Greece

Eurotek SRL Italy

FH Machinery USA

FIB Belgium SA Belgium

Fisk Alloy Conductors BVBA Belgium

FMS Force Measuring Systems AG Switzerland

Fort Wayne Wire Die Inc USA

Foxton Dies Ltd UK

Frontier Composites & Castings Inc Canada

Fuchs Lubricants (UK) PLC UK

G & A Engineering Ltd UK

G Church - Consultant UK

Gauder Group Belgium

Geca-Tapes BV France

Gem Gravure Co Inc USA

GEO Reinigungstechnik GmbH Germany

Golden Technologies Wire & Cable Equipment Co Ltd China

Goodwin Machinery Ltd UK

Guidetti SRL Italy

Gurfil Sanayi VE Elektronik Cih Paz AS Turkey

Gwo-lian Machinery Industry Co Ltd Taiwan

H&R ChemPharm (UK) Ltd UK

H Folke Sandelin AB Sweden

Häfner & Krullmann GmbH Germany

Hans Schmidt & Co GmbH Germany

HB Cables & Components Ltd UK

Heda Industrial Co Ltd China

Heinze & Streng GmbH Germany

Hipo Electrix Science & Technology Co Ltd China

Hoang Hung Long Co Ltd Vietnam

Holton Crest Ltd

Huestis Industrial

Huntstar Trading Ltd

ICE Wire Line Equipment Inc

Inductotherm HW (Radyne)

InnoVites BV

Institute of Spring Technology Ltd

Integer Research Ltd, an Argus Media Company

Interlink Ltd

International Trade Shows Link Ltd

Intras Ltd

Itaya Europe Ltd

JG Tec Ltd

Jiangsu Handing Machinery Co Ltd

Jiangsu Hongtai Stainless Steel Wire Rope Co Ltd

Jina Special Steel Works Pvt Ltd India

Joachim Uhing GmbH & Co. KG Germany

John Binns & Son (Springs) Ltd UK

Kabel.Consult.Ing Germany

Kay Pee Dies India Pvt Ltd India

Kelani Cables PLC Sri Lanka

Key Rate International Co Ltd Taiwan

Kieselstein International GmbH Germany

Knight Precision Wire Ltd

Koner SpA Italy

LA.M.Plast SAS Italy

Lanfang Xinming Cable Machinery Ind Co Ltd China

Lanka Special Steels Ltd Sri Lanka

Lantor BV Netherlands

Leoni Temco Ltd

Lewis Wire Ltd UK

Locton Ltd UK

Lune CHF GmbH Germany

Madem SA Ind E Com de Madeiras Brazil

Maillefer Extrusion Oy Finland

Manentimacchine SRL Italy

Marldon Group Ltd UK

Mathiasen Machinery Inc USA

Medek & Schörner GmbH Austria

Meisenbach GmbH Germany

Metalube Ltd UK

Microdia SA Switzerland

Mikrotek Machines Ltd India

MSS Products Ltd UK

Nanjing Zhongchao New Materials Corporation China

Nano-Diamond America Inc USA

NDC Technologies (Beta LaserMike Products) USA

NeoFil Ltd UK

Nexans Deutschland GmbH Germany

Niehoff Maschinenfabrik GmbH & Co KG Germany

Ningbo Kaite Machinery Co Ltd China

Nota-Zaklad Mechaniki Precyzyjnej Poland

NV Bekaert SA Belgium

OMA SRL Italy

OMA (UK) Ltd UK

Ormiston Wire Ltd UK

P F Consulting UK

Pamica Group Ltd China

Pan Pioneer Co Ltd Taiwan

Peddington Lubricants and Coating Pvt Ltd India

Pentre Group Ltd UK

Permanoid Ltd UK

Pextrusion Ltd UK

Plasmait GmbH Austria

Pneuform Machines Ltd UK

Premier Cables (Pty) Ltd Pakistan

Pressure Welding Machines Ltd UK

Proton Products International Ltd Belgium

Prysmian Group UK

PS Costruzioni Meccaniche SRL Italy

Q8Oils Belgium

QED Wire Lines Inc Canada

Qingfeng Electrical Technology (Hong Kong) Co Ltd Hong Kong

Queins Machines GmbH Germany

Qunye Electrical Co Ltd China

Rautomead Ltd UK

Ravicab Cables Pvt Ltd India

Reb Mech Pvt Ltd Canada

Reber Systematic GmbH Germany

Redies Deutschland GmbH & Co KG Germany

Reelex Packaging Solutions Inc USA

RichardsApex Inc USA

Ridgway Machines Ltd UK

RK Umformtechnik GmbH & Co KG Germany

Roblon AS Denmark

Rollring Industries India

Rosendahl Nextrom GmbH Austria

S K Wiring Products Ltd UK

SACO AEI Polymers UK Ltd UK

Sanxin Wire Die Inc USA

Sarkuysan Elektrolitik Bakir Sanayi ve Tic AS Turkey

Scapa UK Ltd UK

Scott Precision Wire Ltd UK

Shanghai Geili Precision Dies Co Ltd China

Shanghai JNL Industry Ltd China

Shanghai Kechen Wire & Cable Machinery Co Ltd China

Shanghai Singcheer Technology Co Ltd China

SHI Kabel GmbH & Co KG Austria

SI Interline Ltd Russia

Siebe Engineering GmbH & Co KG Germany

Sikora AG Germany

Simplex Rapid SRL Italy

Sinoleader Industries Group Co Ltd China

SKET Verseilmaschinenbau GmbH Germany

Smeets NV SA Belgium

Sneham International India

South African Wire Association South Africa

Southwire USA

Spring Tooling Ltd UK

Stonepark Consultancy Ltd UK

Stride Supplies Ltd UK

Supermac Industries India Ltd India

T Fukase & Co Ltd Japan

TapeFormers Ltd UK

Techna International Ltd UK

Techno Commerce Ltd UK

Technokabel SA Poland

The Worshipful Co of Tin Plate Workers Alias Wire Workers UK

Thompson & Hudson Wire Machinery UK

Tianjin Huayuan Times Metal Products Co Ltd USA

Traxit International GmbH Germany

Troester GmbH & Co KG Germany

U Gear Automatic Machinery Ltd Taiwan

UL International (France) SA France

University of Southampton UK

Uniwire Ltd UK

Untel Kablo AS Turkey

Upcast Oy Finland

Uygar Makina San.Ve Tic Ltd STI Turkey

Vietnam Electric Cable Corp (CADIVI) Vietnam

Vinston US Corp USA

Warbrick International Ltd UK

WCISA c/o Wire Lab Co USA

Weber & Scher Mfg Co Inc USA

Webster & Horsfall Ltd UK

White & Street International Ltd UK

Whitelegg Machines Ltd UK

Windak Group USA

Wintwire Ltd UK

Wire & Cable Technology International USA

Wire & Plastic Machinery Corp USA

Wire Association International Inc USA

Wire Lab Co USA

WOLCO Sp Zo o Poland

WTI Fasteners Ltd UK

XL Technologies UK Ltd UK

Yangzhou Havet Machinery Co Ltd China

YTC America Inc USA

Zumbach Electronic AG Switzerland

IWMA members in Russia...from page 13

I.C.E Wireline will be promoting its wide range of products, including austenitising furnaces, fluid-bed annealing furnaces, fluid-bed quenching furnaces, gas-fired drying ovens, turbo dryers, phosphate and borax coatings, immersion burner galvanising furnaces, top-fired galvanising furnaces, ceramic sinker mechanisms, charcoal wiping systems, gas gravel wiping systems, nitrogen wiping systems, quench tanks, wax tanks and spare parts.

Stand: A44

www.icewireline.com

Intras Ltd

Intras, the world's largest multimedia service company for the wire & cable and tube & pipe industries, will be exhibiting once again at wire Russia. Visit the team to find out more about Intras services.

Stand: B01

www.intras.co.uk

The company’s range includes planetary stranding machines, insulated wire extruders, tape-wrapping machines, wire and cable looping machines, wire extrusion machines, cable extrusion machines, and fibreglass woven silicone rubber wires.

Stand: B66

www.hdxljx.com

Lantor BV

Dutch company Lantor is part of Cathay Investments Limited, a UK holding company for several subsidiaries in chemical distribution and other trading. Lantor, now in its seventh decade, specialises in composite materials and wire and cable waterblocking materials. The

THOUGH it has become more difficult for European companies to make business with customers in Russia in recent years, German wire-drawing machine manufacturer Kieselstein continues to work successfully in this market. This is mainly because of the wide experience and knowhow in wire shaving technology and the product quality that sees the German manufacturer highly regarded worldwide. At wire Russia, Kieselstein will present its latest developments and projects, which will be especially interesting to those looking for wire product quality improvements and greater production efficiency and flexibility. Kieselstein offers ideas that can be implemented as specific, custom solutions for customers dissatisfied with standardised drawing equipment. Besides machines, Kieselstein offers a comprehensive range of services. The company developed its own app,

product range will be on display in Moscow and specialists will be on hand to advise on their many applications. The company’s cable and wire products include waterblocking tapes, non- and semiconductive bedding tapes, flame-retardant tapes and polyester waterblock yarns for water-tightness in power and fibre-optic cables.

Stand: B38

www.lantor.com

Leoni Draht GmbH

Leoni, a global provider of energy and data- management systems for in the automotive and other industries, will be showcasing its latest products and services at wire Russia.

These include its range of Hivocar® products: flexible, temperature-resistant, highvoltage cables for electric and hybrid vehicles power supplies.

Power supply and high-voltage component connection play a special role in electric and hybrid vehicles, and Leoni’s Hivocar products - continually extended with new developments and designs - are specially designed for the role.

Hivocar cables carry the current from the charging socket to the battery and to the

k.connect, which is supplied with new plant. This supports the plant operator during the production process, as well as for maintenance, servicing and spare part purchases. Kieselstein already uses the app in its own assembly process.

Recently, Kieselstein launched a fourstep retrofit programme.

Starting from an audit of the current condition of a plant, the programme recommends retrofit measures then carries these out using companytrained technicians. Cost and time to be taken are transparent to the customer at all times.

Consulting on production optimisation or implementation and support during commissioning and test working complete the company’s range of services.

Stand: C40

www.kieselstein.com

electric motor via the inverter. They serve the internal wiring of the battery array and other high-voltage components, such as air-conditioning compressors and electric heating.

The use of highvoltage cables in electric vehicle systems imposes high demands on the cable’s electrical, mechanical, thermal and chemical properties, as well as on the materials used. Leoni’s Hivocar family meets these demands fully in accordance with the high safety standards and stringent requirements of ISO, SAE, JASO and LV standards.

The cables boast stable and reliable electrical properties and high thermal durability – up to a continuous 200°C with peaks up to 250°C. They are highly electromagnetically compatible and mechanically strong, flexible and abrasion-proof.

Leoni is also working on the development of high-flex, temperature-resistant, sili-

cone-free cable variants that offer the favourable properties of silicone.

The Hivocar range is available in single and multi-core versions, with copper or aluminium conductors, with or without shielding.

A wide variety of designs is possible, according to customer requirements.

Stand: C34

www.leonitemco.com

Maschinenfabrik Niehoff GmbH

NIEHOFF is expanding its activities into larger rotating machines for stranding wires and cables with greater cross sections.

The company has been designing and building rotating machines for the cable industry since the 1960s, typically doubletwist stranding machines of the D and DSI series.

To offer customers larger energy cables, Niehoff began development in 2017 of three further D series machines for spool sizes up to 2000m, as well as rigid stranders. The design of these machines is undertaken by Niehoff engineers in collaboration with their colleagues at Niehoff Stranding Technology SL. The specialists of both teams have extensive experience in the design of rotating machines for cable production.

Until recently, the D series of double twist bunching and stranding machines had seven differently-sized models in righthand or left-hand versions. The new double-twist D-series machines (D1252, D1602and D2002 – D1252 pictured top right) are mainly intended for the manufacture of conductors for energy cables of 6sq mm-500sq mm cross-section. The first machine, the D1252 is a development of the D1251, while the next-larger model, the D1602 is designed for conductors with a 19-wire format. The larger D2002 is for all larger cables. Niehoff is also developing peripheral equipment to match the new models.

Smooth conductor processing is ensured by having all large-diameter pulleys and capstans.

The automatic traverse is equipped with a flange-detection system, so spools are wound perfectly and even at high speeds, spooled wires can be payed-off tanglefree.

Several sensors monitor the quality of the production process.

The design is also optimised by having a

straight conductor path from the secondtwist pulley to the haul-off capstan - enhancing the quality of the wires, which can be compacted by a motorised closing/compacting lubricated die.

The new D-type machines are operated using a network-compatible colour touchscreen monitor known as the Niehoff Machine Interface.

Rigid stranders can be used to make a

wide range of cables – round stranded, round compacted, round with trapezoidal wires, round with Z-shaped wires, straight sector-shaped, pre-spiralled or ACSR conductors.

The machines can also be used for laying up control cables and applying a screening with copper or aluminium wires.

Stand: D58 www.niehoff.de

MAILLEFER will be using wire Russia to showcase its Smart Factory concept and a virtual reality application that allows visitors to simulate various production parameters and set-ups available in Maillefer factories.

There will also be demonstrations of rapid conductor-splicing technology, which provides companies with faster and more reliable conductor splicing compared to conventional technology.

Medek & Schörner’s wire Russia exhibition team will be telling visitors about its high-quality, high-performance cablemarking machines, customer support and high standard of after-sales service. The company manufactures almost all its mechanical, electrical and electronic

Maillefer will also highlight a triplelayer co-extrusion group, designed for processing high-temperature fluoropolymers with physical foaming capability.

The group can produce a variety of LAN, telecom, coaxial, signal and other special cables.

For rubber cable producers, Maillefer will show a new steam process that maximises productivity and cable quality at very low pressure levels.

Stand: B41 www.maillefer.net

components in-house, so is able to respond to customer requirements quickly. The company guarantees unlimited availability of spare parts for all its machines, including older and smaller models.

Stand: C25 www.medek.at

IWMA members in Russia...continued from page 17

The Peddington Group is a market leader in India in the field of wire-drawing lubricants and coating compounds, with state of the art factories in Daman, Dombivli and Khopoli.

The company sells to over 40 countries and has received the Best Supplier award from Tata Steel.

At wire Russia, the company will be promoting its one-stop-shop service, from pre-treatment chemicals to wire-drawing lubricants.

Stand: B21 www.peddingtonlubricants.com

Founded in 1960, PS Costruzioni Meccaniche has developed into a world-leading Company in the design and manufacture of packaging solutions for the wire and cable industry.

Products include automatic coil winding and spooling lines, automatic double take-up machines in tandem with an extruder and rewinding lines.

The company also turns out a line of machinery painted in a bright white finish: “It is appreciated by several customers,” says the company. “White offers a good contrast to safety guards surrounding a line – and gives light and harmony to the working environment...”

Stand: D67 www.pscm.it

German companies Queins and Stolberger have been manufacturing machinery for the last 40 years.

Customers visiting their joint stand at wire Russia will see images of machines delivered to the rope and cable industry. On display, will be all types of high-speed stranding machines, pay-offs/take-ups, taping heads, disc- and belt-type caterpillars and extrusion and sheathing lines. Also on show will be machines for manufacturing continuously transposed conductor strands, umbilicals and steel wire ropes.

Stand: D32 www.queins.com

Reber Systematic GmbH + Co. KG is an expanding and internationally-successful company with a global reputation for its filtration technology.

The company attributes its success to decades of experience and cooperative partnerships.

The company works with customers to develop customised liquid filtration systems for various engineering processes.

The Reber team will be at wire Russia to highlight its work with market leaders in the wire and cable, automotive and supply industry, as well as in the glass and environmental industry which rely on the company’s filtration technology.

Stand: D60

www.resy-filtration.com

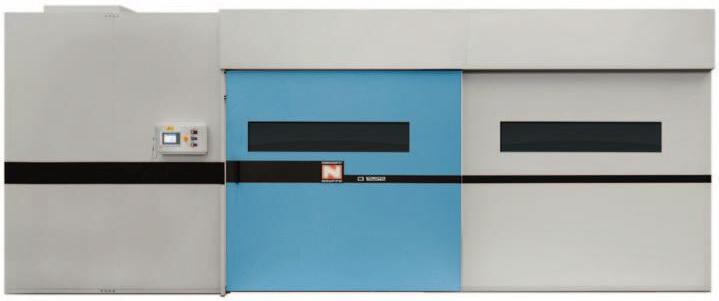

Rosendahl – a business unit of Rosendahl Nextrom GmbH – is the leading global supplier of manufacturing solutions for cable and wire.

The company’s core strengths include extrusion, SZ-stranding, optical fibre and corrugation. The business provides customised solutions and support.

At wire Russia Rosendahl will be showing car technology products, such as this pictured (above) extruder, which uses a polypropylene insulation material to lighten the heavier weight of extra looms and control circuitry in modern self-driving cars.

Stand: C30

www.rosendahlnextrom.com

The company, based in Shanghai, began life 50 years ago as the research and de-

velopment arm of the China Electronics and Technology Group Corporation’s No 23 Research Institute.

Among the company’s products are a dry or micro loose-tube secondary coating line, and a high-speed skin-foam-skin insulation line for Cat 7 signal cables.

Stand: C63 en.kcmachine.com.cn

SI Interline supplies special materials to cable manufacturers in Russia, Kazakhstan, Belorussia and Azerbaijan. The company also distributes and represents global brands such as Lantor, Unigel and DSM Functional Materials, offering a wide range of products to meet the demands of modern cable materials and to serve custom demands. The company carries large stocks of products so can usually supply on demand. Visit the stand for full information.

Stand: B36

www.cableprod.ru

Sikora staff will show wire Russia visitors the company’s latest cable measuring, control, inspection, sorting and analysis technologies.

The newly-launched X-Ray 8000 Advanced will be a highlight of the stand. Sikora’s state of the art, high-speed technology is

tailored to the demands of MV, HV and EHV cable production and as its name suggests, is an advanced alternative to the X-Ray 8000 NXT. The system has 16 sensors and measures the diameter, wall thickness and eccentricity of cables in CV lines at high speeds.

Another attraction will be the 6000 TC preheater (pictured above), for precise preheating of the conductor – reliable preheating during production of highquality cables is essential, to ensure optimal adhesion of insulation to conductor.

Sikora will also present its wide range of measuring systems, including units to measure the diameter and position of the naked and coated fibres, line tension, fibre temperature at hot and cold ends of the tower, coating concentricity and the detection of surface imperfections. The company’s portfolio also contains products for raw plastic material inspection. A system to be shown for the first time is the Purity Concept X, an offline inspection and analysis system based on X-ray technology.

Stand: D43

www.condat-lubricants.com

SKET Verseilmaschinenbau GmbH

SKET designs and manufactures traditional, new and advanced machine systems for cable and wire rope production in over 35 countries.

SKET’s special high-speed tubular stranders and planetary stranding machines are designed for manufacturing long and heavy wire ropes for offshore deep-sea applications.

The company has also developed special planetary stranding machines with backtwist, and vertical stranding machines, for the production of extremely long AC and DC offshore power cables with diameters up to 350mm. SKET staff will be at wire Russia to discuss the company’s latest innovations and product applications.

Stand: D34 www.sketvmb.de

Traxit is one of the largest wire drawinglubricant producers in the world, provides a complete range of lubricants to suit all types of applications. With manufacturing sites in Germany, China and the USA, Traxit lubricants are sold through a network of Traxit companies, agents and representatives in over 150 countries.

Stand: C36 www.traxit.com

Troester GmbH & Co KG is a global manufacturer of complete extrusion systems for the cable industry. At wire Russia the company will present its technology and solutions rubber CV

and CCV lines up to 35 kV, XLPE CCV and VCV lines for power cables up to 500kV, sheathing lines for medium and high voltage cables and insulation lines for LV and MV cables.

X-Compound, a member of the Troester Group, will co-exhibit and present its kneader technology for the continuous compounding of HFFR (LSOH), PVC, XLPE, semi-conductive materials and EPR/EPDM.

Stand: D35 www.troester.de

Upcast is the leading supplier of upward continuous-casting technology across a wide range of applications.

Upcast makes several furnace capacities with various power inductors – smaller unit for lower-capacity jobs and bigger ones for capacities up to 12 tonnes.

Upcast has consolidated sizes over the years to provide a range of furnace sizes for a majority of potential customers.

Stand: A40 www.upcast.com

On the Uygar exhibition stand visitors will be able to see the company’s comprehensive range of machines for cable manufacturing, including extrusion lines and extrusion moulding. The company also offers turnkey projects for various grades of manufacturing.

Stand: A26 www.um.com.tr

Windak will exhibit alongside Lämneå Bruk AB and will present its new packaging products: the QuickPac series of coilers and the MultiPac 360° concept – a collaborative product between Windak Group and Axjo Plastic AB. Information about company spoolers, coilers, rewind

systems, pay-offs, take-ups and accumulators will also be available.

The QuickPac series features high-speed coiling machines (9-12 coils/min) with an exclusive stretch-wrap finish, needing no strappers nor binders.

Also on display will be the space-saving 360° concept: the automatic spool assembly machine MP450_3.0 with Axjo’s MultiPac spools, which are divided in the middle and can be stacked at three times greater density that one-piece spools.

Stand: A51 www.windakgroup.com

Yangzhou Havet Machinery Co Ltd.

Yangzhou Havet makes reels for the cable and wire industry in Yangzhou, China. Products are built to international standards, and the company also offers a design service to customer requirements. The company exports to Europe, South America, North America, Australia, Southeast Asia, the Middle East and Africa. The wire Russia team will be pleased to discuss your requirements.

Stand: A69 www.havet-china.com

Zumbach customers in Moscow will be able to examine the company’s range of measuring and control systems for process monitoring and quality control.

Information will be available on Zumbach’s complete range, including: one-, two- and three-axis Odac® diameter gauges for any cable and wire and any budget. The stand will have new models with special beam geometry, fault detection functions and fast scanning rates.

Zumbach will also show its advanced Odex® non-contact concentricity and diameter gauge for wire extrusion, which uses magnetic and laser technology. Also featured will be new ultrasonic wall thickness and eccentricity scanners of the Umac® series, and advanced high-voltage lump/neckdown detectors with a unique measuring principle and complex optics.

The Zumbach stand will also have data and processing units.

Finally, the busy stand will display the company’s latest Rayex® D series dynamic X-ray measuring and control system for CV lines.

Stand: A63 www.zumbach.com

THIS year’s CabWire was a slightly different but no less successful event than those of previous years. Aimed squarely at newcomers to the cable and wire industry, and those keen to refresh their basic knowledge of various sections of the industry, the IWMA and CabWire organisers took over part of Southampton University in April and eschewed the usual round of technical papers and reports to get right back to basics for a deliberately smaller group – over 80 people – than would normally have visited the “full” CabWire conference.

The result was two days of the very latest information on the industry, on basic industry principles and on the science of wire and cable manufacture – for a group of people who might well form the industry’s core for the next couple of decades.

Opened by IWMA technical committee chairman and Cimteq director Amanda Shehab, day one moved swiftly into a keynote speech by Marcello Del Brunna, CEO of Prysmian UK (pictured, bottom right), which was to play host for a factory tour the following day.

The meat of this year’s event was a series of Fundamentals Workshops by speakers on subjects from cable armouring and fire performance to steel wire drawing, galvanising, induction heating and dies for copper & aluminium drawing.

These short talks – split into ferrous and

non-ferrous sections – were designed to put across fundamental principles of the modern industry (hence the name) in a serious but not too-highly-technical way, to ground newcomers and also to bring highly-experienced participants up to speed on the latest trends in automation and future areas of potential for the industry.

Cimteq CEO Ali Shehab summed up industry progress with his Introduction to Automation Systems – something his company knows a lot about – with references to smart factories and Industry 4.0, and their impact on the business and science of making cable and wire for modern applications in an increasingly technical world.

A highlight of the morning’s ferrous programme was a visit to the university’s Tony Davies High Voltage Laboratory led by lecturer Dr Thomas Andritsch, where delegates watched high-voltage discharge demonstrations.

The second day of the conference included an exclusive tour of the Prysmian factory in nearby Eastleigh, during which delegates were shown the customer centre and telecom and special cables factories.

The two days also brought plenty of opportunities to ask questions and socialise, the former principally during extensive panel sessions with the expert speakers, the latter at a visit to the National Motor Museum at Beaulieu, where delegates had a museum tour and saw the priceless collection of vet-

eran and vintage cars, from Donald Campbell’s record-breaking Bluebird to Chitty Chitty Bang Bang, veteran Formula 1 racing cars and long-retired delivery vans in Harrods and Royal Mail liveries.

Amanda Shehab summed up the two days: “CabWire is one of the highlights of the cable industry calendar, and at the IWMA we consider one of our main functions to be the promotion of industry education and growth.

“CabWire Fundamentals has been the ideal opportunity to share best practice and learn from some of the sector’s leaders.”

THE IWMA says goodbye this issue to former senior members Don Tucker and Terry Robinson. Both were former IWMA chairmen who gave tireless service to the organisation; indeed, Don, (chairman 1980-83), received a special award for 40 years of service in 2010.

Terry Robinson, of XL Technologies UK, served as a board member, chairman (1993-96), treasurer and a member of various sub-committees.

The IWMA sends deepest condolences to their families.

THE Mumbai Convention & Exhibition Centre was home for the seventh time in November 2018 (below) to India’s three major trade exhibitions for the wire and tube industry, wire India, Tube India and Metallurgy India. Around 430 exhibitors from 26 countries, many in national pavilions, exhibited alongside many Indian companies, the total a big jump from the 2016 figure of 310 (itself a healthy increase on 2014). It was another good year for them all, with over 14,600 visitors – up from 12,800 in 2016.

The IWMA was there too, of course, as a major event partner - and one of the association highlights, as in 2016, was the Taste of Bollywood night. Food, Indian beer, a great atmosphere and a chance to try Bollywood dancing (left), proved a big and popular draw!

AFTER two years of product development Ridgway Machines, the world-leading Leicester UK-based taping machine manufacturer, is hard at work building products for customers around the world.

The taping machines currently being manufactured are for a wide variety of applications and are being built to specific customer requirements.

They include a new multi-purpose taping machine that will apply materials such as Kapton, glass and varnish, Daglas and mica to round or flat conductors, and a new-style, high-speed PTFE taping machine that accepts a wide range of cable and conductor sizes.

Also in production are a number of modular high-speed taping machines designed for maximum productivity and increased throughput.

Ridgway Machines sales director Andy Clarke said, “Ridgway has recently moved to a new factory,

invested in the workforce and launched a new website.

“After a couple of years of developing our new range it’s very pleasing to be able to showcase it. The advanced technology on these machines sets them apart; we look forward to welcoming visitors to our factory to demonstrate the hard work we’ve put into these machines.”

Ridgway is keen to demonstrate products at its Leicester factory, by arrangement.

www.ridgwayeng.com

TO ANYONE not in the wire and cable industry, steel rope might seem a relatively ordinary topic for conversation. But not for Steve Smith (right), the 38-year-old metallurgy and testing manager at Bridon-Bekaert’s Doncaster plant, who has just become the latest member of the IWMA’s executive committee.

Steve, from Huddersfield UK, has spent the last 20 years in metallurgy and testing. A decade at Carrington Wire was succeeded by a move to Bridon-Bekaert, where he has risen to the dual role of technical manager and, since it opened in 2012, manager of the group’s technical centre, which carries out research and testing for group facilities worldwide.

“We took over an unused building at the Doncaster factory and had lots of custom test equipment made,” he explained. The result was a unique test and research facility that helps BridonBekaert stay at the forefront of steel rope technology.

Steve is responsible for the day-to-day operations of the lab testing department at the technology centre – known as BBtec – including the testing of samples from all Bridon-Bekaert plants, as well as for research into new products. Taking up a lot of research time at the moment are recently-introduced “hybrid” ropes, which have a wire casing around a synthetic core.

“Outsiders rarely realise the need for so much testing and research,” he explained. “Ropes are subject to all kinds of stresses and work in all kinds of conditions. We need to know how they can best be used and how they shouldn’t be used.”

Steve’s current role is the result of 20 years of experience and expertise, but he didn’t start out that way: “I didn’t want to go to university, and when I was looking round for a job an adviser suggested a technician job at Carrington Wire, so I went along. That was the start of nine years of further education and eventually a first-class degree in metallurgy,” he explained.

“I can honestly say I still love the work after two decades: I enjoy coming to work every day, and it’s always challenging.”

His keenness for training and education encouraged Steve to accept the invitation to join the IWMA board.

“The time when the IWMA was a major source of technical information and research papers is starting to pass, but we have a great direction now in training,” he suggested.

“The CabWire Fundamentals event in April was a chance to pass basic information about the industry to newcomers – I took a couple of apprentices myself – and to expand our general knowledge about a rapidly-changing and increasingly technology-based industry.

“I’m hoping that I will be able to encourage more resources to be put into training: not just the university sponsorship we do now (in fact for BBRG trainee James Bunn), but also for training further down the chain – maybe even modern apprenticeships. We need to encourage the young to enter our industry and become the experts of tomorrow.”

INDUCTION heating specialist

Ambrell Corporation has been recognised as a Manufacturing Leadership Awards winner for an outstanding achievement in Operational Excellence.

In 2018, Ambrell’s operations department undertook a process improvement initiative with the aim of cutting delivery times in half.

“We are honoured to receive this prominent award,” said Tony Mazzullo, President of Ambrell.

It’s the second year running that Ambrell has won at the ML awards – on top of which 2018 was a banner year for the company, which saw rise by 18%.

www.ambrell.com

ROSENDAHL has developed an innovative sensor system for colour measurement in insulation lines.

The SK-400-C is a novel sensor for additional colour monitoring, the main component of which is a PC-based evaluation unit with 360° camera surveillance. The sensor unit is made up of four cameras in a protective stainless steel housing, the interior of which is sealed against the light for stable results.

With a colour space similar to that of the eye, the device recognises main and stripe colours and measures stripe width according to set references. Colour deviations are detected immediately, scrap and waste are significantly reduced, both at the start of the production and during a colour change. Additional steps, such as printing, are easy to integrate.

With a maximum line speed of up to 2500m/min, the system is suitable for high-speed applications and is sufficiently compact to be integrated as a stand-alone unit in new or existing systems.

www.rosendahlnextrom.com

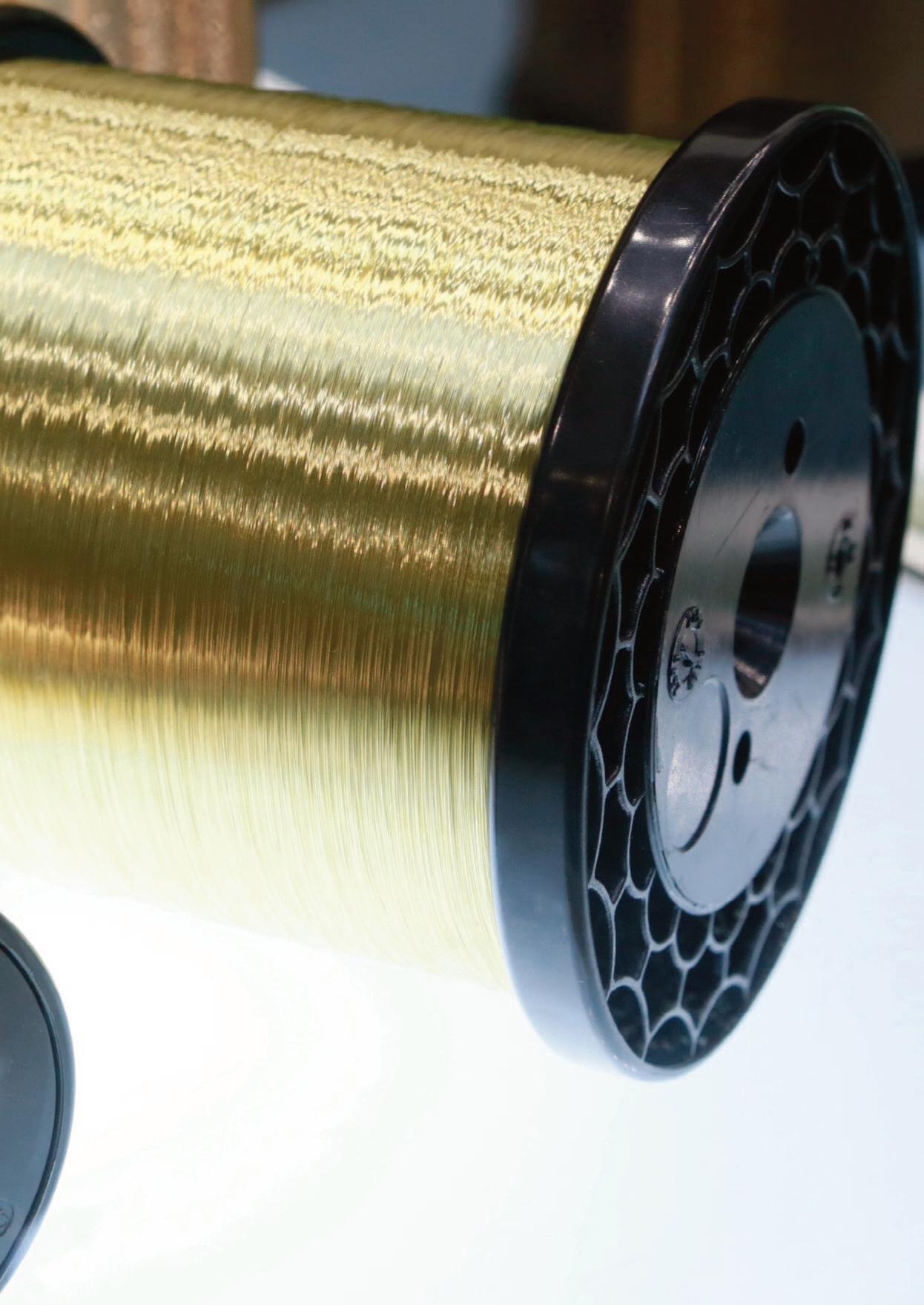

IN THE wire drawing industry, the terms “superfine” and “ultrafine” are commonly used to describe sizes of fine wire. But how do you describe it in your wire-drawing application? And how does wire size relate to life and what you can see?

A human hair is typically 100 microns (μ) in diameter and we, unaided, can see to approximately 50μ.

But in the wire-drawing industry we commonly draw down to typical diameters of 50μ, 22μ, 18μ, 15μ and 10μ for electronic applications,. But 8μ and now 7μ (0.007mm, AWG 60)? That is something quite different...

Synthetic wire-drawing lubricants were developed by our company in the 1980s. We were one of, if not the first, to develop this technology, for magnet wire producers. The use of an oil-free, fully synthetic Wirol wire-drawing lubricant provides exceptional cleanliness and balanced lubrication in the applications of fine and superfine wire-drawing, in all material types, to sizes of less than 15μ.

This application is typically used by speciality wire producers in the fine and super fine industry for electronics, speciality cables and magnet wires. Until recently the smallest size drawn with

Wirol was actually 10μ (0.010mm or AWG 57.5).

Q8Oils’ Germ-Allcard Wirol 2200 is a new-technology fully-synthetic, highlubricity drawing lubricant capable of drawing the finest wire and at the finest quality.

Wirol 2200 can draw various alloys to sizes of 7μ, (0.007mm or AWG 60) and is developed to provide more than 15% extra lubricity for challenging material types in the applications of superfine wire drawing. Typical material types include copper, aluminium, tin plate, silver plate, nickel plate, precious metals, pure

Stuart Duff, Business Development Manager of Metal Manufacturing Products at Q8Oils, talks about the company’s latest product

nickel, nickel chrome and speciality materials.

Over the years the demands of fine and superfine drawing specialists have increased: cleaner wire, enhanced die life, faster drawing speeds, improved surface finish, different material types – Q8Oils consistently meets and exceeds all the technical challenges with its synthetic Wirol products. Wirol 2200, Wirol 2150, Wirol 2020 and Wirol 2000LFG meet users’ demands. Interconnectivity, as well as Industry 4.0, can also be achieved by using our speciality fullysynthetic drawing lubricants.

Our Germ-Allcard Priamus and Wirol range of rod, intermediate, multiwire, fine and superfine wire-drawing lubricants are sold to customers in over 90 countries in all parts of the world. The products provide long life, high lubrication and balanced cleanliness for all applications and are compliant with Restriction of Hazardous Substances (RoHS) requirements. www.q8oils.com

SIKORA claims “maximum performance’ for its latest cable measurement system.

The X-Ray 6000 Pro offers cable quality control directly in the extrusion line within milliseconds. An X-ray image of the product is generated showing all its measured values, in cluding diameter, ovality, wall thickness and ec centricity, all shown on the monitor of processor system Ecocontrol 6000.

The X-RAY 6000 Pro is the measure ment system for multilayered products, and works alongside the Ecocontrol 6000, a display and control system with a 22” monitor that shows measured values numerically and graphically. Wall thickness is shown at eight points around the cable circumference. An intelligent evaluation model also determines minimum wall thickness.

X-RAY 6000 PRO with ECOCONTROL 6000 processor system

The physical model enables visualisation of wall thickness at any position over the total circumference of the cable: as an alternative to the standard display of eight values it might visualise 12 or more. The operator selects the number of point and their position.

The processor system is also used for automatic control of line speed, so can offer better overall quality and production performance. Sikora also produces the X-RAY 6000, which focuses on singlelayer products with data displayed on an integrated 7” monitor at four points.

In combination with an ECOCONTROL 6000, 1000 or 600 processor system, a line control regarding line speed or extruder rpm can also be realised.

www.sikora.net

Basic visualisation at the ECOCONTROL 6000 with eight measured values

wire Russia

18-20 June

EXPOCENTRE Exhibition Centre

Moscow, Russia

Tel: +49 211 4560 7725

Email: AhernsG@messe-duesseldorf.de Website: www.wire-russia.com

wire Southeast Asia

18-20 September

BITEC, Bangkok, Thailand

Tel: +65 6332 9642

Email: beattrice@mda.com.sg Website: www.wire-southeastasia.com

wire South America

1-3 October

São Paulo Expo, Brazil

Tel: +49 211 4560 478

Email: BagciC@messe-duesseldorf.de Website: www.wire-south-america.com

wire Düsseldorf

30 March-3 April

Messe Düsseldorf GmbH Düsseldorf, Germany

Tel: + 49 211 4560 478

Email: BagciC@messe-duesseldorf.de Website: www.wire.de

wire China

23-26 September

SNIEC Shanghai, China

Tel: + 49 211 4560 579

Email: MuellersM@messe-duesseldorf.de

Website: www.wirechina.net

wire India

23-25 November

Bombay Convention & Exhibition Centre

Mumbai, India

Tel: +49 211 4560 579

Email:muellersm@messe-duesseldorf.de Website: www.wire-india.com

Founded in 1970, the IWMA is the world's largest and most influential corporate association for the wire and cable industry.

THE association promotes new technology, education and industry growth through events, conferences and publicity opportunities. These offer an international forum for technological advance and best practice for IWMA members.

Membership offers companies an international platform for the exchange of technology, regular, focused meeting places

THROUGH its educational trust fund and travel award scheme, the IWMA actively promotes the learning of new skills and the gaining of greater experience for tomorrow’s talent, whether the skills are in engineering, management or some related field. Our successful CabWire Fundamentals workshops (see event report, page 20) are aimed precisely at that objective.

The association has always taken a keen interest in helping young people in the industry. The IWMA Educational Trust scholarship programme exists to provide funding to train individuals supported by member companies, and applications can be made through the IWMA website at any time.

The IWMA Educational Trust reviews each application on its merit, before awarding whatever amount it feels will help applicants to achieve their aims

So whether a member company is planning to recruit an apprentice,

supporting an apprentice keen to learn in night classes or a block course, or one trying to achieve higher specialist qualifications, funds could be available from the IWMA Educational Trust to help with the cost. Another IWMAET facility is the travel award scheme, through which we give young newcomers to the industry the chance to attend major events such as the wire Düsseldorf exhibition and CabWire technical conference and Fundamentals workshops by contributing towards their travel costs. Successful applicants get to learn about the latest innovations and meet influential people.

The IWMA has excellent links with universities such as Southampton and De Montfort in Leicester to support education with research papers or training p lacements, for example We are here to help our members by assisting in the training of the next generation of professionals. Wherever possible we will give support.

www.iwma.org/education

for the industry, as well as superb reference sources from a library of past technical conference papers.

The IWMA attends the biggest international exhibitions with a prominent stand that provides support for members exhibiting or just visiting each event.

The stand has been extensively redesigned to provide more and better facilities for members, and offers a range of business services, from private meeting space and printing to internet access and refreshments.

Whether members want to use a private room in which to meet customers and talk business, or just catch up with colleagues over a beer, the stand’s facilities are freely available.

As well as exhibition business facilities, the IWMA also organises networking events for members attending exhibitions, which are always very well attended.

Our friendly stand team is available at exhibitions to help members sort out any problems.

The association offers a great network when members are overseas, and can also help with hotels, transport and other elements of international trade.