THE OFFICIAL IWMA WIRE AND CABLE MEMBER

JANUARY 2026

/ The Road to wire Düsseldorf 2026

/ IWMA Events, Networking & Key Dates for the Year Ahead / Global Markets, Technology & Industry Insight for 2026 NETWORK / INNOVATE / DISCOVER

4 – 6

THE OFFICIAL IWMA WIRE AND CABLE MEMBER

JANUARY 2026

/ The Road to wire Düsseldorf 2026

/ IWMA Events, Networking & Key Dates for the Year Ahead / Global Markets, Technology & Industry Insight for 2026 NETWORK / INNOVATE / DISCOVER

4 – 6

In-Line Profile Measurement Device for Measuring Contours and Dimensions on Cold Profiles of All Kinds

Benefits:

Real-time monitoring of complex profiles providing dimensional, shape and angular measurement and cross-sectional display

Ideal for measuring Sector Cables, Profiled Metallic Wires & Rods, Medical Profiles, Door Lock Extrusion, Overhead Rail Power Conductors and more

Faster start-up times and increased Cpk thanks to improved process control

Improves product quality and reduces costs by minimizing material waste

Detects problems at an early stage

Profile measuring solutions with global references

As we welcome the first edition of IWMA Insider for 2026, I’m very pleased to share with you that this year promises to be one of the most important, active and opportunity-filled years in IWMA’s history. With five editions of Insider planned for this year, there will be more visibility, more member promotion and more opportunities than ever before for you to use IWMA as a powerful platform for your business.

This first edition rightly focuses on the highly anticipated wire Düsseldorf exhibition in April, a defining moment in our industry calendar. IWMA will once again proudly support this exceptional event together with our respected partner, Messe Düsseldorf. We look forward to seeing so many of our members showcase innovation, technology, capability and leadership on the world stage. Düsseldorf is not only a trade fair – it’s a global meeting point for strategy, partnerships and the future direction of our industry, and IWMA is proud to stand firmly in the centre of it.

Alongside Düsseldorf, IWMA will also support wire China and wire India this year, continuing our commitment to strengthening international collaboration and supporting members in major global markets. At each of these exhibitions, IWMA will once again host dedicated networking events, building on the great success of the last two years, where hundreds of members have joined together to exchange knowledge, build relationships and do real business. These gatherings are now an expected and valued part of the IWMA exhibition experience, and we look forward to welcoming you again throughout 2026.

This is also a year where the global political and economic landscape will continue to shape our industry. Ongoing geopolitical tensions, evolving trade rules,

regional industrial policy and shifting supply chains are driving important changes in where and how cable is manufactured, supplied and invested in. We see China continuing to lean on cable exports as domestic construction remains subdued, while in the United States, tariff frameworks and reshoring trends are already encouraging a rebalancing of production and new manufacturing decisions. At the same time, the rapid expansion of data centre infrastructure worldwide is creating unprecedented demand for both metallic and optical cable, supported by trends in electrification, digitalisation, energy transition and grid strengthening. Europe, meanwhile, faces consolidation pressures in optical markets, while innovation in areas such as hollow-core fibre signals the forward momentum of our technology base. In short, 2026 will be a year of adjustment, opportunity and strategic positioning, and IWMA will be here to help our members navigate, connect and respond.

Our wider calendar is also busier than ever. I am delighted to share that our first major event of the year, the IWMA Industry Lunch at Silverstone, has completely sold out. This clearly demonstrates that our members truly value coming together, speaking together and moving the industry forward together. In addition, IWMA will proudly launch our new Training Fundamentals programme this year. These events will bring practical learning, shared knowledge and real industry expertise together in an accessible and modern format. Training, development and knowledge sharing remain key parts of IWMA’s mission, and we are excited to take another strong step forward in this area.

With five editions of IWMA Insider this year, our members have more opportunities than ever before for free editorial exposure, storytelling, thought leadership and company promotion, alongside excellent advertising opportunities for those wishing to elevate visibility further. Insider continues to grow in reach, reputation and influence, and it belongs to you, our members. I encourage you to make full use of it.

More importantly, I encourage every member to truly use their membership. Be active. Be visible. Join us at events. Work with us at exhibitions. Share your news and your ambitions with us. IWMA stands at the centre of the global wire and cable community – connecting businesses, strengthening relationships, opening doors and helping our industry move forward. When you engage with IWMA, your business stands stronger within this community.

Finally, I would like to sincerely thank all members who recently completed the IWMA Membership Survey. Your feedback is extremely important to us. The findings will be formally presented to our Executive Management Committee in February, and we will continue to work hard to respond to your comments, improve our services and push forward the developments you have told us matter most. IWMA exists to support you, represent you and provide value to your business. We are here for you – and we encourage you to grow with us.

I wish you a highly successful start to the year, and I look forward to meeting many of you in Düsseldorf, Shanghai, Mumbai and around the world.

With warm

regards,

Willibert Dautzenberg Chairman, IWMA

Tel : +44 ( 0)1594 820100

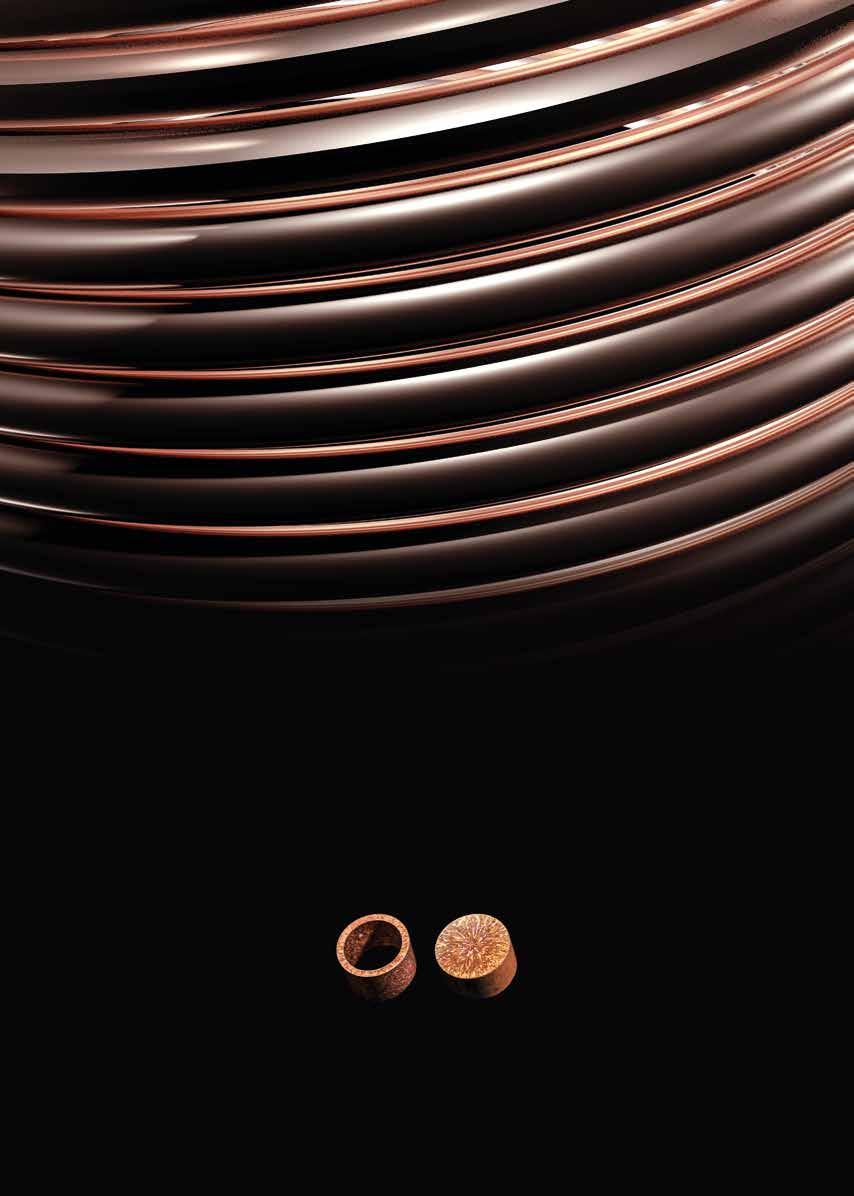

Nickel Plated copper

Up to 27%

Silver Plated copper

Tin Plated copper

Copper

Cu-ETP

Cu-OF

Cu-OFE

Copper-based Alloys

CuMg

CuSn

CuAg

CuNi

CuZn

High strength Cu alloys

Resistance wires for heating

Speciality alloys on request

MIXED /COMPOSITE

CONDUCTORS

combining material types for tailor made properties

INDUSTRY LUNCH UK

IWMA Industry Networking Lunch UK | Silverstone, UK

Thursday 19 February 2026

DÜSSELDORF

wire Düsseldorf Networking Event | Düsseldorf, Germany

Tuesday 14 April 2026

TRAINING FUNDAMENTALS

IWMA Training Fundamentals | TBC

TBC June 2026

GOLF AND SUMMER SOCIAL

IWMA Golf Day and Summer Social | Cheshire, UK

Thursday 2 July 2026

wire China Networking Event | Shanghai, China

Wednesday 23 September 2026 CHINA

TRAINING FUNDAMENTALS

IWMA Training Fundamentals | TBC

TBC October 2026

wire India Networking Event | Mumbai, India

Tuesday 1 December 2026

INDIA

The IWMA is delighted to confirm that the 2026 Industry Networking Lunch at the Silverstone Museum has officially sold out, with demand exceeding capacity and a waitlist now in place. Set within one of the UK’s most iconic venues, this year’s event has captured the imagination of members, reinforcing the growing appetite for high-quality, in-person networking experiences in distinctive and memorable locations.

Set within the legendary home of British motorsport, the Silverstone Museum offers a truly unique backdrop where innovation meets heritage. Attendees will enjoy a day of connection, conversation, and industry insight, complemented by a full museum tour. Lunch will be served overlooking part of the world-famous Formula One circuit and the brand-new Silverstone karting track, where many future racing stars will begin their careers. For dedicated motorsport fans,

exclusive access to a viewing platform will provide even more impressive track views.

The lunch will feature two industry speakers, bringing together strategic market insight and lessons from elite performance environments.

Sebastian Sheppard is an engineering leader with extensive experience in Formula One, a former Engineering Manager at Alpine F1, and a former Royal Navy helicopter pilot. Drawing on real-world stories from both motorsport and military service, Sebastian will explore how data-driven decision-making, speed of execution and risk management in high-pressure environments can be applied to the wire and cable industry. His session will focus on how lessons learned in Formula One and the Royal Navy can help shape leadership, operational performance, and decision-making on the factory floor.

Attendees will also hear from Chi Lee, based in CRU’s London office, who will provide a market outlook for the wire and cable industry. Chi will highlight key global trends, shifting regional dynamics and the

wider economic and political factors influencing the industry, offering delegates a forward-looking view of the challenges and opportunities ahead.

The popularity of this event builds on the momentum of previous IWMA Industry Networking Lunches held at distinctive venues, including the Concorde Conference Centre in the UK and Dr. Thompson’s Seifenfabrik in Germany. IWMA aims to set the benchmark for industry networking events by choosing locations that people genuinely remember, creating experiences that spark conversation long after the day itself. Great events stay with you. Another hotel ballroom rarely does.

With only 100 places available, demand for the 2026 lunch has been exceptional. Members who were unable to secure a ticket are encouraged to join the waitlist by contacting olivia@iwma.or g.

We look forward to welcoming guests to what promises to be an inspiring and memorable Industry Networking Lunch.

As part of a recent effort to give back within the local community, we were pleased to support Rugeley Foodbank, a Trussell Trust foodbank nearby to the IWMA office in Staffordshire, during the recent festive period, helping to provide essential items to individuals and families in need.

The Christmas season can be a particularly challenging time for many, with increased financial pressures and a higher demand for necessities. Rugeley Foodbank, like many other foodbanks across the

UK, experiences increased demand during this period, making additional support especially important.

In response, IWMA provided a donation to enable members of our office team to purchase essential items, which were then delivered directly to the foodbank in support of its vital work within the local community.

Foodbanks play a vital role in supporting vulnerable people throughout the year, and initiatives such as this help ensure that

essential supplies reach those who need them most.

This small contribution reflects IWMA’s wider commitment to supporting local communities and making a positive impact beyond the industry.

Find out how you can support a Trussell Trust food bank in your area at: www.trussell.org.uk

There is no exhibition quite like wire Düsseldorf. Every few years, it brings the global wire and cable industry together in one place, creating an unrivalled environment for business, innovation and connection. And when the exhibition halls close on Tuesday evening, the networking is only just getting started.

On Tuesday 14 April, the IWMA will host what has become one of the most anticipated events in the industry calendar: our exclusive IWMA Members’ Networking Evening, taking place straight after the exhibition closes.

Designed exclusively for IWMA members who are exhibiting at or visiting wire Düsseldorf, this is the

perfect opportunity to step away from the intensity of the show floor and enjoy an evening dedicated to genuine connection. No appointments, no presentations – just great conversations with colleagues, peers, suppliers, clients and friends from across the global industry.

tickets for team members via the IWMA website, ensuring your wider team can also be part of the evening.

After a full day of meetings, this event offers the ideal moment to unwind, reflect on the day’s discussions and strengthen relationships in a relaxed and sociable setting. It’s where longstanding partnerships are renewed, new opportunities are discovered and the true spirit of the wire and cable community comes to life.

Members will receive an allocation of complimentary tickets, with the opportunity to purchase additional

We look forward to welcoming you to an evening that celebrates not just the world’s leading wire and cable exhibition, but the people, partnerships and connections that drive our industry forward.

Further details will be shared soon, but for now, make sure that Tuesday 14 April is firmly marked in your wire Düsseldorf diary.

ROEX extruders are high-performance machines for cable insulation and jacketing. They are equipped with an innovative motor drive concept and can be customized to suit your specific requirements.

Choose the latest extruder technology for your next project and benefit from:

• High flexibility for different materials

• Consistent linear and high output

• Minimized energy consumption

Gone are the days of boring fundamentals events, where learning meant sitting in a room from start to finish, watching slides on a screen and counting down to the next coffee break. With Training Fundamentals, IWMA is introducing a new way of delivering core industry knowledge – combining structured learning, handson experience and valuable networking opportunities.

The concept behind Training Fundamentals is simple: take key areas of the wire and cable industry and give each one a full day to itself. Each event will focus on a specific topic area – for example, “Wire Rope Manufacture and Application Fundamentals”, “Nonferrous Wire Drawing and Stranding Fundamentals”, “Ferrous Wire Rod Fundamentals” and many more –allowing delegates to fully immerse themselves in that subject rather than skimming across multiple themes.

Each event is dedicated to a single area of the industry, such as nonferrous wire drawing and stranding,

taking delegates back to basics and working through the full range of core topics within that discipline. It supports both experienced professionals seeking a refresher and those moving into a new technical area.

But this isn’t confined to the classroom. One of the most exciting elements of the scheme is the chance to see theory brought to life. Delegates will spend the morning learning and then head into the factory environment for tours hosted by IWMA member companies –turning knowledge into something you can see, hear and experience first-hand.

To ensure Training Fundamentals is accessible to as many people as possible, the events will also offer a hybrid attendance option.

Those unable to attend in person will be able to join remotely from their home or office, ensuring they can still benefit from the learning experience.

Following each Training Fundamentals event, delegates will be invited to complete a short questionnaire. Upon completion, they will receive a certificate confirming their participation, which can be shared with employers as evidence of professional development.

And because learning doesn’t stop when the sessions end, every Training Fundamentals event includes an evening networking gathering as part of the ticket price. It’s the perfect chance to relax, continue conversations from the day and connect with peers from across the industry.

The first two Training Fundamentals events will launch in early 2026, and this is just the beginning. We’re excited to build on this new format, breathe fresh life into a longstanding event and create training experiences that are practical, engaging and genuinely valuable for the wire and cable industry.

Voge Composites LLC, based in Atlanta, GA, manufactures high-quality carbon fibre buncher bows for wire and cable machines. Founded in 2009 by Douglas Voge, the company quickly grew into a global leader, serving customers across the USA and in 10 countries worldwide. Built on a redesigned manufacturing process and advanced materials, Voge products deliver superior performance, durability and consistency, using 100% carbon fibre with no fillers. The company also provides custom solutions for unique or older equipment, supported by lean manufacturing, quick lead times and expert service, ensuring customers achieve the best results in wire and cable production.

www.vogecomposites.com

BHAG Digital provides specialised AIdriven Industry 4.0 solutions tailored to wire, cable and fibre-optic manufacturers across the Middle East, Africa and Europe. Their offerings help transform cablefactory processes into transparent, smart operations, improving efficiency, reducing costs and boosting profitability. BHAG supports manufacturers by deploying software and hardware systems that optimise production, quality control and data visibility across the manufacturing chain. Through these solutions, BHAG enables clients to evolve from opaque ‘blackbox’ operations to intelligent, data-enabled factories suited for modern wire and cable production.

www.bhag.digital

M/S Siddhi Technoshrink Pvt. Ltd. started in 2019 as an expansion of Siddhivinayak Industries, specialising in manufacturing cable accessories for the wire and cable industry. The company is ISO 9001:2015 certified and counts major cable brands like Polycab, KEI, Dynamic and Apar among its clients. Their flagship product, the Siddhi End Cap, is a heat-shrink cable end cap made from cross-linked polyolefin. A hot-melt adhesive lining ensures permanent sealing even on irregular cable jacket types, including XLPE, PVC, PILC or rubber sheaths. The end caps meet IP68 ingress protection standards. Beyond end caps, Siddhi Technoshrink supports wire and cable manufacturers by supplying accessories that enhance cable reliability and longevity, especially in demanding environmental conditions. Their products are engineered to withstand weathering, moisture and contamination, while maintaining compatibility with the most common jacket materials used in cable production.

www.siddhishrink.com

RNJ Polymer is a leading provider of highquality polymer solutions specifically designed for the wire and cable industry. With a strong focus on innovation, reliability and customer satisfaction, the company has become a trusted partner for cable manufacturers. RNJ Polymer’s products are engineered to meet the demanding requirements of modern wire and cable applications. Committed to excellence and continuous improvement, the company ensures its solutions not only meet but exceed industry standards.

Frekans Makina Industry and Trade Inc., established in 2008 after operating within Vega Automation since 2004, specialises in the design and production of advanced cable manufacturing machinery. With expertise in turnkey cable factories, wire machines and custom engineering solutions, the company has become a trusted partner to the wire and cable industry. Supported by in-house CNC capabilities and a strong focus on R&D, Frekans Makina has developed six patented products and continues to pioneer innovations, including machinery first produced in Turkey. ISO 9001 certified, the company is dedicated to delivering high-performance, reliable and efficient wire and cable production solutions.

FD Machinery, with over 35 years of expertise, is a leading manufacturer of equipment for tube, pipe and cable production. From its 30,000m² facility, including a 17,000m² plant and a 300×24m testing workshop, the company provides complete solutions for welding, forming and finishing lines. Both cold and hot trial runs can be conducted in-house, ensuring equipment reliability before delivery. Backed by more than 180 employees, including 60 R&D specialists, FD Machinery combines innovation with precision engineering to serve wire and cable manufacturers worldwide, delivering machinery that enhances efficiency, consistency and long-term performance.

www.rnjpolymer.com

www.frekansmakina.com.tr

www.fdmachinery.cn

wire Düsseldorf 13 – 17 April 2026

wire China 21 – 24 September 2026

wire Mexico

23 – 25 February 2027

wire Middle East Africa

6 – 8 September 2027

wire Eurasia

28 April –1 May 2027

wire India

30 November –2 December 2026

Interwire, Atlanta, USA 4 – 6 May 2027

wire Southeast Asia 15 – 17 September 2027

IWMA is a proud wire industry partner of

international trade fair organiser Messe Düsseldorf GmbH, supporting the following exhibitions:

In the November 2025 edition of IWMA Insider, our “The Countdown Is On” feature marked the start of the industry’s journey towards wire Düsseldorf 2026. Now, with just three months to go, that countdown is well and truly gathering pace as plans turn into travel bookings, stand builds and packed diaries.

From 13–17 April 2026, Düsseldorf will once again become the global meeting place for the wire and cable industry, welcoming decisionmakers, engineers, buyers and investors from across the wire, cable, metal, automotive, construction and electronics sectors. Over five days, the exhibition will showcase innovation, technology and technical exchange across the entire production chain, from machinery and raw materials to finished products. This edition is especially significant, marking 40 years since wire first moved to Düsseldorf. What began in 1986 with fewer than 500 exhibitors has grown into one of the world’s most important industry exhibitions, now spanning more than 120,000 square metres and running alongside Tube.

Across the halls, wire Düsseldorf 2026 will showcase innovation at every level of the production chain, from intelligent manufacturing and automation to sustainability and the technologies driving the global energy transition. New and returning feature areas, including World of Cables, will place finished wire and cable products firmly in the spotlight, underlining their vital role across infrastructure, energy, mobility, and digitalisation.

For those planning their visit, a full hall plan and exhibitor list is available at www.wire-tradefair.com , which is continually updated as the show

approaches. IWMA members can also find a dedicated directory of IWMA member exhibitors on pages 16 & 17 of this magazine, making it easy to plan meetings and identify fellow members exhibiting at the show. Visitor tickets are now on sale via www.wire-tradefair.com , and early booking is recommended as demand builds.

For IWMA members, wire Düsseldorf is about far more than the exhibition halls alone. Once again, IWMA will be at the heart of the show in Hall 11, D22, offering a welcoming and practical base throughout the week. The IWMA stand will provide a central meeting point for members and guests, with space to hold discussions through our pre-bookable meeting slots, catch up with industry colleagues, access Wi-Fi and refreshments, and pick up IWMA publications and information. It is designed to be your industry home in Düsseldorf – somewhere to pause, connect and make the most of the week.

A major highlight of the week will be the IWMA Member Networking Event on Tuesday 14 April, where members can unwind and reconnect with industry colleagues. Full details will be released very soon, but members can already look forward to a signature IWMA evening of great company and relaxed networking.

IWMA will also be taking part in the International Wire & Cable FORUM at wire 2026 on Thursday 16 April, contributing to a wider programme of influential speakers and expert insight relevant to the industry. Running throughout the exhibition in Hall 13, the FORUM will make its debut at wire 2026 as a new expert-led platform for discussion, insight and knowledge exchange. Free to attend for all trade fair visitors, it will bring together recognised industry specialists to explore both market intelligence

and the wider challenges shaping the future of the wire and cable industry. As part of the programme, IWMA will host a dedicated day of presentations featuring CRU, who will deliver ferrous and nonferrous market insight alongside expert contributions on topics such as CBAM, attracting and retaining talent, using marketing and social media to win new business, cyber security resilience, and the practical application of AI. Designed to address areas that are often underrepresented at traditional technical events, the sessions aim to help businesses move forward with confidence, manage risk and prepare for an increasingly digital and interconnected operating environment.

With just three months remaining, now is the ideal time to finalise plans. Exhibitors will be looking to progress stand activity, product launches and pre-show marketing, while visitors and exhibitors alike may wish to ensure that travel and accommodation are secured early, as Düsseldorf fills quickly during wire week.

IWMA will support members in the run-up to, and throughout, wire Düsseldorf 2026, sharing exhibitor features, event updates and practical guidance across IWMA’s media channels. This will include the March “Düsseldorf Special” edition of IWMA Insider, produced as a dedicated guide to the show, highlighting IWMA members exhibiting and what visitors and exhibitors can expect in Düsseldorf.

Whether you are exhibiting, visiting for the first time, or returning as a long-standing industry regular, wire Düsseldorf 2026 promises a week of insight, opportunity, and connection. IWMA looks forward to welcoming members from around the world and supporting you throughout another landmark edition of the show!

First thing you do when the doors open on Day One?

“Walk the halls, feel the energy and make the first joint recap of the day with the entire team.”

One must-see trend this year?

“The premiere of the World of Cables and the wire and cable Forum in Hall 13, the large mesh welding machines in Hall 17 and, of course, celebrating 40 years of wire Düsseldorf.”

Only one afternoon at the show?

“Focus on key suppliers and targeted networking.”

What are you most proud of this year?

“The premiere of the World of Cables in Hall 13.”

Daniel Ryfisch discusses the forces shaping wire Düsseldorf 2026 – from resilience and energy transition to AI-driven manufacturing

As the global wire and cable industry prepares to return to Düsseldorf, wire Düsseldorf 2026 arrives at a time of significant transition. Political uncertainty, evolving supply chains, sustainability pressures and accelerating technological change are no longer abstract forces on the horizon. They are shaping strategic decisions across the industry right now. Against this backdrop, wire Düsseldorf continues to act not only as a showcase of technology, but as a global meeting point where the industry pauses, reconnects and recalibrates.

For Daniel Ryfisch , Director Metal Forming & Fabrication Technologies at Messe Düsseldorf GmbH , that role is fundamental to why the event retains its position at the centre of the sector.

“Düsseldorf brings together the entire value chain, global decisionmakers and real innovation in one place,” he explains. “The combination of international reach, technical depth and strong industry partnerships makes wire Düsseldorf the industry’s central meeting point and the number one trade fair in the world.”

That breadth of participation matters more than ever. Each edition of wire Düsseldorf reflects the realities facing manufacturers and suppliers at that moment in time, and as the 2026 show approaches, Ryfisch sees several defining themes shaping the industry’s direction.

“Sustainability, digitalisation and resilience are clearly defining the industry right now,” he says.

“ We see strong momentum in energy-efficient production, smart manufacturing, automation and solutions that help companies adapt to changing global supply chains.”

Renewable energy, the wider energy transition, artificial intelligence and robotics sit firmly at the heart of this momentum. For Ryfisch, these are no longer future talking points but practical considerations influencing investment decisions across the sector. This shift is also visible in how wire Düsseldorf itself is evolving. One of the most notable developments for 2026 is the introduction of the Wire & Cable Forum stage in Hall 13. “The Forum is focused on innovations and trends regarding end products at wires and cables for a wide range of applications,” he explains, signalling a move towards more applicationdriven discussion alongside traditional process and machinery technologies.

Alongside technological change, global uncertainty continues to loom large. Over recent years, geopolitical tensions, shifting trade routes and supply-chain disruption have moved to the forefront of business strategy. Ryfisch sees these pressures clearly reflected in conversations with exhibitors and visitors. “Companies are rethinking sourcing, production locations and partnerships,” he says. “At wire Düsseldorf 2026, this translates into a strong focus on flexibility, regional diversification and technologies that increase supply-chain security.”

As a result, the exhibition floor is increasingly shaped by solutions designed not only for efficiency and output, but for resilience. Businesses are looking for systems that can withstand volatility and adapt quickly in an unpredictable global environment, and wire Düsseldorf has become a place where those solutions can be compared, discussed and evaluated side by side.

Sustainability is another area where the conversation has matured rapidly. Ryfisch is keen to emphasise that what visitors will see in Düsseldorf is no longer about ambition alone. “Exhibitors are presenting concrete solutions, from low-emission production processes to recyclable materials and energy-efficient machinery,” he says. “Sustainability is no longer a vision. It is measurable progress

Companies are no longer just looking for efficiency, but for resilience.

in the exhibition halls at Messe Düsseldorf.”

This practical focus reflects a broader industry shift.

Environmental performance is now closely linked to competitiveness, regulatory compliance and longterm operational resilience, and manufacturers are increasingly expected to demonstrate real results rather than future intent.

Digitalisation and automation are following a similar trajectory. Technologies that once sat on the margins of production are now being deployed at full industrial scale. “AI-supported production control, data-driven quality assurance and highly automated lines are moving from pilot projects to real industrial scale,” Ryfisch notes. For visitors, this means seeing proven systems already delivering tangible improvements in productivity, quality and consistency across wire and cable manufacturing.

Despite the strong emphasis on technology, Ryfisch repeatedly returns to the importance of collaboration. “Innovation today happens through cooperation,” he says. “Manufacturers,

suppliers, research institutions and associations have to work together across borders.” wire Düsseldorf plays a crucial role in enabling this exchange, acting as a neutral platform where international partnerships are formed and longstanding relationships are reinforced.

The global nature of the event remains one of its defining characteristics. Ryfisch points to increasing visitor participation from Asia, the Middle East and North America, alongside strong attendance from China, India, Japan and South Korea. “ We also see networkers from Saudi Arabia, Türkiye, Egypt, the Emirates and other Arabian countries attending wire,” he notes, while emphasising that European visitors remain a cornerstone of the show.

What has changed, however, is how visitors attend. “ Visitor numbers remain lower in Düsseldorf,” Ryfisch observes. “A couple of years ago, companies were represented by three or four people. Nowadays, it is often just one or two.” This shift places greater importance on focused meetings, efficient scheduling and targeted networking during the show.

Looking ahead, Ryfisch expects wire Düsseldorf to continue evolving in line with the industry it serves. “Over the next decade, I expect wire Düsseldorf to develop from a place to see machines and materials into a full-stack industry operating system,” he says. In his view, this means combining a technology showcase with a decarbonisation marketplace, a talent and skills hub and increasingly data-driven matchmaking. “Some of these shifts are already clearly signposted in our focus on AI, robotics and the energy transition,” he adds.

On a personal level, Ryfisch describes the opening moments of the show as a time to absorb the atmosphere. When the doors open on day one, his instinct is to walk the halls, feel the energy and connect with the entire Messe Düsseldorf team. If limited to just one afternoon at the event, his priority would be clear: focused engagement with key suppliers and targeted networking. Among the highlights of the 2026 edition, he points to the premiere of the World of Cables in Hall 13 and the opportunity to celebrate 40 years of wire Düsseldorf.

Tea or Coffee? - Coffee

Early start or Late finish? – Early start

Rhine promenade or Altstadt streets? – Altstadt Street

Well-planned schedule or Spontaneous moments? – Well planned schedule

Big picture or Fine details? Big Picture and fine details ��

Live machinery demonstrations or technical conferences? Live machinery demonstrations

Innovation talk or Real-world results? – Real-world results

In-person exhibitions or Digital platforms? - In-person exhibitions of course ��

Global standards or Regional flexibility? - Global standards but we have a close eye on regional flexibility

Energy transition or Digital infrastructure growth? - Energy transition is not possible without digital infrastructure growth ��

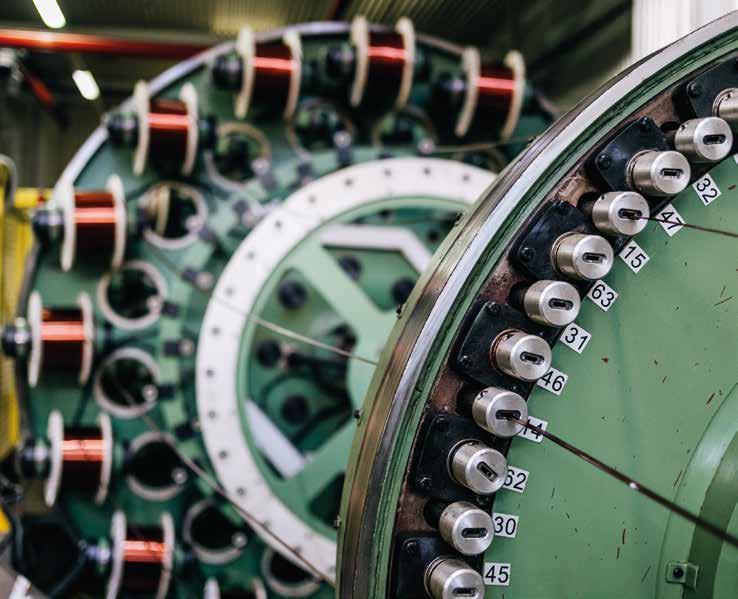

As anticipation builds for wire Düsseldorf 2026, AEI Machines announces its participation at the show. Exhibiting at Hall 11, D14, AEI Machines will present the latest advancements in its stranding machines. AEI Rigid Stranders are trusted globally for precision, durability and customer-focused engineering.

For over 50 years, AEI Machines has remained dedicated to perfecting one product category: highperformance stranding machines. This specialised focus has enabled the company to innovate rapidly, engineer robust solutions and refine the fine details that matter most to cable and conductor manufacturers.

Adding to this momentum, AEI Machines is making a major investment in establishing a new manufacturing facility to significantly expand its production capacity in order to meet growing global demand. This investment reinforces AEI Machines’ longterm commitment to advanced engineering, rapid delivery and enhanced customer support.

Visitors to wire Düsseldorf 2026 can expect a showcase of AEI’s newest developments, including:

• High-speed stranding systems, optimised for maximum output without compromising strand uniformity.

• Energy-efficient drives and controls, designed to reduce operational costs and environmental impact.

• Enhanced tension control mechanisms, delivering consistent and reliable strand formation across a variety of materials.

• Advanced safety and operatorfriendly interfaces, ensuring ease of use, improved ergonomics and seamless integration into modern production lines.

Each machine reflects AEI’s philosophy: to build equipment that enhances output, reduces downtime and offers unmatched reliability.

“The stranding process lies at the heart of cable production,” says Alok Jain, Managing Director, AEI Machines. “Our focus on this single domain allows us to deliver machines that provide consistent quality, operational stability and long-term value.”

The AEI team is looking forward to welcoming you at Hall 11, D14, at wire Düsseldorf 2026.

www.aeimachines.com

Calmec is heading to wire Düsseldorf 2026 with an expanded portfolio of advanced production technologies, including its full range of Strip Armouring Machines up to 125mm – engineered for speed, durability and precision across a wide range of cable constructions.

The company continues to extend its high-speed Concentric and Dual

Eccentric Taping Machine lines, developed for constant-tension application of both metallic and nonmetallic tapes. These systems offer smooth operation, HMI-driven setup and options that minimise downtime while supporting high-throughput production.

Calmec has also broadened its Vision System technologies with practical, real-time monitoring solutions for strip armouring and taping quality. New capabilities include advanced Ovality and Thermal Detection, providing deeper

dimensional insight and enhanced process control.

Calmec looks forward to connecting with industry partners and showcasing these innovations at Hall 9, E20-3, wire Düsseldorf 2026.

www.calmec.com

Shanghai KECHEN Wire & Cable Machinery Co., Ltd. –known as KC Machine – has been a steadfast innovator in telecom cable equipment since its establishment in 1999.

Backed by over 60 years of industry development, the company has earned a reputation for designing and manufacturing specialised, nonstandard machinery that meets the complex demands of transmission line production.

With a workforce of nearly 100 employees – approximately half of whom are design and commissioning engineers – KC Machine leverages deep technical expertise to adapt swiftly to evolving market needs. Its influence is global, with more than 800 specialised wire and cable production lines installed worldwide, underscoring the

company’s commitment to quality and reliability.

KC Machine’s extensive product portfolio addresses a broad spectrum of cable manufacturing requirements, including:

• RF coaxial cable production lines tailored for telecommunications and broadcasting

• LAN, SFP, QSFP, HDMI and mini coaxial cable lines designed for high-speed data communication

• Railway signal cable lines that meet stringent safety and durability standards

• High-temperature extrusion lines for advanced materials such as FEP, ETFE and PFA

• Indoor and outdoor optical cable lines supporting modern fibre infrastructure

• Power and fire-retardant cable metal sheathing and jacketing lines focused on enhanced safety

• Specialised production lines for aerospace, military and aircraft cables

• Core auxiliary equipment, including payoffs, take-ups, capstans and water troughs

KC Machine’s ongoing dedication to meticulous engineering, advanced technology and comprehensive support services positions it as a leader in the wire and cable machinery sector. As the global demand for sophisticated cable solutions grows, KC Machine continues to equip manufacturers with robust, efficient production lines that boost productivity and deliver value.

Visit KC Machine at wire Düsseldorf this April: Hall 15, B43.

Tension measurement in the modern wire industry.

Tension measurement plays a crucial role in production monitoring, quality control and process engineering across the wire and cable industry. Schmidt, a company that celebrated its 75th anniversary in 2023, supplies tension meters that are widely used in these applications, with over 185,000 instruments in operation worldwide.

Schmidt offers a comprehensive range of tension meters, including both handheld and online models, available in mechanical and electronic versions. The product lines are continually updated to meet evolving industry demands. A recent example is the updated DT series of handheld tension meters, capable of measuring tensions up to 60daN and designed with guide rollers suitable for larger cables and wires.

The DT series is designed to provide clear and accurate readings for operators. The display rotates automatically in 90-degree steps for optimal visibility and offers three display modes, including real-time readings, min-max alarms and

a time-tension graph. Users can calibrate the instruments to their specific materials and define custom material names for the display. Peak tension values can be captured with an internal sampling rate of 8kHz. The professional DTX variant also includes a memory for 60,000 readings, multiple data collection programmes and options for PC connectivity via USB or Wi-Fi.

The FS series, known for its reliability, now incorporates advanced digital signal processing, which allows for simplified cable installation, reduced susceptibility to electronic noise and seamless connection to computers for continuous monitoring and data storage. Up to 32 sensors can be linked to a single PC for comprehensive analysis of tension readings.

The MZ series, with its new flat design, is particularly suited to space-constrained environments, such as when cables run in parallel or enter stranding machines. These sensors come with different roller sizes to accommodate various material dimensions and measuring ranges from 0–2,000cN to 100daN.

Standard preamplifiers enhance signal accuracy, and a variety of analogue, digital and current outputs are available.

The SC-PM4 panel-mount display supports up to four tension sensors and offers two display modes: realtime readings with alarm control or bar graphs to track trends. Up to four materials can be calibrated per channel, with optional electronic damping for fluctuating tension. The display provides versatile outputs, including 0–10V, USB and RS422 for integration into broader monitoring systems.

As the wire and cable industry continues to advance, precise and adaptable tension measurement solutions remain essential for manufacturers seeking to maintain high-quality production standards and process efficiency.

Visit Hans Schmidt at wire Düsseldorf: Hall 9, B22.

www.hans-schmidt.com

As the global wire and cable community looks ahead to wire Düsseldorf 2026, the South African Wire Association (SAWA) is preparing to once again take its place among the international exhibitors.

SAWA has been a long-standing participant at major wire industry events, and Düsseldorf remains an important platform for the association and its members. South Africa’s wire manufacturers have built a reputation over decades as

reliable suppliers across a range of international markets, supporting sectors from agriculture and automotive to manufacturing, mining and security.

Since its establishment in 2002, SAWA’s role has centred on helping South African producers engage in global trade, raising awareness of the sector’s economic importance and supporting export-focused growth. Its membership spans large, medium and small manufacturers, many of whom supply tailored products using locally sourced materials. The association also works closely with the South African

Department of Trade, Industry and Competition (DTIC) to support export initiatives.

At wire Düsseldorf 2026, SAWA will be located in Hall 11, H75, where representatives will be available to meet visitors and discuss opportunities for collaboration.

www.sawa.co.za.

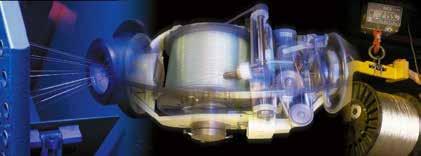

Just a few months separate us from the main trade fair in the wire, cable and rope sector. MFL Group will be there, and our complete customer experience team will be waiting for visitors at the stand that has become a regular meeting point: Hall 11, F60.

With a history of over 125 years, MFL Group is a family-owned company recognised worldwide for advanced solutions dedicated to the wire, cable and rope industries. We design and deliver drawing, stranding, extrusion and treatment lines, together with fully integrated digital solutions, the MFL X ecosystem, developed to improve machine performance, process control, production efficiency and to enhance the overall experience of owning an MFL asset.

The Group is moving increasingly towards digitalisation, and this evolution will also be reflected in our stand. LED walls, monitors and totems will provide a comprehensive

overview of our portfolio. Through these tools, visitors will be able to explore our machinery in operation: our market benchmark drawing lines, continuously evolving rod breakdown machines combined with a wide range of annealers, stranding lines enhanced by automation and new technologies, and treatment lines that complete the process with advanced in-line solutions.

All the latest developments will be explored in greater depth in the MFL arena, where MFL Group experts, together with key customer references, will introduce new solutions, explain recent innovations and share how customers can benefit from them in their daily production.

A dedicated area will focus on our digital ecosystem, MFL X. Together with our main partners, 40Factory and Fruitful AI, we will present a set of applications designed to empower production lines and support operators and maintenance teams. In addition to Acumen, our Industrial IoT application; Scout, a cloud-based app to order spare parts; Emma, our GPT-based chatbot; and Wizard,

a wire drawing line simulator, our visitors will discover our latest app: Eagle. Leveraging machine vision algorithms and high-speed cameras, the new app enables enhanced wire and cable analysis.

Part of the experience will take place in a closed room, designed to offer a more immersive experience of our latest developments.

MFL Care, our division dedicated to aftersales support, is at the centre of all our digital services, which are designed to strengthen it. MFL Care will also be a focus of this edition, where we will present our new service level agreements, a series of packages designed to support our customers and their production lines throughout the entire lifecycle of our machinery.

MFL Group at wire Düsseldorf: Hall 11, F60. www.mflgroup.com

The Wire & Cable Innovation Hub at wire China 2026 reflects IWMA’s continued commitment to creating meaningful platforms for collaboration, visibility and knowledge exchange within the global wire and cable industry.

Developed as an exclusive concept for this year’s wire China exhibition, the Innovation Hub responds to the evolving needs of IWMA members seeking a high-impact yet accessible presence at one of Asia’s most influential industry exhibitions. Taking place from 21 to 24 September at the Shanghai New International Expo Centre, wire China provides an ideal international setting for this collaborative IWMA and Messe Düsseldorf Shanghai initiative.

The Innovation Hub has been designed to move beyond the traditional exhibition model, offering a curated environment where technical expertise, product innovation and industry insight take centre stage. By combining dedicated exhibitor space with a structured technical presentation programme, the Hub enables participating companies to engage visitors through both demonstration and dialogue.

In line with the programme criteria, the Innovation Hub is open to IWMA member companies that did not exhibit at wire China 2024, providing a supported route to first-time participation at wire China 2026 with strong international visibility.

Participants within the Innovation Hub benefit from a turnkey exhibition solution designed to reduce barriers to entry and maximise impact. The Innovation Hub Exhibitor Package, priced at just €2,850, includes a dedicated stand space, access to shared meeting and networking areas and inclusion within the IWMA technical programme through a scheduled speaking slot.

Alongside the physical presence, IWMA supports Innovation Hub participants through coordinated promotional activity and on-site assistance, helping to extend visibility before, during and after the exhibition.

In addition to exhibitor participation, the Wire & Cable Innovation Hub also offers a range of sponsorship opportunities, providing IWMA members with an additional route to visibility and engagement at the exhibition.

Available at multiple levels, sponsorship packages are designed to increase brand presence across the Innovation Hub, including enhanced branding, involvement in IWMA promotional activity and prominent positioning within the technical programme. These opportunities allow sponsors to align their brand with innovation, knowledge sharing and technical excellence, while supporting a platform dedicated to industry collaboration.

At its core, the Wire & Cable Innovation Hub strengthens IWMA’s technical and professional contribution to wire China, reinforcing the association’s role as a connector between companies, technologies and global markets. As preparations for wire China 2026 continue, the Innovation Hub stands as a key feature of IWMA’s presence at the show, supporting members in showcasing innovation, sharing expertise and building lasting industry relationships.

With several companies already signed up and space limited, members are encouraged to register their interest early. To find out more, request an application form or discuss exhibitor and sponsorship opportunities, please contact Jessica Bennett at jessica@iwma.org , or visit iwma.org for full package details.

Following the strong debut of the IWMA Pavilion at wire India 2024, the IWMA is pleased to confirm that plans are well underway to return to the exhibition in 2026, continuing to provide a dedicated platform for member visibility, connection and technical exchange in the Indian market.

Introduced in 2024, the IWMA Pavilion quickly established itself as a central meeting point for members and visitors alike, bringing together international companies in a welcoming environment for networking, knowledge sharing and on-stand engagement. Its success reflected both the strength of IWMA’s global membership and the growing importance of the Indian wire and cable industry.

The next edition of wire India will take place from 30 November to 2 December 2026, with the IWMA

Pavilion returning to the Bombay Exhibition Centre, Mumbai.

Exhibitor space within the Pavilion, located at stand E40, is expected to go on sale in early 2026, allowing members to plan their participation well in advance of the exhibition.

Building on the 2024 format, the Pavilion will once again offer individual exhibitor Space alongside a professionally supported IWMA presence, with signature hospitality, practical resources for meetings and informal networking, and a programme of on-stand activity designed to encourage engagement throughout the exhibition.

Visitors will also be able to access IWMA information and materials, reinforcing the Pavilion’s role as both a networking hub and an information point for the wider industry.

A dedicated IWMA member presentation day will take place on Tuesday, 1 December 2026, providing a focused opportunity for technical exchange and industry insight. IWMA members will be

invited to apply for presentation slots within the Pavilion’s technical programme, offering a platform to showcase expertise, innovation, and technical developments to an international audience. Applications for member presentation slots are expected to open in July 2026 and close in September 2026, with further details to be shared closer to the time.

Members wishing to register early interest in participation or presentation opportunities are invited to contact Jessica Bennett at jessica@iwma.org

Supermac Industries established in the year 1974 is a leader in manufacturing of high end systems and process technology for the wire & cable in Power and telecom sector and related Industries.

Supermac Industries established in the year 1974 is a leader in manufacturing of high end systems and process technology for the wire & cable in Power and telecom sector and related Industries.

The ISO 9001 and CE certified company specializes in offering customized and tailor made solutions to fulfil specific needs of the variety of customers all across the globe.

The ISO 9001 and CE certified company specializes in offering customized and tailor made solutions to fulfil specific needs of the variety of customers all across the globe.

With a highly skilled design team, with the best of manufacturing and highly talented commissioning team, trained experts in cable processes and technology, we offer design to process expertise to bring in the best product for you.

With a highly skilled design team, with the best of manufacturing and highly talented commissioning team, trained experts in cable processes and technology, we offer design to process expertise to bring in the best product for you.

Supermac has expertise providing on line commissioning from remote. Post commissioning customer service support is provided

Supermac has expertise providing on line commissioning from remote. Post commissioning customer service support is provided

from both on site as well as from remote. In our endeavour to conform to industry 4.0 norms, Supermac has taken strong strides forward in implementing several digital initiatives and can provide IIOT enabled extrusion lines supported by Siemens Mind sphere software

from both on site as well as from remote. In our endeavour to conform to industry 4.0 norms, Supermac has taken strong strides forward in implementing several digital initiatives and can provide IIOT enabled extrusion lines supported by Siemens Mind sphere software

The company has three established and running units near New Delhi and are adding another unit under our expansion program.

The company has three established and running units near New Delhi and are adding another unit under our expansion program.

The state-of-the art facilities are equipped with international and indigenous machinery to carry out the process of manufacturing as per the customer’s requirements.

The state-of-the art facilities are equipped with international and indigenous machinery to carry out the process of manufacturing as per the customer’s requirements.

Supermac has strategic partnership with German Company – M/S Scholz to cover CCV Lines, and Simpack USA for Coiling machines and Solutions.

Supermac has strategic partnership with German Companies – M/S Scholz to cover CCV Lines, M/S Rubicon to cover Rubber extrusion Lines and Simpack USA for Coiling machines and Solutions.

Supermac specializes in the following areas:

Supermac specializes in the following areas:

• State of the art CCV Line with Scholz Vulcanization system for Power Cables up to 132 KV XLPE and 33 KV for Rubber

• State of the art CCV Line with Scholz Vulcanization system for Power Cables up to 132 KV XLPE and 33 KV for Rubber

• Rubber extruders for Insulation and sheathing materials

• Rubber extruders for Insulation and sheathing materials

• Silicone extrusion lines with infrared vulcanization system

• Silicone extrusion lines with infrared vulcanization system

• Cat 5.6 and 7 Lines

• Specialized Medical Tubing extrusion lines

• Specialized Medical Tubing extrusion lines

• Proven Triple Extrusion Line for SIOPLAS (XLPE) cables

• Proven Triple Extrusion Line for SIOPLAS (XLPE) cables

• Cat 5.6 and 7 Lines

• FTTH drop cable lines

• FTTH drop cable lines

• Fluoropolymer – FEP, PTFE /ETFE Lines

• Fluoropolymer – FEP, PTFE /ETFE Lines

• High speed Insulation Line and Sheathing Line for House Wiring & Control Cables and medical equipment sector.

• High speed Insulation Line and Sheathing Line for House Wiring & Control Cables and medical equipment sector.

• High output and best in class Insulation Line and Sheathing Line for Power and Optical fiber Cables.

• High output and best in class Insulation Line and Sheathing Line for Power and Optical fiber Cables.

• HCV insulation and sheathing line

• HCV insulation and sheathing line

• Hybrid and composite CCV lines for both XLPE and Rubber.

• Hybrid and composite CCV lines for both XLPE and Rubber.

:

:

A-28 & 29, NARAINA Industrial Area

A-28 & 29, NARAINA Industrial Area

Phase-1, New Delhi-110028, INDIA

Phase-1, New Delhi-110028, INDIA

Ph.: +91-11-45574317

Ph.: +91-11-45574317

E-mail: office@supermacindia.com

E-mail: office@supermacindia.com

• Loose tube/Secondary coating lines for fibre optics

• Loose tube/Secondary coating lines for fibre optics

• Extruders for variety of applications – up to 175 mm

• Extruders for variety of applications – up to 175 mm

• Cross-Head Single/Dual/Triple

• Cross-Head Single/Dual/Triple

• Haul-Off Caterpillar

• Haul-Off Caterpillar

• Capstan

• Capstan

• Take-up and pay-off of all types and sizes and as per requirement above 4.5 meters and 40 MT

• Take-up and pay-off of all types and sizes and as per requirement above 4.5 meters and 40 MT

UNIT-I: Plot No-2, Sector-6, IMT Manesar, Gurgaon Haryana, INDIA

: Plot No-2, Sector-6, IMT Manesar, Gurgaon Haryana, INDIA

Ph.: +91-0124-4690500 | Fax: +91-0124-4690501

Ph.: +91-0124-4690500 | Fax: +91-0124-4690501

:

: Plot No. 18-19, Sector-2A,

Haryana, INDIA

E-mail: jasvinder@supermacindia.com, vkohli@supermacindia.com

E-mail: jasvinder@supermacindia.com, vkohli@supermacindia.com

No. 18-19, Sector-2A, IMT Manesar, Gurgaon, Haryana, INDIA

As we look ahead to 2026, the wire and cable industry finds itself at the centre of some of the most important industrial, energy and infrastructure developments of our time.

In this industry section of IWMA Insider, we explore these dynamics from several complementary perspectives. We begin with an examination of the UK Autumn Budget 2025, which provides important context for our UK members and valuable insight for EU and international members working with the UK market. Alongside this, our 2026 Risk Radar looks at the global political and trade forces increasingly shaping supply chains across copper, aluminium, steel wire and HVDC and subsea cables.

Balancing this policy-driven analysis, we are also pleased to include CRU’s “Top Calls for 2026”, which offers a more market-focused outlook on the year ahead. While less political in nature, CRU’s insights into demand, investment and sector trends sit very naturally alongside these articles, helping to ground policy and risk considerations in underlying industry fundamentals.

Taken together, these features highlight not only the challenges facing our industry, but also the significant opportunities for businesses that are prepared, adaptable and forward-looking. Electrification, energy transition and digitalisation continue to underpin long-term demand, and across our membership we see ongoing investment in innovation, efficiency and sustainability.

IWMA remains confident in the strength and resilience of our global community. By combining political awareness with market insight, our members are well-positioned to navigate uncertainty and to play a leading role in building the infrastructure and technologies that will define the next phase of global growth.

As a UK-based association with a global membership, IWMA monitors UK fiscal policy not in isolation, but as part of a wider landscape of political, regulatory and trade risk shaping the wire and cable industry in 2026.

The UK Autumn Budget 2025, delivered on 26 November, introduced a number of measures that will influence the operating environment for UK manufacturers in the year ahead. While the Budget avoided dramatic headline tax rises, it has been met with cautious, and in many cases frustrated, reactions from businesses. This reflects longer-term structural pressures rather than any single announcement.

This domestic context sits alongside the global political shifts outlined in IWMA’s 2026 Risk Radar, where regulation, trade policy and cost volatility are increasingly shaping supply chains worldwide.

Several Budget measures are directly relevant to the wire and cable sector.

Labour costs continue to face upward pressure following the extension of the freeze on income tax and National Insurance thresholds until at least 2031. As wages rise with inflation, more employees move into higher tax bands, increasing pressure on employers to raise pay simply to maintain real incomes. While gradual, this compounds existing skills shortages and labour cost inflation.

On investment, the confirmation of generous capital allowances, including 100% first-year allowances for qualifying plant and machinery, was one of the more positively received measures. For wire and cable businesses, this supports investment in automation, testing capability, digitalisation and energy efficiency. These themes align closely with the industry’s response to rising geopolitical and regulatory risk.

For energy-intensive industry, the increase in network charging relief from 60% to 90% offers meaningful mitigation for processes such as wire drawing, annealing and heat treatment. However, it does not remove the UK’s structural energy cost disadvantage when compared with many EU markets, a factor that continues to influence competitiveness.

The Budget also reaffirmed continued investment in energy infrastructure, electrification and grid reinforcement, supporting medium-term demand for cables, conductors and associated systems.

Despite these measures, overall sentiment among UK manufacturers remains subdued.

Much of the frustration stems from the cumulative operating environment. The freeze on tax thresholds is widely perceived as a stealth increase in the tax burden, raising employment costs without explicit rate changes. At the same time, businesses see limited relief on day-to-day operating costs, such as business rates, borrowing costs and regulatory complexity.

While investment incentives are welcomed, many firms remain cautious due to:

• Time-limited policy measures

• Planning and grid connection delays

• Uncertainty over long-term tax and regulatory direction

Against a backdrop of global trade tension, energy price volatility and supply chain disruption, all highlighted in the 2026 Risk Radar, UK manufacturers are prioritising resilience and efficiency over expansion.

UK vs EU competitiveness in the context of 2026 risk

When viewed alongside the 2026 Risk Radar, the UK Budget reinforces a key theme: political risk increasingly shapes competitiveness as much as cost.

Energy

Regulatory

Investment

For EU manufacturers, border regulation and carbon pricing dominate the risk agenda.

For UK manufacturers, domestic cost pressure and competitiveness sit alongside global trade risk.

Both, however, face the same strategic reality identified in the Risk Radar: political and regulatory factors are now embedded in supply chain decision-making.

For UK members, the Autumn Budget provides tools to modernise and invest, but within a tightening cost environment and subdued confidence.

For EU and international members, it offers important insight into why UK partners may:

• Invest selectively rather than aggressively

• Focus on automation and efficiency

• Be highly price- and risk-conscious in procurement

When read alongside the 2026 Risk Radar, the Budget underlines that resilience in 2026 will be driven not by geography alone, but by preparedness, flexibility and strategic alignment with policy direction.

The UK Autumn Budget is one part of a much wider picture. Combined with the global political shifts outlined in the 2026 Risk Radar, it highlights how domestic policy, international regulation and geopolitical risk are converging to shape the wire and cable industry.

Understanding these connections will be essential for members navigating sourcing, investment and market strategy in the year ahead.

As the wire and cable industry enters 2026, geopolitical risk is no longer a background concern – it’s a core operational reality. Trade policy, sanctions, carbon regulation and supply-chain security initiatives are now directly influencing raw-material availability, pricing volatility, investment decisions and customer demand across global wire and cable markets.

Below, we highlight 10 key political and regulatory developments from 2025/26 that are expected to have the most material impact on copper rod, aluminium rod, steel wire and HVDC/subsea cable supply chains in the year ahead.

Rather than treating these in isolation, businesses should view them collectively as a risk radar – where overlapping policies amplify both disruption and opportunity.

From January 2026, CBAM moves from a reporting obligation to a cost-bearing regime, requiring importers to purchase certificates linked to embedded carbon emissions.

Risk to supply chains:

• Higher landed costs for steel wire rod and aluminium rod imported into the EU

• Increased compliance burden for suppliers without verified emissions data

• Competitive pressure on non-EU producers supplying EU cable plants

Strategic implication:

CBAM accelerates the shift toward low-carbon metals, favouring EU-based producers and non-EU suppliers able to demonstrate carbon transparency. You can read our article on CBAM later in this magazine.

2. EU sanctions on Russian metals – aluminium supply tightening

The EU’s phased ban on Russian primary aluminium introduces structural supply constraints, even with transitional quotas in place.

Risk to supply chains:

• Reduced availability of competitively priced aluminium for power and overhead conductors

• Higher regional premiums for aluminium rod

• Increased reliance on Middle East and Asian supply

Strategic implication:

Cable producers may need to rebalance sourcing strategies or lock in longer-term supply contracts to manage volatility.

3. United States copper tariffs – Section 232 expansion

In 2025, the US introduced significant tariffs on certain copper and copper-derived imports, with effects continuing into 2026.

Risk to supply chains:

• Distorted global copper trade flows

• Higher costs for copper-intensive components and semi-finished products

• Increased regionalisation of copper processing

Strategic implication:

Copper rod producers and cable manufacturers supplying North America face pressure to localise production or absorb margin erosion.

4. US–China trade measures affecting energy transition materials

Further US tariffs scheduled for 2026 target materials linked to EVs, grids and renewable energy systems.

Risk to supply chains:

• Indirect cost pressure on HVDC and highperformance cable systems

• Delays or redesigns in large infrastructure projects

• Increased uncertainty in long-term project pricing

Strategic implication:

OEMs and EPCs are likely to prioritise suppliers with secure, diversified sourcing and predictable delivery.

5. China export control volatility – strategic uncertainty persists

Temporary easing of some export controls in late 2025 has reduced short-term pressure, but the underlying policy direction remains unpredictable.

Risk to supply chains:

• Sudden restrictions on critical inputs used in specialised wire coatings, electronics and cable accessories

• Heightened geopolitical risk exposure for singlesource suppliers

Strategic implication:

Supply-chain resilience, stockholding strategies and alternative sourcing are now strategic necessities rather than optional safeguards.

6. Canada’s steel derivative surtaxes

Canada’s introduction of a 25% surtax on selected steel derivative products reinforces the broader trend toward protectionism.

Risk to supply chains:

• Increased costs for downstream steel wire products

• Trade friction affecting North American wire and fastener markets

Strategic implication:

Manufacturers serving North America must closely monitor tariff classifications and origin rules to avoid unexpected cost exposure.

7. Strategic stockpiling of critical minerals (Australia and allies)

Moves by Australia and allied nations to establish critical mineral reserves reflect a global pivot toward resource security.

Risk to supply chains:

• Long-term re-pricing of specialty materials

• Increased government influence in raw-material markets

Strategic implication:

This trend supports investment in non-China supply chains, benefiting producers aligned with Western industrial policy goals.

8. Red Sea and Suez shipping volatility

While shipping routes have partially reopened, geopolitical risk in the region remains unresolved.

Risk to supply chains:

• Freight cost volatility

• Longer lead times for machinery, components and metals moving between Asia and Europe

Strategic implication:

Logistics planning and buffer inventories will remain critical throughout 2026.

9. India’s Quality Control Orders (QCOs)

India continues to refine product-specific quality and certification requirements for metals and industrial products.

Risk to supply chains:

• Market-entry barriers for foreign wire and rod suppliers

• Compliance costs and administrative delays

Strategic implication:

For suppliers aligned with India’s electrification and infrastructure growth, compliance is essential to accessing one of the fastest-growing cable markets globally.

10. Forced-labour and supply-chain due diligence requirements

The EU and other regions are strengthening enforcement mechanisms tied to ethical sourcing.

Risk to supply chains:

• Increased documentation and audit requirements

• Risk of import bans or reputational damage for noncompliance

Strategic implication:

Transparency and traceability are becoming commercial differentiators, particularly for large-scale energy and infrastructure projects.

Taken together, these developments point to a clear reality: 2026 will reward resilience, transparency and strategic alignment with regional policy goals.

For copper, aluminium, steel wire and HVDC/subsea cable supply chains, the key risks are not only pricerelated but structural – affecting where materials come from, how they are certified and who ultimately bears the cost.

Companies that proactively assess exposure, diversify sourcing and invest in compliance and sustainability will be best placed to navigate the year ahead.

Risk key

High risk – direct cost, availability or compliance impact likely

Medium risk – indirect exposure or conditional impact

Low risk – limited or marginal impact

Political/trade risk (2025–2026) Copper rod Aluminium rod Steel wire/rod HVDC and subsea cables

EU CBAM – cost-bearing phase (2026) Medium

EU sanctions on Russian metals

US copper tariffs (Section 232 expansion)

US–China trade measures (energy transition inputs)

China export control volatility

Canada steel derivative surtaxes

Critical minerals stockpiling (Australia and allies)

Red Sea/Suez shipping instability

India Quality Control Orders (QCOs)

Forced-labour & supply-chain due diligence enforcement

• Copper rod risk is dominated by trade policy and tariffs, particularly in the US, rather than availability.

• Aluminium rod faces the highest structural risk, driven by sanctions, CBAM costs and supply concentration.

• Steel wire and rod are most exposed to CBAM, protectionist measures and national standards.

• HVDC and subsea cables carry the highest cumulative geopolitical risk, due to reliance on complex, multi-country supply chains, specialist materials, shipping routes and regulatory scrutiny.

Hanover, Germany // 23 - 25 June 2026

The leading event for the electric wire and cable value-chain, worldwide

Celebrating 20 years as the industry’s leading global gathering, the CRU Wire & Cable Connections Summit 2026 will bring together world’s most influential wire and cable decision makers to:

• Gain market insight

• Build high value connections

• Explore the technologies powering a more sustainable future

• Exclusive behind-the-scenes tour of the Nexans Stella Nova plant

Join us in Hanover and be a part of the conversation.

Author: Aisling Hubert, Ahmed Ali | Commodity: Wire and cable, optical fibre and cable

The overall wire and cable industry continues to be supported by global demand for electrification and connectivity. As the world continues to urbanise and industrialise, demand for both metallic and optical cables is growing as the requirements of modern life become increasingly energy- and dataintensive. Over the past year, data centres have continued to emerge as a staggering growth opportunity for cables as the power requirements and data connectivity demands break records of year-on-year growth rates by applications. Combined with the wider themes of decarbonisation, energy security and increasing digitalisation, cable demand is robust and able to weather short-term challenges that may be experienced in specific applications, such as FTTH rollout slowdowns and cyclical construction slowdowns.

#1 Top call – metallic wire and cable

Continued exports of cables from China as low domestic demand persists

Multi-year weakness in China’s construction industry has plagued building wire demand while manufacturing and grid network expansion have continued at pace. Although new anti-involution measures hope to limit the hypercompetitiveness of the industry and try to avoid the continued erosion of margins, we still expect that producers will continue to rely on exports to make up for a poor domestic market. Smaller companies may struggle in this new paradigm of relying on international markets for returns. As a result, we also expect to see increased consolidation of smaller, distressed manufacturers.

#2 Top call – metallic wire and cable

Reshoring of manufacturing to the US as tariffs make imports prohibitive

Some copper and aluminium cables and wire rods’ exposure to 50% Section 232 duties has made imports more prohibitive. Imports currently represent one quarter of US cable supply. As inventories are drawn down, onshoring will become more attractive. Currently, only low voltage copper cables are covered by the Section 232 ruling, but there is scope for the tariffs to be broadened further to other key cable import categories, such as power cables. Longer-term tariffs on refined copper, which are due to come in from 2027, will also fuel investments in more US wire rod manufacturing capacity.

#3 Top call – metallic wire and cable, and optical fibre and cable

Data centre demand to continue at pace as investments reach record highs

The data centre market has become a key driver of both the metallic and optical cable segments. Metallic cables are benefiting from the higher power requirements of data centres, and despite wariness around the sustainability of the investments, data centre demand continues to deliver the fastest year-on-year

growth rates across applications. Power cables for energy applications, as well as low voltage cables for building construction, are receiving a boost from this demand area. We expect that data centres will account for roughly 8% of total US metallic cable demand in 2026. On the fibre optics side, stronger pull from server room connectivity and data centre interconnect is driving a noticeable shift in demand patterns. Optical cable for data centres will reach around 16% of total global demand in 2026, with suppliers increasingly prioritising the requirements of this segment.

#4 Top call – optical fibre and cable

There will be more consolidation among European optical cable suppliers

Europe is likely to see a shrinking ecosystem of active optical cable suppliers in 2026 as consolidation accelerates. This is driven by current price pressure, subdued cable demand and aggressive Asian exports that are squeezing the margins of mid-tier players.

#5 Top call – optical fibre and cable

Hollow core fibre ecosystem will expand but will remain in its early days for commercial rollout

Hollow core fibre will gain momentum in 2026 with more suppliers, trials and technology partnerships emerging across the US, Europe and China. This is due to sustained interest from hyperscalers in its low latency and low attenuation capabilities that align with their data centre infrastructure needs. Investment in hollow core will likely prompt new joint development programmes between hyperscalers, telcos and optical cable and fibre suppliers, as well as accelerating the existing ones. There is also space for start-ups to emerge to serve this niche market and collaborate with established players.

There is a shared momentum across both metallic wire and cable and optical fibre and cable, despite challenges in some specific applications. Metallic cable producers will have to navigate shifting global supply dynamics, most notably China’s export recalibration under antiinvolution policies and the accelerating pull of the US as tariffs and copper price differentials shape trade patterns. On the optical side, competition across the supply chain is intensifying as manufacturers in many regions look for new avenues for growth across regions and applications to compensate for their subdued domestic demand and mounting price pressure. Despite elements of saturation and cyclical challenges, the combined wire and cable industry remains strategically indispensable, increasingly innovation-led and supported by long-term demand fundamentals that appear firmly intact for 2026.

From 1 January 2026, the EU’s Carbon Border Adjustment Mechanism (CBAM) moves into its definitive phase. For many in the wire and cable industry, this marks a fundamental change in how steel and aluminium inputs are priced, reported and traded into the EU.

What began as an emissions reporting exercise will become a real financial obligation at the EU border – with direct implications for cost, compliance and competitiveness.

This article outlines what CBAM means in practice and the key actions IWMA members should be taking now.