text and illustrations in WCN are copyright protected. Copying contents by any means is forbidden without the publisher’s written consent. The publisher, agents, printers and contributors are not responsible for the accuracy of claims printed or implied in the editorial or advertisements published in this, previous or subsequent editions. The publication in this newsletter of brand

ESSICA Lambert’s introduction to the wire and cable world could hardly have been more intense: the IWMA’s new marketing manager started work only three weeks before the year’s biggest wire and cable event – wire 2018 in Düsseldorf.

“In fact it was a great start to the job, because I got to meet lots of members and learn about the organisation very quickly,” she explained. “Wire and cable is a thriving industry, with opportunities to find new ways to connect with members and increase awareness of the IWMA.”

Jessica, from Lichfield in Staffordshire – a dance teacher and choreographer in her spare time – joins from the national chain of Whitewall Galleries and an independent clothing store with a thriving e-commerce business. Her experience is in event management, marketing, PR and social media. How the IWMA promotes itself and members, and how it moves forward as it reaches its 50th anniversary, will be a major focus of her role.

OVER 300 members attended the IWMA gala evening at wire Düsseldorf. IWMA Educational Trust travel award recipients and other award winners joined other guests for an informal networking evening with a buffet of traditional German food and music from entertainers Bergvagabunden

The evening also included several presentations: Dr Simon Sutton of Doble Engineering Company won the CabWire technical award for his paper Predicting Watertreeing Behaviour: How Much Do We Really Know?

David Clowes of Inductotherm received the new Training Fundamentals award for his paper Fundamentals of Induction Heating, collected on his behalf (below left), by Inductotherm MD Wayne Hine from the IWMA’s Peter Large, and Debi Coleman (below right), received a special retirement gift after 15 years with the IWMA.

SUNSHINE and fabulous surroundings made the 2018 members’ golf tournament a very special day at the beautiful Mere Golf Resort and Spa in Knutsford, Cheshire.

The new venue’s extensive facilities meant we could hold daytime and evening activities in the same place –and allowed us to offer extras such as spa experiences and golf lessons with the resident golf pro – all of which were appreciated and enjoyed.

At the end of the day the winners’ board showed a number of proud names: the chairman’s cup for best score went to Craig Rika of Bar Products and Services, and tournament

newcomer Alan Baxter (pictured left with the IWMA’s

Peter Large) of the MSS Products team took

home the guest shield. Winner of the longest drive was David Clowes of Inductotherm, the putting competition winner was Girvin Palfrey of Cable Tapes, and the shot that went nearest the pin was played by Steve Rika of Bar Products and Services.

Next year’s tournament will be back at The Mere on Thursday June 6, 2019.

If you attended the 2018 event you’ll know what a great day it can be; if not, take a look at the video in the member-news section of the website (www.iwma. org/Latest-News/iwmagolf-tournament-success-2018) and make a note to register your team early for next year.

WELCOME to WCN 59! This is a special edition of the newsletter also available for the first time in Chinese, to mark the growing strategic importance of the wire China trade fair and to help members promote their goods and services to Chinese companies.

Away from the immediate business of the show we are also looking forward to welcoming many members to our evening event in Shanghai: a night-time cruise on the Huangpu River – free for up to three people from each company and offering excellent views of both the Pudong business district and the Bund, Shanghai’s amazing waterfront area.

The China show follows the premier wire and cable event of the year, wire 2018, which in April saw huge crowds of exhibitors and visitors in Düsseldorf and was, as usual, a hugely successful event. China offers a lead-in to the second major show of a busy autumn, wire India, in Mumbai (November 27-29, www.wireindia.com), and takes us neatly into 2019, for which we are currently preparing a new CabWire event, previewed in these pages.

And finally, a word about one of the other major roles of the IWMA; helping to train top industry engineers for the future.

To that end the IWMA Educational Trust has just taken up sponsorship of 21-year-old James Bunn from Pontefract UK, whose apprenticeship as a metallurgical technician at Bridon Bekaert in Doncaster will be developed in a three-year materials engineering degree at Sheffield Hallam University from September. I’m proud to say his degree cost will be completely funded by the trust.

You can read about all the IWMA’s current activities (including our latest, sunshine-bathed, golf event, left)) in this edition of WCN, and note we will be doing another special edition of the magazine for wire India, so please send us information about any products you will have on show for the newsletter (and as soon as possible, if you want to be sure of a mention – free to members).

I’m sure you will agree, all this activity is the prelude to a terrific autumn of business for the IWMA and its many member compa-

Martin Van Der Zwan Chairman, International Wire & Machinery Association

CIMTEQ and AESA have formed a strategic partnership for design engineering, manufacturing and quality control.

“It’s essential that manufacturers improve their productivity and profitability in the face of increasingly complex challenges,” said Cimteq CEO, Ali Shehab.

The cable market is continuously evolving, he says, and new, increasingly stringent requirements are regularly introduced that demand manufacturers consistently boost yield and enhance product quality to remain competitive.

“Our new partnership will combine skills, knowledge and products to offer integrated solutions. Customers will become more profitable by saving materials and increasing quality,” he explained Cimteq provides innovative products to manage the design and manufacturing functions of a cable manufacturing business. CableBuilder and CableMES remove waste, improve quality and traceability, reduce lead time and improve customer service, product design, and data and costing accuracy.

AESA, which has provided leading-edge measuring systems and quality-performance services for 40 years, provides clever and cost-effective solutions that offer clients quality and process improvements. The CIQ quality management system supports additional traceability features, as well as extended quality improvement and data management capabilities.

Ali Shehab said: “The partnership will provide the first system that closes the loop between design engineering, manufacturing and quality control, saving materials and improving product quality.”

Manuel Felder, senior area sales manager for AESA, added: “This cooperation will allow us to provide a full solution for the management of production processes for cable manufacturing, from design to final testing.” www.cimteq.com/www.aesa-cortaillod.com

heating specialist Inductotherm is on schedule to deliver a full, turnkey spring-wire production line for an Italian customer. The line will harden and temper automotive-grade spring wire using Inductotherm’s Radyne-brand IGBT induction technology and process control software. The installation will be capable of processing spring wire from 7mm-17mm in diameter, after which the wire will be used for cold-rolling vehicle suspension springs. The line will be able to produce

3000kg of wire an hour continuously –the highest production volume capability in the industry – while guaranteeing parameters such as hardness, tensile strength, elongation, roundness of cross section, avoidance of physical marking and surface condition.

The line will even be capable of detecting the butt-welds between joined lengths of wire – essential to the capacity of the line – and cutting them out before the finished wire is taken up.

www.inductothermhw.co.uk

DAVID Bell (right) has been appointed managing director of Intras Ltd, the publisher of EuroWire, Wire & Cable Asia, wiredInUSA, Tube & Pipe Technology and Tube Products International magazines.

David has also taken a shareholding in the 34-year-old company and will retain his editorship of the wire titles. After almost eight years with Intras, Jason Smith (left) has been promoted to sales director and will continue to be involved in the sales and marketing activities of the wire magazines.

Caroline Sullens has become chairman of the Leamington Spa, UK-based business, and Mark Sullens continues as a director. The company has also chosen a new logo, which will soon be seen on its marketing materials.

www.intras.co.uk

ALLOY Wire International has broken the £10m annual sales barrier for the first time in its eighth decade in business. Major new orders from nuclear, aerospace and petrochemicals customers have made a major contribution to the success.

AWI supplies more than 60 high-performance alloys and puts its expansion down to customer service – including the ability to offer three-week lead times – and growing demand for its Emergency Manufacturing Service

The company has seen sales increase by £3m in the past 24 months thanks partly to heavy investment in raw metal stock. At any time AWI has up to 200 tonnes on hand, its largest-ever holding and the main reason for its fast job turn-round.

Managing director Mark Venables said: “The recovery in oil and gas has certainly been one of the highlights of recent months. I think at the last count we were exporting to 55 countries.

“We have a fantastic team who know our strategy and work very hard to maintain high standards. Wire is our core offer, but our people deliver the biggest competitive advantage.”

As well as its stockholding, AWI recently invested in an extra 4,000 sq ft of production space and launched its own Wire Finder app to help customers find the right wire for a given application.

Mark concluded: “It amazes the team how far our products go. In the past year we have found out our wire is used in space programmes, in nuclear reactors and in some of the world’s fastest car engines.”

www.alloywire.com

ORGANISER of the world’s major wire and cable exhibitions and IWMA partner, Messe Düsseldorf GmbH, has appointed a new managing director, Wolfram Diener (right).

Diener (54), formerly senior vice president at UBM Asia, that region’s biggest exhibitions organiser, takes over in October from popular outgoing Messe chief Joachim Schäfer, who retired in August.

Diener will control global portfolios health and medical technologies and metals and flow technologies (the latter including the familiar wire and tube exhibitions) and other departments. He will also lead the company’s digital strategy and communication division, established in 2017 to cover IT and in-house services, marketing, advertising and trade-press departments. The appointment brings Diener back to Messe: he began his career there in 1992 and has since worked in trade fair companies and hotels, including Chinese/Messe joint venture the Shanghai New International Expo Centre, and major exhibition centres in Macau and Singapore. He had been a senior vice president at UBM Asia since 2011. www.messe-deusseldorf.de

WITH the continuous opening up of trade policies and structural adjustments to domestic industries in recent years, overseas investors have been feeling a new momentum and vitality in the Chinese market.

And just as Asian companies came en masse to the China Pavilion at wire 2018 in Düsseldorf in the spring, western companies will do likewise at wire China in September, where not one but eight special pavilions will group regional companies across seven halls of the vast Shanghai exhibition centre. China is currently focusing on developing its national infrastructure, public transport, new-energy, architecture and energy-saving industries, both nationally and with partners in the so-called Belt and Road Mission – the modern equivalent of the ancient Silk Road and Maritime Silk Road, which cuts across the major land routes to Europe, and by sea down the Indochina corridor and across the Indian Ocean towards East Africa. The vast area of China itself, not to mention the huge potential of these corridors, offer an excellent opportunity to wire and cable suppliers in Europe and America to export products and technology to the region.

Hundreds of manufacturers, service companies and technology specialists have thus flocked to the China show since it began in 2004. The biggest suppliers from Germany, America, Italy, Austria, France, Japan, South Korea and Taiwan have, if anything, increased their presence at wire China, the second-largest event in the industry after Düsseldorf. The likes of Niehoff, Sikora, Troester, Uhing and many more IWMA members use the show for what it is: the foremost event of the year at which to display the latest technologies to domestic Chinese buyers.

For visitors, of course, this is great news: a chance to learn more about the world's leading products and technologies in the wire and cable (and tube) markets over four days of face-to-face talk with the sources of their raw materials or finished goods. Many Chinese companies send representatives to Düsseldorf but a lot more, who may not be able to afford the time and expense of a technical delegation to Germany, save money and time by waiting a few months for their own show – and make it count.

So what exhibiting companies find, especially on their first visit, is not only an amazingly vibrant and world-class city, but also massively enthusiastic visitors and an impressive chain of exhibition halls.

To provide a better atmosphere and a little more space this year, the organisers have given two wire China outdoor exhibition halls a new look, with red and white decoration and distinctive design conforming to German standards for temporary construction and safety. There is even a red-carpet corridor, connecting the outdoor halls with halls W1 and W2.

Make no mistake, the biennial wire China and Tube China exhibitions are among the most important gatherings of industry professionals of the year.

An estimated 46,000 professional visitors from 95 countries and regions will be there, sourcing products and machines, searching for partnerships and familiarising themselves with the still-huge potential of the Chinese market. See over the page for Messe Düsseldorf China MD Axel Bartkus’s view of prospects for the region

As well as the European market leaders, the trade fair will again feature a German pavilion, supported by the German Ministry for Economic Affairs and Energy. The pavilion will have 15 per cent more exhibitors than last time, and that pretty much sums up this year’s event: significant growth.

MEMBERS of the IWMA can get A Taste of Shanghai on our special Huangpu river cruise on September 28.

The private cruise will take passengers along the Bund – Shanghai’s spectacular riverfront area – while enjoying a delicious buffet of local cuisine with colleagues and friends.

Members and guests – up to three, free, from each member company –will meet at the IWMA stand (W1F42) at 17:45 before transferring by bus to the cruise port. The boat will disembark at around 21:00 and a free bus will take passengers back to the Kerry Hotel, Pudong, where taxis will be available for onward travel.

Tickets are subject to availability and will be allocated first-come, first-served. If you need extra tickets – if available – these can be acquired with a donation to our Educational Trust Fund. Email info@iwma.org for details

Though China’s economic growth doesn’t grab the world’s headlines like it used to five years ago, the country’s powerhouse economy remains a huge world player as we head into wire China 2018.

Certainly the numbers for this year’s wire China are impressive: 98 per cent of stands had been sold by July and exhibition space has increased by four per cent. Two upgraded outdoor exhibition halls will provide exhibitors and visitors with a better atmosphere for communication.

As for the country in which the exhibition occurs, China’s focus now is on preserving its gains of recent years by improving national (and indeed regional) infrastructure

through its Belt and Road policy, and as Messe Düsseldorf China MD Axel Bartkus (pictured left) acknowledges, China continues to play a long game, with plans up to 2025 and beyond.

The focus of wire China has thus changed slightly to take account of regional changes and future developments. If wire China in 2016 was the year of Industry 4.0, 2018 looks into the future with twin themes Made in China 2025 and Internet+.

“The concept of Internet+ is being intoduced in many industries in China now, effectively combining the internet with the industry concerned. Made in China 2025 aims to realise intelligent manufacturing

THE IWMA will be in Shanghai, our stand a great place to do business and enjoy refreshments amid the hustle of the event.

The stand has rooms in which members can hold private meetings with contacts and potential customers, and because of that we will also have a translator on hand to make conversation easier.

Other services on the stand will include free wifi, promotional activity for member companies, business services such as printing and copying, a cloakroom and even credit card facilities – so non-members can buy membership on the spot and get immediate access to IWMA benefits. This year our stand will also feature new services: photography and video. Member companies will be able to have profes-

sional photos taken of their staff or stand, which will be available within 24 hours, so they can be used on a website or social media as the show runs.

Video services will be available at heavily discounted rates – please contact our new marketing specialist Jess (jessica@ iwma.org) to discuss your requirements.

Our evening event in Shanghai, a nighttime cruise on the Huangpu river, offers excellent views of both the Pudong business district and Shanghai’s mightily-impressive waterfront, familiar from a million tourist pictures (see left).

IWMA, UK Stand: W1F42 www.iwma.org

by 2025,” said Bartkus. “The exhibition will display the latest trends of this concept and strategies in the wire & cable sector.”

Two years ago, exhibition organisers suggested the current decade would see major growth in regenerative energies in China. Has anything occurred in the intervening two years, we asked, to change the prediction of growth in infrastructure cabling to accommodate nuclear and green power, electric cars, communications technology and other needs?

“In fact China is focusing on promoting the development of infrastructure, public transport, new energy, architecture and energy-saving industries within the Belt

and Road Initiative countries,” Bartkus said. “Over the programme’s four years, Chinese enterprises signed electric power projects for around $93.76 billion.

“Internet+ smart energy action will bring more than $5.9 billion of investment,” he continued.

“Wind, solar and nuclear power will also play an important role. Market demand for nuclear-grade cable is likely to be $0.16 billion in the Chinese market and $0.06 billion overseas.

“From 2020-2025, the demand for newenergy cars will grow quickly, especially in developing cities, and sales are estimated to grow to around eight million in 2025. This will lead to a greater potential market for charging cables.

“We can expect China’s growth mode to continue to be environmentally friendly and energy saving.

“As for communications technology, the first stage of the 5G standard has been launched and will soon be available for commercial use. Capital expenditure on

5G is likely to reach $223 billion between 2019-2025 – so regenerative energies, electric cars and communication technology are still very promising markets in China.

“We expect wire and cable industry income to reach about $296 billion this year, and by 2023 China will continue to be the leader in the Asia-Pacific wire and cable industry.

“Added to that, the Belt and Road Initiative has already brought large benefits to China and some related countries. Trade import and export among China and the countries that are part of the initiative was $109 million in 2017, which is increasing 17.8% year on year.”

What will this growth mean for the wire China exhibition, we asked. Will it one day rival wire Düsseldorf in size and scope?

“I can’t say wire China will one day rival the size of its mother show in Düsseldorf,” said the man in charge of it, “but I am optimistic about the growth of the Chinese economy…”

ACIMAF Italy W1B25

ACOTEQ GmbH Germany W1E57

Alloy Wire International Ltd UK W1G32

August Strecker GmbH & Co KG Germany W1F60

Aymak Makine Mühendislik Turkey W1F23

Hizmetleri San ve Tic

Balloffet SA France W1D35

BWE Shanghai Ltd China W2D83

Carl Bechem GmbH Germany W1F54

CeramTec Group Germany W1D55

Cimteq Ltd UK W1F36

Condat Lubrifiants SAS France W1D41

Eder Engineering GmbH Austria W1D51

EJP Maschinen GmbH Germany W1F47

Esteves Group (Shanghai) China W1A31

FMS Force Measuring Systems AG Switzerland W1B42

Fort Wayne Wire Die, Inc USA W1G15

Gauder & Co SA Belgium W1F25

Golden Technologies Wire & Cable China W2D63

Equipment Co Ltd

Gwo Lian Machinery Industry Co Ltd Taiwan W1A75

H Folke Sandelin AB Sweden W1F63

Hipo Electrix Science & China, W3F63

Technology Co Ltd

Intras Ltd UK W1G26

Jiangsu Handing Machinery Co Ltd China W2D03

Joachim Uhing GmbH & Co KG Germany W1D48

Kieselstein International GmbH Germany W1F52

Maillefer Extrusion Oy Finland W1F24

Medek & Schörner GmbH Austria W1D45

Metalube Ltd UK W1F38

Microdia SA Switzerland W1C55

Nanjing Zhongchao New China W5D43

Materials Corporation

Maschinenfabrik Niehoff Germany W1F63

GmbH & Co KG

Ningbo Kaite Machinery Co Ltd China W4E78

Proton Products International Ltd Belgium W1D82

Qunye Electrical Co Ltd China W2C43

Rautomead Ltd UK W1B36

Reber Systematic GmbH Germany W1F55

RichardsApex Inc USA W1F20

Roblon AS Denmark W1G14

Rosendahl Nextrom GmbH Austria W1D43

Shanghai Geili Precision Dies Co Ltd China W4B85

Shanghai Kechen Wire & China W2B23

Cable Machinery Co Ltd

Sikora AG Germany W1F62

Sinoleader Industries Group Co Ltd China, W4B77b

Sket Verseilmaschinenbau GmbH Germany W1E60

Sneham International India W1A47

Tianjin Huayuan Times Metal USA W5A31

Products Co Ltd

Traxit International GmbH Germany W1G48

Troester GmbH & Co KG Germany W1F43

Vinston Machinery Ltd USA W5C03

Zeller+Gmelin GmbH & Co Ltd Germany W1A41

Zumbach Electronic AG Switzerland W1E22

MAILLEFER’S stand in China will feature the company’s latest machine digitalisation developments and will introduce a Smart Factory virtual-reality experience for real-time production optimisation.

Maillefer Smart Factory combines a physical factory model with additional instrumentation and predictive online diagnostics. Using the show’s virtualreality application, visitors can simulate different factory production parameters and set-ups.

Maillefer is also launching a turnkey solution for factory-made submarine cable joint processing and manufacturing.

Among other innovations are a new Smart Dosing technology for peroxide and antioxidant in-line dosing, and new compression technology for fibreoptic cables that improves fibre length control.

Maillefer will also have a new nonlinear modelling tool for rubber cable producers, and the Round Premium Value Package, an industry breakthrough for VCV lines.

Maillefer Extrusion Oy, Finland Stand: W1F24 www.maillefer.net

THE Tianjin Huayuan Industry Company stand at wire China will feature the company’s extensive range of galvanised wires (EG, HDG & ZnAl), PVC-coated wire, wire rope, gabion mesh, T-posts, moulds and an assortment of fabricated products. In the 25 years since it was founded, Tianjin has grown to cover 800 acres, employ almost 3,000 workers, record a net worth of around £230 billion and export around 500,000 tonnes of wire products a year to over 70 countries.

Tianjin Huayuan Times Metal Products Co Ltd, USA Stand: W5A31 www.huayuanwire.com

GLOBAL lubricants specialist Metalube Ltd will showcase its latest innovations in lubrication technology at wire China, as well as offering advice and information on its entire range of non-ferrous wire-drawing lubricants. Though traditional lubrication techniques continue to meet many industry challenges, Metalube has identified processes requiring improvement and will be promoting two new products to improve the wire-drawing process in two demanding areas.

New product Lubricool 250B is a fully-synthetic wire-drawing lubricant for copper and plated copper wires on high-speed multi-wire drawing machines. The oil-free chemistry on which Lubricool 250B is based delivers maximum cleanliness and lubrication on multiwire machines drawing down to 0.050mm. The product helps in leaving drawing cones and dies debris-free, to reduce breakage and achieve optimum line speeds, ease of filtration and bio-stability.

Second new product Alumol 615W is a water-miscible aluminium wire-drawing lubricant for rod, intermediate and multi-wire machines. The traditional weaknesses of neat oil technology in the drawing of aluminium wires on highspeed slip machines are greatly reduced in the water-miscible alternative. The lubricant offers significant improvements in machine cleanliness and operator acceptability, as well as ease of filtration and cleanliness of the drawn wire. The product is particularly suitable for automotive and enamelled wire production. Global product manager Albert Molloy said: “wire China is a great platform for us.”

Metalube exports 95 per cent of its production to over 90 countries worldwide and has offices in Manchester, Dubai, Mumbai, São Paulo and Shanghai. The Manchester base has a fully-integrated lubricant manufacturing facility and state of the art laboratories.

Metalube Ltd, UK Stand: W1F38 www.metalube.co.uk

CABLE extrusion systems manufacturer Troester GmbH & Co will be at wire China through its local subsidiary, Troester Machinery Shanghai, which is responsible for sales, service and production for the domestic Chinese market. The company team (right) will demonstrate its wide product range, including new developments in CCV and VCV Lines for medium, high and extra-high voltage cables up to 1000kV; rubber CV and CCV-Lines up to 35kV; silicone insulation lines with TRIOX ovens and production equipment for submarine cables.

kneader technology for the continuous compounding of HFFR (LSOH), PVC, XLPE, semi-conductive materials and EPR/EPDM.

Troester’s range encompasses everything from CV Lines for XLPE and rubber cables and silicone insulation lines to a complete range of downstream equipment, such as winders, capstans and accumulators.

Troester subsidiary X-Compound, which specialises in complete systems for the compounding of plastics, will present

Troester GmbH & Co KG, Germany Stand: W1F43 www.troester.de

FORCE Measuring Systems AG has new strand-tension monitoring and control devices on show in Shanghai FMS’s radio-transmission tension monitoring systems precisely measure wire tension in cage and tubular-type stranding machines, to give more consistent product quality. In conjunction with new RTM monitoring and control software (right), the system offers fully-automated, closed-loop tension control, improved visibility and easier operation, with a recipe manager, continuous data logging and easy generation of quality reports offering full data.

The software also has newly integrated user administration and safety features.

Also new is the FMS Cradle Guard (below right), which offers wireless transmission of safety-relevant signals from the pay-off cradle to the operator's station. Cradle Guard is wireless and battery-powered and has no need for slip rings (two standard 9V batteries last for several months).

It is also compact, easy-to-retrofit and capable of being fitted in most machines.

The design is robust for production environments, offers four inputs for pintle lock status, cradle tilt alarm and other functions, offers text message location of faults and a single modular system can monitor up to 42 cradles.

FMS Force Measuring Systems AG, Switzerland Stand: W1B42 www.fms-technology.com

CONDAT will share its expertise on wire-drawing lubrication at wire China, with new formulations for the Asian market as well as its existing wide product range. To reduce residues, limit costly degreasing operations and improve wire quality, Condat’s new range of water soluble Vicafil SL soluble oils meets the latest wet-drawing requirements. Enhanced with biocide and anti-foaming properties, the Vicafil SL range can be used for drawing low- or high-carbon steels with various surface preparations, whether bare or pre-drawn wire, acid-picked and phosphate-coated wire to galvanised wire. Vicafil SL is easy to put in solution and leaves a clean surface finish.

Steel cord production requires not only high-speed running but also a high level of quality and finish on the wire. New Condat developments answer these requirements – even for extra-high-tensile steel cord.

These include an additive for borax surface treatment baths to improve the coating weight deposit on the wire, which assists lubricant pick-up and extends die life. New, high-performance, low-borax and borax-free sodium-based soaps for high-speed drawing, allow low lubricant consumption and excellent surface finish. A water-soluble polymer-based product replaces lead-based wire-patenting operations and offers a cleaner working environment.

Condat Lubrifiants SAS, France Stand: W1D41 www.condat-lubricants.com

AUSTRIAN cable marking and coating specialists

Medek and Schörner will display their latest Industry 4.0 developments in wire China’s Austrian pavilion.

The company’s newest machines have network capability and offer intelligent camera supervision, and ringmark and colour-loss detection. Cameras monitor production and can collect full data for extensive evaluation of the finished item.

Medek and Schörner have combined several processes, enabling the machinery to colour and ringmark, as well as proof-test, optical fibres for better workflow.

Inline proof testing is designed for speeds up to 300m a minute. The machines are equipped with extensive diagnostics systems, even allowing break positions to be captured for microscopic analysis. The developments are part of a range of products for cable marking and optical fibre coating and testing.

Medek & Schörner GmbH, Austria Stand: W1D45 www.medek.at

MICRODIA of Switzerland will be attending wire China through subsidiary Microdia Asia Pacific.

The local branch of the company is located in Shanghai’s Swiss Centre, a pilot free-trade zone near Pudong airport, opened in 2016.

Microdia’s booth at wire China will display fully-functional examples of the company’s best-selling crossheads. Mandarin, English, French, German and Italian speakers will be on hand to help with inquiries and technical information.

Microdia SA, Switzerland Stand: W1C55 www.microdia.ch

SWISS manufacturer of on-line measurement systems, Zumbach, will be displaying its latest Profilemaster systems at wire China, developed from a core set of proprietary camera and laser modules and software.

Zumbach’s technologies measure dimensions and detect surface flaws during the production of extruded plastic and rubber tubes, hoses, profiles, wire and cable, plastic composites, steel rod, bar, profiles and even wood and other materials.

The company offers a full range of Profilemaster gauges, dependent on the user’s application, and even has models for small, precision profiles from 0.5mm coldformed tubes and profiles, as well as medium-sized products up to 600mm. Profilemaster systems are available with up to eight laser and camera modules, which continuously measure the cross-section of the moving profile. A powerful PC-based processor combines the images from individual cameras to produce an instant profile cross-section, with dimensions such as width, height, angle and radius or other

geometric quantities computed to give a full picture of the material being worked. Zumbach claims the Profilemaster system can effectively reduce start-up time, offer complete, real-time inspection, improve repeatability, reduce scrap, quickly detect

problems and eliminate the need for postproduction inspection.

Zumbach Electronics AG, Switzerland Stand: W1E22 www.zumbach.com

CONNECTICUT company Wire and Plastic Machinery will be exhibiting at Shanghai with pictures, video, and an interactive presentation of its inventory.

Rahul Sachdev and Erik Macs will be on the stand and will be happy to help potential customers select the most suitable equipment for their needs.

Wire & Plastic Machinery Corporation is the largest reseller of high quality, secondhand wire, cable and optical-fibre manufacturing equipment for wire drawing,

stranding, bunching, cabling, braiding, extrusion and other cable-making needs. Machines are offered in any combination, from individual components to complete lines and can be delivered immediately from eight US locations or completely reconditioned in-house. The company has around 30,000 machines for all aspects of non-ferrous wire and cable production.

Wire & Plastic Machinery Corp, USA Stand: W1G05 www.wireandplastic.com

AHIGHLIGHT of the Sikora stand at wire China will be the new X-ray 8000 Advanced system (right), offering high speeds tailored to the demands of MV, HV and EHV cable production.

The new machine offers an advanced alternative to the well-established X-Ray 8000 NXT, and is equipped with 16 sensors to measure the diameter, wall thickness and eccentricity of cables in CV lines up to 10 times faster than the NXT.

Centring the cable is easy, as each change of the centring screws is immediately registered and visualised. Four times more measuring points than the NXT means almost instant measurement and control – both factors optimising cable quality at maximum material and cost savings. High Speed Technology (HST) is Sikora’s latest innovation, with a focus on efficiency enhancement due to fast centring and the automatic control of product parameters. For the fast update of scan data, the system optimises scanning time by automatically adapting the scan path to the cable diameter.

Sikora will also show a drawing tower model (left) featuring the company’s broad range of measuring systems for optical fibre quality control.

Systems fitted to the tower will measure the diameter, position and tension of the naked and coated fibre. Gauge heads measure the fibre temperature at the hot and cold ends of the drawing process, either for control of the furnace or to assess the helium dose for cooling, reducing costs in each case. A head for the evaluation of the concentricity of the coating, as well as for the detection of lumps on the coated fibre’s surface, will also be on show.

In the field of plastics, Sikora’s purity scanner will be on the stand. The system’s combination of X-ray and optical cameras is currently the only technology that can reliably detect contamination both on the surface and inside plastic pellets, then automatically reject contaminated pellets.

Sikora AG, Germany Stand: W1F62 www.sikora.net

KIESELSTEIN is exhibiting at China’s most important trade show for the wire industry.

China is a major trading partner for Chemnitzbased machine man ufacturer, whose wire-drawing and wire-shaving machinery has established a strong hold in the Asian market.

The show will see the company’s latest machine engineering and staff will inform visitors about the latest approaches in wire shaving and drawing.

also add comprehensive production support, maintenance and servicing. Its digital products are also available to customers for their own production systems. Staff have expertise in production opti-

Kieselstein offers machines for a wide range of wire materials and diameters, for steel, aluminum or titanium wire shaving, hot-drawing, wet-drawing and wire coating.

The company offers product modifications to suit individual customers and can

misation and implementation, commissioning support and operating trials, as well as retro-fitting to existing plants, and can advise on all such matters.

Kieselstein International GmbH, Germany Stand: W1F52 www.kieselstein.com

EDER Engineering GmbH has been active in China for 40 years. Among items on display at wire China from the Austrian company will be machines for the working of tungsten carbide dies (model ETC-1/HF) and the uniquely-efficient ultrasonic ma chine USP-Twin (right), for achieving double output when working diamond and PCD dies.

Eder offers efficient and technically leading-standard semi-automatic and fully automatic machines covering the reconditioning and production of ultra-hard precision drawing die tools made from tungsten carbide, natural diamond and synthetic PCD. It also offers technical assistance for all advanced equipment and for advanced die-tool processing.

Eder Engineering GmbH, Austria Stand: W1D51 www.eder-eng.com

A Karpat Ltd Canada

ACIMAF Italy

ACOTEQ GmbH Germany

Acuity Products Ltd UK

AESA Cortaillod Switzerland

AFH-Antriebstechnik GmbH Germany

Ajex & Turner Wire Dies Co India

Aleados del Cobre SA Spain

Aliaj Fanar Omid Industrial Co Iran

Alloy Wire International UK

Ambrell Group Netherlands

Anglia Metal Ltd UK

Arcelor Mittal Luxembourg

Associated Engineers & Industrials Ltd India

AstroPlast, Kunststofftechnik GmbH & Co KG Germany

August Strecker GmbH & Co KG Germany

Australasian Wire Industry Association Australia

Automated Wire Bending Ltd UK

Aversion Technologies Europe SL Spain

Aymak Makine Mühendislik Hizmetleri San ve Tic Turkey

Badger Wire Australia

Balloffet SA France

Bar Products & Services Ltd UK

BASEC (British Approvals Service for Cables) UK

Bonakdar Ind & Com Group Iran

Bongard Machines GmbH & Co KG Germany

Bridon International Ltd UK

British Diamond Wire Die Co Ltd UK

BSC Corporation Ltd China

BWE Ltd UK

Cable Tapes UK Ltd UK

Calmec Precision Ltd Canada

Cape Gate (PTY) Ltd UK

Carl Bechem GmbH Germany

Ceeco Bartell - Bartell Machinery Systems USA

Cemanco LC USA

Central Wire Industries UK Ltd UK

CeramTec GmbH Germany

Chaplin Bros (Birmingham) Ltd UK

Chemetall Ltd UK

Cimteq Ltd UK

Commission Brokers Inc USA

Comsuc Technology Development Ltd China

Condat Ltd France

Consultex SP Zo o Poland

Control and Power Engineering Ltd UK

Copperweld Bimetallics UK Ltd UK

CRU Events UK

CSM Metalurji Imalat Sanayi Ve Muhendislik Ltd STI Turkey

Danross Engineering UK

De Montfort University UK

Deutsches Kupferinstitut Berufsverband EV Germany

DLB Draht und Litzen GmbH Germany

Dongguan XinMei Precision Mold Co Ltd China

Drahtwerk Waidhaus GmbH Germany

DRT Impianti SRL Italy

DSE Test Solutions AS Denmark

Ducab UAE

E Braude (London) Ltd UK

Eder Engineering GmbH Austria

EFD Induction AS Norway

EJP Maschinen GmbH Germany

Er-Bakir Elektrolitik Bakir Mamulleri AS Turkey

Esteves Group Spain

Eurobend GmbH Greece

Eurotek SRL Italy

FH Machinery USA

FIB Belgium SA Belgium

Fisk Alloy Conductors BVBA Belgium

FMS Force Measuring Systems AG Switzerland

Fort Wayne Wire Die Inc USA

Foxton Dies Ltd UK

Frontier Composites & Castings Inc Canada

Fuchs Lubricants (UK) PLC UK

G & A Engineering Ltd UK

G Church - Consultant UK

Gauder Group Belgium

Geca-Tapes BV France

Gem Gravure Co Inc USA

GEO Reinigungstechnik GmbH Germany

Golden Technologies Wire & Cable Equipment Co Ltd China

Goodwin Machinery Ltd UK

Guidetti SRL Italy

Gurfil Sanayi VE Elektronik Cih Paz AS Turkey

Gwo-lian Machinery Industry Co Ltd Taiwan

H&R ChemPharm (UK) Ltd UK

H Folke Sandelin AB Sweden

Häfner & Krullmann GmbH Germany

Hans Schmidt & Co GmbH Germany

HB Cables & Components Ltd UK

Heinze & Streng GmbH Germany

Hipo Electrix Science & Technology Co Ltd China

Hoang Hung Long Co Ltd Vietnam

Holton Crest Ltd UK

Huestis Industrial USA

Huntstar Trading Ltd UK

ICE Wire Line Equipment Inc Canada

Inductotherm HWT (Radyne) UK

Induflex NV Belgium

InnoVites BV Netherlands

Institute of Spring Technology Ltd

Integer Research Ltd

Interlink Ltd

International Trade Shows Link Ltd

Intras Ltd

Itaya Europe Ltd

JG Tec Ltd

Jiangsu Handing Machinery Co Ltd China

Jina Special Steel Works Pvt Ltd India

Joachim Uhing GmbH & Co. KG Germany

John Binns & Son (Springs) Ltd UK

Kabel.Consult.Ing Germany

KamKat LLC Russia

Kelani Cables PLC Sri Lanka

Kieselstein International GmbH Germany

Knight Precision Wire Ltd UK

Koner SpA Italy

LA.M.Plast SAS Italy

Lanfang Xinming Cable Machinery Ind Co Ltd China

Lanka Special Steels Ltd Sri Lanka

Lantor BV Netherlands

Leggett & Platt Wire Group USA

Leoni Temco Ltd UK

Leviton UK

Lewis Wire Ltd UK

Locton Ltd UK

Lune CHF GmbH Germany

Madem SA Ind E Com de Madeiras Brazil

Maillefer Extrusion Oy Finland

Manentimacchine SRL Italy

Marldon Group Ltd UK

Mathiasen Machinery Inc USA

Medek & Schörner GmbH Austria

Meisenbach GmbH Germany

Metalube Ltd UK

Microdia SA Switzerland

Mikrotek Machines Ltd India

MSS Products Ltd UK

Nanjing Zhongchao New Materials Corporation China

Nano-Diamond America Inc USA

NDC Technologies (Beta LaserMike Products) USA

NeoFil Ltd UK

Nexans Deutschland GmbH Germany

Niehoff Maschinenfabrik GmbH & Co KG Germany

Ningbo Kaite Machinery Co Ltd China

Nota-Zaklad Mechaniki Precyzyjnej Poland

NV Bekaert SA Belgium

OMA SRL Italy

OB Mallas SRL Bolivia

OMA (UK) Ltd UK

Ormiston Wire Ltd UK

P F Consulting UK

Pan Pioneer Co Ltd Taiwan

Paramount Conductors Ltd India

Peddington Lubricants and Coating Pvt Ltd India

Pentre Group Ltd UK

Performance Springs Ltd UK

Permanoid Ltd UK

Plasmait GmbH Austria

Pneuform Machines Ltd UK

Premier Cables (Pty) Ltd Pakistan

Pressure Welding Machines Ltd UK

Proton Products International Ltd Belgium

Prysmian Group UK

PS Costruzioni Meccaniche SRL Italy

Q8Oils Belgium

QED Wire Lines Inc Canada

Qingfeng Electrical Technology (Hong Kong) Co Ltd Hong Kong

Queins Machines GmbH Germany

Qunye Electrical Co Ltd China

Rautomead Ltd UK

Ravicab Cables Pvt Ltd India

Reb Mech Pvt Ltd Canada

Reber Systematic GmbH Germany

Redies SRL Italy

Reelex Packaging Solutions Inc USA

RichardsApex Inc USA

Ridgway Machines Ltd UK

RK Umformtechnik GmbH & Co KG Germany

Roblon AS Denmark

Rosendahl Nextrom GmbH Austria

S K Wiring Products Ltd

UK

SACO AEI Polymers UK Ltd UK

Sanxin Wire Die Inc USA

Sarkuysan Elektrolitik Bakir Sanayi ve Tic AS Turkey

Scapa UK Ltd UK

Scott Precision Wire Ltd UK

Shanghai Geili Precision Dies Co Ltd China

Shanghai HOSN Machinery Technology Co Ltd China

Shanghai Kechen Wire & Cable Machinery Co Ltd China

Shanghai Singcheer Technology Co Ltd China

SHI Kabel GmbH & Co KG Austria

SI Interline Ltd Russia

Siebe Engineering GmbH & Co KG Germany

Sikora AG Germany

Simplex Rapid SRL Italy

Sinoleader Industries Group Co Ltd China

SKET Verseilmaschinenbau GmbH Germany

Smeets NV SA Belgium

Sneham International India

South African Wire Association South Africa

Spring Tooling Ltd UK

Stonepark Consultancy Ltd UK

Stride Supplies Ltd UK

Supermac Industries India Ltd India

T Fukase & Co Ltd Japan

TapeFormers Ltd UK

Techna International Ltd UK

Techno Commerce Ltd UK

Technokabel SA Poland

The Worshipful Co of Tin Plate Workers Alias Wire Workers UK

Thermogreen Solutions Czech Republic

Thompson & Hudson Wire Machinery UK

Tianjin Goldsun Wire Rope Ltd China

Tianjin Huayuan Times Metal Products Co Ltd USA

Traxit International GmbH Germany

Troester GmbH & Co KG Germany

U Gear Automatic Machinery Ltd Taiwan

UL International (France) SA France

University of Southampton UK

Uniwire Ltd UK

Untel Kablo AS Turkey

Uygar Makina San.Ve Tic Ltd STI Turkey

Vietnam Electric Cable Corp (CADIVI) Vietnam

Vinston US Corp USA

Warbrick International Ltd UK

WCISA c/o Wire Lab Co USA

Weber & Scher Mfg Co Inc USA

Webster & Horsfall Ltd

White & Street International Ltd

Whitelegg Machines Ltd

Windak Group

Wintwire Ltd

Wire & Cable Technology International

Wire & Plastic Machinery Corp

Wire Association International Inc

Wire Lab Co USA

WOLCO Sp Zo o Poland

WTI Fasteners Ltd UK

XL Technologies UK Ltd UK

Yangzhou Havet Machinery Co Ltd China

YTC America Inc USA

Zeller+Gmelin GmbH & Co KG Germany

Zumbach Electronic AG Switzerland

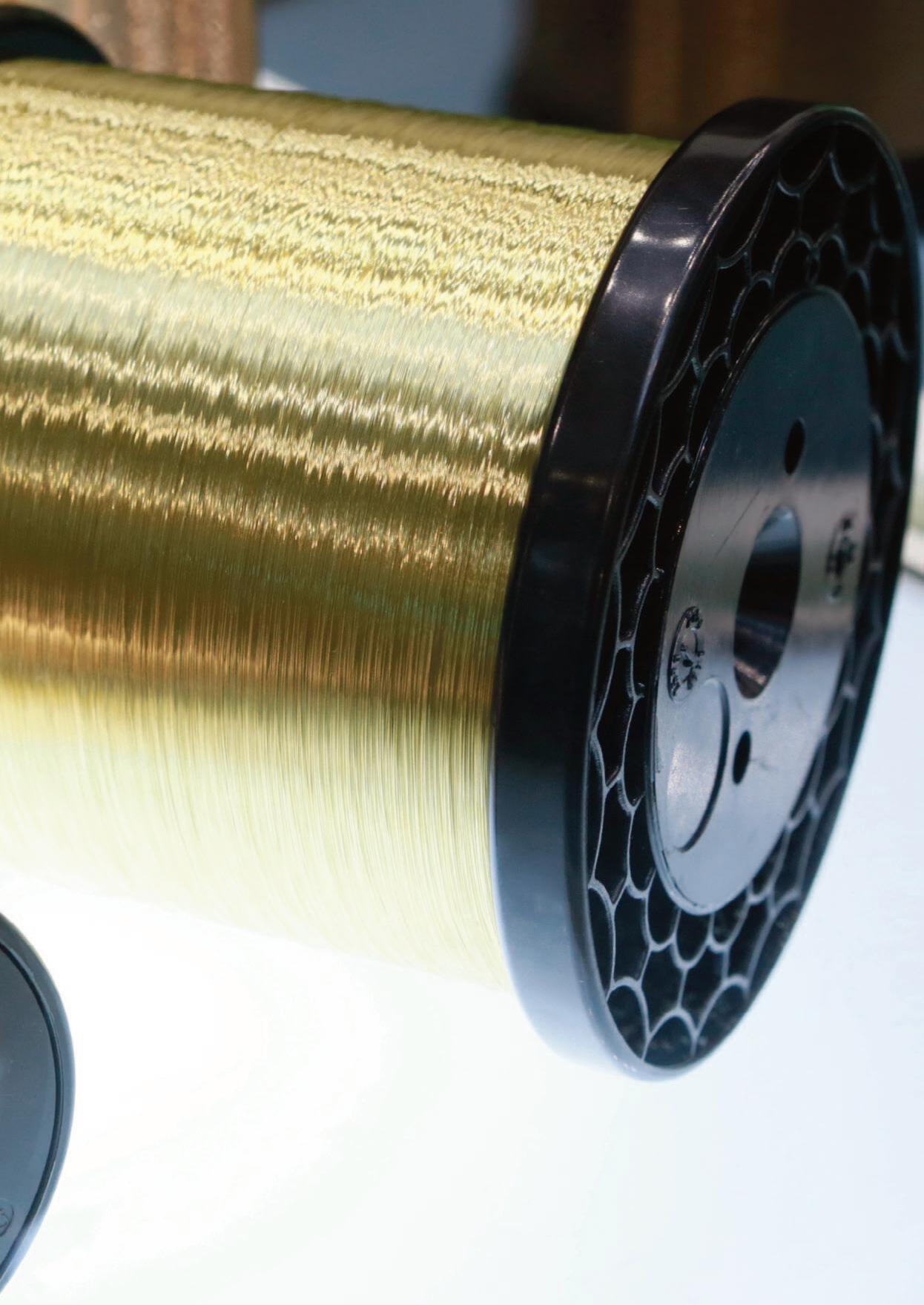

THE statistics speak for themselves: the wire and cable industry’s lull of recent times seems well and truly over, if wire 2018 is any indication.

A total of 1,442 exhibitors from over 50 countries in Düsseldorf presented technology highlights to over 70,000 visitors (up more than three per cent on 2016) from more than 130 countries across 65,000sq m of eight exhibition halls – that figure almost eight per cent up on the previous exhibition. As usual, most exhibitors were from the traditional industrial nations of Europe, but a significant number had travelled from the Americas, south east Asia and China.

Around 70 per cent of visitors were international, a third of these from overseas.

There was a new buoyancy throughout the halls, reflecting rapidly-filling order books across the industry and greater international investment in infrastructure projects demanding large quantities of cable and wiring, from communications to transport and energy supply to automobiles.

It has often been said that the metals industries are a good indicator of the state of industry in general –in which case the world economy, if not booming, is at least on the road to recovery.

A highly international feel to the fair this time promised wide contacts, contracts and excellent follow-up business.

Over half of the exhibition’s visitors reportedly arrived with an intention to invest – and over twothirds of visitors were senior managers and executives with the power to make decisions.

IWMA staff welcomed many members at the stand (pictured right) and the business centre was well used for client meetings and to talk to colleagues. Refreshments helped the conversations flow and good use was made of our stand’s meeting room and seating.

Show research indicates that trade visitors were primarily interested in machines for processing and producing wire and cable, steel bar and strip and process engineering tools, as well as all the usual machines, equipment, tools and auxiliaries.

Forming technology and auxiliary materials were also in high demand at the show, with around 20 per cent of visitors polled claiming an interest in finished products.

Recently-retired managing director of organisers Messe Düsseldorf GmbH, Joachim Schäfer was delighted by the results of the five-day event. “We have once again succeeded in offering the wire, cable and pipe industries a global platform in Düsseldorf as a basis for business,” he said.

The IWMA capitalised on its imposing presence by signing up nine new member companies and resigning two former member-companies during the exhibition.

So a warm welcome from IWMA management to Acuity Products Ltd, AESA Cortaillod, Aversion Technologies Europe SL, Comsuc Technology Development Ltd, Deutsches Kupferinstitut Berufsverband eV, Golden Technologies Wire & Cable Equipment, Hipo Electrix Science & Technology Co Ltd, Pan Pioneer Co Ltd, Ravicab Cables Ltd, Thermogreen and Uniwire Ltd.

Find

BAR Products & Services Ltd’s wire strand compaction technology is becoming popular worldwide The company has supplied six of the units to clients so far this year and inquiries from the USA, Europe and China look likely to result in more orders. Several companies have placed second and third orders.

The units, which combine four pairs of profiled rollers and can be used on carbon and stainless ca bles, are designed for ease of installation and opera tion thanks to their short set-up time, rollers that can typically be changed in a few minutes, and a design that allows rapid repair of stranding problems with minimal downtime.

COTT Precision Wire of Manchester UK has appointed Martin Barr as its managing director, succeeding Dave Austin, who has continued to support the business following his retirement. Martin has worked in commercial and sales roles in the resistance and thermocouple wire industry for nearly 25 years – for the past five years as sales director at Scott Precision Wire. Chairman John Broadhurst said: “Dave enjoyed nearly 10 years as business leader here and has transformed the business and developed the hard-working and dedicated team we are today. We will miss Dave, but know we can count on his experience, knowledge and enthusiasm as Martin takes over.”

www.scottprecisionwire.com

Bar offers rollers to suit any stranding requirements and can supply sets worldwide. Units are available for 2mm-40mm strand diameters, and com paction can be ap plied to a full range of con structions, with compaction levels from 5%-25%, de pending on construction and the wire’s tensile grade.

www.barproductsandservices.com

AJEX & Turner ‘s revolutionary TCD-10 grinds and polishes angles and bearing in one operation, which saves time, energy and is highly costeffective, with savings on diamond slurry and paste and reduced power consumption.

The 24,000rpm machine can recondition dies quickly, providing accurate and precise angles on re-cut dies. Customers can achieve a mirror polish using diamond suspension and steel pins with compressed air pressure. The TCD-10 is suitable for die holes size 0.5mm-20mm.

www.ajexturner.com

IWMA member CeramTec has won a second coveted Innovation Through Research award in three years from Germany’s Stifterverband science and technology foundation.

The industrial ceramics expert is among less than one per cent of German companies actively engaged in research and development to develop new products and create innovation and growth. CeramTec previously took the award in 2016. The company supplies advanced ceramic components for automotive, electronic, construction and industry sectors, and

has more than 3,500 employees and production sites and subsidiaries in Europe, America and Asia.

Stifterverband is one of the largest private promoters of science in Germany and offers awards after a thorough investigation of the candidate’s budget for research and development, R&D personnel and other considerations. Stifterverband’s collected data is also used by the German government to help to chart Germany’s economic, innovation and technology policy.

www.ceramtec.com

ENERGY and telecom cable systems group Prysmian has won a contract to develop a submarine cable system for the Borssele III and IV offshore wind farms.

The farms are part of a large wind farm zone near the southern border of the Dutch exclusive economic zone, about 25km offshore, and will have a total capacity of 731.5MW – just under 10MW per turbine.

Prysmian will design, manufacture, supply and test about 175km of 66kV, three-core cable with XLPE insulation of various cross-sections, plus all related accessories. All cables will be produced in Prysmian’s centre of excellence in Pikkala, Finland, and delivery is expected in early 2020.

“This award confirms our leading role in the development of offshore wind farms in Europe and in the growing

inter-array market,” said the company’s projects executive vice president, Hakan Ozmen.

The farms will provide sustainable, and CO2 friendly electricity to more than 800.000 Netherlands households as part of a wider government energy plan aimed at providing 16 per cent of total generated electricity from renewables by 2023.

www.prysmiangroup.com

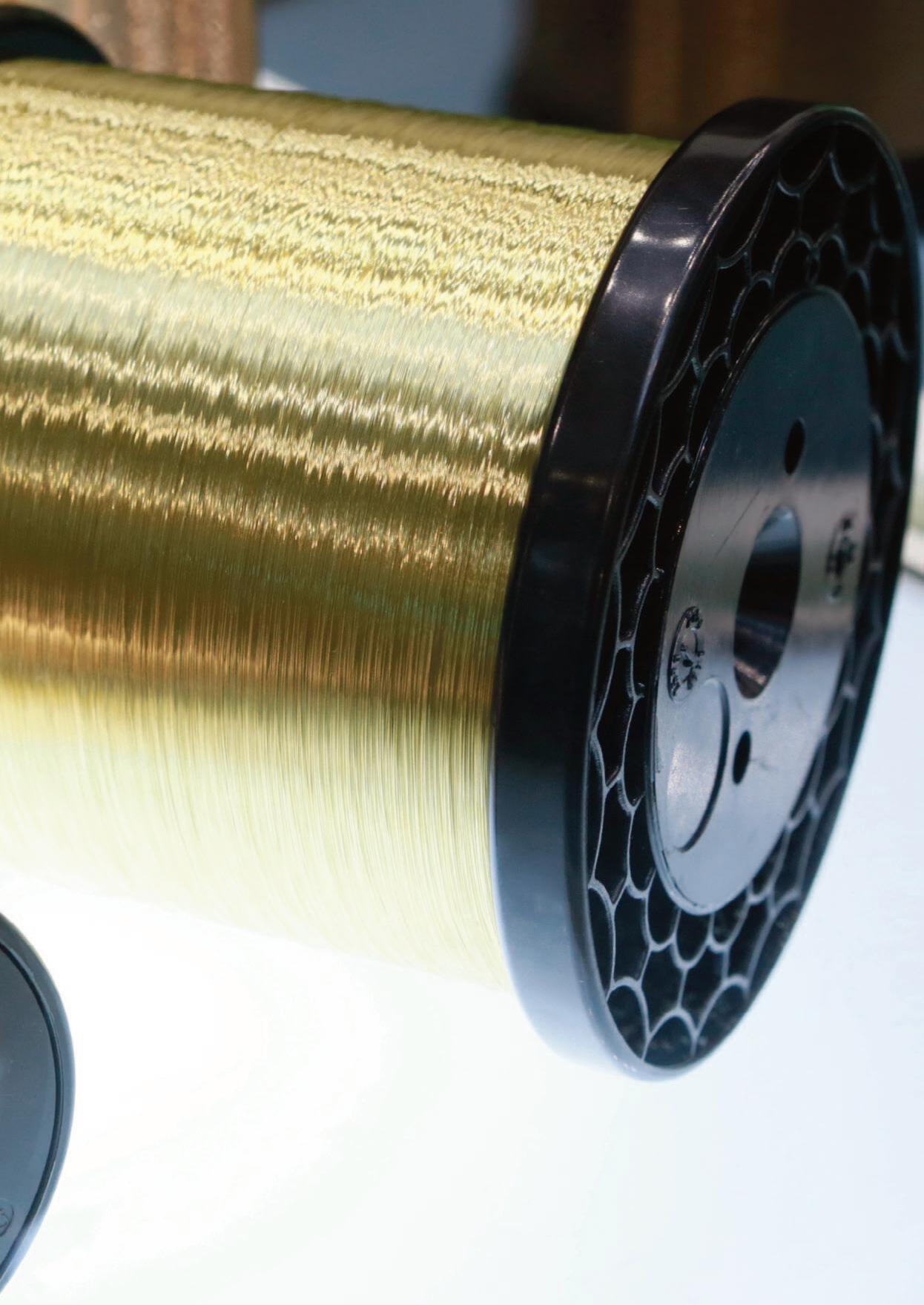

BEKAERT Group is to buy out a teaching pension fund’s share in the Bridon Bekaert Ropes Group, to take the subsidiary back into full Bekaert Group ownership. The Ontario Teachers’ Pension Plan held a 33 per cent share in BBRG, which was formed in June 2016 when ropes company Bridon Group merged with the steel ropes and advanced cords businesses of the Bekaert Group. The companies had been close partners as separate companies.

Bekaert Group CEO Matthew Taylor said it made sense for the company to follow this direction: "Taking full control will allow us to drive greater synergies between BBRG and the Bekaert Group

and take advantage of the complementary nature of the businesses,” he said. Taylor has assumed the role of CEO of the ropes business, replacing former CEO Bruno Humblet.

The agreement, subject to various conditions and approvals, is expected to be completed soon.

Bekaert Group is based in Belgium and employs almost 30,000 people. It is the world's largest independent manufacturer of drawn-steel wire products, with sales of more than £4.2 billion a year. The Bridon Bekaert Ropes Group accounts for 2,500 of those employees and had a turnover of just over £400 million in 2017. www.bridon-bekaert.com

NEW Leoni CEO Aldo Kamper (right) is to take up his new role earlier than planned, to help lead a major transformation.

One of Mr Kamper’s principal jobs will be to drive Leoni’s realignment in line with increasing industry digitalisation, and to accommodate future trends such as electro-mobility and autonomous driving.

The company is gaining ground in automotive and other industries as a global provider of energy and data-management solutions.

“I am pleased Mr Kamper will start here sooner than planned,” said the chairman of Leoni’s supervisory board, Dr Klaus Probst. “Business performance has been very encouraging recently, meaning he starts in a favourable setting.”

“I’m really looking forward to my new role,” said Mr Kamper. “The company has an impressive history and very good prospects. The transformation towards becoming a solutions provider as well as development and systems partner to customers is a challenge I’m happy to face.”

Karl Gadesmann will continue his role as chief financial officer.

The Leoni group is a global provider of products and services for energy and data management in the automotive and other industries, covering wire, optical fibres, standard and specialised cables and systems, intelligent products and smart services.

The group employs more than 87,000 people in 31 countries

www.leoni.com

ROSENDAHL

Nextrom reckons it has created the fastest loose-tube coating line for fibre-optic cables – and has proved it by pitting its speed against that of project manager Thomas Köck!

Thomas (right) runs the 35.8m line in 6.49s – but the line runs three times faster, at around 60kph. The line offers speed and precision operation over a wide product range, great repeatability thanks to production monitoring and tube wall thicknesses down to 0.15mm, making it ideal for much-in-demand, small sized products.

The line’s crosshead is optimised for secondary coating lines both for dry and jelly-filled applications and its clenching capstan minimises excessive shrinkage of the tube during production. A longer life cycle, high uptimes and easy operation, with online monitoring, support reliability, and there are fibre cutter, rewinding mode and dual take-up for automatic reel changes.

www.rosendahlnextrom.com

CALIFORNIAN wire and cable instrumentation company Proton products Inc has moved to Industry 4.0 compliance on a broad suite of its intelligent products, communications protocols and flexible automation capability. Compliance is based on three technology trends: connectivity, intelligence and flexible automation. Proton was among the first companies to offer smart field instruments, namely the InteliSENS range, using embedded Ethernet TCP/IP, RS232 and CANbus communications.

Ethernet IP, DeviceNet, ProfiBus, ProfiNet, Bluetooth and wifi have since been added, allowing these to be networked with PLC, DCS and other compliant platforms.

Plantwide connectivity has helped Proton’s customers to bridge their digital and physical assets.

The Proton Products InteliSENS family also

neck defects, temperature, insulation capacitance and spark testing. Diameter measurement can be achieved at up to rates of up to 10,000 scans per second per axis, and speed and length measurements of 200kHz. These intelligent sensors provide reliable data sources for high-value process modelling, advanced controls and information analysis.

Operators can now also view InteliSENS data on tablet devices in real-time.

supports intelligent decision-making for the wire and cable industries, with fast, accurate data. Measurement includes wire speed and length, wire diameter, lump and

In terms of flexible automation, Proton has continued to collect, share and analyse information with customers to help build their digital environment. InteliSENS digital concepts and integrated solutions now offer a modular approach to the value chain that supports the smart factory concept with physical measurement, connectivity and intelligence to minimise production cost and maximise output.

www.protonproducts.com

UK SPRING wire supplier Stride Supplies of Redditch, West Midlands, has achieved BSI certification, opening up new opportunities in global aeronautical engineering markets.

Certification to prEN9120:2016 and ISO 9001:2015 is recognised worldwide as a standard of operational and product quality, paving the way for the company to look for customers in new markets.

“We’re delighted the hard work has paid off,” said Stride Industrial Group chairman, Graham Howes.

“We can now go after new customers in the aeronautical industry, where we have only had fairly limited reach up to now.”

The company has built its reputation as one of the leading springwire stockholders for automotive, medical and other industry applications.

haul of our day-to-day operational and documentation practices,” said Adams.

exceed its sales target for 2018, said sales and operations director, Stuart Hipkins.

“The aeronautical industry is a hard market to get into, and the quality standards demanded are very stringent,” said George Adams, Stride’s quality management chief, who led the programme.

“Preparation involved a thorough over-

“That has positioned us to exploit opportunities in new markets but has also benefited existing customers.

“We are very proud of what we’ve achieved.”

The 35-year-old company is on track to

“We’re growing strongly, despite the challenging trading conditions of the past couple of years and the continuing debate over diesel engines, which is suppressing demand from some car manufacturers.”

www.stride-supplies.co.uk

NIEHOFF’S popular Niehoff Package System (NPS) can now be acquired with full Industry 4.0 sensor and control capacity.

The new system, first shown at wire 2018 in Düsseldorf, has sensor technology that records machine data such as motor and drive information, rotational and linear

speeds, vibration and main drive temperature. The new Niehoff Digital Assistant+ 4.0 collects this information, as well as process and production information, to ensure maximum production efficiency through continuous process monitoring and machine condition analysis.

The new Niehoff system ran at wire 2018 on Niehoff’s NPS double spooler type

SV402D for automotive wires. The system uses SV type spoolers and collapsible NPS plastic multiway spools.

The SV402D operates inline with extrusion lines and can spool insulated wires with a cross section of 0.13mm², copper wire strands of 0.22mm²-6mm² cross section, and copper alloy strands at up to 1,800 m/min. Spool change is automatic, and the wire-laying technology offers a stable and tangle-free package.

Empty NPS spools can be dismantled and so need less return shipping space than traditional spools. www.niehoff.de

THE proliferation of counterfeit and substandard wire and cable products in the marketplace makes the verification of a cable’s UL certification status more critical than ever. False labelling can mean the wrong type of cabling might be fitted in public areas, which in extreme cases can mean the difference between life or death from poisonous fumes in the event of a major fire, or in less-critical cases, poor performance in signal or power handling.

Identifying the source and quality of cabling can be a grave matter – no pun intended –for end-users.

UL has been certifying the quality of cables and many other products and processes around the world for decades on behalf of the US Occupational Safety and Health Administration (OSHA).

The company evaluates more than 70 different wire and cable product categories to national and international standards for markets in North America, Latin America, the Middle East, Europe and Asia.

When a product successfully completes UL certification, the manufacturer is authorised to attach the UL Mark to the finished product to note it has reached an approved standard.

The manufacturer receives a follow-up service procedure from UL, describing the overall product and its individual components as originally submitted to UL. The procedure also defines the terms and conditions under which the UL mark can be applied to the product. UL’s post-certification Mark Integrity Programme helps to ensure continuing compliance with UL requirements.

Through this, procedures such as factory inspection visits could include three types of checks – an examination of UL-labelled

AROUND the world several private companies, such as Basec in the UK and UL Group in the USA, provide certification services for manufacturers and specifiers. Companies and group organisations, often composed of international experts, help government agencies and organisations – such as ISO – to build and regulate standards, often in the name of the government concerned. In the case of companies such as UL, certification is accepted as a standard of quality across many parts of the world.

products and factory testing; factory sample selections of UL-labelled products and testing at a main UL testing office, and market surveillance-sampling of UL-labelled products, and testing at a main UL testing office. During factory inspection visits, determining that the components used in UL Certified products are consistent with their descriptions in the procedure is key to compliance with UL requirements.

Determining the compliance of components used in UL-certified products is also an important step in bringing safer products to market. Maintaining the traceability of these components helps to support the continuing integrity of the supply chain, resulting in

higher levels of confidence that components being received meet requirements. This certification can break down when wire and cable manufacturers sell their products to distributors and processors, who in turn process or respool the original product. The original UL label – primary evidence of UL certification – may no longer accompany the product when it leaves the distributor or processor’s factory. A surface-printed UL mark on the cable product is a supplemental way of tracing the product, not the primary evidence of certification. Without that primary evidence, the user may encounter traceability issues and even held shipments if they cannot prove the cable is in fact a UL-certified cable.

Traceability issues aren’t limited to endproduct manufacturers: if processed or respooled cable is sold directly to installers, construction may be halted if the installer is unable to provide evidence, on inspection, of UL certification for the cables being installed.

Fortunately, UL helps to support supply chain integrity with two traceability programmes for the wire and cable industry. Processed and respooled wire: This programme provides traceability for UL-certified wire and cable types processed after original manufacturing and UL-labelling –anything from cutting to lengths, stripping insulation and tinning the ends or fitting terminations. These processed products bear UL’s Processed Wire label (above left). Products respooled into smaller quantities carry UL’s Processed Wire Respooled label (also shown). For both services, the UL label is attached to the tag, reel or smallest container into which the product is packaged. The distributor or processor is responsible for transferring to their own tags all the engineering markings provided by the origi-

you have bought is the wire and cable you expected to buy...

nal manufacturer. The UL certification service under which the wire was originally made (Listed/Classified or Recognised), determines which type of UL Processed or Respooled label is applied by the distributor or processor.

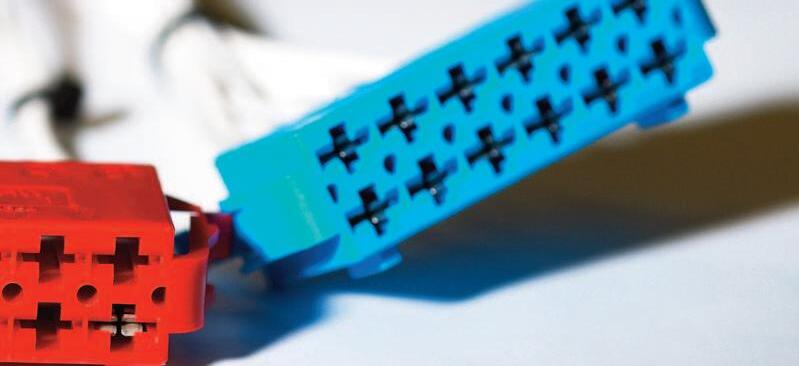

Wiring harnesses: This solution provides traceability for wiring harnesses assembled at off-site locations for use as factory-installed components – car wiring harnesses, for example.

Harnesses are defined as components with two or more wires joined electrically or mechanically, and may include connectors, plugs, strain reliefs, splices and other components. Harnesses must be constructed in accordance with a harness diagram or engineering specification provided by the endproduct manufacturer.

A UL field engineer will verify that each component used in the harness complies with the end-manufacturer’s specification. One of the verifications includes the UL certification status for the wire and cable used in the harness, and whether it was sourced directly from a UL-certified cable manufacturer, processor or respooler.

Harness manufacturers may also use products processed under the Processed/Re spooled traceability program. If the har ness is in compliance, it can be shipped with UL’s nised Wiring Har ness label.

Additional traceability checks are performed at the end-prod uct manufacturer’s factory to help assure all harness features comply with the end-product follow-up service procedure.

Wire and cable manufacturers who subscribe

to these traceability programs differentiate themselves from other wire processors because their factories voluntarily undergo audits, documentation reviews and physical product inspections by UL field engineers to demonstrate their determination to source wire and connection products from UL-certified companies and meet the requirements of their customers.

Manufacturers under UL’s traceability programmes can demonstrate that their processing operation has been independently certified by UL, since their traceability certification appears in UL’s online certification directory for all to see. www.ul.com

Jerry Matiatos is an engineering manager based in UL’s Melville, New York office, responsible for new work certification services and follow-up sample tesing of wire and cable products.

Contact him at: Jerry.Matiatos@ul.com.

KABEL.CONSULT.ING’S Energy Light drive system has been awarded the German Design Council’s first-ever Innovation Award.

The award rewards products and solutions from multiple industries, selecting only those that raise public awareness of outstanding innovations or offer improvements over existing products.

Patent holder Juan Carlos González Villar (right) accepted the award in the Energy Solutions category at a ceremony in Berlin.

The Energy Light drive system significantly improves the energy efficiency of an application using patented motor technology and lightweight construction. The drive minimises drive output while maximising generator output, and standardises the drive system as a complex total application.

Originally developed for machines that wind high-voltage cables, the principle behind Energy Light can also be used in other applications, including electric vehicles. www.kabelconsulting.de

nCRU Group, the leading provider of analysis, prices and consulting in mining, metals and fertiliser markets, has launched a wholly foreign-owned enterprise (WFOE) company, CRU (Beijing) Consulting Limited.

The new company marks a change in CRU’s legal status in China, from representative office to full trading entity. The group’s premises in Shanghai will expand to become a branch office of CRU (Beijing) Consulting.

www.crugroup.com

THE IWMA’s newest protégé is 21-year-old James Bunn from Pontefract, who over the next three years will undertake a part-time foundation degree in materials engineering at Sheffield Hallam University. The IWMA Educational Trust will pay all the degree fees.

The degree will allow James to build on his existing BTEC Level 3 qualification in manufacturing engineering metallurgy.

James, an apprentice metallurgical technician at Bridon Bekaert of Doncaster, was nominated for support by the company’s group metallurgy and testing manager, Steve Smith.

Once James has completed his

degree he hopes to work as a metallurgist for the company.

“This is fantastic news; it takes a real load off my mind about paying for the course,” said a delighted James.

Following his application to the trust, James was interviewed by its chair, Peter Large, and trustees Stephen Wood and Andy Lewis at wire 2018 in Düsseldorf, which James attended as one of the association’s travel awardees – the cost of their attendance paid by the IWMA.

James’s boss Steve said: “We’re really pleased for James. I know he has real potential and this fantastic award from the IWMA Educational Trust will help him to fully achieve that potential.”

Highly-successful changes to the IWMA’s international CabWire Industry Forum in 2017 will continue with a new, separate Educational Trust-sponsored event in Southampton, UK, in April 2019.

In 2017 the usual run of CabWire technical papers and industry discussion ran alongside a new series of CabWire Fundamentals –workshops covering the basics of non-ferrous metals good practice, aimed at newcomers to the industry and those keen to have a refresher on current developments and trends.

and manufacturing, and other basic operations common to wire and cable manufacture.

“The decision to run a full CabWire Fundamentals event came out of the success of 2017, when all the sessions were very well attended,” said IWMA education director, Peter Large.

“The Fundamentals programme falls nicely within the IWMA’s education programme, so the Educational Trust will be sponsoring the day and providing free places for students, graduates, apprentices and entry-level staff.”

wire China

26-29 September

SNIEC Shanghai, China

Tel: + 49 211 4560 579

Email: MuellersM@messe-duesseldorf.de

Website: www.wirechina.net

wire India 27-29 November

Bombay Convention & Exhibition Centre

Mumbai, India

Tel: +49 211 4560 579

Email:muellersm@messe-duesseldorf.de

Website: www.wire-india.com

For 2019, the latter will be the focus of a new CabWire Fundamentals Workshops event, featuring 12 separate, 30-minute sessions and other attractions.

The full programme will be available later in the year and will double the number of topics, covering polymer extrusion for cables, cable design, wire drawing, stranded wire design

The Fundamentals day also offers other attractions: attendees will get the chance to enjoy a networking event and will be able tour the factory of Prysmian UK – a member of the world’s biggest cable and wiring manufacturing group.

The event will run alongside the International Tube Association conference and will feature keynote speakers and a small products and services “tabletop” exhibition.

Interwire 13-16 May

Georgia World Congress Center, Atlanta, Georgia, USA

Tel: +1 203 453 2777

Email: sales@wirenet.org

Website: www.wirenet.org

wire Russia 18-20 June

EXPOCENTRE Exhibition Centre

Moscow, Russia

Tel: +49 211 4560 7725

Email: AhernsG@messe-duesseldorf.de

Website: www.wire-russia.com

wire Southeast Asia

19-21 September

BITEC, Bangkok, Thailand

Tel: +65 6332 9642

Email: beattrice@mda.com.sg

Website: www.wire-southeastasia.com

wire South America 3-5 October

São Paulo Expo, Brazil

Tel: +49 211 4560 478

Email: BagciC@messe-duesseldorf.de

Website: www.wire-south-america.com

wire Düsseldorf

30 March -3 April

Messe Düsseldorf GmbH

Düsseldorf, Germany

Tel: + 49 211 4560 478

Email: BagciC@messe-duesseldorf.de

Website: www.wire.de

Acuity Products Ltd offers engineering solutions to improve industrial manufacturing processes and supports cablemaking with ultrasonics technology and research. www.acuityproducts.co.uk

Peddington Lubricants and Coatings Ltd is a pioneer in wire-drawing lubricants and coating compounds in India and exports to more than 40 countries. www.peddingtonlubricants.com

Aversion Technologies Europe SL produces high-performance anti-rodent and anti-termite compounds for the wire and cable, tube, pipe and compounding industries. www.aversiontech.com

Uniwire Ltd is one of the UK's leading agricultural and industrial fencing manufacturers, providing a range of tailored fence specifications.

www.uniwire.co.uk

Reb Mech specialises in the design, manufacture, installation and maintenance of steel towers for the telecommunications and broadcast industries.

www.rebmech.com

Comsuc Technology Development Ltd is the leading maker of high-quality plastic and steel reels, spools, bobbins and drums in China for the wire and cable industry worldwide. www.comsuctech.com

The Deutsches Kupferinstitut represents regional copper industry centres and members and offers leadership, policy and strategy, as well as finance for international initiatives www.kupferinstitut.de

Golden Technologies Wire & Cable Equipment Co Ltd produces wire-extruding machinery, cable-twisting machines and cable coiling and packing machines, and exports worldwide. www.gtcablemachine.com

Kabel.Consult.Ing provides engineering services including customer-specific consultation, design, development and technical systems and machines.

www.kabelconsulting.de

H&R ChemPharm (UK) Ltd is a leading manufacturer of mineral oil lubricants, cable filling compounds, ozone protection waxes and other compounds.

www.hur.com

Hipo Electrix Science & Technology Co Ltd produces field service and related equipment and instruments for highvoltage cable testing and inspection.

www.hipo-electrix.com

John Binns & Son (Springs) Ltd uses the latest technologies for the production of springs and wireforms.

www.jbsprings.co.uk

Lanka Special Steels Ltd is the leading galvanised steel wire manufacturer in Sri Lanka.

www.lankassl.com

Pan Pioneer Co Ltd offers custom-designed extrusion, wire-drawing, takeup, pay-off machines, annealing machines and annealers.

www.pan-pioneer.com

Ravicab Cables Private Ltd makes, markets and distributes copper, aluminium wires and cables for domestic, industrial and speciality markets.

www.ravicab.com

SHI Kabel GmbH & Co KG works closely with clients to ensure the highest standards of quality and professionalism in cable consulting services.

www.shi-kabel.de

WIRE and Cable News brings you the best print round-up of what’s going on among wire and cable industry members – but you can now also enjoy watching the pick of IWMA events and show footage on the IWMA YouTube channel.

28/09/2018 wire China social event Huangpu river cruise, Shanghai

23/11/2018 Annual IWMA dinner dance Royal Garden Hotel, Kensington, London

28/11/2018 wire India social event Sheraton Hotel, Mumbai

We will be making our YouTube channel a goto place for members, dedicated to IWMA news and member developments, shot by our own camera operator.

Take a look now: go to (www.youtube.com and search for IWMA channel).

Over the coming months we will be adding lots of videos from the shows we visit, the members we talk to and the events we hold –all free for members to enjoy.

Companies get many other benefits from joining the IWMA, one of which is a dedicated, members-only area of the website.

This has access to a catalogue of past technical papers useful in research – thousands of pages going back to the 1970s – and lots of events and other news and information of specific interest to members.

Check it out at www.iwma.org

IWMA: industry partner to the major wire and cable exhibitions

www.iwma.org

13/02/2019 AGM and industry luncheon The Mere Golf Resort and Spa, Knutsford, Cheshire, UK

19/6/2019 wire Russia social event Moscow. April 2019 Cabwire Fundamentals Workshops Southampton, UK

06/06/2019 Annual golf tournament

The Mere Golf Resort and Spa, Knutsford, Cheshire, UK