wire Düsseldorf: show report

Products & Services Ltd 23 Cimteq Ltd 23 GURFIL Sanayi ve Elektronik Cih Paz AS 23

Maschinenfabrik Niehoff GmbH & Co KG 23 Maillefer 22

Rosendahl Nextrom GmbH 22

Zeller + Gmelin GmbH & Co KG 22

wire Düsseldorf: show report

Products & Services Ltd 23 Cimteq Ltd 23 GURFIL Sanayi ve Elektronik Cih Paz AS 23

Maschinenfabrik Niehoff GmbH & Co KG 23 Maillefer 22

Rosendahl Nextrom GmbH 22

Zeller + Gmelin GmbH & Co KG 22

SINCE July 2016, the IWMA has been partnering with Metsearch, an internet portal for the metals industry created by the IWMA’s industry partner Messe Düsseldorf

Metsearch’s wire and cable industry category is to include IWMA branding and each member company page will include an IWMA member badge “The IWMA is always looking for ways to extend and improve membership benefits,” explained executive manager Andy Lewis

Metsearch (www metsearch net) offers comprehensive international company and product information for the wire and cable industry

Users can locate specific products, c o m p l e x m a c h i n e s o r f i n d a particular company and check on the trade fairs at which it will be exhibiting

Metsearch also continually updates company and industry news, including topic of the month, where users can discover the latest

discussed within the industry

“Metsearch is a modern, user-friendly and comprehensive service that gives members access to valuable industry information,” continued Andy “Members will find the portal familiar; much of the database information is already in place and the codes match those used in the catalogues for the international wire and cable exhibitions organised by Messe

“Members can access the directory through the IWMA or the Messe Düsseldorf websites, or through search engines ”

ON ONE of the hottest days of the year, in June, IWMA members and their guests enjoyed an entertaining day

The event, at Fairhaven championship golf course at Lytham St Annes, is one of the IWMA’s most popular networking events.

Players began with a fortifying breakfast of bacon rolls before taking to the course and at day’s end the results were close: Jez Alston from Metalube’s team took the chairman’s cup for best member-score

Gary Kelly from the IST was runner-up, while Ben McNamara of Copperweld Bimetallics took third-place

Guests didn’t leave without prizes either; for the second year, Ian Deuchars of Handelsbanken took the guest shield for best guest score Ian Nesbit of

Global Wire was runner-up, with Frank Dearnaley of Brand Rex, in third place.

Don Neville of RichardsApex Europe

L t d won the longest drive and TWOs

The day concluded with a formal dinner at the nearby Glendower hotel, when the IWMA’s Peter Large presented the prizes He thanked Interlink ImportExport Ltd, RichardsApex Europe Ltd, Cable Tapes UK Ltd and Bar Products & Services Ltd for sponsoring the day’s prizes

“It was a marvellous day; fantastic weather, great company and a fine day’s golf,” he said “What more could we ask for? We hope to see a strong turn-out again next year ”

CABWIRE World Conference will take place on 7 November, 2017 at the Congress Center in Düsseldorf, Germany

The format will stay the same, with technical presentations from international speakers and a tabletop exhibition This time the event will run in conjuction with the International Tube Association (ITA) conference

“We’re delighted to return to the Congress Center It’s a perfect venue and even better for this event as we’ll be in a bigger space,” explained IWMA executive manager, Andy Lewis

“Working with the ITA enables us to expand the event and attract top speakers We are also able to enhance the service we offer members, including sourcing the best deals on travel and accommodation ”

The full itinerary will be announced later in the year

“We are in touch with potential presenters,” Andy continued “We also want to hear from members who would like to submit their technical papers for consideration They can contact me by email at andy@iwma.org or give me a call at the IWMA ”

IT’S TIME to brush off your party gear and buff up your dancing shoes: the IWMA annual dinner dance is just around the corner

The popular event at London’s Royal Garden Hotel is always well attended and tickets sell quickly If you’d like to reserve yours, contact the IWMA (see contact details on the events calendar on page 5)

ELCOME to the latest issue of WCN, in which we look ahead to a busy autumn schedule with not one but two more major trade shows – wire China in Shanghai and Wire & Cable India in Mumbai, both industry centres showing growth despite industrial doldrums in other parts of the world.

I’m particularly looking forward to my first visit to the Mumbai s h o w ( 5 - 7 O c t o b e r ) ; w

c ompanies from the sub-continent and it will be nice to put faces t

extraordinarily energetic business community

But that’s for the autumn: what a year it’s been so far!

The changes we have made to extend and brighten our services and facilities for members this year seem to be paying off in a big way

Our new, larger and improved stand, with its better facilities for members, was introduced at Düsseldorf ’s huge wire 2016 exhibition and was an immediate success So far this year the IWMA has acquired a record 21 new member companies – you can see the full member list (at least at the time of printing) in our centre pages. Are your competitors there? You should be too! Find out more, and what other companies say about our services, on page 11 – and if you aren’t already a member, get in touch and find out more

Elsewhere in this issue we introduce Adam Burgess, who is studying hard to become the new metallurgist at the renowned Institute of Spring Technology in Sheffield He is spending the n

financial help – to take over the job of the IST’s metallurgy specialist Margaret O’Malley, who retires next year after 40 years of problem solving and testing for IST members worldwide

So the first half of the year has been hectic and the second half will bring a lot more work and travel to amazing foreign cities. Will we see you there?

Amanda Shehab Chairman, International Wire & Machinery Association

SO FAR 2016 has been a stellar year for Metalube To meet demand for its high quality lubricants, the company has expanded its Manchester headquarters by acquiring the adjacent industrial unit The one hectare site has increased the size of the company’s plant by over 70 per cent, to provide 2,500 sq metres of factory, warehousing and office space alongside a state-of-the-art laboratory opened last year At the same time, Metalube has opened an office in Dubai and signed an exclusive US distribution agreement with Indianapolisbased Fusion Chemical, a supplier of metalworking fluids and speciality chemicals to manufacturing industries across America.

To cap an already excellent year, Metalube has received ISO 14001 certification: the international standard for environmental management systems (EMS) and the most widely used in the world. ISO14001 is the principal management system standard which specifies requirements for the formulation and maintenance of an EMS and helps control environmental aspect, reduce impacts and ensure legal compliance www metalube co uk

THE IWMA is to launch a members’ area on its website this autumn. Members will be able to access past papers from technical conferences, legislation updates, industry news and business advice. “Members will have access to the IWMA’s vast wealth of technical knowledge and business expertise,” explains IWMA executive manager Andy Lewis. “Members can network online, share best practice and find help to solve problems.”

EDER-Austria has designed two special machines, each with two independent workstations

The Ultrasonic machine, (USP- TWIN) (above), with two workstations, allows a single operator to recondition two dies at the same time, virtually doubling output One workstation (UF) handles smaller dies (from 0 05 up to 3 mm dia ) and the other one (F) handles medium to large dies (1 to 8 mm dia )

For subsequent sizing/calibration of the dieś bearing portion and to keep pace with the larger quantity of dies from the USP-TWIN, the HGM-21(right) high speed, wire-type machine h

Both machines are easy to understand and operate and offer outstanding versatility and potential for all die- workshops

The rate at which diamond/PCD dies need to be reconditioned is increasing as more wire drawing manufacturers use high-speed multiwire drawing machines, using several expensive dies simultaneously The dies wear out r

reconditioned at die workshops where skilled operators are often in short supply

The growing number and importance of precision drawing die sets in use and their regular and perfect reconditioning becomes an absolute criteria if drawing efficiency in multi-wire drawing machines is to be maintained at a necessary high level

www.eder-eng.com

MANCHESTER-based Cable Tapes Ltd has teamed up with Barcelona company EOX Masterbatches

Cable Tapes, one of the UK’s leading suppliers of all cable lapping tapes and twines, will represent EOX in the United Kingdom, Middle East and India

EOX Masterbatches, manufactures high performance colour and additive master batches for the wire and cable industry for use in cables for, among others, the power,

energy, automotive and telecommunication industries.

Cable Tapes Ltd managing director Mark Heneghan commented on the agreement, “ The products and services offered to o u r c u s

expanding portfolio well and we are confident that this new agreement will benefit both sides.”

www.cabletapesuk.com

ALLOY Wire International has launched a 84-page brochure listing over 60 different types of exotic nickel alloys

The glossy, A4 publication (above) provides specification data sheets on each alloy, detailing helpful information on post heat-treatment guidance and mechanical properties useful to customers when designing wire forms

“ T h e b r o c h u r e g i v e s d e f i n i t i v e information on all of the alloys we supply,” explained company MD Mark Venables

“With such a lot of data it can be quite difficult to read, so we have

spent a lot of time improving the design and layout We’re proud of the result ”

Alloy Wire is celebrating 70 years in business this year and in that time has grown into one of the world’s leading manufacturers of wire, supplying 4000 customers in 15 sectors

The company has recently added high performance alloys Nitronic 50 (0 025mm-5 50mm) and Super Duplex (0 025mm-6 50mm) to its extended range and can now draw from 21mm in many different alloys

www alloywire com

THE Uhing Motion Drive (right) has been designed for winding and traversing processes in the wire and cable industry, and for handling and XY gantry systems.

Other feasible applications include general drive technology processes in which limited linear motion is required

The latest innovation from Joachim Uhing GmbH is based on an Uhing rolling ring drive, e x t e n d e d b y s e n s o r s a n d a n e l e c t r o n i c control unit with software also developed by the company The combination ensures hardware and software are perfectly matched.

The existing rolling ring drive is modified in the new unit because the reversing lever and pitch-setting scale are no longer required A stepping motor, controlled by a Siemens S7 PLC, undertakes these functions.

Freely-definable parameters provide flexibility: “The drive allows the user to define a great number of parameters, which can be saved in the control unit,” explained Uhing technical director Jörg Wadehn

The user specifies key application data and stores them in the software This can be maximum stroke width, shaft speed and pitch per shaft rotation roughly corresponding to the width of the material being wound This also applies to the spool type: the motion drive can handle spools of any contour

Users can specify action points, which identify points where a repetitive action – a reversal, speed change or stop and start, for example –can be triggered Winding patterns can also be defined

The highly-flexible drive reduces process costs and errors, and can be integrated with existing Uhing drives or control units – even custom software modification

wire China

26 - 29 September 2016

SNIEC Shanghai, China

Tel: +49 211 45 60 77 68

Email: ryfischd@messe-duesseldorf de Website: www wirechina net

Wire & Cable India

5 - 7 October 2016

Bombay Convention & Exhibition Centre, Mumbai, India

Tel: +49 211 45 60 77 68

Email: ryfischd@messe-duesseldorf de Website: www wire-india com

IWMA Annual Dinner Dance 25 November 2016

Royal Garden Hotel, London, UK

Tel: +44 121 781 7367

Email: info@iwma org Website: www iwma org

CabWire World Conference 7 November 2017

Congress Center, Düsseldorf, Germany

Tel: +44 121 781 7367

Email: info@iwma org Website: www iwma org

AGM & Members’ Lunch 1st February 2017

The Mere Golf Resort & Spa, Knutsford, UK

Tel: +44 (0)121 781 7367

Email: info@iwma org Website: www iwma org

wire Russia 5-8 June 2017

Expocenter, Moscow, Russia

Tel: +49 211 4560 7793

Email: RyfischD@messe-duesseldorf de Website: www wire-russia com

wire Southeast Asia 19-21 September 2017

BITEC, Bangkok, Thailand Tel: +65 6332 9642

Email: beattrice@mda.com.sg

Website: www wire-southeastasia com

wire South America

3-5 October 2017

Sao Paulo Expo, Brazil

Tel: +49 211 4560 478

Email: RotthoffJ@messe-duesseldorf de Website: www wire-south-america com

26-29 Sept 2016

Axel Bartkus MD at Messe Düsseldorf

China and Messe Düsseldorf Shanghai looks ahead to this year ’s exhibition

IF YOU are coming to wire China 2016, welcome! We’re the region’s essential exhibition for the wire and cable industries and this year there will be plenty to see at Shanghai’s New International Expo Centre from September 26-29, organised as usual by Messe Düsseldorf with partner the Shanghai Electric Cable Research Institute

Chinese and international companies will use wire China as a shop front for their latest products and innovations, but as well as this the huge Asian market uses the exhibition as a major networking event; even if you aren’t exhibiting, it makes sense to attend!

This year we expect developments concerning Industry 4 0 to be top of the agenda The coming d e c a d e f o r e

energies (wind, solar and nuclear power) for China, w

and nuclear power cables, as well as other more specialised products With a growing awareness of green and energy-saving developments, smart grids have become important and are being closely watched in many countries This also gives wire and cable industries new challenges – smart energy, smart cities and the smart grid will drive innovation in the field of wire and cable

Due to the swift development of the Chinese economy and the increasing urbanisation of the country the number of high-speed and suburban trains and e-vehicles is also rising rapidly, the consequence of which is a greater demand for bare wire, electric wires and cables and power and communication cables The nation is investing in infrastructure items, from energy and construction to communications

Almost 60,000sq m of exhibition space have already been rented out to 1,000 Chinese and international e x h i b

processing machinery to measuring, control and detection products and services As a result wire China 2016 is expanding its wire and cable materials and wires and springs sections in a joint venture with the Shanghai Fastener & Tech trade fair Read all about it at www.wirechina.net, and we’ll see you there!

FRENCH members of the Gauder Group, Pourtier and Setic, will offer the widest range of cable twisting and stranding machines at wire China

Chinese group member Daloo will show medium-cost machinery based on the same quality standards while fellow companies C2S and Bow Technology and used-machine supplier Gauder will complete the group’s presence in Shanghai

Pourtier has a renowned range of heavyduty stranders, cablers and armoured lines for ferrous and non-ferrous cables and has made impressive achievements in submarine and umbilical cables, supplying large armoured lines and laying-up lines

Its high-efficiency, revolutionary multi-wire concentric stranding line is also widely used for low and medium power cable production These machines are specially designed for the production of high- and extra-high voltage power cables, from overhead to insulated types to AC types using high quality Milliken conductor for land, or DC types using large round compacted conductor or trapezoidal wires for both land and submarine cable All are made in Europe to the highest standards

Setic provides high-speed, double-twist bunchers/stranders (above) for the automotive industry, as well as complete equipment for the production of high quality LAN, special and control cables

The company’s stand will also feature tandem mica taping/bunching; special high-speed lines for battery cable, and new high-speed

lines for special and instrumentation cables

Most machines are made in France, though some are also produced by Gauder Group in China to the same quality standards for direct Asian market supply

Daloo extends the group’s global cable production offer with an attractive range of stranding lines and accessories for power and communication cables, made in China to

Gauder Group quality standards but at a lower price than new machines made in Europe

Gauder Group SA, Belgium Stand: W1F25 www.gauderonline.com

RICHARDSAPEX, a leading global manufacturer of wet lubricants for wire drawing and hot-rolling applications, will be a significant exhibitor at wire China.

The company produces semi-synthetic and synthetic compounds for the wet drawing o f n o n - f e r r o u s a n d f e r r o u s w i r e , a s w e l l as protective coatings, cleaners, corrosion inhibitors and oil-form lubricants for all nonferrous and ferrous wire and tube alloys The company’s core products can be produced at

all its locations in the US, Europe, Australia and Mexico Over its 114 year history

RichardsApex has established a wide global sales network with on-site support and technical sales assistance. The company has subsidiaries in the UK and Australia and representatives in dozens of countries worldwide

RichardsApex Inc, USA Stand: W1F20 www richardsapex com

A Pourtier power regenerative high speed Concentric Strander module of four reels with three wires each

GERMAN machine manufacturer Queins Machines GmbH and Stolberger-KMB will share a wire China stand Visitors will be able to see displays and v i d

including high-speed stranding machines, machines for CTC conductors, pay-offs, take-ups, taping heads, disc- and belttype caterpillars and capstans, as well as recent projects such as the manufacture and installation of a large planetary strander for subsea cables – designed to strand power conductors with an individual conductor weight of 55 tonnes

Queins Machines GmbH, Germany Stand: W1G57 www queins com

THE IWMA’s new satellite stand will make its first appearance at wire China and uses the same design as the one that scored a hit with visitors to wire Düsseldorf The stand is used as a hub for members and contacts alike, and offers a place to meet, talk business and enjoy IWMA hospitality

IWMA, UK Stand: W1F42 www.iwma.org

26-29 Sept 2016

REBER Systematic GmbH – better known to the industry as RESY, will show its recently developed filtration and delivery system for high-viscosity lubricants at wire China

The system does for high-viscosity oils what the company’s widely-used Compact Band Filter system does for the thinner liquids used in general wire production

The new system is appropriate for aluminium lubricant filtration

The current method for this task is simply to allow particle sludge to fall to the bottom o f t h e l

periodically be cleaned out, taking lubricant with it

Another effect of the aluminum particles is even greater thickening of the lubricant, making it less effective

The new system is modular and consists of a centrifuge, a delivery pump, heater, cooling system and electrical control Each one is built to the customer ’s requirements and can be integrated in existing systems

Lubricant is cleaned and cooled continuously during operation, meaning the concentration of particles in the liquid stays at an acceptable level and ensures high quality and more consistent production

Reber Systematic GmbH & Co. KG, Germany Stand: W1F56 www resy-filtration com

AJEX & Turner Wire Dies Co will be demonstrating its revolutionary vitrified nanocrystalline technology (VST) nano dies at wire China.

The global wire industry is in the middle of an expansion period and the latest technology must be able to draw materials with good wear resistance and surface properties, so quality isn’t compromised.

Ajex & Turner has developed VST nano dies for copper, aluminium, aluminium alloy, stainless steel, MIG and high- and low-carbon wire, all meeting high standards

The company will also display its full range of dies and die maintenance machinery, such

as the revolutionary TCD-10, which can grind and polish angles and bearings in one operation This technology will also be on display at Wire & Cable India (see show preview)

Visitors to the Ajex & Turner stand will be able to see product demonstrations, videos of products in action, and will be able to take part in technical discussions. Members of staff can also discuss free trial possibilities

Ajex & Turner Wire Dies Co, India Stand: W1A70 www ajexturner com

Software sensor view

TROESTER GmbH will present new developments in CCV and VCV lines for MV, HV and EHV cables up to 1000 Kv; rubber CV and CCV-lines up to 35 kV,CV-technology for production of HV Cables on CCV lines, and production equipment for submarine cables at wire China

Representatives from Troester group company X-Compound will also be on the stand to discuss kneader technology for the continuous compounding of HFFR (LSOH), PVC, XLPE, semiconductive materials and EPR/EPDM

In China, Troester, a world-leading supplier of cable machines, is represented by Troester Machinery Shanghai

Troester GmbH & Co KG, Germany Stand: W1F43 www.troester.de

HANS Schmidt & Co GmbH will be promoting a new feature on its online tension sensors at wire China

The company’s well-known FS series can now be equipped with a patent electronic gravity force compensation and wifi module, so applications in rotating machines such as bunchers and stranders can be equipped with tension sensors without wiring or slip-rings

Readings can be sent to a display unit or direct to a PC, and one system can control up to 16 sensors

Used with the SC-PM4 display, readings from up to four sensors can be viewed at once

Output signals can be used for PLC control or downloaded to a PC

Schmidt will also be showing its new SF and TSR-1 roller tension sensor series, for measuring the tension of cables and wires of up to 2000N

The sensor is installed at an existing guide point depending to the sensor model

The sensor needs an amplifier to get analog output, or an external amplifier (such as the Schmidt SCV-1) is required.

Hans Schmidt & Co GmbH, Germany Stand: W1F78 www hans-schmidt com

MAILLEFER’S stand at wire

China will show the company’s tremendous experience and depth, the result of over 4,000 line deliveries over many years, and reveal the company’s latest developments

Maillefer concepts on show include the Maillefer Factory System - which can plan and realise a green-field factory with the lowest possible risk and cost. Maillefer ’s Factory System is a unique way to outsource a factory project once the end product has been defined, or extend existing facilities

Maillefer Consultation is a new service

b u i l t

o u n d t h e w i

e a n d c a b l e production process It exploits the company’s core knowledge to offer targeted advice and improve the skills and processes of wire and cable manufacturers

Maillefer will also introduce a new Value Package to the Chinese market With the Round Value Package Premium, production is controlled under very precise tolerances in a new curing concept which guarantees

GERMAN welding equipment maker August Strecker ’s wire China show stand will feature the newly-improved FPC full parameter control unit

The second-generation unit, now available for retrofit as well as single-phase welding machines from Strecker, offers (depending on the model), precise current control for consistent welds, longer jaw-insert lifetime thanks to a zero-gap clamping arrangement, and hydraulically-optimised motion control, w h i c h a u t o m a t i c a l l y m a i n t a i n s p r e c i s e position without further adjustment

The new unit maintains all the existing FPC advantages, from easy welding-recipe storage to constant weld parameter monitoring

August Strecker GmbH & Co KG, Germany Stand: W1F60 www.strecker-limburg.de

high-precision roundness in HV cable production

The company’s new Three Layer Crosshead THX 100/180 LR redefines extrusion for large conductor sizes a

’s application offering has grown to include aviation, and the company’s experts will be on hand to discuss products such as the new aviation and aerospace wire insulation lines, TEL 15X/Enter and TEL 25X//Extend

Maillefer ’s materials know-how will be displayed by showing how a rheometer (for testing rubber curing p

Calculation Program NSS give the best possible production run recipe

Stand staff will be happy to test any rubber cable samples brought by visitors, who will also be able to see cable samples and experiment with the new cable roundness meter, the CRM 180

Measurements for sudden cable geometry

errors can be examined in minute detail –which makes it easier to maintain quality in CV line production

Maillefer, Finland Stand: W1F24 www.maillefer.net

NIEHOFF has been active in China since the early 1970s, and with Chinese engineers has successfully introduced rod breakdown, m u l t iwire and super-fine wire drawing technology to many Chinese cable factories

Niehoff and Chinese subsidiary Niehoff Machinery Changzhou Co Ltd will display several major items of machinery at the Shanghai show

These include the MMH121 multiwire drawing machines from Germany (see page 18), and Chinese-made D631 5 and ARP630 highspeed double twist bunching machines

The company will share its stand with partner company

H Folke Sandelin AB, specialists in horizontal lead extrusion and cable repair and recovery systems

The modular MMH121 + RM201, ideally suited to electronics and building wire production, can draw 16 wires simultaneously for diameters ranging from 0 20mm1 05mm at up to 40m sec, combined with in - l i n e a n n e a l e r R

631 5 + ARP 630 type high speed

screen and simplified navigation Another feature is high-precision tension control for strand winding Niehoff ’s MSM 86 rod-drawing machine is

the latest development of a machine that has been in use all over the world and a top seller since the early 1960s

are modular and can be built to the specific requirements of customers.

The D631.5 single-bow double-twist buncher machine and ARP 630 pay-off are built by NMC under Niehoff licence The machine is designed for strands of 0 09-6mm² cross section, with a steplessly-variable lay length of 6-100mm They can achieve up to 6,500 twists per minute at 300 metres per minute

The machine has AC drive, contactless internal data transmission, energy-saving capabilities and a touch-screen display with a colour

Designed for wires of copper, copper alloys, aluminum, aluminum alloys and other nonferrous metals, the machine can be combined with a continuous annealer (R 502, RA 501 or RI 420 types), which are extremely powerful and highly energy-efficient, with power savings of up to 10%

Maschinenfabrik Niehoff GmbH, Germany Stand: W1F63 www.niehoff.de

26-29 Sept 2016

ROSENDAHL Nextrom is focusing on increasing customer value using advanced manufacturing technology The added value can be immense: Industry 4.0, which Rosendahl calls Smart Factory, is becoming a reality and opening new doors for suppliers and manufacturers alike.

Predictive maintenance, process backtracking and online monitoring are just some of the benefits

The Rosendahl Integrated Operation system meets Industry 4 0 requirements and automatically collects, organises and displays production information, which can be saved locally or in the cloud for analysis or report and optimisation Users can see information about production performance and quality, reel protocols, error message-related statistics, energy usage, OEE figures and more

The Smart Factory module of RIO has reporting and analysis tools that offer users live status reports and allow the retracing of each of the production processes This permits structural element identification by RFID chip to avoid set-up errors, problem prevention thanks to the intelligent evaluation of the stored data and early warning of problems or wear, and advance notice of a line or component that needs service

Rosendahl’s mobile reporting system SmartGlance® gathers data and reports and can be accessed anywhere Data are encrypted for security

Rosendahl Nextrom has also made developments in high-temperature materials processing and silicone rubbers, the high-speed production of loose tubes with fibre over-length control, helium recycling during fibre drawing, and more

Rosendahl Nextrom GmbH, Austria Stand: W1D43 www.rosendahlnextrom.com

Ajex & Turner Wire Dies Technologies India W1A70

August Strecker GmbH & Co KG

Germany W1F60

Aymak Makine Mühendislik Hiz San Ve Tic Ltd Sti Turkey W1F23

Bekaert NV/SA Belgium W1F44/W1G43

BWE Ltd China W3D43c

Carl Bechem GmbH Germany W1F54

Ceeco Bartell Products, Bartell Machinery Systems LLC

CeramTec GmbH

China Southern (Group) HK Ltd

Cimteq Ltd

Condat SA

Dongguan XinMei Precision Mold Co Ltd

Eder Engineering GmbH

Esteves China (Shanghai) Diamond Dies Co Ltd

Euroalpha SRL

Eurodraw Wire Equipment SRL

FMS Force Measuring Systems AG

Fort Wayne Wire Die Inc

Gauder & Co SA

Gwo-lian Machinery Industry Co

H Folke Sandelin AB

Hans Schmidt & Co GmbH

Hefei Smarter Import & Export Co Ltd

Inductotherm HWT (Radyne)

Intras Ltd

Jiangsu Handing Machinery Co Ltd

Jiangsu Qunye Electrical Co Ltd

Joachim Uhing GmbH & Co KG

KIESELSTEIN International GmbH

Maillefer

Maschienenfabrik Niehoff GmbH & Co KG

Medek & Schörner GmbH

Metalube Ltd

Microdia SA

Nanjing Zhongchao New Materials Corp

Proton Products International Ltd

QED Wire Lines Inc

Queins Machines GmbH

Reber Systematic GmbH + Co KG

RichardsApex Inc

W1G06

W1G69

W1B76

W1F36

W1D41

W1D51

W1D07

W1B27

W1B25

W1F82

W1F63

W1G24

W1G32

W2C03

W1F24

W1F63

W1D45

W1F38

W1C55

W5D43

W1D82

W1G37

W1G57

W1F56

W1F20

RK Umformtechnik GmbH + Co KG Germany W1G52

Rosendahl Nextrom GmbH Austria W1D43

SAMP Sampsistemi Italy W1C03

Shanghai Geili Precision Dies Co Ltd China W4B85

Shanghai HOSN Machinery Technology Co Ltd China W2D23

Shanghai Kechen Wire & Cable Machinery Co Ltd China W2B23

Shanghai Nanyang Equipment Co Ltd China W2B21

Shanghai Singcheer Technology Co Ltd China W2E03

Sikora AG Germany W1F62

Sket Verseilmaschinenbau GmbH Germany W1E60

Trafco SRL Italy W1B23

Traxit (Tianjin) Chem Co Ltd China W1G34

Traxit International GmbH Germany W1G48

Troester GmbH & Co KG Germany W1F43

WCISA USA W1G08

Wire & Plastic Machinery Corp USA W1G05

Zeller+Gmelin GmbH & Co KG Germany W1E51

Zumbach Electronic (Shanghai) Co Ltd China W1E22

Exhibition support

“The IWMA presence and stand provides a fantastic facility for members at major international exhibitions”

DOUGLAS HUNT, Commercial Director, Metalube.

“ The IWMA offers a great network when you’re overseas; help with hotels, transport and great support while you are there.”

KEVIN BENNETT, Sales Director, BWE Ltd

A key benefit of IWMA membership is the support the association provides at major international trade events

IN A global industry, trade shows and c o n f e r e n c e s p r o v i d e a n i n v a l u a b l e opportunity to meet clients from all over the world in one place – b u t exhibiting can be costly

The IWMA attends the biggest international exhibitions to provide support for members whether they are exhibiting or just visiting Kevin Bennett, sales director at BWE, often relies on advice and support from the IWMA team when he attends exhibitions

“The IWMA offers a great network when y o u ’ r e o v e r s e a s ; h e l p w i t h hotels, transport and so on –and you get great support while you are there,” he says.

As a wire industry partner with Messe Dusseldorf GmbH, the IWMA can get preferential deals for its members

continued “Whether members want to use a private room to meet customers and talk business, or just catch up with colleagues over a beer, our stand facilities are freely available ”

Metalube’s commercial director, Douglas Hunt, is another fan of the IWMA’s stand and exhibition support

“I like to make sure our stand is near the IWMA’s so our team can use the business services and have a quick coffee break or two away from our own stand,” he said “The IWMA presence and stand is a fantastic facility for members at international exhibitions,” he added.

“A record 21 companies have already become members this year.”

“We can negotiate favourable rates for shipping, accommodation and so on,” explains IWMA executive manager, Andy Lewis.

The IWMA has made some big changes to its own stand this year The space has been completely redesigned to provide more and better facilities for members

“We have a very friendly team available throughout exhibitions to help members with any problems,” said Andy

The new full-size stand had its first outing at wire Düsseldorf, while smaller, “satellite” versions will be availablet wire China and Wire and Cable India

“We can offer a range of business services on the stand, from meeting space and printing to internet access and refreshments,” Andy

The improved facilities offered by the IWMA are helping to new m e m b e r s . S o f a r t h i s y e a r t h e association has attracted 21 new companies (see the new member list on the back cover)

“We get stronger with each new member, and strength can only be good for the association and for members,” said Andy

As well as business facilities, the IWMA also organises networking events for members attending exhibitions

“It’s the perfect opportunity to meet customers, colleagues and potential clients in a relaxed atmosphere,” Andy continued

Adrian May of the IST (Institute of Spring Technology) agrees: “The IWMA excels at networking and organising exhibitions It is staggering how many companies attend the networking events To get among the people in the industry I’d really recommend joining the IWMA, it’s great value for money ”

NEW York-based Oden Technologies has introduced its most advanced analytics for manufacturers, which includes monitoring realtime data from production lines, diagnosing problems by the second and seeing trends over time by product, shift, line or factory

“It is a very easy to use system that allows manufacturers to understand the nuances of their OEE and production without massive time commitment,” said Oden co-founder

Peter Brand

“We worked closely with several wire and cable factories for over a year before launching our end-to-end production analytics platform in the plastic extrusion market We now aim to roll out our smart factory concept to the wider market ”

Oden originally collaborated with a number

of large European manufacturers and found that many of them lacked the ability to record production data and present it to their teams in an useful way

Oden developed a very efficient solution: connecting a small device to the manufacturers' existing machinery made it possible to collect data from the production line in real time. Information is instantly sent to a cloud-based analytics platform in which process flows

c a n b e o b s e r v e d a n d a n a l y s e d t o f i n d a n y distortions or glitches

The manufacturer can then start predicting inconsistencies and receive alerts before problems arise

“We want to relieve manufacturers of extra spreadsheets, code, and lengthy projects,” Peter continues “We have customised our analytics toolbox for the plastic extrusion industry and can demonstrate its value in improving quality and efficiency By hosting our platform on the cloud we can tailor and evolve the tools available to clients ”

SPlasmait GmbH of Lebring, Austria, have collaborated to develop a new drawing line for fine stainless steel and nickel alloy wires with an inline annealer

Until recently, the annealing of stainless steel and nickel alloy wires has been achieved almost exclusively in traditional tube furnaces in a multi-line setup The companies’ new plasmaANNEALER can now be installed

vertical annealer, suitable for smaller fine wire diameter ranges, as demonstrated at wire Düsseldorf

PlasmaANNEALER was selected among the top products of 2014 by Wire and Cable Technology magazine, as the first annealer able to anneal fine stainless steel wire in-line with drawing.

It can also be used in combination with rolling mills or stranders. The new integrated drawing /annealing line can be used for different types

Horizontal annealer configuration and double-head take-up with automatic spool changeover functionality

in-line with Schmidt fine wire-drawing machines producing stainless steel wires of diameters from 1mm to 0 1mm at a speeds from 4 to 15metres a second

This set-up avoids the need for 10-20 lines in a traditional tube furnace, removing expensive multi-line take-ups and pay-offs with all the associated material handling and manpower needs

Installation can be with a horizontal annealer and double-head take-up with automatic spool changeover Alternatively, the integrated line is available in a compact design with a

of materials used in applications such as fine wire for mesh and textile, filter wire, brush wires, EMS mesh wire, resistance wires, heating element wires, medical, jewellery, aerospace, automotive and similar applications

The new integrated drawing-annealing line is initially available in Europe and Asia, and will be available later in North America

www.plasmait.com

THE latest dual-axis measuring head from Zumbach’s ODAC® laser measuring unit series is among the most accurate, robust, reliable and adaptable currently available

Thanks to the compact design, the ODAC®

14XY (pictured) measuring he in virtually every manufacturi the wire and cable, plastics an steel and metals industries

Zumbach laser units combine th cutting edge technology, with diodes as light sourc offer simple and flex use in your line proces Zumbach’s long-stand experience as a pion of in-line measuring technology allows the company to offer the ODAC series with a very strong price to performance ratio

THE supervisory board of LEONI AG,

N ü r n b e r g , G e r m a n y, h a s appointed Karl Gadesmann as chief financial officer with effect from October 1

Karl will also take charge of the company’s information management department

Karl has expertise in the car and commercial vehicle industry. He has been a member of the executive board and CFO of the Dräxlmaier Group, and worked at MAN Truck & Bus AG.

www leoni com

Among the high-end features of the unit ar calibration, single sca and high data rate ou 125 data packages a The measuring heads can be used with all line speeds, and machine vibration during production has noticeable influence on measurement accuracy

The 14XY is specially suited for wire applications including fine and extra-fine wires, enamelled wires, cables, steel cords and other fibres ODAC 14XY comes in two measuring ranges, a micro version handling 0 015mm-3mm (0 0006in-0 12in ), and a standard unit covering 0 06mm-16mm (0 0024in-0 64in) A special laser allows to low-range

range

Adaptive signal processing in both units increases accuracy

All measuring heads in the ODAC series have patented adaptive signal processing which makes regular recalibration unnecessary, except where components need to be replaced All the relevant accuracy parameters are continuously monitored by the system and recalibrated, which also takes into account long-term changes in the scanner motor or internal electronics

www.zumbach.com

MADEM Brazil has received over 90% approval rating from its customers in a customer survey earlier this year.

Madem Brazil contacting 96 wire & cable manufacturing clients in 21 countries Of the 76 (79%) responses in three categories: bad, regular, good and very good, with 91,05%

of responses rated service as good and very good.

The survey looked at claim response, quantities shipped X received, documentation, deliveries, quality inspections, performance, and packing.

“We are very proud of our product continuity, considering we supply products to several countries, each with its own requirements We are delighted with the survey results, and will continue to work towards 100% customer satisfaction for all our global customers,” said Leandro Mazzoccato, corporate director of sales and marketing

The next customer satisfaction survey in Brazil plant will be conducted in Jan 2017

Madem Group is the leading nailed wooden reels producer in the world, producing over 400 containers and trucks of knock down reels a month www.mademreels.com

A Karpat Ltd Canada

Er-Bakir Elektrolitik Bakir Mamulleri AS Turkey

ACIMAF Italy

ACOTEQ GmbH Germany

Advaris GmbH Germany

AESA Cortaillod Switzerland

Ajex & Turner Wire Dies Co India

Alecosa-Aleados del Cobre SA Spain

Alloy Wire International UK

Anglia Metal Ltd UK

Apple International Engineering Works Pvt Ltd India

Arab Co for Cable Polymers Ltd Saudi Arabia

Asia Sim Co Iran

Associated Engineers & Industrials Ltd India

Assomac Machines Ltd India

AstroPlast, Kunststofftechnik GmbH & Co KG Germany

August Hildebrandt GmbH - Kabeltrommeln Germany

August Strecker GmbH & Co KG Germany

Australasian Wire Industry Association Australia

Aymak Makine Mühendislik Hizmetleri San ve Tic Turkey

Balloffet SA France

Bar Products & Services Ltd UK

BASEC (British Approvals Service for Cables) UK

Bennett Mahler Ltd UK

Bongard Trading GmbH & Co KG Germany

Bridon International Ltd UK

British Diamond Wire Die Co Ltd UK

BWE Limited UK

Cable Tapes UK Ltd UK

Calmec Precision Ltd Canada

Cape Gate (Pty) Ltd UK

Can-Eng Furnaces Ltd Canada

Carl Bechem GmbH Germany

Ceeco Bartell - Bartell Machinery Systems Canada

Cemanco LC USA

Central Wire Industries UK Ltd UK

CeramTec GmbH Germany

Chaplin Bros (Birmingham) Ltd UK

Chemetall Ltd UK

China Southern (Group) HK Ltd Hong Kong

Cimteq Ltd UK

Commission Brokers Inc USA

Comsuc Technology Development Ltd China

Condat Ltd France

Consultex Sp z o o Poland

Control and Power Engineering Ltd UK

Copperweld Bimetallics UK Ltd UK

Cortinovis Sictra Italy

Costa Machinery GmbH Germany

CRU Events UK

CSM Metalurji Imalat Sanayi Ve Muhendislik Ltd sti Turkey

Daewon Cable Co Ltd South Korea

Danross Engineering UK

Data M Sheet Metal Solutions GmbH Germany

De Montfort University UK

Dongguan XinMei Precision Mold Co Ltd China

Drahtwerk Waidhaus GmbH Germany

DRT Impianti SRL Italy

DSE Test Solutions A/S Denmark

E Braude (London) Ltd UK

Eder Engineering GmbH Austria

EOX Masterbatches SL Spain

Esteves Group Spain

Euroalpha SRL Italy

Eurobend SA Greece

Eurodraw Wire Equipment SRL Italy

FH Machinery USA

FIB Belgium SA Belgium

Fisk Alloy Conductors BVBA Belgium

FMS Force Measuring Systems AG Switzerland

Fort Wayne Wire Die Inc USA

Foxton Dies Ltd UK

Frontier Composites & Castings Inc Canada

FUCHS Lubricants (UK) Plc UK

G & A Engineering Ltd UK

G Church - Consultant UK

Gauder Group Belgium

Geca-Tapes BV France

Gem Gravure Co Inc USA

General Copper Co Ltd China

GEO Reinigungstechnik GmbH Germany

Goodwin Machinery Ltd UK

Guidetti SRL Italy

GURFIL Sanayi ve Elektronik Cih Paz AS Turkey

Gwo-lian Machinery Industry Co Taiwan

H Folke Sandelin AB UK

Häfner & Krullmann GmbH Germany

Hans Schmidt & Co GmbH Germany

HB Cables & Components Ltd UK

Hefei Smarter Import & Export Co Ltd China

Heinze & Streng GmbH Germany

Holton Crest Ltd UK

Huestis Industrial USA

Huntstar Trading Ltd UK

ICE Wire Line Equipment Inc Canada

Inductotherm HWT (Radyne) UK

Induflex NV Belgium

InnoVites BV Netherlands

Inosym Ltd New Zealand

Institute of Spring Technology Ltd UK

Integer Research Ltd UK

Interlink Import-Export Ltd UK

International Trade Shows Link Ltd UK

Intras Limited UK

Itaya Europe limited UK

JG Tec Ltd UK

Jiangsu Handing Machinery Co Ltd China

Jina Special Steel Works Pvt Ltd India

Joachim Uhing GmbH & Co. KG Germany

Kelani Cables PLC Sri Lanka

KIESELSTEIN International GmbH Germany

Koner SpA Italy

LA M PLAST SAS Italy

Lamifil NV Belgium

LCP TPOE (Baker Hughes, Centrilift) Russia

Leggett & Platt Wire Group USA

LEONI Draht GmbH & Co KG Germany

Leoni Temco Ltd UK

Lewis Wire Ltd UK

Locton Ltd UK

Lune Prozesstechnik GmbH Germany

Madem SA Ind E Com de Madeiras Brazil

Maillefer Finland

Manentimacchine SRL Italy

Marldon Group Limited UK

Maschinenfabrik Niehoff GmbH & Co KG Germany

Mathiasen Machinery Inc USA

Medek & Schörner GmbH Austria

Media-Holding "RusCable" Russia

Meisenbach GmbH Germany

Menam Stainless Wire Public Co Ltd Thailand

Metalube Limited UK

MGS Manufacturing Inc c/o Northampton Machinery UK

Microdia SA Switzerland

Mikrotek Machines Ltd India

Mittal Steel Kent Wire Ltd UK

Nanjing Zhongchao New Materials Corp China

Nano-Diamond America Inc USA

NeoFil Ltd UK

Nexans Deutschland GmbH Germany

NOTA-ZAKLAD MECHANIKI PRECYZYJNEJ Poland

NV Bekaert SA Belgium

O M A SRL Italy

OB Mallas Bolivia

Oden Technologies Ltd UK

OMA (UK) Ltd UK

Ormiston Wire Ltd UK

P F Consulting UK

P W Hall Ltd UK

Pakistan Cables Ltd Pakistan

Paramount Conductors Ltd India

Pentre Group Ltd UK

Permanoid Ltd UK

Plasmait GmbH Austria

Pneuform Machines Ltd UK

Pressure Welding Machines Ltd UK

Proton Products International Ltd UK

Prysmian Group UK

PS Costruzioni Meccaniche SRL Italy

Q8Oils UK

QED Wire Lines Inc Canada

Qingfeng Electrical Technology (Hong Kong) Co Ltd Hong Kong

Queins Machines GmbH Germany

Qunye Electrical Co Ltd China

Rautomead Limited UK

Reber Systematic GmbH Germany

Reelex Packaging Solutions Inc USA

RichardsApex Europe Ltd USA

Ridgway Machines Ltd UK

RK Umformtechnik GmbH & Co KG Germany

Roblon A/S Denmark

Rolf Schlicht GmbH Germany

Rosendahl Nextrom GmbH Austria

S K Wiring Products Ltd UK

SACO AEI Compounds Ltd UK

SAMP SpA - Sampsistemi Division Italy

Sant Engineering Industries India

Sanxin Wire Die Inc USA

Sarkuysan Elektrolitik Bakir San ve Tic Turkey

Scott Precision Wire Ltd UK

Shanghai Geili Precision Dies Co Ltd China

Shanghai HOSN Machinery Technology Co Ltd China

Shanghai Kechen Wire & Cable Machinery Co Ltd China

Shanghai Kingway Technology Group Ltd China

Shanghai Nanyang Equipment Co Ltd China

Shanghai Singcheer Technology Co Ltd China

Sictra Cortinovis Italy

Siebe Engineering GmbH & Co KG Germany

Sikora AG Germany

Simplex Rapid SRL Italy

Singhania International Ltd India

Siri Wire USA

SKET Verseilmaschinenbau GmbH Germany

Smeets SA - Loypos Belgium

Sneham International India

South African Wire Association South Africa

Spring Tooling Ltd UK

Stanaway Wire Ltd UK

Stonepark Consultancy Ltd UK

Stride Supplies Ltd UK

Supermac Industries Ltd India

SWR Limited UK

T Fukase & Company Ltd Japan

T M Associates UK

TapeFormers com UK

Techna International Ltd UK

Techno Commerce Ltd UK

Technokabel SA Poland

The Worshipful Co of Tin Plate Workers alias Wire Workers UK

Thompson & Hudson Wire Machinery UK

Tianjin Goldsun Wire Rope Ltd China

Trafco SRL Italy

TRAXIT International GmbH Germany

Troester GmbH & Co KG Germany

U Gear Automatic Machinery Ltd Taiwan

University of Southampton UK

Untel Kablo AS Turkey

Vietnam Electric Cable Corp (CADIVI) Vietnam

Vinston US Corp USA

Warbrick International Ltd UK

WCISA c/o Wire Lab Co USA

Weber & Scher Mfg Co Inc USA

Webster & Horsfall Ltd UK

White & Street International Ltd UK

Whitelegg Machines Ltd UK

Windak Group USA

Wintwire Ltd UK

Wire & Cable Technology International USA

Wire & Plastic Machinery Corp USA

Wire and Tube News UK

Wire Association International Inc USA

Wire Koerner GmbH Germany

Wire Lab Company USA

WOLCO Sp z o o Poland

WTI Fasteners Ltd UK

XL Technologies UK Ltd UK

YTC America Inc USA

Zeller + Gmelin GmbH & Co KG Germany

Zephyr - One Ltd UK

Zumbach Electronic AG Switzerland

Zyklomat Erich Fetzer GmbH & Co KG Germany

HE wire and cable industry in India is largely driven by demand from the retail segment and government investment.

The market has been growing steadily pected to reach around ₹572 billion 5 billion) by 2018

asing importance of power, light and cation has kept demand for wires and gh, and this trend is set to continue as or reliable, efficient energy and data cations grows

stry is a volume driven product and has rom the unorganised to the organised s the new government is focusing on India as an industrial call to arms, the s expected to grow at a similar rate for ive years.

üsseldorf India – which organises Wire & dia – has been one of the pioneers in ng and organising a range of industry continued opposite

GERMAN butt-weld machine maker

August Strecker will be taking its new machine control unit to Wire & Cable India.

The wide-ranging device adds strong new features to its already-impressive list, which includes automatic programme selection, precise voltage control, voltage harmonisation across machines and other features.

The Evo 2 model adds current control for precise weld temperature stability, an innovative “zero-gap” clamping arrangement that removes the need for readjustment, and hydraulic motion control, to maintain position across many welds

August Strecker GmbH & Co KG, Germany Stand: E02 www.strecker-limburg.de

With the new government focus on ‘Make in India’, the wire and cable industry is set to grow over the next five years Thomas Schlitt, general manager of Messe Düsseldorf India looks at what will be on show and why you should be there.

integrated platforms for exhibitions for the wire and cable sector in India since 2010. Exhibitors from across India and other countries have come to the fair and its cousins – Tube India and Metalurgy India – to offer their latest products and services.

Wire and Cable India 2016 comes to the Bombay Convention and Exhibition Centre (BCEC) October 5- 7 in Hall 1 and will stretch over 18,000sq m of floor space, with 130-plus Indian exhibitors and more than 150 international exhibitors from 25 countries

Not surprisingly, Wire and Cable India is actively supporting the Indian government’s Make in India initiative The fair is supported by the International Wire and Machinery Association (IWMA) and others - the International Wire and Cable Exhibitors Association (IWCEA), the Italian Wire Machinery Manufacturers Association (ACIMAF), the Wire and Cable Industry Suppliers Association USA (WCISA), the Steel Wire Manufacturing Association of India (SWMAI) and the All-India Weld Mesh Manufacturers Association (AIWMA) The show is also supported by all the leading publications and web portals

As well as the exhibition, there will be a conference on Polymers in Cables and Wires (PCW 2016) on 7 October 2016 at the same venue, jointly organised by Messe Düsseldorf India and Color Publications Pvt Ltd

Recently, the use of polymers in the cable and wire industry has increased, both for convenience and functionality The conference will look at the entire supply chain to offer a better understanding of best practice and new products and cables.

the conference will cover:

• The use of polymers in wires and cables

• Reinforced polymers and materials for wire and cable applications

• Flame-retardancy and related standards

• Intra- and inter-material replacement in wires and cables

• Value-addition in the polymer space for wires and cables

• Automation in wire and cable manufacturing

The target audience is manufacturers of wires and cables, compound suppliers, RM suppliers, equipment suppliers and end-users in the segment

• Engage with leading polymer suppliers to the industry

• Engage with technical experts

• Evaluate new materials and new suppliers

• Understand new trends and possibilities in material replacement in wires and cables

• Understand wire and cable manufacturers’ expectations from the polymer industry

HOW do you define competitiveness?

For Maillefer it means i n c r e a s i n g t h e l i f e t i m e v a l u e o f t e c h n o l o g y in different production and market circumstances

Maillefer does it by empowering people, production and productivity, and equipping customers with the right expertise.

To better answer the diverse needs of wire and cable manufacturers around the world, Maillefer ’s portfolio is organised on three levels: /Enter, //Extend and ///Explore, which vary in capacity, cost, automation, flexibility, product range, space requirements and maintenance needs

If you require a qualified concept to develop a complete factory with the lowest risk and cost, let us show you a new way to sieze your business opportunities – the Maillefer Factory System

The company also offers 30 know-how products through Maillefer Consultation, with which cliens can maximise the value of their technology, access best practice and improve processes according to their needs At the show Maillefer will offer details on

these and on products such as new Round Value Package Premium, which guarantees high-precision precision roundness in high voltage cable production

Visitors can see a display of the company’s new Cable Roundness Meter CRM 180, which offers a new way to reliably measure cable core roundness and concentricity of medium, high and extra high voltage cable cores without errors

Visit the Maillefer booth to hear details of other products and services, including Quick Conductor Splicing, the FO Cable Secondary Coating Line OEL 40, the MV CCV Line EPL 30, and the HV CCV Line EPL 50

Maillefer also runs a 24/7 service support desk, spare part delivery and technical visits

Maillefer, Finland Stand: C12 www.maillefer.net

5-7 Oct 2016

Preview

ROSENDAHL Nextrom, a leading supplier of production technologies for cables, wires and optical fibres, will present the latest advances and technological highlights at Wire & Cable India 2016 These include state of the art achievements in solar cable production in co-extrusion and tandem extrusion, automotive wires, technologies for optical fibre UV coating, fibre proof testing and the manufacturing of fibre-optic cables. Industry 4 0 – Smart Factory – is becoming a reality and opening new doors for manufacturers Rosendahl will be able to offer technologies to help to make the concept reality

Rosendahl Nextrom GmbH, Austria Stand: E14 www.rosendahlnextrom.com

AESA Cortaillod Switzerland D18A

Ajex & Turner Wire Dies Co India B02

Associated Engineers & Industrials Ltd India A52

Assomac Machines Ltd India A02

August Strecker GmbH & Co KG Germany E02

Bongard Trading GmbH & Co KG Germany A156

Carl Bechem GmbH India A72

Ceeco Bartell - Bartell Machinery Systems Canada C30

Condat Ltd France D78A

Eder Engineering GmbH Austria F07

Eurodraw Wire Equipment SRL Italy C26

FIB Belgium Belgium E56

Fort Wayne Wire Die Inc USA tbc

Gauder & Co SA Belgium D08

H Folke Sandelin AB Sweden E02

Hefei Smarter Import & Export Co Ltd China F25

InnoVites BV India C80

Inosym Ltd New Zealand C38

Intras Ltd UK D36

Jiangsu Handing Machinery Co Ltd China E15

Maillefer Finland C12

Maschinenfabrik Niehoff GmbH India E02

Medek & Schörner GmbH Austria F15

Metalube Limited India E05

Mikrotek Machines Ltd India D02

Nanjing Zhongchao New Materials Co China D26

Proton Products International Ltd UK C04

Queins Machines GmbH Germany G34

Reber Systematic GmbH Germany H39

RichardsApex Inc USA C30-3

RK Umformtechnik GmbH & Co KG Germany G38

Rosendahl Nextrom GmbH Austria E14

SAMP SpA - Sampsistemi Division Italy C14

Sant Engineering India A109

Shanghai HOSN Machinery Technology Co Ltd China E42

Shanghai Kechen Wire & Cable Machinery Co Ltd China G57

Sikora AG Germany G48

SKET Verseilmaschinenbau GmbH Germany G49

SMEETS NV/SA Belgium D12

Sneham International India C49

Supermac Industries India Ltd India C02

Troester GmbH & Co KG Germany G30

WCISA c/o Wire Lab Company USA C30-5

Wire & Plastic Machinery Corp USA C30-1

Zeller+Gmelin Germany E02

LIKE many IWMA members, Ajex and Turner will be moving from a significant presence at wire China 2016 in September to do it all again in Mumbai in October at Wire & Cable India

The New Delhi-based company will have its latest products and equipment on show, and along with high-tech VNT nano dies will also display a range of PCD and carbide dies, busbar dies and shape dies, as well as die polishing machines for PCD and carbide, die polishing accessories and die inspection microscopes.

A&T will bring to Mumbai the first range in the country of VNT Nano dies for compacting and drawing copper, aluminium, stainless steel and other high and low carbon wires in intermediate sizes from 0.8mm-70mm. The company believes the new range will provoke interest from all kinds of wire and cable makers for their excellent price to performance ratio

“Tungsten carbide dies are the most popular due to their low prices, but quickly lose their tolerance and don’t have the desirable lowfriction characteristics,” explained an A & T spokesman

“At the other end of the scale, PCD dies are better than tungsten but are more expensive, and the cost increases with hole diameter Nano dies are both economical and a great

performer, thanks to a multi-layered coating of pure nanocrystalline diamond The diamond coating offers little friction so offers a good surface finish and maintains high accuracy throughout its working life They are a big step forward; better than PCD at lower cost ”

As well as its wide range of dies for a wide variety of applications, Ajex and Turner will show its latest die polishing and grinding machine, the TCD-10 (above)

The equipment can polish and grind angles and bearings in one operation, at high speed The TCD-10 can recondition dies very quickly to give precise angles on the new surfaces

Ajex & Turner Wire Dies Co, India Stand: B02 www.ajexturner.com

MASCHINENFABRIK Niehoff

has been active in India for more than 30 years and is a keen exhibitor at the Mumbaibased Wire & Cable India

Niehoff of India (NoI), Niehoff ’s subsidiary founded in 1997, is the country’s market leader for machinery for rod breakdown, multiwire drawing and bunching

NoI operates a modern, well-equipped factory near Hyderabad opened in 2007 and enlarged in 2011/2012 The company builds rod breakdown machines, annealers, spoolers, bunching machines and pay-offs conforming to Niehoff standards, mainly destined for the Indian market.

NoI is also responsible for all after-sales service and official Niehoff replacement parts under the Niehoff Original+ banner

At Wire & Cable India the company will

have on display a similar equipment range shown at wire China a month before, including the MMH 121 multiwire drawing machine (above), designed to draw 16 wires in one level for a diameter range from 0 20 mm up to 1.05 mm. The MMH 121 is combined with an inline annealer (type RM 201) and can work at up to 35 m sec.

The Neihoff stand will be shared by partner companies August Strecker of Germany, Zeller+Gmelin of Germany and H. Folke Sandelin AB of Sweden

Maschinenfabrik Niehoff GmbH, Germany Stand: E02 www.niehoff.de

WIRE 2016 is behind us and what a week it was! Global economic upheaval, a worldwide steel crisis, new climate regulations

s p a n n i n g t h e g l o b e a n d a c l a s s i c industry on its journey into the new Industry 4 0 digital age were the main topics for exhibitors and visitors alike

Almost 70,000 visitors representing 2,600 companies from 130 countries visited wire Düsseldorf 2016 and its sister Tube Düsseldorf 2016, the two taking up almost 111,000sq m of exhibition space across 16 halls - a new record

Of the two, wire Düsseldorf had 1,337 exhibitors from 53 countries across 59 700sq m, showcasing wire manufacturing and finishing machinery, process engineering tools and auxiliary materials as well as materials, special wires and cables Innovations in measurement, control, test engineering were also major subject areas

This year ’s event was special as it marked wire 2016’s 30th birthday Over the 15 biennial exhibitions the event has grown from its original 488 exhibitors in 2,400sq m of floor space to today’s vast numbers

The event is truly international, too: at the first event in 1986 were 488 exhibitors from 23 countries and 45% of guests hailed from outside Germany.

Today the figure is 65%, two-thirds from Europe and the remainder from overseas

“Major deals are made in Düsseldorf; it serves as the global communication and business platform for industry heavyweights, SMEs and international associations alike,” said FriedrichG e o rg K e h r e r, M e s s e ’s g l o b a l portfolio director for metals and flow technologies

Exhibitors were very pleased with the customer contacts and deals made across the week

And wire 2016 was a huge success for the IWMA too. The association’s new stand was a big hit as a place to meet and talk business for members old or new, without a company stand or just visiting

The stand’s business centre facilities and meeting room were in constant demand and became a busy hub for members and visitors alike.

We were also delighted to see so many IWMA members at wire 2016 and at our industry dinner

OVER 230 members and guests attended the prestigious IWMA industry dinner at wire Düsseldorf 2016 at the Congress Center. Welcoming guests, IWMA chair Amanda Shehab said since the association was founded 46 years ago it had contributed to, and supported, the development of over 50 conferences, in Düsseldorf and around the world

“We look forward to continuing that work and expanding the support we give our members in the years to come,” she added

The dinner was also the occasion for the presentation of IWMA awards, notably to the winners of the HW Bennett award for the best ferrous and non-ferrous t e c h n i c a l p a p e r s f r o m t h e

CabWire 2015 conference

The non-ferrous award went to M r F r a n c o B e n s i a n d M r

Rupert Parmenter of SICME

Italia Impianti for the paper Revolutionising the Wire Manufacturing Process The ferrous award was given to Mr René Branders of FIB Belgium SA. for his paper New Design in Open Fire Furnaces

Mr Bensi’s paper appeared in last edition of WCN, and Mr Branders’ paper appears on page 24 of this issue.

Through its educational trust fund and travel award scheme, the IWMA actively encourages industry newcomers to gain new skills and experience. The John C Hogg travel award scheme contributes towards costs for

successful applicants to attend industry leading events

This year ’s winners (pictured above): Sagar Somanche of Sneham International, India; Rahul Shah of Innovites BV, India; Jack Witherington of Ridgway Machines Ltd, UK; A n d re w S t e p t o e o f B r i d o n International Ltd UK; Ms Jia Qi Liang of Shanghai Kechen Wire & Cable Machinery, China; Ashley Cox of Cimteq Ltd, UK; Aran Brady of Prysmian Cables

At the exhibition:

Left: Andrew Wright and Davina Hancocks of specialist machine toolmakers Spring Tooling of Bromsgrove UK

Right (top) the team from Holton Crest, Poole, UK, based extrusion machine manufacturer Below right: the senior team from the IST (Institute of Spring Technology), a service for the spring industry, based in Sheffield, UK

& Systems Ltd, UK and Ms Sai Jyothi Sree Ramavarapu Niehoff of India Pvt Ltd India, received VIP invitations to the dinner, entry to wire Düsseldorf, toured member stands and were presented with commemorative certificates by IWMA chairman Amanda Shehab and by Daniel Ryfisch, Messe Düsseldorf ’s deputy global portfolio director for metals and flow technologies

What some of our members had to say about wire 2016

“THIS was a really powerful and highly energised wire Düsseldorf!

We enjoyed being part of a show for which the entire industry gets together

“It was a very successful event that allowed

“DÜSSELDORF was very successful for Maillefer We met many new and existing customers and partners from all over the world

us to demonstrate what drives us to best performance

“Industry 4 0 – Smart Factory as we like to call it – is becoming reality and opening new doors both suppliers and manufacturers It

“A number of new business opportunities were initiated and agreements closed during the week, and generally we saw positive signs in the wire and cable industry

“The core theme for us in 2016 is Competence that Counts, which reflects our extensive background and

experience in the industry “Several technologies in wire and cable manufacture today are our innovations ” Maillefer will be attending the Shanghai and Mumbai shows (see China and India previews, this issue)

information management

Our service lounge was very well received and many visitors reviewed the possibilities offered by maintenance or upgrades ”

“WE were pleased with the number of visitors to our wire 2016 stand,” said Wolfgang Kienle, product manager at Zeller+Gmelin

Many of the 300 or so visitors to the stand had travelled from abroad, mainly Europe and Asia Wolfgang reports a larger than expected number of visitors from Iran

“The easing of the economic sanctions against Iran has had a direct influence on trade fair contacts,” he suggests

The total number of visitors increased by almost 30% compared to 2014

“We were delighted that, in addition to existing customers, almost half of the visitors were prospective customers ” Zeller+Gmelin’s Multidraw drawing lubricant range was a key feature of the stand.

AT wire Düsseldorf a large Niehoff team from headquarters, from our subsidiaries and from representative companies welcomed many visitors from all over the world Our two-level stand was one of the largest at what was the biggest wire exhibition yet, in terms of exhibition space

“We showed our new rod breakdown machine (MSM 86), which offers improved wire quality, energy efficiency and cost savings We also demonstrated our Niehoff Original+ spare parts label; energy and materials efficiency and reducing manufacturing costs were very keen topics among visitors

“We came to Düsseldorf convinced wire 2016 would be a great success again – and we were rewarded for our efforts,” said Arnd Kulaczewski, Niehoff president and CEO

“ALLOY Wire used wire 2016 as a showcase for its new brochure, 84 pages listing more than 60 types of exotic nickel alloys, including Inconel®, Nimonic® and Ni-Span C902®. More than 300 copies were distributed to automotive, aerospace, defence, oil, medica and nuclear sectors.

WE’VE been coming to wire Düsseldorf for 35 years; it’s the most important event on the cable industry calendar, and participating has been crucial for us We meet current customers and make new business contacts

“Over the five days this year more than 750 specialists, product and business development managers, R&D people and engineers from the world's leading cable manufacturers asked for detailed information about our products Samples were also available

“Taking part in such a large scale event is a great experience for our team; it lets us survey our customers to find out their preferences; we make deals and meet old friends It all helps us to deliver better products ”

were excellent and the calibre of innovations was at an all-time high,” said Amanda Shehab, not just a Cimteq director but also IWMA chairman

“BAR had good reason to enjoy its visit to wire 2016 in Düsseldorf: the company secured a major contract with China after discussions that began there Bar MD Steve Rika revealed: “The contract, for machines and tooling, will be delivered in two stages and will hopefully be the start of a continuous supply relationship in the future ”

Significant other orders made wire Düsseldorf Bar ’s most successful-ever exhibition

“We were extremely pleased with the attention our booth received from familiar visitors and new faces keen to discuss the features of our cable design and manufacturing software systems

“The exhibition was the perfect arena for Cimteq and our partner, InnoVites, to unveil our latest joint venture, CableSuite, which provides a varied set of tools in one unit CableSuite is a complete, fully-integrated enterprise software suite that supports all business functions of cable manufacturers and distributors

“As anticipated, interest in the product was high and the exhibition was considered to be an extremely successful showcase by both our companies ”

René Branders is CEO of FIB Belgium SA. He has worked in R & D, engineering and quality control, including work on the development of technologies related to fluidised beds. He has worked in the wire industry since 1988, and is president of the European Committee of Industrial Furnace and Heating Equipment Association (CEOCOF).

Open fire furnaces – a new concept for a more efficient use of energy by René Branders

FURNACES that heat wires directly to austenise or anneal them are common in wire drawing because they offer several advantages, not least in the avoidance of heavy-metal use and extensive maintenance required by other methods

These furnaces have not been terribly heat efficient - something that has to be addressed if many older models are to comply with forthcoming EU regulations concerning thermal efficiency and power consumption

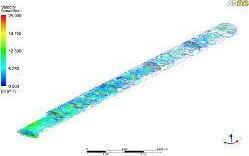

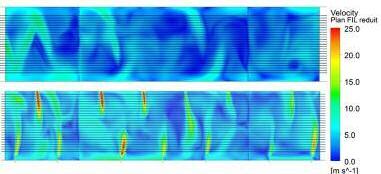

By using recycled combustion fumes from the furnace’s burners and optimising heat transfer within the furnace by revising the internal spaces it is possible to offer a new thermal equipment category that cuts energy consumption by up to 27%

Open fire furnaces are a familiar technology in the production of high carbon wires for the cable and low-carbon industries With high carbon wires, the furnace’s combination of convected and radiated heat converts the steel of the wire into Austenite In low-carbon wire production, the wire is annealed Such equipment is generally working at temperatures between 980C and 1100C

Wires – often still with drawing residues – enter a preheating tunnel, warmed by flue gases from the downstream burners. The wires then enter a succession of burner-equipped heating zones The zones transfer heat by convection and radiation, the latter from the burner walls back to the wire field

The consistency of the results depends on the capacity of the equipment to transfer heat evenly. As far as the radiated heat goes, the furnace is a “black body”, with no effective way to improve radiation effects, except by minimising losses from openings

The quality of the convected heat input thus becomes decisive. Zones of low convection caused by vortex effects or obstacles should be avoided, and high flue-gas circulation speed obtained over the whole field Knowing this, the geometry of the furnace’s inner chamber and distibution of the burners must be designed for maximum efficiency. My company has carried out extensive thermal analysis of classicallydesigned furnaces and has noted disturbing elements that limit the efficiency of heat convection.

In the two diagrams top right we can see the furnace vortex In such a swirl (lower diagram), convected heat transfer is no longer guaranteed, especially for areas outside the wire field

The shape of the chamber and the convection effects and countercurrents also lead to a rapid concentration of flue gas in the top part of the furnace, obviously limiting heating effectiveness at the wire field below Consequently we have seen some relatively low gas circulation speeds in the wire field, which as it happens are homogeneous and thus an advantage

Thus burners are positioned to cover the wire field in such a way that hot gases cannot blast the wires directly, mainly by way of a judicious gap between the the burner brick and the wire field This is, however, detrimental to the speed of the hot gases across the wires

When considering recovery of flue gas from the area around the burners, we also noted some unhelpful flows on the wire bed The introduction

of hot gas stirring fans, for instance, leads to intense convection flows inside the chamber, which can cause uneven heating of the wire field, as seen in the diagram above

Using hot gas recovery and reapplication, the furnace is effectively divided into two zones, the first in which hot gases from the burners are redirected to the preheat zone, which has no burners; and the second, in which the wire bed is heated with convected and radiated heat.

I n t h i s c o n f i g u r a t i o n , c o n v e c t e d h e a t i s

distributed according to this curve (below)

As you see, despite the existence of convective flows in the furnace, the wire field is heated quite evenly across its width Experience shows that such arrangements permit the treatment of wire fields up to around 1 7 metres wide, while guaranteeing even physical characteristics in the wire produced – whatever its position in the furnace wire field

Optimisation of the internal shape of the furnace and careful distribution of the burners adds a substantial increase in the convection heating speed of the wire The curve (top right) shows the evolution of a wire in an optimised furnace compared to a traditional one The wire is heated much more rapidly in the optimised furnace; preheating with heat from the burner gases is optimised, meaning the

wires can be heated to much higher temperatures than in ventilated pre-heat designs

The consequence is better use of residual heat and an overall increase in the furnace’s thermal efficiency – while saving around 1 5kW previously used on the circulation fan

In the active heating part – where the burners are positioned – the wires enter at a higher temperature, so the power needed to heat them is reduced In these zones too, the optimisation of the internal chambers of the furnace allows more efficient use of the convected heat

When comparing the profile of the gas speed in this new configuration (right, centre), with the previous flow diagram (previous page) we see not only a useful increase in convected

h e a t t r a n s f e r, b u t a l s o m o r e e v e n h e a t distibution across the whole wire field, as you can see in the chart above right

The result of these changes for our example furnace was an overall efficiency improvement greater than 10%-15% The optimal use of the residual flue-gas heat requires a slight extension of the preheating zone, but nonetheless allows operation without stirring fans at high temperature, reducing cost

The optimisation of convected heat within the chambers leads to a substantial decrease i

This solution to a common situation is based simply on optimising the shape of the furnace, nothing more, but permits operation without high-consumption auxiliaries that can break down easily and are very expensive to maintain

The change also conforms to forthcoming European policy related to furnace design and energy use, due to be imposed on existing equipment throughout Europe.

Position (m)

COME July 2017, pretty much every coil of cable made or sold throughout the EU will need to be CE safety-marked for its resistance to fire.