VALUABLE INSIGHTS

Chairman’s Welcome

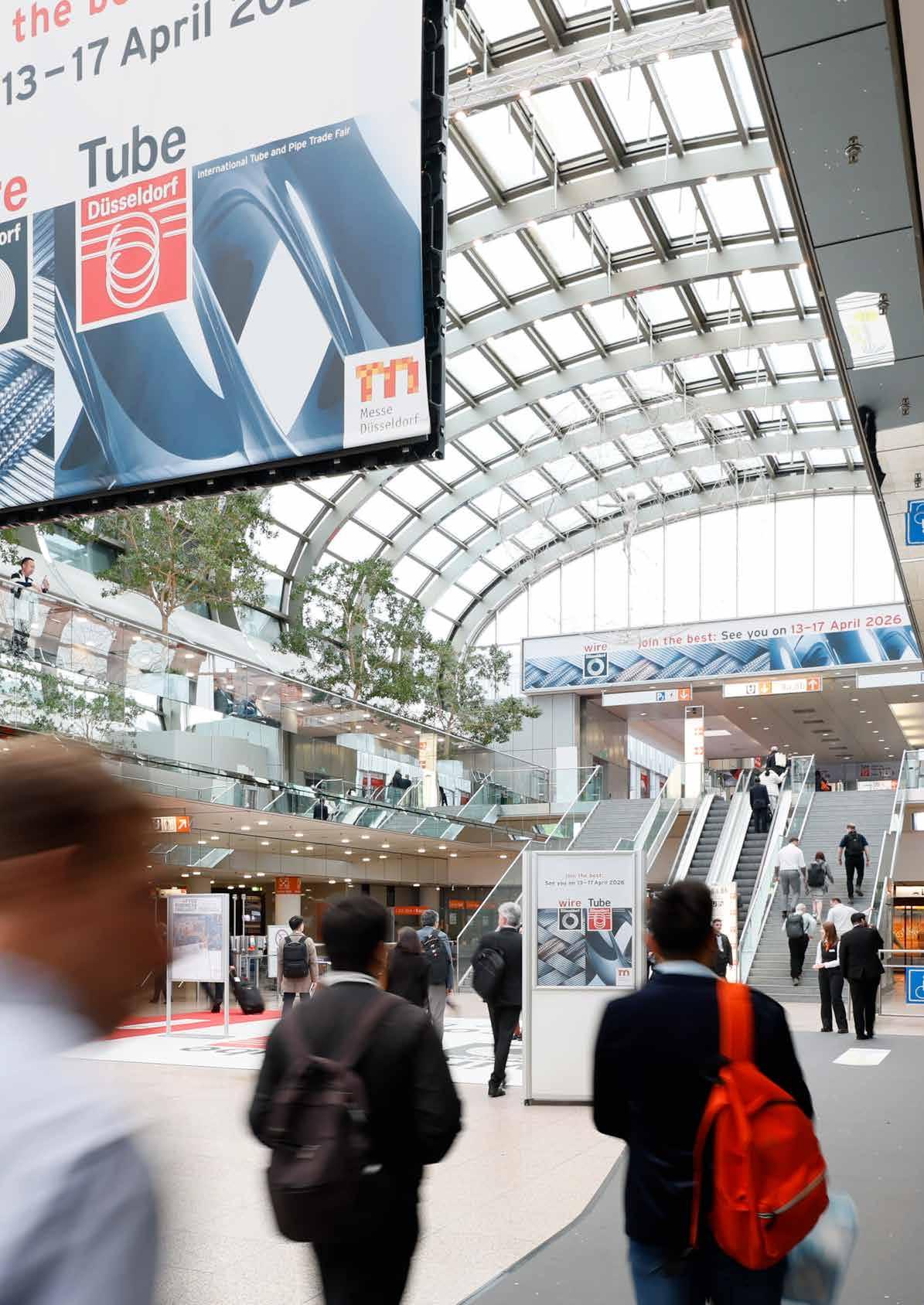

Welcome, one and all, to another edition of the new IWMA Insider, and if I’m in an ebullient mood it’s because I’m still buzzing from IWMA’s appearance at wire Düsseldorf in April.

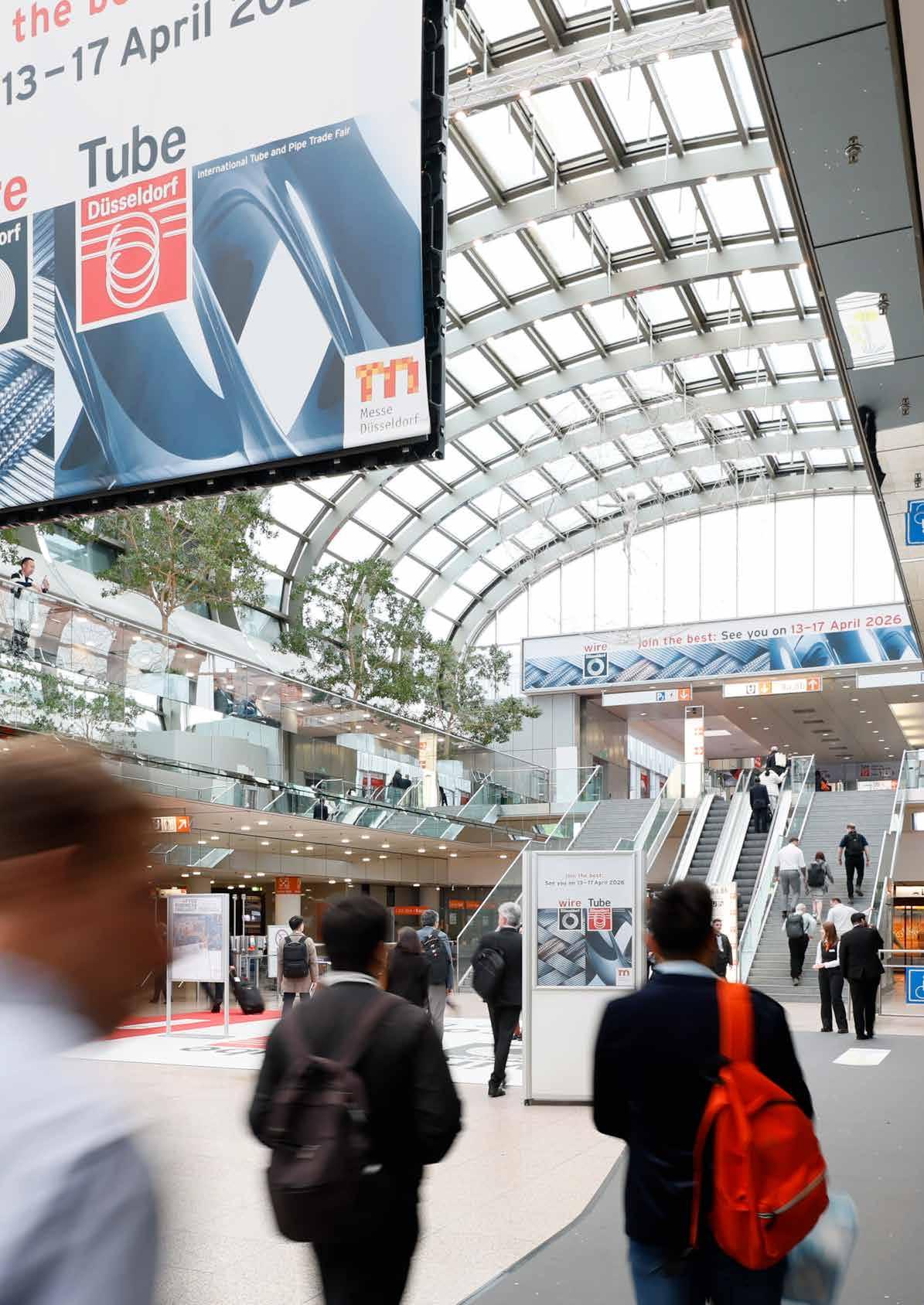

I know we said a while back, after Covid, that the industry would take some time to bounce back after the international shutdowns – and we meant years – but it’s amazing to see just how powerfully the wire and cable industry has been getting back to business. For those who had doubts, a day or two at the Düsseldorf show was all that was needed.

The event was packed, the largest yet, confirming its standing as the world’s go-to destination for wire and cable makers and users. Our partner Messe’s organisation of the event was exemplary.

In the midst of all this activity, IWMA’s stand was also a hive of energy. Our new team, led by executive manager Jessica Bennett and members of the executive group such as myself and new president Bernd Lohmüller, was in fine form in its first big outing, fielding questions, advising on membership inquiries, and meeting friends and members new and old. The stand was the busiest it’s ever been, and we couldn’t have been happier with the reception we received and the level of interest in joining us.

In the middle of this were our industry awardees –10 up-and-coming young engineers and wire and cable newcomers, sponsored by IWMA to visit the show and see what kind of business they were getting themselves into! Suffice to say the industry didn’t let us down; the wave of enthusiasm they showed for this bustling, vibrant section of world industry was palpable, and hopefully they will help it to stay that way in long and successful careers.

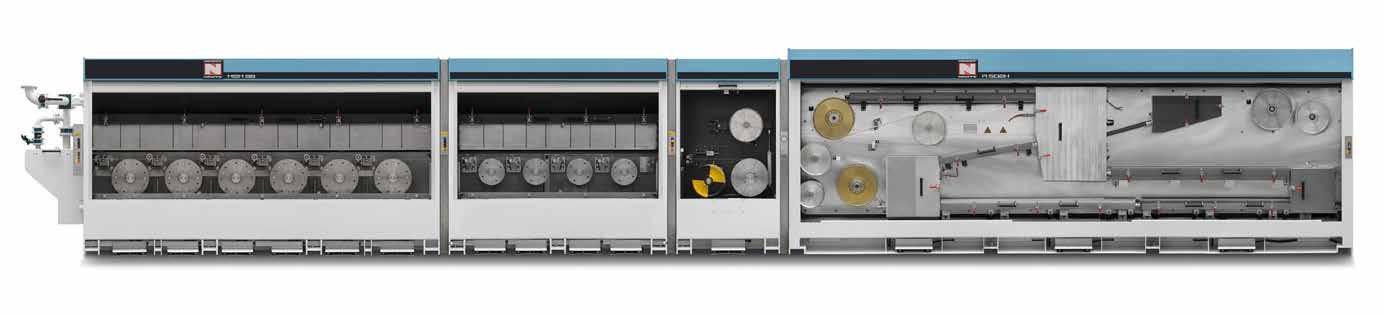

Following the high of the show, IWMA’s executive management committee held its most recent meeting at the headquarters of new president Bernd Lohmüller –namely the Niehoff world HQ in Schwabach.

After a terrific tour of the nearby beautiful and historic city of Nuremberg and a traditional Bavarian dinner, the meeting was very productive. As you might know, we are planning the organisation’s strategy for the next five years. More details will be shared soon! The meeting was followed by another treat for members in our business: a tour of Niehoff’s factory, an industry powerhouse if ever there was one, with products in use for many years on all continents thanks to the company’s sworn intent to maintain and upgrade its products wherever possible.

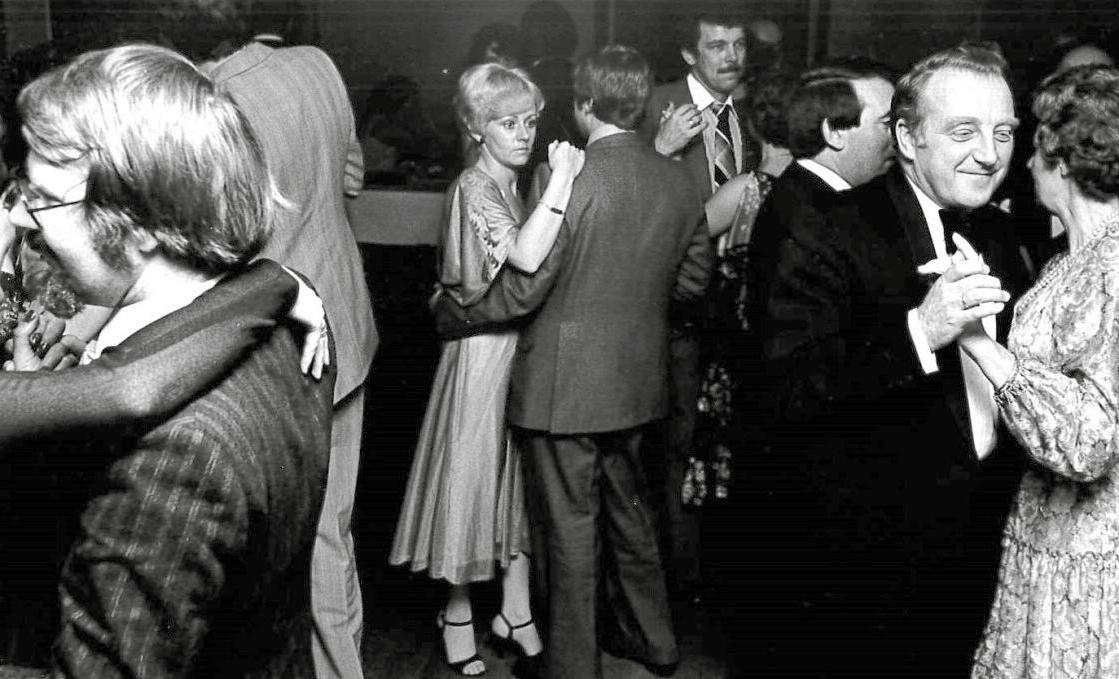

As we enter the second half of the year, we have much to look forward to; as well as our attendance at the Chinese and Indian wire shows - the next-largest after Germany we have IWMA’s premier social event in the offing –the return of our annual dinner dance – now to be annual once again following the long post-Covid lay-off.

This year the event will take place at the lovely Leonardo Royal Hotel London St Paul’s, a short walk to both the cathedral and the Thames. Our much-loved social event has always been a starred item on everyone’s calendar, so we are thrilled to be back, and in a new location in the centre of the City of London on November 15th. Tickets are now on sale, the details of which you can find elsewhere in this magazine as well as on the website, so don’t delay if you are coming, it’s certain to sell out long in advance!

And finally, back to those two forthcoming major exhibitions in Shanghai and Mumbai, when we will be reintroducing our popular wire exhibition networking events (on the second evening of each event).

We can’t wait to bring members together again for a grand networking session and social catch-up on the back of our industry partner’s terrific and extremely busy shows. Our networking events are fun get-togethers that give a flavour of the country being visited and allow members to relax among friends. Come and say hello!

The two shows will also have new features for members and visitors. One will be space for member presentations; the other, in India, will be the presence of local member companies in our new pavilion space – more about which can be found on page 21.

It’s been a great half-year so far; here’s to an equally successful second half!

I look forward to seeing you at our much-anticipated Dinner Dance on 15th November or at one of our upcoming exhibitions.

My very best wishes to you all

Don Neville Chairman, IWMA

wire Düsseldorf 2024: A global gathering uniting industry leaders from around the world

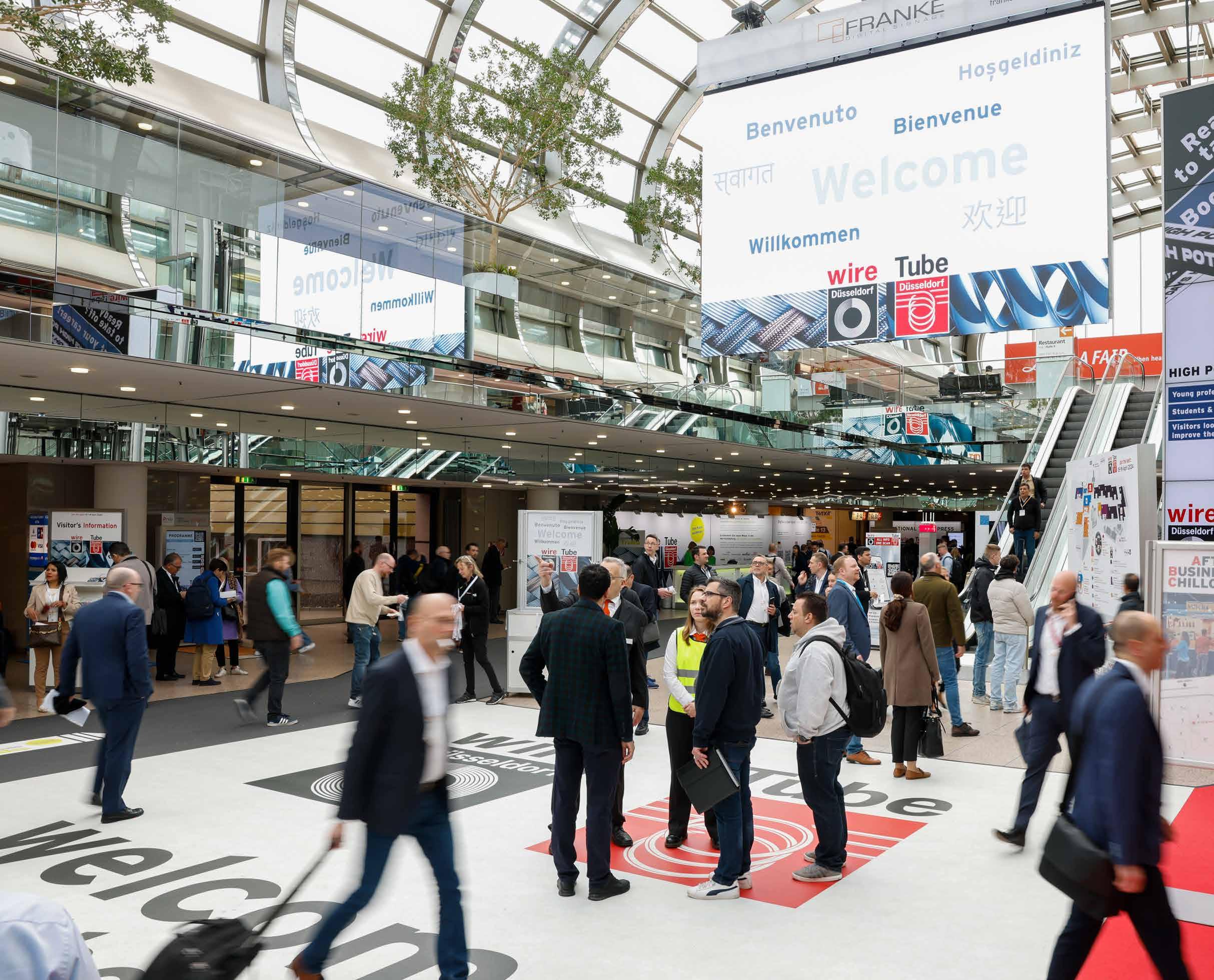

From 15th to 19th April, Düsseldorf was a bustling hub of activity as industry leaders, innovators, and stakeholders from 135 countries converged to share insights, forge new connections, explore cutting-edge technologies, and discuss environmental issues, against the backdrop of an ever-evolving economic and geopolitical landscape. The exhibition halls of wire Düsseldorf were buzzing with excitement as a record-breaking number of exhibitors, over 1500, showcased the latest advances in wire and cable machines, glass fibre technologies, mesh welding machinery, spring making, and connection and fastener technologies.

One of this year’s standout features was the extensive lineup of side events that complemented the main exhibition. For the first time, attendees could benefit from a packed program of lectures, presentations, curated shows, and digital guided tours, and alongside this, special areas and digital trails focused on hot topics such as ecoMetals, hydrogen, plastic pipes, separating, cutting, sawing, and stainless steel, offering a comprehensive view of the latest trends and innovations.

The event was a resounding success – a global gathering on a grand scale which celebrated a shared vitality and a lasting commitment to innovation and sustainability. Once more, it provided an outstanding platform for nurturing those connections and exchanges of ideas and information that will drive our industry forwards in the years to come.

Shaping the industry’s future

As always, the event offered an outstanding platform for the presentation of new ideas. As well as being a hub for technical innovation, it demonstrated a wealth of ways in which we can proactively shape the industry’s technological, commercial, and ethical future; from mechanising procedures in the context of skilled labour shortages, to ‘pushing the pace’ on a major energy transition by electrifying prospects for automotive manufacturers and their suppliers. Exhibitors were delighted with both the high number of visitors to the various stands, over 43,000 from every sector of the diverse wire industry, and with the enthusiastic response to the countless new developments on show.

Connecting continents

This year’s wire Düsseldorf was a genuinely global gathering which united industry leaders from around the world. The diverse international presence demonstrated the critical role of the wire, cable, tube, and pipe industries on the global stage; apart from Germany, major trade visitors came from Italy, Spain, Belgium, France, Austria, the Netherlands, Turkey, Switzerland, Great Britain, Sweden, Poland, the Czech Republic, the USA, Canada, South Korea, Taiwan, India, and Japan. This year also saw a noticeable increase in visitors from Central and North America, Turkey, and Asia, who praised the comprehensive lineup, the innovative nature of the trade fair stands, and the presence of such a high percentage of market leaders which offered a wealth of opportunities to network and to meet new suppliers.

Sustainable innovation

The environment was, of course, high on the agenda. Experts from numerous exhibiting companies took to the stage to discuss their sustainability strategies and progress toward green transformation. Subjects under discussion revolved around energy and climate policy, decarbonisation, and the successful implementation of sustainable practices within the industry. Notable items included the wire & Tube Convention, ITA-Forum, BDS Forum, SawExpo Forum, and the Special Area Plastic Tubes & Pipes, and the high level of participation, creative thinking and positive feedback highlighted the industry’s resilience and readiness to tackle future energyrelated challenges. The range of skills demonstrated that in the global mission to ensure energy security with renewable energies, our industry is an indispensable part of the solution.

IWMA – role and recognition

This year’s exhibition marked the largest in the nearly 40-year history of wire Düsseldorf, and IWMA is immensely proud to have been a part of such a landmark occasion! Many of our member companies actively participated in the event, either as exhibitors or by utilising our meeting and hospitality services, and your presence and engagement made a major contribution to what was a hugely successful wire for IWMA. We’d like to extend our sincere thanks to all who joined us; the positive

feedback we received from everyone and the addition of new members to the IWMA community further enriched the network and promised some exciting future developments. Stay tuned for more details on these new members in the upcoming editions of IWMA Insider magazine!

We were delighted to honour our 2024 wire Düsseldorf Education Awardees with certificates presented personally by Friedrich-Georg Kehrer, Global Portfolio Director for wire/Tube and Flow Technologies at Messe Düsseldorf - in recognition of their participation in the 2024 wire Düsseldorf Education programme. It was a privilege to host such talented individuals, and we’d like to extend both our congratulations on their achievements and our thanks for their outstanding contributions to the week’s activities! Each of these talented young industry professionals gave educational presentations on their own companies as well

as taking part in several enlightening tours and talks from IWMA member companies to learn more about the industry.

wire Düsseldorf is set to return from 13th–17th April 2026 and we’re already excited to see you all there and offer our signature IWMA member services. Until then, we will of course continue to support our members and connect our community through an exciting mission to champion continuous growth and innovation within our industry.

You can find out more about upcoming IWMA events on our website at iwma.org/events.

Don’t forget the IWMA Dinner Dance, Friday 15th November 2024 in London. Secure your tickets at iwma.org/events

Welcome to our New IWMA Members

Cabletec

Cabletec are the UK’s leading manufacturer of EMI screening braids, earth bonding leads, earth leads, copper braids, flexible busbars, and power shunts. In addition to their braiding facility, they have manufacturing capabilities to produce customised multicore cables and assemblies, and stock a wide range of high-performance wire and cable

Vikas Spool Private Limited

In 1984, a young man from a village embarked on a journey to the city with big dreams, marking the beginning of Vikas Spool’s success story. Founder, Mr. S J Chaudhary, started out as a wire machine operator, but he dreamt of achieving more. So, he came up with the idea of trading spools.

GMM Cable Machinery

Güven Mühendislik Makine Sanayi ve Ticaret Ltd Şti (GMM) established in 2000 is one of the leading machinery manufacturers in Turkey.

Founded by three engineers with a combined experience of over 30 years, GMM has become a well-known company in machinery industry in Europe, Africa and Asia.

The production is performed at a fully integrated plant with total floor space of 130,000 sq ft and site area of 215,000 sq ft with the latest technologies and using the most advanced machinery.

Their quality standards are supported by the most experienced staff and GMM is certified by ISO 9001, ISO 14001 and OHSAS 18001.

www.gmmcable.com

Wire & Cable University, established in 2021, operates as a virtual training hub primarily serving Spanish and Portuguese-speaking countries, with plans to expand to English-speaking audiences soon. Wire & Cable University programs cater to process engineers, operators, project managers, supervisors, maintenance technicians, and team leaders in the electrical wire and cable industry and focus on imparting comprehensive knowledge of manufacturing processes, machinery, equipment, materials, maintenance, and accessories, ensuring participants are well-equipped to excel in their roles.

www.wireandcableuniversity.com

Novametal Group extends its heartfelt gratitude to everyone who visited our booth at wire Düsseldorf

Your presence significantly contributed to the success of the event, and it was a pleasure for us to see and speak with so many of you in person. The interesting conversations we had were valuable. We look forward to continuing a close working relationship with each and every one of you.

Wishing you all continued success and we look forward to welcoming you on our booth once again in 2026!

Networking at its Finest:

IWMA’s Spectacular Shanghai Huangpu

River Cruise Returns!

As anticipation builds for the wire China exhibition, we are thrilled to announce that the IWMA will be making a significant appearance. Our stand will be a hub of activity, offering members an array of opportunities including on-stand presentations and the usual warm IWMA hospitality. Visitors to our stand can look forward to free Wi-Fi, comprehensive support services, and expert translation assistance.

One of the highlights of this year’s event is the return of our popular evening networking event, which promises to be bigger and better than ever. For the first time since 2019, IWMA will host an evening cruise down the iconic Huangpu River in Shanghai on Thursday 26th September 2024. This exclusive event was a sell-out success in 2019, and to accommodate the high demand, we’ve secured more tickets for this year’s event.

The 2019 cruise was a memorable evening, featuring clear skies, stunning nighttime views of Shanghai, and a delightful buffet of local cuisine and drinks. We are excited to recreate this magical experience. Guests will be collected from the IWMA stand at wire China and transported via coach to the dock for a two-hour cruise, before being returned to the exhibition hall or the Grand Mercure Shanghai Century Park Hotel.

Member companies are eligible for two complimentary tickets, with additional tickets available for purchase at 60 euros each. This spectacular event promises a night of unparalleled networking and sightseeing. Tickets will go on sale on 25th July. Make sure to keep a keen eye out for more information to secure your spot at this showstopper event.

Don’t miss out on what is set to be an unforgettable highlight of wire China 2024!

Shanghai, China 25 — 28 September 2024

EXCLUSIVE

Advertising opportunities for members only in 2024, with prices starting from as little as £200!

SUBMISSION DEADLINES

for 2024/25 magazine content

We are now offering exclusive advertising slots in our quarterly IWMA Insider magazine! Advertising space is limited in each edition and will be allocated on a first come, first served basis.

The benefits of magazine advertising are huge, and we wanted to offer our members an even greater opportunity to hit their target market and get noticed in our industry magazine. We’re pleased to be able to offer FREE editorial slots for all members, as well as the above advertising opportunities.

September Edition 2024

PR/ Editorial deadline: 3rd July

Advertisements deadline: 17th July

December Edition 2024

PR/ Editorial deadline: 4th October

Advertisements deadline: 18th October

March Edition 2025

PR/Editorial deadline: 17th January

Advertisements: 31st January

June Edition 2025

PR/ Editorial deadline: 2nd April

Advertisements deadline: 23rd April

For more information, please contact Katie at katie@iwma.org

Messe Düsseldorf: wire Düsseldorf Industry Trade Success

Record trade fairs face economic challenges: key technologies wire, cable and tube and pipe remain system-critical

What a great trade fair season! With 1,500 exhibitors from 60 countries on 67,400 square metres, the biggest wire in its almost 40-year Düsseldorf success story; and Tube with around 52,200 square metres, and 1,200 exhibitors from 54 countries that now increasingly looks to energy efficiency and sustainability!

A total of 2,700 exhibitors came to Düsseldorf, proving over five trade fair days and on around 120,000 square metres net exhibition space, that the wire, cable and tube and pipe industries and their upstream suppliers are ready for future energy-related challenges. The fact that they are among the system-critical sectors worldwide also strengthens the position of their world- leading Düsseldorf trade fairs.

The desire for personal exchange in these – economically and geopolitically – difficult times was clearly noticeable in the industry. “The world seems to turn faster and we turn with it. Every two years our industries get together here in Düsseldorf – the community stands by its location on the Rhine. We are very grateful for this and are working consistently to ensure that wire and Tube will also remain their industries’ No. 1 trade fairs in future,” delights Daniel Ryfisch, Director wire, Tube & Flow Technologies.

Exciting line-up of side events in the exhibition halls However, insights into the exciting transformation processes going on in their industries did not only come care of the 2,700 exhibitors.

For the first time, a packed programme comprising lectures, presentations, special shows and digital guided tours accompanied the hustle and bustle in the exhibition halls. Special Areas and digital trails on such hot topics as ecoMetals, hydrogen, plastic pipes, separating, cutting, sawing and stainless steel provided information on their news and trends.

Experts from numerous exhibiting firms presented their companies’ sustainability strategies, discussed paths towards the green transformation and energy and climate policy with the audience, or presented successes already achieved on the way to decarbonisation. Be it the wire & Tube Convention, ITA-Forum, BDS Forum, SawExpo Forum, Special Area Plastic Tubes & Pipes or the digital ecoMetals and high potential trails – the exhibition halls were brimming with innovations.

wire and Tube: fit for the requirements of the future

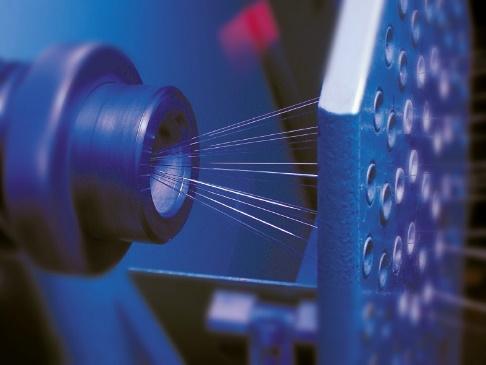

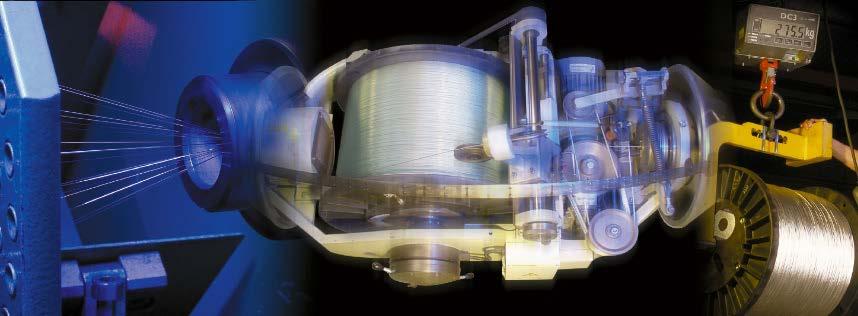

Trends in wire and cable machines, in wire and cable manufacture, in the trade as well as the latest developments in the field of glass fibre technologies, mesh welding machinery, spring making and connection and fastener technologies were presented in exhibition halls 9 to 17.

“wire & Tube is the place where the future of the wire and tube industries is actively shaped and we introduce the innovations of the last two years to our customers,” rejoices Dr.-Ing. Uwe-Peter Weigmann, board spokesman at WAFIOS AG.

“This year our new developments received extremely positive feedback, which was also reflected by the high number of visitors at our exhibition stand. Alongside new machine concepts such as the modular transfer bending machine BQ10, the theme of “assisted machinery” went down especially well in the context of skilled labour shortages. This machinery assists new staff in setting up, performing individual process steps independently. With four levels WAFIOS has laid the foundation to incorporate machines with their assistive functions long term,” adds Weigmann.

The exhibition stands in Halls 1 to 7.1 made it clear that the tube industry not only “thinks big” but also boasts convincing, sustainable concepts for the use of renewable energies and the reduction of CO2 emissions. The sectors using tubes and pipelines are as highly diverse as the requirements for the material properties and sorts/grades.

Here plastic pipes play an increasingly important role, as mirrored by the consistently high footfall in the Special Area Plastic Tubes & Pipes in Hall 1.

Trade visitors from 135 countries in Düsseldorf And from which countries did the trade visitors hail? The major producing countries have also traditionally been where most trade visitors come from. Apart from Germany itself, these once again included Italy, Spain, Belgium, France, Austria, the Netherlands, Turkey, Switzerland, Great Britain, Sweden, Poland, the Czech Republic, the USA, Canada, South Korea, Taiwan, India and Japan.

Noticeably more visitors than before came from Central and North America, Turkey and from Asia. They awarded top marks for the comprehensive line-up and innovative nature of the trade fair stands and praised the presence of almost all market leaders. Networking, exploring innovations at the stands and meeting new suppliers were at the forefront of trade fair visits.

In 2026 wire and Tube will again fly their flags in Düsseldorf, from 13 to 17 April. Until then we would like to keep you informed and entertained 24/7/365 at www.wire.de and www.Tube.de. Be sure to also follow us on LinkedIn: www.linkedin.com/showcase/wire-and-tubeleading- international-trade-fairs

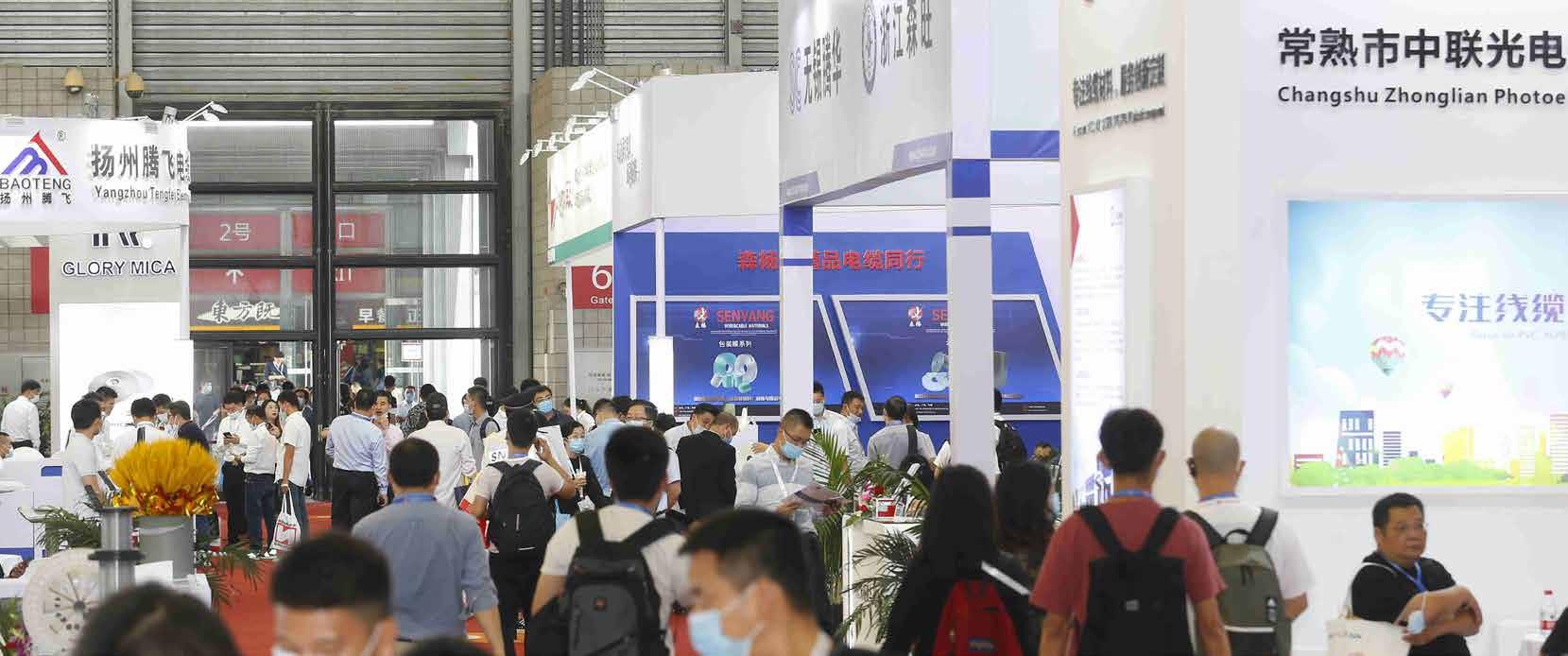

wire China & wire India: The Countdown Begins

It’s a busy year for Messe Düsseldorf and its partners: having already organised the biggest wire and cable show ever – April’s wire Düsseldorf –they now remain in top gear for wire China and wire India.

If wire Düsseldorf is anything to go by, both the Mumbai and Shanghai exhibitions will healthily beat attendances set at their last runs in 2022 and 2023 respectively –especially India, which in 2022 was still feeling the effects of the COVID-19 shutdowns and was the first show for four years. Even so, it exhibited strong growth, with over 17,000 visitors and almost 400 exhibitors, showing more than 500 products from 21 countries.

The extra year to the Chinese show, last year, clearly revealed the renewed confidence within the industry after the five-year Covid gap. Almost 41,000 visitors from 96 countries turned up in Shanghai – almost 31 per cent more attendees than in 2018.

This time, wire India is expecting over 400 exhibitors from two dozen countries across 23,000 sqm of floorspace at the Bombay Exhibition Centre. Meanwhile, wire China will occupy nearly 70,000 sqm at the Shanghai New International Expo Centre over four days, anticipating surpassing the 1,500 exhibitors of 2023.

While wire Düsseldorf is at the heart of the wire and cable industry, China and India are two of the world’s biggest wire and cable hotspots and their event sizes reflect this. wire India, taking place from November 27-29, is the third-largest wire and cable show in the world. Meanwhile, wire China, occurring from September 25-28, is the second largest, following only Germany.

India’s 1.4 billion population grows at a rate of almost one per cent a year, and the biggest south-Asian economy has become a powerhouse in several sectors, from software and tech to automotive and machinery. All this is indicative of a growing and increasingly wealthy nation.

Though COVID-19 gave the Indian economy a big hit, progress is returning, partly thanks to public sector investment. GDP rose by 8.2 percent in 2023-24 and is predicted to fall by only one percent by 2025. Currently a $10 trillion economy, India is projected to grow to possibly a $25-35 trillion economy in the next 25 years. Even if the national economy doesn’t reach such heights, personal GDP is expected to increase significantly and even double, especially among India’s poorer social classes, as education expands and the demand for skills increases.

Wire and cable products are indispensable for investments in India’s growing infrastructure, including house, road, bridge, and canal construction, as well as in the oil, gas, water, and wastewater sectors. No modern industry can function effectively without the technologies provided by these industries.

The Chinese success story is well known, and, in some ways, it served as a model for India’s: a vast, resourcerich, and populous nation that did not effectively engage economically with the rest of the world for decades.

The turnround has been dramatic. China’s industrial revolution has, in the past 30 years, turned it into the world’s biggest industrial power after the USA. From a starting point mimicking or just plain plagiarising Western

machinery and cars, China now fights at the front of the field, its technologies equal those of the major tech and industrial nations: China’s BYD car brand sells more cars than Tesla, and the nation’s wealth is staggering: in 2022 the USA’s GDP was $21.5 trillion, while China’s was $25.6 trillion.

China remains the top cable consumer in several areas. The demand from Chinese construction is the world’s largest single cable end-user, accounting for almost 12 percent of total global demand, despite a significant slowdown in Chinese construction over the past couple of years.

The boom in renewable energy supply and EV cars has also driven significant consumption. Any slowdowns in demand in these areas have been offset by increased demand from government projects.

Like India, the influx of people moving into the cities in China creates a demand for more housing, more roads, and additional infrastructure– all of which demands large quantities of wire and cable, supplied predominantly by Chinese manufacturers.

These factors make wire India and wire China must-attend events for the world’s top wire and cable companies!

Save the Date! Join the Premiere IWMA Pavilion at wire Mexico 2025!

wire & Tube Mexico Monterrey, Mexico

11 – 13 Feb 2025

As the second staging of wire Mexico draws closer and following the success of our pavilions at wire Southeast Asia, as well as the superb response to our forthcoming IWMA wire India pavilion, we are thrilled to announce the launch of our very first pavilion at wire Mexico. We invite you to exhibit with us as part of our group at this prestigious event, scheduled to take place from 11th – 13th February 2025 at the CINTERMEX Centro Internacional de Negocios in Monterrey.

Engage with exhibitors from around the world, connect with attendees, and explore new products, as wire Mexico 2025 serves as the gathering point for the Latin American wire and cable and tube and pipe sectors.

We’re excited to introduce our pavilion at wire Mexico for the first time. This new opportunity offers our members unrivalled advantages, including a prime exhibition

location and extensive support from IWMA throughout all stages of the exhibition process. Exhibitors will benefit from our personalised hospitality services, Wi-Fi connectivity, and a guaranteed spot in the IWMA member seminars, providing a prestigious platform to showcase your expertise. Our dedicated stand builder will be available to assist you with all aspects of the build package, and flexible solutions will be offered to enhance your presence.

Don’t miss out on this opportunity to strengthen your exhibition impact and solidify your position at wire Mexico 2025. Contact us today to secure your space!

For further information on pricing, full details of our ‘IWMA premium stand and build package,’ to discuss your requirements, or to request an application form for our wire Mexico pavilion, please email Jessica at jessica@iwma.org.

Fermin Téllez

2024-25 Exhibition Dates

Following substantial interest and the success of our pavilions at wire Southeast Asia, we are thrilled to offer you the final opportunity to exhibit with us at wire India, scheduled to take place at the Bombay Convention & Exhibition Centre in Mumbai from 27th29th November 2024.

Participating in the IWMA Pavilion at wire India means enjoying the premium benefits of our exclusive stand & build package at our prime stand location. Our strategic support also aims to elevate your exhibition impact and solidify your industry position, promising a highly beneficial experience at wire India!

Here’s what makes our pavilion the place to be:

• Extensive support throughout the exhibition phases for a smooth experience

• Personalised hospitality services and Wi-Fi to keep you comfortable and connected

• Guaranteed spot in IWMA member seminars to showcase expertise

• Dedicated stand builder on hand to support with the build package for hassle-free setup

• Flexible solutions to customise your stand and enhance presence

Don’t miss out! For pricing details, specifics on the ‘IWMA premium stand and build package,’ to discuss your requirements, or to request an application form, please email Jessica at jessica@iwma.org today!

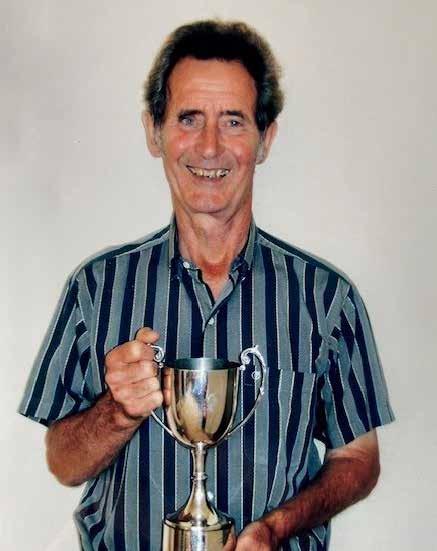

Man of Steel: Geoff Church’s

Impressive Seven Decade Career in the Industry

One of the highlights of this year’s wire Düsseldorf was an address by IWMA member and executive management committee member, Geoff Church, to an audience of aspiring young engineers. Geoff’s remarkable career has spanned seven decades and taken him from the factory floor to the position of Chief Engineer. His hands-on experience at every level has provided him with unparalleled insights into both the practical and strategic facets of the industry. For those of you who were not privileged to hear what he had to say, here is a summary of Geoff’s fascinating take on life and work, and how to balance them.

Geoff began his working life at the age of 16; for the first eight years, he left the house at 5.15 to cycle to work (a 16-mile round trip) and spent one day and two evenings a week studying to become a professional chartered engineer. Amazingly, he was also training to become a professional footballer with two first division clubs, or Premiership as we would call them now, until an accident at work put paid to this ambition. His mother consoled him by pointing out that this was the wiser path as there was more money to be made from engineering than from the beautiful game – how times have changed!

72 Years in the Iron, Steel, Wire and Rope Industry

Since he qualified, Geoff has worked in cogging mills, rod mills, strand plants, and roperies. He has acquired expertise in multiple fields including complex transportation, small capacity open hearth furnaces, electric and oxygen convertor furnaces, the casting of steel into ingots and billets, and the conversion of billets into rod, rod into wire, wire into strand, and strand

and wire into rope. Notably, he has made significant contributions to major structural projects such as the Dartford QEII bridge over the Thames and the Yangtse river crossing in China. For the last 20 years of his career, he held the position of Chief Engineer at Bridon, a global leader in high tensile wire and rope, managing expansion projects and operations all over the world. He has also been visiting the bi-annual wire Exhibition ever since it started in London, way back in 1967! His vast range of experience has convinced Geoff that while methods and technology have changed almost beyond recognition, the core principles of how to make progress in this, or any industry, have not. He outlined some of these for the wire education awardees, focusing on the importance of relationships, the best ways to navigate change, and the value of maintaining a healthy work-life balance.

A staunch advocate of networking, Geoff has forged countless relationships within the industry that have helped him to learn, grow, and advance professionally. In his early years of practical engineering training on the shop floor he gained huge respect for the knowledge and skill around him. He has maintained strong relationships with his colleagues ever since, consulting with them about working methods and finding their expertise invaluable. In another example, he exchanged business cards with a Technical Director from one of Bridon’s biggest competitors and kept in touch. Consequently, he was invited to see the inside of four of their factories over the years, and he and his wife stayed in the director’s home in Burgundy on several occasions. So, if you meet someone who interests you, Geoff’s advice is to ask for their business card and follow up; it is likely that both of you will reap the benefits.

When a career progresses well, instigating and managing change is likely to be a significant challenge along the way. Time and again, Geoff witnessed companies struggling because of ignoring the need for immediate action, underestimating the effort required, or moving too quickly without adequate preparation. He describes these failings as the ‘three deadly sins,’ and he offered his audience some powerful examples of the ways in which committing them could be disastrous on a tactical, strategic or ‘human’ front.

Geoff has seen more than 16 world-leading companies in Europe alone either going out of business or becoming a shadow of their former selves by committing the first of these ‘sins’. When challenged to improve their plant or machinery for instance, they have seen themselves as too busy and successful to spend time or effort on improvements, and in the long run, this has proved to be a fatal tactical decision. In terms of strategy, he used the example of a large company who acquired a small

business with an exciting future. Within two years, they discovered that the business had committed the third ‘sin’ of moving too fast without adequate preparation and accrued liabilities of over £20 million, resulting in the parent company being bought out. Geoff also amused his audience with some cautionary tales of human error, including one which involved a rainstorm, a stolen garden roller, and a police officer with very flat feet – you had to be there! But the same lessons ran through all of his examples; the three deadly sins must be rigorously avoided in order to achieve success in every area of your professional career.

Reflecting lastly on work-life balance, Geoff recounted an experience at a summer school at Keble College, Oxford. On his way to the Great Hall for dinner, he was given a note saying ‘You are tonight’s after dinner speaker and your subject is ‘Should Married Women Work?’ At the age of 20, Geoff was horrified, but somehow made a creditable effort. Afterwards, he was bought a congratulatory drink by the senior tutor, who quizzed him on his hobbies and interests and advised him that keeping a good work-life balance was vital. On his first ever business trip abroad therefore, Geoff resolved that as soon as he could, he would invite his wife to accompany him on every work trip if she wished to (at the time she herself was bringing up their three children at home). It was a decade before they could afford to make this a reality, but since then they have enjoyed trips to New Zealand, Canada, Mexico, Dubai and more – a pretty impressive work-life balancing act for both of them!

After a unique seven-decade career forged in steel, Geoff has not only made a huge contribution to the industry but has gained wisdom which is well worth imparting. His message for the future generation at wire Düsseldorf was clear: respect the experience of others; anticipate tactical, strategic, and human error when navigating change; avoid procrastination, indecision and arrogance and always be prepared; when you decide on a course, act promptly and with integrity; and of course, always balance ambition with life, and value your experiences and relationships.

2013: Geoff marks the Golf Club’s centenary with his late wife, Jean

2006: Geoff Celebrates his 70th birthday by winning the IWMA Golf Day Trophy

EU Imposes Tariffs on Chinese EVs

On June 12, the European Union (EU) announced plans to impose up to 38.1% tariffs on electric vehicles (EVs) imported from China. This decision follows an investigation revealing that Chinese EVs are heavily subsidized by their government, giving them an unfair competitive advantage in the European market. The tariffs, set to take effect on July 4, 2024, come on top of these vehicles’ existing 10% import duty, potentially raising costs significantly for Chinese manufacturers like BYD, Geely, and SAIC.

EU counters rising Chinese EV market share

Chinese car exports to the EU have surged in recent years, with their market share projected to reach 15% by 2025. In contrast, the EU aims to safeguard its automotive sector - which is also critical to its steel industry. The automotive industry accounts for about 17% of steel consumption in Europe. According to the Taiwan-based Yieh Corporation, “Although the auto industry accounts for only 5.5%–6.5% of China’s total domestic steel consumption, any drop in auto production critically affects (trading of) hot-rolled coils, cold-rolled coils, and hot-dip galvanized products.”

Talks aim to resolve trade dispute

In response to the EU’s announcement, both China and the EU have agreed to hold talks in an attempt to resolve the issue amicably. High-level discussions between EU Trade Commissioner Valdis Dombrovskis and his Chinese counterpart Wang Wentao have commenced, aiming to address concerns over subsidies and trade practices.

The outcome of these talks will be crucial in determining the future of EU-China trade relations in the automotive sector, with potential implications for global trade dynamics and the stability of the automotive supply chain.

EU tariffs and the broader trade landscape

The EU’s tariffs raise concerns about a potential domino effect. European automakers themselves argue that tariffs and restrictions harm free competition, the global flow of goods, and the free market. Underlying these concerns is the fear of Chinese retaliation, as China is a major market for European car manufacturers.

The EU’s announcement follows the US’s decision on May 14 to significantly increase tariffs on Chinese EVs, bringing them to 100%.

www.Expometals.net

Digital Dopamine: Why We Can’t Stop Reaching for Our Phone

Written by Sam Flynn

We spend an average of 4 hours and 12 minutes on our phone. That’s a quarter of our waking day!!! And time is something we all claim to be poor in. Yet, we still find ourselves reaching for our phone and struggling to find the willpower to put it down. Why is that?!

The Role of Dopamine

The main reason we pick up our phone is to chase the release of dopamine. Dopamine is the hormone released when we experience something pleasurable, and it is often linked to addiction as we keep chasing that dopamine high. There are so many aspects of phone use that lead to dopamine release:

1. Unboxing our first phone - simply the unboxing process, and the thrill of our new device, will have led to the release of dopamine.

2. Receiving lovely messages - messages of love or joy will lead to the release of dopamine and that pleasure-based feeling.

3. Social media engagement – a like on our social media post, or a favourable comment, will trigger a dopamine release.

4. Funny or joyful content – seeing something that leads us to feel joy will lead to a dopamine rush.

5. Adrenaline rush – watching scary content can lead to an adrenaline rush, which also triggers the release of dopamine.

This may all sound great. Surely, we want to experience pleasure and feel happy and joyful?

The problem is that the dopamine hit only lasts a short period of time before it dips. And so, we want more. We pick up our phone chasing that hit and the cycle continues.

Our brains quickly learn to associate the release of dopamine with our phone due to this reward sequence. And, over time, that dopamine hit can feel harder and harder to get through your phone, so you spend longer looking for that hit.

How To Overcome the Dopamine Cycle

Willpower alone is often not enough when it comes to reducing our phone use, as the need for dopamine can be very difficult to overcome.

Instead, you need to create friction between you and your phone use, making it harder to pick it up and easier to put it down. This friction causes a pause to move from an unconscious action to a conscious action.

Some examples include:

1. Keep your phone out of sight so you don’t automatically reach for it

2. Turn off your notifications so you are not triggered to pick up your phone

3. Turn on screen time limits to stop access to certain apps at certain times

4. Add an elastic around your phone that you need to physically remove to be able to scroll on your phone

5. Keep your hands busy to make it harder to pick up your phone, such as doing a craft or doodling

6. Do something that will help release dopamine, such as dancing to your favourite song, to fulfil that dopamine demand!

So, next time you reach for your phone, remind yourself it is your brain chasing that dopamine hit. What action could you take to help you pick up your phone less?

Sam Flynn is a digital culture and wellbeing trainer, coach, and speaker. She works with organisations to improve digital culture, performance, productivity, and wellbeing. You can find out more about Sam and her workshops at

www.samflynn.co.uk

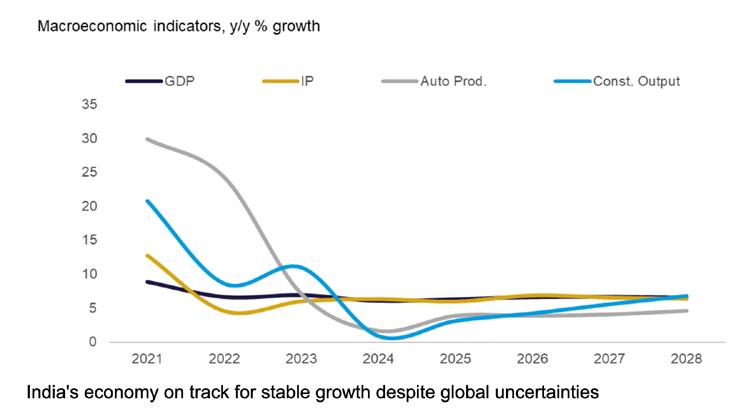

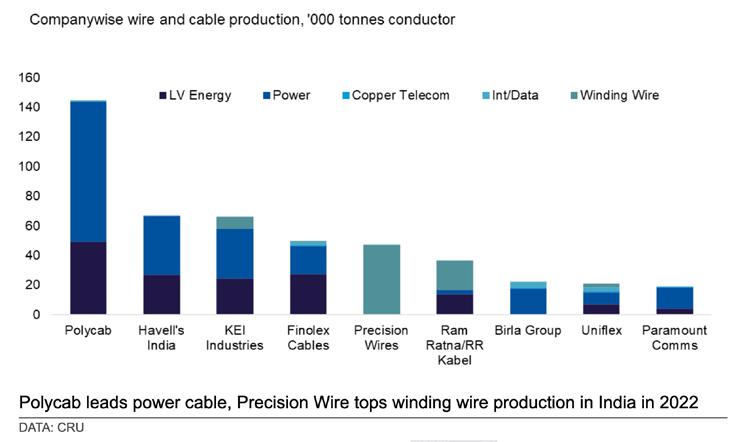

CRU Group: State Policies and Clean Energy Boost India’s Cable Market

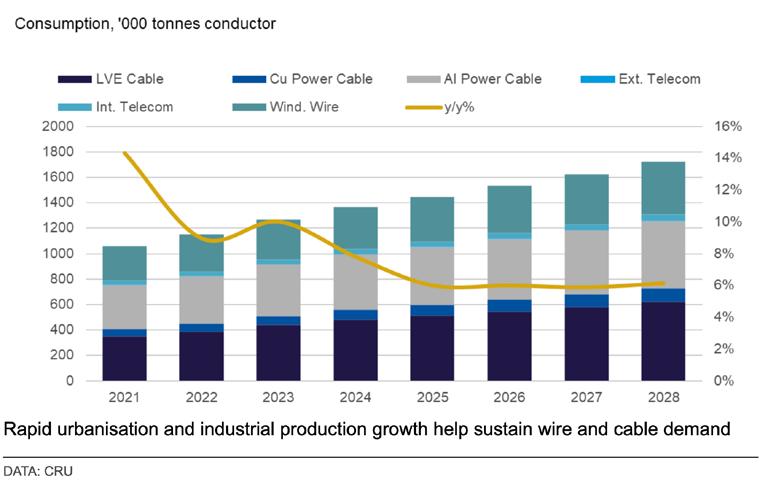

India, the third largest cable market globally, consumed a total of 1,266 kt of insulated metallic wire and cable in 2023, comprising almost 6% of world consumption, only behind China (42%) and the US (9%). India’s insulated metallic wire and cable demand is expected to grow 7.8% y/y in 2024 and is expected to exhibit healthy growth of 6.4% CAGR between 2023–2028.

Despite a global economic slowdown, India’s economy remains vigorous. Following a 7% GDP growth in 2023, it is expected to maintain a strong 6.1% growth in 2024, slightly tempered by election disruptions. This growth is driven by robust domestic demand and a thriving manufacturing sector.

In 2023, India’s construction output grew 11% y/y, attributed to the government’s persistent focus on infrastructure development coupled with the ongoing housing market boom. This growth is supported by increasing household incomes, a pronounced housing shortage in major urban centres, and robust population expansion. India now is the world’s most populous nation and as such, the construction sector is the primary consumer of cables, comprising 32% of the country’s total cable demand.

Vishnu Patidar Senior Analyst

Low Voltage Energy (LVE) cables command the largest market share, accounting for 34.7% of total cable demand. Rapid urbanisation has escalated the demand and investment in residential and commercial infrastructure, which primarily requires LVE cables. India’s Finance Ministry has allocated over $9.5 bn to the ‘Pradhan Mantri Awas Yojana’ (PMAY) scheme, reflecting the government’s commitment to infrastructure and housing. This has boosted demand for LVE cables, which is expected to remain strong in 2024. The construction sector is set to maintain growth above 10% y/y, and LVE cable consumption is projected to increase by 9.5% y/y.

The industrial segment is the second largest contributor of India’s wire and cable demand, accounting for 30% of the market. In 2023, India’s industrial production grew 7% y/y, with the manufacturing sector expected to sustain strong momentum in 2024, achieving over 6% y/y growth. This sector predominantly utilises winding wires for various applications such as motors, transformers, switchgears, domestic appliances, and fast-moving electrical goods. Winding wire consumption in India reached 312 kt conductors in 2023 and is forecasted to grow by nearly 6% y/y in 2024.

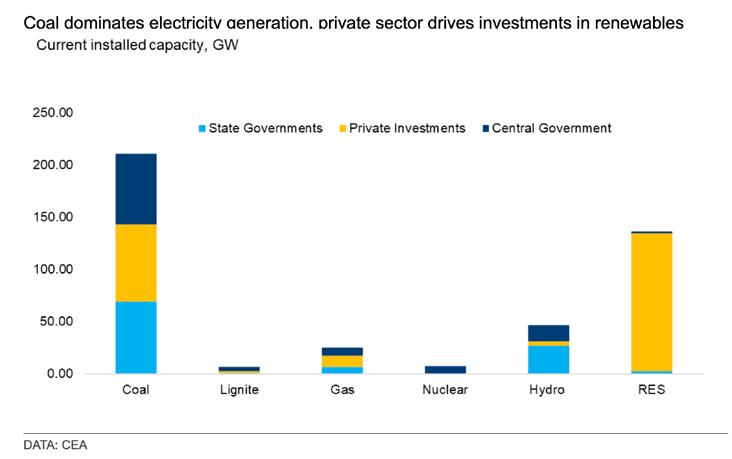

Modernised infrastructure elevates power cable need

India is the third largest producer and consumer of electricity globally after China and the US. According to CRU’s Power Transmission Service, the nation’s installed power generation capacity of 517 GW in 2023, projected to rise to 781 GW by 2028, necessitating a robust power transmission and distribution infrastructure. However, the per capita annual electricity consumption in India stands at around 1,327 kWh, well below the global average of per capita annual electricity consumption, which is estimated to be around 3,700 kWh.

India’s manufacturing and services sectors are the two largest consumers of electricity. Despite being the world’s most populous country, the residential sector is the third largest consumer of electricity, with most of the consumption largely concentrated in major urban centres, Tier 2 and 3 cities as well as surrounding areas; rural areas lag due to infrastructure limitations.

In order to deal with this issue, the country is making strides in strengthening its transmission and distribution infrastructure to cater to this need. Under the ambitious PM Gati Shakti National Master Plan, India’s National Grid capacity is set to experience substantial growth, with an anticipated addition of about 28,700 circuit km capacity by the fiscal year 2024-2025.

The power utility sector in India accounts for nearly 30% of the total consumption of wires and cables in the country. In the year 2023, the consumption of copper power cables in India was recorded at 70.8kt conductors, while aluminium power cables accounted for 404.5kt conductors. The Indian market, characterised by its price sensitivity, has traditionally favoured aluminium power cables due to their costeffectiveness when compared to copper power cables.

The transition towards modernising India’s electricity transmission and distribution infrastructure is being propelled by government-led initiatives like the Revamped Distribution Sector Scheme (RDSS). This is launched to aid DISCOMs in enhancing their operational efficiencies and financial sustainability, by providing result-linked financial assistance to bolster their supply infrastructure, contingent upon meeting pre-qualifying criteria and achieving basic minimum benchmarks. This scheme represents a significant investment of $35.8 billion, inclusive of budgetary support nearing $12 billion.

In addition to the RDSS, other significant initiatives such as the Integrated Power Development Scheme (IPDS) and the National Smart Grid Mission (NSGM) are playing a pivotal role in the overhaul and modernisation of India’s electricity transmission and distribution infrastructure. By harnessing advanced technologies and intelligent grid solutions, they aim to bolster grid reliability, optimise energy utilisation, and integrate renewable energy sources. This progress is, in turn, fuelling the demand for power cables within the country.

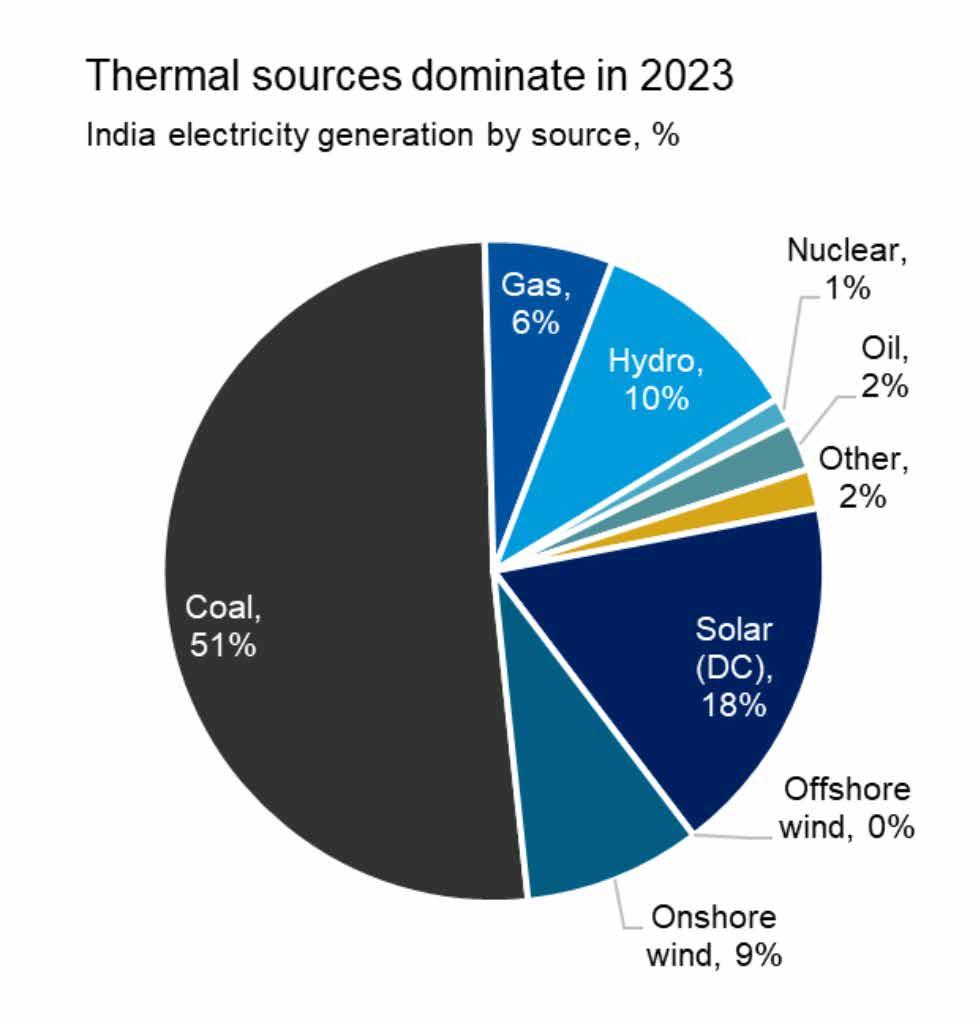

Green energy pledges fuel action and investments

India, being the world’s third largest contributor to greenhouse gas emissions, accounts for 7% of the global total on an annual basis. Despite its substantial dependence on coal, the nation has pledged to attain “net-zero” emissions by 2070. This commitment is accompanied by ambitious objectives to augment renewable energy capacity, fulfil half of its energy requirements from renewable sources, and curtail greenhouse gas emissions by one billion tonnes by 2030.

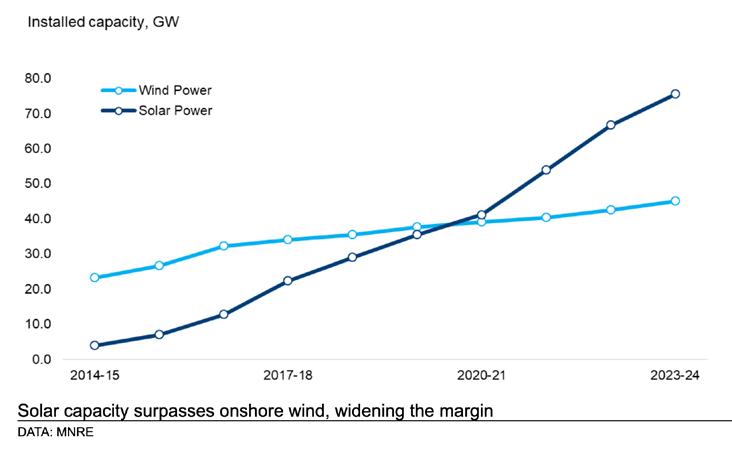

Central to India’s renewable energy ambitions is the objective of producing 500 GW of energy from renewable sources by 2030, an endeavour projected to necessitate investments exceeding $30 billion. This initiative signifies a transformative shift in the country’s energy paradigm, with solar energy poised to play a pivotal role. By capitalising on the plentiful solar resources, India aims to diversify its energy portfolio and diminish its dependence on traditional energy sources.

India’s renewable energy goal of 500 GW by 2030 comprises 280 GW from solar and 140 GW from wind power. With an earmarked fund of nearly $1.8 billion for key capital investments to reach net-zero emissions and secure energy, India is poised to exploit renewable energy potential, thus boosting demand for essential components such as wires and cables.

The government’s plan to install 140 GW of wind energy by 2030 requires substantial sector investment, increasing demand for specialised cables. India’s current wind energy capacity is 45.8 GW, all from onshore projects. The aim is to add over 30 GW from offshore projects by 2030, with the ‘First Offshore Wind Project of India’ (FOWPI) being the only one in the pipeline, at 200 MW. To stimulate offshore wind power development, the recent interim budget announced viability gap funding for an initial 1 GW capacity, and a bidding process for a 4 GW offshore project off Tamil Nadu’s coast has been initiated.

Solar energy’s dominance in India’s renewable sector is driving demand for solar E-beam cables. These cables, made with electron beam cross-linking technology, feature metal wire conductors, rodent resistance, and UV-stabilised PVC sheathing. They provide superior insulation, vital for high-temperature short circuits.

The shift from thermal to renewable energy transforms the future power dynamics

CRU Power Transition Service

India’s renewable energy capacity stands at 143.6 GW, reaching nearly 190 GW with large hydropower plants. To meet the 500 GW target, an additional 310 GW is needed within six years. To address this, the Ministry of New and Renewable Energy (MNRE) in April 2023 announced plans to bid for 50 GW annually until 2028.

In a parallel effort, the Indian government is encouraging rooftop solar adoption to meet renewable targets. The ‘PM Surya Ghar Muft Bijli Yojana’ scheme, with a $9 billion investment, aims to equip 10 million homes with subsidised rooftop solar panels. Households can sell excess electricity back to the grid, receiving 300 KWh of free power monthly. India’s current grid-connected solar rooftop capacity is 11.8 GW, with a goal of 40 GW by 2026, reinforcing its commitment to sustainability.

EV ecosystem to boost future wire and cable demand

India’s EV push has opened up opportunities across sectors like mobility, energy storage, and charging infrastructure. This includes EV franchising, OEM market, battery infrastructure, solar charging stations, and battery swapping technology. As EVs require electricity for charging, the need for wires and cables at charging stations is crucial. The shift towards EVs in the automotive sector is increasing the demand for charging stations and electrical components, leading to a surge in demand in the wire and cable industry.

India aims to electrify 30% of its vehicles by 2030. This is supported by policies like the FAME scheme for EV adoption, the PLI scheme for domestic manufacturing, and the Battery Swapping Policy for charging infrastructure. Stricter emission rules and ICE vehicle restrictions also promote this shift. India’s EV market, currently at 4.5% of LDV sales, is expected to grow by 82% from 2023 to 2028. Two and three-wheeler segments are adopting faster, especially in smaller cities. The FAME-II scheme, with a $1.2 billion budget, aims to support the adoption of 7,000 e-buses, 55,000 e-passenger vehicles, 0.5 million e-three wheelers and 1 million two wheelers nationwide.

India is committed to strengthening the EV ecosystem through manufacturing and charging infrastructure support. It encourages e-bus adoption for public transport. Major EV players include TATA, Mahindra, JBM, MG, KIA, Hyundai, BMW, Ashok Leyland, Volvo and soon Tesla. With rising EV sales, India may need 2.1 million charging stations by 2030.

The growth of India’s EV market will significantly impact the wire and cable industry due to the need for specialised cables as EVs necessitate a higher amount of specialised cables and wiring for power transmission, battery management, and other electronic systems compared to conventional Internal Combustion Engines (ICE).

Post-Covid surge: car production achieves stability with sustained growth outlook

Rail and datacentre growth to boost cable demand

India’s fourth-largest global railway network is modernising under the 2020 National Rail Plan, with aim to increase freight transport share from 30% to 45% by 2030 through infrastructure and technology investments. Currently, 95% of Indian railways are electrified, with a $778 million budget for further projects, aligning with zero carbon emissions by 2030.

The country is advancing its urban transportation systems, with 60 phases in 28 cities and plans for metro systems in 75 cities by 2027, as outlined in the ‘Gati Shakti Master Plan’ requiring $35.5 billion.

India’s digital transformation and the rise in data consumption necessitates more datacentres, supported by a $1.7 billion government incentive and $35.9 billion investment over five years. This will significantly increase the demand for telecommunication and power cables.

Unorganised industry trumps major brands

Major players like Polycab, Havells India, KEI Industries, and Finolex Cables collectively hold 28% of India’s fragmented wire and cable market. Unorganised players still hold over 50% market share. As of 2022, the market is valued at $9.6 billion.

To find out more about the financial performance of the main publicly listed producers, their strategies, expansion plans, mergers and acquisition activity, please read “Indian cable producers raise FY 2023 sales on lucrative exports”. Readers will require a subscription to the Premium Package, which includes Wire and Cable News.

Effective Success for Gürfil at wire Düsseldorf

This success we have demonstrated at the fair is an indicator of how much importance we attach to the sector.

How was wire Düsseldorf fair this year?

We think that this fair, which we have been participating in for a long time, is very important for the sector. Meeting potential customers from all over the world is priceless. This contact has always taken things to a different dimension. In general, it was a fair that met our expectations.

What were your featured products?

This year, as in previous years, our fair team made a magnificent effort to provide visitors with an extraordinary stand experience. Especially our transparent machine experience and product diversity enabled us to be one of the most effective stands of the fair. Particularly the interest of European companies in our machines was extraordinary. In addition, our products in the foil, film and tape category attracted high interest as usual.

What are the factors and results of your success at the fair?

First of all, there is also a before the fair. So much so that we are talking about approximately 50 years of experience. In addition, Gürfil’s interest in continuous improvement and innovation ensures that it is always a leading manufacturer in the sector. Strategies such as product diversity, quality, operational capacity increase, machinery investments, efforts to comply with regulations and new standards, and developments in human resources are the main factors in establishing our successful line at the fair and in the sector. All of these make Gürfil a reliable and leading company in its sector.

What awaits Gürfil from now on?

First of all, I would like to state that we took action as quickly as possible to meet the demands of the companies we contacted at the fair. In addition, as a result of the interest and demand in our company, we will continue totake steps in quality and sustainability, which is already one of Gürfil’s most important principles.

Adopting these principles, which Gürfil management stands behind and its employees internalize, with the firmest steps offers us absolute success.

I would like to take this opportunity to thank all the companies that participated in the fair and showed interest in our stand. I hope our collaborations will continue to grow in the most efficient and healthy way.

These products are:

Foil, Film and Tape Group

ALU/PET, ALU/PET/ALU, ALU/PET/SY, ALU/COPOLY

Laminates

CU/PET, CU/PET/SY Laminates

POLYESTER FILM

PET/ PE, PE/PET/PE laminates

Mica tape (phlogopite, alcined muscovite and synthetic)

SILICONE BACKED (Inorganic Layer coated) Phlogopite

MICA TAPE

PP Identification tape

Polyester non-woven tape

Aluminium foil & Copper foil

Fiberglass tape

PP foam tape

Kraft paper

Crepe paper

Semi-conductive tape

Swelling tape

Yarns

Fiberglass yarn

Ripcord yarn

Waterblocking yarn

Wire Group

Aluminium Alloy Wire (0.12 mm, 0.16 mm)

CCA and CCS

Skin-Foam-Skin 3 Layer Physical Foamed Conductors

Machinery Group

At the moment we offer the following machines together with commissioning, after sales service and all the spare parts from our warehouse with professional service personnel 7 days a week, 24 hours a day.

• High Speed Vertical Braiding Machines (16 and 24 carrier)

• High Speed Vertical HEAVY Braiding Machine (16 and 24 carrier)

• High Speed Horizontal Braiding Machine (24, 32, 36 and 48 carrier)

• High Speed Mica Taping Machine (1,2,3 carrier, Pad and Spool head options)

• Wire rewinding line (semi and fully automatic)

• Pay-Off and Take-Up

• Spare parts for all equipment

• Air Wipe Units, ABS Spools

We are not going to stop at what has already been accomplished and we will do our best to ensure that the range and quality of products manufactured by GURFIL coincides with the requirements of the modern market and is available to customers anywhere in our country and abroad.We are sure that Gurfil will be a reliable partner for you.

www.gurfil.com

Ajex & Turner wire Technologies Pvt. Ltd.

As wire Düsseldorf 2024 concludes, we deeply appreciate your pivotal role in its success. Your presence and engagement have transformed it into a dynamic hub of innovation and collaboration in the wire and cable industry.

AJEX proudly unveiled cutting-edge innovations like the Contact Tube, Buncher Bows, Nano, and Pressure Dies, showcasing our commitment to precision and progress. These advancements enable seamless performance in demanding environments.

wire Düsseldorf is more than just a showcase; it’s a vital platform for industry leaders to exchange ideas and shape the future together. We eagerly anticipate seeing you at WIRE DUSSELDORF 2026 as we journey towards excellence and prosperity together.

www.ajexturner.com

Alloy Wire: Wired for Growth A Hat Trick for Metalube

as the company is presented with the King’s Award for Enterprise

Manchester based lubricant leader Metalube was today thrilled to welcome The Lord-Lieutenant of Greater Manchester, Mrs Diane Hawkins JP LLB to its Irlam headquarters in Manchester. The company was formally presented with The King’s Award for Enterprise: International Trade 2023. This is Metalube’s third award of this type, and it is one of only three businesses in the Northwest to have received such an accolade.

The 2023 King’s Award recognises steady growth in international exports. The company has been recognised for outstanding continuous growth in overseas sales over the past five years and and has triumphed over stiff competition. Commenting on this success, Managing Director, Robert Brown says: “Today was a very proud day for the company and we were thrilled to welcome The Lord-Lieutenant of Greater Manchester to our factory.

She did a fabulous job of making it a memorable occasion and helped to hand out Easter Eggs to all our staff. I am privileged to work alongside such talented and dedicated colleagues, who have all helped to achieve these fantastic results. It is very gratifying to have our hard work and commitment recognised.”

The Metalube Group is a group of industrial lubricants brands – Metalube, Molyslip and Vapor-Tek. The company exports 95% of its production to over 100 countries worldwide and has offices in Manchester, Dubai, Mumbai, São Paulo and Shanghai. Its UK headquarters are in Irlam, Manchester, where the company has a fully integrated lubricant manufacturing facility, including state-of-the-art science laboratories.

www.metalube.co.uk

Paul Chatterley, Sales Executive of Alloy Wire International (AWI), takes a look back at a week in Germany and why wire Düsseldorf never disappoints.

There’s nothing quite like wire Düsseldorf. Over 1300 exhibitors crammed across 15 halls, showcasing the latest advancements and technology to nearly 40,000 visitors from across the world.

After a myriad of global challenges, it was refreshing to see a show brimming with optimism and renewed confidence for the year ahead.

Our Alloy Wire International (AWI) stand – the largest we’ve taken at the event – hosted hundreds of visitors during the exhibition and that included a mix of longstanding customers and visitors keen to discover our capabilities and our 60-strong range of Exotic Alloys.

Discussions were wide and varied and there were some exciting enquiries taken for potential projects in aerospace, automotive, nuclear and oil and gas.

Inconel grades were top of the wish list and that came as no surprise to our 10-strong team in Germany. It’s a versatile material family that serves many industries and end-use applications.

Central Meeting Point

wire 2024 has again proved a very useful means of catching-up with our international clients.

AWI representatives from Israel, the UAE, Singapore, and the US joined us during the five days, whilst our German and Italian representatives helped organise many meetings with European customers that we don’t usually get to meet face to face as often as we would like.

Just to give you an idea, we probably saved about 15 days of international travel by meeting everyone in one central place.

Another key AWI objective for wire 2024 was getting our production team out and about across the halls, exploring the latest technology that can help us offer even quicker lead times and increased operational efficiencies.

This proved a very useful exercise, especially around new inline cleaning machinery we can potentially install in the UK.

Looking back

We are very proud of our rich history, with AWI manufacturing material for more than 78 years.

In addition to the latest samples of round wire, flat wire and profiles, we also decided to use our stand at wire 2024 to showcase some memorabilia dating back to the 1940s.

This included some old production tools, imagery of traditional machinery and our original factory in the Black Country, alongside a selection of original wire drawing measuring tools and workbooks.

Our international customers love conversations about our history and how far the company has come with the technology we now use today.

Whilst the machinery and equipment may have changed, the philosophy we started Alloy Wire International on in 1946 still applies in 2024…’manufacturing quality, delivering reliability’.

www.alloywire.com

(L-R) Stephen Olley, Oliver Smith, Mark Venables, Lee Knight, Mattew Cobb (at back)

Unveils New Branding: A Symbol of Commitment to Innovation and Excellence

Mikrotek, a ground breaker in the technology sector, proudly announces the launch of its new logo, marking a significant milestone in its journey of innovation and excellence.

Renowned for pioneering manufacturing techniques and delivering cutting-edge solutions, Mikrotek has consistently set industry standards. The new logo reflects Mikrotek’s commitment to evolution and adaptation in an everchanging technological landscape. With its sleek design and modern aesthetic, the logo embodies the company’s forward-thinking approach and dedication to staying at the forefront of industry trends.

“We are excited to unveil our new logo, symbolizing our continued commitment to innovation and excellence,” said Kamal Babu, Managing Director at Mikrotek.

“As we embark on this new chapter, we remain dedicated to delivering superior products and solutions that meet the evolving needs of our customers”.

The logo signifies Mikrotek’s confidence in its future and its unwavering dedication to pushing boundaries and driving progress in the diamond die business. Stay tuned as Mikrotek continues to lead the way with innovative solutions and unparalleled expertise!

www.mikrotek.org

Rosendahl Nextrom: wire 2024 Exceeds all Expectations!

The leading industry trade show once again attracted an impressive audience from all over the world. The diverse product range showcased at the Rosendahl Nextrom booth generated significant interest among cable manufacturers.

This year Rosendahl Nextrom put a focus on balancing quality, productivity and sustainability in production. This theme resonated with many visitors. Interactive and creatively staged exhibits engaged visitors and sparked discussions. The company was overwhelmed by the positive response and engagement from the audience.

Hairpin insulation with PEEK drew attention

Rosendahl’s 1st industry-ready extrusion line for hairpin insulation attracted numerous interested parties seeking to learn more about this pioneering technology. Compared to the enamel process, extrusion offers many advantages for the process, for product quality and the environment.

Power cables: sustainable solutions on the rise

The industry increasingly favors solutions that emphasize sustainability and energy efficiency. Streamlining the medium-voltage insulation process is what many cable producers are looking for. Rosendahl Nextrom noted a growing interest in its MV insulation solution featuring polypropylene.

The company’s versatile metal shielding solution for high-voltage cables also gained considerable attention. Expanding the renewable energy infrastructure and meeting climate goals is a priority in many countries around the globe. Having a provider who can serve all key processes, including the corresponding know-how, is a clear benefit for manufacturers.

Artificial Intelligence delivers real-world results There is always room for improvement. Machine learning, AI, and intelligent solutions are included in our RIO line control and are here to help with daily production challenges. Visitors explored the capabilities of Rosendahl’s RIO line control through interactive modules. Notable highlights included the integration of Artificial Intelligence into process control, the new maintenance management system and the ESG CO2 footprint module.

“Overall, we are very happy with the show’s outcome and the industry’s response to our manufacturing solutions”, says marketing manager Bianca Kranz.

www.rosendahlnextrom.com

Cold Weld Specialist PWM

Celebrates 40 yrs of Service

British company PWM, which manufactures and supplies high-performance cold pressure welding machines and dies, celebrates 40 years of service to the global wire and cable industry in 2024.

The company’s original 1984 portfolio featured a handheld cold welder for fine wire, a larger machine for medium wire and a pneumatically-powered rod welder. Today, PWM produces a comprehensive range of manual and powered machines for a variety of applications. Cold welding dies are individually hand-made in matched sets, in standard or custom sizes to suit round or profile wire. As a specialist manufacturer, PWM designs and builds its cold welding equipment in-house to stringent quality standards.

“We are proud to celebrate this milestone in the company’s history and I would like to thank the PWM team and our customers for their support,” said Steve Mepsted, managing director of PWM.

“Working closely with customers to improve productivity, save resources and reduce costs has been a priority for the

last four decades. We will continue to develop and deliver innovative cold welding solutions as the industry evolves.”

On-going research and development enables PWM to keep pace with manufacturers’ changing needs. To save effort and reduce downtime, the company introduced mobile air/hydraulic cold welders in the 1980s and 90s. User-friendly and energy-efficient, these machines are designed to be moved easily to the work area, saving effort and reducing downtime. The 1990s saw a requirement for more powerful machines to weld large diameter rod. PWM’s P1500, for non-ferrous material up to 30mm, was the first hydraulically powered, electronically controlled, heavy-duty rod welder on the market. More recently, PWM developed the CP180, an innovative machine housed in a carry pack, and the ST40, an air/hydraulic welder for strip.

A new cold welding machine, designed specifically for trapezoidal wire used in the build-up of sub-sea cable, will be launched at wire 2024, stand 9B41.

www.coldpressurewelding.com

Inspiring Young Minds: Pakistan Cables Children’s Art Contest 2024

3rd Pakistan Cables Children’s Art Contest 2024 showcases creative ideas for Pakistan Climate Action Plan 2025

The 3rd Pakistan Cables Children’s Art 2024 was organized by Pakistan Cables recently. The contest invited entries from the Company employees’ children from two age groups between 6–11 years and 12–14 years old. This year the theme, Pakistan Climate Action Plan 2025, was selected to highlight the climate change issues and the priorities to combat the impact of climate change.

Contestants attended a colorful prize distribution ceremony held at the TDF Magnifiscience Centre, Karachi. The Chief Guest at the ceremony, Mr. Faraz Maqsood Hamidi, a well known creative leader of Pakistan’s advertising industry, encouraged children to challenge the norms and never give up their creative pursuits. An esteemed panel of judges included renowned visual artist, Ms. Durriya Kazi, Ms. Bina Ali (Founder ARTEL) and

Mr. Naveed Shaikh, Project Manager, Sindh SDGs Unit, UNDP. This year the contest received 87 entries from six cities across Pakistan.

Speaking on the occasion, Ms. Bina Ali encouraged the children to continue using art as a form of expression and authenticity. Mr. Naveed Shaikh also appreciated the participants who have expressed their vision on a difficult yet essential topic. An engaging story telling session was conducted by the CEO of GOREAD, Ms. Nusser Saeed, which was enjoyed by everyone in the auditorium. The event was widely attended by participants, parents, esteemed judges and senior management of the Company. Winners were awarded special prizes and certificates while contestants also received certificates, story books from Goread.pk and gift vouchers.

Pakistan Cables is an advocate of environmental conservation and through the art contest it engages its employees and their families to support the cause.

www.pakistancables.com

Protecting what Connects

SCGC’s Polyethylene Keeps Cables Safe and Reliable

In our increasingly interconnected world, cables are the hidden heroes, silently transmitting reliably. This is where polyethylene (PE) comes in and SCGC is a leading supplier of high-performance PE jacketing solutions for a wide range of wire and cable applications.

Polyethylene: A Versatile Choice for Cable Jacketing Polyethylene (PE) is a type of plastic known for its exceptional balance of properties that make it ideal for cable jackets;

• Durability: PE is known for its excellent mechanical strength, offering superior toughness. This protects cables from physical damage during installation, use, and harsh environments.

• Environmental Resistance: PE compounds, especially black formulations, offer excellent resistance to UV radiation, moisture, and chemicals. This ensures cables perform well when exposed to sunlight, rain, and other harsh elements.

• Flexibility: a range of PE grades balance flexibility with strength, allowing for easy cable installation without compromising protection.

• Cost-Effective: PE is a readily available and relatively inexpensive material, making it a practical choice for various cable applications.

• Recyclable: PE and other thermoplastic jacketing materials can be recycled, contributing to a more sustainable cable manufacturing process.

SCGC leverages different PE grades, including Linear LowDensity Polyethylene (LLDPE), Medium-Density Polyethylene (MDPE), and High-Density Polyethylene (HDPE), to deliver cable jacketing solutions to specific needs.

• LLDPE (SCGCTM LLDPE L546WC): LLDPE is known for its flexibility and impact resistance, it is ideal for applications requiring bendability and

protection against physical impact. This makes it suitable for low-voltage power cables, data transmission cables, and telecommunication lines.

• MDPE (SCGCTM MDPE M545WC):

Offering a balance between LLDPE’s flexibility and HDPE’s rigidity, MDPE provides good mechanical strength and excellent environmental stress crack resistance (ESCR).This makes it a good choice for power distribution cables, automotive wiring, and applications requiring a balance of properties.

• HDPE (SCGCTM HDPE H624WC):

Offering superior strength and rigidity, HDPE excels in applications demanding high abrasion resistance and puncture protection. It’s a popular choice for underground power cables, building wires, and outdoor applications where cables might face harsh environmental conditions.

SCGC’s Commitment to Quality and Innovation SCGC understands that cable jacketing materials need to perform consistently and reliably. That’s why they focus on:

• Rigorous Quality Control: SCGC adheres to strict quality standards throughout the production process, ensuring consistent material properties and reliable performance in the final cable product.

• Technical Expertise: SCGC’s team of engineers provides technical support to cable manufacturers, ensuring optimal selection and application of PE jacketing materials.

Using SCGC’s PE solutions, cable manufacturers can create reliable and long-lasting products that meet the demands of diverse applications. This ensures the cables we depend on every day are well-protected, keeping our homes, businesses, and communities connected.

www.scgchemicals.com

Arcole Invests in Setic Pourtier

to accelerate its growth and sustainable development

Arcole, a French private equity fund, in partnership with longstanding shareholder and CEO Thierry Collard, is excited to announce a new phase of growth of Setic, a global leader in designing and manufacturing machinery for the wire and cable industry based in Roanne and Paris, France. This strategic investment aims at accelerating Setic’s development and enables a drastic deleveraging. The company is thus in a very good position to capitalize on the favorable market trends anticipated in the coming years.

Setic will fully embrace its role as a French industrial leader at the service of energy transition. The first steps on this path include enhancing the sales structure of the U.S. subsidiary, upgrading facilities in Roanne with new R&D capabilities, and rebranding the group as “Setic Pourtier” on the occasion of its 75th anniversary, combining the legacy of both historical brands.

Thierry Collard, CEO and strategic shareholder of Setic Pourtier, expressed his satisfaction: “I am delighted to have secured the redeployment of Setic Pourtier, keeping ownership in French hands and ensuring a promising future for our team while consolidating our growth trajectory that has taken us from a period of crisis to outstanding financial performance in just two years.”

Delphine Inesta, Managing Partner at Arcole, shared her enthusiasm: “We are thrilled about this investment, that gives Arcole the opportunity to support an industrial company with a French footprint and a global reach, based on a centurylong legacy of technical excellence and innovation.”

Renaud Sueur, also a Managing Partner at Arcole, commented, “We have discovered a vibrant group rich in expertise and skills, active in a fast-growing market, with very exciting challenges ahead. I am very happy to partner with Thierry Collard, the CEO of Setic Pourtier, whose experience and knowledge of the market have been decisive in our will to invest in the Group.”

Advisors:

Arcole: Financial: Titanium Partners (Thomas Blard), Eight Advisory (Shafik Hosni, Arthur Romelli); Legal: Depoix-Robain (Nicolas Depoix-Robain, Amandine Grima, Lorraine Monteilhet).

https://arcole.com

Setic Pourtier: Financial: MPRD & Partners (Marco Pezzetta); Legal: Racine (Antoine Diesbecq, Julie Molinie).

www.setic-pourtier.com

Sikora Awarded as World Market Leader Champion 2024

The Bremen-based SIKORA AG is again among the 450 secret world market leaders of the Germanspeaking economic area in 2024. This is the result of the University of St. Gallen in cooperation with the magazine WirtschaftsWoche and the Academy of German Business Leaders.

Since 2016, SIKORA has been listed six times in the ranking of the world market leader champions,which is published annually by the WirtschaftsWoche. For this purpose, 450 companies are selected as world market leader by the University of St. Gallen and the Academy of German Business Leaders according to a strict procedure. The winners are number one or two in at least one relevant market segment and have annual sales of at least 50 million euros, at least 50 percent of which is generated abroad on at least three continents. Only official figures are included in the evaluation, such as published annual financial statements from the Federal Gazette or the latest annual financial statements of listed companies. In the current survey, SIKORA was one of three companies from Bremen, Northern Germany, to receive the award.

New Welding Machine from T Fukase & Co Ltd

T. Fukase & Co., Ltd., in partnership with its parent company, Hakusan Co., Ltd., will introduce a new welding machine for copper rods. As manufacturers of wire rod welding machines, they are set to unveil their latest model, which utilises heat pressure welding methods. These methods, known for their proven welding performance and durability, have been employed in Japan and internationally for over 50 years.

“Since our company was founded over 50 years ago, SIKORA has been known for future-oriented technologies,” says Dr. Christian Frank, CEO at SIKORA. “We are delighted about the repeated award as World Market Leader Champion. This is an absolute team effort. Our aim is to offer innovative solutions for our customers. This includes further developments of existing products as well as new technologies that meet the diverse requirements of our customers.”

Every year, SIKORA invests more than 10% of its revenue in the research and development of new measuring and control technology as well as inspection, analysis and sorting systems for quality assurance during the production of wires and cables, tubes, hoses, pipes and sheets, optical fibers or plastics. With around 400 employees in Bremen, Germany, and its 13 operating international subsidiaries, the company offers innovative solutions and customized customer service.