You manufacture cable screenings or braids from copper, aluminum, stainless steel or artificial yarns and fibers for diverse applications. High productivity, economical use of materials and faultless products are what you require from your equipment. Your braiders must run reliably, at top production speed and unattended for extended periods. Space requirements must be low and all braiding products you manufacture must be of perfect quality.

What we offer: the latest model of our BMV rotary lever arm braiding machine series. The BMV 16 type including three patented innovations – for your success.

How you benefit: You will increase your braiding output by 10% and, simultaneously, reduce your braiding material consumption by 15% or even more. With the help of the integrated NIEHOFF WTC system you control your braiding process and document the uniform braiding wire tension.

What will convince you: the ideas behind the details. Let´s talk about them.

Expertise, Customer Driven, Service – in Good Hands with NIEHOFF

Maschinenfabrik NIEHOFF GmbH & Co. KG

Walter-Niehoff-Strasse 2, 91126 Schwabach, Germany

Phone +49 9122 977-0

info@niehoff.de

As we gear up for wire India 2024, I am excited to extend a warm welcome to all our members, exhibitors, and attendees. This year’s event promises to be one of the most important gatherings for our industry, not only in India but on the global stage. With the remarkable growth of the wire and cable sector in India, it’s no surprise that this exhibition is set to be the largest ever, drawing attention from industry leaders across the world.

At the heart of this year’s exhibition is the IWMA Pavilion, a significant milestone for us, as it marks the first time that we have brought this initiative to India. We are proud to present five of our member companies— Rautomead, Proton Products, RichardsApex, Aversion Technologies, and Fisk Alloy—who will be showcasing their innovative products and services at the pavilion. This collective presence will highlight cutting-edge developments in manufacturing, technology, and materials, and it’s an excellent opportunity for these companies to connect with key players from across the industry. You will find more information about our pavilion and the members exhibiting with us on pages 10 & 11.

in sectors like telecommunications, energy, and automotive, where India is emerging as a major player. The transition to renewable energy, the widespread adoption of 5G technology, and the rapid growth of the electric vehicle (EV) market all present significant opportunities for our industry, and wire India 2024 is the ideal space to explore them.

Our networking event, ‘Colours of the World’, is set to be a highlight of the exhibition, bringing together industry professionals in a relaxed and vibrant atmosphere. This event, organised in collaboration with Mikrotek Machines and Niehoff India, will offer attendees the chance to unwind, build new relationships, and strengthen existing ones. These personal connections are the backbone of our industry, and I encourage all members and exhibitors to take full advantage of this opportunity to engage with peers and potential partners. You will find more information on this event on page page 12.

As we look forward to a dynamic few days in Mumbai, I want to thank all our members and partners for their continued support. The IWMA Pavilion and our events would not be possible without the dedication and commitment of our community. I am confident that this year’s exhibition will provide invaluable opportunities for growth, innovation, and collaboration for everyone involved.

I look forward to seeing many of you on the IWMA stand over the course of the exhibition and sharing in what will undoubtedly be a successful and inspiring event.

Convincing Quality

wire India is more than just a trade show— it’s a crucial platform for networking, learning, and exchanging ideas. India’s rapidly growing industrial and economic landscape makes this exhibition the perfect venue for international collaborations and partnerships. The demand for advanced wire and cable solutions is increasing, particularly

With so much happening at wire India this year, the IWMA is excited to support our members in making the most of the exhibition. Our goal is to help businesses expand their reach, showcase their capabilities, and, most importantly, connect with the global market. Whether you are an exhibitor or attendee, wire India is the place to be if you want to stay abreast of industry trends and capitalise on the opportunities that India’s booming market has to offer.

www.niehoff.de Warm regards, Don Neville Chairman, IWMA

Innovative Solutions Worldwide on Site

wire India Networking Event | Mumbai, India

Thursday 28th November 2024

IWMA Industry Lunch Germany | Düsseldorf, Germany

Wednesday 12th March 2025

wire Eurasia Networking Event | Istanbul, Türkiye

Thursday 10th April 2025

IWMA Golf Day | TBC

Wednesday 18th June 2025

IWMA Industry Lunch UK | TBC

Thursday 19th June 2025

Alliance

wire Southeast Asia Networking Event | Bangkok, Thailand

Thursday 18th September 2025

Wire & Cable Conference | Krakow, Poland

Tuesday 14th October 2025

IWMA Dinner Dance 2025 | TBC, UK

Friday 21st November 2025

trade fair organiser Messe Düsseldorf GmbH supporting the following exhibitions

Excitement Builds for the IWMA’s First Industry Lunch in Germany, Coming in 2025!

Save the date: Wednesday 12th March 2025. Prepare to be part of an exciting and unforgettable event.

We are delighted to announce the IWMA’s much-anticipated Industry Lunch, set to take place in Germany on Wednesday 12th March 2025. For the first time ever, this event is being hosted in Düsseldorf, marking a significant milestone in our 54-year history; as the home of the world’s leading international trade fair for our industry, the city is already a familiar location to many of us, and as we await the specific venue announcement, the anticipation continues to build!

The day will begin with the IWMA Annual General Meeting, which all members are very welcome to attend free of charge.

The AGM will provide a platform for reflection on the past year’s achievements, as well as setting the stage for the future under new leadership, as we witness the formal handover from outgoing Chairman, Don Neville, to our new Chairman, Willibert Dautzenberg.

The lunch itself promises to be a memorable experience, as always. After catching up with friends and reconnecting with industry peers at an informal drinks reception, we will enjoy a three-course meal with excellent food and wine. Speeches will be delivered by Don Neville, who will reflect on his tenure as IWMA Chairman before passing the role to our first-ever German Chairman, Willibert Dautzenberg. Bernd Lohmüller, IWMA President, will also share his vision for the future as part of the dynamic German duo now leading our association.

Finally, a highlight of the day will be the announcement of the Young Employee of the Year 2025. This coveted accolade recognises the brightest young talents in their fields and provides a fantastic opportunity to showcase the rising stars within your organisation.

We invite all member companies to nominate their outstanding young professionals when applications open soon. We’re excited to learn who you see as the future leaders of our industry. Keep a keen eye out for more details of how to apply.

Tickets for the Industry Lunch will also be available soon, and with the anticipation surrounding this event, we expect high demand. Be sure to book early to secure your place and join us in Düsseldorf for a day of celebration, networking, discussion, and forward-thinking!

RichardsApex is pleased to announce their latest wholly owned subsidiary RichardsApex International located in Singapore with an operations team managed by Vishal Handa. As worldwide metalworking demands continue to expand and intensify, so does the commitment of RichardsApex in providing knowledgeable, experienced, and professional personnel available to manufacture, distribute, and service all metalworking markets. This strategically located subsidiary combines our growing global network, including distributors and agents, who are ready to serve the needs of our customers throughout the world. Customers can access RichardsApex products through this subsidiary while receiving the same support, expertise, and attention to detail they have experienced through our global network for many years. We invite all customers to review the enhanced sales and service network at our website:

www.richardsapex.com

wire India, at the Bombay Convention & Exhibition Centre in Mumbai (November 27-29) is a hotly-anticipated event on the annual calendar of wire and cable exhibitions.

It’s the third-largest show after Germany and China, and the biggest on the Indian sub-continent. Given the large number of manufacturing businesses in the region, its economic value cannot be ignored.

The same goes for the rewards on offer: last year the Indian wire and cable market was worth around $13 billion, but with a strong projected growth for most of the next decade, the early 2030s might see a value nearer $35-40 billion, which is a very healthy sector indeed.

No surprise, then, that the most recent wire India, in 2022, attracted over 17,000 visitors (almost three times the attendance in 2010) and 400 exhibitors from 21 countries across 23,000 sq m of halls; predictions for this year are for even higher numbers.

In addition to Indian companies, the exhibition attracts exhibitors from Belgium and the Netherlands, Austria and Germany, the United Kingdom, Turkey, Italy, France and Spain and Scandinavia, and there are also many overseas companies from the USA and Canada, South East Asia, South Africa and China. The forthcoming event will also feature pavilions gathering companies from Germany, Italy, Switzerland, and an International Pavilion from IWMA along with a comprehensive conference programme.

India has been the global success story of the past 15 years; where China has led, India now follows.The two nations are remarkably similar in many ways: both have similarly-sized and huge populations of around 1.5 billion, both have vast working-age populations, both major in education, technology and manufacturing, both are among the top users of cable and wire (China top, India third), both have vast industries supporting green energy, each is the major exporter to the other, and not

surprisingly, they stand at first (China) and third (India) in the world economic rankings, either side of the USA.

Admittedly, India’s GDP is around $13.5 trillion while China’s is nearer $31 trillion, but China is currently beset by trade wars and export tariffs, while India is affected mainly by its own bureaucracy and a slightly strained relationship with the outside world. But India imports far more than it exports, which makes it a favoured destination for manufacturers from the largest producing nations.

Like China several years ago, India is undergoing a transition into a modern industrial nation, and nowhere is this seen better than in the growing demand for wire and cable.

Though the country is currently suffering a small economic downturn, like most nations, the underlying economy remains vibrant and is predicted to grow at around 6.1 per cent this year, against seven per cent last year.

India has been investing heavily in infrastructure and transport projects, the power grid, renewables and smart technology – all great for the wire and cable industry (power utilities already consume 30 per cent of all the cable used in India). The investment pushed construction growth last year by 11 per cent over 2022 – a slightly artificial result, since India was still rebounding from the pent-up demand from Covid. Now the curve is getting back to normal, growth should rise at a slower but far steadier rate.

Increasing Indian urbanisation will demand extra power, and even though India is the world’s third-largest producer and consumer of electricity, its current generating capacity is nowhere near the anticipated demand.

The Indian government has plans to more than double the present capacity of around 420GW by 2030, by adding 500GW of green generation.

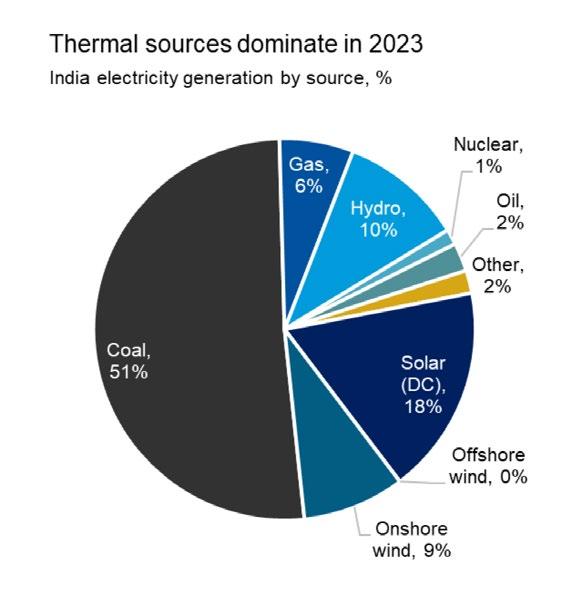

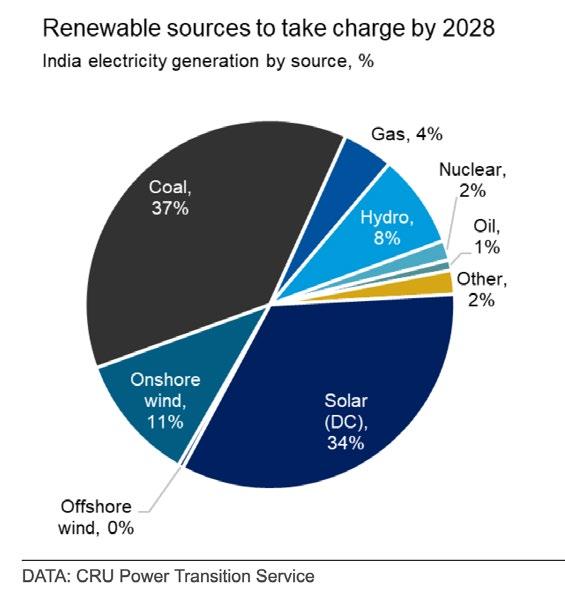

India’s existing generating capability relies heavily on coal and oil; the government’s aim

Correct as of 13th November 2024

IWMA Pavilion – Hall 1, L47

Aversion Technologies Europe S.L

Fisk Alloy Conductors BVBA

Proton Products International Ltd

is for renewables – some wind generation, but mainly solar to overtake fossil-fuel generation in the next seven years and for the nation to be net-zero by 2070 (a vast job, since renewable capacity by 2070 would need to be around 7,500GW and it will cost an extra $5 trillion for measures just to halve estimated CO2 output over the next halfcentury). India is currently the world’s thirdlargest producer of greenhouse gases.

The leap to 2030 alone demands the addition of around 50GW of new capacity a year, partly achieved at the consumer level by a scheme to encourage up to 10 million householders to install solar panels, with the usual grid buy-back schemes. This should increase rooftop generation from 12GW to 40GW within two years. A parallel scheme offers financial incentives to the power distribution companies to improve the network, alongside general modernisation using smart grid technology.

Falling into step with proposals to generate power are plans to use it: India’s intentions for the rail network (already 95 per cent electrified) and for electric vehicles (including buses and two- and three-wheelers) are as ambitious as those for other aspects of power generation. India hopes to electrify almost a third of its vehicles by 2030 – as with the Western model, by a mixture of incentives and tighter emissions standards.

The rail network is already subject to technology and infrastructure improvements to make it more efficient, but is being augmented by metro transport schemes for around 75 cities in the next handful of years – offering not only better public transport but a welcome reduction in traffic congestion and pollution.

The shift to EVs in urban India is opening up massive demand for network cabling, and of course for wiring in the manufacture of EV motors and batteries. India’s future plans are a big reason for the continued growth of the nation’s wire and cable market – and the popularity of wire India.

Rautomead Limited

RichardsApex

Company Booth

AESA SA Hall 1, K59

Ajex & Turner Wire Technologies Hall 1, K01

Associated Engineers and Industrials Private Limited Hall 1, F35

Assomac Machines Ltd. Hall 1, E07

August Strecker GmbH & Co Kg Hall 1, I07

Bongard Machines GmbH & Co. KG Hall 1, J55

Condat SA Hall 1, M47

CSM METALURJI IMALAT SANAYI VE MUH.

LTD.STI Hall 1, K64

DRT Impianti S.r.l. Hall 1, F47

FIB Belgium Hall 1, J67

FUHR GmbH & Co. KG Hall 1 , K54

H.Folke Sandelin AB Hall 1, I07

Hans Schmidt & Co. GmbH Hall 1, J51

KEI Industries Ltd. Hall 1, M35

Klüber Lubrication GmbH Hall 1, L71

Madem SA Industria e Comercio de Madeiras e Embalagens Hall 1, J65

Maillefer Extrusion Oy

Medek & Schoerner GmbH

Nappoo Hi Command Hall 1, I77

NIEHOFF of India Pvt. Ltd. Hall 1, I07

Q8 Oils Hall 1, D83

Reber Systematic GmbH + Co. KG Hall 1, I49

Rosendahl Nextrom GmbH Hall 1, I59

Setic SAS Hall 1, N48

SIKORA

Sipcon

As the 2024 wire India exhibition begins, we are thrilled to announce IWMA’s significant appearance at this global event. Following the success of our pavilions at wire Southeast Asia and responding to substantial interest, we’re excited to debut our member pavilion in India for the first time.

We will be joined by member companies from across the globe, including RichardsApex, Aversion Technologies, Proton Products, Rautomead, and Fisk Alloy, who will be showcasing their companies as part of the IWMA International Pavilion. The IWMA section of the pavilion will be its usual hive of activity, serving as a central hub for our members and guests. It will offer a wealth of resources and networking opportunities, along with on-stand presentations and our signature IWMA hospitality and support services. Refreshments, Wi-Fi connectivity, and bookable meeting tables for business discussions or casual chats with colleagues will all be available. In addition, a range of printed materials, including the latest IWMA Insider magazine, membership directories, and benefits booklets, will also be available to keep you informed about our upcoming events, exhibitions, and the myriad benefits of being part of the IWMA Community.

The IWMA Pavilion is your hub for industry expertise and member collaboration. Representing the IWMA at wire India will be Don Neville, IWMA Chairman, Jessica Bennett, Executive Manager, and Katie Houston, Marketing Executive. The team is eager to meet you and discuss how the IWMA can support your business and professional growth. Be sure to visit us to access valuable information, explore resources, and connect with our featured members to see their innovations on display. We look forward to welcoming you.

We are excited to offer our IWMA members the opportunity to showcase their expertise and latest developments during wire India at our ‘IWMA Member Presentations’ on Thursday, 28th November 2024. These presentations, covering a variety of topics, will take place in the dedicated member presentation area at the IWMA stand (L47). Participants will have the chance to share their insights with a global, diverse audience and expand their presence within the Indian market. Attendees will gain valuable insights from these sessions, so don’t miss the chance to engage with key industry professionals. We look forward to welcoming you at the stand—please ask a member of the IWMA team for more details on the presentation topics and the day’s schedule.

Fisk Alloy develops high-performance copper alloys that are used in the electrical, electronic, and automotive industries. Their unique lead-free alloys combine superior conductivity, strength, and flexibility, while meeting stringent environmental standards. Fisk Alloy will showcase their latest innovations in material technology at wire India, highlighting their commitment to sustainability and high performance.

www.fiskalloy.com

Rautomead specialises in continuous casting technology for non-ferrous metals, including copper and copper alloys. Their systems offer high-efficiency solutions for wire and cable manufacturing, producing consistent, high-quality metal products. Rautomead’s advanced technology is known for its sustainability and cost-effectiveness, positioning them as a leader in the global wire market.

www.rautomead.com

RichardsApex is a global leader in providing lubricants and chemical solutions for the wire drawing and metalworking industries. With over 100 years of experience, they specialise in high-performance drawing lubricants, cleaners, and coatings that enhance the efficiency and quality of wire production processes. Their dedication to innovation and sustainability makes them a trusted partner in the global wire industry. www.richardsapex.com

Aversion

Aversion Technologies offers advanced coatings and additives that protect products from microbial growth and corrosion, key concerns in demanding wire and cable manufacturing environments. Their innovative solutions help manufacturers extend the lifespan and durability of their products, with a strong focus on sustainability and performance. At wire India, they will showcase their latest protective technologies.

www.aversiontech.com

Proton Products: L47-5

Proton Products is a world-renowned provider of precision measurement and control systems for the wire, cable, and fibre optics industries. Their portfolio includes laser Doppler speed and length measurement devices, non-contact thickness gauges, and flaw detection systems. Proton Products is committed to improving manufacturing precision and consistency and will be presenting their latest innovations at wire India. www.protonproducts.com

‘Colours of the World’ IWMA

One of the highlights of this year’s wire India exhibition will be the return of our popular evening networking event, which promises to be the best yet!

Our last event in India, held in 2018 at the prestigious Hotel ITC Maratha, was a resounding success. Titled ‘A Taste of Bollywood’, the event captivated attendees with a vibrant mix of Indian culture and invaluable networking opportunities. The energy and excitement from that memorable evening still resonate, as captured in the accompanying photos showcasing the dynamic atmosphere our attendees enjoyed.

This year, IWMA is set to co-host ‘Colours of the World’—a networking cocktail dinner—alongside Mikrotek Machines and Niehoff of India. This unforgettable evening will take place on Thursday, 28th November 2024, at the prestigious Hotel ITC Maratha in Mumbai, India, creating the perfect backdrop for building new relationships and strengthening existing connections.

Event Highlights:

• Date: Thursday, 28th November 2024

• Event Time: Approx. 19:00 – 22:00

• Location: Hotel ITC Maratha, Mumbai, India.

• Transport: Complimentary transportation will be provided from the IWMA stand (Hall 1, L47) at wire India to the venue. Please meet at the stand at the end of the exhibition day for your transfer.

This spectacular evening promises live Bollywood entertainment, a feast of traditional Indian cuisine and a welcoming atmosphere. It’s the perfect opportunity to unwind after a day at the exhibition, share insights, and network with industry peers.

Tickets: Due to limited availability, each IWMA member company is eligible for three complimentary tickets. If you haven’t yet reserved your tickets and would like to join in the celebrations, please reach out to the IWMA team on stand or email events@iwma.org for more information.

Don’t miss out be sure to join us for a night filled with music, culture, and connections— we can’t wait to see you!

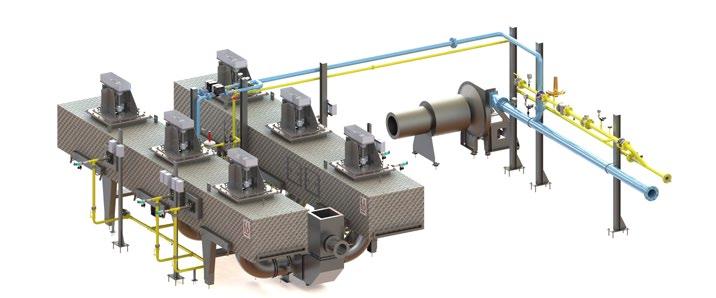

Offering sustainable solutions at the cutting edge of technology is the guiding principle of FIB BELGIUM and its dedicated teams. Renowned globally as a key player in the supply of equipment for the thermal, chemical, and surface treatment of steel wires, FIB BELGIUM is marking several significant anniversaries in 2024.

Thirty years ago, FIB BELGIUM delivered its first electrically heated furnace. Since then, numerous installations using electricity as a heating method have been completed by our teams, consistently delivering outstanding performance and satisfaction.

With a strong commitment to reducing consumption and minimizing environmental impact, FIB BELGIUM has been continually advancing its open fire furnaces. A decade ago, we developed the IMFLEX® open fire furnace, which reduces gas consumption by up to 27%.

All our installations are equipped with 4.0 technology, ensuring traceability and quality control throughout your production process. Whether you need a patenting line, an annealing-galvanizing line, or a bell furnace, FIB BELGIUM offers a range of

cables produced meet the standards required in the renewable energy sector, particularly for large-scale applications like wind farms, solar power plants and grid infrastructure.

solutions designed to help you reduce your environmental footprint.

Join us in celebrating these milestones at the wire India exhibition. We will be pleased to present our equipment whether powered by electricity or gas as well as our Saver and e - solution ranges.

www.fib.be

AEI Machines: Leading the Change with Industry 4.0Rigid Stranding Solutions for Renewable Energy at wire India

AEI Rigid Stranding Machines are equipped with advanced features that embody the essence of Industry 4.0.

As the global energy sector pivots towards renewable sources, the need for advanced manufacturing technology has never been more critical. AEI Machines, a recognised Rigid Stranding Machine manufacturer of more than 50 years, is at the forefront of this transformation. Embracing the principles of Industry 4.0, AEI Machines offers state-of-theart equipment that not only meets the demands of today’s energy landscape but also sets new standards for efficiency, safety, and flexibility in cable manufacturing.

AEI Rigid Stranders produce high-performance cables, key components in renewable energy infrastructure. The company’s dedication to high-quality manufacturing ensures that the

Fully Networked Architecture, enabling seamless communication between different components of the manufacturing process, resulting in higher efficiency and reduced errors. Remote Access and Monitoring of machine data and control systems from anywhere in the world, allowing for realtime adjustments and troubleshooting. Data Collection and Transmission that can be analysed to optimise processes, predict maintenance needs, and improve overall productivity. Also, High Production Flexibility and Enhanced Safety are ensured by predictive maintenance and real-time monitoring, reducing the likelihood of accidents and equipment failure. AEI Machines are equipped with advanced sensors and automated systems that ensure operations are safe and compliant with industry standards.

At wire India 2024, the AEI Machines team are looking forward to welcoming visitors from all over the world to showcase latest developments in AEI Stranders that enhance the production of cables that are essential for renewable energy infrastructure. By integrating Industry 4.0 features into AEI Stranders, AEI is not only improving manufacturing processes but also contributing to the broader goal of sustainable energy production.

Some of the applications include machines for the manufacture of:

• Highly compact round conductor up to 2500 mm2 in single pass for EHV cables

• Milliken segments for conductor up to 3000 mm2 / 500 kV

• High speed manufacture of conductor for low voltage cables

• New generation HTLS conductor TW/CFCC

• High speed manufacture of various overhead conductor ACSR/AAAC

• Copper wire screening of high voltage cables

• Steel wire/strip armouring

• Laying up of control cables

Traxit and Kemtree to Showcase Innovations at wire India 2024

Traxit Wire Lubrication, a brand of Klüber Lubrication and a leading provider of highquality drawing lubricants, is pleased to announce its participation in wire India 2024 alongside its esteemed distribution partner, Kemtree International. Kemtree International will be showcasing our high-quality products and innovations at wire India 2024.

Our booth will be in Hall 1, booth number L71.

High-Quality Drawing Lubricants for Various Industries

As a leading provider in the industry, we offer a wide range of high-quality drawing lubricants used across various industries. Our products are

AUGUST STRECKER GmbH & Co. KG Unveils Latest Technologies at wire India 2024

AUGUST STRECKER GmbH & Co. KG has been producing high-quality buttwelding equipment for the wire and cable industry since 1933, serving both the ferrous and non-ferrous sectors. STRECKER is the first point of contact for customized solutions in welding technology. The products enjoy an excellent reputation for their quality and reliability and are used not only in Germany but in more than 110 countries worldwide.

We invite you to visit us at wire India, Hall 1, Booth I07, where we will be showcasing our Type SE1 for welding stranded conductors, Type 2a for welding ferrous and non-ferrous rod, and our latest development, the Type LP10 brazing gun for brazing flat copper conductors (e.g., CTC conductors).

known for their durability, high performance, and environmental friendliness, making them the ideal choice for companies committed to sustainable and efficient production.

This year, our exhibition will center around sustainability and efficiency. We are proud to present solutions that are not only high-quality but also environmentally friendly and resourceefficient. Our products are designed to optimize production processes while minimizing the ecological footprint.

Development of Tire Bead Wire for the Automotive Industry

A key highlight of our exhibition will be the development of tire bead wire for the automotive industry. In collaboration with Kemtree International, we will showcase our product range that meets the stringent demands of this challenging sector. Our products help enhance the safety, efficiency, and longevity of vehicles. Leading wire drawing companies for tire bead wire are already using our products.

Partnership with Kemtree International Kemtree International (www.kemtree.in)

is a trusted partner with extensive market knowledge and a strong distribution network in India. Together, we aim to expand our presence in the Indian market and make our products accessible to a wider audience. We are confident that this partnership will significantly contribute to the success of our exhibition and strengthen our market position.

We warmly invite all interested parties to visit us at wire India 2024. Experience our innovative products firsthand and learn about the latest developments in the industry. Our booth provides an ideal opportunity to engage with our experts and discover more about our sustainable and efficient solutions.

insulation lines, sheathing and insulation lines, and a comprehensive range of downstream equipment such as winders, caterpillars, capstans, and accumulators.

AESA Cortaillod Strengthens its First Level Service Support in India

Sci-Mach Industrial and AESA Cortaillod have teamed up to offer First Level Service Support in the Indian region for all AESA measurement equipment, now providing joint calibration and maintenance services in the most efficient way. In addition, AESA now also calibrates third-party Automatic LAN Cable Testing Systems.

With this First Level Service Support, companies using AESA Cortaillod equipment in India can be assured of receiving the highest level of service around the clock.

Explore AESA’s innovative solutions and discover how their technology can help achieve higher yields and better sustainability at wire India.

Hall 1 Booth K59

www.aesa-cortaillod.com

At wire India 2024, TROESTER will present the latest information and developments in the following areas:

and

and Sheathing Systems** CV Tubes and Components, including the variable Endseal TRENDSEAL Silicone Insulation Lines with TRIOX ovens Production Equipment for Submarine Cables

The Compounding Division of TROESTER (X-Compound) specializes in complete compounding systems, covering conveying, melting, dispersing, mixing, and degassing. At wire India 2024 they will showcase their Kneader Technology for continuous compounding of HFFR (LSOH), PVC, XLPE, semiconductive materials, and EPR/EPDM.

The increasing power demand as well as the growing share of renewable energies are leading to new challenges: Wind parks, solar farms and further decentralized power generation requires expansion and restructuring of the existing power transmission grids with new cable networks on land and under water. Troester CV and sheathing lines deliver their contribution to this energy transition and provide excellent extrusion lines for those requirements. www.troester.de

Windak to Present Sustainable & Efficient, fully automated Cable Packing Machines at Wire India 2024, Booth I65

Windak, a global leader in automated cable packaging solutions, is excited to announce its participation at wire India 2024, taking place from November 27-29.

At Booth I65, Windak’s experts will discuss their innovative coiling and spooling technologies, designed to meet the demands of India’s expanding cable manufacturing sector.

Windak will focus on its coil-in-a-box solution, which eliminates the need of any plastic by automatically placing the ready coil directly inside the box. This innovation minimizes the impact on machine performance caused to manual handling and optimizes both output and efficiency.

Additionally, Windak is eager to discuss its solar cable Spooling Solutions, particularly the AR model spooler, which has been successfully tested with solar cables and can operate either inline with an extrusion line or offline from a drum using a Payoff. The AR Spooler features an option to switch between left-to-right and right-to-left operation, includes a ‘Change on the Fly’ feature, an Intelligent Scrap Handling System, and ‘NO BREAK’ stretch wrap system, making it one of the most efficient and reliable spooling machines on the market today.

“As India’s cable manufacturing industry continues to expand, automation is crucial for increasing efficiency while maintaining sustainability and competitiveness,” said Dieter Gerger, Sales Manager at Windak Group. “At Wire India, we love to discuss with the cable manufacturers about automating their cable packaging department and how we can work together to increase output and improve reliability so that they can meet the growing market demands.”

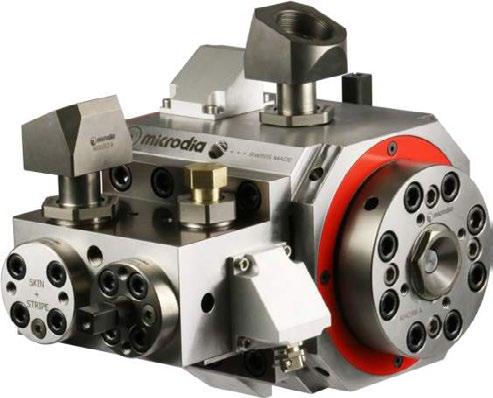

Leader of the wire, and cable extrusion crosshead manufacturers, Microdia founded in 1979 is nowadays one of the oldest wire and cable crosshead makers.

Its facilities are located in Yverdon-les-Bains in Switzerland where all Microdia products are designed and manufactured.

Microdia precision cross heads are preferred by major wire and cable factories all over the world because of their time saving design during cleaning and color change, and their unique modular design making possible all kind of configuration whether for automotive, electronics, or other industries.

On the booth Mr Victor Grigore, Sales Manager, expert in the field of wire and cable technology will gladly present Microdia extended range of families cross heads: 9000, Avantis, Ecomex, Romex and Dual-Flow.

Best sellers:

Microdia Mflex series, fixed center cross-heads with manual fine tuning, for concentricity close to 1.

Skin-foam-skin + stripe cross heads for high frequency cable.

Dual-flow cross head (Microdia patent), for PA, PET, PEEK, PEKK etc. insulated flat profiles.

All available for standard or fluoropolymer compounds.

Microdia: swiss precision for the world.

Hall 1 Booth K63

www.microdia.com

As the demand for energy grows and the energy transition advances, the wire industry faces new challenges, particularly in producing rectangular magnet wires. FUHR GmbH & Co. KG, headquartered in Steinheim, recognizes these shifts and has positioned itself to meet these demands.

FUHR offers tailored machine solutions for two key sectors: flexible production of wires for large generators and motors, and continuous high-volume production of winding wires for electric vehicle motors. For the flexible sector, FUHR’s 5-stand rolling mills allow for quick adjustments to varying wire dimensions, supported by precise measuring devices and data-logging software.

For the automotive sector, FUHR’s compact IPU320 machine ensures stable, high-quality production of ‘hairpin-wire’, while the larger IPU500, developed in 2023, addresses the growing market for transport and mobile machines (TMM).

With nearly 100 IPU320 units sold and the first IPU500 successfully delivered, FUHR continues to innovate for the future of wire production.

Hall 1 Booth K54

www.fuhr-wire.com/en

RichardsApex Celebrates 120 Years of Excellence in Lubricant Manufacturing with Launch of Cutting-Edge RA400

RichardsApex, a distinguished global leader in lubricant solutions, proudly marks 120 years of industry innovation and excellence. Renowned for its top-tier lubricants tailored for wire drawing and hot rolling applications, RichardsApex continues to set the standard in the lubricant sector with its advanced product offerings and unparalleled technical expertise.

Specialising in semi-synthetic and synthetic lubrication compounds, RichardsApex provides essential solutions for both non-ferrous (including copper, aluminium, and brass) and ferrous wire drawing. The company’s comprehensive product line also includes protective coatings, cleaners, corrosion inhibitors, and oil-based lubricants suitable for all non-ferrous and ferrous alloys in wire and rod rolling applications.

A leader in the Indian market, RichardsApex supplies over 95% of the lubricants and protective coatings for copper wire rod manufacturing, including its flagship SK series,

HRAL, and CC40 products. This dominant market presence underscores RichardsApex’s deep understanding and technical prowess in rod and wire production, marking it as a core competitive advantage.

In response to the evolving needs of today’s high-efficiency machinery, RichardsApex is dedicated to exceeding customer expectations through cutting-edge technology. The company’s latest innovation, RA400, exemplifies this commitment. Developed through extensive research and rigorous on-site testing, RA400 is a modern, water-soluble copper wire drawing lubricant designed to meet the demanding requirements of a global customer base.

RA400 features advanced friction modifiers tailored for contemporary machinery, dies, and operational speeds, while offering lower lubricant consumption compared to competing products. This ultra-modern lubricant generates a stable, low-foaming emulsion that minimizes copper soap formation, enhances tank life, and improves wire drawing performance with fewer breaks per ton of wire produced. Suitable for copper, copper-plated alloys, and EC aluminium, RA400 excels in rod breakdown, single and multi-wire machines, and inline annealing

processes. RA400 has rapidly become Richards Apex’s fastest-growing wire drawing lubricant, reflecting its global success and widespread market appeal.

With a robust global sales network and over 120 years of history, RichardsApex provides exceptional on-site support and technical sales assistance worldwide. This network enables RichardsApex to help clients enhance productivity, improve quality, and reduce manufacturing costs effectively.

For more than 60 years, RichardsApex has proudly served the Indian market, maintaining a strong presence with dedicated employees and product representatives. The company’s service philosophy remains central to its global success in wire drawing, copper tube production, and rod rolling markets. RichardsApex remains steadfast in its commitment to delivering products and services that foster long-term relationships with both Indian and international customers.

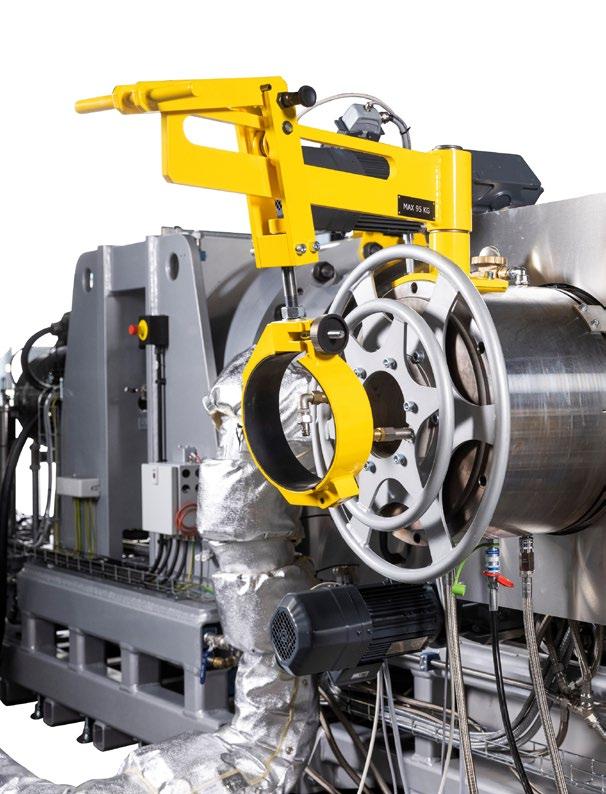

High-Quality Multiwire Drawing Equipment: Niehoff at wire India 2024

Maschinenfabrik Niehoff and its subsidiary, Niehoff of India (NoI), will exhibit at the wire India 2024 trade fair at Hall 1, Booth I07. On display will be an MMH 121 + RM 201 type multiwire drawing line.

The MMH 121 multiwire drawing machine on display was built by Niehoff in Schwabach and is combined with an RM 201 type resistance annealer built by NoI under Niehoff license. The drawing machine is designed to draw 32 wires on two levels simultaneously. Some key features of the line include its compact design, high productivity, and low wire break rate.

The RM 201 type resistance annealer uses the field-proven 2/3 zone annealing process, which can be selected with or without wire reheating. The results are optimal wire drying and economical energy use for larger wire sizes.

The line is designed for copper wires and is operated via the standardized NMI (NIEHOFF Machine Interface), a networkcompatible touchscreen that enables easy, intuitive operation.

The machine’s intelligent technology allows for the measurement, storage, and use of machine data, production data, and process data in accordance with Industry 4.0 standards. Wires drawn on this line exhibit highly homogeneous characteristics and narrowly tolerated properties along their entire length. These wires can be processed into multiwire bundles with outstanding qualities and are ideally suited for final applications or downstream processing into high-quality strands or braids.

Technical Data: MMH 121

- Max. production speed: 35 m/s

- Wire inlet diameter: 2.00 or 1.80 mm*

- Wire finished diameter: 0.16 ... 0.50 mm

- Max. number of wires: 32

- Number of wire drafts: 22

- *Cu hard

Discover the Latest in Tension Measurement Technology with Hans Schmidt & Co. GmbH at wire India 2024

Hans Schmidt & Co. GmbH, a renowned name in precision tension measurement, has been at the forefront of the industry for over 75 years. This year, at wire India 2024, the company is set to present a range of cuttingedge innovations designed to meet the evolving needs of production and process engineering professionals.

With a global footprint and over 180,000 tension meters in use worldwide, Hans Schmidt has established itself as a trusted partner in production monitoring and quality control. The company boasts the largest selection of tension meters on the market, offering both mechanical and electronic models tailored to a variety of applications.

One of the highlights at this year’s exhibition will be the newly updated DT series of hand-held tension meters. Featuring an intuitive, easy-to-read display with multiple viewing modes, this series is equipped with a unique forcereduced material catching system and allows users to calibrate the device for specific materials directly on the display.

In addition, Hans Schmidt will introduce the enhanced FS series of online tension sensors, now incorporating digital signal processing technology for superior accuracy and seamless connectivity. The company will also showcase the new MZ series, specifically designed for environments with limited space, such as stranding machines, offering a compact design and adaptable guide rollers.

Make sure to visit Hans Schmidt & Co. GmbH at wire India 2024, Hall 1 Booth J51 (German Pavilion), to experience these state-of-the-art solutions firsthand and discover how they can elevate your production processes.

Hall 1 Booth J51

www.hans-schmidt.com

Metalube to Expand Horizons at wire India 2024 in Mumbai

Following its participation in wire China, UK-based industrial lubricant manufacturer, Metalube, will continue its international outreach by exhibiting at wire India 2024 in Mumbai this November. This event is a pivotal gathering for the rapidly growing wire and tube sectors in India, offering Metalube a significant opportunity to tap into one of the fastest-growing industrial regions globally.

wire India is crucial for Metalube as the company aims to further establish its presence in the Indian market. With a dedicated team and robust operations in the region, Metalube India is well-prepared to meet the rising demands for industrial lubricants, delivering high-quality products and tailored solutions to the unique needs of the Indian market.

Team Metalube at wire India 2024: - Andy Lewis, Commercial Manager Wire & Tube - Amit Gupte, General Manager India

Hall 1 Booth L79

The newly developed SKET CENTRAL STRANDER “MKZ” offers customers cuttingedge technology that sets a new global benchmark. The MKZT/S Central Strander series has revolutionized the production of overhead lines, delivering unprecedented standards across all designs. With stranding cage speeds reaching up to 500 rpm and a pay-off bobbin capacity of approximately 510 kg—around three times the previous standard—these machines provide productivity benefits that were once unimaginable. Depending on the specific requirements of the application, the stranding units are equipped with either mechanically or pneumatically controlled flyer systems, guaranteeing top-tier product quality. Having successfully delivered over 100 of these central stranders to customers worldwide, SKET’s reputation for reliability and customer satisfaction is well established.

SKET’s central strander technology is specifically designed for high production rates, consistent wire products, and minimal adjustments in wire size, ensuring superior quality with every output.

In addition to the MKZ range, the 245 series have been introduced as a versatile option within the portfolio, particularly suited for aluminum and overhead cable

constructions. The ‘245’ stands out not only for its applicability to aluminum wire stranding but also for its impressive capacity—a filling mass of up to 550 kilograms of aluminum, equating to about 245 liters per spool. To put this into perspective, a standard 630 DIN spool holds only about 40% of this volume, which translates to significantly longer stranding operations without interruptions compared to traditional stranding machines like rigid stranders.

The ‘245’ MKZ is equipped with an advanced wire guide system and various spool braking options that set new industry standards. Operating at high speeds, this machine is optimized for cost-effectiveness without sacrificing quality. Moreover, the availability of a ‘twin’ version of the machine—allowing for simultaneous stranding and loading—minimizes downtime and significantly boosts productivity.

This focus on economical operation is a hallmark of all MKZ machine sizes. Companies that have adopted these machines not only report enhanced efficiency but also benefit from reduced foundation requirements, significant energy savings, and lower maintenance demands.

SKET Verseilmaschinenbau GmbH looks forward to welcoming you at wire India between 27th - 29th November 2024.

www.sketvmb.com

TKT Group to Unveil Exciting Innovations at wire India 2024

TECNOVO and KONER, the renowned manufacturing companies under the TKT Group, are thrilled to confirm their participation at wire India 2024, taking place from November 27th to 29th. The TKT Group will be presenting at their exclusive booth, highlighting a selection of their most recent advancements in wire and cable manufacturing technologies.

The following innovations will be showcased at wire India:

High-Performance Wire Drawing Lubricants: These new lubricants, designed for both dry and wet wire drawing, are eco-friendly, free from dust and borax, withstand very high temperatures, and provide excellent lubrication.

State-of-the-Art Press Machine: Introduced at the KONER plant in late 2023, this automatic press machine with a 120-ton pressing force is designed to produce hard metal products with diameters up to 120mm.

Cutting-Edge Drawing Dies: TKT Group continues to advance with the production of various drawing dies and custom parts, using micro-grains that offer zero porosity and higher density and hardness, without compromising toughness.

Upgraded D-lab Instrument: The popular D-lab tool, known for measuring the diameter and ovality of dies, now features a larger touch screen, enhancing usability for operators after its international success.

Efficient Butt Welder Machine: A new butt welder machine that is easy to operate, reducing welding process time significantly by combining welding and annealing in one efficient operation, thereby increasing productivity and savings.

Superior Wiping Pads for Galvanizing: These high-performing wiping pads, designed with special coatings and lubrication, are adaptable for various applications and meet diverse customer needs.

Comprehensive Wire Cleaning Solutions: Offering both chemical and mechanical integrated solutions for the effective cleaning of wire and wire rod.

TKT Group looks forward to welcoming visitors to their booth at wire India 2024, where they will be available to discuss these cutting-edge products and how they can benefit your operations.

Hall 1 Booth G47 www.tktgroup.it

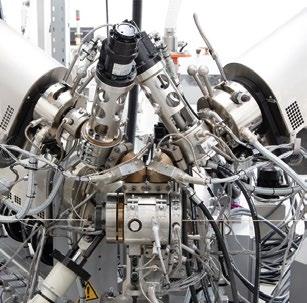

SIKORA inspection and measuring systems ensure the highest quality for HV and EHV cables with reliable quality control along the entire CV line using the latest technology.

HV and EHV cables, essential for transporting electricity in offshore and underground applications, demand the highest standards in function and production. A report identifies cable failures as one of the biggest challenges for offshore and wind power and predicts around 3,600 cable failures between 2024 and 2035, potentially costing 61.5 billion euros. To address this, cable manufacturers rely on advanced inspection and measuring technologies to ensure quality throughout the CV line as provided by SIKORA.

The PURITY SCANNER ADVANCED inspects 100% of XLPE material before extrusion, removing contaminants to ensure high material purity, which reduces the risk of breakdowns and extends cable lifespan. The ULTRATEMP 6000 measures melt temperature, thus ensuring an optimised melt temperature to prevent premature cross-linking, enabling an optimised extruder efficiency by 15%, which can lead to extended production lengths by 115%. This also reduces the number of cable joints and improves quality and costs.

SIKORA’s X-RAY 8000 ADVANCED system measures cable dimensions like wall thickness, eccentricity, diameter, and ovality during extrusion directly after the crosshead, while the X-RAY 8700 NXT measures cold values at the end of the line.

The combination of both devices determines the shrinkage values for all three insulation layers of the cable. Also, the operator is shown a possible change of the eccentricities of the individual layers and the ovality between the hot and cold measuring points, which is crucial during crosslinking in the CV tube.

Finally, the LM SMART length measurement system at the end of the CV line ensures that the required cable length is precisely maintained – a further contribution to quality assurance and resource conservation.

By integrating these systems, manufacturers can ensure the continuous quality of HV and EHV cables, enhancing reliability, safety, and cost efficiency— all of which are indispensable for modern energy infrastructures.

www.sikora.net

Medek & Schörner, along with our trusted partner KHU, are excited to announce our attendance at wire India 2024 where we will showcase innovative solutions for cable and optical fibre manufacturers. Our premium machines, designed for high performance and tailored to customer needs, deliver significant productivity improvements and top-quality results, with decades of experience and expertise, we guarantee comprehensive, joint consultation at the highest level.

We are proud to present our latest innovations, including:

• Newly designed optical fiber coloring line with increased production speed of more than 3,000 m/min and coloring of up to 3 optical fibers simultaneously

• Optical fiber coloring and curing station using LED irradiation units, resulting in 93 % less downtime and 81 % lower energy costs

• New ring marking technology

• Intelligent and highly improved hot foil sequential meter marker FMS 5 with an innovative marking wheel that memorizes and automatically aligns to different cable diameters

• Cutting-edge intermittent ribbon technology

For the first time at the French Pavilion in India, SETIC, POURTIER, and C2S will participate in the 9th International Exhibition for the Wire and Cable industry at wire India. Visit the rotating machinery and services team; Sales Representative: Benjamin Grasset, Thierry Pietriniro & local representative at booth N48 in the French Pavilion.

SETIC: leader in special, data communication & LAN cables machinery for Automation, Low & medium voltage, AI, Robotics, aerospace and data analytics sectors and a major actor in the automotive wire equipment’s.

POURTIER: heavy-duty rotating machines to produce all types of power cables: overhead, submarine, High Voltage and Extra-high Voltage.

To ensure optimal performance and extend the lifespan of machines, a comprehensive range of services are available: The C2S Customer Services department serves as the ideal partner for maintaining machine productivity and improving product quality.

Additionally, BOW TECHNOLOGY offers high-grade carbon bows suitable for all sizes and brands of double twist equipment.

SETIC, POURTIER, and C2S have been at the forefront of the wire and cable industry for decades, providing cutting-edge solutions and technologies that meet the evolving needs of our customers. Our commitment to innovation and quality has established us as leaders in the market. Looking ahead, we are excited about our upcoming projects, including the development of new technologies and expansion into emerging markets. Our goal is to continue leading the industry with innovative and sustainable solutions.

Benjamin Grasset, Sales Manager says “India represents a key market for the cable industry, with rapid growth driven by urbanization, industrialization, and increased infrastructure investments. The Indian wire and cable market continues to grow at a steady pace. Participating in wire India allows us to strengthen our presence in this strategic market and connect with our key customers.

As a leading supplier in the data and power cable industry, we aim to be partners in India’s growth and development.”

Leading the Way in Top-Quality Lead Extrusion Equipment Since 1958

H. Folke Sandelin AB (HFSAB), an independent company of the NIEHOFF Group and a global market leader in lead extruders as well as cable stripping and repair machines, will be exhibiting at the NIEHOFF booth during wire India. Find us in Hall 1, Booth l07.

Decades of consistent development, combined with our team’s expertise, service as a core competency, and close partnerships with customers, have driven our success. These principles have been fundamental in the past and will continue to be so in the future.

Our modernised horizontal lead extruder LEH, released in 2022, prioritises ease of use and cost savings. One of its standout features is the semi-automatic centring device, which simplifies the die adjustment process. This feature reduces setup times and operator errors while enabling more precise adjustments, resulting in material savings. The centring device is available as an option for new machines of all die block sizes and can also be retrofitted to existing horizontal and vertical extruders.

With headquarters in Motala, Sweden, HFSAB is your reliable partner for meeting the global demands of tomorrow, today.

www.hfsab.com

Horizontal lead extruder LEH in revised modern design with a focus on ease of use and cost savings

What we offer: well-proven technology in floor standing design How you benefit: continuous, extremely reliable and high energy and cost-efficient production of a high-quality sheath.

Visit us at the WIRE INDIA 2024

27 - 29 November, Hall1 Booth I07

Experience in Top-Quality Lead Extrusion Equipment since 1958

Challenge accepted

At the upcoming show in Mumbai, Rosendahl Nextrom will showcase a strong portfolio of new and improved solutions, focusing on efficient material use, reducing wear, and enhancing energy efficiency.

Boosting production capacity in datacom and telecom

With the rise of AI, the demand for highspeed data cables is growing. Rosendahl’s high-temperature physical foaming lines can produce cables with ultra-low data latency and bandwidths up to 800 Gbps for use in AI supercomputers. The new datacom core insulation lines have been optimised for CAT 7 and CAT 8 cables with skin-foamskin construction. The latest fibre optic cable innovations include high-speed fiber launching, rewinding, enhanced prooftesting and colouring.

Nextrom’s preform manufacturing combines Vapor Axial and Outside Vapor Deposition technologies, enabling large-sized preforms with low operational costs. The telecom fiber drawing process now reaches speeds of up to 3,500 m/min.

Future-proof e-mobility solutions

In EVs, new types of cables and wires are needed. Rosendahl provides innovative solutions for the production of busbars, high-end charging cables and data cables. A highlight is the world’s first turnkey extrusion line for hairpin insulation for safe and reliable power supply at 800V+.

Innovating smartly and responsibly

Rosendahl has introduced AI-supported process control, ESG-compliant CO2 measurement, and maintenance management within the RIO line control.

In fibre optics, a Helium Recovery System recovers up to 90% of used helium, and the Nextrom Induction Furnace significantly reduces energy consumption.

In the medium-voltage segment, the use of recyclable polypropylene-based compounds eliminates the need for energyintensive cross-linking. In high-voltage, a sustainable concept for forming, welding, and jacketing has been developed to accommodate flexible materials and product sizes on a single production line.

The automotive industry is competitive and constantly changing. With more and more sensor technology being installed in vehicles, the demands on cable and wire production are growing.

Rosendahl develops efficient manufacturing concepts that deliver high performance and excellent products for the vehicles of tomorrow.

• Reliable machine setups for high speeds

• Flexibility for your production

• Real-time quality monitoring

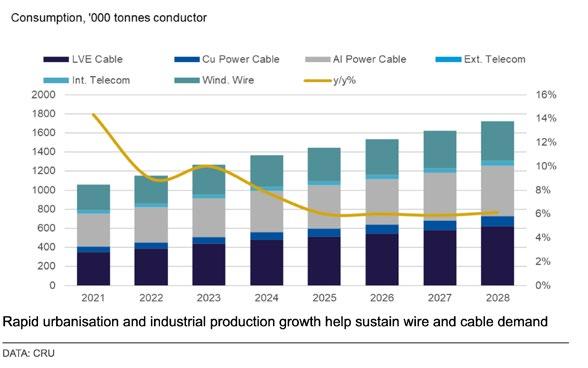

India, the third largest cable market globally, consumed a total of 1,266 kt of insulated metallic wire and cable in 2023, comprising almost 6% of world consumption, only behind China (42%) and the US (9%). India’s insulated metallic wire and cable demand is expected to grow 7.8% y/y in 2024 and is expected to exhibit healthy growth of 6.4% CAGR between 2023–2028.

Despite a global economic slowdown, India’s economy remains vigorous. Following a 7% GDP growth in 2023, it is expected to maintain a strong 6.1% growth in 2024, slightly tempered by election disruptions. This growth is driven by robust domestic demand and a thriving manufacturing sector.

In 2023, India’s construction output grew 11% y/y, attributed to the government’s persistent focus on infrastructure development coupled with the ongoing housing market boom. This growth is supported by increasing household incomes, a pronounced housing shortage in major urban centres, and robust population expansion. India now is the world’s most populous nation and as such, the construction sector is the primary consumer of cables, comprising 32% of the country’s total cable demand.

Vishnu Patidar Senior Analyst

Low Voltage Energy (LVE) cables command the largest market share, accounting for 34.7% of total cable demand. Rapid urbanisation has escalated the demand and investment in residential and commercial infrastructure, which primarily requires LVE cables. India’s Finance Ministry has allocated over $9.5 bn to the ‘Pradhan Mantri Awas Yojana’ (PMAY) scheme, reflecting the government’s commitment to infrastructure and housing. This has boosted demand for LVE cables, which is expected to remain strong in 2024. The construction sector is set to maintain growth above 10% y/y, and LVE cable consumption is projected to increase by 9.5% y/y.

The industrial segment is the second largest contributor of India’s wire and cable demand, accounting for 30% of the market. In 2023, India’s industrial production grew 7% y/y, with the manufacturing sector expected to sustain strong momentum in 2024, achieving over 6% y/y growth. This sector predominantly utilises winding wires for various applications such as motors, transformers, switchgears, domestic appliances, and fast-moving electrical goods. Winding wire consumption in India reached 312 kt conductors in 2023 and is forecasted to grow by nearly 6% y/y in 2024.

Modernised infrastructure elevates power cable need

India is the third largest producer and consumer of electricity globally after China and the US. According to CRU’s Power Transmission Service, the nation’s installed power generation capacity of 517 GW in 2023, projected to rise to 781 GW by 2028, necessitating a robust power transmission and distribution infrastructure. However, the per capita annual electricity consumption in India stands at around 1,327 kWh, well below the global average of per capita annual electricity consumption, which is estimated to be around 3,700 kWh.

India’s manufacturing and services sectors are the two largest consumers of electricity. Despite being the world’s most populous country, the residential sector is the third largest consumer of electricity, with most of the consumption largely concentrated in major urban centres, Tier 2 and 3 cities as well as surrounding areas; rural areas lag due to infrastructure limitations.

In order to deal with this issue, the country is making strides in strengthening its transmission and distribution infrastructure to cater to this need. Under the ambitious PM Gati Shakti National Master Plan, India’s National Grid capacity is set to experience substantial growth, with an anticipated addition of about 28,700 circuit km capacity by the fiscal year 2024-2025.

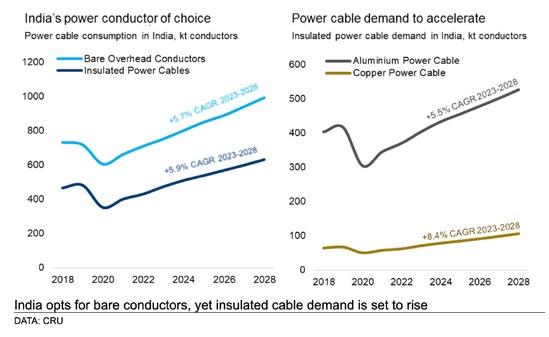

The power utility sector in India accounts for nearly 30% of the total consumption of wires and cables in the country. In the year 2023, the consumption of copper power cables in India was recorded at 70.8kt conductors, while aluminium power cables accounted for 404.5kt conductors. The Indian market, characterised by its price sensitivity, has traditionally favoured aluminium power cables due to their costeffectiveness when compared to copper power cables.

The transition towards modernising India’s electricity transmission and distribution infrastructure is being propelled by government-led initiatives like the Revamped Distribution Sector Scheme (RDSS). This is launched to aid DISCOMs in enhancing their operational efficiencies and financial sustainability, by providing result-linked financial assistance to bolster their supply infrastructure, contingent upon meeting pre-qualifying criteria and achieving basic minimum benchmarks. This scheme represents a significant investment of $35.8 billion, inclusive of budgetary support nearing $12 billion.

In addition to the RDSS, other significant initiatives such as the Integrated Power Development Scheme (IPDS) and the National Smart Grid Mission (NSGM) are playing a pivotal role in the overhaul and modernisation of India’s electricity transmission and distribution infrastructure. By harnessing advanced technologies and intelligent grid solutions, they aim to bolster grid reliability, optimise energy utilisation, and integrate renewable energy sources. This progress is, in turn, fuelling the demand for power cables within the country.

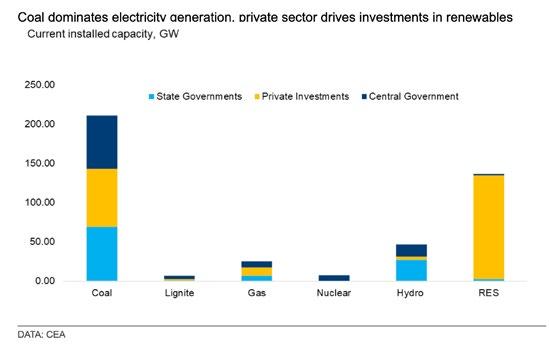

India, being the world’s third largest contributor to greenhouse gas emissions, accounts for 7% of the global total on an annual basis. Despite its substantial dependence on coal, the nation has pledged to attain “net-zero” emissions by 2070. This commitment is accompanied by ambitious objectives to augment renewable energy capacity, fulfil half of its energy requirements from renewable sources, and curtail greenhouse gas emissions by one billion tonnes by 2030.

Central to India’s renewable energy ambitions is the objective of producing 500 GW of energy from renewable sources by 2030, an endeavour projected to necessitate investments exceeding $30 billion. This initiative signifies a transformative shift in the country’s energy paradigm, with solar energy poised to play a pivotal role. By capitalising on the plentiful solar resources, India aims to diversify its energy portfolio and diminish its dependence on traditional energy sources.

India’s renewable energy goal of 500 GW by 2030 comprises 280 GW from solar and 140 GW from wind power. With an earmarked fund of nearly $1.8 billion for key capital investments to reach net-zero emissions and secure energy, India is poised to exploit renewable energy potential, thus boosting demand for essential components such as wires and cables.

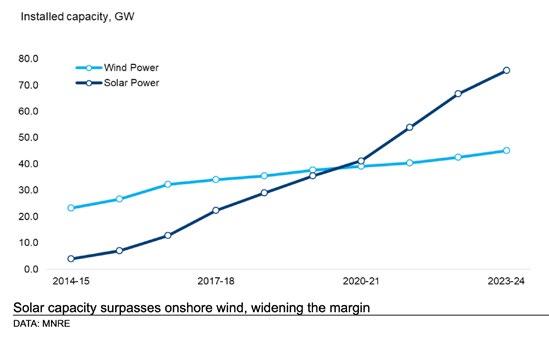

The government’s plan to install 140 GW of wind energy by 2030 requires substantial sector investment, increasing demand for specialised cables. India’s current wind energy capacity is 45.8 GW, all from onshore projects. The aim is to add over 30 GW from offshore projects by 2030, with the ‘First Offshore Wind Project of India’ (FOWPI) being the only one in the pipeline, at 200 MW. To stimulate offshore wind power development, the recent interim budget announced viability gap funding for an initial 1 GW capacity, and a bidding process for a 4 GW offshore project off Tamil Nadu’s coast has been initiated.

Solar energy’s dominance in India’s renewable sector is driving demand for solar E-beam cables. These cables, made with electron beam cross-linking technology, feature metal wire conductors, rodent resistance, and UV-stabilised PVC sheathing. They provide superior insulation, vital for high-temperature short circuits.

The shift from thermal to renewable energy transforms the future power dynamics

CRU Power Transition Service

India’s renewable energy capacity stands at 143.6 GW, reaching nearly 190 GW with large hydropower plants. To meet the 500 GW target, an additional 310 GW is needed within six years. To address this, the Ministry of New and Renewable Energy (MNRE) in April 2023 announced plans to bid for 50 GW annually until 2028.

In a parallel effort, the Indian government is encouraging rooftop solar adoption to meet renewable targets. The ‘PM Surya Ghar Muft Bijli Yojana’ scheme, with a $9 billion investment, aims to equip 10 million homes with subsidised rooftop solar panels. Households can sell excess electricity back to the grid, receiving 300 KWh of free power monthly. India’s current grid-connected solar rooftop capacity is 11.8 GW, with a goal of 40 GW by 2026, reinforcing its commitment to sustainability.

EV ecosystem to boost future wire and cable demand

India’s EV push has opened up opportunities across sectors like mobility, energy storage, and charging infrastructure. This includes EV franchising, OEM market, battery infrastructure, solar charging stations, and battery swapping technology. As EVs require electricity for charging, the need for wires and cables at charging stations is crucial. The shift towards EVs in the automotive sector is increasing the demand for charging stations and electrical components, leading to a surge in demand in the wire and cable industry.

India aims to electrify 30% of its vehicles by 2030. This is supported by policies like the FAME scheme for EV adoption, the PLI scheme for domestic manufacturing, and the Battery Swapping Policy for charging infrastructure. Stricter emission rules and ICE vehicle restrictions also promote this shift. India’s EV market, currently at 4.5% of LDV sales, is expected to grow by 82% from 2023 to 2028. Two and three-wheeler segments are adopting faster, especially in smaller cities. The FAME-II scheme, with a $1.2 billion budget, aims to support the adoption of 7,000 e-buses, 55,000 e-passenger vehicles, 0.5 million e-three wheelers and 1 million two wheelers nationwide.

India is committed to strengthening the EV ecosystem through manufacturing and charging infrastructure support. It encourages e-bus adoption for public transport. Major EV players include TATA, Mahindra, JBM, MG, KIA, Hyundai, BMW, Ashok Leyland, Volvo and soon Tesla. With rising EV sales, India may need 2.1 million charging stations by 2030.

The growth of India’s EV market will significantly impact the wire and cable industry due to the need for specialised cables as EVs necessitate a higher amount of specialised cables and wiring for power transmission, battery management, and other electronic systems compared to conventional Internal Combustion Engines (ICE).

Rail and datacentre growth to boost cable demand

India’s fourth-largest global railway network is modernising under the 2020 National Rail Plan, with aim to increase freight transport share from 30% to 45% by 2030 through infrastructure and technology investments. Currently, 95% of Indian railways are electrified, with a $778 million budget for further projects, aligning with zero carbon emissions by 2030.

The country is advancing its urban transportation systems, with 60 phases in 28 cities and plans for metro systems in 75 cities by 2027, as outlined in the ‘Gati Shakti Master Plan’ requiring $35.5 billion.

India’s digital transformation and the rise in data consumption necessitates more datacentres, supported by a $1.7 billion government incentive and $35.9 billion investment over five years. This will significantly increase the demand for telecommunication and power cables.

Unorganised industry trumps major brands

Major players like Polycab, Havells India, KEI Industries, and Finolex Cables collectively hold 28% of India’s fragmented wire and cable market. Unorganised players still hold over 50% market share. As of 2022, the market is valued at $9.6 billion.

To find out more about the financial performance of the main publicly listed producers, their strategies, expansion plans, mergers and acquisition activity, please read “Indian cable producers raise FY 2023 sales on lucrative exports”. Readers will require a subscription to the Premium Package, which includes Wire and Cable News.