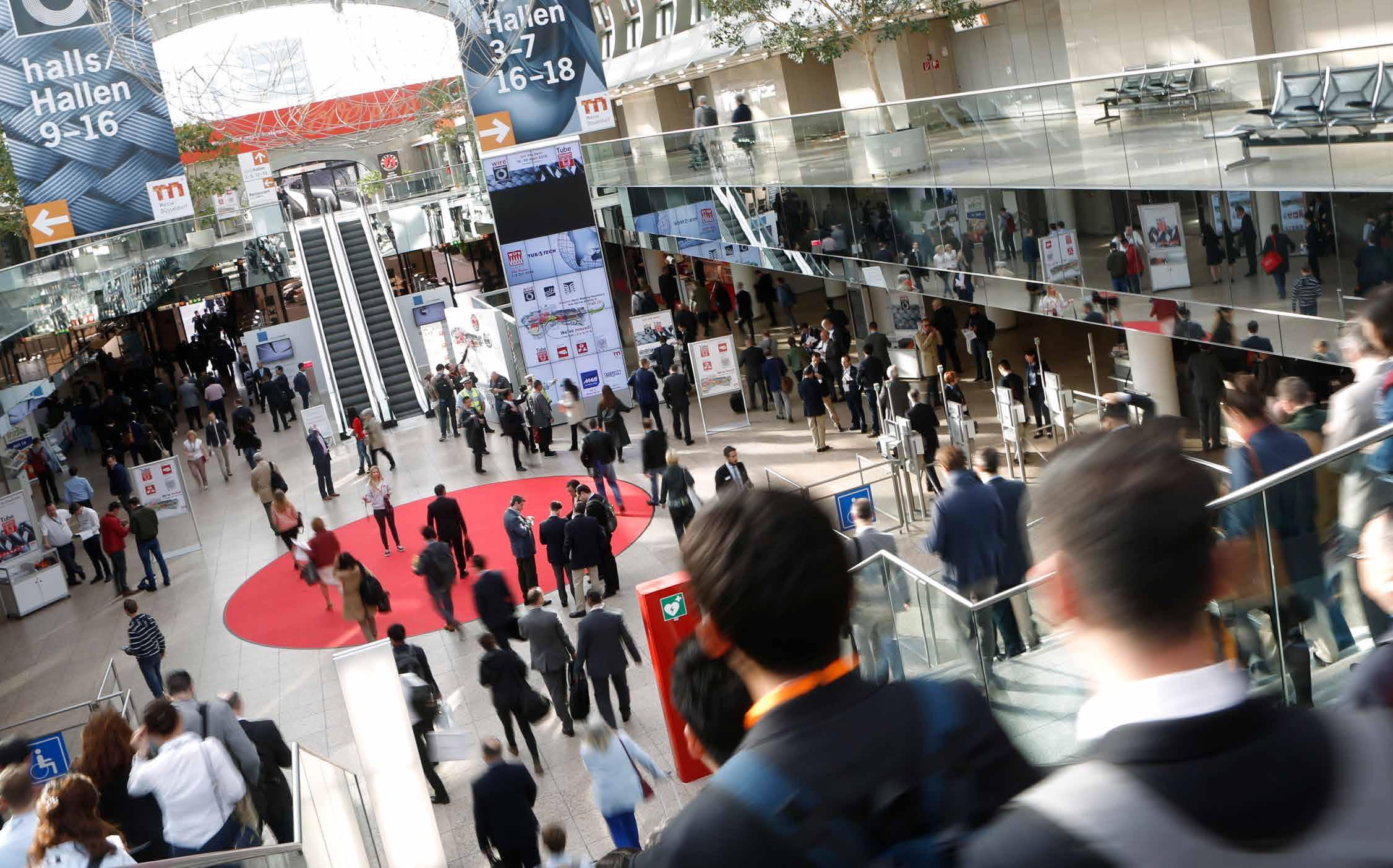

Join the best: wire Düsseldorf 2022

IWMA Welcome New Chairman

CRU Review – Metallic Wire & Cable: Lockdown, war and logistic woes

IWMA Members exhibit at wire Düsseldorf

IWMA Welcome New Chairman

CRU Review – Metallic Wire & Cable: Lockdown, war and logistic woes

IWMA Members exhibit at wire Düsseldorf

Well, we’re back, and I couldn’t be more excited.

It’s my first wire Düsseldorf as IWMA chairman, and that of course makes it an event of great interest to me personally. But more than that I’m looking forward to being back in the show halls again, seeing friends and colleagues, members and future members alike!

Look out for me as you go round the stands; I’ll be here, there and everywhere for the whole of the five days and to be honest, I don’t think I’ll be on the IWMA all stand that much – there will be so much to catch up on and so many people to get reacquainted with! So, if you don’t catch me in the halls, visit the IWMA stand and leave a message and I’ll certainly get back to you.

The whole industry missed out on a lot when wire Düsseldorf was cancelled in 2020, and especially so the IWMA, since we were due to mark our 50th anniversary and launch bright new branding.

But that’s in the past; we’re here now and you will be able to see the rebrand and the new-look, open-aspect stand when you come and say hello. As well as me, there will be our past chairman, current directors and other senior IWMA figures to talk to, answer your questions and learn why the IWMA is a great organisation for any wire and cable industry company to be involved with.

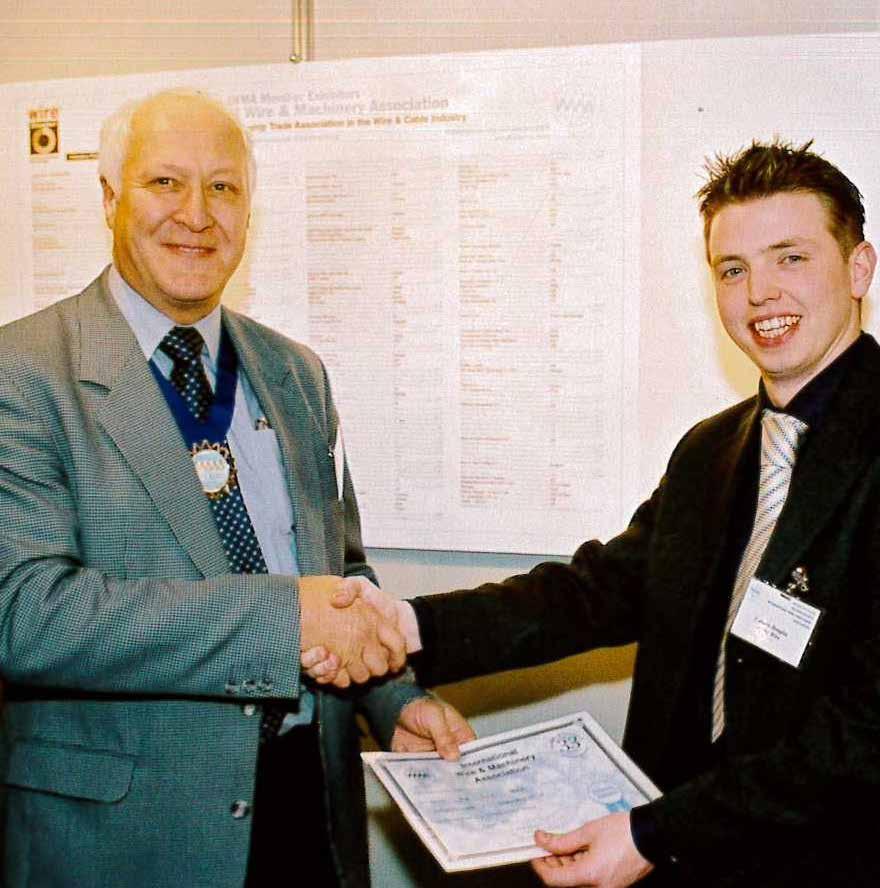

One of my great pleasures during this year’s show will also be to look after the seven young industry newcomers who have received this year’s IWMA Education Awards (previously called the IWMA travel awards).

We have renamed the awards to give them a more general function. They are used to pay for a group of industry newcomers to attend the show, take some industry tours, talk to wire and cable veterans and prominent figures and generally find out why the industry is one of the more amazing career choices they can make.

I’ll be introducing them round, and I’m excited about that too. They are the future, so there can’t be a better use of their time – and mine – than talking to their peers and looking at various aspects of the industry they have joined at the biggest show in the world.

Are you excited about it too?

My very best wishes to you all

Don Neville Chairman, IWMA

09 IWMA Members state of play

35 Connecting Expertise – IWMA Members sign partnership contract!

37 Farewell to Paul Wright

11 Q8Oils at Wire & Tube 2022

13 Step into Maillefer’s Circle at wire 2022

26 New investments by Untel Kablo ensures cable quality

34 New regulations ahead… switch to BORAX FREE lubricants with Condat!

36 UL Construction Product Safety Services for CE and UKCA Marks Help Companies Maintain Post-BREXIT Market Access

04 IWMA at wire Düsseldorf 2022

38 Dates for the 2022/2023 wire Exhibitions

39 IWMA confident of Southeast Asia wire success

Features

CRU Review –Metallic Wire & Cable: Lockdown, war, and logistic woes 05

Global insulated metallic wire and cable demand recovered strongly last year and we expect this momentum to continue in 2022, albeit at a slower rate of growth…

IWMA Welcome New Chairman 07

Don Neville was named chairman of the International Wire and Machinery Association at its Annual General Meeting on February 9. He knows only too well the challenges both his chairmanship and the wider organisation face during his three-year tenure…

Exhibit at wire Düsseldorf 2022 09–34

Find stories from our members exhibiting at wire Düsseldorf here

If you are among the IWMA members en route to wire Düsseldorf, we can’t wait to see you in person again on our stand in Hall 11 D22.

The IWMA’s bright new stand – designed in our new branding that we had hoped to reveal for our 50th anniversary at the 2020 show – can help you with on stand hospitality, Wi-Fi internet access, charging points, cloakroom services, and general business services as usual, and we have a Germanspeaking interpreter, if you need one.

Unfortunately, due to the Covid regulations we have had to say goodbye to our Gala for this show but are very much looking forward to hosting two networking stand parties on Tuesday 20th and Wednesday 21st June from 6pm – 9pm. Each of these networking events will be a great opportunity for us to meet with members and members to meet with each other to discuss the show, take advantage of our on-stand hospitality and have a great evening reconnecting with friends and colleagues we may not have seen for nearly 3 years.

Also new for 2022 is our meeting “pods” – four areas on the stand, each of which offers up to six people an informal meeting space. These are free for member companies to use for up to an hour each day, with a small charge for meetings of over an hour.

“The charge for longer meetings is simply to maintain turnover,” explained IWMA executive manager Andy Lewis. “We think the pod spaces will be very useful; they offer a degree of privacy and unlike the previous single room, several meetings can go on at

once. Previously we sometimes had two or three people in the room, which meant we couldn’t accommodate any other group. This way we are far more useful to far more members.”

The organisation’s usefulness to members also extends beyond meeting spaces this year. With coronavirus preventing the attendance of member-companies from countries with travel limitations, the IWMA will be playing host to representatives from several members who will using our stand as their base.

“We may be a little down on member-exhibitors overall, simply because not everyone is able to attend. It’s a pity because this wire Düsseldorf looks like being one of the most exciting for some time. That’s why we are making a special effort for nonexhibiting companies,” said Andy.

“We are expecting more visitors than ever from non-exhibiting members, and we’ll be helping non-attendees to get as much out of the five days as possible. The stand will be well staffed by our chairman, former chairmen and directors, as well as myself and our Marketing Manager, who will be able to help answer questions from visitors – and encourage potential new members.

“It’s more important than ever this year that people who can’t be in Düsseldorf don’t lose out,” said Andy. “We are extremely keen to help where we can. We hope we have risen to the challenge.”

Global insulated metallic wire and cable demand recovered strongly last year and we expect this momentum to continue in 2022, albeit at a slower rate of growth. Cable consumption is expected to grow by 3-4% y/y this year, reaching almost 20 Mt conductors – well above pre-pandemic levels. The total wire and cable market value is forecast to rise by more than 10% y/y in 2022, after a remarkable 39% y/y rise in 2021. This rise in value terms is largely driven by higher commodity prices arising from global uncertainty surrounding metal supply due to international sanctions against Russia, the looming threat of energy insecurity and the subsequent impacts on smelting and manufacturing.

Most major market pessimism such as Chinese residential construction weakness, continued lockdowns in major hubs such as Shanghai and the Russian-Ukrainian War have already been accounted for in CRU’s overall 2022 forecast. In this edition, the largest downgrades for this year have been driven by a weaker than anticipated cable market in North East Asia, specifically Japan. Japanese cable consumption in telecom, power and construction sectors all suffered a contraction in 2021, while machinery, appliances, and automobile’s strong growth were only just able to offset this with the country’s overall cable market growth of 1% in 2021. We have subsequently lowered Japan’s 2021-2026 cable demand by more than 150 kt conductors.

For 2022, the outlook for China has remained largely unchanged. The negativity surrounding the outlook for the residential construction sector remains and the current supply chain shocks resulting from continued Covid-19 lockdowns are expected to be offset by a strong rebound in 2022 H2, similar to the market strength experienced in late 2020. 2021 Q4 saw overall Chinese GDP drop to 4.0% y/y on the back of full-year results of 8.1% y/y, evidence of the country’s slowing economic momentum.

In the mid-term, LVE, power cable and winding wire have all seen upgrades as major markets such as North America, China and key European nations continue to execute on national housing and construction targets, major infrastructure and utility upgrades as well as ensuring security of energy supply through increasingly ambitious energy projects.

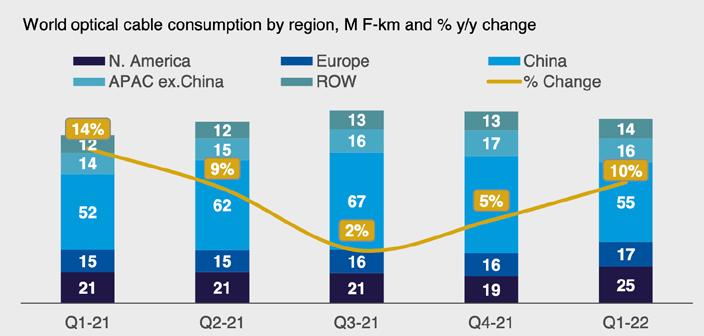

The global optical fibre and cable market largely maintained its upward momentum in early 2022. Cable consumption grew by almost 10% y/y in Q1, surpassing 126M F-km. This is greater than 2017 Q1, the previous Q1 peak demand on record. North America contributed the most year-on-year net increase in terms of absolute cable volume (almost 4M F-km), and remains as the fastest growing region (+19% y/y). Though the tightness on fibre and cable supply, and the increased cost of FTTH deployment, could begin to constrain future demand.

Despite lockdowns and logistical challenges in China, cable deployment by major operators has largely not been impacted. The country’s cable consumption has grown by 6% y/y in Q1 and we maintain our view for a 6-7% y/y growth for the whole year. In Europe, domestic bare fibre spot prices increased noticeably off the back of reduced fibre availability and rising raw materials prices. This is despite of some early indications of demand wanning in France, the Netherlands, Italy and the Nordic countries. We have also further downgraded near-term Eastern European cable demand as a result of the war in Ukraine.

Elsewhere, India has been slightly underperforming as BharaNetrelated deployments are yet again facing delays. However, optical cable demand in ASEAN and Latin America markets remains healthy. This is supported by their respective national FTTH expansion programmes.

Raw material price hikes, tight supply for helium gas, SiCl4 and HDPE, coupled with logistical issues, have once again pushed up fibre and cable prices. CRU understands producers are facing growing resistance from their customers to accept further price increases. Please contact CRU for our latest view on global G652.D bare fibre spot prices.

In terms of other market developments, the UK launched both an anti-dumping and anti-subsidy investigation into imports of optical cables from China in late-April. India has also opened an anti-dumping investigation into bare fibre imports originating from China, Indonesia and South Korea in early-May.

8 -10 June 2020

CRU brings its global gathering of cable makers and thought-leaders to London for the first time in its history

Great reasons to attend CRU Wire & Cable 2020

Hear from global wire and cable manufacturers and other industry thought leaders sharing their strategies visions and market views

Gain first-hand insights into emerging market opportunities and regional perspectives on changing trade dynamics from industry experts

Hear from CRU analysts on the outlook for the global markets in 2020 and beyond to help inform your business decisions

Understand the impact on the wire and cable supply chain of power, communication, construction and automotive industry developments

Gain technical insights on the latest wire and cable products and raw materials

Get involved in strategic discussions with an influential audience of senior industry executives to help inform your business decisions

Secure valuable new business contacts and meet with senior decision-makers from across the sector

Meet with leading innovators and experts looking to build partnerships; and improve energy and communication network deployment

Andrew Shaw, Managing Director, Ducab

Don Neville

Don Neville, managing director of RichardsApex Europe Ltd, the UK subsidiary of RichardsApex Inc., USA – was named chairman of the International Wire and Machinery Association at its Annual General Meeting on February 9. He knows only too well the challenges both his chairmanship and the wider organisation face during his three-year tenure. We asked him what he sees as his main tasks in the coming months.

American-born Don Neville (67) has been in the wire and cable industry since 1990, and takes up the position of IWMA chairman from popular leader Martin van der Zwan, who in the face of the pandemic agreed to stay at the helm for a fourth year, to give the association greater continuity.

“I know I speak for the entire membership in thanking Martin for his commitment and dedication to the association during these extremely frustrating times,” said Don. “He saw us through our 50th anniversary and rebrand – sadly without the celebration we had planned for the ultimatelycancelled Wire Düsseldorf in 2020.

“But the lack of fanfare in no way diminished the significance of our milestone anniversary, nor the contribution Martin has made as chairman. He will now be joining our advisory committee of past chairmen, and I know his continuing contribution will be of enormous value to us all.”

As a senior member of IWMA’s management team, Don is well aware his own chairmanship will have challenges: “We reckon it might be as many as three to four years before we get back to pre-Covid funding levels, for example,” he explained.

But he also recognises that the reverse is true: the devastation – “it’s not too strong a word” – of the past two years also presents opportunities to give IWMA new impetus and benefit for its international membership.

“All organisations begin to get set in their ways the longer they are around,” Don suggested. “There aren’t many associations like IWMA that have been around for 50 years – so if nothing else, the pandemic has given us a chance to shake things up. Few organisations in this field have our breadth, expertise and international reach – we have members on just about every continent.”

The pandemic, he says, has helped IWMA’s board think about what the association does and in which direction it should be heading.

“New things have already come out of Covid,” he added. “Leaner work practices, new ways of working, online meetings and so on. As an organisation we have always been highly flexible, so the pandemic gave us the chance to implement, relatively easily, online technologies that weren’t around even a decade ago to everyone’s benefit. We all now mostly prefer to talk online from wherever we are in the world than spend days on planes for something that might last a fairly short time. It makes meetings more inclusive too, allowing members a voice who wouldn’t before have considered making the trip.”

Exhibitions are a different matter, he adds. “There is really no online substitute for Messe Düsseldorf’s international shows – we’re all missing them a lot. Hopefully wire Düsseldorf will go ahead this year and things will get back to a state closer to normality in the coming year.”

The new chairman also sees the length of his tenure as an opportunity: “If you’re a politician, or even a CEO, you might work across a year or so at a time, and there’s little chance to do much more than keep things running smoothly. Over three years you get the chance to consider ideas longer-term: even if you don’t get the opportunity to complete them all, you can build foundations that will propel the organisation for years to come.”

In which areas does Don believe IWMA can build for the future?

“Education, certainly,” he says without pause. “I had an interesting conversation with a CEO recently who was lamenting the difficulty in finding new hires with even an inkling of how a machine might work, let alone a specific production process. Most company bosses are desperate to provide continuity within the industry, so where do we go for our newcomers, and how do we train them?

“It’s not as if you can go – as far as I’m aware – to a specific school or university to study the intricacies of cable-making, for example. There’s nothing that will take a youngster from the fundamentals of what a machine is and does, to the mind-boggling science behind the work of some of the world’s brightest engineers.

“I am very keen to see in what ways IWMA can help to maintain our members’ breadth of expertise and pay it forward to recruits – perhaps even encourage the brightest newcomers to consider wire and cable first. As an industry we need to find innovative ways to improve the way people are helped and trained,” he said.

“One way will be for IWMA to further expand its education and training role, for which, with the right content and industry-wide accreditations, funding may be available. Members have asked for this: they want to know where they will get the next generation of operators, process supervisors and other specialists, and we think as an association we should try to preserve the vast amount of specialist knowledge member companies have in their ranks. It won’t be a wholesale move into education, but it will mean identifying opportunities with members for ways to improve skills development within their organisations”.

The other major rock on which IWMA’s immediate future will be built, Don suggests, is that of communication.

“In the past, networking has been a central part of our activities,” he admitted. “At exhibitions and conferences we have talked to each other, but not necessarily to members in other industries, or indeed to the public at large. Our members are involved in some of the most amazing projects on the planet and it should be part of our role as an association to speak up for them.

“I’m really looking forward to talking to our members from around the world about what they need and what we can do to help them be more successful. At 50 years old, we don’t want to be perceived as an anachronism; quite the opposite. We have half a century of wide industry experience and a body of knowledge among members that defines us as both modern and truly expert.

“We have some of the world’s leading companies in their field among our members, and within those companies are some truly iconic names of the manufacturing, design and engineering world. Some of our members are pushing back the boundaries in green energy and sustainable manufacturing, for example; as an association we should be a knowledge, information and media hub for members, drawing the world’s attention to their achievements.”

As he suggested, one thing Don can’t wait to see return is the annual run of wire and cable exhibitions. The pandemic has shown that not every conversation has to be with everyone together in a room but, he suggests, communication at exhibitions is one thing that can’t be supplanted by an online presence.

“Messe and its partners have introduced more shows around the world in recent years for a very good reason: they expand business like nothing else,” he explained. “For most of us, exhibitions can’t return quickly enough; there’s a huge pent-up demand. “To help our smaller, newer member companies attend these shows and understand how valuable and useful they can be, we already offer them business and hospitality services on the IWMA stand. We will be exploring ways to expand and enhance that support in the future.”

As Don spends his first few weeks as chairman, he sees an IWMA continuing to evolve and developing new, more innovative ways to stay in touch with its members.

“We want to give even greater value and benefit for the fairly modest membership fees,” he said. “When I look back on the next three years I want it to be on an IWMA that has become more aware of its members’ needs and is more responsive and supportive towards them and the industries we all serve, and that our diverse global membership continues to thrive.”

We asked members for their thoughts on the current state of the wire and cable industry – and the responses show some companies thriving, post-pandemic, while other factors are now often causing even bigger problems.

IWMA members are working through some of the most volatile market conditions of the past decade, with some companies holding record orders, others barely able to fulfil and deliver goods, and raw materials increasingly difficult to source and obtain.

Though from the outside, the wire and cable industry appears buoyant, the deeper picture is of wild fluctuations, between those companies sitting on full order books and others scrabbling for cover.

The war in Ukraine has added to the drain of the pandemic, and the total effect on trade is still being worked out. But sanctions, higher import duties and the search for alternative sources of raw materials is already having serious effects in some sectors.

Instability is the biggest factor. Some members have been able to double the value of their order books thanks to surging demand, while some have lost a huge part of their business through the direct effect of the war. Some companies are in a very difficult position: Russia could be their biggest market, but due to sanctions or because of the morals of doing that business, they are not accepting orders. One IWMA member company received a £1million order from Russia on the day of the invasion, and had to walk away from it that same day. Others have seen their global sales halved because the bulk of their trade was with Russia or Ukraine. A lot of members’ sales territories have disappeared in a few weeks, forcing them to completely refocus on what they sell, and where.

The repercussions of the pandemic have been seen in raw materials shortages and greatly-fluctuating delivery times and transport costs. The soaring price of energy is another red flag to the industry, whose processes often use large amounts of power.

One British IWMA member related signing a pre-pandemic contract for energy at £0.06 a kilowatt, and is now looking at renewing at a 600 per cent increase. Prices have been dropping, but the fall often isn’t being passed to consumers. After surviving the pandemic and Brexit, some believe the energy crisis could be the final straw for some companies.

There is currently a boom in cable manufacture for EV automobiles and charging station infrastructure, but many cable companies find themselves unable to accommodate demand. One cable-making member could potentially have doubled its 2020-21 turnover, but while demand has increased, capacity hasn’t been able to follow as quickly.

Members report order backlogs because they can’t get the raw materials to fulfil demand, and when they can, transport companies – particularly to the UK – can’t guarantee capacity to deliver it. For goods outwards, deliverers can rarely quote prices and delivery pick-ups the few weeks ahead that manufacturers might require, because they don’t know if trucks will be available that far ahead. Orders are delayed by many months because of these pressures, and while the contract price usually remains the same, the cost of fulfilling the contract rises every week –and not by small increments.

Supply chains are a major problem. One example of the Russian effect on the supply chain is a simple material like plywood, used by several companies to make such things as cable reels. Russia supplied almost 50,000 containers of plywood a year, but that has largely dried up, and that which does make its way to Britain suffers a 35per cent import duty. Makers are now getting supplies from China, and the Chinese product can be very good – or simply not good enough to support the weight of the heavy cable wound on it. Cable makers can’t be completely sure and often find out the hard way. One IWMA member has even written to cable manufacturers to ask them to consider other materials, because of the looming crisis in wooden reel manufacture. Ukraine adds a second a problem in this regard: the country supplied 40 per cent of EU demand for some steel products, and currently that demand isn’t being supplied.

The constant instability in raw pricing is a massive problem for many IWMA member companies. Many members are buying what they can – virtually at any price – to allow them to carry on working. The market for many wire and cable products is steady and even improving, but members can’t predict with certainty where the raw materials will come from.

“As members with common interests, we simply have to reach out to each other to help where we can,” suggested IWMA chairman, Don Neville. “None of us know if the good time some of us might be enjoying at the moment will still be that way next month.”

Security of supply, unrivalled lead times and technical expertise will be just three of the major talking points when the UK’s leading manufacturer of round, flat and profile wire takes its largest ever presence (Stand 11 E26) at wire 2022 between 20th and 24th June.

Alloy Wire International (AWI) is returning to Düsseldorf for the first time since Covid-19 and is expecting to target spring, semiconductor and fasteners manufacturers involved in automotive, aerospace, electronics and the booming oil and gas sector.

The company, which has recently invested more than £500,000 into a new warehouse extension in the UK, will take ten staff over to Germany as it looks to reinforce its reputation as a hub of technical knowledge for clients and suppliers.

This will be reinforced by sales representatives covering more than 13 individual territories, reflecting the truly global nature of Wire 2022.

Mark Venables, Managing Director at AWI, commented: “This event has been a long time coming and will be a fantastic showcase for everyone connected with the wire industry.

“With all the uncertainty caused by the pandemic, our customers are really looking for security of supply and that involves knowing there is the right volume and variety of material available and that we can still deliver within our expected short lead times”

He continued: “Every decision we made during Covid-19 was taken to ensure we continued to give the same level of

manufacturing quality and reliable delivery, and this has paid off with the start of this year turning out to be our busiest yet, something we hope to build on at Wire 2022.

“Our biggest ever stand will have display cases with sample round, flat and shaped wire alongside a video screen showing behind-the-scenes manufacturing processes of wire being produced in our factory in the UK.”

Alloy Wire International will also use the industry’s largest show to introduce INCONEL: 617®, a nickel-chromium-cobaltmolybdenum-aluminium alloy.

This is its latest addition to a 60+ range of alloys and delivers a combination of increased strength and stability at elevated temperatures (up to 1100°C/2012°F), whilst retaining the high temperature resistance of INCONEL® alloy 601.

Mark concluded: “When the new warehouse is complete, we will have more than 400 tonnes of stock in place at any one time and that should give our global customer base significant confidence in our ability to deliver what they need, when they need it.

“Our technical team has also been busy at work in the research of nickel alloy wire for additive manufacturing and a number of other exciting R&D projects we hope to discuss in more detail at Wire 2022.”

For further information, please visit www.alloywire.com or follow @alloywire on twitter.

Visit Q8Oils at stand 11 D21 at wire & Tube 2022 to discuss its many products and service-led initiatives available for the worldwide wire, tube and cable market.

Q8Oils’ innovative wire & tube, drawing & rolling lubricants together with technical solutions are specifically developed to reduce manufacturing cost, increase productivity and provide the safest working environment for the customer with technology that exceeds the highest legislation.

Q8Oils is a major European developer, manufacturer and supplier of a comprehensive range of lubricants for the worldwide metal industry, in all applications from drawing, rolling, forming, removal and protection.

The specialist range is for the metal manufacturing processes of copper, brass, phosphor bronze, beryllium copper, aluminium, aluminium alloy, plated metals, precious metals, nickel chrome and stainless steel.

With its strong brand, Q8Oils is committed to the worldwide wire and tube market with sales of specialised lubricants to customers in over 90 countries worldwide from the Americas to Asia via Q8Oils staff and a network of agents and distributors.

• Complementing the existing PRIAMUS, WIROL and ALUDRA ranges are new wire drawing lubricants which utilise the latest additive technology to provide enhanced lubrication, meeting all of the latest worldwide environmental legislation. Hence not only do they reduce the user manufacturing cost but are very safe in use. The new Germ-Allcard WIROL 2200 is already proven in drawing applications to the finest quality wire with finishing sizes of 0.007mm, seven microns, AWG 61.

• Germ-Allcard PRIAMUS emulsions for the drawing of aluminium and aluminium alloys.

• Tube forming and protective products for all welded tube applications in steel, stainless and galvanised.

These product lines complement the existing successful and widely sold product range for the drawing and rolling of copper and aluminium alloys as well as the extensive Q8Oils Metal Manufacturing product range and services. Supporting the customer with QCare service led initiatives including technical and application support, factory visits, product analysis, seminar training programs, equipment, system design advice and Q8Oils Engineers Guides, which are endorsed by the Health and Safety Executive.

With decades of lubricant expertise, Q8Oils is in the unique position to share knowledge and industry insights with its customers. On the newly developed Q8Oils website you can find a variety of interesting articles on a broad range of topics. This is the place to be if you want to increase your technical knowledge or keep up with the latest evolutions in lubricants and their applications.

Stuart Duff, Business Development Manager for Metal Manufacturing of Q8Oils, having over 37 years’ experience in the wire & tube industry has had many published technical papers. Recent publications include wire drawing productivity and emulsions for aluminium drawing, where Q8Oils is a leading supplier with water soluble products for aluminium rod and wire drawing.

For further information on Q8Oils products for the wire, tube and cable industries then contact Q8Oils at wire@Q8Oils.com and please make an appointment to visit us at our exhibition stand 11 D21.

On the 20th of June, 2022 Windak Group will be exhibiting at Wire 2022, taking place in Düsseldorf, Germany, at the stand 10F37.

This will be a very long-awaited exhibition for our company, as it has already been postponed several times due to the pandemic.

“Communicating with other business owners gives us a great opportunity to broaden our business perspective and exchange contact information, thus enabling the growth of our brand message and leading to partnerships”, says Olga Berlinberg, Marketing Manager of Windak Group.

Windak offers standard and customized automatic spooling, coiling and rewinding lines with a variety of different options.

This year we would like to focus on the theme of “Packaging” and demonstrate to our customers the various packaging options for wires and cables that can be produced on our equipment.

We continuously update our designs and services to improve performance.

Successful manufacturers getting future-ready by applying intelligence along three dimensions: efficiencies, experiences, and innovation. We inform you about all new software and mechanical updates, the latest know-how as well as the latest technical Industry 4.0 implementations.

The company’s core business is to provide its customers with high speed innovative automated cable packaging equipment to help them achieve their business goals, improve their returns and reduce costs.

Windak team is looking forward to your visit! Tradeshow info olga.berlinberg@ windakgroup.com

Wolco Ltd. celebrates its 30th anniversary in 2022. It is an excellent opportunity to sum up the company’s activities and set goals for the next years. At the moment, we are a leading producer of fine wires with a low-carbon steel core coated with other metals in Poland. Today our products are present in over 20 markets around the world, starting from EU countries and ending with North America.

Our main product is the welding wire for collated nails. Together with the wires supplied to the lighting and cable industries, they are the core of our business.

In 2019, we opened the Research and Development Center, which deals with the improvement of our current products, but what is more, it allows us to develop new products that have not been available on the market so far. It is equipped with the most modern testing devices, such as the X-RAY spectrometer for testing the applied coatings.

Our mission is to provide our clients the best value for money.

We hope that participation in Wire 2022 (for the third time as an exhibitor) will help us to set the above-mentioned goals.

You will want to be present at the most important industry event happening in Düsseldorf, Germany, from June 20 to 24, 2022. Everyone who is anyone in the cable industry will be there. We are keeping with the biennial tradition of inviting our customers and visitors to Maillefer stand 10 / C22, where they will be greeted with innovation, exciting technology, smart solutions, and, most importantly, a competent and welcoming face. Discover how just another four years’ worth of progress and developments are changing our industry.

A showcase of products will surround the Smart Circle, which is at the heart of the Maillefer stand. Leading technologies are integrated into our lines and components. Get to experience Smart Buffering, Roundness Optimization, Defect Detection, Preventive Maintenance, Sim Factory, Web NCC Curing Calculation, and more within the Smart Circle. With its neural networks and predictive models captured from real industry environments, artificial intelligence is thrusting production performance and product quality forward while ensuring that you stay well in control of the demanding extrusion process.

Two complete lines will be visible on our stand – a fiber optic secondary coating line and an imposing high-voltage CCV line. Curiously, they both fit on just a few square meters! Thanks to virtual reality and some powerful rendering, we are able to take visitors on an exploratory tour that reveals the winning designs and inner workings of the two lines.

Maillefer Smart Monitoring will be at work during the show, taking a variety of data from the stand, then crunching, compiling, correlating, and consolidating it into an informative display of the Smart Factory. Its remarkable flexibility makes it a

decisive tool for successful factory operation that adapts easily and evolves rapidly to individual needs.

Exemplary production sites around the globe are pushing the limits of wire & cable manufacturing. We are proudly listing more than a dozen of them as industry references. Learn about each of their successes and how Maillefer gets involved with practical solutions, know-how, and services.

For those who need to get their hands around real steel components, we will have lots of them on the stand. The exhibits include topography scanning of energy cable surfaces, new dual take-up for telecom wire, a choice of crossheads and extruders for low-voltage and fiber optic cables, a tape folding system, and more.

Much has happened over the past couple of years. Sustainability has taken a strong hold on our product designs and caused us to look closer at how we operate as a leading provider in the industry. Here too, we are excited to highlight the advantages our solutions provide in answering customer concerns regarding sustainability. Longer lengths, less scrap, optimum material consumption, tight tolerances, longer run times, equipment durability, and extended lifecycles through services and upgrades are immediate answers that Maillefer provides to today’s customers.

Our multinational team is eager to welcome you to our freshly looking stand. We are joined by colleagues from Davis-Standard, as well as agents and representatives from around the world. Step into Messe Düsseldorf’s hall 10 stand C22 during the fastapproaching five-day event; because being there is everything.

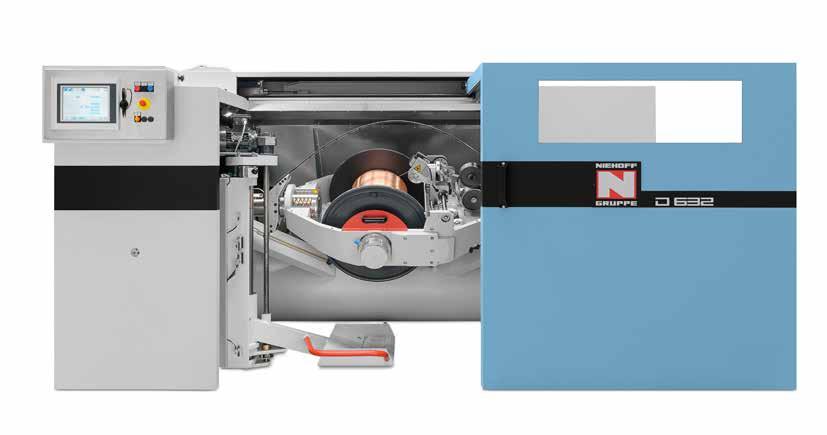

Maschinenfabrik Niehoff will show at the wire 2022 trade fair at booth 10C06:

- a multiwire drawing line type MMH 112 + RM 202 + S 632,

- a BMV 16 type rotary braiding machine with integrated BAS 800 take-up and pay-off unit, and

- a D 632 type double twist bunching machine with ARP 630 pay off.

The MMH 112 + RM 202 + S 632 type line embodies a new generation of multiwire drawing lines for more energy savings and higher production speeds.

The BMV 16 type braider is connected with digitizing technologies enabling a considerable increase of rotational speed, material savings and quality improvement.

The D 632 type double twist buncher with new functions is able to produce hard copper-alloy strands e.g. CuSn0.3 with up to 7,000 tpm. The BMV 16 and the D 632 will be operational and can be demonstrated with wire.

Furthermore, visitors will learn how they can benefit from Niehoff’s after-sales-service, from machinery upgrading possibilities and from Niehoff’s digitization concept with the web application myNIEHOFF, formerly known as Niehoff Digital Assistant+.

Niehoff machines are characterized by an outstanding good energy efficiency. This means that during their operation the users can save considerable energy costs. In view of dramatically rising energy prices, this is a major competitive advantage. Furthermore, all Niehoff machines are designed to ensure sustainability, longevity and an economical consumption of materials. Tolerance specifications can be fully exploited.

British company PWM (Pressure Welding Machines) Ltd will exhibit its full range of high-performance cold welders, including the best-selling EP500 rod welder, at wire 2022 (stand 9B41). Visitors will also be able to see demonstrations of PWM’s P1500 machine, for material up to 30mm (1.181”).

Sales of the pneumatically-powered EP500 more than doubled during 2021. Popular with manufacturers looking for energyefficient equipment to support green production initiatives, the EP500 can be connected to a central air supply or a dedicated compressor. Electrical power is only required for the operating system. No set up is required and the EP500, for rod 5mm to 15mm (.197” to .590”), is low maintenance, reliable, user-friendly and safe.

The larger P1500 machine is equally energy-efficient. It is driven by three hydraulic pumps and only requires electrical power for the 11Kw pump motor.

Also on show will be PWM’s lightweight hand-held manual machines for fine wire 0.10mm to 1.20mm (.0039” to .047”) and a range of manual and powered models for wire 0.30mm to 6.50mm (.0118” to .256”) that can be used on a workbench or supplied with a cart.

The company’s precision-engineered products are designed and made in-house and tested to ensure total accuracy. PWM manufactures industry-standard cold welding dies and can produce custom-made dies for specific applications.

The IWMA board is saddened to report the death of Ian Forster (78) of Altrincham, Cheshire UK, a former director of Leigh Cables and MD of IMF & B Ltd and Fine Wires Ltd.

Ian Michael Forster was born in November 1944, the youngest of three children. As a young adult he joined British Gas and met his wife Beverley, whom he married in 1971. The couple had two daughters, Jeanette (1976) and Lyndsey (1979).

Ian later worked for Nuclear Power, and from there moved to BICC as a purchasing manager. The move to the cable industry was a turning point, and he went on to start his own business, Performance Materials, supplying BICC and employing some former BICC staff – and his eldest daughter.

Ian started a second company, Fine Wires Ltd, and threw much of his energy into making it a success. Though his family thought he might never retire, in 2012 a routine medical check revealed a kidney problem that in 2015 resulted in Jeanette donating one of hers. He closed the business, allocating contracts and staff to other companies, but still continued to work a couple of days a week, as well as doing other small jobs to keep busy – his personal motto “Get on with it!” – coming heavily into play.

Ian’s health deteriorated further during the pandemic, the onset of mobility problems resulting in falls, hospital stays and increasingly serious infections, to which he finally succumbed.

“Dad was always there for us and was a kind and generous man,” said Jeanette.

“Since his death we have discovered just how generous he was to everyone who came into his orbit.”

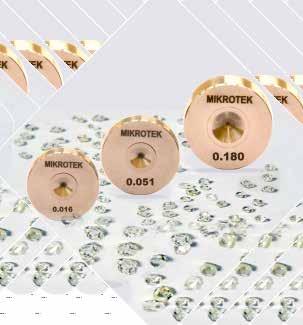

ONE STOP SHOP ONE STOP SHOP FOR DIE SHOPS FOR DIE SHOPS

N a t u r a l D i a m o n d D i e s

P C D D i e s

M o n o D i a m o n d D i e s

S o l i d E n a m e l l i n g D i e s

T C T a p e r i n s e r t s & Tc D i e s

D i e P o l i s h i n g E q u i p m e n t

D i e S h o p C o n s u m a b l e s

Ask for Free Evaluation samples

We are marked for our Quality and Quick Deliveries For More Details

Headquartered in Kyoto, Japan, Kyocera is a world leader for manufacturing of fine ceramic components for the technology industry. Kyocera has been developing advanced materials, focusing on fine ceramics technology, for over 60 years. Kyocera now provides over 200 kinds of ceramic materials including oxide, non-oxide and some special composites, with cutting edge technology and services designed to meet the individual needs. We possess internationally recognized know-how in the field of high-performance ceramics, especially for ceramic-to-metal assemblies.

Kyocera supplies the most diverse industries and customers throughout the world with high-performance fine ceramics, ranging from very precise components to complex shaped parts of various sizes and dimensions for challenging applications. With our production and development location in Germany, Kyocera is able to respond quickly to the growing market demand for fine ceramic components in Europe even more. Kyocera companies benefit from the group’s cross-departmental

way of thinking and working that goes beyond different industries and countries - ensuring maximum reliability for our customers.

The technology of machines and systems for wire drawing has been proven and reliable for over 50 years. In this wellestablished system Kyocera stands out by offering high-quality products, that can help reducing wear and optimizing production steps. With decades of experience, KYOCERA Fineceramics Precision GmbH achieves outstanding product quality. Furthermore, Kyocera supports its partners in all questions concerning the wire drawing process. Our employees are always happy to provide their customers with competent advice, whether it is the use of lubricants, the correct draft, assistance if wire breaks occur or if there is excessive wear on the ceramic parts. Thanks to their excellent networking in the industry and their comprehensive knowledge, our experts can quickly help you with all questions concerning the wire drawing process.

Supermac Industries India supplies a variety of extrusion lines for Power – HV and LV Cables (including CCV lines), Automotive and telecom cable segment . Supermac is the largest supplier of CCV Line in India since 2005.

In its endeavour to continuously improve and with strong R&D efforts, it is now fully geared up to offer Cat 5, 6 and 7 , Data cable , FTTH drop cable, Fluoropolymer products -FEP, PTFE etc and Silicone lines with an Infra-red vulcanization system.

5G is shaping the future of communication and will even push fibre optics all the way to homes. Worldwide demand of FTTH cables is on the rise. Supermac offer a high speed FTTH optical fibre line which is a masterpiece of Supermac product portfolio. The line is equipped with very high precision tension control devices, which runs in a complete closed loop system. The special design extruder offers the perfect extrusion and provides the online diameter control, capacitance monitoring system. There are various combinations e.g. Tandem, Co extrusion or Single Extrusion, with incorporation of many types of fillers, yarns and on line corrugation facility.

Supermac offers state of the art high speed tandem line for data cable manufacturing. The tandem Extrusion machine for LAN Cables intakes the solid copper and draws and anneals it on line before putting it through the extrusion process. The special design extruder design and cross head gives the high eccentricity. The line has an online diameter control, capacitance monitoring system on wire. The line is equipped with high speed dual take up for continuous production.

To meet FEP/PTFE cable requirements for military applications, aerospace and aircraft equipment, OEM and Nuclear power products, Supermac offers specially designed high speed extrusion lines for FEP/PTFE. Fluoropolymers are among the most corrosive materials for processing in standard extrusion systems. The screw and barrel are specially designed and special material is used to take care of highly corrosion-resistant materials during extrusion. Custom-designed screws meet the differing processing temperatures of FEP.

Supermac is also heavily focusing on medical equipment extrusion lines in global markets. Supermac, provide innovative solutions not only for the equipment but also thrust a lot on the automation and exceeding the needs of the customer in terms of higher productivity and lesser operational cost. Supermac offers quality products and offer new technologies and costeffective solutions.

Supermac Industries in its endeavour to conform to Industry 4.0 norms has taken strong strides forward in implementing several digital initiatives, especially with regard to Industry Internet of Things or IIoT, which plays a key role in enhancing the areas like Process Optimization, Quality Control, Cross-vendor Shop Floor Integration, Energy Efficiency Predictive Maintenance, Data Security. We have been able to implement such initiatives in wire and cable industry successfully and looking forward to collaborate with our existing and future customer base and scale up on this initiative.

Worldwide there is a strong focus on safety. For its customers who are in need of equipment required for making fire alarm and high temperature Silicone cables, Supermac can offer a complete end to end solution.

Company Description

Established in 1962, Ajex & Turner is a technology-driven company. The company manufactures range of solutions such as Diamond wire drawing dies, Diamond tools for Fastener , Automobile, wooden, tool room industries. In 1976, the company partnered with Dee Beers, England, The outcome of the associaon was Diamond Tools with the technical support from Dee Beers. Then in 1982, the company forayed into diamond wire drawing die industries with technical support from Mr. David Turner, Chairman, Turner & Sto Limited, UK.

Following the legacy in 1998, Mr. Ravi Bansal, Son of Mr. J.S. Gupta, on boarded the company and received his training from Hoosier Ajax, USA.

Main Areas of Company Activity

In 2000, the company acquired a few financially struggling companies including – Johnson Metals & Dies, Adelfi, TDDP dies which were pioneers in manufacturing wire dies in Europe and USA. Consequently, all the American as well as European producons lines were installed in the Ajex Plant with new and improved technology and abilies. Today Ajex & Turner exports globally all products.

Product Range of the Company

Ajex & Turner has been consistently providing a complete range of tooling, machineries, and accessories for various industries including the wire and cable industry. We manufacture , PCD, natural diamond, trapezoidal shape dies, extrusion tools, Diamond Tools, Cross Heads, Spiral brush, Sector Rollers , Automac Polishing & Grinding machines and Lubricants for Copper, aluminium and Steel industries

New Development

In 2011, the company had started manufacturing VNT Nano dies (Vetrified Nano Technology) and become the only company in the world to manufacture VNT dies for so and hard wires. These dies find extensive applicaons in bunching, compacng, stranding dies made for copper as well as aluminium 50mm to 2000 sqmm and which ensures savings of both energy and metal of around 3-4%. The VNT nano dies acts as an excellent replacement of PCD Dies which are less expensive than PCD. However, VNT Nano Dies are cost-efficient and scratch free for low carbon wire, CO2, and stainless steel wires, thereby being the suitable alternaves to replace PCD Dies.

New Development – Extrusion Tips & Dies

In 2010 Ajex & Turner procures Swiss Technology for manufacturing extrusion tools tips and dies. Ajex & Turner extrusion tips and dies are used in the manufacturing of power cables, control cables, telecommunications, optical fibre, speaker cables, etc. The extrusion tips and dies are being manufactured as per customer specification, with very high quality, in Hardened Steel, PCD and TC insert

In 2015 Ajex & Turner Developed in house Lubricants for Copper & Aluminium Wire Drawing. Masterlube Lubricants are very cost effective & efficient quality.

Our company is equipped with all kinds of technologicallyadvanced manufacturing testing equipments in wire drawing dies and our workforce consists of professionals. With time, Ajex & Turner has established close technological communication with all major and well-known domestic and foreign manufacturers of the wire and cable industry.

The global industrial cables market is expected to witness significant growth over the forecast period owing to high capital spending and investments in industries worldwide. Raw material prices coupled with rapid industrialization is expected to drive the market growth over the forecast period. In recent times, several developing economies have witnessed rapid infrastructure development, which has further spurred the market growth. Additionally, increasing energy demand and utilization in emerging markets such as Asia Pacific is also projected to fuel market growth. Increasing electricity consumption paired with the consequent need to expand the distribution network may fuel the demand for the industrial cables industry.

Government interest in the power sector is estimated to primarily drive the industrial cables market growth over the coming years. The market is poised for growth owing to strengthening of regional transmission networks paired with increasing electricity demand. Surging demand across the electric power industry in Asia Pacific. Data communication, rail transit, automobiles, and shipbuilding industries are also expected to catapult market growth.

Manufacturers are expected to adopt strategies to counter the competition and survive in the market which primarily includes mergers and acquisitions .

The demand for wires and cables has been exponential in the past few years. The expansion in the power sector and the revamping of power transmission lines across the country has been providing a sharp impetus to the growth of the industry. Moreover, telecom-related initiatives along with rising number of data centres have been a major driver of the growth in the optical fiber cable segment. As far as my foresight about the wire and cable dies market is concerned, the demand in these various segments in addition to rising investments in the same, are going to be conducive for the growth of Dies and tools for wires and cables , accordingly we at Ajex are also expanding our Production facility with fully automatic machines.

•RHEOLOGICAL AND THERMAL BEHAVIOUR CALCULATION

It solves the processing issues by locating the root cause, improves the extrusion line performances, and reduces the time-to-market while dealing with a new project.

•LARGE-SIZED EXTRUSION HEADS

For the extrusion of off-shore pipes, HV cables, cables up to 300mm.

•SPECIALIZED EXTRUSION HEADS

For special applications such as fiber optic cables, flat cables, fluoropolymers, technopolymers, and so on.

For over 3 decades we have been producing extrusion tooling, extrusion heads and related accessories for companies specialized in the production of electric cables, pipes and manufacturers of extrusion lines.

Eurotek extrusion heads are designed for all types of extrusion processes, and each one of them can be customized.

We manufacture a wide choice of multiple ranges of standard and customized extrusion tooling for any kind of application along with spare parts for extrusion heads, AirWipes and Precision Cutters.

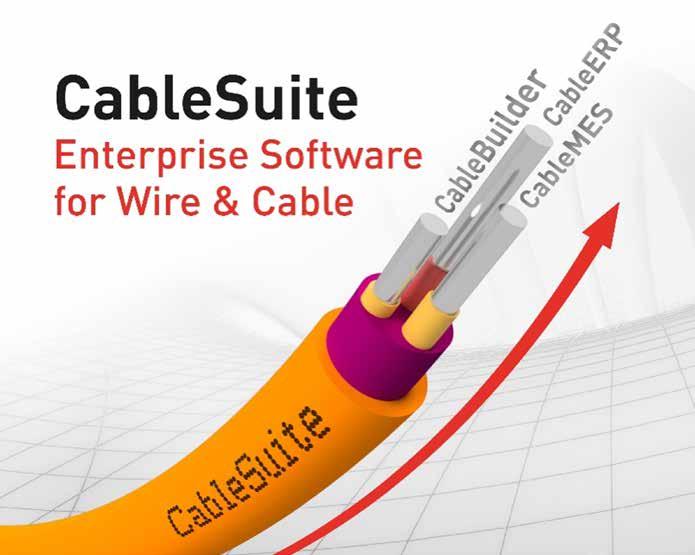

InnoVites CableERP is an ERP software, exclusively developed for the wire & cable industry. Starting in 2007 InnoVites has continuously enhanced CableERP, based on the Microsoft Dynamics technology.

CableERP brings the best practices of the industry to our customers, leveraging our in-depth knowledge of the business issues in the wire and cable industry and the innovative Microsoft technology.

Features

The CableERP software is a comprehensive cloud-based ERP solution built on top of Microsoft Dynamics 365 for Finance and Operations (D365FO). InnoVites adds industry specific functionality to this world-class enterprise platform:

• Capturing detailed cable requirements of the customer, like lengths, length tolerances, drums, put-ups to maximize customer satisfaction

• Material price module, to manage Comex/LME pricing and minimize risk of price volatility

• Length optimization in cutting, planning and production to minimize material costs

• Full traceability of lengths and drums

• Full integration in CableSuite to provide our customers the benefit of an integrated business solution covering all business functions in the company

As a Microsoft Dynamics partner, InnoVites is the global competence center for the wire&cable industry. We always work with local partners close to our customers. This gives our customers the best of two worlds: a local partner for optimal support and industry specialists that understand the unique business challenges in the wire&cable industry.

We look forward to meeting you at our booth at the Wire Düsseldorf: 11C16! Alternatively, contact us anytime if you are interested in a demonstration of our software solutions.

Cimteq looks forward to welcoming manufacturers from across the industry on their stand at the forthcoming Wire Düsseldorf event between 20 – 24 June 22.

Speaking about the event, Amanda Shehab, Director at Cimteq, said: “Wire Düsseldorf is an important event on the wire and cable manufacturing calendar. With the long break in face to face events, we are certain that this year’s show will be better than ever. I will line up alongside expert members of the Cimteq team to showcase the unrivalled software programmes we offer to help manufacturers maximise productivity and profitability.

“We welcome the opportunity to meet with existing and prospective customers and would like to invite anyone interested in securing a meeting with us to email info@cimteq.com.”

Powered by state-of-the-art technology, Cimteq’s innovative software and support services: Cablebuilder Enterprise, CableMES and ERP integration enable manufacturers across the globe to be more profitable through the streamlining of business and manufacturing processes.

Using the latest Industrial Internet of Things (IIoT) to optimise cable manufacturing operations, Cimteq can work with companies of all sizes, from small, single-plant manufacturers to multi-plant global entities.

Cimteq’s innovative software solutions, designed specifically for the global wire and cable manufacturing industry, are live in over 250 plants across 44 different counties.

Visitors to Wire Düsseldorf are already securing meetings with Cimteq to view demonstrations of all products. So don’t miss out on the opportunity to book your appointment.

Cimteq will also be officially launching a partnership with AESA Cortaillod at the event. Both companies will be able to showcase how Cimteq’s CableBuilder Enterprise and AESA’s quality management software, CIQ, can bring added benefits to manufacturers when working in unison.

Visit Cimteq – Hall 11 / D15

“What’s new?” - This will probably be the most frequently asked question IDEAL-Werk will receive from its booth visitors at “Wire 2022”. As in every year of the exhibition, IDEAL-Werk will present the answer to this question in form of two different exhibition machines.

As a small preview for this year, the GAM_816 as a classic machine for the industrial sector and the CSR_102 as an NC jig welding machine for individual wire products will be presented and shown comprehensively at the “Wire 2022”.

In today’s modern times, the quality of products usually takes quality over quantity.

In order to achieve full customer experience and satisfaction, both areas are addressed and innovations are divided into solutions for both: more quantity and more quality. IDEAL-Werk achieves this by drawing on years of experience and customer satisfaction to keep its finger on the pulse.

With the new GAM_816, IDEAL-Werk has succeeded in developing a new cross wire magazine with over 200 strokes.

Furthermore, the machine has a penetration depth control. This item controls the quality of every single cross weld and increases the quality assurance.

The NC jig welding machine for individual wire products is predestined for free and stepless use. The machine offers unlimited flexibility and great advantages in templating. To push this advantages in the future, all welding presses will be NC-driven and individually controllable.

In order not to lose sight of the important aspect of sustainability, IDEAL-Werk is moving away from pneumatic steering to electrically powered steering in our machines.

This energy requirement is taken from renewable resources.

After a long “Corona forced break” IDEAL-Werk is looking forward to get in touch again in person at the “Wire 2022” and to have interesting discussions with all customers and visitors about these and many other topics.

TapeFormers LTD will be exhibiting their full range of TapeFormers, Model H Plus to replace the Model I which has been discontinued, its 200cm long with a curved entrance and Model A Profile E2 double wrap TapeFormers. Our dedicated TapeFormer brochure will be available from our stand. Directors/Engineers Robert (Bob) and Ashley will be attending Wire 2022 and available to discuss any upcoming projects / product developments or if you have any questions on our products, they will be more the happy to answer them. TapeFormers LTD is based in the Midlands – United Kingdom – on receipt of your order our skilled and experienced team will manufacture your order to your specific requirements we do not hold any stock of TapeFormers.

Madem Reels Group the leading wooden cable reels supplier in the world.Madem Group with headquarters in Brazil has forests, sawmill and manufacturing plants in Brazil, Spain, Bahrain, USA , Mexico and Colombia with more than 700 employees and produces 450 containers/trucks of knock down reels per month supplying 150 cable plants in 45 countries.

Today the Madem name represents over 70 years of industry experience. The Madem team constantly strives to build trust and confidence by offering customers a superior quality product.

http://www.mademreels.com/en/

Ambrell, a leading manufacturer of induction heating solutions, will be exhibiting at Wire Düsseldorf. At the event, an Ambrell EASYHEAT induction heating system will be on-display for induction demonstrations. Additionally, an expert applications engineer will be available to discuss attendee heating applications. Visitors are encouraged to bring parts and/or drawings to the stand.

RichardsApex, a leading global manufacturer of wet lubricants for the ferrous, nonferrous and alloy wire and tube industries will be displaying the latest technology in Hall 9 Stand 9F06-05. From wiredrawing, tube drawing and hot-rolling applications, RichardsApex Inc., provides semi-synthetic, full synthetic and straight oil form compounds for wet drawing of nonferrous and ferrous wire as well as protective coatings, cleaners, corrosion inhibitors for all nonferrous and ferrous alloys for both wire and tube applications. Its core products can be made at all of our manufacturing locations in the U.S., Europe, Australia, Mexico. With our rich history, RichardsApex has an established global sales network to service customers throughout the world, including on-site support and technical sales assistance. The company has subsidiaries located in both the U.K. (RichardsApex Europe) and in Australia (RichardsApex AustralAsia), and representatives in Canada, China, Greece, India, Italy, Japan, Korea, Malaysia, Mexico, Peru, Poland, Russia, Taiwan, Thailand, Turkey, Venezuela and Vietnam, with many other countries serviced by the subsidiaries and representatives. Please stop by and see how partnering with RichardsApex can help your company achieve your goals for production and cost savings. www.richardsapex.com.

Induction is a rapid, non-contact, precise and efficient method of heating. It’s also a greener option and part of many electrification initiatives where companies switch from gas flame and oven heating methods. Induction offers instant heating, so there’s no ramp up time, and there’s no open flame making for a safer working environment.

The technology is used for an array of heating applications, including the preheating, post heating and annealing of wire. Ambrell offers complimentary parts testing and has sold over 17,000 systems into more than 50 countries. Systems are available ranging from 500 W to 1,000 kW. To learn more you’ll find Ambrell in hall 11, stand C15 or visit www.ambrell.com.

Mathiasen Machinery will be displaying photos of a wide variety of new and secondhand wire and cable manufacturing machinery. The NEW machinery is offered on behalf of WiCa GmbH in Austria, makers of twisting and extruding equipment and Pratto S.A. in Greece, makers of Mesh Welding Machinery. Secondhand machines are bought and sold internationally.

Do you have any surplus machinery for sale? MMI has interest in locating individual machines, complete lines or entire plants. They also offer consignments, warehousing, rebuilding, appraisals and liquidation services. Serving the domestic and international Ferrous and Non-ferrous wire machinery markets for 40 years. Customers are asked to bring their surplus machinery list and photos for evaluation.

For over 30 years METALUBE has delivered high performance products that have optimised production on the latest wire drawing machinery.

At WIRE 2022, METALUBE will highlight next generation advanced wire drawing lubricants, including full synthetic technology, and bring together their team of highly trained development chemists, engineers and industry experts from around the world. METALUBE’s latest synthetic range of lubricants are helping customers achieve environmental targets, whilst also optimizing quality and performance for their wire production.

Visit METALUBE at Hall 11, stand G21 to learn how METALUBE can help you. www.metalube.co.uk

UPCAST® casting process produces top quality Cu rod and cast tube for various applications. It is a simple, reliable and cost-effective process with easy operation through an advanced control system. UPCAST® process allows you to cast different rod sizes simultaneously and both production output and product mix can be easily adjusted according to the daily market demands. Also, its optimized energy consumption minimizes the production costs at the end.

UPCAST® lines are well suited for various materials, main applications being pure OF-copper and copper-based alloys as well as other non-ferrous metals.

Now that automotive industry is going more and more electric and also the need for high-speed trains is growing, UPCAST® can offer the technology to produce high-quality rod for these growing sectors.

UPCAST OY has been the leading innovator in using recycled material, which is, as we all understand, more and more important in today´s environment.

The lines are available for a wide capacity range in single-, double- and triple-furnace configurations. Triple-furnace configurations offer advanced solutions for the handling of recycled material.

UPCAST® lines can be customized to match the needs of each specific customer.

Customer Service Team is ready to assist and deliver to you original UPCAST® spare parts and consumables as well as answering your requests for any matter requiring service or instructions.

We are at your service via email or on the phone or on site if required – continuously!

YOU ARE WELCOME TO VISIS US at wire & Tube Düsseldorf to discuss the solution for your needs - Stand No. 9C06 / wire and No. 6A01 / Tube

o Online quality control of cables to increase quality, efficiency and sustainability

o Future oriented X-ray measuring technique ensures maximum material savings

o Premiere: extremely fast tension measurement of optical fibers with the FIBER TENSION 6003

o Interactive exchange in the “Solution Corner” – customer visions for a measuring technology of the future

At wire 2022 in Düsseldorf, from June 20-24, 2022, SIKORA presents a broad portfolio of future-oriented measuring and control systems for an efficient and sustainable quality control for the wire and cable, optical fiber and plastics industries.

Numerous intelligent technologies, for example, for online measurement of wall thickness, eccentricity and diameter of cables, confirm SIKORA’s claim to develop and provide innovative and sustainable measuring solutions for the global cable market. For almost five decades, SIKORA measuring systems have contributed to quality control and a simultaneous reduction of plastic material during cable production. This saves costs and contributes to a sustainable production. Up to 5 million tons of carbon dioxide are saved annually by using SIKORA measuring devices.

At wire, visitors can experience the performance of the measuring devices during extensive product demonstrations. One highlight is the X-ray measuring system X-RAY 6000 PRO that is used for the measurement of wall thickness,

eccentricity, the diameter and ovality of cables with up to three different material layers, for example in insulating and jacketing lines. As a pioneer in X-ray measuring technology for cable extrusion, SIKORA has been setting trends for 30 years. The combination of the X-RAY 6000 PRO with the processor system ECOCONTROL 6000 allows for an automatic control of the wall thickness. By reducing the wall thickness by, for instance, 5 %, not only raw material consumption is reduced, but plastic material savings in the six-figure range are also achieved.

The quality of a cable starts with the pureness of the raw material. Thus, SIKORA also offers online and offline inspection, sorting and analysis systems for plastic pellets. By using inspection and sorting systems, contamination can be detected and automatically sorted out, breakdowns eliminated and material costs saved. Besides economic advantages, the environment can be preserved at the same time due to less waste.

With the premiere of the FIBER TENSION 6003, SIKORA widens its product family for quality control of optical fibers. The gauge head offers an extremely fast, reliable and precise tension measurement and control. Due to the high measuring rate of up to 10 kHz and the application of the birefringence principle, the stand-alone gauge head is particularly attractive for manufacturers of high-end solutions. The FIBER TENSION 6003 is predestined for optical fibers that are further processed into premium optical fiber cables. The FIBER TENSION 6003 can be used for hot as well as cold measurement of the bare fiber.

Maintaining the availability and efficiency of the SIKORA systems at the customer’s site is SIKORA’s top priority. At wire, the SIKORA service team presents the entire range of its service portfolio. From installation and commissioning of the devices to consulting and training, always fitting to the individual customer requirements.

X_RAY_6000_PRO

The X-ray measuring system X-RAY 6000 PRO ensures precise measuring and control of the cable dimensions for more cost efficiency and sustainability.

Turning ideas into innovations and product developments that achieve the highest quality, sustainability and cost effectiveness in the wire and cable as well as plastic industry is SIKORA’s claim. The company emphasizes this at wire with the “Solution Corner”. Customers are invited to personally discuss with SIKORA experts their ideas, visions and technical requirements on the systems for quality control for the future of measuring technology in a creative atmosphere. SIKORA’s presence at the wire 2022 promises pure quality, innovation and sustainability.

The new FIBER TENSION 6003 measures the tension of optical fibers in the drawing tower.

Our world has faced severe global issues during the past few years, namely the Covid-19 pandemic, political crisis, trade wars, and international wars, all of which have affected supply chains. Due to recent geopolitical and trade issues, some companies have moved their supply chain activities out of China and now from Russia. These are all very challenging aspects of the current situation the world finds itself. On the other hand, it has created advantages for some countries and companies, too.

It won’t be wrong to say that the cable industry has been doing well across the World. Many cable manufacturers are satisfied with increasing demand, and reputable Turkish cable manufacturer Üntel Kablo, which has celebrated its 50th anniversary in 2022, is no exception, by delivering a solid financial position during challenging times, and resulting in the company committing some critical investments in its cable facilities, machinery, staff, crucial certifications and quality standards.

Üntel, which has operations in Kocaeli, northwest of Turkey, has years of experience in manufacturing rubber and special cables since its foundation 50 years ago. Since moving to its new facility in 2010, it has kept solid and continued investment in machinery and new technologies.

To increase its production and capacity, Üntel is planning to construct the second phase of its cable manufacturing plant, once all the necessary planning permissions are approved.

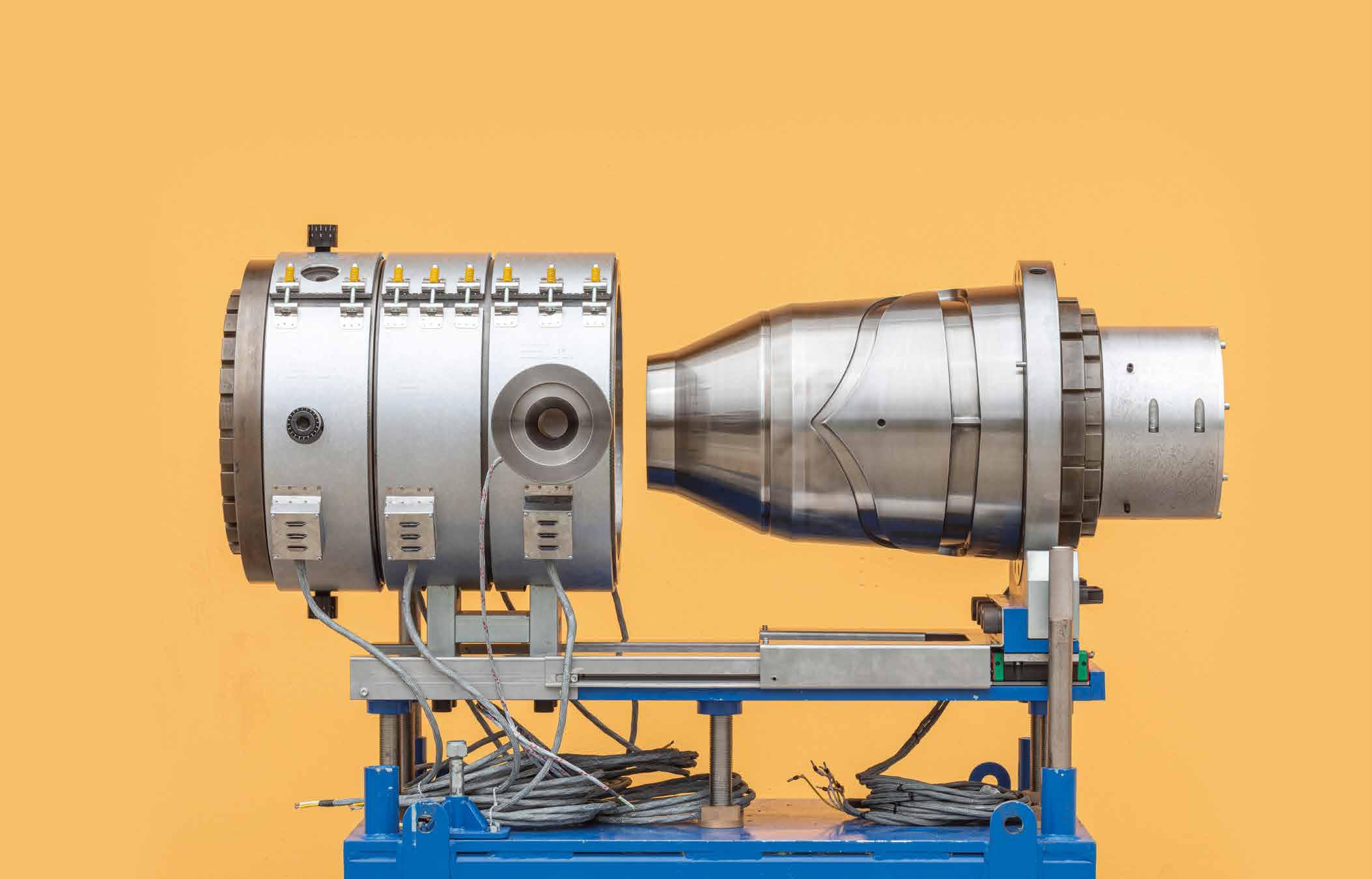

Moreover, during the summer of 2022, the company plans to add a new CCV line for rubber cables and twisting machines & bunchers to help increase demand and shorten lead times for its partners and end-users – all good news for the industry.

The cable manufacturing plant equipment and expansions are all acquired from global leading cable machinery manufacturers to uphold its end cable product quality. Furthermore, to ensure cable quality, the company has developed its team with quality staff in its plants and service departments – to build on its already respected reputation amongst its partners from various industries, globally.

The new machineries will manufacture new product groups, which build on Üntel’s recent investment in its new R&D facility and team, who are working hard to develop and enter new global vertical markets through vigorous research, testing and quality. The continued investment in certification and type approvals from leading certification and standards bodies ensures peace of mind from its partners and end-users.

Üntel is a registered and preferred supplier of many of the world’s leading companies. It exports cables to over 80 countries on 6 continents, with 60% of its manufacturing dedicated to these markets, bosting over 250 International Certificates for its 15,000 strong cable product range. The company has also achieved ISO Turkey’s Top 500 Industrial Enterprises last year for the first time in its history to rank higher in 2022.

St Helens, UK

Design & Manufacture of Offshore

Steel Drums, Cradles & Lifting Beams

Leigh, UK

Wood & Plywood Reels

Plastic & ABS Process Reels

Pentre gear up for a future increase in electrification.

A new electrically powered age will take years to play out however Pentre is well positioned to serve accelerated developments in all sectors of the Wire & Cable industry.

2021 has been an intense year, full of new developments such as s t r e n

Engineering Division and a planned phase of capital investment for all three of Pentre's sites. New plant and upgrading to more energy efficient equipment and further development of 3D Modelling, SAP software and storage facilities. Total spend in the year to 31st March 2022 of £1 million pounds.

Founded in 1988 by Mike Seymour (the business is currently owned by its second generation) now employs 175 people on 3 manufacturing sites, two in the North West of England and since the year 2000 one in the Czech Republic.

Pentre Group has a 30 year history of operating in Europe and the USA with its principal Sales Offices in Greater Manchester U.K., Copenhagen, Denmark, Saalfeld, Germany and Atlanta, USA.

Despite the trend to online sales we still believe in face to face factory visits to gain a better understanding of customer needs. We are now confident to resume these & look forward to welcoming customers to Wire 2022 in Dusseldorf this June at Hall 9 Stand E25.

Rakovnik, Czech Republic

Steel Reels & Drums

Key Personnel

Mike Seymour

Director and Founder

Richard Johnstone

Director & General Manager

Wood & Plywood reels

Plastic & ABS Process Reels

Craig Currie

Technical Sales Manager

ABS & Steel Reels

Teddy Crockwell

Technical Manager Offshore Engineering

Lucie Dražilová

Commercial Manager

Pentre Kovo Czech Republic

Hans Vielmuth

Sales Manager

Germany & Eastern Europe

Thomas Gørrissen

Sales Manager

Scandinavia & Netherlands

Operating on the cable market since 1981, Gurfil has established itself as a reliable supplier of Braiding and Taping machines, as well as a cable raw materials manufacturer. Exporting 75% of the goods manufactured by the company, Gurfl presents its products to the international markets in more than 35 countries. In order to keep up to date with industry trends and developments Gurfil attaches great importance to a participation in major exhibitions that cannot be missed. After all, any exhibition is like a mirror: it reflects the trends and prospects of the industry.

As Gurfil over the years we are proud to be one of the exhibitors within the leading international trade fair for wire and cable production. After the pandemic-related break in 2020, Wire will finally open its doors in Messe Düsseldorf in June 2022. By using this platform Gurfil finally has a possibility to introduce booth visitors its last solutions, discuss cooperation opportunities and exchange ideas in person with decision makers in the industry. Gurfil as a member of IWMA, official sponsor of Wire Düsseldorf is proud to serve its customers throughout the world with Foil – Film – Tape products together with Machinery, offering commissioning, after-sales technical service and all spare parts from its warehouse with professional service team. Gurfil products are divided into three main groups:

1) Machinery group including: High Speed Vertical Braiding Machines and Mica Taping Machines in various modifications; Accessories and spare parts.

2) Foil, Film and Tape Group : flexable raw materials such as ALU/PET, ALU/PVC, ALU/PET/SY, CU/PET. Cu/PET/ SY laminates, Polyester film, Pure Copper tape, Mica Tape, Foamed PP Tape , Kraft Paper & Crepe Paper , PP Identification Tape , Fiberglass Tape , Semi Conductive Tape & Swellable Tape , Non Conductive Polyester Non-Woven Tape , Rip Cord Yarn, fiberglass Yarn, Waterblocking (Swellable) Yarn;

3) Wire Group including, Aluminum Alloy Wire (0.12 mm, 0.16 mm), CCA and CCS, Skin-Foam-Skin 3 Layer Physical Foamed Conductors

Based on over 40 years of experience and our own research results, we introduce equipment and technologies for the cable industry, supplying not just machines and raw materials, but developing complex technological solutions designed to satisfy all the production needs of our customers’ cable production.

FIB BELGIUM is a world leader in supplying heat-processing lines such as patenting, galvanizing, oil tempering and annealing lines, bell and pit furnaces for cold heading quality and batch annealing wires but is also a supplier in the framework of hot dip galvanizing plants for pieces.

Since 1936 FIB BELGIUM has designed the finest technology, employing automation for its equipment to reduce operating costs as well as using a modular concept that allows for adaptation of further upgrades while minimizing the investment costs.

Our teams having faced new challenges related to energy transition, water savings, limitation of CO2 emissions, more friendly Human Machine interface, safety for the operators, compactness, remote support and diagnosis, those thematics have been especially worked in the design of our lines and equipment.

Microdia S.A. Switzerland. Hall 11, Booth D25

For more than 40 years Microdia has designed and supplied high quality tooling and cross heads for the wire & cable industry and precision tubes manufacturer.

Microdia’s precision cross heads program comprising manual center, fixed center and MFLEX, fixed center with manual fine centering will be presented, along with fully operational “bleed out”, “cross flow” quick color change cross modules and skinfoam-skin + stripe cross head with 3 or 4 extruders. Single, double or triple layer cross heads application ranges from medical tube, precision pneumatic tubes, optical fiber buffering, micro-coaxial, automotive wires, flat cable, fluoropolymer insulated wires and more.