Greetings! wire Düsseldorf is now far behind us and that means the next-biggest shows, in China and India, are quickly approaching. So, once again I’m writing in hot anticipation of what promises to be two top-class, heavily attended exhibitions.

In fact, even more so this year, because the Shanghai (this month) and Mumbai (in November) exhibitions are likely to be the biggest-ever for both nations, just as April’s wire Düsseldorf was for Europe.

From IWMA’s point of view, both will offer great opportunities for members to show what they can do. One is our new member presentation opportunities on the IWMA stand, from which members can expand on their respective companies’ businesses and products to a wider audience; while the other is the IWMA Pavilion – a first for wire India, which is allowing several member companies to exhibit there for the first time offering extensive support, stand-building assistance, personalised hospitality services and flexibility in stand creation and customisation. The whole package! You can find details about both of these opportunities elsewhere in Insider or on the website but act quickly because spaces are limited.

As well as the business aspect of the exhibitions, we will be restoring our ultrapopular exhibition networking events, on the second evening of each show. IWMA networking events have always been fun gettogethers that give a flavour of the country being visited, encourage networking among like-minded businesses, and allow members to relax among friends. The rise of Zoom and Teams might have worked wonders for travel budgets in the last few years, but they also gave personal interactions – still the life blood of business – a distance these networking events aim to resolve, if only for a couple of nights!

China’s event will be a terrific night-time cruise on the Huangpu River (and book quickly; it sold out rapidly when we last offered it, in 2018), that will offer great local cuisine with a chance to see the stunning Shanghai skyline at night. Our India event will be Colours of the World, more details on

this will be released early October but we are looking forward to joining forces with Mikrotek Machines and Niehoff India once again to put on this fantastic event.

Just before wire India, IWMA will enjoy its revived annual dinner-dance, on Friday 15th November in London – the first for five years. Join us at the luxurious Leonardo Royal Hotel for an evening of wonderful food, elegance, and celebration at one of IWMA’s most popular annual events. Tickets are selling fast, and we have secured a block of rooms at the hotel for a preferential rate for those of you who would like to stay over. Check the website for full details: just be assured it’s the social event of our year!

After that and India we look forward –though for me that might not be quite the right word – to March and our AGM, where after three years I will be handing over the chairmanship of our great organisation to my friend and colleague, Willibert Dautzenberg, who is joint-CEO of Acoteq, the automation, manufacturing and consulting company founded in 2016 by Willibert and Gabriela Queins, daughter of Hans Georg Queins, founder of the manufacturing company of that name.

Willibert has had wide experience in the machinery industry since 1993, as a controls designer, commissioning engineer and, before starting Acoteq, as a senior member and then managing director of Queins.

I’ve had a great time as chairman over the past three years, even though the early part of my tenure was, shall we say, unexpectedly attenuated by forces beyond our control. But we have still achieved good things. some of which I hope to reflect on in the next issue of Insider.

The dynamic pairing of new chairman Willibert and President Bernd Lohmüller gives us our first German team at the top and is the reason why this AGM and the following Industry Lunch will for the first time be held in Germany. This puts our leaders at the centre of the European industry, backed by a strong group of IWMA senior management ready to build on what we have achieved

and advance the cause of our ever-growing association.

What’s coming, of course, might be a little tougher than we expected, given the surge of wire and cable demand since 2021. With America and China, and to a lesser extent Europe, embroiled in a trade war of sorts, imports and exports will be taking on a new level of complication in some countries. Let’s hope politics and protectionism don’t get in the way of good business sense...

Finally, IWMA continues to grow to meet the needs of its members, and to that end we have welcomed Natasha Salmon, who joins us as Marketing and Events Assistant. It’s her first job since graduating from university with a first-class honours’ degree, and we have no doubt she will be a great asset to the team.

And the business of IWMA continues: the next event on the schedule, this month, is a meeting of our executive management committee, with a further meeting in November. At these we will continue to steer the association forward with new initiatives, exhibition plans and events to ensure the IWMA voice remains a force for change and development within the industry.

Like me, you should continue to watch this space…

My very best wishes to you all

Don Neville Chairman, IWMA

Excitement Builds for the IWMA’s First Industry Lunch in Germany, Coming in 2025! Save the date: Wednesday 12th March 2025. Prepare to be part of an exciting and unforgettable event.

We are delighted to announce the IWMA’s much-anticipated Industry Lunch, set to take place in Germany on Wednesday 12th March 2025. For the first time ever, this event is being hosted in Düsseldorf, marking a significant milestone in our 54-year history; as the home of the world’s leading international trade fair for our industry, the city is already a familiar location to many of us, and as we await the specific venue announcement, the anticipation continues to build!

The day will begin with the IWMA Annual General Meeting, which all members are very welcome to attend free of charge. The AGM will provide a platform for reflection on the past year’s achievements, as well as setting the stage for the future under new leadership, as we witness the formal handover from outgoing Chairman, Don Neville, to our new Chairman, Willibert Dautzenberg.

The lunch itself promises to be a memorable experience, as always. After catching up with friends and reconnecting with industry peers at an informal drinks reception, we will enjoy a three-course meal with excellent food and wine. Speeches will be delivered by Don Neville, who will reflect on his tenure as IWMA Chairman before passing the role to our first-ever German Chairman, Willibert Dautzenberg. Bernd Lohmüller, IWMA President, will also share his vision for the

future as part of the dynamic German duo now leading our association.

Finally, a highlight of the day will be the announcement of the Young Employee of the Year 2025. This coveted accolade recognises the brightest young talents in their fields and offers you the opportunity to showcase the rising stars of your organisation.

We would like to invite all member companies to nominate their outstanding young professionals when applications open on 10th October, and we look forward to finding out who you expect to be the future leaders of our industry.

Tickets for the Industry Lunch will also go on sale on 10th October, and given the buzz surrounding the event, we anticipate high demand. So, book early to secure your place and join us in Düsseldorf for a day of celebration, networking, discussion and forward-thinking!

Leonardo Royal Hotel London St Paul’s, London, Friday 15th November.

Don’t miss your last chance to secure a spot at the most anticipated event of the year! The IWMA Dinner Dance, a tradition that began in Stratford-upon-Avon in 1975, is making its grand return in a brand-new area of London for 2024, and you don’t want to miss it!

Join us at the luxurious Leonardo Royal Hotel London St Paul’s on Friday, 15th

November, for an evening of celebration. Tickets include welcome drinks, a delicious four-course dinner, and a selection of wines. After dinner, enjoy after-dinner drinks and live entertainment by a dynamic band as we dance the night away in style!

For those who wish to extend the celebration, IWMA has arranged a block booking of hotel rooms at a special rate. Guests can enjoy a seamless transition from the evening’s festivities to a restful overnight stay at the Leonardo Royal Hotel London St Paul’s.

This is a historic occasion that promises to be a highlight of the industry calendar. Get ready to be part of the grand ‘Return’ of the IWMA Dinner Dance!

We look forward to celebrating with you!

Tickets are limited and selling fast! Further details, including ticket bookings and hotel accommodation, can be found by visiting iwma.org/events or contacting events@iwma.org

Building on the success and positive feedback from our pavilion at wire Southeast Asia, IWMA is thrilled to announce the global expansion of the IWMA Pavilion concept.

This initiative will extend to wire satellite exhibitions around the world, enhancing visibility and networking opportunities for our members on a global stage. The IWMA Pavilion aims to become a cornerstone for collaboration and innovation within the wire and cable industry, offering a dedicated space for members to showcase their products, share expertise, and connect with industry leaders and innovators from diverse markets.

At our pavilions, we offer members a variety of booth sizes, including 9sqm, 12sqm, 15sqm, and 18sqm, designed to suit different needs and preferences with several stand customisations available. We aim to make your exhibition experience seamless by providing a dedicated stand build team that guides you through every step, from the application form to build-up day. Our IWMA team will be on hand to support you throughout the exhibition, ensuring

you can focus on what matters mostconnecting with industry peers and showcasing your innovations.

In 2025, IWMA pavilions will be featured at wire Mexico, wire Eurasia and wire Southeast Asia. Applications for wire Mexico are already open, while applications for wire Eurasia will open very soon. Early in 2025, we will also launch our Southeast Asia Pavilion. These exhibitions will not only serve as prime venues for showcasing your products but also as dynamic networking opportunities. We will host exclusive networking events at these exhibitions, offering a significant benefit to members participating in the pavilion. Exhibitions are crucial for the wire and cable industry, providing unmatched opportunities to connect with industry leaders, discover new technologies, and establish your brand on a global stage. wire exhibitions are renowned as the best in the field, offering unparalleled opportunities for growth and innovation.

As part of our pavilion services, you will benefit from being included in our marketing campaign leading up to the exhibitions, and we offer free graphic design assistance to help you enhance your booth’s visual appeal. Additionally, we can assist with room reservations at our preferred

hotels near the exhibition venues, allowing you to take advantage of our block bookings and transportation to and from the exhibition hall. While these services are chargeable, they are designed to make your exhibition experience as smooth and stress-free as possible.

Exhibitors will also benefit from personalised hospitality services throughout the exhibition and complimentary Wi-Fi to ensure they stay connected. Moreover, a guaranteed spot in IWMA member seminars offers a prestigious platform for showcasing your expertise.

Our strategic support aims to enhance your exhibition impact and solidify your industry position, promising a highly beneficial experience. We are thrilled to support our members as we introduce our pavilion at wire India for the first time this November, from the 27th to the 29th. Stay tuned for more updates on the launch of our wire Eurasia pavilion, along with details of future pavilion locations and dates!

For further information on pricing, our IWMA premium stand and build package, or to discuss your requirements, please email Jessica at jessica@iwma.org

Founded in 1951 by Henry Carris in Rutland, Vermont, Carris Reels has grown from a small operation into a multimillion-dollar business. Known for its commitment to operational excellence, the company thrived under Henry’s leadership until his retirement in 1980. His son, Bill Carris, expanded the business through strategic start-ups, acquisitions, and geographic outreach.

In 1995, Bill initiated the transition to an Employee Stock Ownership Plan (ESOP), culminating in full employee ownership by 2008. Under subsequent leaders like Mike Curran and Dave Ferraro, Carris Reels continued its growth trajectory, acquiring J. Hamelin Industries in 2015 and Lone Star Reel in 2016.

As of 2021, Alberto Aguilar, who joined Carris in 2000, serves as President & CEO, aiming for continued improvement and operational excellence. Carris Reels remains a testament to its founding principles of longevity, dependability, accomplishment, and teamwork.

www.carris.com

Founded in 1968, KEI Industries began as a partnership focused on producing rubber cables for house wiring. Over the decades, it has evolved into a global powerhouse in the wire and cable industry. Today, KEI provides comprehensive wire and cable solutions, serving clients in over 55 countries through a network of more than 30,000 channel partners.

With a strong workforce of 5,385 employees, KEI is headquartered in New Delhi, supported by 38 branch offices and 23 warehouses nationwide. KEI’s product range includes Extra-High Voltage (EHV), Medium Voltage (MV), and Low Voltage (LV) power cables, catering to both retail and institutional markets, and making significant strides in the Engineering, Procurement, and Construction (EPC) services industry.

As an industry leader in India and a preferred supplier globally, KEI offers end-to-end solutions tailored to diverse client needs across Retail, Institutional, and Export segments. Listed on major stock exchanges including the BSE, NSE, and Luxembourg Stock Exchange, KEI continues to drive innovation and growth, expanding its capabilities and manufacturing facilities to meet the demands of power utility, infrastructure, industrial, and construction projects. With over five decades of passion and dedication, KEI remains a catalyst for power and progress.

www.kei-ind.com

Sipcon Technologies Pvt Ltd, established in 1974, is a leader in the wire and cable industry, recognised for its innovative cable measurement devices. By 2008, the company achieved $1 million in revenue, solidifying its market position. Today, Sipcon exports to 25 countries, underscoring its global reach and expertise.

The company specialises in advanced cable measurement devices for insulation thickness, sample preparation, and material testing. Sipcon’s commitment to innovation and quality is evident in its portfolio, with 7 patents secured for its products. Their technology significantly reduces material costs while ensuring 100% fail-safe cables. Sipcon’s product range includes precision cable slicers for materials like XLPE and PVC, and a state-of-the-art chipping device for delicate materials, maintaining the integrity of insulation thickness measurement.

Sipcon also offers comprehensive testing apparatus for quality assurance, including microscopes, ovens, and devices for tensile strength and deformation testing. Additionally, Sipcon has expanded into the steel wire industry with its Die Genie and Wire Drawing Die Inspector, revolutionary die inspection tools. The company’s patented Cable Genie is widely acclaimed, with installations in prestigious laboratories globally. With over 7,500 customers worldwide, Sipcon continues to grow in popularity across Europe and the Middle East.

www.sipconinstrument.com

Join us on November 15th at the Leonardo Royal Hotel London St Paul’s to celebrate a fresh chapter of this cherished tradition, set against the stunning backdrop of St. Paul’s Cathedral.

First launched in 1975, the Dinner Dance promises an elegant evening with welcome drinks, a sumptuous four-course dinner accompanied by perfectly paired wines, and live entertainment from a dynamic band, as we dance the night away in style!

The second largest of the major international wire and cable exhibitions, wire China (September 25-29), covers nearly 60,000 sq m, and is again expecting over 900 exhibitors and over 40,000 visitors from around the world, engaging buyers with meetings and presentations on various related subjects, many in pavilions linking manufacturers from major international regions or product types.

China remains the world’s top cable consumer in several areas: national construction demand remains the world’s largest single cable enduser, accounting for almost 12 per cent of total global demand. The statistics remain impressive, and with the expected visitor numbers currently based on the 2023 show—a record-breaking year with over 30% more visitors than the 2018 exhibition—there is every reason for optimism.

While this will be the second wire China event within 12 months, many manufacturers may adjust their attendance, but the event continues to attract significant interest and offers a great platform for future growth and innovation.

But wire China isn’t known simply for numbers – over the past two decades, first in Hong Kong and now in Shanghai, wire China has been the measure of Chinese influence on the wire and cable market. After starting out as the world economy’s centre of production, China is now an innovator in several fields, and the most cutting-edge equipment, both European and Chinese, is to be found at the show.

The 11th wire China since 2004, again at Shanghai’s New International Expo Centre, will put a premium on international carbon goals and will explore the wire and cable industry’s move (mainly through automation and sustainable practices) to ever-more efficient operations to meet CO2 targets. The exhibition will showcase innovative products and technologies, as well as offering a hub for information, sharing and collaboration.

Despite a reputation as a polluter, with its heavy industries and coal-fired power plants, China produces over 60 per cent of

the batteries that help nations to approach their emissions targets; is a world leader in electric car production (producing as many as most other manufacturing nations combined, and buying around half the annual global production); makes 80 per cent of the world’s solar panels, and is finally cleaning up its power generation act, to be carbon-neutral by 2060 – quite an achievement, given its starting point. All this requires vast amounts of wire and cable infrastructure. And while the rest of the world rapidly seeks out new reserves of minerals vital to the manufacture of panels and batteries, China has a virtual monopoly on the mining and refining of the raw rare earth materials and lithium that go into them. No-one in the business of green power generation – currently the world’s biggest business - can avoid Chinese products, somewhere along the line.

All the forecasts show Asia will be a main driver of the global economy in future years, not only as buyers and manufacturers but also as innovative designers. Thousands of Chinese companies now exhibit not only at the Asian shows, but also at many of the biggest international trade fairs; in fact, in 2023 Chinese companies amounted to 14 per cent of all Messe Düsseldorf’s trade fair exhibitors.

Messe Shanghai’s managing director for the past five years, Marius Berlemann, believes China’s growth has been partly because the country remains a vast, developing market in which many Chinese companies are keen to experiment.

“You might fail in certain areas; not everything we have started here was a success, but some things we started have been a great success,” he explained.“

Many Western markets are very mature and don’t have the capacity to establish new things; in China we don’t see that yet, so people are driving for the next new things, especially when we talk about digital innovation, or innovation in general. This is the advantage of China.”

It has to be admitted that China’s success is not admired globally, especially by rivals and politicians. China’s aggressive production and exporting has led effectively to tariffs, import duties and tacit trade wars with America and to a lesser extent, Europe, where traditional industries are threatened by the wave of Chinese cars and other products.

Current economic forecasts show that China’s economy has slowed down compared to 10 or even five years ago. However, we shouldn’t compare it directly to the economic struggles in the West. While China’s domestic economy, especially the property market, has seen a downturn like many others, its overall growth for the year is still expected to be just under five percent— a rate many countries would be eager to achieve. There’s also confidence that the economy will continue to improve in the future.

After 30 years of unparalleled growth as a global source of cheap, high-volume products, China is in a period of transition, standing near the top of the global economic tree and accommodating the problems and responsibilities that come with it. These include a slowdown in domestic property investment, the need to provide for an ageing population that previously was barely considered; proper health care and public health policies, and the building or extending of national infrastructure. All of this requires large amounts of money.

The Chinese government is already putting huge reserves into infrastructure and similar projects, to maintain jobs, production and spending power, all of which, we should note, require the sort of materials made by IWMA members. China remains a huge market.

China’s exports and business growth are still strong, despite challenges from external factors. With foreign governments adopting protectionist policies, the appeal of affordable, well-designed products from China continues to be a strong motivator for these governments to protect their own industries. We will need to wait and see how the balance of trade is restored, but restored it will be...

as of 4th September 2024

Company Booth

ABZ (SHANGHAI) SMART TECH.CO.LTD E2A01

ACIMAF E1B12

AESA Cortaillod E1F17

August Strecker GmbH & Co KG E1D43

BWE Limited E2D83

Condat Ltd E1F37

Conoptica E1E31

CSM Metalurji Imalat Sanayi Ve Muhendislik Ltd sti

GmbH E1A51

E1C15

Setic s.a.s

EDER Engineering GmbH E1B38

FMS Force Measuring Systems AG E1A16

Hans Schmidt & Co GmbH E1D31

Intras Ltd E1G37

Jiangsu Singcheer Intelligent Equipment Co Ltd E2A03

Klüber Lubrication GmbH (Traxit) E1C35

Maillefer Extrusion Oy E1D21

Medek & Schorner GmbH E1F14

Metalube Limited E1E13

Microdia SA E1B05

Niehoff Maschinenfabrik GmbH & Co KG E1B51

Ningbo Kaite Machinery Co Ltd E4F21

One of the highlights of this year’s wire China exhibition is the return of our popular evening networking event, which promises to be bigger and better than ever!

For the first time since 2018, IWMA is thrilled to host an enchanting evening cruise down the iconic Huangpu River in Shanghai on Thursday 26th September 2024. This exclusive event was a sell-out success back in 2018, and we are eager to recreate the magical experience for our members, securing more tickets than ever to accommodate the high demand.

This year’s cruise is set to be a truly memorable evening, featuring clear skies, stunning nighttime views of Shanghai’s illuminated skyline, and a delightful buffet of

local cuisine and drinks. Attendees will be treated to the vibrant atmosphere of Shanghai by night, with its dazzling lights and dynamic energy.

The night cruise on the Huangpu River is a major highlight of Shanghai tourism, offering visitors a chance to experience the city’s unique blend of historical and modern scenery. The journey includes iconic landmarks such as The Bund, with its historic illuminated buildings; the Oriental Pearl Tower, showcasing stunning lighting effects; and the modern Lujiazui Financial District, home to towering skyscrapers like the Jin Mao Tower and Shanghai Tower. Guests will also pass under the beautifully lit Yangpu and Nanpu Bridges, adorned with dreamlike lighting, and enjoy scenic views along Binjiang Avenue and the North Bund. Finally, not to be overlooked is the Shanghai International Convention Centre, whose

distinctive architecture appears even more magnificent under the glow of lights at night.

Guests will be collected from the IWMA stand at wire China after exhibition hours and transported via coach to the dock for the twohour cruise, which will start at approximately 19:30. The journey will offer ample opportunities for networking in an informal setting, allowing participants to connect with industry peers while enjoying the scenic beauty of Shanghai. After the cruise, guests will be returned either to the exhibition hall or the Mercure Shanghai Century Park Hotel at approximately 22:00.

This spectacular event promises to be an unforgettable highlight of wire China 2024. Limited tickets remain secure yours now by visiting www.iwma.org/events

We look forward to seeing you there!

Once again, we are thrilled to be participating at wire China 2024. Positioned at stand E1C21, the IWMA stand is set to be a central hub for our members and guests, offering a wealth of resources and networking opportunities tailored to enrich your exhibition experience.

Understanding the needs of our members, the IWMA stand will feature on-site hospitality services, including refreshments, Wi-Fi connectivity to catch up on emails, and bookable meeting tables for business discussions or casual chats with colleagues. Our stand will also offer a range of printed materials, such as the latest IWMA Insider

magazine, membership directories, and benefits booklets, to keep you informed about our upcoming events, exhibitions, and the numerous benefits of being part of the IWMA community.

Meet the IWMA Team

Representing the IWMA at wire China will be Richard Johnstone, Executive Management Committee member; Jessica Bennett, Executive Manager; and Katie Houston, Marketing Executive. The team are eager to meet you all and discuss how the IWMA can support your business and professional growth.

Member Presentations: Showcasing Expertise

We are excited to provide our IWMA members with the opportunity to showcase their expertise and latest developments during our IWMA Member Presentations

on Thursday September 26th, and Friday September 27th. These presentations will take place in the member presentation area of the stand and will be translated by our on-stand translator, ensuring they reach a truly global and diverse audience.

As a proud industry partner to Messe Düsseldorf GmbH and its wire exhibitions, IWMA is committed to enhancing the industry’s growth and connectivity. We look forward to you joining us at wire China to explore the latest industry trends, innovations, and opportunities for collaboration. Let’s connect, learn, and grow together in the spirit of advancing the wire and cable industry for mutual success!

See you at wire China: Visit us at Stand E1C21

RichardsApex Celebrates 120 Years of Excellence in Lubricant Solutions

RichardsApex, a distinguished leader in the global lubricant industry, proudly celebrates 120 years of innovation and excellence. Specializing in high-quality lubricants, RichardsApex serves the wire drawing and hot rolling sectors with a comprehensive range of advanced solutions.

Our extensive product line includes semisynthetic and synthetic lubricants designed for the wet drawing of both non-ferrous (copper, aluminium, brass) and ferrous wire and rod. Additionally, we offer an array of protective coatings, cleaners, corrosion inhibitors, and oil-based lubricants, tailored for all non-ferrous and ferrous alloys, used in wire drawing and rod rolling applications.

With over a century of expertise, RichardsApex continues to set the standard for performance and reliability in lubrication technology.

RichardsApex remains dedicated to delivering superior lubrication products that meet the evolving needs of the global industry.

Introducing SK-1: A Breakthrough in Copper Rod Rolling Lubricants

After years of rigorous on-site testing and development, RichardsApex proudly introduces SK-1, a lubricant engineered to meet the demanding requirements of our global copper rod rolling customers. SK-1 is designed with advanced friction modifiers to accommodate today’s high-performance continuous cast operations, while also reducing lubricant consumption compared to competitive products. SK-1 features a stable, low-foaming emulsion that is low in reactivity, supports longer tank life, and enhances rod rolling performance, to

Cable Marking Machines and Optical Fiber Processing Lines

We at Medek & Schörner are pleased to announce that we will be attending wire China 2024. Our renowned business partner Herkula will be sharing their stand with us. Herkula offers speciality inks for the cable and plastics industry, such as optimized UV-LED inks, which are perfectly suited for our newly developed optical fiber UV-LED curing unit.

Medek & Schörner, established in 1929, is a leading supplier of cable marking machines and optical fiber processing lines.

We are constantly confronted with new requirements and are consistently engaged in the development of cutting-edge solutions that exceed these requirements. Our latest innovations are:

• Newly designed optical fiber coloring line with increased production speed of more than 3,000 m/min and coloring

of up to 3 optical fibers simultaneously

• Optical fiber coloring and curing station using LED irradiation units, resulting in 93 % less downtime and 81% lower energy costs

• New ring marking technology

• Intelligent and highly improved hot foil sequential meter marker FMS 5 with an innovative marking wheel that memorizes and automatically aligns to different cable diameters

• Cutting-edge intermittent ribbon technology

The depth of our in-house expertise, combined with our high-performance machines and our highly qualified and experienced workforce, gives us the ability to help our customers to develop better solutions – in effect, to turn their good ideas into the best ideas.

Our product range begins with simple coding machines and extends all the way to fully automated high-speed production lines using cutting-edge technology. Here is a brief overview of our product portfolio:

Cutting-Edge Wire and Cable Manufacturing Equipment: Niehoff and NMC at wire China 2024

Maschinenfabrik Niehoff and its Chinese subsidiary, Niehoff Machinery Changzhou (NMC) Co., Ltd., will be exhibiting at wire China 2024, Booth E1B51.

support superior wire quality outcomes, for the downstream customer. SK-1’s proven global success across diverse OEM’s, establishes it as an ultra-modern, universal rod rolling solution.

Commitment to Service and Excellence

RichardsApex’s service philosophy has been a cornerstone of our success in the wire drawing, copper tube production, and rod rolling markets. As a founding partner at wire China, we remain committed to delivering products and services that foster long-term relationships with our customers, both in China and globally.

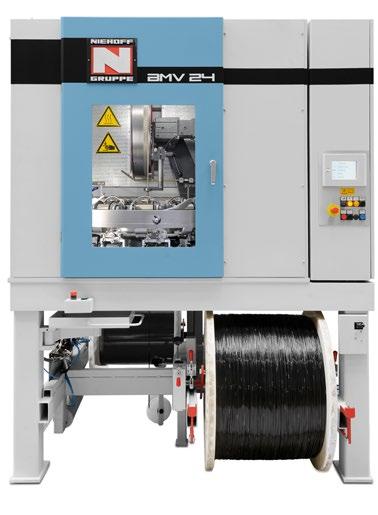

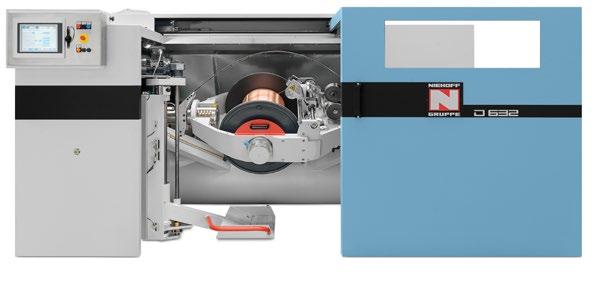

On display will be a MMH 121 + RM 201 type multiwire drawing line, a D 632 type double twist bunching machine with an ARH 630 type pay-off, and a BMV 24 type vertical braiding machine.

Future-Focused Multiwire Drawing Technology

NMC, under Niehoff’s licence, builds MMH type multiwire drawing lines for the Chinese market. These lines consist of components both from the Niehoff headquarters in Germany and from NMC. The mechanics of the MMH drawing machine are provided by Niehoff, while the annealer, switch cabinet, and spooling system are made by NMC. All components are assembled at NMC, where test runs are also conducted. Only after successfully completing the test runs is the line delivered to the customer, where NMC technicians handle installation and start-up.

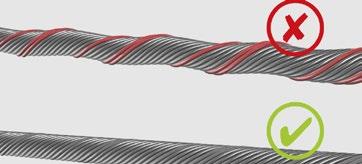

The D 632 type double twist bunching machine, built by NMC under Niehoff’s licence, is characterised by high productivity and delivers high-quality products on perfectly filled spools. The single-bow design, combined with the energy-saving Eco-Bow installed in this machine, ensures significant energy savings and, consequently, lower energy costs compared to conventional bunching machines. Other features include electric lay-length adjustment (changing lay-length without changing gears) and constant tension control of the strands from empty to full spool. As the D 632 produces bunches with very tight tolerances, only the minimally required copper cross-section is generated. This results in considerable material and operational cost savings. Due to the adjustable and controlled wire tension—regardless of spool filling—and the integrated opto-electronic NBAT (Niehoff Bunching Automatic Traverse) system, the spools are filled with a perfect winding pattern. As a result, the bunches can be paid off tanglefree, even at extremely high pay-off speeds.

Because of the precise operation and the automatic NBAT system, one operator can supervise multiple machines simultaneously, leading to substantial labour cost savings. The D 632 buncher is ideally suited for processing fine wires made from copper alloys, such as CuSn0.3, into strands for automotive cables. Using the patented Stretch Forming and Straightening Technology, the D 632 avoids the crowning and spiralling effects typical of wires made from certain copper alloys.

• Optical fiber color coating systems including ring marking, tight buffering, proof testing

• Production lines for optical fiber ribbons, compact fiber units (CFU) and intermittent ribbon

• High-quality gravure printers

• Offset markers for irregular cable surfaces

• Embossing meter markers and hot foil sequential meter or footage markers

• High-speed embossing printer for indent or raised marking

• High-performance ring markers

• Video systems for monitoring the printing quality of high-speed printing machines

• Laser marking systems for cables

• Custom-made cable marking machines and optical fiber solutions

• IOT/Industry 4.0 ready interfaces

Booth E1F14

www.medek.at

The main advantages of the MMH 121 + RM 201 type multiwire drawing line on display include a compact design that saves production space, high productivity, and a low wire break rate. The RM 201 type resistance annealer uses the field-proven 2/3 zone annealing method, which can be selected with or without wire reheating. This results in optimal wire drying and economical energy use for larger wire sizes. The wires drawn on this line maintain very homogeneous and closely controlled properties over their entire length. Such wires can be processed into multiwire bundles with excellent specifications and are ideally suited for final applications or downstream processing into high-quality strands or braids.

Technical Data: MMH 121

- Max. production speed: 35 m/s

- Wire inlet diameter: 2.00 or 1.80 mm*

- Wire finished diameter: 0.16 ... 0.55 mm

- Max. number of wires: 24 - *Cu hard

Technical Data: D 632

- Max. production speed: 300 m/min

- Strand cross-section*: 0.09 … 6.00 mm²

- Lay length (steplessly variable): 6 … 100 mm

- Max. number of twists: 7000 twists/min

- *Cu soft

Precision Braiding with High Efficiency and Versatile Applications

The BMV 24 type vertical lever-arm rotary braiding machine, equipped with 24 bobbin carriers, offers several key advantages, such as infinitely adjustable electronic control of line speed and braiding pitch, as well as an automatic central lubrication system. Multiple monitoring systems enable unattended operation over longer periods without frequent operator intervention.

BMV type braiders can be equipped with three patented systems that offer additional benefits. The braiding speed of the BMV 24 model can automatically be accelerated from 110 rpm to a maximum of 130 rpm, while the BMV 16, the 16 spool carrier version, can accelerate from 175 rpm to 200 rpm. This results in a 10% increase in braiding performance. At the same time, the frequency of lubrication intervals is reduced depending on the slideway temperature. Consequently, less lubricant is used, and less oil contamination occurs on the braids.

With Niehoff’s Wire Tension Control System, all braiding wires—from full to empty braiding bobbin—are applied to the product under uniform tension, resulting in faultless shielding. Niehoff’s Coverage Control System ensures a constant braiding coverage ratio at the set value. Since only the absolutely necessary amount of braiding wire is applied, up to 10% braiding material savings can be achieved.

BMV type braiders are suitable for a wide range of applications. They are designed for processing bare or plated round or flat wires made from copper, aluminium, or stainless steel, as well as artificial yarn and fibres. The braiders can be used to manufacture cable screenings, copper braids, hollow braids, stranded braids, textile braids, and steel wire braids with different braid patterns.

Technical Data: BMV 24

- Cross-section: 0.02 ... 0.56 mm²*

- Max. braiding pitch: 6 … 180 mm

- Central passage: 50 mm

- *Cu soft

www.niehoff.de

AESA Cortaillod Marks

Milestone with 10th ResTest 813x Installation in China

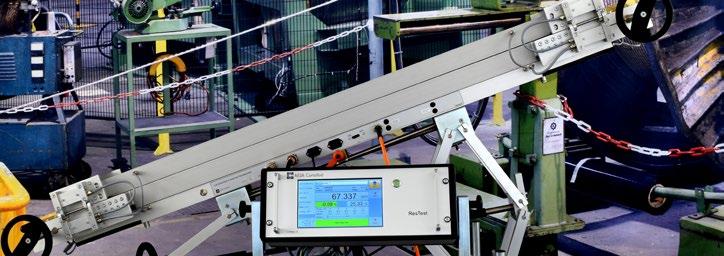

AESA Cortaillod, a world-renowned name in cable metrology, has successfully installed its 10th ResTest 813x instrument in China, highlighting its growing influence in the region. This milestone installation underscores the company’s commitment to providing state-of-the-art solutions for the cable and wire industry.

AESA Cortaillod’s ResTest 813x family of instruments addresses the need of measuring the resistance of conductors directly on the assembly line using a unique, patented technology. This innovative approach allows for a significant reduction in safety

As an internationally active family business, STRECKER has been working in a progressive and future-oriented manner with high quality awareness since 1933. STRECKER offers complete solutions for individual manufacturing processes in welding technology.

At this year’s wire 2024, welding machines for different applications will be on display: electric buttwelding machines for steel, copper, aluminum, brass, for solid wires or stranded wires and conductor cables. There will be fully hydraulic butt welders with automatic deburring and pneumatic welding machines for bulk wire products, as well as cold welding machines for non-ferrous wires.

The continuous optimisation of proven welding machines will also be addressed: the user-friendly version of electric strand buttwelding machine type SE1, with handle for easy movement, cable holder and optional cover of the mimic to protect the mechanics and large collecting tray for smashed ceramics.

Customers can experience welding directly on the stand and, of course, discuss individual requirements for special, tailor-made machine constructions with the experts on site.

Booth E1D43

www.streckerusa.com

margins and raw material usage, thanks to its unbeatable accuracy in on-theline measurements of linear resistance.

The ResTest 813x masterfully manages uncertainties related to temperature, length, and current distribution, all within a single integrated and movable device.

The instrument’s ability to connect to IT networks and its bespoke software tailored specifically for the cable industry enable manufacturers to optimise processes and produce sustainably. AESA’s presence in Asia is further strengthened by its subsidiaries in Shanghai and Hong Kong, ensuring long-term

reliability and efficient technical support. Besides the ResTest 813x, AESA Cortaillod will showcase other cutting-edge solutions at wire China in Shanghai.

At wire China, attendees will have the opportunity to explore these innovative solutions as AESA Cortaillod demonstrates how their technology can help cable manufacturers achieve higher yields and better sustainability.

www.aesa-cortaillod.com

FMS Force Measuring Systems AG to exhibit at wire China 2024

Together with our Chinese distributor, Suzhou FCN Mechanical and Electrical Technology, we will showcase our innovative solutions for the wire and cable industry.

Come and visit us on Booth E1A16 to discover more about our product range.

RTM X42 – Wire tension monitoring and closed-loop control for stranders.

RTM X42 – Equal tension on all strands.

RTM MP – Wireless drop-in replacement for defective sliprings.

Illustration: RTM MP Substitute for defective sliprings.

FMS-cradleGUARD – Safety monitoring of all cradles

Illustration:

FMS cradleGUARD - Reliable signal transmission for wire break, pintle lock status, tilt.

Meet our experts Joey Zheng and our General Manager Jörg Inhelder who will be at your disposal to discuss your requirements.

Booth E1A16

www.fms-technology.com

The SETIC team is committed to meeting specific customer needs. Talk to our representatives about tailored cable machinery solutions and discover our latest advancements in highperformance cable machinery and sustainable solutions.

SETIC is a leader in cable machinery designed for special data communication, and LAN cables, serving the automation, AI, robotics, aerospace, and data analytics sectors, as well as a major player in automotive wire equipment.

“We are pleased to announce the reopening of Gauder Group’s China operations, including a sales office in Shanghai. Our newly established structure, Gauder Group Shanghai, manufactures SETIC machines made in China. These machines meet the dynamic and critical demands of the Chinese and Asian markets, offering modern design, European quality, and performance standards. We provide comprehensive local services in China to ensure competitive levels of support.

This strategic move underscores our commitment to our Chinese customers and solidifies our position as a global leader in providing rotating machinery for the wire and cable industry. We eagerly anticipate building lasting relationships with our Chinese partners.”

POURTIER manufactures heavy-duty rotating machines to produce all types of power cables: overhead, submarine, High Voltage and Extra-high Voltage. Our team of experts will be available to discuss your specific needs.

POURTIER is the top choice when it comes to producing rigid, screening and planetary stranders, single twist cablers, and drum twisters for all types of energy cables from low voltage up to overhead, high and extra high voltage as well as submarine cables. POURTIER also offers complete know-how for process guarantee.

All of these machines are designed and manufactured with the highest standards in design and manufacturing to produce all types of high-voltage and extra-high-voltage power cables.

From overhead cables (including ACCC™ , ACSS-TW and ACSR-TW) to submarine or land cables AC type (using high quality Milliken conductor) or DC type (using large round compacted conductor or profiled “Keystone” wires).

Our presence again this year at the wire China show demonstrates our commitment for a better understanding of the Chinese market while observing the trends, the consumer needs, and present our new technologies.

POURTIER connects its customers to all energy sources. Demand for Clean energy including improved infrastructures has been on the rise in the past few years, resulting in new market challenges. POURTIER has the most advanced solutions to meet these challenges for sustainable clean energy and infrastructure.

C2S Customer Services department is the ideal partner to maintain machines productivity and enhance products quality.

Rich of a long and successful experience, the C2S Services division has an overall efficiency booster to maintain wire and cable production lines productivity and products quality, whatever the brand of the equipment. C2S is being assigned spare parts, upgrades

and maintenance projects, as well as transfer and restart operations of complete lines.

Upgrades are a sustainable approach. By extending the life of existing machines, customers reduce their environmental impact by minimizing the need of new equipment. C2S solutions are a way to save Energy and “Go Green”.C2S is involved in smart factories in their Industry 4.0 processes.

BOW TECHNOLOGY sells customized bows for ALL sizes and ALL brands of double twist equipment.

BOW TECHNOLOGY is the answer to cable makers concerned by quality and long-life reliable bows for all brands of double twist machines from 560 to 2000 mm. With a comprehensive range of 650+ all sizes designs the division offers a global service from conception to production. The patented GreenBow2 is a closed-bow model ensuring important energy savings (up to 30%) on high-speed double twist bunchers (560 to 800mm). It’s time now to take your part of environmental questions towards a positive climate change, also in your industrial and professional life!

The team is ready to discuss any model matching the customer’s production needs.

www.setic-pourtier.com

SIKORA bring new products and an innovative booth to wire China

At wire China 2024, from 25th-28th September in Shanghai, SIKORA, a manufacturer of innovative measuring, control, and sorting technologies, will present its range of new and proven systems for quality control and cost optimization in wire and cable extrusion, as well as material production and processing. Visitors can look forward to product premieres and a new booth concept.

Premiere of the CENTERVIEW PRO: Eccentricity Measurement on a New Level

With the new CENTERVIEW PRO, SIKORA continues its 50-year tradition of measuring the eccentricity of conductors in cable insulation at a new level. The CENTERVIEW 10 and CENTERVIEW 25 are two innovative models designed for product dimensions from 0.1 to 25 mm. Using a combined inductive and optical measuring method, the system reliably measures the diameter and ovality of cables in addition to eccentricity.

With 5,000 high-precision measurement values per second per measurement axis, and an extremely short exposure time of less than 1/1,000,000 seconds, the CENTERVIEW PRO enables accurate measurements, even at high line speeds and during product vibrations. Each individual measured value achieves an extraordinarily high single-value accuracy.

Premiere of the LASER PRO: New Standards in Diameter Measurement

With the new LASER PRO, SIKORA sets new standards in cable diameter measurement. Based on the proven LASER Series, which is used in numerous extrusion lines worldwide, this new model family offers extended advantages for users. The LASER PRO comprises three innovative models for product dimensions from 0.1 to 51 mm. The diffraction analysis, combined with pulse-controlled laser diodes, produces an impressive 500,000 measuring points per second per measurement axis across the entire measuring field. These are summarized into 5,000 high precision measured values per second per axis, ensuring that the values supplied are both accurate and repeatable. Thanks to the extremely short exposure time of less than 1/1,000,000 seconds, the individual precise measured values are recorded with maximum image sharpness, ensuring

absolute measuring accuracy even at high line speeds and during product vibrations.

Premiere of the LM SMART: Smart Length Measurement of Wires and Cables

With the LM SMART, SIKORA expands its product range with an innovative length measuring device. The system measures lengths without contact, with an extraordinary accuracy of 0.05%. Compared to conventional contact-based solutions, there is no slippage or wear. Once the device is set up, no calibration or re-parameterization is required. The LM SMART measures accurately and reliably over the long term.

X-RAY 8000 ADVANCED/NXT: Remarkably Efficient in CV Lines

In the field of power cable production, the X-RAY 8000 has been providing precise measurement values and maximum reliability for over 30 years. These features ensure the quality of the cables during production, leading to material and cost savings. At wire China, SIKORA presents the 3rd generation measuring system based on X-ray technology, the X-RAY 8000 ADVANCED, which measures the wall thickness, eccentricity, and diameter of cables in CV lines immediately after the injection head. It provides measured values for centering and control without distortion.

Another highlight is the X-RAY 8700 NXT, which measures the final product dimensions at the end of CV lines, both horizontally and vertically aligned. By using SIKORA measuring systems at both the beginning and the end of production, shrinkage values are determined for all three insulation layers of the cable, ensuring optimum process control for maximum efficiency.

PURITY SCANNER ADVANCED: Pure Plastic Pellets for Insulating Power Cables

In the manufacture of high-voltage and submarine cables, it is essential to prevent contamination from entering the insulation of power cables. The PURITY SCANNER ADVANCED uses X-ray technology and optical cameras to detect contaminants, such as metal, as small as 50 µm in the pellets, and automatically sorts out impurities. This ensures that only pure material is processed further, minimizes breakdowns, guarantees cable quality, and saves follow-up costs. The system’s function and advantages will be clearly demonstrated at wire China using a hybrid exhibit.

New Stand Concept Underlines SIKORA’s Commitment to Perfection

SIKORA presents itself at wire China with a new booth concept, underlining its commitment to perfection.

“Our customers can not only experience new products live but also our new booth concept, which invites them to linger and exchange ideas with our experts. We want our customers to feel completely comfortable at our stand,” says Wanbin Chen, President of SIKORA China. Booth E1D51

www.sikora.net

The new CENTERVIEW PRO measures the eccentricity and diameter of cables. The measured values are displayed on ECOCONTROL

Big News from TKT Group to Be Presented at wire China 2024

TECNOVO and KONER, two leading manufacturing companies within the TKT Group, are excited to announce their participation in wire China 2024 from September 25th to 28th. Visitors to the event can find TKT Group’s latest innovations at their dedicated booth, where they will showcase a range of groundbreaking products and solutions tailored to the wire and cable industry.

Among the highlights that will be presented at wire China are:

• Innovative Lubricants for Wire Drawing: High-performance lubricants suitable for dry and wet wire drawing, featuring “green” formulations that are dust and boraxfree, resistant to extreme temperatures, and provide superior lubrication.

• New Automatic Press Machine: Installed at the KONER plant at the end of 2023, this press machine boasts a pressing force of 120 tons and can produce hard metal products with an external diameter of up to 120mm.

• Advanced Drawing Dies: The production of various drawing dies and custom-designed parts using sophisticated micro-grains, offering zero porosity and enhanced density

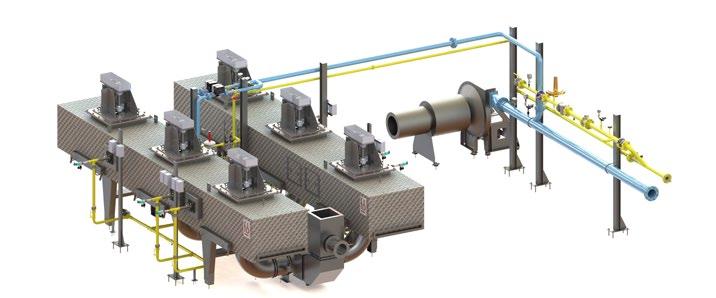

With its newly developed SKET CENTRAL STRANDER “MKZ”, customers benefit from world leading technology. The new range of MKZT/S Central Stranders sets new and previously unthinkable standards in the production of overhead lines of all designs and standards. Stranding cage speeds of up to 500 rpm and a pay-off bobbin capacity of around 510 kg, some three times more than was previously possible, bring about productivity benefits which were previously unimaginable.

and hardness, while maintaining high toughness standards.

• D-lab Enhancements: The D-lab, an innovative instrument for measuring the diameter and ovality of dies, has been upgraded with a larger touch screen for improved ease of use, following its global market success.

• New Butt Welder Machine: This efficient and user-friendly machine significantly reduces welding process time for steel wire, combining welding and annealing into a single operation for high productivity and cost savings.

• High-Performance Wiping Pads: Specifically designed for galvanizing operations, these wiping pads come with specific coating treatments and lubrication, suitable for all applications and tailored to customer needs.

• Integrated Wire Cleaning Solutions: Comprehensive chemical and mechanical solutions for cleaning wire and wire rod.

TKT Group eagerly anticipates meeting industry professionals and clients at their booth at wire China 2024, where they will share more about these innovative products and solutions.

Hans Schmidt & Co. GmbH: Pioneering Tension Measurement Solutions at wire China 2024

As a global leader in precision tension measurement, Hans Schmidt & Co. GmbH has been setting industry standards for over 75 years. At wire China 2024, the company will showcase its latest innovations, including advancements in both hand-held and online tension meters.

Hans Schmidt’s Tension Meters, used by over 180,000 professionals worldwide, are essential in production monitoring, quality control, and process engineering. The company offers the largest selection of tension meters globally, with models available in both mechanical and electronic versions. The latest hand-held model, the DT series, features a large, easy-to-read display with multiple viewing modes, a unique force-reduced material catching system, and the ability to calibrate on user-defined materials.

Additionally, Hans Schmidt is unveiling the enhanced FS series online tension sensors, now equipped with digital signal processing for improved accuracy and connectivity. The new MZ series, designed for tight spaces, offers a flat profile and customizable guide rollers, making it ideal for applications like stranding machines.

Visit Hans Schmidt & Co. GmbH at wire China 2024 to explore these cutting-edge solutions and discover how they can optimise your production processes. Booth E1D31

www.hans-schmidt.com

Dependent on the technological needs of the application, the stranding units are fitted with either mechanically or pneumatically controlled flyer systems, ensuring a product of the highest quality. Having delivered over 100 of these central stranders to customers all over the world, reliability and customer satisfaction are proven.

SKET’s central strander technology is perfect for high production rates, uniform wire products, and minimal wire size adjustments, ensuring a superior quality product.

As an addition, the 245 series have been developed as a “joker” in the MKZ portfolio for aluminum and overhead cable constructions. It is not just this manufacturing option and the use in aluminum wire stranding that makes the “245” a size with many advantages. This includes a filling mass of up to 550 kilograms of aluminum about 245 liters of volume per spool. In comparison: a 630 DIN spool only has about 40% of this filling volume. This in turn guarantees longer stranding without interruption compared to stranding machines (e.g., rigid stranders) with conventional spools.

The special wire guide and various spool braking systems that can be made available to the customer also set standards. The “245” MKZ works at high speed and scores overall with a working method that is strongly geared towards cost-effectiveness without compromising quality standards. The fact that the machine is available also as “Twin” version, which means stranding and loading of the machine at the same time, ensures minimum standstill times and enormous gain in productivity.

This economical working is part of all sizes of the MKZ machines. Companies that already use them have seen not only increased efficiency but also far lower foundation requirements and can be confident that there will be significant energy savings and less maintenance.

SKET Verseilmaschinenbau GmbH will be welcoming you at wire China between 25th28th September at SNIEC – Shanghai New International Expo Center, Shanghai, China. Booth E1C32

www.sketvmb.de

TROESTER Group Exhibits at wire China 2024

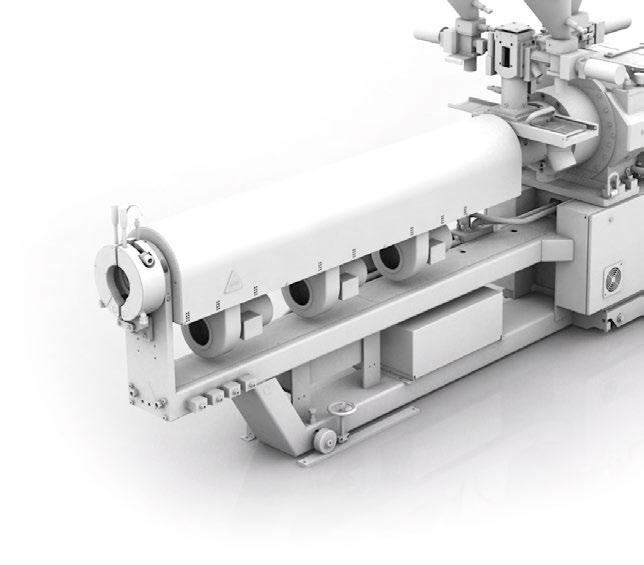

TROESTER GmbH & Co. KG is a worldwide leading manufacturer of complete extrusion systems for the cable industry, comprising CV Lines for XLPE and Rubber Cables, Silicone Insulation Lines, Sheathing and Insulation Lines as well as the complete range of downstream equipment, like winders, caterpillars, capstans, and accumulators. In China TROESTER is represented by its subsidiary TROESTER Machinery Shanghai (TMS), which is responsible for the sales and after sales service and production for the domestic market.

At wire China 2024 TROESTER will present information and new developments in the field of:

• CCV and VCV Lines for MV, HV and EHV Cables up to 1000 kV

• Rubber CV and CCV-Lines up to 35 kV

• Production Equipment for Submarine Cables

The Compounding Division of TROESTER (X-Compound) specializes in complete systems for the compounding of plastics with the process steps conveying, melting, dispersing, mixing, and degassing.

Compounding Division will present: –Kneader technology for the continuous compounding of HFFR (LSOH), PVC, XLPE, and Semiconductive Materials.

The TROESTER Group warmly welcomes visitors to discuss their requirements and to learn about new developments in CV technology and market developments at wire China between 25th - 28th September 2024.

www.troester.de

WIRE CHINA 2024

September 25 – 28, 2024

Shanghai, PR CHINA

Booth No. E1B39

WIRE INDIA 2024

November 27 – 29, 2024

Mumbai, INDIA

Booth No. J46, Hall 1

The increasing power demand as well as the growing share of renewable energies are leading to new challenges: Wind parks, solar farms and further decentralized power generation requires expansion and restructuring of the existing power transmission grids with new cable networks on land and under water. Troester CV and sheathing lines deliver their contribution to this energy transition and provide excellent extrusion lines for those requirements. www.troester.de

Metalube to Showcase at wire China 2024: Connecting with Asia’s Market Leaders

UK-based industrial lubricant manufacturer, Metalube, is set to participate in one of the most significant wire and tube industry events in Asia: wire China 2024, held in Shanghai this September. As the largest event of its kind in Asia, wire China attracts professionals and companies from around the globe, providing a vital platform for showcasing top products and services to the dynamic markets of China, Central, and Southeast Asia.

At this prestigious event, Metalube will spotlight its premier wire drawing lubricants and the unmatched technical services that have become a cornerstone of its global operations. This exhibition offers Metalube an opportunity to connect with Asia’s market leaders, reinforcing its position as a key player in the industry.

Maillefer Reveals the Meaning of “More” at wire China This September in Shanghai!

Get ready to witness a convergence of revolutionary technologies where innovation meets excellence through our live components showcase. Experience technological leadership at the Maillefer booth E1D21, within our House of Experts.

Master More with Less

The huge push towards renewable energy and the sustainable use of resources gives meaning to our main theme—Master More with Less. We offer optimum extrusion solutions to produce more quality products with less material, less energy, less waste, and less effort.

What’s New

The components exhibited at our stand boast efficiency, evolving production demands, and ever-increasing precision. We are introducing a game-changing lineup that spans diverse industry needs, including:

- ECH 35/45 Crosshead - THC 50/90 Crosshead - EKP Card Rack Replacement

As Metalube prepares for wire China, the company is eager to engage with industry professionals and showcase its innovative solutions that cater to the needs of the Asian market. Andy Lewis, Commercial Manager for Wire & Tube at Metalube, expressed his excitement for the upcoming events, stating,

“We are incredibly excited for the upcoming wire China and wire India 2024. These events are a key opportunity for Metalube and the industrial wire and tube industries throughout the Chinese and Indian markets. We look forward to two successful shows and seeing how the wider wire and tube markets are changing and adapting.”

Team Metalube at wire China 2024:

- Andy Lewis, Commercial Manager Wire & Tube

- Cao Jie, General Manager China

- Gavin Gu, Sales Manager, Wire Drawing

Booth E1E13

www.metalube.co.uk

The crosshead developments feature exciting centering techniques that achieve exceptional centricity.

Traxit Wire Lubrication, a brand of Klüber Lubrication, will be present at wire China from September 25th-28th, 2024. Visit us at the German Pavilion ‘Made in Germany’ in Hall E1, Booth C35, where we will be represented by our Chinese subsidiary, Traxit (Huzhou) Lubrication.

Our subsidiary in Huzhou is a leading local manufacturer of high-quality drawing lubricants, produced according to international standards and distributed throughout China and the Asian region. At the trade fair, we will present our latest innovations and key topics related to the wire drawing industry, with a focus on high-quality drawing lubricants, sustainability, energy efficiency, and local proximity, thanks to our state-of-the-art production facility in Huzhou. Our local production allows us to be present in central markets, enabling fast availability of goods and reduced transport routes—to the benefit of both our customers and the environment.

Sustainability is a key concern for Traxit Wire Lubrication. We rely on environmentally friendly production processes and sustainable materials to minimize the ecological footprint of our products. Our innovative drawing lubricants are designed to reduce energy consumption and extend the service life of wire drawing systems, bringing both ecological and economic benefits.

Our aftermarket services include an effective card rack upgrade to extend the lifetime of EKP 50 & 60 dual take-ups.

Our specialists are ready to share details about recent technologies, such as our new high-volume NXW 225-22D extruder, intelligent induction, round premium value package, PP processing for MV and HV cable, MV extrusion line upgrades, and more.

Participate in the Transformation

Join us at this key industry event to gain insight into tomorrow’s technology. This is a unique opportunity to participate in a transformation that underlines our dedication to pushing the boundaries.

The focus is on the transition towards green energy sources and manufacturing best practices. Attending the show means you’re involved and actively seeking competitive solutions. Prepare yourself for the game change. Plan your visit with us at wire China in Shanghai from September 25th 28th, 2024.

www.maillefer.net

Innovation plays a decisive role in our corporate philosophy. Research and development are central pillars of our company, ensuring the best possible product development for our customers and setting new standards in the wire drawing industry. Our research and development center in Huzhou works closely with our European center. At wire China 2024, we look forward to engaging in dialogue with our customers to jointly make the wire drawing process more efficient and sustainable.

Product quality is our top priority. Our drawing lubricants are manufactured under strict quality controls and meet the highest standards. Thanks to our presence in Huzhou, we can respond quickly and flexibly to the needs of our local customers.

We cordially invite you to visit our stand to learn more about our products and solutions. Discuss with us how we can overcome the challenges of the wire drawing industry together and discover how Traxit is contributing to the future of the industry through sustainable and energy-efficient solutions.

We look forward to your visit and the opportunity to exchange ideas with you!

Booth E1C35

www.traxit.com

ROEX extruders are high-performance machines for cable insulation and jacketing. They are equipped with an innovative motor drive concept and can be customized to suit your specific requirements.

Choose the latest extruder technology for your next project and benefit from:

• High flexibility for different materials

• Consistent linear and high output

• Minimized energy consumption

wire India, at the Bombay Convention & Exhibition Centre in Mumbai (November 27-29) is a hotly-anticipated event on the annual calendar of wire and cable exhibitions. It’s the third-largest show after Germany and China, and the biggest on the Indian sub-continent. Given the large number of manufacturing businesses in the region, its economic value cannot be ignored.

The same goes for the rewards on offer: last year the Indian wire and cable market was worth around $13 billion, but with a strong projected growth for most of the next decade, the early 2030s might see a value nearer $35-40 billion, which is a very healthy sector indeed.

No surprise, then, that the most recent wire India, in 2022, attracted over 17,000 visitors (almost three times the attendance in 2010) and 400 exhibitors from 21 countries across 23,000 sq m of halls; predictions for this year are for even higher numbers.

In addition to Indian companies, the exhibition attracts exhibitors from Belgium and the Netherlands, Austria and Germany, the United Kingdom, Turkey, Italy, France and Spain and Scandinavia, and there are also many overseas companies from the USA and Canada, South East Asia, South Africa and China. The forthcoming event will also feature pavilions gathering companies from Germany, Italy, Switzerland, and an International Pavilion from IWMA along with a comprehensive conference programme.

India has been the global success story of the past 15 years; where China has led, India now follows.The two nations are remarkably similar in many ways: both have similarly-sized and huge populations of around 1.5 billion, both have vast working-age populations, both major in education, technology and manufacturing, both are among the top users of cable and wire (China top, India third), both have vast industries supporting green energy, each is the major exporter to the other, and not

surprisingly, they stand at first (China) and (third) in the world economic rankings, either side of the USA.

Admittedly, India’s GDP is around $13.5 trillion while China’s is nearer $31 trillion, but China is currently beset by trade wars and export tariffs, while India is affected mainly by its own bureaucracy and a slightly strained relationship with the outside world. But India imports far more than it exports, which makes it a favoured destination for manufacturers from the largest producing nations.

Like China several years ago, India is undergoing a transition into a modern industrial nation, and nowhere is this seen better than in the growing demand for wire and cable.

Though the country is currently suffering a small economic downturn, like most nations, the underlying economy remains vibrant and is predicted to grow at around 6.1 per cent this year, against seven per cent last year.

India has been investing heavily in infrastructure and transport projects, the power grid, renewables and smart technology – all great for the wire and cable industry (power utilities already consume 30 per cent of all the cable used in India). The investment pushed construction growth last year by 11 per cent over 2022 – a slightly artificial result, since India was still rebounding from the pent-up demand from Covid. Now the curve is getting back to normal, growth should rise at a slower but far steadier rate.

Increasing Indian urbanisation will demand extra power, and even though India is the world’s third-largest producer and consumer of electricity, its current generating capacity is nowhere near the anticipated demand.

The Indian government has plans to more than double the present capacity of around 420GW by 2030, by adding 500GW of green generation.

India’s existing generating capability relies heavily on coal and oil; the government’s aim

is for renewables – some wind generation, but mainly solar to overtake fossil-fuel generation in the next seven years and for the nation to be net-zero by 2070 (a vast job, since renewable capacity by 2070 would need to be around 7,500GW and it will cost an extra $5 trillion for measures just to halve estimated CO2 output over the next halfcentury). India is currently the world’s thirdlargest producer of greenhouse gases.

The leap to 2030 alone demands the addition of around 50GW of new capacity a year, partly achieved at the consumer level by a scheme to encourage up to 10 million householders to install solar panels, with the usual grid buy-back schemes. This should increase rooftop generation from 12GW to 40GW within two years. A parallel scheme offers financial incentives to the power distribution companies to improve the network, alongside general modernisation using smart grid technology.

Falling into step with proposals to generate power are plans to use it: India’s intentions for the rail network (already 95 per cent electrified) and for electric vehicles (including buses and two- and three-wheelers) are as ambitious as those for other aspects of power generation. India hopes to electrify almost a third of its vehicles by 2030 – as with the Western model, by a mixture of incentives and tighter emissions standards.

The rail network is already subject to technology and infrastructure improvements to make it more efficient, but is being augmented by metro transport schemes for around 75 cities in the next handful of years – offering not only better public transport but a welcome reduction in traffic congestion and pollution.

The shift to EVs in urban India is opening up massive demand for network cabling, and of course for wiring for in the manufacture of EV motors and batteries. India’s future plans are a big reason for the continued growth of the nation’s wire and cable market – and the popularity of wire India.

As anticipation builds for the wire India exhibition, we are thrilled to announce that IWMA will be making a significant appearance.

Reber Systematic GmbH

Rosendahl Nextrom GmbH Hall 1, I59

Setic s.a.s Hall 1, N48

Sikora AG Hall 1, I53

SKET Verseilmaschinenbau GmbH Hall 1, L48

Sneham Taping Solutions Private Limited TBC

Synergy Steels Limited TBC

TKT Group (Koner) Hall 1, F47

Troester GmbH & Co KG Hall 1, B39

Uygar Makina San.Ve Tic Ltd.Sti Hall 1, H65

VDKM - Verband der Draht- und Kabelmaschinenhersteller e.V

Vikas Spool Private Limited

Vinston US Corp Hall 1, I64

Following the success of our pavilions at wire Southeast Asia and responding to substantial interest, we’re excited to debut our member pavilion in India for the first time. We will be joined by member companies from across the globe including RichardsApex, Aversion Technologies, Proton Products, Rautomead and Fisk Alloy who will be showcasing their companies as part of the IWMA International Pavilion. The IWMA section of the pavilion will be its usual hive of activity, serving as a central hub for our members and guests. It will offer a wealth of resources and networking opportunities, along with on-stand presentations and our signature

IWMA hospitality and support services. Refreshments, Wi-Fi connectivity, and bookable meeting tables for business discussions or casual chats with colleagues will all be available. In addition, a range of printed materials, including the latest IWMA Insider magazine, membership directories, and benefits booklets, will also be available to keep you informed about our upcoming events, exhibitions, and the myriad benefits of being part of the IWMA Community.

We are also excited to offer an incredible opportunity for IWMA Members to showcase their expertise and latest developments at wire India. Members are invited to submit their proposals for presentations, which are scheduled to take place in the presentation area of the IWMA stand on Thursday, 28th November 2024. Each presentation will last between 20 to 30 minutes and can cover any topic of the presenter’s choice. While we are particularly interested in presentations of a technical nature, there is also room for sharing information about your company and its recent advancements.

This is a fantastic platform to highlight your company’s innovations and technical prowess. It also provides a unique opportunity to engage with a diverse and influential audience, allowing you to expand your reach within the Indian market. Given the limited slots available, we encourage early submissions to ensure your participation. Proposals must be received by the closing date on Friday, 25th October 2024.

Visit the IWMA Pavilion at wire India, located at Hall 1 Booth L47

One of the highlights of this year’s exhibition will be the return of our popular evening networking event, which promises to be the best yet!

Our last event in India, held in 2018 at the prestigious ITC Maratha in partnership with Mikrotek Machines and Niehoff India, was a resounding success. Titled “A Taste of Bollywood,” the event captivated attendees with a vibrant mix of Indian culture and invaluable networking opportunities. The photos accompanying this article vividly capture the energy and excitement of that memorable evening, showcasing the dynamic atmosphere our attendees enjoyed.

This year, IWMA is set to co-host another vibrant Bollywood extravaganza with Mikrotek Machines and Niehoff India, titled ‘Colours of the World,’ on Thursday, 28th November. Join us for a night where East meets West and experience the glitz and glamour of Bollywood in a dazzling display of colour and culture. Enjoy an array of traditional Indian cuisines, vibrant decorations, and live Bollywood music and dance performances, all designed to create the most memorable experience for our members.

Member companies are eligible for up to three complimentary tickets. This spectacular evening, filled with vibrant music, colourful dance, and delicious food, promises a night of fun, laughter, and cultural exchange—the perfect setting for building new connections and strengthening existing ones!

Tickets will go on sale on 26th September 2024. Don’t miss out on what is set to be an unforgettable highlight of wire India 2024! Save the date and be ready to book your tickets at iwma.org/events to secure your spot at this show-stopping event!

Celebrating Milestones and Leading the Way in Sustainable Steel Wire Treatment

Offering sustainable solutions at the cutting edge of technology is the guiding principle of FIB BELGIUM and its dedicated teams. Renowned globally as a key player in the supply of equipment for the thermal, chemical, and surface treatment of steel wires, FIB BELGIUM is marking several significant anniversaries in 2024.

Thirty years ago, FIB BELGIUM delivered its first electrically heated furnace. Since then, numerous installations using electricity as a heating method have been completed by our teams, consistently delivering outstanding performance and satisfaction.

With a strong commitment to reducing consumption and minimizing environmental impact, FIB BELGIUM has been continually advancing its open fire furnaces. A decade ago, we developed the IMFLEX® open fire furnace, which reduces gas consumption by up to 27%.

All our installations are equipped with 4.0 technology, ensuring traceability and quality control throughout your production process. Whether you need a patenting line, an annealing-galvanizing line, or a bell furnace, FIB BELGIUM offers a range of

cables produced meet the standards required in the renewable energy sector, particularly for large-scale applications like wind farms, solar power plants and grid infrastructure.

solutions designed to help you reduce your environmental footprint.

Join us in celebrating these milestones at the wire India exhibition. We will be pleased to present our equipment whether powered by electricity or gas as well as our Saver and e - solution ranges.

Hall 1 Booth J67

www.fib.be

AEI Machines: Leading the Change with Industry 4.0Rigid Stranding Solutions for Renewable Energy at wire India

As the global energy sector pivots towards renewable sources, the need for advanced manufacturing technology has never been more critical. AEI Machines, a recognised Rigid Stranding Machine manufacturer of more than 50 years, is at the forefront of this transformation. Embracing the principles of Industry 4.0, AEI Machines offers state-of-theart equipment that not only meets the demands of today’s energy landscape but also sets new standards for efficiency, safety, and flexibility in cable manufacturing.

AEI Rigid Stranders produce high-performance cables, key components in renewable energy infrastructure. The company’s dedication to high-quality manufacturing ensures that the

AEI Rigid Stranding Machines are equipped with advanced features that embody the essence of Industry 4.0.