Welcome to IWMA in 2024!

Quite a lot has happened since my last message in December; for one we ended the year on a high with our two-day Energy Innovates conference, and for another we launched our new version of the IWMA magazine, IWMA Insider.

I enjoyed the conference immensely; the presentations made everyone there fully aware – if they weren’t already – of the extent to which the industry is playing its part in the future, with visionary engineers and companies finding new ways to produce and distribute the power the world needs, in a mix of ever-more-elaborate control systems and massively-impressive entrepreneurism. All with the help of lots, and lots, of new cable!

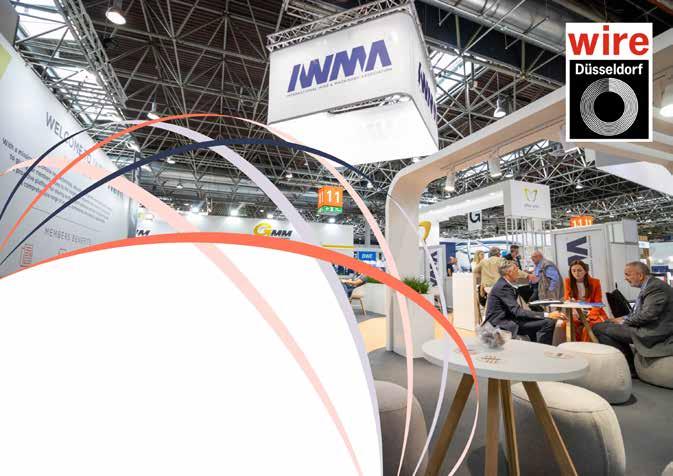

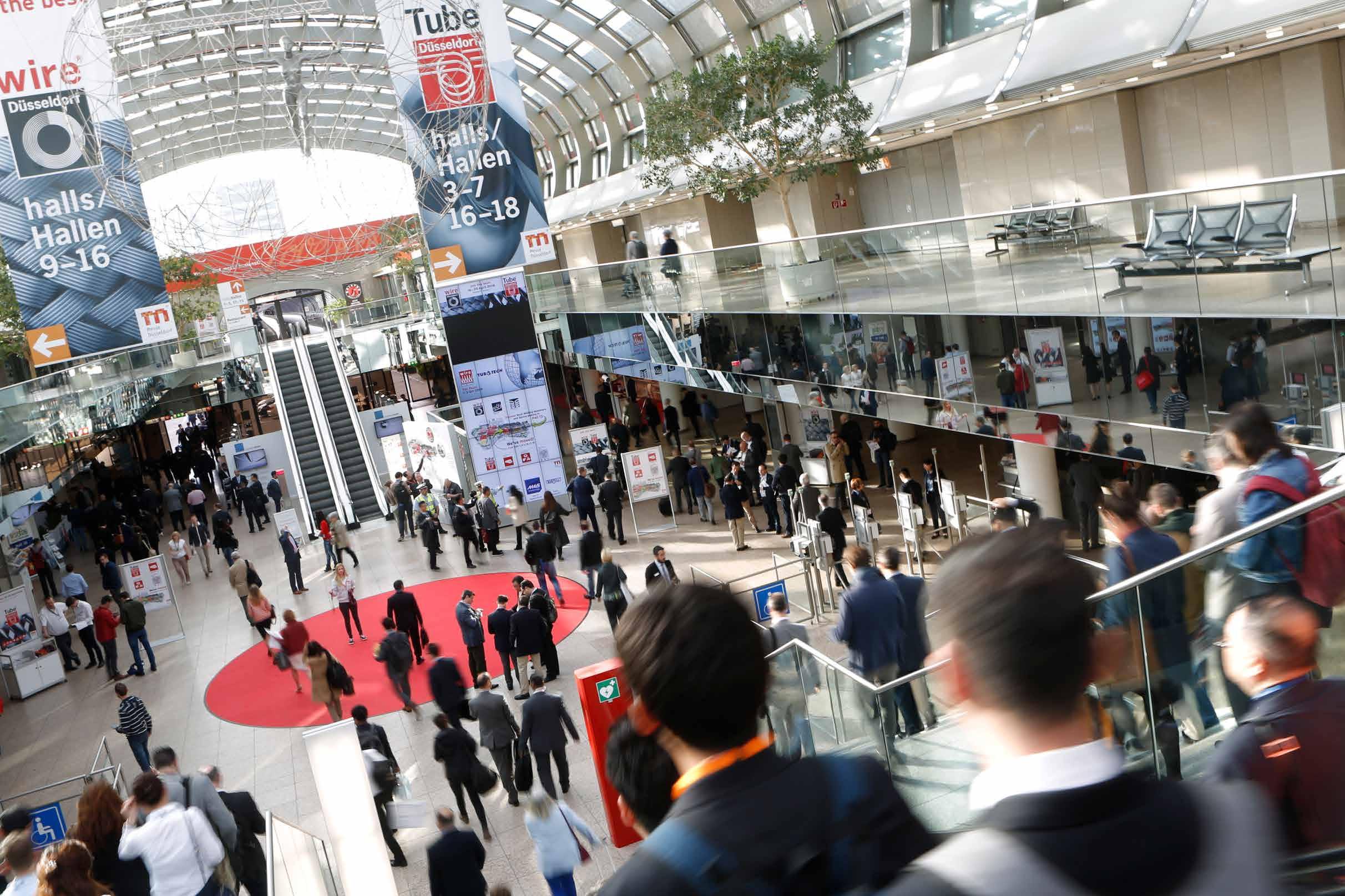

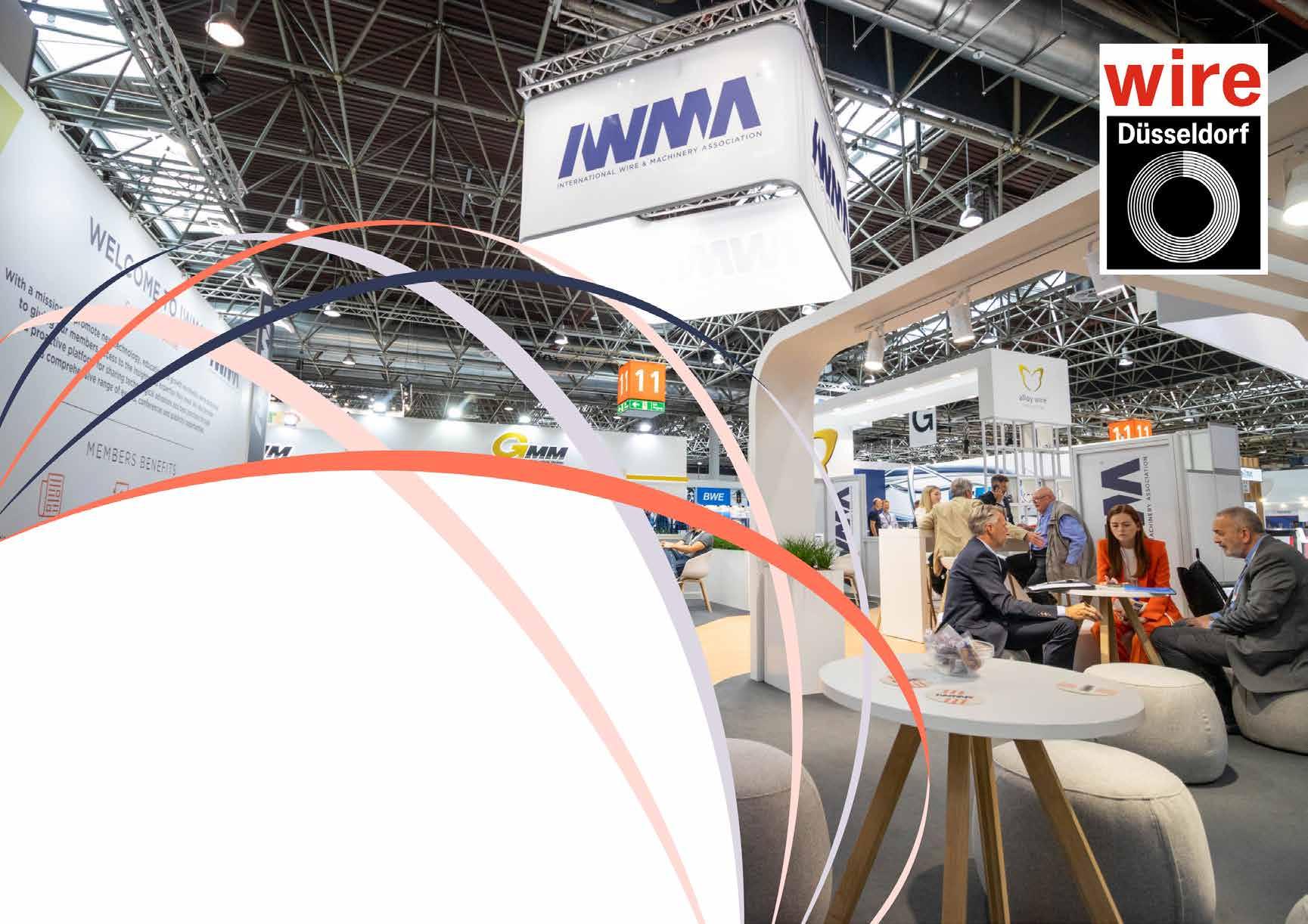

In February we launched our 2024 calendar with our traditional IWMA Industry Lunch. In addition to guests having the chance to network and meet up with old friends we also heard from Friedrich Kehrer, Global Portfolio Director at Messe Düsseldorf GmbH about the upcoming wire Düsseldorf exhibition – an event no one

will want to miss – and named our IWMA Young Employee of the Year, more about which you can read later on page 8.

We’re excited to be back again in Düsseldorf this year. We will be in hall 11, stand D22 and will offer our usual hospitality to members and potential members alike, as well as meeting tables for members to meet guests and possible clients. Members will be able to enjoy light lunches (but when the sandwiches are gone, they’re gone!), each day from 12.30pm-1.30pm, and we will be running two full networking events on the stand, on the Tuesday and Wednesday evenings. Find out more about the IWMA stand on page 35.

Also in Düsseldorf, we will be welcoming this year’s ten wire education awardees. Our awardees, who will receive free travel to Düsseldorf, accommodation, and admission to the wire show, will have the chance to meet industry leaders, ask questions and chat to experts in their chosen fields. This year’s award attracted more applications than ever before, and it was hard to narrow them down to only ten. We are extremely encouraged by the growing success of our wire education awardee programme and encourage all our members to be sure to nominate their candidates for this programme in the future.

The other big shows we are looking forward to with great anticipation this year are wire China in September and wire India in November. At both we’ll be returning to our popular networking events (find out more on these on page 35) and there will also be opportunities for members to give presentations in our stand’s new seminar and presentation area. Stay alert for our emails to see how you can be part of this.

To round out our 2024 events this year will see the return of our popular IWMA dinner dance, which has been part of the IWMA scene since the mid-1970s. Full info on page 9.

Throughout 2023 IWMA worked on developing a 5-year plan to provide essential operational continuity, membership growth and to strengthen its delivery of member benefits. One of the many actions we’ve initiated to successfully achieve these objectives has been to re-introduce the role of a president for IWMA.

With this in mind, I am extremely happy to share, as no doubt many of you will already know, that my friend and fellow IWMA executive management committee member Bernd Lohmüller – joint managing director of machine makers Maschinenfabrik Niehoff – will be our president, while I continue as chairman. I will continue to handle the day-to-day work of the association while Bernd, as you can read in an extended profile in this edition, will spearhead a move to attract new members and enhance the influence of IWMA around the world.

That’s all for this time. I look forward to seeing you in Düsseldorf. Please be sure to come and visit us in Hall 11, Stand D22.

My very best wishes to you all

Don Neville Chairman, IWMA

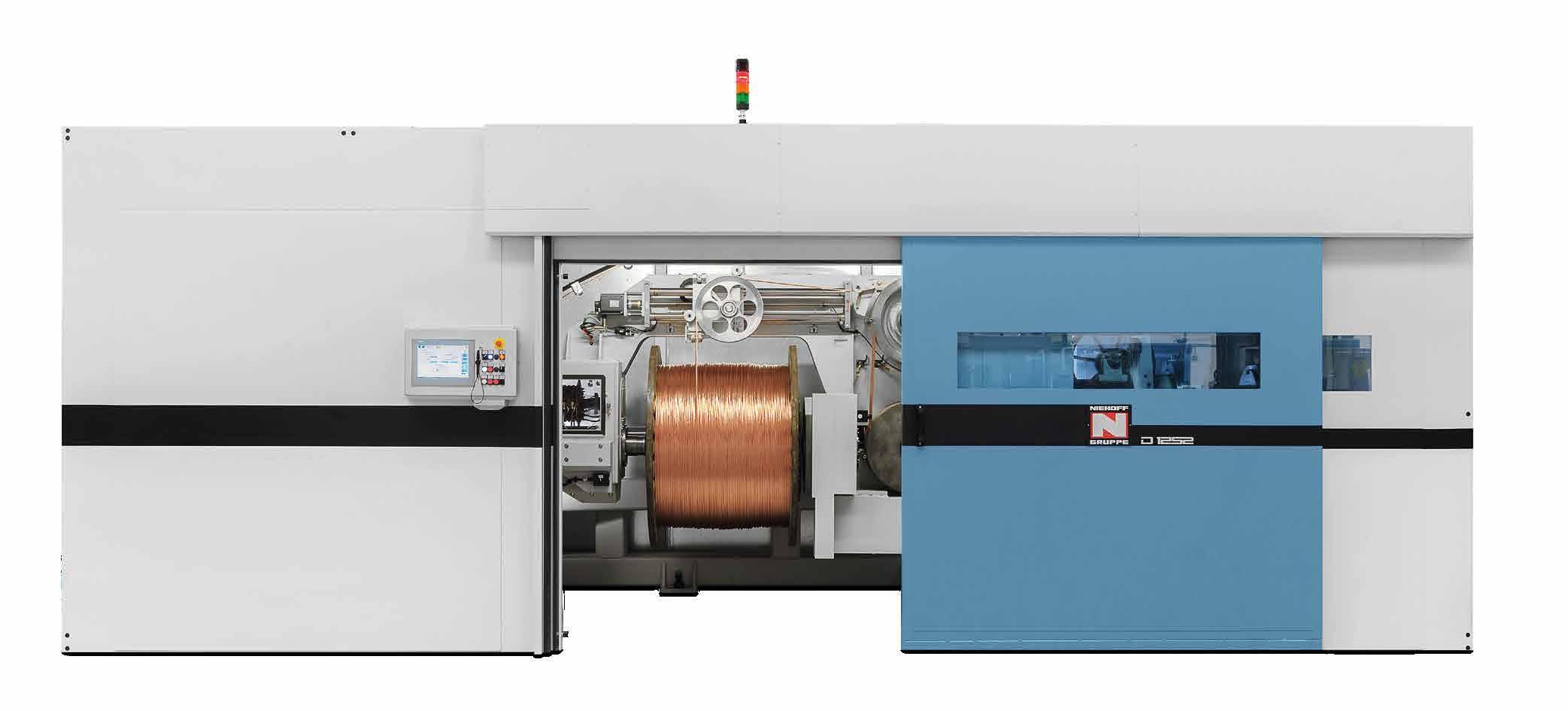

The company, founded by Walter Niehoff in 1951 (he too was an IWMA president, in 1983), ran as a family business for many years, with the founder very much in charge. Niehoff is renowned for producing rod breakdown lines, multiwire lines, Double Twist stranders, braiders, tin plating lines, and much more wire processing equipment.

It took newly-announced IWMA president Bernd Lohmüller a little over a decade to realise – with the help of American colleagues – that while he had joined German wire and cable machinery giant Maschinenfabrik Niehoff as a mechanical engineer, his true calling might be in sales.

After joining Niehoff from university in 1988 as a 23-yearold mechanical engineer, he had spent the 1990s with engineering teams developing coilers and annealers; indeed, he acquired three international patents for his work.

“Then I moved to our American subsidiary, Niehoff Endex, in 2000 to be technical manager, and in 2002 became its Managing Director,” smiled the 58-year-old, current Niehoff Group joint managing director.

“Our sales team there was always asking me to go along to sales meetings and used to call me their best salesman, even though I protested I was an engineer. The reason was simply that as an engineer, I could explain the machines to fellow engineers in detail, so they trusted us, and we made sales on the strength of that trust.”

It was a lesson for the future, certainly. Bernd began his growth in sales and service at Niehoff Endex – based in New Jersey - and has continued in the same vein.

In his current group role, he is responsible for the company’s global sales and service operations.

“I greatly enjoyed my time in the US,” he said. Born and raised in Niehoff’s hometown of Schwabach, Bernd has spent time away from the town only twice: to run Niehoff Endex, and earlier when he studied mechanical engineering (at Nuremberg University, only 20km away).

When he returned to Germany from the US in 2005, it was to take charge not of technical matters but as manager of Niehoff’s global sales and service operations, serving under two CEOs; the highly respected Heinz Rockenhauser, who was responsible for growing the company internationally for two decades until 2013, and his successor, Arnd Kulaczewski, who left the company in 2017.

After the latter’s departure, the senior management role was split three ways: Bernd became MD in charge of sales, his long-term colleague Elena Graf became MD and retained her role as financial officer, and Ralf Kappertz joined to be MD in charge of production and engineering.

“The set-up works very well; we all have expertise in specific areas and together we form a powerful team,” Bernd explained.

As Bernd explains, Niehoff’s strength lies not simply in keeping its machines running, but in upgrading, enhancing, and automating them in ways never envisioned by their original engineers – people like himself – when they were designed and built 20, 30 or even 40 years ago.

“Our business today has two sides,” he explained, “Machinery for expansion, and machinery for substitution. The first is self-explanatory, and it’s not really enough to sustain the company.

“But we have clients running machines up to 60 years old, so we advise replacing the oldest machines because new ones are more efficient, easier to operate and use less power. If it’s something like the M85, it can still command good money second hand, so makes up the down-payment on a replacement.

“But if a machine was installed, say, in the past 25 years, the owner is less likely to want to replace it. In those circumstances we can upgrade it: new electrical cabinets; AC rather than DC motors; new control equipment, and so on. That way the machine is good for another 15-20 years.”

The two sides of the operation, plus overhauls and repairs, have seen Niehoff grow in 20 years from 700 or so to 1,200 staff, and turnover rose impressively after Covid shutdown. Despite its negative connotations, the Covid crash proved to be an extraordinary catalyst for positive change. Niehoff has seen rapid growth in the past three years.

“The market exploded after 2020; at first, we thought it was an anomaly based on pent-up demand, but the growth of renewables for generation and distribution, moves to upgrade the US power grid and electric vehicles and the charging infrastructure, have all come at the same time. They are all increasing the demand for cable and wire and will for years to come.”

As a company, Niehoff Group has an advantage over most, because is allowed by its shareholders to invest a big share of its annual profits. “It means most of the company’s annual profits can be reinvested; it’s a big asset,” explained Bernd. “We have been able to invest in our HQ campus and factories; buy the latest machine tools and so on, and money can be invested in research and development.

“Another factor in our success has been our ability to present the same face to customers, year after year. Many staff join us as young people and stay with us their whole career. It means we can rely on their expertise, and customers have long relationships with people they trust.”

Relative market domination does, of course, require constant attention, and Niehoff works on five-year strategy cycles, a new one of which is set to be taken up in the next few months as Niehoff looks towards 2030 and the demands made by international limits on carbon emissions.

“It’s very clear which way we need to move,” explained Bernd. “It’s all about energy, automation, training, and customer services.

“Our machines need to save energy and CO2, especially with CO2 charging on the way. The less power our machines consume, the less CO2 they produce.

“We also need to work on automation. With automation you are minimising the influence of an operator, and it makes things more efficient overall. But in some areas, you must have an operator, and it is important to ensure they know what they are doing – which isn’t easy if there is a high turnover of people. If a customer has to train new operators every few months, tools are needed to improve the process, so we are working on tutoring concepts to make this easier. Away from the company, Bernd’s latest “job” is to be president of the IWMA. “To be honest I wasn’t looking for more work,” he laughed, “but I have been an executive management committee member since 2005, so for me the role made sense”.

“Niehoff has traditionally been an IWMA member, but following Walter Niehoff into the role is about more than tradition. I was simply looking for more influence on the global wire and cable trade.

“Trade shows are important for marketing, sales, and networking and the biggest and best one is in Düsseldorf.

But there is a lot of competition; many smaller organisers want to have their own shows, but this isn’t necessarily good for the industry. Ideally, we want one major show each cycle – Düsseldorf – and some satellite shows, but in India, for instance, there are three wire and cable shows a year. So, a major reason to accept the president’s role was to have a measure of control. Apart from that, networking has always been a major part of the IWMA, with members all over the world.

“As for splitting the senior role in two once again, with a chairman and now a president, with all respect to (current chairman) Don Neville and my colleagues, people around the world know Niehoff and know me; it will help us to grow the organisation. My goal is to increase membership over the coming years; I like the association and together, especially with more members, we can help to structure things better.

“In some ways I’m president of the IWMA, not just for the IWMA but for the industry as a whole; and I love the industry…”

The IWMA Industry Lunch, a cornerstone event in the wire and cable industry, recently marked another milestone in our history. This year’s gathering shone a spotlight on innovation, achievement, and the bright future of our industry.

Highlights of the event were insightful presentations from esteemed industry leaders. Andrés Cartagena Ruiz of MFL Group took the stage with an enlightening talk on “Industrial Troubleshooting with GPT Language Models,” showcasing the transformative potential of AI in addressing complex industry challenges. His presentation not only demonstrated the practical applications of AI but also sparked conversations on future tech integrations in our workflows.

Adding to the excitement, Friedrich-Georg Kehrer, Global Portfolio Director of Metals and Flow Technologies at Messe Düsseldorf GmbH, delivered an engaging update on the eagerly anticipated wire and Tube trade shows. His update provided a glimpse into wire Düsseldorf, what promises to be a landmark event, further cementing its status as a must-attend for industry professionals along with its satellite exhibitions globally.

The event also celebrated the achievements of rising stars within our community. Fabrice Pfefferli of AESA Cortaillod SA was honoured as the Young Employee of the Year for 2024, recognising his contributions as an Electronic and SW Engineer. His award is a testament to the talent and dedication that continues to drive our industry forward.

A momentous occasion was the introduction of the new IWMA president, Bernd Lohmuller, Managing Director of Maschinenfabrik Niehoff. With over two decades of service on the Executive Management committee, Lohmueller’s transition into the presidency marks a new chapter for the IWMA. His inaugural speech reflected on the legacy of his predecessor, the late Walter Niehoff, and shared his excitement for the future.

The lunch concluded with closing remarks from Don Neville, Chairman of the IWMA, who reminded attendees of the significance of the IWMA dinner dance, a tradition since 1976. His words left us looking forward to the future with anticipation and excitement for the continued growth and success of our industry.

It’s not only award season in Hollywood! On February 21st we were delighted to announce the winner of this year’s IWMA Young Employee of the Year award at the IWMA Industry Networking Lunch held at the Delta Hotels by Marriott Manchester Airport. The awards honour the industry’s most promising young talents, not just for their professional achievements, but also for their commitment to personal growth in alignment with their company’s goals and their ability to effectively engage and collaborate with their peers. It wasn’t easy, but our panel whittled down an impressive list of nominees to a shortlist of four outstanding candidates before choosing Fabrice Pfefferli as the 2024 Young Employee of the Year.

Fabrice’s dedication, technical prowess, and contributions to innovation make him a worthy winner. Working as an Electronic and SW Engineer in the R&D department of AESA Cortaillod SA, Fabrice spearheaded the development of METIS, a groundbreaking scientific software for data cables now globally integrated into AESA’s measuring instruments, and his expertise also led to the complete redesign of the Dragon electronic board, equipped with new communication protocols, to enhance AESA’s Automated Test Equipment. Beyond technical innovations, Fabrice has been instrumental in signal analysis, developing a user-friendly support app, mentoring students and peers, and driving a collaborative project for future VNA technology. His enthusiasm for sharing knowledge through training underscores his commitment to collective growth and adds an extra dimension to an already exceptional contribution. Congratulations Fabrice – we will watch your future career with interest!

Honourable mention must go to the other three candidates who were on the shortlist: Ebony Maher, Forensic Team Leader, Bridon-Bekaert the Ropes Group, Janelle

Gerardi, Senior Product Development Chemist, RichardsApex Inc., and Rabia Ashfaq, Executive Quality Control Technical Department, Pakistan Cables Limited. Ebony’s swift progression from a forensic technician to a key contributor in developing innovative techniques has inspired her colleagues to tackle new challenges. Janelle’s collaborative skills, ability to navigate a complex regulatory environment, and dedication to professional development have combined to make her a role model for young professionals. Beyond her creative and impactful contributions to advancing quality improvement, Rabia embodies the values of her organisation and actively contributes to addressing gender disparities in STEM fields in Pakistan. Industry doesn’t progress if it doesn’t constantly encourage new entrants to use their education and skills to take current standards to new levels, and each of our shortlisted candidates have done this, delivering innovation and excellence.

They have also made an exceptional and enduring contribution to their team, their company, and the industry as a whole, and exceeded expectations for someone at this stage of their career.

The awards were hosted by Stuart Duff, Executive Management Committee Member & Business Development Manager CEE & ROW at Metal Manufacturing Products, Q8 Oils, and presented by Friedrich-Georg Kehrer, Global Portfolio Director wire / Tube and Flow Technologies, Messe Düsseldorf GmbH. Thank you to them, and to every experienced professional who nominated a young colleague for this award, demonstrating the wealth of talent and dedication within our industry.

Mark your calendars and dust off your dancing shoes as we proudly announce the revival of the IWMA Dinner Dance! After a hiatus, we are bringing back this cherished tradition that first graced the scene in February 1975 in Stratford-upon-Avon. This time, we are thrilled to unveil a fresh chapter in a brand-new area of London, with the iconic St. Paul’s Cathedral providing a breathtaking backdrop. Join us at the luxurious Leonardo Royal Hotel London St Pauls on Friday 15th November for an evening of elegance and celebration.

Your ticket will include welcome drinks, a delicious four-course dinner, and perfectly paired wines. After dinner, continue the evening with after-dinner drinks

and live entertainment by a dynamic band as we dance the night away in style!

For the convenience of our guests, IWMA has secured a block booking of hotel rooms at a preferential rate for those wishing to extend the celebration with an overnight stay at the Leonardo Royal Hotel London St Pauls, ensuring a seamless transition from the grand festivities to a night of restful relaxation. Don’t miss your chance to be part of this historic event. We look forward to welcoming you to the grand ‘Return’ of the IWMA Dinner Dance— get ready to revel in a celebration decades in the making!

Details regarding pricing, ticket bookings, and hotel accommodation will be released in early May — keep a keen eye out for more information!

wire Düsseldorf Networking Events

Tuesday 16th and Wednesday 17th April 2024

BCC Bangkok Cable

wire China Networking Event

Thursday 26th September 2024

wire India Networking Event

Thursday 28th November 2024

IWMA Dinner Dance

Friday 15th November 2024

IWMA Industry Lunch 2025

Date TBC

With six decades of sustainable growth, Bangkok Cable has established the reputation and success of being Thailand’s leading manufacturer of electric wires and cables.

We are proud to be a wholly Thai-owned company, pioneering the way with continuous innovation to develop industry leading solutions that will deliver unrivaled value for our customers. BCC is proud to showcase the best of Thailand’s engineering minds and expertise on the global stage. Since our company’s founding in 1964, BCC has grown from strength to strength to best serve the demands of our customers. Integrated into our values is an unparalleled dedication to excellence with state-of-the-art manufacturing technologies, innovation throughout the manufacturing process and unrivaled product quality. The BCC brand symbolizes the best quality products in Thailand, superior customer service, competitive prices and achieves the highest trust from our customers and partners around the world. With the emergence of Thailand’s 4.0 economy and the growing opportunities through the ASEAN economic community, BCC remains fully committed to invest, develop and create infrastructure resources that will become the center piece of the flow of electricity across the region, ultimately developing the region’s economy to transform people’s lives for the better.

www.bangkokcable.com

Cables & Solutions was started in the course of 2023 by David Cavassa who has spent his entire career within the W&C industry ever since he started working for then Pirelli Cables (Prysmian) in the UK in 1999, then working with Geca-Tapes, PolyOne (Avient) and UL.

The company operates out of Lille in France and is active in Europe and beyond. As per its motto, “Connecting the Industry”, its ambition is to provide companies with the strategic support, information, and connections they need to expand their footprint, grow their revenue, and improve their operations and profitability.

Cables & Solutions partners with leading and emerging companies in niche markets and delivers consulting services that cover business strategy, M&A due diligence, market intelligence, compliance management, as well as product and business development.

www.cablesandsolutions.com

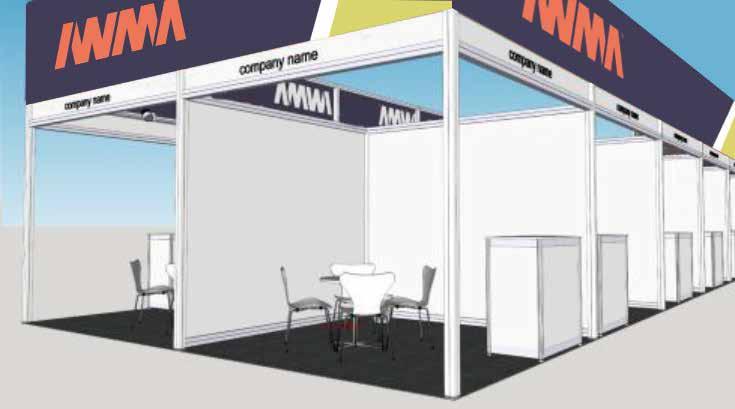

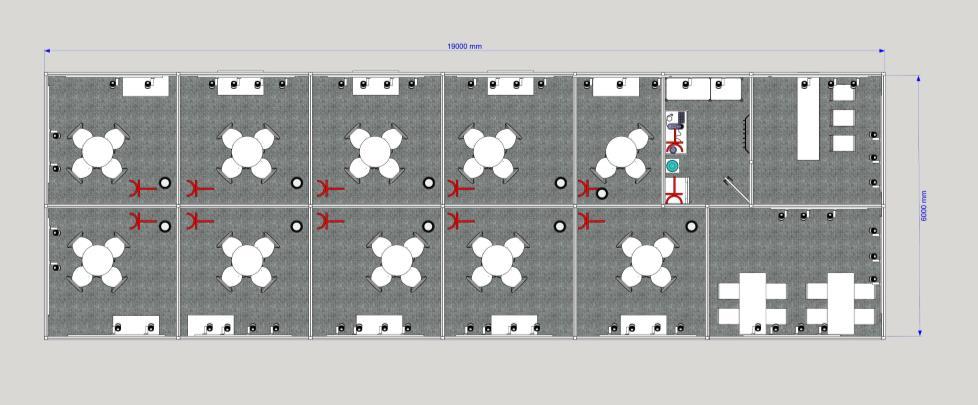

Join the IMWA wire India Pavilion!

After the success of our pavilions at wire Southeast Asia, we invite you to exhibit with us as part of our group at wire India, scheduled to take place from 27th - 29th November 2024.

¤335.00/sqm with IWMA premium stand & build package + ¤335.00 one off IWMA management fee

Prices to include the following:

Carpet: coloured grey, directly on floor | Maxima Profile with laminated plywood wall panels | Maxima system structure above stands, approx. 1200mm high | Horizontal fascia board | 300mm high including company lettering and stand number | 1pcs Round table with white top | 4pcs Chair in black | 1pcs lockable counter (1m in height) | 1pcs wastepaper bin | 4pcs spotlights | 1pcs Socket

220V | Wi-Fi for up to 4 users | Complimentary IWMA Hospitality | Use of IWMA Meeting Room | Guaranteed presentation slot at IWMA Member Seminars

For further information, to discuss your requirements, or to request an application form, scan here to email Jessica at jessica@iwma.org

After significant interest, we’re thrilled to introduce our pavilion at wire India for the first time.

Participating in the IWMA Pavilion at wire India, situated at the prime location of F32, offers unparalleled advantages. IWMA provides extensive support throughout the exhibition phases, ensuring a smooth and impactful experience for our members. Exhibitors will benefit from personalised hospitality services throughout the event and Wi-Fi to keep them connected and comfortable. Moreover, a guaranteed spot in the IWMA member seminars offers an esteemed platform for showcasing expertise. Our dedicated stand builder is on hand to support you with the build package, and should you wish to further customise your stand, they can offer flexible solutions to enhance your presence. This strategic support aims to enhance your exhibition impact and solidify your industry position, promising a highly beneficial experience at wire India.

In a remarkable stride towards industry development IWMA are pleased to present the 2024 wire Düsseldorf Education Awardees –a distinguished group of ten individuals poised to make significant strides in the wire and cable industry through their exceptional talents and dedication to learning and growth.

This prestigious programme, an evolved version of the John C. Hogg Travel Award Scheme, promises enhanced learning experiences and benefits for all participants. The 2024 wire Düsseldorf Education Award attracted an unprecedented volume of applications, presenting a significant challenge in finalising our selection.

The chosen awardees are scheduled to kick off their immersive journey on Monday, April 15th, with a Meet & Greet Event at the Novotel Düsseldorf City West, where they will be accommodated for four nights. The programme will unfold with complimentary access to wire 2024 and a tailored three-day itinerary featuring the IWMA Training Fundamentals Programme, intricately woven into an exclusive tour of the show.

Geared towards newcomers in the industry and wire exhibitions, the programme provides an up-close encounter with the wire show. It also offers a unique opportunity to learn

from industry-leading experts and network at our exclusive IWMA wire networking event. Additionally, participants will enjoy a guided evening tour of Düsseldorf with food and drink, culminating in a presentation by IWMA and Messe Düsseldorf GmbH upon completion of the programme.

Demonstrating IWMA’s commitment to nurturing talent and fostering industry connections, we look forward to witnessing the growth and development of these ten exceptional individuals. Follow their journey and stay tuned for updates on their enriching experiences and contributions to the wire and cable industry in the upcoming editions of our magazine!

We look forward to welcoming the below awardees from member companies to Düsseldorf:

• Jonathan Reeves, AESA SA

• Aaron Heath, Bridon-Bekaert The Ropes Group

• Ebony Maher, Bridon-Bekaert The Ropes Group

• Handre Linstrom, Cape Gate Pty Ltd

• Dominik Ippisch, DLB Oberviechtach GmbH & Co. KG

• Hardik Patel, InnoVites B.V.

• Syed Ammar Zaidi, Pakistan Cables

• Joshua Burley, RichardsApex Australasia

• Sharon Lu, Shanghai KECHEN Wire & Cable Machinery Co., Ltd.

• Sushant Surajkar, Sneham Taping Solutions Private Limited

This year wire and Tube will have a phenomenal 2,600 exhibitors across 119,000 sq m of halls –almost 1,500 of them, from 62 countries across 67,000 sq m of floor space, showing wire- and cable-related products and services.

This means wire 2024 has surpassed the excellent result of the previous-best 2018 exhibition, when 1,441 exhibitors from 53 countries occupied around 65,000 square metres.

The surge is partly down to production and sales getting fully back to normal post-Covid, and also to the massive upturn since 2020 in wire and cable for automotive and renewable-energy technologies.

Strong exhibitor growth has come from Turkey, Italy, Austria, Spain, Switzerland, Sweden and the Benelux countries, while exhibitors from India, South

Korea, Taiwan, China and the USA have boosted the international element.

“This is a great result, and a clear signal that wire Düsseldorf continues to be the international No 1 trade fair for wire and cable,” said Friedrich-Georg Kehrer, Global Portfolio Director for Metals and Flow Technologies, Messe Düsseldorf.

This year both wire and Tube will be part of Messe’s “eco-metals” initiative, which highlights companies and processes heavily invested in green operations from the extraction of raw materials in the least damaging way, through energy-saving production to innovative ideas that will spur new, greener technologies. So far nine companies have joined the eco-metals drive and some will be heavily involved in the show through forums and conferences, for more information visit www.wire-tradefair.com/en/Programme/ecoMetals

AYMAK MAKINE Mühendislik Hiz. San. ve Tic. Ltd. Sti. 11 J77

Bongard Machines GmbH & Co. KG 11 A21

BOZBROS DIS TICARET ANONIM SIRKETI 11 J31

BWE Ltd. 11 E25

Central Wire Industries UK Ltd. 11 A22

DRTImpianti Srl / DRT. 11 C57

Ducab Metals Business LLC 11 G74

EUROTEK S.r.l. 11 G22

FIB BELGIUM S.A. 11 C60

FMS Force Measuring Systems AG 11 E32

GEO Reinigungstechnik GmbH 11 A32

InnoVites Cable ERP Software BV 11 C16

Intras Ltd. 11 A09

Intras Ltd. 11 E63

IWMA - International Wire & Machinery Association Limited 11 D22

Joachim Uhing GmbH & Co. KG 11 B40

Koner Srl 11 A56

Madem S.A. 11 H25

Metalube Ltd. 11 B25

Microdia S.A. 11 D25

Novametal S.A. 11 H06

Proton Products Europe N.V. 11 J60 Q8Oils 11 D21

Reichenbach Equipamentos Indústria e Comércio Ltda. 11 B42

Ridgway Machines Ltd. 11 J01

SNEHAM TAPING SOLUTIONS PRIVATE LIMITED 11 J39

With a commitment to sustainable practices and a keen eye on emerging technologies, AEI Machines is poised to shape the future of connectivity by manufacturing machines that produce quality products while implementing energy-efficient technologies.

The AEI Machines team looks forward to welcoming visitors from all over the world and showcasing new developments on AEI Stranders for high production flexibility, enhanced safety, reduced downtime, and minimum maintenance efforts.

Transatlantic deal puts Alloy Wire International in good shape for wire 2024

The UK’s leading manufacturer of round, flat and profile wire is heading to wire 2024 off the back of one of its largest ever export orders.

Alloy Wire International (AWI), which is taking its 60-strong range of exotic alloys to Düsseldorf in April (15-19th), has just sealed a $400,000 contract with a US springmaker to supply a high strength nickel cobalt alloy.

The DFARS compliant material will be used in an aerospace application that requires heat and corrosion resistance, with the company chosen for its world class quality and the ability to process the order in just a matter of weeks.

It is these two qualities, along with a sector-leading 400 tonne stockholding, that AWI will be pushing in Germany when it looks to increase its international sales even further.

Exhibiting on stand E26 in Hall 11, the company will be represented by staff from the UK and agents from Germany, Italy, and the US.

Tom Mander, Managing Director of Alloy Wire International, commented: “Wire 2024 is the biggest global show in our sector, so it is great news that we are heading there after winning such a sizeable export order.

“It illustrates how UK manufacturers can remain competitive through investment in the latest technology and a commitment to work with our customers to deliver exceptional technical advice and access to significant amounts of stock at short notice.”

He continued: “The US order really does typify what AWI is all about. We received the enquiry about two months

ago, went back quickly with a quote, agreed the deal, and processed the large quantity and despatched it in a matter of weeks.

“wire 2024 gives us another opportunity to take our key selling points to a global audience and we’ve invested heavily in creating our biggest stand yet and a new timeline that charts some of the big moments in our 78-year history.”

Alloy Wire International manufactures round, flat and profile wire in 60 exotic alloys, such as Inconel, Monel, Hastelloy, Nimonic and Waspaloy.

From its two factories in the West Midlands and Yorkshire, the company continues to be a critical supplier to the UK manufacturing sector whilst also growing its export business, which currently accounts for nearly 55% of its £17.9m sales.

This means AWI now supplies 6000 customers across 50 countries and 15 different market sectors and, despite global supply chain disruption, is still delivering material in just three weeks from the order being placed.

Tom went on to add: “We’re seeing growth across all industries, with automotive up 6%, aerospace 3% and a resurgent oil and gas marketplace (10%+). There are also big opportunities in space, medical and nuclear, as firms strive for material that delivers the performance they require in the end application.”

He concluded: “The team can’t wait to travel over to wire 2024 and meet up with colleagues, suppliers and customers in Düsseldorf, as we look to champion the power of UK manufacturing to the world.”

Hall 11,

www.alloywire.com or follow @alloywire on twitter

As an internationally active family business, STRECKER has been working in a progressive and future-oriented manner with high quality awareness since 1933. STRECKER offers complete solutions for individual manufacturing processes in welding technology.

At this year’s wire 2024, welding machines for different applications will be on display: electric buttwelding machines for steel, copper, aluminum, brass, for solid wires or stranded wires and conductor cables. There will be fully hydraulic butt welders with automatic deburring and pneumatic welding machines for bulk wire products, as well as cold welding machines for non-ferrous wires.

The continuous optimisation of proven welding machines will also be addressed: the user-friendly version of electric strand buttwelding machine type SE1, with handle for easy movement, cable holder and optional cover of the mimic to protect the mechanics and large collecting tray for smashed ceramics.

Customers can experience welding directly on the stand and, of course, discuss individual requirements for special, tailor-made machine constructions with the experts on site.

Hall 10, A21

www.streckerusa.com

Celebrating 170 years of lubrication excellence!

2024 marks a significant milestone for CONDAT as the company celebrates its 170th anniversary! Based on embodied values, such as its historical one ‘Build to last’, CONDAT has demonstrated its ability to adapt, innovate and reinvent itself over the decades, leveraging its extensive and steadfast expertise.

As evidence, CONDAT provides a comprehensive range of borax-free products, from surface treatments to wire drawing soaps! Pioneering interest in this area over 20 years ago, CONDAT has expanded its borax-free range with a focus on operator health and environmental sustainability. Similarly, CONDAT meticulously selects raw materials for its formulations, striving to minimize the use of CMR components and hazardous materials.

Renowned for its commitment to responsible performance, the French lubricant manufacturer continues to lead the way in offering products with minimal environmental impact without compromising on performance and productivity. Its lubricants are recognized as a world reference in the wire drawing industry.

While product quality and efficiency are paramount, CONDAT distinguishes itself with personalized advice on implementing lubrication solutions. Recognizing the unique needs of each wire drawing plant, CONDAT experts prioritize guiding partners towards optimal lubrication strategies.

BWE Ltd, a leading British engineering firm, specialises in continuous extrusion machines and cold pressure welders. Their Conform™ and Conklad™ technologies are renowned in the non-ferrous, cable, and tube industries. SheathEx™, developed in 2005, seamlessly sheathes high-voltage cables with aluminium, now available in both corrugated and smooth options. This cost-effective process ensures a continuous, weld-free aluminium sheath with excellent conductivity. BWE’s innovations extend to Wire Arc Additive Manufacturing, 3D printing, Electric Vehicles, and Precious Metals. Headquartered in Ashford, Kent, they offer trials and demonstrations, showcasing their commitment to technological advancement. BWE also provides a range of cold welders and dies for efficient non-ferrous material welding.

Hall

www.bwe.co.uk

DRT is pleased to welcome you to wire Düsseldorf from 15 to 19 April 2024.

DRT’s staff will be happy to present to you some of our main products:

Automatic batch Pickling House fully equipped for wire rods | APH

Automatic Handling System for wire rods | AHS

Automatic Regenerating System of sulfuric acid | ARS

We look forward to seeing you.

www.drtimpianti.com

Aligned with its ethos of responsible performance, CONDAT’s objective is not to encourage excessive consumption but to assist wire producers in consuming less while consuming better! In connection with eco-use, the CONDAT team can conduct on-site assessments to reduce total wire drawing costs, minimize workshop dust, enhance productivity, and maximize the effectiveness of precoating’s and wire drawing soaps.

Empowered to tackle technical, environmental, and societal challenges, while fostering innovation and sustainable practices, CONDAT has been awarded the PLATINUM medal for its Corporate Social Responsibility (CSR) by EcoVadis since 2021 and renewed in 2023. This result places CONDAT among the TOP 1% of the best rated companies in the world.

Rely on CONDAT lubricants, honed through 170 years of pioneering expertise in lubrication technology.

Visit our stand for professional advice and expertise

EDER Engineering presents cutting-edge machines for working with drawing die tools, optimizing die longevity, tonnage drawn, reconditioning accuracy, and operational costs. Featured models will include the ETC-1/HF for tungsten carbide die grinding (0.70 mm to 20 mm), the USP-TWIN for PCD die refurbishment, an ultrasonic model with dual workstations covering 0.05 mm to 8.0 mm sizes, the ETC-2 LS for sizing tungsten carbide dies (1.0 mm to 40 mm), and the larger “ETC-3 EL” for round TC dies (up to 70 mm bore size). Explore additional equipment for diamond/PCD dies, such as the ultrasonic USP-115 and the high-speed wire-type HGM-21 sizing/calibrating machine.

Yichang Geili Diamond Industrial Co., Ltd, also known as GEILIVABLE, is renowned as a wire drawing dies factory with 400 employees and a 2024 capacity exceeding 4,000,000pcs. We offer PCD/ND/AD drawing dies, enamelling dies, and customized dies with a minimum hole size of 0.005mm.

With sales offices in Shanghai, Germany, and Japan you can contact us via email at sales@geilivable.com.cn or visit our website www.geilivable.com.cn for more information.

Hall 14, A04-2 & A04-3 www.geilivable.com.cn

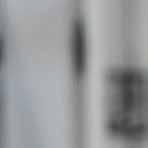

Maillefer Unveils Cutting-Edge Innovations at wire –Get a Sneak Peek into Our Showcase

Get ready to witness a convergence of revolutionary technologies at the upcoming wire Düsseldorf show, where innovation meets excellence. Our live components showcase promises to be a game-changer by featuring a lineup that spans across diverse industry needs.

Live Components Highlights

Immerge into the future of precision with our advanced Topography Scanner 2.0, where cutting-edge technology meets unparalleled accuracy. Explore the possibilities of seamless topography scanning. Get up close to high-resolution surface scanning that redefines industry norms.

From our aftermarket offerings, start discovering reliability like never before with our most recent Nomos Process Supervisor Unit. The PSU is a testament of our commitment towards uninterrupted operations. You will also experience an upgrade of enhanced efficiency with our automatic take-ups, featuring a revolutionary EKP 50/63 card rack replacement for extended lifetime and functionality.

Maillefer Factory System lets you witness the seamless integration of technologies designed to optimize production processes and enhance overall efficiency.

Get a Glimpse

Gurfil is committed to carbon neutrality and sustainability, continually enhancing practices since 2023 through its quarterly CBAM report. Operating in the cable market since 1981, Gurfil is a global supplier of Braiding and Taping machines, exporting 75% of its products to over 35 countries.

Specializing in Machinery, Foil-Film-Tape products, and Wire-Yarn groups, Gurfil offers high-speed machines, laminates, tapes, wires, and yarns.

Visit our stand to explore our showcase of innovative solutions and collaboration opportunities.

Visit www.gurfil.com for more information

You’ll elevate your operation levels with the ECH 35/45 Cleaning & Handling System. It sets new standards for efficiency and performance. Experience the precision of automated die centering with the ECH 35/45 Automatic Crosshead Centering. It helps you gain the upper hand in streamlining processes. The power of the THC 50/90 Crosshead is ready to be unleashed with unparalleled efficiency in cable manufacturing.

Delve into the future with the fiber optics FTU/FPO Take-up & Pay-off technology. The components are designed to meet the evolving production demands generated by high-speed data transmission. Experience a seamless connection with innovative design.

The next-generation Drop Cable TM1250 takes cable technology to new heights by offering a perfect blend of durability and performance. Stay ahead in the competitive landscape with this cutting-edge solution. Because throughput matters, our NXW 225 Extruder is there for you to explore the future of extrusion technology. The sizeable machine sets standards for precision and output in cable manufacturing.

Join us at this key industry event and gain insight into tomorrow’s technology. You’ll have an exclusive opportunity to participate in an experience that transforms. The Maillefer showcase reveals our dedication to pushing forth the boundaries of innovation.

The technology highlighted is tightly coupled with our transition to green energy sources and manufacturing best practices. Attending the wire show means participating in the needed changes for our industry while taking a competitive step ahead to realize those changes.

Be prepared to glimpse the future and witness the changes unfolding before you. Count on being with us at wire Düsseldorf this spring. We’re counting on you.

Hall 10, C22 www.maillefer.net

METALUBE to Showcase Cutting-Edge Lubricants and Global Support at wire Düsseldorf 2024

METALUBE, a leading UK-based manufacturer of specialist industrial lubricants, is thrilled to announce its participation in wire Düsseldorf 2024, a premier international trade fair for the wire and cable industry. With over 30 years of experience, METALUBE has been at the forefront of delivering high-performance lubricants that optimise production on the latest wire drawing machinery.

Commercial Director Douglas Hunt says: “We are excited to return to Düsseldorf in April, our focus for 2024 is not just about our first-class products but on our range of expertise including our commitment to technical service which underscores our dedication to providing innovative solutions and expertise to enhance wire drawing processes.” He adds: “METALUBE’s comprehensive after-sales support is something we’re proud of and ensures that customers receive ongoing assistance, contributing to the longevity and efficiency of their operations and equipment. Our presence in over 100 countries, ensures seamless access to our highquality lubricants on a global scale and our commitment to local availability means that customers can access our products promptly, no matter where they are located.”

Serving the domestic and international Ferrous and Non-ferrous wire machinery markets for more than 40 years, Mathiasen Machinery are pleased to announce that they will be displaying photos of a wide variety of new and secondhand wire and cable manufacturing machinery at the forthcoming wire Düsseldorf show for 2024.

NEW machinery is offered on behalf of WiCa GmbH in Austria, makers of twisting and extruding equipment and Pratto S.A. in Greece, makers of Mesh Welding Machinery.

MMI buys and sells secondhand machines globally, offering services for surplus machinery, including consignments, warehousing, rebuilding, appraisals, and liquidation. Bring your machinery list and photos for evaluation.

Contacts: Mike Mathiasen, Mark Mathiasen Hall 12, C59 www.mathiasen-machinery.com

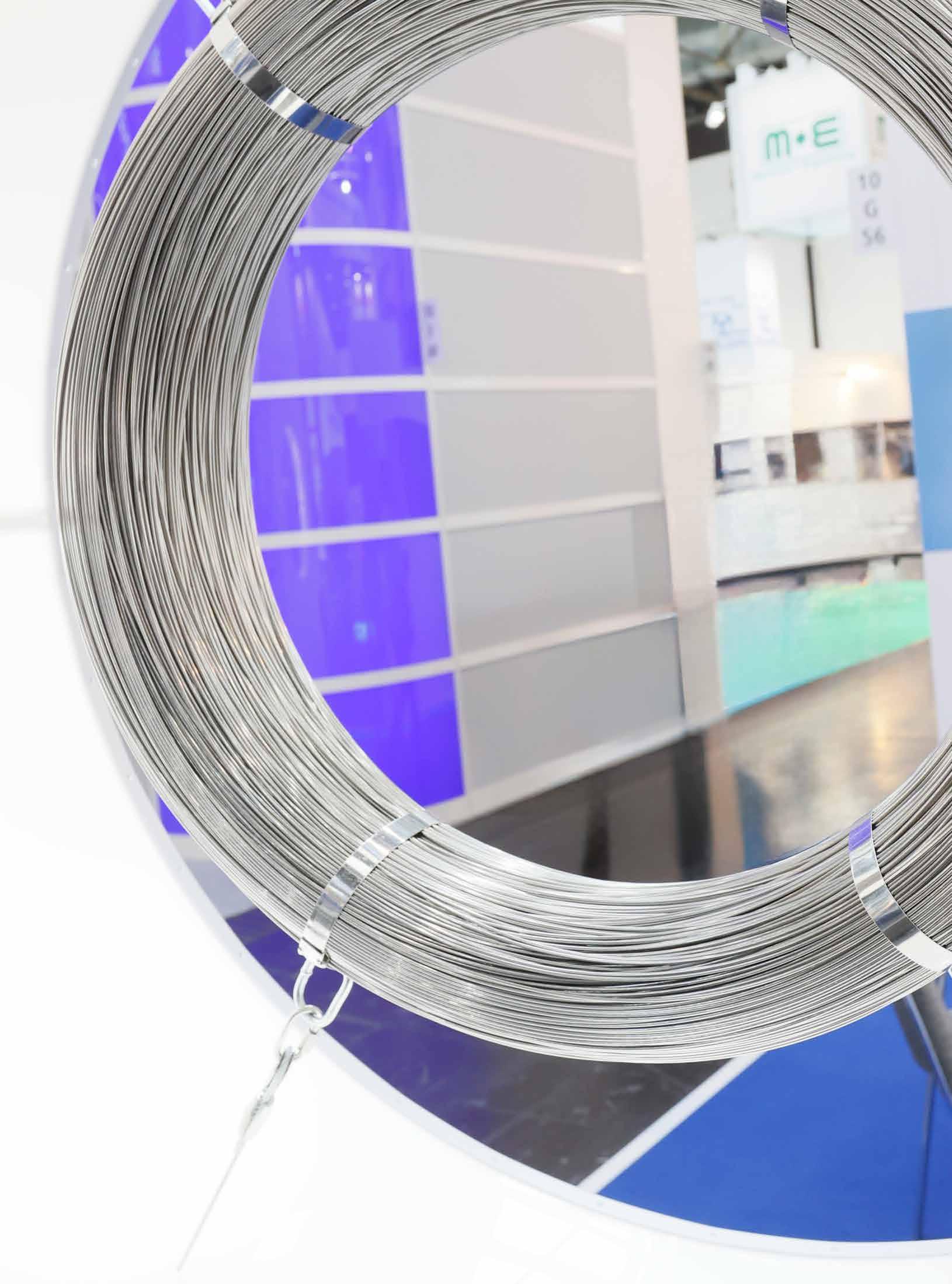

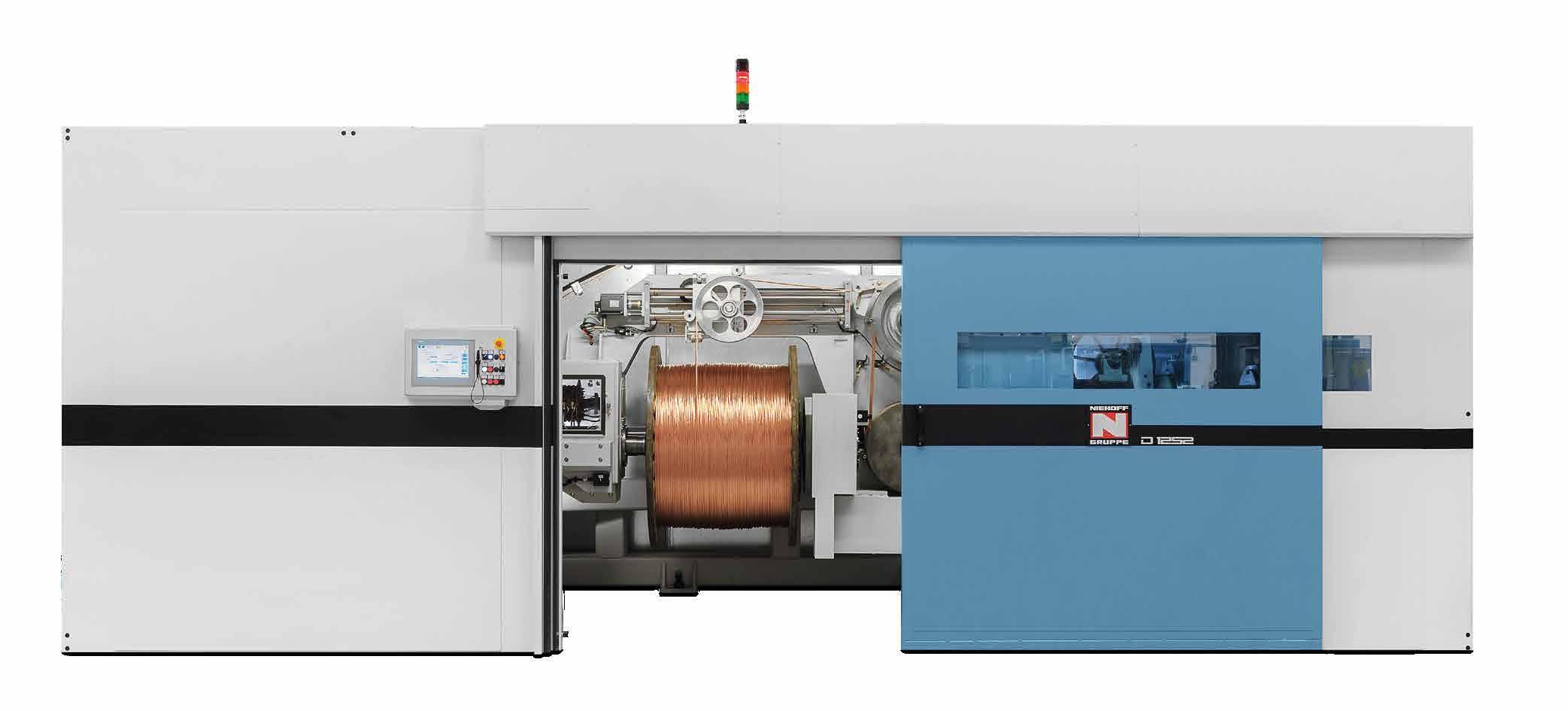

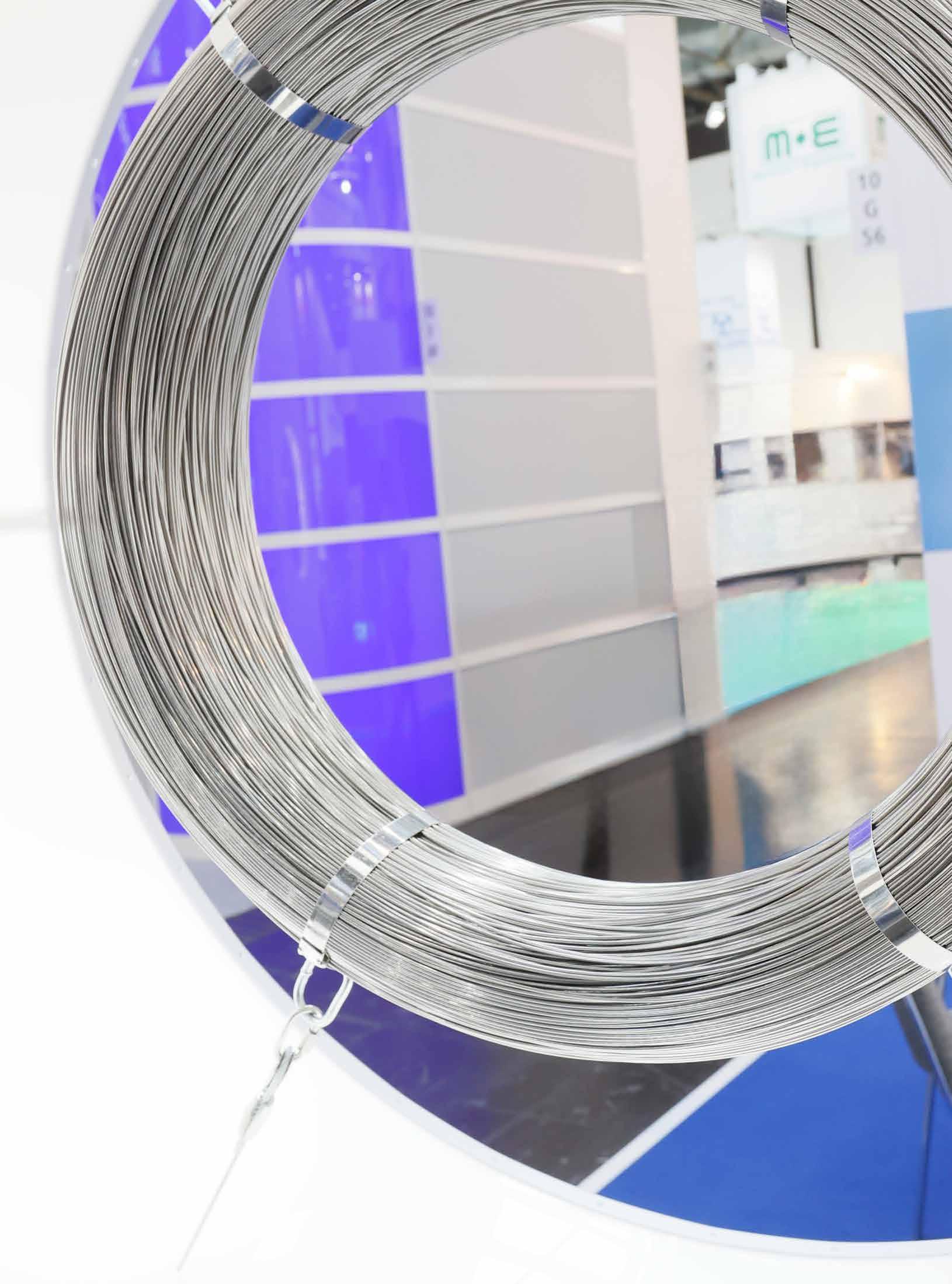

Maschinenfabrik Niehoff will present the new nextgeneration rod breakdown (RBD) line type MSM 88 – R 502.H for copper and aluminum wires. The line is characterized by a high performance combined with enormous savings in energy costs and CO2 emissions. Furthermore, there will be live demonstrations of a braiding machine type BMV 16, a new automatic rewinder for braiding bobbins type SMB, and an SV 403 D type double spooler of the cable handling system NPS (Niehoff Package System) which enables production speeds of up to 2400 m/min.

The Niehoff after-sales service will be presenting its wide range of spare parts with the “Niehoff Original+” label, contributing to further increase the efficiency of Niehoff systems in the long term. Other service offers include the modernization of earlier Niehoff machines and machine relocations. Visitors to the Niehoff booth will also learn how to best benefit from the new digital service platform myNIEHOFF.

Complete solutions from a single source With more than 70 years of experience in the wire and cable industry, Maschinenfabrik Niehoff develops and manufactures machinery required for the production of non-ferrous wires and their downstream processing into automotive, power, data and special cables – the only exception are extruders. Niehoff is member of the “Blue Competence” sustainability initiative of the German Engineering Federation VDMA and with regard to its corporate social responsibility (CSR) cooperates with the international platform for sustainability ratings EcoVadis.

Niehoff Group has a workforce of over 1100 worldwide and is comprised of its headquarters, manufacturing subsidiaries in Brazil, the US, the Czech Republic, India, China, and Sweden along with sales and service centers in Japan and Singapore.

METALUBE, headquartered in the UK, has expanded its reach to over 100 countries worldwide, with offices strategically located in Manchester, Dubai, Mumbai, São Paulo, and Shanghai. The company boasts a fully integrated lubricant manufacturing facility in Irlam, Manchester, equipped with state-of-the-art laboratories.

The core of METALUBE’s business revolves around the production of lubricants for drawing non-ferrous wire and tubes. Key products such as Lubricool, Alumol, and Tubol remain integral to the company’s portfolio. Recent additions, including the OCG range of protective greases for overhead line conductors, as well as metal forming fluids, wire rope lubricants, and chain oils, further demonstrate METALUBE’s commitment to innovation.

wire Düsseldorf attendees are invited to visit METALUBE at Hall 11, Stand B25 to explore the full range of products and discuss individual requirements with METALUBE’s expert team. Hall 11,

PWM to launch new cold welder for trapezoidal wire at wire 2024

British company PWM, which celebrates 40 years of service to the wire and cable industry in 2024, will launch a new cold-welding machine for trapezoidal wire at wire 2024. The company’s full range of products, including the P1500 cold welder for rod up to 30mm will be on show.

The new TR45 cold welder is designed specifically for nonferrous trapezoidal wire used in the build-up of sub-sea cables. The machine has a small footprint of 750 x 610mm (29” x 24”) and is mobile, so can be moved easily to the work area. Powered by an advanced air/hydraulic system, the TR45 will weld trapezoidal material up to 45mm².

PWM’s P1500 machine offers wire and cable manufacturers a quick and cost-effective way to weld large nonferrous rod. The machine is extremely energy efficient since it is driven by three hydraulic pumps and only requires electrical power for the 11Kw pump motor. Clean, quiet, and user-friendly, the P1500 produces reliable permanent welds stronger than

REELEX to Debut New Multi-Package Machine at wire 2024

REELEX Packaging Solutions, Inc. will be debuting the new S320e multi-product combination spooler/REELEX machine in Düsseldorf at wire 2024.

Exhibiting in hall 9, booth F06-1, REELEX will demonstrate the new S320e rewinder featuring the capability to wind spools, REELEX® coils and other linear winding patterns on one safe, easy-to-use machine. The S320e represents the latest in REELEX’s new equipment and coiling technologies and allows the user to make reels, spools, REELEX or linear coils all on one machine via a programmable variable traverse. Bolt-on custom shafts accommodate a variety of spool sizes, and quick-change mandrels allow a wide variety of cable sizes to be wound in REELEX. Featuring an ISO standard safety design, physical safety cage, interlocks, safety PLC and Category 4 devices, the S320e can be used safely by experienced and novice operators alike in distribution or manufacturing operations. Whether used as an entry-level REELEX machine or a multipurpose winder, the S320e offers exceptional capabilities to manufacturers and distributors big and small. The S320e

the parent material, helping manufacturers reduce operating costs, save resources and minimise waste.

The smaller best-selling EP500 pneumatic cold welder for rod 5mm to 15mm (.197” to .590”) is equally energy efficient. It can be connected to a central air supply or a dedicated compressor and only needs electrical power for the operating system.

The full PWM range includes small, lightweight hand-held manual machines for fine wire up to 1.20mm (.047”); manual and powered models that can be used on a workbench or supplied with a trolley for wire 0.30mm to 6.50mm (.0118” to .256”) and large, freestanding rod welders for material up to 30mm (1.181”).

PWM’s products are designed and made in-house and tested throughout manufacture to ensure total accuracy. PWM manufactures industry standard dies and can produce custom-made dies for specific applications.

Hall 9, B41

www.coldpressurewelding.com

is affordably priced at less than US$100,000, with leasing options available. For more information, please visit: www.REELEX.com/machines/s320e.

REELEX will also exhibit physical examples of a variety of reelless packaging technology available to cable manufacturers, including the REELEX AIR® package offering a slimmer profile, greater payout performance, a more environmentally friendly waste profile and lower material costs than current REELEX and other packaging options. REELEX AIR enables cable producers to put more product on a pallet while reducing waste and eliminating bulky and costly spools and reels.

REELEX is a patented method of winding any flexible filamentary material into a precision-wound figure-eight coil. This unique coil dispenses from the inside-out without twists, tangles, snags or overruns and may be placed into a wide range of containers from cardboard boxes to shrink film to environmentally sustainable packaging.

For all inquiries, please contact Timothy Copp at timcopp@reelex.com or sales@reelex.com.

Hall 9, F06-1

www.reelex.com

Rautomead will be introducing its new RIC 400 model, break-ring, continuous casting technology which has been developed to process cobalt alloy, nickel alloy and iron alloy wire rods from 2.5mm to 50mm diameter.

Rautomead will be presenting its RS range of graphite furnace continuous casting machines for the manufacture of extra-low oxygen content CuOF rod and for production of high-quality conductor alloy rods such as CuMg, CuSn and CuAg for signal data transmission wires and for railway contact & catenary wire applications. The patented pulse motion control offers users the ability to alter and adjust the casting sequence and speed according to the alloy and rod diameter being produced. Optimal settings may be stored in the PLC memory to ensure consistent production parameters from cast to cast.

Rautomead will also be promoting its (patented) RSL sealed lid continuous casting technology, designed for processing progressive alloy rods such as copper chrome zirconium for subsequent manufacture of welding tips and small diameter

drawn wires. This fully enclosed furnace features multiple, independently controlled, feed mechanisms which deliver cored wire and CuOF rod to the furnace to match the melting casting output rate whilst maintaining precise alloy composition.

Sample coils for any of the above materials can be manufactured to order and produced on continuous casting equipment installed at the Rautomead facility in Dundee, U.K.

For more information or to arrange an appointment for a meeting on the Rautomead stand during the exhibition, contact Jan Barclay at jan.barclay@rautomead.com.

Hall 10, F54

www.rautomead.com

Rosendahl Nextrom challenges conventional cable and wire production methods with their latest advancements in manufacturing technology. At the upcoming wire trade show, they will showcase a strong portfolio of new and improved solutions for the market.

Explore innovative extrusion technology and sustainable manufacturing solutions with interactive exhibits and experience a touch of magic at our stand.

www.rosendahlnextrom.com

SeticSETIC, a leader in special data communication and network cable machines, and a global solution provider for automotive wire equipment, will be at Hall 10, stand F59 at wire Düsseldorf.

The revolution in EV automobiles has led SETIC to develop new high-speed double-twist bunchers, single-twist take-up with back-twist pay-off, and strander solutions for charging battery and data cables. Its one-step and two-step processes also offer solutions for 5G, IIOT and robot devices, and strong growth in the global network cabling market.

Setic’s large double-twist range has been expanded to 2,600mm to produce 400mm-500mm aluminium wires for low and medium voltage cables, compacting up to 61 wires and offering both a productivity boost and a reduction in operating costs. The range is versatile enough to allow tailormade solutions and new concepts for everything from special high-speed lines for battery cables to new high-speed lines for special control and instrumentation cables.

The company’s developments offer strong social responsibility and a lower carbon footprint through improved organisation, methods and machines. Setic’s Düsseldorf presentation will offer solutions for Industry 4.0, featuring a complete high speed 630mm pairing line/quadding line composed of a modernised-design, single-bow back-twist pay-off, and doubletwist machine for data, automotive and LAN cables.

Also on show will be a 1000 mm high speed single-twist assembling machine (AST1000R) illustrating solutions versatility (covering LAN, control, instrumentation, data, EV charging and battery cables) and flexibility (laying-up, stranding, wirearmouring process).

Website: www.setic-pourtier.com

Pourtier will exhibit as part of the SETIC stand (Hall 10,F59) showing the ways it can connect customers to all energy sources.

The company specialises in heavy-duty rotating machines (rigid and planetary stranders, single-twist cablers, drum twisters) that produce all types of power cables – from overhead and lowpower cables to high voltage, EHV and submarine cables.

Demand for clean energy, including improved infrastructures, has been on the rise in recent years, resulting in new market challenges. Pourtier has advanced solutions to meet demands for sustainable clean energy.

Recognised aound the world for its engineering prowess, Pourtier produces heavy-duty stranders, cablers, screening and armouring lines. Its high-efficiency, revolutionary multiwire concentric stranding line is also widely used to boost productivity for low- and medium-energy cables, and all types of high-voltage and extra-high-voltage power cables.

Pourtier continues to expand its wide range of machines, with rigid stranders handling up to 156 wires, a pulling capstan of up to 80 tonnes and XL drum twisters up to 55 tonnes.

Like sister company Setic, Portier’s engineering conforms to the latest objectives for social responsibility and decarbonisation.

Products Showcase: Digital immersion in a world of bigger DC cables (rigid stranders 127/156/171 wires, up to 5000mm²) and longer AC cables (opened cradle drum twister 55T) www.setic-pourtier.com

C2S customer services department, which will exhibit as part of the Setic stand (10, F59) is the ideal partner to maintain machine productivity and enhance product quality.

The company believes upgrades are a more sustainable approach to maintenance, extending the life of existing equipment and reducing environmental impact by minimising the need for replacements.

The C2S services division can boost the efficiency of most wire and cable production lines and improve productivity and product quality, whatever the equipment’s brand. The company is regularly engaged to replace parts and complete upgrade and maintenance projects, as well as the transfer and recommissioning of complete production lines. C2S is also involved in smart factories and Industry 4.0 processes.

Bow Technology is at wire Düsseldorf on the Setic stand (10, F59), and sells customised bows for all sizes and brands of double-twist equipment.

Bow Technology is the answer for cable makers keen to buy high quality and long-lived, reliable bows for all brands of double twist machines, from 560mm-2000mm. With a comprehensive range of over 650 sizes and designs, the division offers global service from conception to production. The patented GreenBow2 is a closed-bow model, ensuring energy savings of up to 30 per cent on high-speed, double-twist bunchers of 560mm-800mm.

Hall 10, F59 www.setic-pourtier.com

2 1

SIKORA, manufacturer of innovative measuring, control and sorting technologies, will present the entire range of current, improved and new products for quality control and cost optimization in cable production at wire 2024 in Düsseldorf from April 15 to 19. Visitors can look forward to three world premieres.

“Moving forward”: World premiere of new products (IMAGE 1)

At wire 2024, SIKORA will unveil three innovative measuring devices that redefine the segment of measuring technology for cable production lines. The accompanying marketing campaign “Moving forward” underlines SIKORA’s commitment to offering its customers futureoriented solutions. The campaign presents the three new systems as a promise of further development and as a statement for progress. “With the new products, we are bringing movement to measuring technology. Our customers can look forward to reliable, futureoriented products that continue to lead the way with their performance and make a significant contribution to increasing productivity and cost efficiency in production,” says Katja Giersch, Head of Corporate Communications at SIKORA. Visitors can familiarize themselves with the advantages of the systems live at the exhibition stand.

X-RAY 8000 ADVANCED/NXT: Remarkably efficient in CV lines (IMAGE 2)

In the field of power cable production, the X-RAY 8000 has been providing precise measurements and maximum reliability for over 30 years. These are features that ensure the quality of cables during production and lead to material and cost savings. At wire, SIKORA presents the 3rd generation measuring system based on X-ray technology, X-RAY 8000 ADVANCED, which measures the wall thickness, eccentricity and diameter of cables in CV lines directly after the crosshead. It therefore provides measuring values for centering and control without delay.

Another highlight is the X-RAY 8700 NXT, which measures the final product dimensions at the end of CV lines, both horizontally and vertically. By using SIKORA measuring systems, both at the beginning and at the end of production, shrinkage values are determined for all three insulation layers of the cable. This ensures optimum process control for maximum efficiency.

3

PURITY SCANNER ADVANCED: Pure plastic pellets for the insulation of power cables

Particularly in the production of high-voltage and submarine cables, it is essential that contamination, which can occur during production, does not enter the insulation of power cables. The PURITY SCANNER ADVANCED uses X-ray technology and optical cameras to detect contaminants such as metal down to 50 µm in the pellet and automatically sorts out impurities. This ensures that only pure material is processed further, minimizing breakdowns, ensuring the quality of the cable and preventing follow-up costs. The function and benefits of the system will be clearly demonstrated at wire using a hybrid exhibit.

X-RAY 6000 PRO: Fascinating in insulating and sheathing lines thanks to cost savings (IMAGE 3)

With the X-RAY 6000 PRO, SIKORA introduces another member of the X-ray system family. This system continuously provides measuring data on wall thickness, eccentricity and diameter in insulating and sheathing lines. These are clearly displayed on the monitor of the ECOCONTROL 6000 processor system. The X-RAY 6000 PRO can be used either after the extruder, between two cooling sections or at the end of the line for cold measurement. From the first day of commissioning, the system enables the wall thickness to be reduced to the smallest permissible value. This results in significant material and cost savings for the user.

4

FIBER Series 6000: Distinctive measuring rate for optimum tension measurement (IMAGE 4)

SIKORA’s gauge head models of the FIBER Series 6000 promise the highest performance and fiber quality. From the measurement of diameter, fiber position, vibration frequency, temperature and spinning to the detection of airlines and lumps, the innovative measuring devices monitor and control the entire drawing process. The improved measuring rate of the FIBER TENSION 6003 of up to 50 kHz enables optimum tension measurement. This makes the measuring head particularly suitable for optical fibers that are further processed into premium optical fibers. Visitors to wire will be able to see the performance of the measuring heads live in the drawing tower.

Service To Perfection: For reliability and availability of SIKORA systems

When it comes to the reliability and availability of SIKORA systems in the production line, the SIKORA service team in Bremen and worldwide subsidiaries are always there for their customers. At wire, SIKORA presents the entirety of its service portfolio. From the installation and commissioning of the devices to consulting and training, always tailored to individual customer requirements.

“Moving forward Lounge”: Conversations with culinary delights

In addition to the SIKORA products on the first floor, visitors will find space for discussions with the SIKORA experts in the “Moving forward Lounge” on the booth’s 2nd level. Visitors can look forward to freshly prepared culinary delicacies and a selection of refreshing beverages and coffee specialties in a relaxed atmosphere. An impressive view of the SIKORA technologies rounds off the stay in the lounge.

Hall 9, B41 www.sikora.net

The South African Wire Association looks forward to wire 2024.

SAWA (South African Wire Association) is looking forward to participating in and representing our members at wire 2024 in April.

SAWA has been a regular exhibitor at the prestigious wire exhibitions.

South African wire manufacturers are reputed suppliers of innovative, quality products at competitive prices with many years of international trading experience.

Our products include wires of different grades and qualities servicing agriculture, automotive, security, mining, and manufacturing industries.

Established in 2002, SAWA is specifically tasked to assist members to participate in global markets by creating an awareness of the importance and benefits of this export economic sector for our industry.

Our membership base includes large, medium, and small manufacturers who can accommodate specific client requirements crafted from South African materials. The South African Department of Trade and Industry (DTIC) is an active partner with SAWA for export promotion.

Visitors and clients are invited to meet us at Hall 11, D32 at the wire & Tube Exhibition.

Once again LOYPOS and SMEETS will be joining hands at wire Düsseldorf.

LOYPOS is the leading manufacturer of semiconductive and non-conductive woven tapes for HV & EHV cables and submarine cables.

SMEETS is the exclusive global distributor for LOYPOS tapes since more than 20 years.

LOYPOS-SMEETS’ products are used in every type of cables in more than 50 countries on 5 continents and include, among other things:

Tapes: semi-conductive and non-conductive woven, nonwoven, waterblocking (incl. sea water), bitumen, mica, glass, and other special applications

FRP and yarns (waterblocking, glass, aramid, PP, paper) Films: PET, PP, PP foam, Al/PET…

· Accessories and components: thermo and cold shrink products, drum protection, mastic tapes

LOYPOS and SMEETS are constantly working with their customers to deliver quality products and world-class technical advice and service.

Our dedicated team combines a large international experience in the Wire and Cables industry with a global presence to support customers worldwide.

Hall 10, B46

www.loypos.com www.smeets1921.com

TECNOVO and KONER, manufacturing companies of the TKT group and leaders in the respective sectors of lubricants and drawing dies would like to inform customers and operators that they will participate with their booth at wire 2024 in Düsseldorf from 15th to 19th of April 2024.

In recent years TKT group has consolidated and expanded its position in the market, and carried out important research and development programs, by investing in new machinery and technologies as well as expansion of TKT products portfolio, to offer its customers increasingly innovative, integrated and synergistic solutions.

www.koner.cn

The TROESTER Group is a worldwide leading manufacturer of complete extrusion systems and compounding solutions for the cable industry. The excellent results produced by its technology makes TROESTER a competent and reliable partner in the cable industry.

TROESTER will present its state-of-the-art extrusion equipment for the production of Low, Medium, High and Extra High Voltage Cables, this comprises CCV and VCV Lines for Underground and Submarine Cables, Insulation and Sheathing Lines as well as single machines and components for efficient cable production.

X-Compound, will present their kneader technology for the continuous compounding of HFFR (LSOH), PVC, XLPE, Semiconductive Materials and EPR/EPDM. X-Compound specialises in the planning and construction of complete systems for the compounding of plastics with the process steps conveying, melting, dispersing, mixing and degassing.

The team of specialists from TROESTER and X-Compound looks forward to meeting you at hall 10, F60 and will be happy to discuss your specific requirements with you.

As the largest reseller of high-quality secondhand wire, cable, and optical fiber manufacturing equipment, Wire & Plastic Machinery has a vast selection of in-stock machinery. Machines offered as individual components through to complete lines and can be delivered immediately from 8 USA locations or completely reconditioned by an in-house engineering team.

Wire & Plastic Machinery has a comprehensive range of over 30,000 machines in stock located in over 3 million square feet of warehouse space for all aspects of non-ferrous wire and cable production.

During wire Düsseldorf 2024, Wire & Plastic Machinery will be showcasing pictures, video, and an interactive presentation of its inventory offering within a 72 square meter area.

Beverages and snacks will be available within the expanded lounge area and an enclosed meeting room will be available for detailed private project discussions. Booth visitors will have access to web-enabled stations for a live product search with detailed specifications and pictures.

Experienced personnel will be available to assist in selecting the most suitable equipment for your application and process.

Hall 9, E20-3

www.wireandplastic.com

Exclusive member only events

Tuesday 16th April & Wednesday 17th April 18:00-21:00

We are thrilled to announce our participation at the upcoming wire Düsseldorf exhibition this April. Positioned strategically in Hall 11 stand D22, the IWMA stand is gearing up to be a central hub for our members and guests, offering a wealth of resources and networking opportunities tailored to enrich your exhibition experience.

In addition to these amenities, the IWMA Insider magazine, alongside other key printed materials such as the membership directory and benefits booklets, will be readily available at the stand. These resources are designed to keep you informed about our array of upcoming events, exhibitions, and the myriad benefits of being part of the IWMA community.

Understanding the dynamic needs of our members, the IWMA stand will feature comprehensive on-site hospitality services, including secure bag storage facilities and high-speed Wi-Fi connectivity. To facilitate meaningful interactions and discussions, the stand will also offer bookable meeting tables and a cosy lounge area. Networking is at the heart of IWMA’s mission, and we’re excited to provide ample opportunities for members to connect with industry peers, whether it’s over a light lunch available daily from 12:30 to 13:30, while catching up on emails with a refreshing hot or cold beverage, or during a casual chat in our lounge area with business colleagues and associates.

We will also be hosting two exclusive member only evening networking events, designed to foster connections in a relaxed setting. These events are bookable through the IWMA website and will be hosted on the IWMA stand from 6-9pm on Tuesday 16th and Wednesday 17th April, offering an ideal platform for deepening business relationships and creating new ones. As a proud industry partner to Messe Düsseldorf GmbH, the wire Düsseldorf exhibition, and its satellite exhibitions, the IWMA stand is committed to enhancing the industry’s growth and connectivity. Join us at wire Düsseldorf to explore the latest industry trends, innovations, and opportunities for collaboration. Let’s connect, learn, and grow together in the spirit of advancement of the wire and cable industry and mutual success.

Advertising opportunities for members only in 2024, with prices starting from as little as £200!

Advertising opportunities for members only in 2024, with prices starting from as little as £200!

SUBMISSION DEADLINES for 2024/25 magazine content

We

We are now offering exclusive advertising slots in our quarterly IWMA Insider magazine! Advertising space is limited in each edition and will be allocated on a first come, first served basis.

The

be

The benefits of magazine advertising are huge, and we wanted to offer our members an even greater opportunity to hit their target market and get noticed in our industry magazine. We’re pleased to be able to offer FREE editorial slots for all members, as well as the above advertising opportunities.

June Edition 2024

June Edition 2024

PR/ Editorial: 3rd April

PR/ Editorial: 3rd April

Advertisements: 24th April

Advertisements: 24th April

September Edition 2024

September Edition 2024

PR/ Editorial: 3rd July

PR/ Editorial: 3rd July

Advertisements: 17th July

Advertisements: 17th July

December Edition 2024

December Edition 2024

PR/ Editorial: 4th October

PR/ Editorial: 4th October

Advertisements: 18th October

Advertisements: 18th October

March Edition 2025

March Edition 2025

PR/Editorial: 17th January

PR/Editorial: 17th January

Advertisements: 31st January

Advertisements: 31st January

For more information, please contact Katie at katie@iwma.org

For more information, please contact Katie at katie@iwma.org

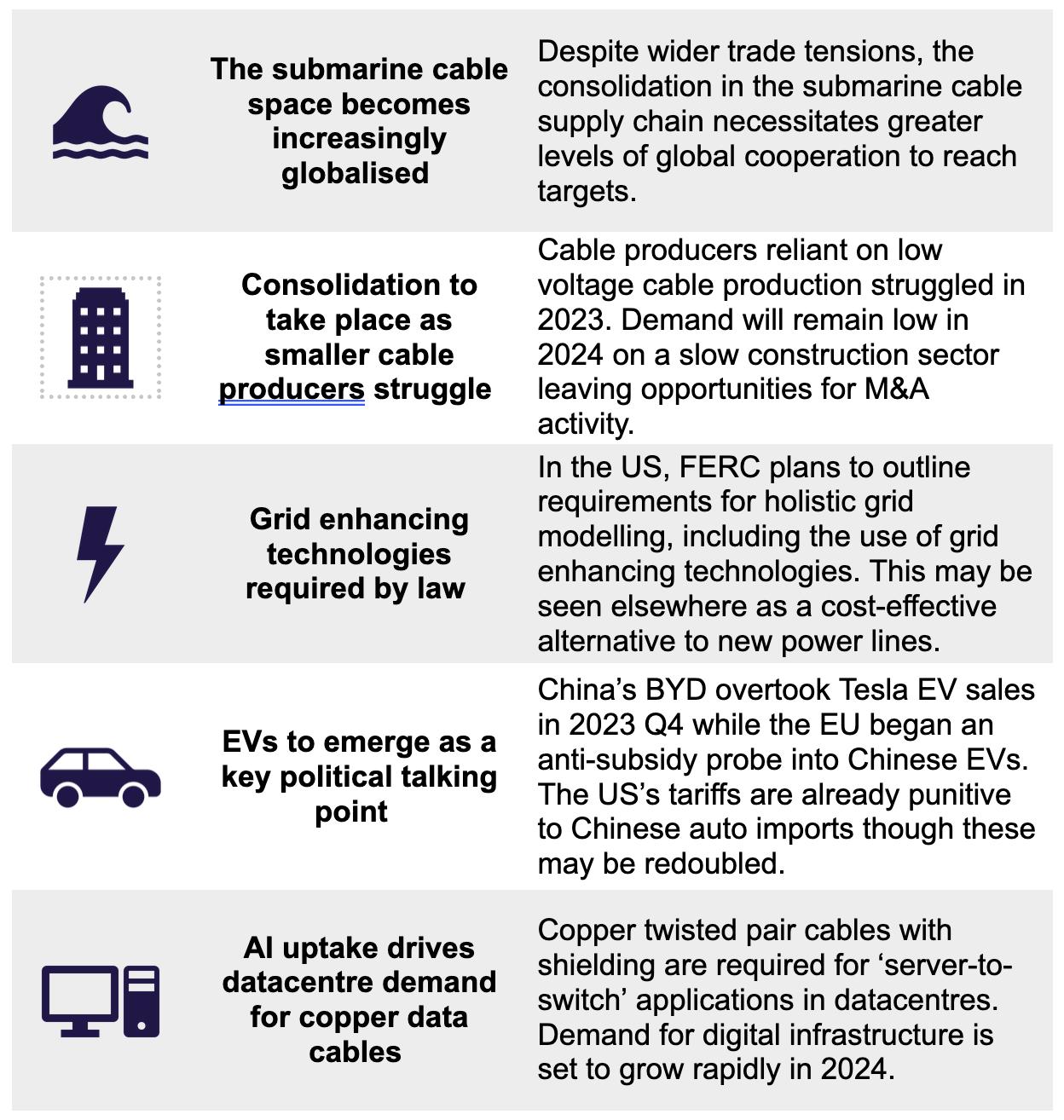

CRU’s metallic Wire and Cable service offers unrivalled independent market analysis on the supply and demand of copper and aluminium cables. The service also offers key insights into the requirements of the global construction industry, manufacturing as well as power generation, transmission, and distribution.

In this Insight, CRU takes a step back to review the key cable market developments of 2023. We also form our outlook for 2024 and identify the key trends which we anticipate will steer the market over the coming year.

2023 in review: Poor low voltage energy cable demand as construction struggled with high interest rates

High interest rates to combat high inflation were a defining aspect of 2023. The subsequent higher borrowing rates hindered construction investment and, thus demand, for residential property, supressing low voltage cable demand. Generally, non-residential and infrastructure projects fared better as government spend propped up demand. Additionally, infrastructure became the major lever of growth which was employed by China to support the struggling economy. Overall, power cable demand continued to remain resilient as these infrastructure and utility investments in green technologies continued despite wider slowdowns.

Over 2023, we saw greater levels of protectionism develop as nations responded to the supply chain weaknesses which were exposed during the Covid-19 pandemic. The US’s Inflation Reduction Act, the CHIPS and Science Act as well as the Infrastructure Investment and Jobs Act stipulated conditions which support domestic manufacturing. This paved the way for Europe’s response which was to launch its own Net-Zero Industry Act which

Aisling Hubert Wire and Cable Senior Analyst

aims to ensure that the region remains competitive in future clean technology manufacturing. Overall, domestic manufacturing of future-critical technologies has emerged as a key political focus.

Review of selected calls from 2023:

China cable demand rebound from Q2:

Though China’s demand did largely return, several areas of weakness were exposed – not least the highly leveraged property sector. Lower construction demand has been entirely compensated for by government investment via state-owned enterprises, though there are questions about the sustainability of this approach.

Sustained high Cu price as underfunding of supply bites: Copper finished 2023 at $8,608/t, slightly up compared to the $8,375/t which it started 2023. Despite uncertainties, the opening of the Chinese economy and some supply disruptions – including cessation of copper supply from First Quantum’s Cobre Panama – lifted the price. European demand also appears to have reached a lower bound.

Offshore wind installations to surpass targets: High interest rates have created a challenging financial environment which has impacted some investors in offshore wind projects. Several projects on the US East Coast are currently under renegotiation and will likely be delayed due to challenging financials. Installations in China progress expeditiously.

CRU Wire and Cable Top 10 calls for 2024

CRU’s Top Ten Calls for 2024 are outlined on the next page.

These topics will be covered in detail throughout the year in our Wire and Cable Market Outlook service.

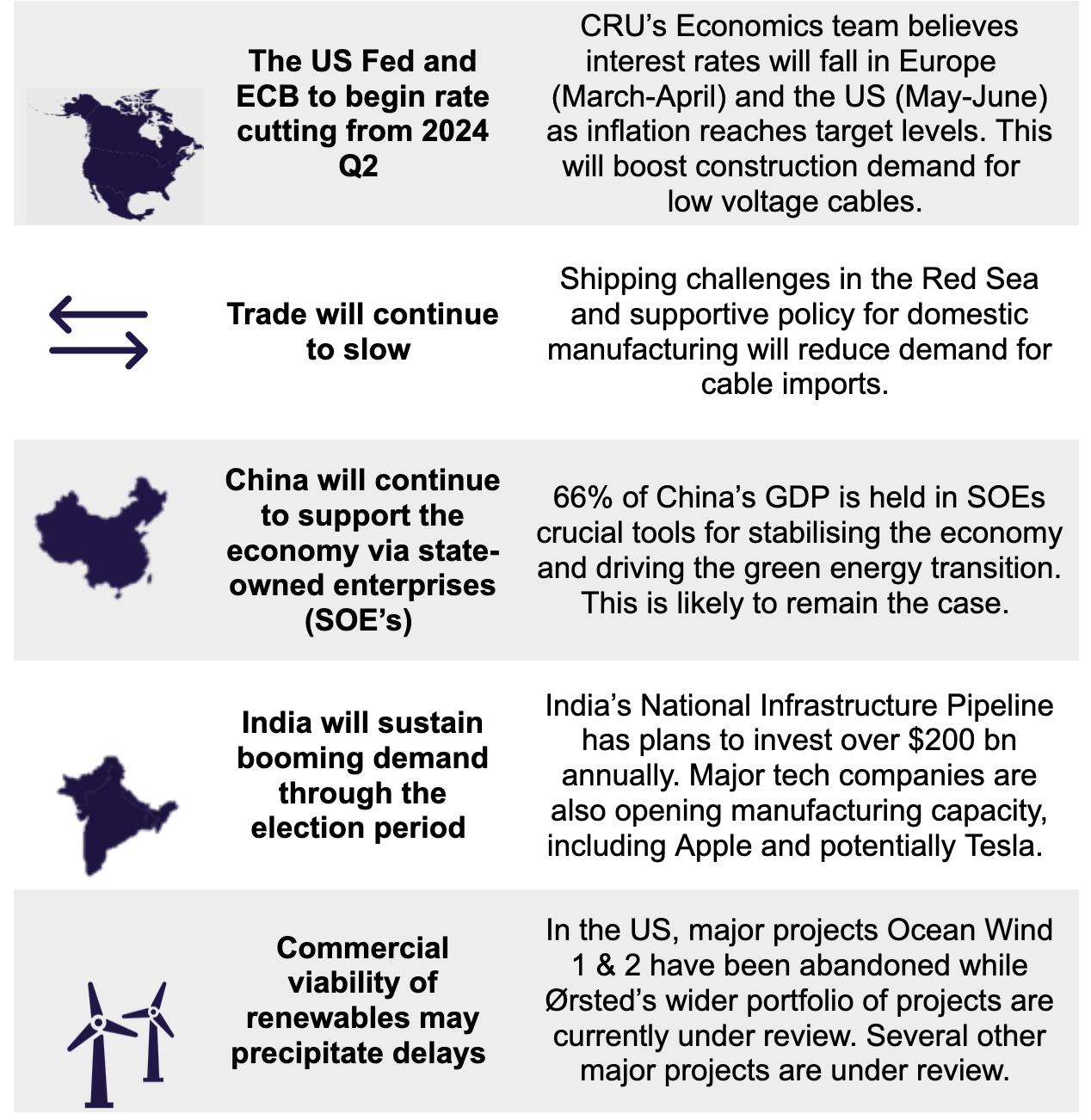

Digital solutions form the basis of how most organisations operate. They are seen as something that fosters productivity and performance, and that should propel organisational success.

But, what if the opposite is true? What if the digital solutions used within an organisation are actually leading to overwhelm, burnout, reducing productivity and performance, and negatively impacting the wellbeing of your employees?

What Is A Negative Digital Culture?

A negative digital culture exists when the digital solutions used within organisations impact employees’ productivity, performance, and wellbeing.

A culture can become negative for a number of reasons:

1. Digital Disruption

The average office worker is interrupted every 3 minutes, yet it takes 23 minutes on average to regain full focus on a task (University of California, 2008). As a result, we never achieve full focus!

With constant interruptions from emails, Teams chats, and other digital notifications, performance and productivity are negatively impacted. This also leads to a loss of focused time, an inability to complete all tasks, and overwhelm and stress for employees.

2. Digital Presenteeism

While the flexibility of modern technology enables employees to work from anywhere, anytime, it has also blurred the boundaries between work and personal life. The urge to stay connected leads to employees logging in during their downtime, at the loss of precious leisure and family time. This “always-on” culture can lead to stress, burnout, and diminished performance.

3. Digital Burnout and Overwhelm

Learning new solutions, knowing which to use when, lack of sufficient training, and too many digital solutions in use can all lead to burnout and overwhelm.

Spending all day staring at a screen can also have a negative impact on wellbeing, sleep, anxiety, depression, and stress. With employees staying switched on for longer and longer and more digital solutions in use, this can have a negative impact on productivity, performance, and overall wellbeing.

Improving Digital Culture in Your Organisation

The first step to improving your digital culture is understanding the current situation and identifying areas in which improvement may be required.

Further actions can then be taken to move towards a more positive digital culture.

Those steps could include:

1. Turning Off Notifications

Interruptions from notifications can lead to a lack of productivity and performance, as well as causing stress and overwhelm. Turning off notifications and time blocking activities, such as email management and responding to Teams chats, is a great first move to regaining control of your working day.

2. Establish Working Hours Boundaries

Creating a ‘working hours charter’ that states that working outside of hours is discouraged, with a focus on wanting employees to enjoy their free time, is a great step towards reducing presenteeism. This may require an additional step in understanding why employees are unable to complete all tasks during the working day.

3. Encouraging Switch Off Time

Breaks during the day allow the opportunity to step away from screens. Encourage employees to get outside during lunch breaks and take the opportunity to get fresh air, exercise, and time away from screens.

4. Role Modelling by Leaders

When leaders log in outside of hours or work through their lunch, employees may feel that this is required to excel within the organisation. It is essential that leaders are the role models in creating a more positive digital culture, and that they take these actions to improve their own wellbeing and performance.

5. Focused Digital Culture and Wellbeing Training

When leaders and employees gain a greater understanding of the impact of a negative digital culture and the steps that can be taken to improve it, it can have a profound impact on actions being taken and culture change.

What actions are you going to take in your organisation to improve the digital culture?