KICKING GOALS

BY GEOFF ADAMS

A DECLINE in the national dairy herd will contribute to lower milk volumes, according to the latest ABARES agricultural commodities report.

The Australian Bureau of Agricultural and Resource Economics and Sciences points to a fall in volume of about one per cent this financial year.

However the report notes a higher farm gate milk price this year, forecasting value of production to rise by seven per cent.

The industry is, however, facing subdued export prices due to increasing global production and restricted global demand.

Farm gate milk prices are forecast to rise to 70.5¢/ litre in 2025-26, up by eight per cent from 2024-25, to be just below the five-year average in real terms.

Prices are expected to rise as milk supply tightens, reflecting a decline in domestic milk production, while domestic demand for market milk is expected to remain stable.

The forecast value of milk production in 2025-26 has been revised up by $0.2 billion since the June 2025 Agricultural Commodities Report.

Despite an expected rise in the value of milk production, the value of Australian dairy exports is forecast to fall by seven per cent to $3.5 billion in 2025-26 from record highs in 2024-25

This reflects both falling export volumes and prices across all major exported Australian dairy commodities.

While lower export volumes are consistent with expected lower milk production, export prices are expected to fall given relatively strong global exportable supply:

Whole milk powder export values are forecast to fall by 15 per cent to $406 million.

Skim milk powder export values are forecast to fall by 11 per cent to $686 million.

Cheese export values are forecast to fall by four per cent to $1.2 billion.

Butter export values are forecast to fall by one per cent to $189 million.

Milk powder export values are expected to fall by more than other dairy exports given lower Australian export volumes as well as falling

global prices (given increased global production from key powder producers such as New Zealand and subdued demand in key milk powder export destinations).

By contrast, the falls in the export values of high-milk fat products are expected to be less significant due to relatively low production of milk fats in Europe, which is expected to support butter and cheese prices relative to milk powders.

The forecast value of dairy exports in 202526 is $0.1 billion higher than the June 2025 Agricultural Commodities Report, due to an upwards revision in export prices given recent price data.

While rising, farm gate milk prices are forecast to remain below the historical highs seen in 2022-23.

Processor competition to secure milk volumes in 2025-26 is expected to be lower than in 2022-23, given weaker consumer confidence

in overseas markets and lower expected global prices.

The farm gate milk price has been revised up from the 68¢/litre in the June 2025 Agricultural Commodities Report following the announcements of milk prices and step-ups in June and July.

The ABARES report said global export prices are expected to fall in 2025-26 as trade uncertainties and macroeconomic pressures weigh on global demand.

Low domestic consumption from China, driven by constrained economic growth, is expected to reduce demand for imported dairy.

In addition, global supply, driven by production in New Zealand and the United States, is expected to rise.

Butter prices are expected to fall only marginally, supported by robust demand for milk fat relative to other milk solids, and continued effects of biosecurity incidents in the Northern Hemisphere, reducing exportable milk supply.

DELEGATES AT this year’s Dairy Research Foundation Symposium will hear from Tasmanian dairy farmer, Troy Ainslie, about his life-changing experience with virtual fencing.

The technology was introduced in June 2023 on the 540-cow herd that Troy manages at Woodrising Dairies, near Launceston.

While pasture utilisation has improved, the impact has been far-reaching, including increased production and a six-week in-calf rate, savings in fuel and machinery costs and greater team wellbeing.

Registrations are now open for the symposium, which will be held from November 26 to 27 at WIN Stadium in Wollongong.

Symposium organiser Professor Yani Garcia said the event was designed to bring together leading researchers, dairy farmers, and industry innovators under the theme of IT’S TIME: To connect, learn, and be inspired

Day one features a diverse line-up of speakers who will challenge thinking and spark ideas.

Sessions will explore topics such as harnessing the power of the cow, the genetic future of dairy, and uncovering what is both holding the dairy industry back and driving it forward.

The program also includes the always popular Emerging Scientist Awards and an important focus on redefining grazing in a changing climate.

Day two will open with Dairy Australia’s Annual General Meeting at WIN Stadium, followed by the Dairy Innovation Farm Tour.

Delegates will see innovation in practice at Philip and Craig Tate’s progressive Albion Park dairy farm, a showcase of forward-thinking management and technology.

For more information and the full program, go to: https://drfsymposium.com.au/

To register to attend, go to: https://www. trybooking.com/DCWIF

EASTAUSMILK RECENTLY co-hosted with Halter a farmer delegation to the NSW Parliament to support the introduction of virtual fencing.

In April, NSW Agriculture Minister Tara Moriarty committed to legalising virtual fencing technology in her state.

EastAUSmilk government relations manager Denise Spinks told members that in an appearance before a parliamentary committee, the minister again stated the government’s support and her aim to have the regulation before the parliament within two months.

“The Animal Justice Party is still pushing back on the changes, but there remains strong support from the Shooters and Fishers Party and the National Party — their support of the Labor Party change is important to ensure the regulation gets through parliament,”

Denise said.

“EAM will continue to monitor these parliamentary processes on behalf of farmers.

“Once the regulation passes, the collar providers will apply for necessary licences — speaking with Halter representatives it is thought the best-case timing scenario is that

all going well, collars could be rolled out early in the new year.”

The EAM delegation included James Neale, Scott Hurrell, Andrew Farr and Denise.

The delegation also included NSW beef industry representatives and a Tasmanian farmer who has been using the herding technology on his farm.

The farmers spoke with the minister’s chief of staff and an adviser directly about the opportunities this technology will bring to their operations.

“We also took the opportunity to follow

up other matters, including disaster recovery assistance and on-farm development processes,” Denise said.

“In response to farmer concerns raised by EAM recently, the minister intervened to double the department resources processing disaster relief claims — hopefully this will make a real difference.

“Farmers also got to speak with Halter about their particular product and associated costs.

“It was interesting to hear from the Halter team that they are getting an increased uptake in Queensland where the technology is legal.”

BY DJEMBE ARCHIBALD

THE VICTORIAN Government’s plan to dismantle Dairy Food Safety Victoria and replace it with a broader food safety regulator has ignited strong backlash from the dairy industry.

Safe Food Victoria is a new statutory authority that will merge several food regulators under one body by 2026.

Victorian Agriculture Minister Ros Spence and Health Minister Mary-Anne Thomas said the move would “cut red tape” and streamline a system currently governed by four separate laws and multiple regulators.

The United Dairyfarmers of Victoriaand Australian Dairy Farmers have condemned the decision, warning it risks compromising safety and increasing costs.

UDV president Bernie Free said Dairy Food Safety Victoria underpinned Victoria’s $2.5 billion dairy industry and 73 per cent share of national dairy exports.

“Replacing a proven, cost-neutral, specialist regulator with a one-size-fits-all bureaucracy just won’t work,” Mr Free said.

“Safety must not be compromised, and costs must not be increased.”

ADF president Ben Bennett echoed the concerns, describing the government’s consultation process as “tokenistic” and the reform as a “solution in search of a problem”.

He said dismantling DFSV could undermine technical expertise developed in Victoria, home to most of Australia’s milk production.

“Given we’ve not seen a business case for the transition to Food Safety Victoria, and nobody can outline any grounds for improvement at DFSV, we see this as a clear and blatant cash grab by the debt-stricken Victorian Government,” Mr Bennett said.

“DFSV doesn’t cost taxpayers anything — it’s funded by farmers.”

The government has rejected claims the reforms will erode standards.

It said all staff, expertise and cost-recovery models would transfer to Safe Food Victoria, ensuring no redundancies or loss of specialist knowledge.

Officials argue that a consolidated regulator will give businesses simpler processes, more consistency and faster approvals, while still maintaining high safety standards.

“This consultation phase seeks the views and ideas of Victorians to inform the new regulator’s focus and operating approach,” Ms Spence said.

BY GEOFF ADAMS

FRUIT AND drink processor, SPC Global, has entered into an agreement with major dairy processor Fonterra.

The deal was disclosed in SPC’s annual financial report, in which it announced a $30 million EBITDA profit.

Under the arrangement, Nature One — a division of SPC Global — will manufacture Fonterra’s branded products sold overseas

The Nature One Carrum Downs site will be producing the Fonterra-branded products.

Fonterra recently announced it had sold its Australian assets to major French dairy company, Lactalis.

Asked about the impact of the sale on the SPC deal, SPC managing director Robert Iervasi said he had a good working relationship with the two companies and there would be no impact on the arrangement.

Earlier this year SPC Global’s new dairy division scored a multi-million dollar deal for distribution in China.

Nature One Dairy, will export milk powder

“Most states and our close neighbours, such as New Zealand, successfully operate under similar consolidated models.”

ɋ Victorians are being invited to contribute to the consultation process via engage.vic.gov. au/foodsafety

“Safe Food Victoria will provide simpler processes and greater consistency for Victorian food businesses, while maintaining the excellent standards and expertise from existing regulators.

products made in Australia, to a company which has outlets in the special administrative regions of Macau and Hong Kong.

The product, made at the Carrum Downs factory, includes infant milk formula and powders aimed at a range of ages and needs.

SPC’s main factory, with its fruit processing facilities, is in Shepparton in northern Victoria.

Imagine

Because

BY JEANETTE SEVERS

THE STORY of Mt Lyall Dairies is one of innovation, risk and improving the business for the next generation.

As Chris Lancey said to Dairy News Australia, the latest innovation — building a 100-bail rotary dairy on a greenfield site for $5 million — was about investing in a new platform for the next generation to inherit.

He didn’t want to give them a new dairy sitting on an old concrete base. Instead, the business invested in an entirely new build from the ground up.

The new build also invested in new technology for the business, at Nyora and Loch in South Gippsland, Victoria.

The Lancey family has created four generations of innovation and expansion, with three generations currently involved in the dairy business — Graeme, Chris and his wife Leanne, son Callum, and son-in-law David Lewis with their daughter Maddy.

Although in a wheelchair, Graeme is still involved in the business, especially in making decisions about which bulls and semen are used for breeding.

“Dad loves breeding and has done it forever. He chooses the bulls with great care for genetics,” Chris said.

“We breed a medium-stature Friesian cow, with good teat alignment and feet, quiet temperament, and producing high components. Annual milk production averages 8000 litres/cow.”

The business is a Saputo supplier.

The origin of Mt Lyall Dairies

Patricia and Graeme Lancey started dairy farming at Poowong North in 1968.

Between 1977 and 1981, they ran two dairy farms, milking 130 cows on the home farm, and then Graeme would drive three miles to their second farm and milk 70 cows.

In 1981, they sold both those farms and bought a 400-acre farm at Nyora, milking 200 Friesian cows in a five-a-side herringbone dairy. Chris said they walked the herd the 6km distance to the new farm.

That farm became the genesis of Mt Lyall Dairies, and Graeme and Patricia used it to build their business for successive generations, a passion inherited by Chris.

“I started working full-time with them when I left school at 15 years old,” Chris said.

“We stretched the herringbone dairy to 11-a-side. In 1988, we were milking 350 cows and changed the herringbone for a 42-bail rotary, so we could grow the herd again.”

By 2001, they had grown the herd to 700 cows and installed a 70-bail rotary.

“We wanted to grow the herd again,” Chris said.

“The year we put the 70-unit in, we bought the property next door which was 200 acres.

“We already had another 200 acres behind

us, so we were up to 800 acres from the original 400.”

The home farm continued to expand from the original 400 acres to its now about 2000 acres.

As additional land has been acquired, Chris has overseen extensive work on fencing, laneways and reticulated stock water systems to improve productivity.

The basic business model has been followed throughout the decades — milking the split-calving herd twice-a-day and growing their own pasture and fodder on a dryland farm in a, normally, reliable rainfall pattern.

“Buying additional land is about building the size of the herd, being able to keep developing pastures and basically being self-sufficient,”

Chris said.

The farm supports a considerable workforce, including Australian, Irish and Philippine workers among the 15 employees.

Chris said he was keen on continuous expansion of the farm business, and his willingness to take risks included using debt to grow the business, rather than remaining debt-free with a smaller operation.

“I reckon being willing to take risks is the only way to get ahead,” he said.

In 2016, Chris and Leanne purchased a second farm nearby, of 650 acres, which was milking 200 cows in a herringbone dairy.

They installed a 50-unit rotary dairy, which they bought secondhand from a farm near Bendigo, dis-assembled it and reassembled it on the farm.

Advertising Rachel Fowles 0429 675 962

rachel.fowles@dairynewsaustralia.com.au

Editor Sandy Lloyd (03) 5820 3252 editor@dairynewsaustralia.com.au

Regional editor news@dairynewsaustralia.com.au

Purchasing this dairy farm replaced a leased 450-acre farm at Yannathan where Chris milked 450 cows. He also leased 350 acres at Nyora for 10 years where he milked 300 cows, until 2015.

He still leases 300 acres at Nyora for growing out young stock and to produce silage.

The entire land footprint ensures the business is largely self-sufficient, growing their own pasture and fodder.

“We usually cut 1000 to 1200 acres of bulk silage and make 1000 round bails,” Chris said.

They also supplementary feed the herd on the feedpad, mixing silage with celery and leeks from a large-scale vegetable producer at Tarwin.

“About 10 to 15 per cent of the cow’s diet is made up of these vegetable products. Over a year, I reckon we would average about three to four kilograms of dry matter per cow per day,” Chris said.

A unique aspect about the home farm at Nyora is the number of sheds.

As well as the loafing barn and feedpad, hay is stored undercover, there is a calf rearing shed, the springers are undercover, the entire platform for the new dairy is undercover, and there are numerous large sheds housing trucks, machinery and equipment, fodder, and bedding.

Chris compares the cost of buying fodder for lean years and shedding it, against the cost and availability of buying nearby land to increase the grazing rotation.

Chris’s resourceful approach to

Publisher Shepparton Newspapers Pty Ltd

Printed by Newsprinters Pty Ltd

Head Office

7940 Goulburn Valley Highway

Shepparton, VIC 3630

Phone (03) 5831 2312

Postal address PO Box 204

Shepparton, Victoria 3632

Australia

infrastructure development is repaid — he said he now receives inquiries about if he wants to buy a shed that is being deconstructed.

On Boxing Day, 2022, he and Callum purchased the shed and concrete walls of the old Warragul saleyards, which became an 8000 square metre covered loafing barn and another 2000 square metres over the feedpad alongside it.

“We’ve had the feedpad since 2009, and we extended it to 4000 square metres in 2020, and now half of it is under the roof,” Chris said. Callum said that even at that size, there is still a considerable amount of steel left over for another project.

The barn has been in use since January 26, 2023, and allows them to keep cows off pastures during wet winter conditions, and provides shelter for the herd during hot summer nights.

“It doubles our rotation to 60 days in winter,” Chris said.

“In summer the cows have the option of walking to the paddock and some just walk to the barn and loaf. In autumn, it’s great for holding cattle off the paddocks as pastures shoot.”

The concrete walls surround the barn, providing a perimeter that also helps keep the bedding material in the barn, which they turn daily.

“In winter, we top up the bedding probably every two weeks — about 200 cubic metres every two weeks,” Chris said.

Eventually, the bedding is used as compost, probably incorporated into the soil to grow a corn crop, he said.

Dairy News Australia welcomes contributions from stakeholders in the dairy industry, and particularly from organisations wishing to advance the industry.

Contributions and photos can be sent to: editor@dairynewsaustralia.com.au

Letters to the editor on topical issues are also welcome.

Letters should be concise and carry the name and town address of the author, as well as a contact phone number, not for publication.

Continued from page 6

A games factory at Dandenong was bought, deconstructed and reconstructed to house silage and woodchips for the calf shed. The springers wait to calve in their own undercover expanse.

“We keep about 750 to 800 heifers a year as replacements, which has been good while we’ve been growing the herd, but now we’re not growing the herd so much, it’s plenty,” Chris said.

The business also sold heifers to the export market, while it was a financially worthwhile proposition. Now Chris is rethinking his heifer breeding strategy.

“We have a strict culling policy on the milking herd. Some cows only last one season, some last six seasons,” he said.

“Normally, you need 20 to 25 per cent replacements, but when you have 750 heifers for our herd size, that’s more than 35 per cent. We’ve just sold 60 heifers, to lighten the load.”

Four years ago, they built a new calf shed — 88m by 20m, with pens and outdoor areas — to raise 450 calves each season.

Calf rearing in their split-calving system, with the size of the herd, takes nine months of the year.

“We have a full-time calf rearer, with Callum and other people backing up,” Chris said.

“The calves start in individual pens, then progress to groups of two, groups of five, and then two groups of 60.”

Chris has innovated feeding, making a long stainless steel trough with 66 teats that is used by the calves from when they are three weeks old.

“Depending on how active they are, calves are weaned at 12 to14 weeks.”

They then go to contract rearers and return to the farm one month before calving.

Building a new 100-bail dairy will enable the business to grow the milking herd by about 100 cows, but it will also improve operator and cow welfare.

It is the first dairy unit with auto-drafting that Chris has installed. He also added posiarms [position arms], which drop the cups down under the platform, lifts them up, and positions the cups right behind the cow so they’re ready for the operator to put them on to her teats.

In early 2024, Chris, Leanne, Callum and David started talking about building a new dairy. They were beginning to consolidate their wish-list when they attended the Raising the Roof conference in the Hunter Valley in March 2024.

“At that stage, we might still have been considering a 94-bail rather than 100,” Chris said.

“We mainly went to the Raising the Roof conference to get ideas about how we can better use the loafing barn.”

That led them to Western Australia and Victoria’s Western District, to look at dairies.

Callum also went to the United States to look at some large rotary dairies and barns.

“We pretty well knew what we wanted once we’d been to Western Australia,” Callum said.

“We settled on the 100-bail and decided on the auto-drafting and posi-arms.”

At the same time as these decisions and plans were being made, the herd began wearing cow collars.

“We started using them in 2024 for heat detection at milking,” Chris said.

“We didn’t have the auto-draft technology

Pac Cool Dealer - Australia

Packo & Pac Cool Spare Parts

- A milk vat to suit all herd sizes, pick up schedules & entry temperatures

- Cooling & wash controls - user friendly, simple & effective

- Glycol chiller cooling & traditional direct expansion cooling systems

when we started using them, so they weren’t being used to their potential.

“That all changed with this new rotary, as they’re drafted automatically when they go through the draft and race.”

Construction on the new dairy shed began on November 28, 2024.

“I wanted to have the footings in by December 18,” Chris said.

Two thousand square metres of concrete was poured.

“The first part of the shed went up in January. It was flat out every day since,” Chris said.

Milking in the new dairy began on July 2.

“The cows have been performing exceptional throughout the build and in the transition,” Chris said.

While the new dairy is built on a greenfield site, it is connected to the sheds of the previous two dairies on the farm.

“We built one shed and new dairy, then we built the next one beside that,” Callum said.

“This new dairy shed is built alongside the second shed. So they’re all connected, and all we’ve done is remove the hardware.

“With each build, we’ve converted the previous dairy space to undercover cow yards.

“Where the cows are coming in now, that’s where our three dairy sheds have been built side-by-side, from 1981 to 2001 to 2025.”

Chris wanted to set up the new 100-bail rotary dairy on a new concrete platform — he said it was important to ensure everything was a new build for the next generation, rather than using one of the old bases.

As the cows come into the dairy for milking, they progress along a large concrete yard, incorporated under the old shed roofs, with a forcing gate used to gently move them towards the bails.

- New & secondhand sales, spare parts & wash system upgrades for all makes Call Dairy-Tech Refrigeration today for a no hassle quotation

PHONE: 03 5662 3277 EMAIL: pgoiris@dairytechrefrig.com.au

WEB: www.dairytechrefrig.com.au

AU34439

Walkways have been incorporated above and below a concrete funnel which the cows traverse across to enter the rotary bails.

What’s next

“I want to get the farm all set up pretty well so I can take off in a caravan at a later stage, and let these blokes [Callum and David] have a go at it,” Chris said.

Planning for succession with David and Callum and a successful transition to the next generation is also on the to-do list for Chris and Leanne.

“We haven’t really started having those conversations with the next generation, but we will,” Chris said. “I don’t know how we’ll do it, but down the track we will work it out.”

The Lancey family opened their new dairy to public scrutiny during the South Gippsland Dairy Expo in September. More than 300 people attended the two-hour event and toured the dairy, which was led by Chris and Callum Lancey.

ɋ Find an extended version of this story and more photos at: www.dairynewsaustralia. com.au

As reported in a previous article in Dairy Farmer, results from the long running dsm-firmenich Global Mycotoxin Survey consistently identified that the three major mycotoxins of economic importance in feedstuffs for ruminants in Australia are deoxynivalenol (DON), fumon-isins (FUM) and zearalenone (ZEN), with aflatoxin and ergot alkaloids making regular appearances. Looking into data for the last three years with a focus on ruminants, fumonisins were the most frequently detected mycotoxin class (70% of samples had FUM). ZEN was detected in 54% of samples with an average contamination level of 574 ppb, which is deemed to be a high risk for ruminants. The majority of the very high detections of ZEN came from silage samples. ZEN was also detected in grains and by-products. As mentioned in previous articles, the presence of two or more mycotoxins, often from different feedstuffs, can have a much more significant impact on the animal than the level of a single mycotoxin.

In simple terms, ZEN is chemically very similar to the female hormone oestrogen and will bind to the oestrogen binding sites in breeding animals therefore inhibiting the proper action of oestrogen, effectively putting heifers and cows on a ‘contraceptive pill’. Oestrogen receptors are found in the uterus, mammary gland and parts of the brain thus the effects of ZEN can have wide ranging impacts and include premature udder enlargement, false oestrus, unsuccessful insemination and in some cases abortions. While ZEN

is typically considered a female hormone, the effect on bulls can also be quite marked with ZEN intake known to influence testicular atrophy and poor semen quality.

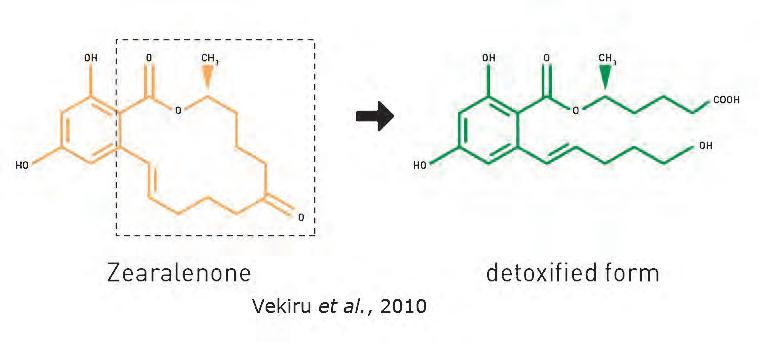

Like many of the mycotoxins, ZEN has a chemical structure that does not permit it to be easily bound by simple binders. Some microbes in the rumen can degrade ZEN, however they result in compounds which can be up to 60 times more oestrogenic than ZEN itself. Therefore, the most effective way of reducing the impacts ZEN have in the breeding herd is to have ZEN enzymatically cleaved in the rumen into non-oestrogenic products before it is absorbed. Irreversible deactivation of ZEN is achieved through the use of Mycofix® Plus, as shown in Figure 1. As seen in the previous article, Mycofix® Plus is also proven to deactivate DON and other mycotoxins, further reducing the impacts that can occur from multiple mycotoxin contamination.

Figure 1: Schematic of the enzymic deactivation of zearalenone by Mycofix® Plus to non-toxic forms

BY JEANETTE SEVERS

A CENTURY of breeding and milking was celebrated at the recent Warwick Farm and Progressive Holsteins on-farm sale, at Greendale, NSW.

The sale was held on September 17, on the family farm in the Bega Valley, owned by generations of the Pearce family.

This year, the Pearce family is celebrating a century of breeding dairy cows at Warwick Farm. The current ownership is a three-way partnership between Norm and Narelle Pearce and their son, Tom, who is also the herd manager.

Warwick Farm Holsteins brought artificial insemination into their breeding management in 1980, and have been registering cows with this prefix and the Progressive Holsteins prefix since 1988.

Now their entire dairy herd is registered. In 2019, the family began genomic testing their cattle.

With many young cattle coming into the 250-head registered milking herd this season, the Pearce family decided to sell a run of twoyear-old Holstein cows and heifers.

The on-farm sale was an opportunity for other farmers to buy fresh young cows and in-calf heifers, to boost the supply curve of spring milking and increase their herd numbers after a couple of challenging years in the dairy industry.

Tom Pearce said there was also a surplus of their well-bred heifers available after the collapse of the export market.

“Like a lot of people, we’ve lost our export heifer market and we had really geared our business for that. We got pretty good at breeding quality heifers for that market,” Tom said.

“We thought about our options for selling, whether to sell privately or do something else.

“Brian Leslie from Dairy Livestock Services was in the district and I contacted him to discuss the logistics of going down the live auction path.

“Given the pedigrees behind the cattle, we decided that was a good option. It all came together really quickly.”

Tom was pleased with the sale result.

“There were a lot of people at the farm, and there were 130 people watching online, with 31 bidders registered online,” he said.

“I think 60 per cent of the lots were bid for online, and 32 lots were actually sold to online bidders.

“The top-priced cow sold to an online bidder.”

Brad Fraser, of Denman in the Hunter Valley, NSW, bid the highest to take home lot 38, Warwick Farm Caffeine Sweet, born 16/3/2023 and calved 10/7/2025, paying $7100.

Her sire was Warwick Farm Unstoppabull Caffeine and she had grand-dams bred from the Blondin family.

Brad also purchased lot 4, paying $3750 for Warwick Farm Hano Georgetta, born 17/4/2023 and calved 6/7/2025.

“She isn’t a big cow, but she stood out with a nice udder,” Tom said.

A volume buyer was the Watts family from Pyree, near Nowra in NSW.

“They bought a nice group of cows,” Tom said.

“Those four lots were some of the nicer cows in the sale.”

The sale’s highest price paid was $7100, for an average of $3385, with 72 lots sold.

The average was held up with many cattle selling between $3000 and $4000.

Lot 21, Progressive Hano Fussy, born 27/5/2023 and calved 17/8/2025, sold at $4750.

Lot 54, Warwick Farm Mirand Rain, a heifer pregnancy-tested-in-calf to Siemens Parbo and due on 10/10/2025, sold at $4750.

“I was really happy with how the heifers came together in the group,” Tom said.

“There were some fairly high square heifers with good udders underneath, that looked good on paper.

“I chose the line-up of heifers on paper, because I knew if I went out to look at them in the paddock, I’d second-guess myself.”

Lot 15, Warwick Farm Mirand Luster-po, born 10/4/2022 and calved 9/7/2024, and due 13/2/2025 PTIC to Walnutlawn PG Brantley,

sold at $4500.

Lot 39, Warwick Farm Woodman Licorice, born 11/9/2022, calved 17/2/2025, sold at $4400. Lot 17, Warwick Farm Unix Marigold, born 29/3/2023 and calved on 17/7/2025, sold at $4250.

Lot 72 rounded out the sale, sold at $4200. Warwick Farm Mirand Grace-po, born 22/8/2022 and calved 4/3/2025, she was sold PTIC to Siemers Halliant-p (sexed and due on 17/3/2026.

There were also several straws of semen that went up for auction.

Eight straws of Braedale Goldwyn sold at $900 each, against very keen bidding. The sale was facilitated by Dairy Livestock Services, and integrated online with Stocklive.

Caring for your crop at key times will help maximise yields and ensure your livestock get the most from the Forage brassica crops. Exirel® uses clever chemistry to protect forage brassicas from destructive pests like Cabbage white butterfly, Centre grub, Diamondback moth, Native budworm, Soybean looper and Grey cabbage aphid. It’s also gentle on key beneficial insects. Visitag.fmc.com/au for more information.

BY JEANETTE SEVERS

UP TO 20 per cent of a milking herd is lame, and it’s important to identify these cows early and treat or manage them.

That’s been the message at hoof care workshops in Gippsland, in southern Victoria, held over the past year.

Dean Rowley, of Gippsland Hoof Care, has been demonstrating hoof care for cows in workshops on dairy farms on behalf of GippsDairy.

He has been demonstrating cleaning the hoof to investigate its health, trimming, identifying and treating lesions, and how to apply a block.

Dean recommends drying-off as the ideal time for annual hoof care for cows, when the follow-up care post-trimming includes rest in the paddock.

“We’re always going to have lame cows in the herd,” he said.

“A 600kg cow with 40 litres of milk under her is at risk of foot problems.

“During lactation, 15 to 20 per cent of your herd will be lame.”

Dean said modern dairy farm production systems set cows up for foot problems, irrespective of their breeding. Farms are bigger, cows are standing longer in the dairy yard, but there are ways of managing that to minimise the impact on a cow of moving and standing.

“A healthy hoof grows four millimetres in a month and we’re making cows walk kilometres a day — and they’re not designed for that. Cows should only walk 100 metres a day.

“We’re pushing cows for maximum production and their feet are getting minimal attention. So you need to manage her feet accordingly.

“Good hoof care means the cow is better with management.

“It’s important to identify lame cows early, identify the extent of lesions, and minimise their impact early.

“Lactating cows need to be able to rely on the maximum weight bearing surface of their feet, for production.”

Dean said it was important to take pressure off the surface under the foot, to reduce the risk of tendon rupture.

“Blue metal is a hard stone, and it’s traditionally been used in dairy yards,” he said.

“And steps and up and down ramps in the dairy yard add pressure to cows hoofs and legs.”

An alternate is rubber matting in the dairy yard — for the comfort of cows and workers.

“On 90 per cent of farms I visit, I see loose stones sitting on concrete in the yards,” Dean said.

He recommends ensuring every loose stone is pressure washed out of the dairy and yard, before the cows arrive for milking.

“The dorsal wall is the thickest wall and we’re looking at not compromising the sole cushion.

“When we see bruising, it’s an indication of bleeding around the capsule, when the sole is haemorrhaging.”

Woodchips are also an issue. Dean has seen woodchips penetrate the hoof and create footrot — which requires more intense care and anti-inflammatories for the cow.

Doing the demonstration workshops on dairy farms means Dean has been able to choose cows for the audience that enable him to discuss and demonstrate identifying and treating basic lesions.

“The number one lesion in Australia is the white line. This leads to cracks, puncture in the sole, splits the horn, and you will see a pus discharge,” Dean said.

“If you notice swelling around the back of the dew claw, something has split the skin. Consider the condition of your laneways and tracks — your cow might have picked up a stone.

“I make a lot of money from stones.”

Management includes investigating what has caused the lameness, treating with a possible pain block, rest in a paddock to reduce how much the cow walks, and penicillin only if necessary.

“Farmers waste a lot of money on penicillin when they don’t have to,” Dean said.

“Clean up the hoof, put a block on it to relieve the pressure of the cow’s weight, and potentially use some anti-inflammatories or penicillin depending on the farm policy.

“Weight bearing on the block takes 70 per

cent of the pressure off the toe.

“And 60 per cent of the cow’s weight is carried on the front feet.

“Structurally, we want to keep the foot sound and retain stability in the cow.

“I believe the blocks save cows lives. It’s a minimum cost for maximum reward.”

One of the more common issues he deals with is trimming the lateral claw to balance against the medial claw.

Another common problem is identifying internal haemorrhage of the pedal bone, and reducing the risk of an ulcerating sole.

Genetics can also make a difference, and the farmer may choose to cull for genetic selection the cows with repeat or severe lameness.

Dean said before starting any work, it was important to ensure the cow was balanced at the time she needs hoof trimming.

He has been demonstrating a range of ways to ensure the cow is balanced and her weight

is supported. That includes how ropes and belly slings or supporting harnesses and pulley systems are used, as well as purpose-built cow lifters and cattle crushes.

“Minimise the impact on the cow by doing little things right first,” Dean said.

“We want to put the cow back out in the paddock in better condition than she comes in to the crush.”

Other management impacts include using a footbath. Dean spoke about some cows in certain climates and conditions that do not lay down thickness in their sole, and a footbath can be used to address risk around this.

“It’s all one percenters that help the cow get through lactation.”

Digital dermatitis is very contagious and the farm policy should be to cull these animals. ɋ For more photos from the hoof care workshops, find this story at: www.dairynewsaustralia.com.au

DAIRY FARMER and football netball club president Royston Nettleton has added another win to his record of service on and off the field. From Orbost in south-eastern Victoria, Royston has been named WorkSafe Victoria’s 2025 Footy’s Favourite Farmer.

Known in the Snowy River community as ‘Doc’, the mental health advocate and 2024 Orbost Citizen of the Year recently played a major role in donating 17 truckloads of hay and silage to drought-stricken farmers in southwest Victoria.

As Footy’s Favourite Farmer, the 500-game legend has won $10,000 worth of safety improvements tailored to his business, and a further $10,000 to spend on safety upgrades for the Orbost Snowy Rovers Football Netball Club, where he has been president since 2012. The annual competition, in collaboration with AFL Victoria and Netball Victoria, celebrates the unsung heroes and unique role of sport in farming communities.

Royston has spent his life on the land with workplace safety as a priority, but he said mental wellbeing became a focus more recently, since facing the burden of drought on top of the milk price crashing in 2016.

“I went to the doctor and I told him my problems, and pretty much his answer was going on a holiday, go and enjoy yourself,” he said.

“It was so important for me to keep playing footy — it was an outlet, off the farm.

“It’s just a great place to be, and it’s so

important, not just for my family, but for everybody to have a good footy netball club to be able to come and hang out at.”

SAPUTO DAIRY Australia has give $10,000 to the Orbost Snowy Rovers Football Netball Club to support the installation of a new electronic scoreboard at the Lochiel St Reserve netball courts.

Just minutes from SDA’s AG Warehouse store and in the heart of eastern Victoria’s dairying region, this investment will help modernise the club’s facilities and significantly enhance the game-day experience for both players and spectators by improving visibility and engagement.

This funding was made possible through Saputo’s Legacy Program, which supports the improvement of local sport and health facilities to build a lasting legacy in the communities where we operate.

Orbost Snowy Rovers Football Netball Club president and SDA supplier Royston Nettleton said the new scoreboard was a fantastic asset — not just for the netball club and visiting teams, but for the wider community as well.

“From the young players in our

weekly NetSetGo program to students at Orbost Community College, this upgrade will enhance the experience for everyone involved,” Royston said.

“We’re incredibly thankful to Saputo for their generous support and for investing in the future of our club and community.”

The Orbost Snowy Rovers Football Netball Club is a cornerstone of the local community, with many AG Warehouse customers, Saputo suppliers and their families actively involved in the club.

SDA’s milk supply and planning director Kate Ryan said the scoreboard reflected Saputo’s continued support for grassroots sport and community wellbeing through its legacy program.

“We’re proud to contribute to the club’s future and are pleased to play a part in this exciting new addition,” Kate said. ɋ For more information, visit: https://www. saputodairyaustralia.com.au/en/our-promise/local-community-partnerships

WorkSafe chief executive officer Ash West said Royston’s experience as a farmer and footballer gave him first-hand insight into the benefits of good mental health and physical wellbeing.

“Volunteers like Doc make a huge difference to the vitality of country football and netball clubs, helping them thrive in rural and regional communities,” he said.

“As Footy’s Favourite Farmer for 2025, Doc is a great champion for WorkSafe’s message — that we can all do our bit to create a safer workplace, which benefits everyone in our circle.”

Royston, who supplies Saputo, said he was honoured to be named Footy’s Favourite Farmer to help raise awareness for mental health, as well as safety at both the farm and sporting clubs.

“I’m fully aware that accidents can happen at home and you have to be extra cautious,” he said.

“With the footy netball club, we’re badly in need of some improved wheelchair access for our social rooms.”

The competition received more than 200 nominations with Royston chosen from three finalists, who all received a farm safety pack valued at almost $2000, an independent OHS Essentials workplace safety consultation, along with footballs and netballs for their club.

0–3 mths

Veanavite® No.1

3–12 mths

Veanavite® No.2

Veanavite® pellets have been the products of choice for Australian farmers for over 35 years. Each product provides a highly palatable blend of readily fermentable carbohydrates and high quality proteins to support optimal growth, development and immune system function at each growth stage. Contact your local reseller or go to www.veanavite.com.au to find out more.

12–23 mths

Veanavite® No.3

THE AGRICULTURAL Shows Australia

national championships at the Royal Adelaide Show saw the sashing of the country’s top young dairy judge — Luke Gardiner.

Twenty-year-old Luke is studying agriculture at the University of Melbourne and grew up on a stud dairy farm at Nar Nar Goon, where his interest in breeding and showing cattle began.

He has developed a strong interest in judging, inspired by his father John Gardiner.

“Dad taught me everything I know and Mum jumped on a plane at the last minute to be here. It’s a blessing I was able to come,” Luke said.

“I started competing because I love judging and aspire to judge major shows across Australia and the world.”

Runner-up was awarded to William Dudfield, 22, from Somerset in Tasmania.

William has been around the show ring since he was three years old, and joined parader competitions at just nine.

Growing up on a dairy farm sparked his love for cattle, and even though he now works in civil construction, showing remains a big part of his life.

“I’m pretty pleased with myself, and might sneak back to the cattle sheds now to have a cold one with the cattle donors,” William said after the competition was complete.

Third place was awarded to Chris Thompson, 19, of Urrbrae in South Australia.

Chris grew up on a small family property, started showing dairy cattle while still at school and soon developed an interest that led him to establish his own Holstein and Jersey stud.

Throughout high school, Chris gained hands-on experience working on farms, and now in his first year at the University of Adelaide, he continues to show cattle at most South Australian events and some in Victoria. His involvement in young judges competitions began at smaller country shows and quickly progressed — placing third at the South Australian final one year and taking out the top spot the next, before placing third nationally in

Open to competitors aged 15 to 25, the national championships showcase the best from each state, with entry earned through success at regional and state agricultural shows.

Agricultural Shows Australia chair Jacqueline Wilson-Smith said the championships showcase agricultural excellence, boost the industry and shine a light on outstanding achievements.

“These young competitors are the future of agricultural show competitions, which are so important to the growth of Australia’s food and fibre industries,” she said.

“The nationals are a fantastic opportunity for them to develop their skills, gain valuable experience, and go head-to-head with the best in the country.”

The national competition is sponsored by global livestock company Vytelle.

SIENNA ROSS, from Katamatite in Victoria, was crowned champion young dairy parader at the the Agricultural Shows Australia national championships in Adelaide.

Sienna, 17, is a proud first-generation dairy farm kid growing up milking cows, rearing calves and driving tractors.

Now in Year 12 and school captain at Sacred Heart College Yarrawonga, Sienna hopes to one day become a qualified embryo technician. She also competed last year, where she was awarded runner-up.

“My family definitely are the main reason I now have such a love for showing dairy,” she said.

“I have Dad’s love of cows, Mum’s support and her determination for me to succeed, my brother’s skills building all my new gear, and my sister by my side at all the shows to learn new things.

“I grew up on a dairy farm and started with American cattle with my family, which we run together.”

When asked about winning, Sienna said, “I’m pretty stoked, not many words I can say.”

She received a halter from Goulburn-based store The Cattle Shop.

Runner-up was William Phillpot from Murray Bridge representing South Australia at the show competition on September 3.

Showing dairy cows has been a big part of William’s life since he was 12, when he attended the SA Dairy Youth Camp and met mentor Bridget Liebelt.

Today, William regularly shows top-quality stock alongside Bridget at local and interstate events, and works at Daish Irrigation and Fodder in his home town.

“I can’t believe it,” William said after the competition was run.

“I never thought I would make it this far and I guess if you keep trying and keep practising you can make it to achieve your goals.

"I started competing with dairy cattle at a young age, with what started as a small hobby, quickly grew into a lifelong passion and skill.

“My dedication and willingness to learn

helped me progress my talent and skills into the show ring.

“I have had so many amazing opportunities to compete in handlers’ classes, with much success along the way.”

Third place was awarded to Patrick English, 20, from Malanda representing Queensland. Patrick has been hands-on with the preparation and presentation of his family’s large show teams from a young age.

He works full-time at the Mareeba Saleyards and part-time on the family’s dairy farm.

A standout moment in his show career was the Royal Queensland Show when his family claimed both Supreme Intermediate Female and Supreme Champion Cow in 2019.

“My family are multi-generational dairy farmers and have exhibited dairy cows at every Malanda Show since 1916,” he said.

“Our family has always been competitive — with six siblings there is always competition — and I have enjoyed parading animals since I could walk.”

Dairy farmers looking to maximise spring pasture growth can adopt proven strategies for nutrient and fertiliser management to ensure effective pasture production

Trace elements in pastures – molybdenum (Mo), copper (Cu), boron (B) and zinc (Zn) –help maintain productive pasture systems and livestock productivity.

Understanding and diagnosing deficiencies is critical for effective nutrient management.

Test before you invest by using a plant tissue test to clarify exactly how much of each nutrient a plant is accessing in the soil, and whether the levels are sufficient, or limiting to production.

Plant tissue tests provide a more accurate reflection of nutrient uptake than soil tests alone, and this is particularly important for Mo, as tissue testing is the only way to determine sufficiency.

Spring is the perfect time to do a plant tissue test, as pastures are actively growing and it’s easy to select a good representative sample. In pasture systems, plant tissue testing offers insights into animal nutrition and wellbeing.

Deficiencies in Cu, for example, can impact ruminant health, while Mo plays a key role in nitrogen (N) fixation for legumes and can influence nitrate accumulation in grasses.

Incitec Pivot Fertilisers’ (IPF) Nutrient Advantage ® Laboratory offers a complete pasture tissue testing service.

Once you know the nutrient status of your pasture, use an NPKS fertiliser blend such as an IPF Boosta, or a Greentop blend to help meet nutrient requirements in a single pass. Green Urea NV®, from IPF’s Smart range of enhanced efficiency fertilisers can protect up to 25% of applied N from loss.

Green Urea NV® slows the conversion of urea to ammonia, keeping more N in the soil.

Remember that rounding out nutrient budgets with plant tissue testing is a sound strategy to help correct deficiencies this season while also providing a head start in planning for next season’s fertiliser program.

For more information please visit https://www.incitecpivotfertilisers.com.au/ productivity-pays-in-spring-pastures

BY JEANETTE SEVERS

WILCO DROPPERT and Sandra Jefford are feeling over-exposed in the dairy industry, but it is for good reasons.

They are the principals of Wilandra Farms and they have been taking risks to improve the viability of their farm, as they work towards becoming a carbon neutral business.

In the process, they have been hosting multiple field days and attending speaking engagements, to explain their business model.

Wilco and Sandra were dairy farming in another region of Victoria’s Gippsland, where rainfall was plentiful and regular; when they decided they wanted a bigger challenge.

They bought a dryland dairy farm at Clydebank, and over several years they have converted a substantial percentage of the property to irrigation, and adopted technology to considerably improve their efficiency and reduce their emissions footprint.

It is a progressive journey that is challenging and rewarding, and they are embracing it.

Since 2011, Wilco and Sandra have implemented significant renewable energy solutions and technology on their farm.

The farm is 370 hectares of sandy loam over clay soils on flat to slight undulating country, across eight titles.

They milk 380 cows year-round, an increase of 30 head in recent years as more irrigation country is developed and re-pastured.

Wilco and Sandra began farming organically as soon as possible after purchase, and their farm has been certified organic since 2020.

“We’ve been certified organic milk producers for five years, but because we farmed organically prior to certification, no synthetic fertiliser is used on the farm,” Sandra said.

In recent years, they have invested in four wind turbines and a considerable number of solar panels to harness renewable energy, which enables them to power pumps to irrigate paddocks during the daytime.

This change alone has improved their wellbeing; with no irrigation at night they have excluded occupational risk around operating machinery in the dark.

They now identify and resolve irrigation problems during the day. Operating costs are cheaper than grid power. The couple also sleep better.

“We irrigate 185ha with pivots, and we were using K-line sprinklers on other paddocks, but now we’ve converted to permanent sprayers,” Wilco said.

Water is directed from the nearby Avon River and two bores, into storage dams, and

pumps and management control systems use renewable energy to irrigate their pastures and crops.

As more water storage points are built, Wilco and Sandra add more renewable energy to enable more irrigation to occur.

They have 249 kilowatts of solar panels and 20kW of wind turbines.

Their journey in using renewable energy began with the first installation of 29kW of solar panels, in 2017, on their dairy shed roof. They installed a CO2 heat pump to replace a conventional hot water service, and use solar power during the middle of the day — the alignment of the panels enables solar power generation in the middle of the day.

Both changes achieved about a 40 per cent energy reduction.

Sandra said, in hindsight, they may have been better off installing more solar panels, improved the orientation for energy generation, and continue to use a conventional hot water service.

Other modifications included replacing old vacuum pumps with a low vacuum pump in the dairy.

What Wilco and Sandra didn’t know, was how much irrigation cost them in real terms.

“In 2017, a very dry year, we used approximately 500,000 kW hours of electricity and 23,000 litres of diesel for irrigation,” Sandra said.

“This resulted in massive greenhouse gas emissions and huge energy bills.”

Wilco and Sandra realised they wanted to change the way they were farming, and to invest in technology that would reduce their energy bills and their farm’s emissions and carbon footprint.

There are further complications because each of their eight titles has its own electricity meter, which means they are paying multiple times for the right to use grid power. It also prevents them from balancing the use of renewable energy on one title against grid power on another title.

A farm-scale change needed to occur.

“In 2018, we conducted an energy audit and received recommendations about reducing energy use in the dairy,” Sandra said.

These recommendations included changing their submersible pump to one that would more efficiently work in their system, producing greater flow capacity; and they installed wider piping, again to improve efficiency. Those changes reduced their energy use by 38 per cent, and the return on investment was final within 4.5 years.

Wilco said some of the inefficiencies were

around friction loss through irrigation pipe that was the wrong diameter and using the wrong pumps.

“Once we changed to a submersible pump, the power used went down to 25 per cent of what we were originally using per megalitre,” he said.

They also replaced a diesel pump with two electric pumps and, because these were powered by solar panels, utilised daytime hours to move water around their property.

“Under the audit, it was estimated we would save about $18,000 a year, with a payback period of 2.4 years,” Sandra said.

“Before we even look at solar, we saved so much money. When we did that energy audit, we had a 55 kW bore pump in one bore, which is more suited to a 37 kW pump,” Wilco said.

“We learned to look at the efficiency point at each pump and then basically figure out what we want.

“We want to be most efficient when we’re using the most amount of power, when all the sprinklers are working; and turn off all those pumps that operate at lower speeds when there’s only one bay running.

“So we spent a bit of time just figuring out what pump we were going with to make sure we got the right pump for the job, and use it as efficient as we can.”

Wilco and Sandra successfully applied for funding through Agriculture Victoria’s Agriculture Energy Investment Plan, to help them to upgrade their infrastructure and install 200kW of solar panels and 20kW of wind turbines along with an energy management system that automatically controls water pumping based on the available renewable energy.

Their bank provided them with a loan package that recognised how their investment in technology improved the carbon footprint of their agribusiness.

Through on-farm experimentation and trial, Wilco and Sandra have realised solar power is the energy source with the most valuable return on investment.

Irrigation costs dropped from $80,000 in 2021, to about $1200 in 2022. They also put power back into the grid, so their cost per kW hour has reduced from 24 cents to -3 cents.

They have also saved themselves time — about 15 hours a week — and are considerably less hands-on with their irrigation system, especially since installing fixed sprinklers in paddocks where a K-line system was used.

At a field day hosted by Wilandra Farms, Wilco discussed a project to utilise surplus power they were generating from a bank of solar panels, to change the K-line system to a

fixed sprinkler system across 20ha of paddocks, at a cost of close to $6000/acre.

The project received 10 per cent funding from the West Gippsland Catchment Management Service, which Wilco said justified he and Sandra’s intent to proceed with their plans.

These paddocks had been problematic, with insufficient water flow to justify laser graded irrigation. The K-line sprinkler pods required significant labour and were often left to flow while other work took priority elsewhere on the farm.

“At this bore we have 50kW of solar panels and we wanted to mop up some of that surplus power — which was going into the grid — and use it to pump water for fixed sprinklers on this part of the farm,” Sandra said.

As a result of their water audit, the couple had already increased the diameter of the pipeline that was moving the water from the bore to a dam.

A major infrastructure change saw Wilco build a bigger storage dam to support the new irrigation system. At its centre, the dam is five metres deep.

To maximise efficiency, Wilco decided to float the pump on the dam. He said this decision minimised energy requirements to the pump, because it was so close to the water source.

A new pump house was built beside the dam, which is all close by the already-installed solar panels.

“With using solar energy, it’s just a different thought process because you don’t have constant power generation,” Wilco said.

The irrigation system is designed to maximise how much solar power is available.

The management system divides sprinklers into banks; and on a good solar day, enough power is generated to run multiple banks of sprinklers and pump water from the bore into the holding dam.

The system is programmed to prioritise filling the dam, then with sufficient power generation the sprinklers are activated.

“In the morning, the irrigation pump is running at 14 to 15 kW, and we’ll have a valve open and one bank of sprinklers are spraying,” Wilco said.

“Then after about an hour, the bore pump comes on at around 15 kW, when there’s enough excess solar here; and the second lot of sprinklers come on.

“During the middle of the day, we’ll have three valves open, and the system will keep running the rest of the day to absorb all of the solar energy.”

There was no intention to use these paddocks for silage, which complemented the grid of fixed sprinklers. These paddocks are close to the dairy and ideal for grazing.

The fixed sprinklers are laid out in a rectangular pattern, at 35-metre spacing.

“Clydebank bore water is pretty harsh, so we also wanted the spacing to make sure we didn’t coat the sprinklers with the harsh water and reduce the risk of corrosion,” Wilco said.

“So we’ve actually spread the distance between sprinklers out an extra metre to try and look after the infrastructure.”

Wilco chose to use large diameter pipes to reduce the pressure requirements in the new system. Water from the dam initially travels along 200mm diameter pipes that split into six-inch and then 100mm pipes near the sprinkler valves. Each sprinkler rig is designed to use five litres/second of water.

The sprinklers work to ensure at least two and up to eight millimetres of water is sprayed across the paddocks on each shift.

“When I look at the pasture I can’t see any difference from one spot to another, and I think that’s good enough for me,” Wilco said.

He now intends to apply the same principles to another area of the farm that Wilco and Sandra want to bring on with irrigation.

“This system has to be low maintenance, we’ve got to get away from the labour component of irrigating the farm,” Wilco said.

Wilco said that in considering what to do on this part of the farm, choosing a fixed sprinkler system over a mobile lateral spray also enabled

them to include 12 rows of trees, incorporating 10 ha of the farm.

Wilco and Sandra support renewable energy production and expanding irrigation with a philosophy based around regenerative farming techniques, that includes revegetation.

“We plant trees to provide cattle with shelter and shade, and to support biodiversity on the farm,” Sandra said.

A forestry consultant has guided them to achieve successfully planting 11,000 trees, including 9000 agroforestry plantings using a mix of yellow stringybark, red ironbark, spotted gum, coastal grey box, sheoak and sugar gum.

They have committed to planting 20,000 trees by 2030, to provide shade, create windbreaks and sequester carbon.

Wilco and Sandra are actively managing their land to increase soil carbon — they have learned as much as they can about soil biology and planting for biodiversity. They have also started a registered soil carbon project.

“We can see a lot of future benefits in planting the trees the way we’re doing it now,” Wilco said.

“We’ll get shelter and shade for the cows, biodiversity for birds on the farm – we’ve got 98 species of birds here now, so we expect to get more.

“And it’s a more pleasant place to work.

“Having the sprinklers has enabled us to integrate more trees and that’s just going to be an ongoing thing for us.”

ɋ Find more photos with this story online at: www.dairynewsaustralia.com.au

THE NEW Zealand-based Fonterra Co-operative group has reported a financial year profit of NZ$1.7 billion, up from NZ$1.5 billion the previous year.

The after tax profit was NZ$1.1 billion, equivalent to earnings per share of 65¢.

The group, which includes its Australian business, reported revenue of NZ$26 billion and delivered NZ$16.2 billion in total cash returns to shareholders.

The final farm gate milk price for the 2024-25 season was $NZ10.16/kg MS,

equating to NZ$15.3 billion in milk payments to New Zealand farmers, up NZ$3.8 billion on last year.

The group also announced a full year dividend of 57¢ fully imputed, and at the upper end of its dividend policy, equating to NZ$916 million of cash to shareholders and unit holders. This is comprised of a 22¢ interim dividend and 35¢ final dividend.

Chief executive officer Miles Hurrell said FY25 was one of the co-op’s strongest years yet in terms of shareholder returns.

“We continue to see good demand from global customers for our high-quality products made from New Zealand farmers’ milk and this is driving returns through both the farm gate milk price and dividends,” Mr Hurrell said.

“Our vision is to be the source of the world’s most valued dairy.

“Our strategy is designed to grow end-toend value for farmers by focusing on being a B2B dairy nutrition provider, working closely with customers through our high-performing Ingredients and Foodservice channels.

“During the year, we’ve taken important steps towards this goal, including running a robust divestment process for global Consumer and associated businesses.

“This resulted in an agreement to sell the businesses to Lactalis for NZ$4.22 billion, subject to approvals.

“We’re also positioning the co-op to deliver further value through our Foodservice and Ingredients businesses, including continuing to invest in new manufacturing capability to meet growing customer demand for our high-value products.

“We have a pipeline of potential growth investments we’re assessing, with plans to invest up to NZ$1 billion over the next three to four years in projects to generate further value and drive operational cost efficiencies.”

Mr Hurrell said in line with its strategy to focus on its Ingredients and Foodservice businesses, during the financial year, Fonterra undertook a dual-track divestment process for its global Consumer and associated businesses.

The company is selling the Oceania division, which includes Australian operations, to Lactalis.

AGRONOMIC ADVICE and insights were supplied in spades at the 2025 Valley Seeds Field Day in north-eastern Victoria.

Held at Yarck on September 3, attendees had a hands-on look at demonstration and trial pasture plots that showcased products from across the pasture industry, and also their research and development efforts in driving data-based advice and products.

Led by agronomist Adam Meusburger, the trials demonstrated how sowing rates influence both yield and feed quality.

“We’re testing a variety of Persian clover x Italian ryegrass sowing rates,” Adam said.

“The aim is to gather empirical data to support pasture decision-making for dairy farmers by comparing feed quality to yield at different sowing rates.

“Our research and development teams work closely with us to ensure we provide pastures that deliver high feed quality — not just empty bulk feed.”

The trials will empower agronomists to create data-driven tailored pasture solutions for different dairy operations.

Adam said ensuring bulk feed does not come at the expense of quality is essential.

Quality feed is high in protein, energy-rich, and easily digestible, supplying animals with the nutrition needed to maintain growth and milk production even when paddocks brown off in summer,“ he said.

“It’s about giving farmers the right feed, at the right time, for their system. More digestible feed means higher intake, faster growth in heifers, and improved milk yields.”

Valley Seeds also showcased its VSeries Hay & Silage Blends – Early and Late.

Adam said these blends provide balanced energy and protein and are versatile for both grazing and silage production, offering farmers

a reliable, high-quality, high-yield feedbase throughout the season.

Key takeaways for dairy farmers from the field day:

ɋ Sowing rate matters: Talk to your agronomist about the best sowing rate for your farm operation goals.

ɋ Q uality feed counts: High-yielding pastures don’t always mean high-quality feed. Understand the balance of quality versus yield.

ɋ Tailor to your system: Use sowing rates to match herd size and operational goals — one size doesn’t fit all.

“I can truly say: The Astronaut A5 Next is the best colleague I’ve ever had”

Alessandra Cabrini, herdmanager

“ The Astronaut A5 Next gives me more control, and the cows more comfort.”

When the Lely Astronaut A5 Next takes over the repetitive process of milking, you can allocate your expertise where it is needed most: managing herd health, farm management, and spending time with your family.

Insights from the Lely Horizon app ensure the link between you and your animals by putting the right information at your fingertips.

The new automatic milk filter eliminates the need to replace filters manually - making the process easy, convenient, and less labourintensive. The Astronaut A5 Next also supports the use of Ear Tag ID for basic identification.

Stay ahead of your future Visit our website to learn more about the Astronaut A5 Next.

GIPPSLAND FARMER Daryl Hoey has had numerous bulls go into the AI system, but his latest addition is something special.

GT, which is joining the Genetics Australia Jersey portfolio this spring, has been named in honour of Daryl’s great mate, Greg Tiller.

While it’s a bittersweet moment, it also gives Daryl great pride to recognise the contribution Greg made to his Beulah Jerseys herd and to the cattle breeding industry in general.

Greg died suddenly on August 20, 2023, after a 20-year career as a Genetics Australia field sales representative based at Rochester in northern Victoria.

Daryl now farms at Wonthaggi but met Greg not long after he bought his previous farm at Katunga in 2002.

“Greg started at GA a few months after we bought the farm and he became one of my best friends,” Daryl said.

“We spent plenty of hours on the phone or at the kitchen table discussing genetics.

“My enjoyment out of breeding cows and breeding bulls has never been the same since the loss of Greg.

“I’ve lost someone that I spent so much time discussing and debating genetics with. His death left a massive hole in my life — I just don’t have those same conversations with anyone else.”

The connections Greg made with farmers went well beyond genetics.

“Apart from just calling on farms to make sales, Greg would talk about farming and life and making sure people were okay,” Daryl said.

“Greg was always there if you needed those conversations. He was always conscious of

other people’s circumstances and always checked in on people and made sure everyone was okay.”

Despite Daryl’s loss, GT the bull is set to do GT the man proud.

While Daryl has had plenty of bulls in AI, GT is special not only for the emotional connection but for his outstanding potential.

“I don’t necessarily strive to put a bull into AI,” he said.

“With over 80 per cent of semen used being sexed, breeding bulls is not a focus. I just strive to breed better genetics in my herd and then sometimes the genetics come together to produce something special.

“If you have consistent cow families and high-indexing animals then the chances of that happening is greater. The high genomic animals keep coming to the top if you keep breeding your better lines to good bulls.”

GT comes from a long line of cows stemming back to south-west Victorian farmers Rosemary and Pat Roache’s Fairy cow family, which produced the bull Outinfront that Genetics Australia bought more than 20 years ago.

This led to the Fairy family in Daryl’s Beulah Jerseys, one of his strongest cow families.

GT’s mother Dougg T Fairy was the number one genomics heifer in Australia, and is still ranked ninth, and his grandmother Triple N Fairy was one of the top genomic animals in her year group.

“The cow family for four or five generations has always been high on genomics for the year level and GT seems to have picked up a lot of his sire’s attributes,” Daryl said.

“He’s got strong mammary and fertility, which are some of the key areas that I’m focusing on at the moment.

“Fertility is something the breed seems to have forgotten about. He’s a really solid bull, not necessarily outstanding in one particular area but solid across the board.”

Dougg T Fairy was sent to Genetics Australia’s TLG centre at Camperdown to be flushed and when they got two heifers and two bulls, Daryl was determined to make sure a bull was named in recognition of Greg.

“We didn’t always agree but he never told you that you were wrong,” Daryl said.

“Greg always let you decide yourself but he challenged you and threw different options on the table. He always kept the communication lines open.”

Daryl now milks about 300 cows, 95 per cent Jersey, on 177 hectares near Wonthaggi.

SHOWCASE YOUR FINEST CHEESES, BUTTERS, YOGHURTS AND DAIRY PRODUCTS ON AUSTRALIA’S MOST PRESTIGIOUS STAGE.

The Sydney Royal Cheese & Dairy Produce Show has traditions dating back to the 1870s and is considered one of the most prestigious competitions in the industry, awarding coveted accolades to outstanding producers.

With classes in milk, butter and cheeses, including cheddar, labneh and haloumi, as well as gelato, yoghurt, buttermilk, custard and other milk products from cows, sheep, goats, bu alo and camels, this is the ultimate stage to showcase your craft.

Seize the opportunity to win a coveted Sydney Royal Medal and enjoy the significant benefits and promotional opportunities that come with a Sydney Royal victory. Enter your cheese and dairy products today.

Entries close Wed, 22 October 2025.

BY LEIGHTON HART AND GREG MORRIS

DAIRY FARMERS across Australia are reflecting on a tough 18 to 24 months marked by erratic weather, depleted feed reserves and soaring input costs.

In regions like south-west Victoria and southeast South Australia, droughts, floods and shortened growing seasons have forced many to rely heavily on purchased feed, often at record prices.

Spring presents a valuable window to establish forage crops that can bridge feed gaps through summer and autumn. These crops offer rapid growth, high digestibility and flexibility in grazing or conservation.

Brassicas — such as turnips, forage rape and leafy turnips — are fast-growing and highly digestible, making them ideal for summer grazing and bridging feed gaps.

Regrowth varieties allow multiple grazings.

Chicory, with its deep roots and drought tolerance, provides high energy and protein, suitable for grazing from late spring to autumn.

Annual or Italian ryegrass offers cheap sowing costs, quick establishment and options for grazing and silage or hay, with minimal paddock disturbance.

Sorghum is known for its rapid dry matter accumulation in warm conditions, water efficiency and low insect pressure, making it suitable for summer grazing or silage.

Maize, a high-yielding silage crop with excellent energy density, provides high yield

potential and is best suited to irrigated systems or high-input dryland farms.

To make home-grown feed work, it is essential to plan early, matching crop choice to soil type, rainfall and stock needs.

Using diverse blends can offer balanced nutrition and soil health benefits. Monitoring soil temperature ensures optimal germination conditions, and managing grazing rotations helps maintain feed quality.

For purchased feed, accurate forecasting of needs using feed budgeting tools is crucial.

Securing supply early by locking in contracts before peak demand periods can prevent shortages. Testing feed quality and allocating

high-value supplements strategically can optimise feed use.

The past two years have highlighted the vulnerability of dairy systems to external pressures but also the opportunity to build resilience through smart feed base management.

Spring forage crops offer a cost-effective, high-quality feed source that can reduce reliance on purchased inputs and improve farm profitability.

As we plan ahead, it’s important to remember that you don’t have to do it alone.

It’s also a good time to engage with your financial adviser or bank to review cashflow and plan for future investment in feed strategies.

And just as importantly, if the past couple of years have taken a toll on your wellbeing, reach out to your GP or a rural support service.

These have been tough times, and it’s okay to ask for help.

Building resilience isn’t just about feed, it’s about looking after yourself, your team and your business for the long haul.

Lean on your trusted advisers, whether that’s your agronomist, nutritionist or farm consultants. They are experts in this field and can help you make informed decisions about cropping, feed budgeting, and risk management.

Leighton Hart and Greg Morris are dairy specialists for Pioneer Seeds.

MFP® Feed Supplement provides HMTBa methionine in a highly bioavailable, dry powder form, helping to support rumen health and optimize milk fat synthesis. Backed by NOVUS expertise, it’s a trusted tool to help maintain consistent milk fat production as part of your nutrition program.

Increase rumen microbial production

Increase milk fat response & milk protein production

Speak with your Novus representative today to learn more about the role of MFP® Feed Supplement in your feeding strategy or visit Novusint.com

Novus Nutrition Pty Ltd | info@novusint.com +61 472 599 247

VikingHolstein cows are bred for long-term success, with exceptional fertility, longevity, and feed efficiency. They are easy to manage and cost-effective to maintain. Their ability to produce lots of milk high in components ensures long-term profitability for your dairy business.

BY JEANETTE SEVERS

REPORTING FARM crime to Victoria Police has helped build a profile of criminal activity in local police districts within each of the state’s four police regions.

VH Sable P

equipment to a fixed object. Install a locking mechanism on trailers, and when vehicles are not being used they should be disabled — remove the battery, spark plugs or distributor cap.”

Items could also be marked or engraved with a unique number, code or symbol, to ensure their traceability if stolen.

VH Stens

Teat length and placement where you need them. Teat placement front 105 & rear 95.

458 ASI 248 OT 100 MS 102

Senior Constable Troy Bryan, Leongatha police officer, and Leading Senior Constable Nick Carlson, from Wonthaggi’s Active Policing Unit, are both farm crime liaison officers in the Gippsland region and had a display at the recent South Gippsland Dairy Expo.

“Also, keeping records of serial and model numbers, and photographs of equipment and tools, and invoices, helps us identify your tools and equipment when we find them,” Troy said.

Remedy for short close rear teats. Good attachments and udder width. Teat placement rear 94, teat length 109. BPI 410 ASI 231 OT 105 MS 103

Our latest catalogue is available. Order now!