June 14 2023

Vol. XXV • No. 12

June 14 2023

Vol. XXV • No. 12

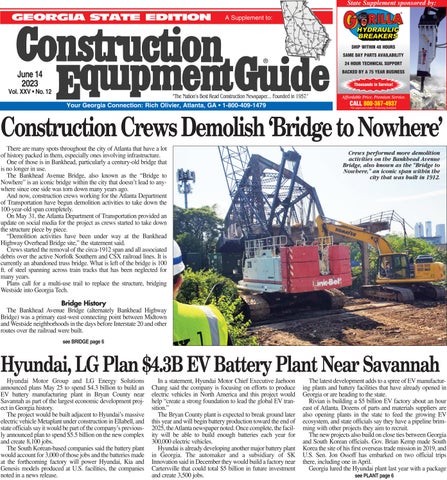

There are many spots throughout the city of Atlanta that have a lot of history packed in them, especially ones involving infrastructure.

One of those is in Bankhead, particularly a century-old bridge that is no longer in use.

The Bankhead Avenue Bridge, also known as the “Bridge to Nowhere” is an iconic bridge within the city that doesn’t lead to anywhere since one side was torn down many years ago.

And now, construction crews working for the Atlanta Department of Transportation have begun demolition activities to take down the 100-year-old span completely.

On May 31, the Atlanta Department of Transportation provided an update on social media for the project as crews started to take down the structure piece by piece.

“Demolition activities have been under way at the Bankhead Highway Overhead Bridge site,” the statement said.

Crews started the removal of the circa-1912 span and all associated debris over the active Norfolk Southern and CSX railroad lines. It is currently an abandoned truss bridge. What is left of the bridge is 100 ft. of steel spanning across train tracks that has been neglected for many years.

Plans call for a multi-use trail to replace the structure, bridging Westside into Georgia Tech.

The Bankhead Avenue Bridge (alternately Bankhead Highway Bridge) was a primary east-west connecting point between Midtown and Westside neighborhoods in the days before Interstate 20 and other routes over the railroad were built.

see BRIDGE page 6

Crews performed more demolition activities on the Bankhead Avenue Bridge, also known as the “Bridge to Nowhere,” an iconic span within the city that was built in 1912.

Hyundai Motor Group and LG Energy Solutions announced plans May 25 to spend $4.3 billion to build an EV battery manufacturing plant in Bryan County near Savannah as part of the largest economic development project in Georgia history.

The project would be built adjacent to Hyundai’s massive electric vehicle Metaplant under construction in Ellabell, and state officials say it would be part of the company’s previously announced plan to spend $5.5 billion on the new complex and create 8,100 jobs.

The South Korean-based companies said the battery plant would account for 3,000 of those jobs and the batteries made at the forthcoming factory will power Hyundai, Kia and Genesis models produced at U.S. facilities, the companies noted in a news release.

In a statement, Hyundai Motor Chief Executive Jaehoon Chang said the company is focusing on efforts to produce electric vehicles in North America and this project would help “create a strong foundation to lead the global EV transition.”

The Bryan County plant is expected to break ground later this year and will begin battery production toward the end of 2025, the Atlanta newspaper noted. Once complete, the facility will be able to build enough batteries each year for 300,000 electric vehicles.

Hyundai is already developing another major battery plant in Georgia. The automaker and a subsidiary of SK Innovation said in December they would build a factory near Cartersville that could total $5 billion in future investment and create 3,500 jobs.

The latest development adds to a spree of EV manufacturing plants and battery facilities that have already opened in Georgia or are heading to the state.

Rivian is building a $5 billion EV factory about an hour east of Atlanta. Dozens of parts and materials suppliers are also opening plants in the state to feed the growing EV ecosystem, and state officials say they have a pipeline brimming with other projects they aim to recruit.

The new projects also build on close ties between Georgia and South Korean officials. Gov. Brian Kemp made South Korea the site of his first overseas trade mission in 2019, and U.S. Sen. Jon Ossoff has embarked on two official trips there, including one in April.

Georgia lured the Hyundai plant last year with a package see PLANT page 6

We help build the roads that connect goods to markets, people to communities and families to one other. Astec pavers, screeds, mills, stabilizers and MTVs yield innovative and reliable Rock to Road solutions that create value and connection. We are inspired to connect with our customers through innovative design for safe and reliable roads. astecindustries.com

Fort Stewart’s Building 633, a 46-year-old Volunteer Army barracks at the base in Savannah, Ga., is undergoing extensive internal renovations, and the old doors, cabinets and other hardware items that were removed are being repurposed at various locations on the installation and throughout Georgia.

The U.S. Army Corps of Engineers (USACE) said in a news release May 30 that the military construction project will replace all failing systems currently within the building, convert the four-soldier living units into two-soldier spaces, bring the building into compliance with current Life Safety and Accessibility Codes, and as closely as possible within current Army Standards for Permanent Party Soldiers and Unaccompanied Enlisted Personnel Housing compliance.

“Two soldiers will share a living space that includes a kitchen, laundry and dining area,” said USACE, Savannah

District, Project Engineer Susan Smith. “Each soldier will have their own bedroom suite, with bathroom, desk space and a walk-in closet.”

As part of the construction process, the Department of Public Works (DPW) lets USACE know what is needed, and the Corps oversees the project from the beginning to completion.

“As the project engineer, I work onsite during the construction,” Smith explained. “The DPW lets us know what they want, and we develop a scope of work that is ultimately put out for bid. Once the bid is awarded by us [USACE], we manage the project through design and then construction. We hand it over to the DPW, once it’s complete.”

The barracks renovations are set to be completed in October 2024 at a cost of $17.5 million.

As part of every Army Corps’ military construction project, contractors must divert usable building supplies taken from an old structure.

“Over the years I’ve been a part of many construction projects,” she said. “[But] this is the first time I’ve seen the contractor reach out to donate to a local charity.”

The building firm, Bristol Construction Co., headquartered in Anchorage, Alaska, made the effort to contribute usable doors, cabinets and other like items to a local charity, as well as the Fort Stewart Home Builders Institute, and base fire department.

Richard Tyler, Bristol’s project superintendent, also repurposed doors into a

conference table for the construction office and made other wood signs for the building site.

“The [contract] specifications require that we have five waste diversion streams,” said Tyler. “Concrete, metal and cardboard are the simplest ones to meet, but taking care of the last two can be challenging. I started reaching out to the different ReStore locations in a 100-mi. radius to see what we might be able to repurpose and found that the Coastal Empire Habitat for Humanity Inc. could [use] the items.”

“These donations will mean the world to each affiliate and will quickly be put to good use,” explained Zerik Samples, CEO of Coastal Empire Habitat for Humanity. “If appropriate, we will see if these items can be placed in our current build projects; if not, we will sell them in our ReStores across our four-county service area, resulting in development funds to purchase supplies and equipment for new construction.”

“Since we are not building a new [structure at Fort Stewart, but] renovating the interior and all electrical and mechanical systems, this is actually a sustainment, restoration and modernization [SRM] funded project,” noted Alykhan “Anakin” Gangji, the Georgia Execution Team project manager for USACE, Savannah District.

He added that because it is a large SRM construction and renovation effort, it requires approval from the Deputy Assistant Secretary of the Army for Installations, Housing and Partnerships, in addition to funding approval from the Army’s Installation Management Command (IMCOM).

“Each installation sends up their list of priorities to IMCOM and those are further prioritized for funding,” Gangji explained.

Bristol Construction’s Tyler said that when working with the USACE, “the expectations are high, but we rise to the challenge.”

Students at Canton, Ga.’s Cherokee High School are closer to having a new school campus, projected to open in 2026.

The Cherokee County School Board (CCSD) on May 18 unanimously approved a $179 million contract with Carroll Daniel Construction, a Gainesville, Ga., firm, to erect a new building for the school.

The contract is the largest CCSD has ever awarded for a high school, but the cost per square foot is in line with market rates for school construction, the district said.

Rising costs for materials and labor, coupled with the school’s size, led to a higherthan-expected price tag, according to CCSD. After a cost analysis by the CCSD staff, Superintendent of Schools Brian V. Hightower recommended that the district not delay the project because prices are likely to continue rising.

The new campus, expected to open in August 2026, will include 473,761 sq. ft. of space. The building is designed for 3,000

students; the current enrollment at Cherokee High is about 2,800.

CCSD noted that there are no plans to change the attendance boundary lines for the school — the entire enrollment will move to the new school when it opens.

The new building also will feature 152 classrooms, a 1,000-seat auditorium and a 4,500-seat football stadium.

“I’m so impressed by the design and the state-of-the-art labs,” said Cherokee County School Board Member Susan PadgettHarrison, a former principal at the high school. “When I see how beautiful the front of that school is [going to be], I’m excited to vote for it tonight.”

Most of the construction’s cost will be funded with Education Special Local Option Sales Tax (Ed-SPLOST) revenue and associated bonding. In addition, CCSD will receive $31 million from the state of Georgia to help pay for the new school.

This will be the first time CCSD will fund

construction through Ed-SPLOST, as the entire cost for replacing the county’s Free Home Elementary School, now under construction, was covered with funds already in hand, according to the school district.

Site preparation for the new Cherokee High, which was approved through a separate contract, currently is under way in the Riverstone Plaza shopping district and adjacent to Teasley Middle School.

The current high school is the district’s oldest facility, with the core buildings on the campus opening in 1956. There have been numerous additions and renovations over the years, including more than $16 million in investments since 2002, CCSD noted.

School Board Member Patsy Jordan, who could not attend the May 18 meeting due to a prior commitment, passed on her remarks to Kyla Cromer, the board’s chair, to be shared during the session.

A Cherokee High School graduate herself, Jordan said she knows how long the

community has waited for this day to come.

“I’m looking forward to many generations of Cherokee High School students being educated in this new school,” she said, noting she also is anxious to see the current campus be repurposed.

Hightower said he supports the immediate return of Canton Elementary School upon the new campus’s completion. In 2018, that school was absorbed into the current Cherokee High campus to relieve overcrowding.

Once vacated, the old high school building also could potentially house additional preschool classes and assessment services, he explained. Additionally, the main campus could be the expanded home for CCSD school choice programs, such as the Cherokee College and Career Academy, as well as a possible second location for the evening high school program provided by Mountain Education Charter High School, a CCSD partner.

Caterpillar is t

performingho

proudly made performing ho 2 of % 20 ff

Market-leading parts availability f ONE-STOP

CONVENIENCE

or fast turnaround.

For Cat equipment, all mixed-fleet

EXPERT

SUPPORT

t machines and other industry appl

Our hose experts use the latest to

s last. See website for add ROS.COM/HOSE20 800-282-1562 Call: | ed herein, are trademarks of Caterpillar and may not ello K, their respective logos, “Caterpillar Corporate Y

QUALITY

PARTS and inspection standards to ensu

Cat hoses, couplings and assembl

fit, extreme durability and maximu

re long, dependable hose life. ols and up-to-the-minute routing, a

ies are rigorously tested to ensure

m safety

assembly E T GE TITHE TITRIG Offer valid thr LEARN M Tood Contact Us T Cat “Modern Hex” trad and All Right r. © 2023 Caterpillar

ications. ough 6/30/23 while supplie YAANCEYB AT ORE ATY YanceyBros.com Visit: | ay e dress as well as corporate and product identity us TERPILLAR, LET’S DO THE WORK , CA T, s Reserved. CAT

itional details. e used without permission. b w”, the “Power Edge”

It closed in 1991. The eastern half of the bridge was removed for a gigantic parking lot, which is why the bridge seems to lead to nowhere. It’s a marker of how the city once operated and how much has changed over the years. Plans for the remaining structure to serve as a retail slab with skyline views fell apart long ago, according to the Bridge Hunter database.

This truss bridge was originally used to help carry

Bankhead Avenue over the railroad tracks. This was in the heyday of trains when train traffic was bustling in and out of the city at all times. There needed to be another pedestrian route, which resulted in the bridge being built.

But when the automotive traffic on the bridge began to lessen in the 1950s, the train tracks underneath were rerouted to another nearby underpass.

(All photos courtesy of Atlanta Department of Transportation.)

of $1.8 billion in tax breaks and other incentives, shattering the previous state record. It was not immediately clear if any additional inducements were offered to Hyundai and LG to finalize plans for the battery plant, the Journal-Constitution noted.

Georgia leaders quickly praised the new plant as a showcase of the strength of the state’s evolving economy, though they differed sharply on what led the firms to pick Georgia.

Ossoff, a Democrat, said the landmark climate and healthcare law that President Joe Biden signed into law last year was key to securing the investment. The law includes billions in investment and production tax credits for EV and battery manufacturers.

“The IRA’s manufacturing incentives continue to bring jobs and investment to Georgia,” Ossoff said, referring to the Inflation Reduction Act. “My goal remains to make Georgia the world leader in advanced energy production.”

Kemp credited “the strong partnerships carefully built on the state level” with the two firms. He and other state officials said Hyundai and LG’s announcement offered

the final details of a project that was outlined before the federal tax measure was signed into law.

“This is exactly what we envisioned when Georgia landed the Hyundai Metaplant in May of [2022], and this project is the latest milestone in Georgia’s path to becoming the EV capital of the nation,” Kemp said.

Georgia officials have recruited a string of massive projects tied to the transition away from fossil fuels, including a major expansion of solar giant Hanwha Qcells, another Korean manufacturer. But they have differed over the impact of the federal tax and climate measure, which passed the U.S. Congress without Republican support.

Kemp recently told the JournalConstitution that he supported a repeal of the legislation, which he said should “never have passed to start with.” But he said that Biden should at least tweak regulations to allow Hyundai and other manufacturers with projects underway to benefit from the breaks.

That refers to a provision in the law that

would require all EVs to undergo final assembly in North America to qualify for a $7,500 customer tax break. Since Hyundai’s Georgia auto factory will not be operational until 2025, customers could lose out on the break until then.

In a recent interview with the JournalConstitution, Ossoff said both parties should rejoice over clean energy incentives that have made Georgia a magnet for the indus-

try. And he said Hyundai can take advantage of the breaks as soon as it begins production of the vehicles in the state.

“Georgia has benefited more than just about any other state in the country from these manufacturing incentives,” Ossoff explained. “We should be celebrating that rather than politicizing it, because Georgia’s economic development should be a team sport and not a political contest.”