Testing requirements for irrigation water are among recent changes to regulations around produce safety. Find details of two major regulatory updates on pages 8-9.

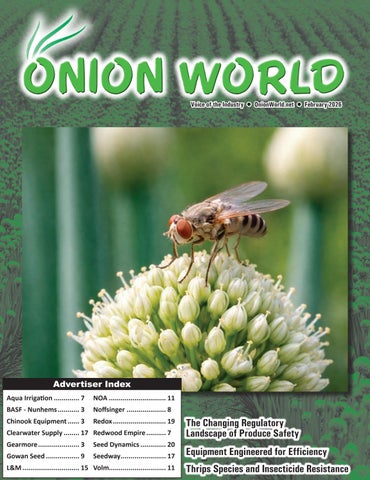

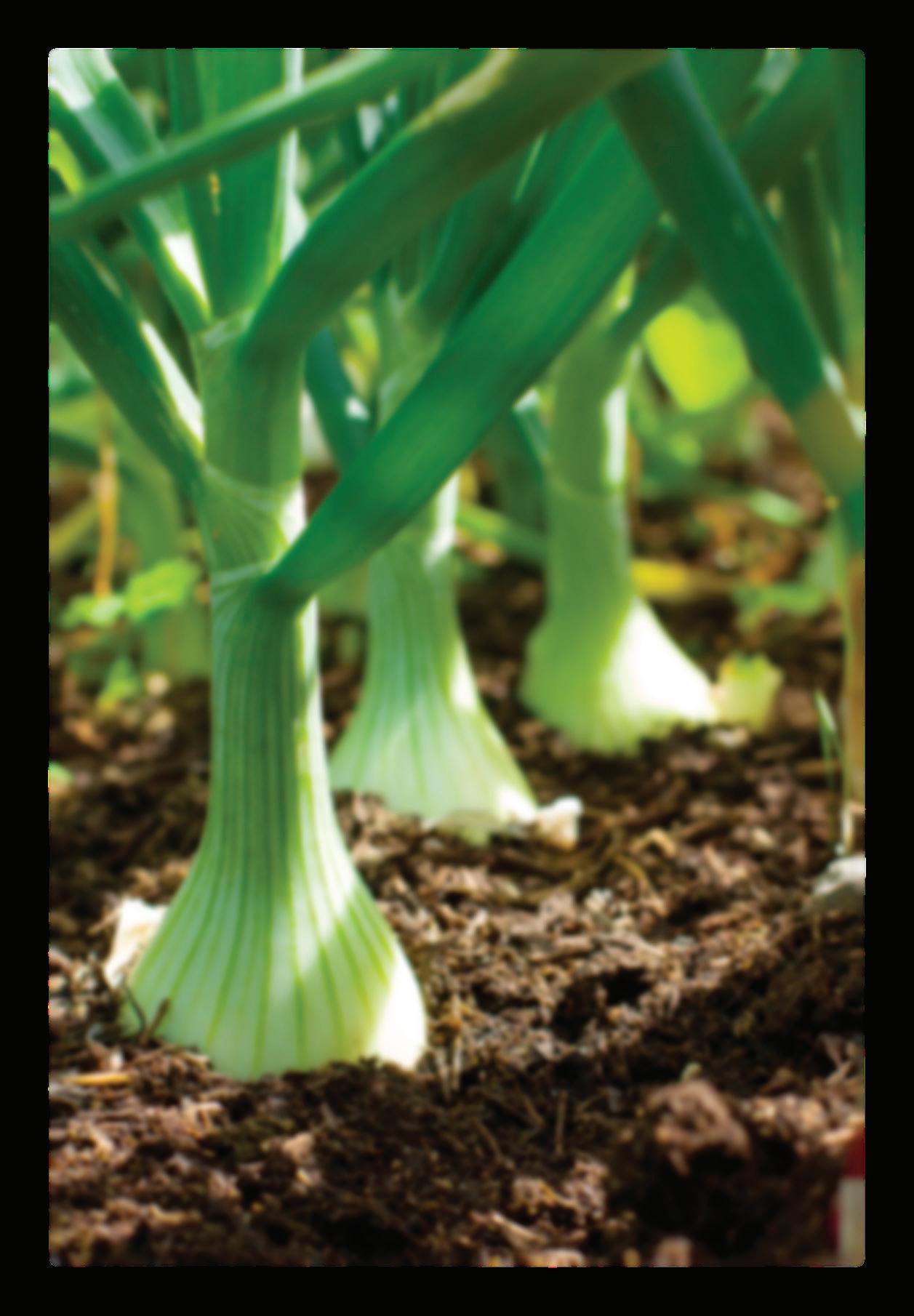

An Allium leaf miner alights on an onion bloom. For a look at products designed to protect crops from pests and diseases, check out our Crop Protection Essentials on pages 12-15.

PO Box 333 Roberts, Idaho 83444

Telephone: (208) 520-6461

Circulation: (503) 724-3581

OnionWorld.net

OniOn WOrld COntaCts

Editor Denise Keller editor@ColumbiaMediaGroup.com

Publisher / advertising Manager

Dave Alexander dave@ColumbiaMediaGroup.com

director of Operations

Brian Feist brian@ColumbiaMediaGroup.com

EditOrial inFOrMatiOn

Onion World is interested in newsworthy material related to onion production and marketing. Contributions from all segments of the industry are welcome. Submit news releases, new product submissions, stories and photos via email to: editor@ColumbiaMediaGroup.com.

adVErtisinG salEs

For information on rates, mechanics, deadlines, list rental, direct mail, inserts or other information, call (208) 520-6461 or email: dave@onionworld.net

sUBsCriPtiOns

U.S. $24 per year

Canada $40 per year

Foreign $80 per year

subscribe online at: www.OnionWorld.net/subscribe or call (503) 724-3581.

Email address changes/corrections to brian@ColumbiaMediaGroup.com or mail to:

Onion World PO Box 333 Roberts, ID 83444

Onion World magazine (ISSN 0892-578X), is published eight times a year and mailed under a standard rate mailing permit at Idaho Falls, Idaho and at additional mailing offices. Produced by Columbia Media Group PO Box 333, roberts, id, 83444. Copyright 2026. all rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, for any purpose without the express written permission of Columbia Media Group. For information on reprints call (208) 520-6461.

By Wouter Schoot Uiterkamp, SU-Tech

As onion production systems continue to evolve worldwide, SU-Tech, a Dutch manufacturer of onion harvesting and loading equipment, is staying true to its roots in the field while building a reputation for practical, field-proven engineering. Founded by growers, the company strives to design and build machinery that reflects an understanding of how onions are harvested, cleaned and handled in the field.

SU-Tech began in the Netherlands within an arable farming business, where the need arose for a practical and efficient onion machine. What began as a single on-farm solution developed into a dedicated engineering effort. The founders, drawing on their own experience operating and maintaining harvesting equipment, set out not to invent new technologies, but to combine proven ones into a new, more effective machine. This approach grounded in field experience and supported by Dutch

engineering precision laid the foundation for SU-Tech’s growth.

Over the years, SU-Tech has focused on developing machinery for lifting, cleaning and loading onions. Equipment is designed to move the crop from the field to storage in as few handling steps as possible.

Across the world, onion production follows different harvesting systems, each shaped by local climate conditions.

In Western Europe, where weather can change quickly and rainfall is frequent, onions are typically topped in the field during windrowing. This allows a shorter field period. This approach fits well within the maritime climate and helps reduce the risk of crop losses from wet conditions.

In regions with a continental climate, the harvest system is typically different. There, the onions are lifted without

removing the leaves, and the topping takes place later during loading. In some cases, growers only cut the roots. This way prevents damage loss and sunburn under intense sunlight.

SU-Tech’s product line is meant to accommodate both approaches. The same base machine can operate as a loader for windrowed onions or be equipped with a direct harvesting system and an integrated topper that removes the leaves during loading. This flexibility has made the equipment suitable for a wide range of conditions and harvest methods around the world.

The company’s design philosophy is rooted in practical engineering, creating machines that are meant to be easy to understand, straightforward to maintain and built for long service life. Each component serves a clear

function. From the conveyor layout to the hydraulic system, SU-Tech focuses on minimizing complexity while maintaining performance. Growers value the open construction, intuitive operation and durable build that withstands long harvest days and challenging soil conditions.

No two onion operations are the same, and SU-Tech designs its machines accordingly. Differences in field size, soil type, harvest method and logistical setup all influence what growers need from their equipment. The company builds each machine to match those specific conditions, from smaller models to high-capacity systems for large-scale contractors.

With loading capacities of up to approximately 150 tons per hour, SUTech machines can handle demanding operations while maintaining gentle product handling. Every configuration

is designed to balance throughput and care, ensuring that the onions reach storage in the best possible condition.

One of SU-Tech’s key developments has been the onion loader with topper, a machine that lifts, cleans and loads onions while removing the remaining leaves in a single, continuous process. In this system, onions are picked up from the field with their tops still attached. As they move through the machine, a fan and knife section work together to cut and remove the leaves before the onions are gently conveyed toward the trailer. The process produces a clean, uniform crop ready for storage or further handling.

Because the same machine can also be used for direct harvesting, it must fit seamlessly with the grower’s working width and row configuration. SU-Tech

therefore builds the topper loaders in various models and track widths to match different harvest systems. The design has proven reliable, effective and easy to maintain in a wide range of working conditions.

In addition to its standard lineup, SU-Tech also builds custom machinery to meet specific requirements from growers, contractors and research organizations. This includes specialized trial-field loaders for onion and potato breeding programs, as well as adapted machines for unique soil types, harvest methods or logistical setups.

Each custom project begins with close cooperation between SU-Tech engineers and the end user, ensuring that every technical decision serves a clear, practical purpose. This customerdriven approach continues to define the company’s reputation as a builder of straightforward, durable and productive equipment that helps growers move their crops efficiently and with care.

Feb. 26

2026 Commercial Vegetable Grower Meeting

USU Brigham City Campus Auditorium Brigham City, Utah Mike Pace, (435) 695-2541 or mike.pace@usu.edu

July 8-11

nov. 18-19

Pacific Northwest Vegetable Association Conference and Trade Show

Three Rivers Convention Center Kennewick, Wash.

Sheri Nolan, (509) 585-5460 or www.pnva.org

Editor’s note: To have your event listed, please email Denise Keller at editor@columbiamediagroup.com. Please send your information 90 days in advance

By Claire Murphy, Extension Specialist, Washington State University

The Food Safety Modernization Act (FSMA) was signed into law in 2011 and was the most significant update to U.S. food safety regulations in more than 70 years. Its core goal is to shift the nation’s food system from reacting to contamination to preventing it. FSMA created several major rules, including the Produce Safety Rule, Preventive Controls rules for human and animal food, and the Foreign Supplier Verification Program. Together, these rules require farms, processors, importers and distributors to identify hazards, put preventive measures in place, maintain better records and improve traceability so that contaminated food can be removed from the market more quickly.

The regulations surrounding produce safety are changing, with two major regulatory updates from the U.S. Food and Drug Administration shaping how farms grow, handle, and track fruits and vegetables: the revised Subpart E of the Produce Safety Rule focused on preharvest agricultural water and FSMA’s Traceability Rule (Section 204).

Subpart E is the part of the Produce Safety Rule that covers pre-harvest agricultural water - water used for irrigation, frost protection, crop spraying and any other activity that touches the edible portion of the crop before

harvest. The original version of Subpart E set microbial quality criteria (generic E. coli indicator levels) and testing schedules for agricultural water. Growers, scientists and regulators all found this approach too rigid and too difficult to implement, especially since water quality can vary widely due to weather, wildlife and regional conditions. The revised Subpart E (final rule published May 6, 2024) shifted away from mandatory routine water testing to requiring farms to complete a Pre-Harvest Agricultural Water Assessment. This assessment helps farms identify risks from (i) the source of the water (surface water, groundwater, etc.), (ii) how the water is applied, (iii) nearby land use that could introduce contamination, (iv) weather conditions, (v) crop characteristics, (vi) water distribution system infrastructure and (vii) history of water testing. This approach recognizes that risk depends on the whole system, not just on a single test result. If the farm identifies risks, it must take action to reduce risks. This type of systems approach recognizes that water safety is context-dependent and gives growers more flexibility to implement targeted mitigations.

FSMA 204, also known as the Traceability Rule, focuses on improving how certain foods are tracked through the supply chain. The rule applies to foods on the Food Traceability List (FTL), which includes products with a history of being involved in outbreaks, such as leafy greens, melons, tomatoes and fresh-cut vegetables. Under the rule, businesses must record specific Key Data Elements (KDEs) at Critical Tracking Events (CTEs) – points in the supply chain such as harvest, packing, receiving and shipping. Examples of KDEs include lot numbers,

product descriptions, harvest or packing dates, quantities, and the names of the businesses that sent or received the product. The purpose of these requirements is to make it possible to quickly locate and remove contaminated product during a foodborne illness investigation, reducing the number of people who might get sick and limiting unnecessary product loss.

It’s important to note that fresh onions are not currently on the FTL, so technically, onion growers are not covered by FSMA 204. However, many buyers are going to require all suppliers – regardless of whether they are on the FTL – to follow the traceability rule. This is because buyers want consistent records and the ability to track any fresh produce. For growers, this means keeping clear, organized records of lot numbers, harvest dates, packing dates and shipments – even if you don’t yet fall under the official regulation.

The original compliance date for the traceability rule requirements was Jan. 20, 2026. However, the FDA has proposed to extend the compliance date by 30 months to July 20, 2028. This gives the industry additional time to develop recordkeeping systems and coordinate with buyers. The extension also allows regulators sufficient time to provide guidance, clarify expectations and define enforcement procedures before full compliance is required.

Author’s note: Anyone needing guidance on compliance with either the revised Subpart E or the Traceability Rule can contact Claire Murphy, extension specialist at Washington State University’s School of Food Science (claire.murphy@wsu.edu).

This material is provided courtesy of Rui Liu, Associate Professor of Weed Science, Washington State University.

This weed emerges later in the summer, usually after onions have established (Photo 1). The seeds of this weed are contained in spiky burs (Photo 2). What is this weed? And what can be done to control it?

answers on page 19

Since 1962, beginning as a crop consultancy, Gowan Company has been rooted in agriculture, providing trusted expertise and innovative solutions for growers. This familyowned, American business works to understand growers’ challenges and is committed to delivering products and services that maximize yield and quality. Gowan provides solutions for the unique needs of onion producers.

Gowan’s dedicated sales representatives and development teams regularly work with onion growers and researchers to ensure that each product performs optimally in the field. The company’s fungicides include Gavel, Reason and Zing. The herbicide lineup includes Prefar 4-E, Sonalan HFP and Treflan HFP.

Fosphite from JH Biotech, Inc. is a potassium phosphite tool built for onion disease programs where oomycetes drive risk. After uptake, Fosphite moves within plant tissues and delivers two practical benefits: it suppresses oomycete development and supports the onion’s own defense response.

In the field, growers apply Fosphite ahead of infection pressure to help reduce the incidence and severity of oomycete-related diseases. Post-harvest, Fosphite fits into storage-protection programs to help limit oomyceteassociated decay and protect bulb quality and marketability. Since it combines systemic movement with a preventive role and a low resistance-risk profile, Fosphite works well as a dependable backbone product in an integrated program alongside good irrigation and sanitation.

Torac insecticide controls thrips in onions and other bulb vegetables (Crop Group 3-07). The active ingredient in Torac, tolfenpyrad, works by blocking cellular respiration and is effective on immature and adult stages of thrips. Because Torac causes rapid cessation of feeding in the pest, it also aids in reducing the transmission of Iris yellow spot virus (IYSV).

Torac belongs to the METI (Mitochondrial Electron Transport Inhibitor) class of compounds and is an IRAC Group 21A insecticide. Torac is an excellent rotational option to manage resistance in spray programs for onions. For effective resistance management, Torac should be used in rotation with insecticides of different modes of action.

Arino is a novel, liquid insecticide/nematicide powered by RinoTec Technology that can help crops get off to a strong start. This new technology controls nematodes and wireworms on root, tuber and bulb vegetables, such as onions, potatoes, sweet potatoes and carrots. Applied in-furrow at planting time, Arino is easy to work with and compatible with a wide range of fertilizers and crop protection products. This product offers an alternative that complements most integrated pest management (IPM) strategies, allowing growers to diversify and reduce their reliance on traditional pesticides, while managing resistance to conventional technologies.

Because RinoTec was recently awarded the U.S. Environmental Protection Agency’s (EPA) Green Chemistry Challenge Award for Design of Safer and Degradable Chemicals, this product can help users achieve sustainability certifications and goals. Minimal PPE requirements, a four-hour re-entry window after application and a zero-day pre-harvest interval application timing make Arino a safe and stress-free product to work with.

Combat thrips and protect crops with Rango, a triple-action bio-pesticide. Packed with over 150 bio-actives like azadirachtin, Rango targets thrips, worms, mites and diseases. With no known resistance, and with EPA registration and OMRI approval, this USA-formulated solution delivers disease, insect and mite control – all in one jug.

Rango offers multiple modes of action: insect growth regulation, anti-feedant, molting disruption and repellency. With a zero-day post-harvest interval and a four-hour re-entry interval, it’s an ideal tank-mix and rotation partner for resistance management.

When it comes to protecting an onion crop, growers don’t need every new product on the shelf. Instead, they can focus on those with a reputation of delivering consistently season after season.

Sectagon prepares the soil from the start, creating a cleaner, healthier environment for early crop growth. Linex provides dependable pre and post crop emergence weed protection, helping keep pressure down when it matters most. And when insects threaten yield potential, Lannate offers fast, flexible and effective in season protection.

Decades of proven effectiveness have allowed producers to gain confidence in these products.

Soil diseases like pink root, Rhizoctonia and Fusarium can severely damage an onion’s root system, reducing both size and yield. Chloropicrin, the active ingredient in Strike soil fumigant, effectively manages these diseases, helping to maximize the crop’s yield potential.

Vive Crop Protection delivers onion growers practical, high-performance solutions designed to support healthy stands, strong plant development and efficient applications.

AZteroid FC 3.3 provides targeted control of soil-borne diseases while promoting early vigor, stronger root development and improved stand uniformity during emergence.

AZterknot builds on that foundation with broad-spectrum disease protection and plant defense activation, helping onions withstand stress from environmental challenges while supporting nutrient uptake and photosynthetic efficiency.

Averland FC offers a cost-effective, low-use-rate option for managing inseason nematode pressure, protecting above-ground plant health at critical growth stages.

All three products mix easily with foliar nutritionals and other crop inputs, reducing compatibility concerns and simplifying tank mixes. Vive’s onion portfolio helps growers protect plant health, maximize efficiency, and support yield and quality potential throughout the season.

By Marcelo Dimase, University of Idaho

Thrips remain one of the most economically damaging insect pests of onion in the western United States, but growers face an increasingly complex challenge: the pest populations they manage may not all be the same species. For many years, onion thrips (Thrips tabaci) have been considered the primary threat in commercial onion fields in Idaho, Oregon and Washington. However, new observations suggest that western flower thrips (Frankliniella occidentalis) can also be present in meaningful numbers at certain times of the season. These species are difficult to distinguish in the field, yet they differ

in their biology and how they respond to insecticides. As growers report inconsistent performance of familiar products, the need to understand species composition has become essential for effective management and for preventing resistance from becoming more widespread.

The balance between onion thrips and western flower thrips is more than an academic question. It is directly related to how well insecticides perform. Onion thrips typically dominate early in the season, but the proportion of western flower thrips may increase as temperatures rise and spray intervals tighten. Because these two species vary in their susceptibility to commonly used insecticides, even a modest shift in their relative abundance can influence the success of a spray program. When a grower sprays a product expecting to target onion thrips but the field is dominated by western flower thrips, the outcome may appear to be resistance even when the issue is species composition. Without knowing which species are present, management becomes more uncertain and costly.

To address this challenge, Marcelo Dimase from the University of Idaho Parma Research and Extension Center is leading a multi-state effort including Washington, Oregon, Idaho, Utah and New Mexico to conduct a coordinated survey of thrips species composition in major onion-growing regions. Beginning in late spring 2026 and continuing through the summer, thrips will be collected weekly from onion fields in these regions. Each sample will be

processed so that adults and larvae can be identified using morphological keys. This effort will provide the first regionwide baseline of how thrips species composition changes over time and among farms with different insecticide programs. Early patterns are expected to indicate that onion thrips remain prevalent across most fields, but western flower thrips can appear later in the season and may be more abundant in certain locations. Understanding these patterns will allow growers to anticipate when species shifts are likely and adjust management accordingly.

Species identification alone is not enough. Growers also need to know how each species responds to the insecticides commonly used in onion production. To complement the regional surveys, Dimase and colleagues will conduct insecticide bioassays using thrips collected directly from growers’ fields and comparing them to long-term laboratory colonies with no history of insecticide exposure. These bioassays are performed using maximum labeled field rates of products such as abamectin, spinetoram, methomyl and lambdacyhalothrin. The goal is to detect early signs of reduced susceptibility and to determine whether onion thrips and western flower thrips differ in their responses. This is especially relevant as growers continue to report variability in the performance of key insecticides, particularly in areas with heavy spray pressure.

The combination of species composition data and insecticide susceptibility information provides

a much clearer picture of what is happening in growers’ fields. If a field is dominated by onion thrips but shows signs of declining susceptibility to a particular product, resistance is likely the cause. If western flower thrips dominate later in the season and a product performs poorly, the issue may be species-specific reduced susceptibility rather than true resistance. These distinctions matter because they help guide decisions about product selection, spray intervals and IRAC-group rotation. They also help prevent unnecessary applications that may further intensify resistance pressure.

Our team will share results from both the species composition surveys and the insecticide bioassays with growers through workshops and commodity meetings in the participating regions. These sessions will focus on how species composition shifted during the season, how thrips populations from different regions responded to commonly used insecticides and what these patterns mean for designing more effective rotation programs. These workshops will also encourage dialogue with growers, whose observations help refine recommendations and identify regions where additional monitoring may be needed.

By establishing a clear baseline of species composition and susceptibility, the research team is laying the foundation for predictive models, improved economic thresholds and decision support tools tailored to specific regions. Ultimately, the goal is to help growers maintain the effectiveness of the limited insecticides available for thrips control and to safeguard production against increasing pest pressure.

If you are interested in collaborating or receiving updates as results become available, contact Dimase at marcelod@uidaho.edu.

UNITED STATES

UNITED STATES

MEXICO

MEXICO

California (661) 699-0055

Lancaster & San Joaquin Valley (661) 978-5342

Irapuato

+52 (462) 220-0453

Torreón, Coahuila (461) 117-3878

Desert Southwest (928) 446-7737

California, New Mexico (661) 300-9109

Torreon

+52 (461) 117-3878

Colima, Col. (461) 104-0134

Colorado & New Mexico (970) 396-9728

Southern California, Arizona (760) 791-0325

Chihuahua

+52 (648) 109-1597

San Luis Potosi (461) 140-9452

Colorado (208) 550-7733

Idaho, East Oregon, Utah & Nevada (208) 941-1421

San Luis Potosi

Chihuahua (461) 171-9401

+52 (449) 196-1848

Idaho, Eastern Oregon, Utah, Nevada, North Dakota (208) 941-1421 (208) 550-7733

Skagit Valley, Washington (360) 941-7503

Rio Grande Valley & West Texas (956) 618-5574

Washington, Western Oregon (509) 820-9887

Texas (956) 618-5574

Tamaulipas

Tamaulipas (461) 134-2421

+52 (461) 346-1531

Irapuato, Gto. (461) 546-5792

Colima

+52 (461) 104-0134

By René Hardwick, National Onion Association Director of Public and Industry Relations

If you’ve ever driven past the wide-open fields of North Dakota, you might have glimpsed the roots of America’s next National Onion Association president. Barry Vculek, owner

of Four Star Ag in Oakes, North Dakota, takes the reins from Jared Gutierrez for the 2026-28 term, bringing a blend of hands-on farming experience and a passion for advocacy that runs as deep as the soil he tills.

Vculek’s connection to the land is generational. By seventh grade, he was

managing 500 acres – land he still farms today – and now oversees about 1,000 acres, specializing in onions since 2008. What started as a transition from potatoes has grown into a lifelong commitment to America’s favorite allium.

Active in the NOA for nearly 13 years, Vculek has served on the executive board and is a familiar face at the annual Washington, D.C., Fly-In.

“Food safety and international onion trade – both imports and exports – are some of the most pressing challenges facing our industry,” he says. “The NOA exists for the benefit of U.S. onion growers, and that focus needs to remain front and center. I plan to lean on my executive committee, utilizing their knowledge and experience to guide the association on these issues and more.”

Vculek also hopes to inspire onion growers across the country to get involved.

“The legislative work we’ve been doing over the past several years has made a real difference, but it’s only possible when growers engage with the association,” he says. “I want more of our growers to join NOA, lend their voices, and help shape policies that protect and advance our industry.”

Politics isn’t new to Vculek. Alongside running his farm, he maintains strong connections in North Dakota politics.

“From my experience in D.C., mostly through NOA trips, the bureaucracy moves slowly. But a call or letter from a senator or congressman can really move things along,” he notes.

With his wife, Robin, a daughter, Larissa Vculek, flying high as an airline pilot and another, Bree Vculek, shaping policy as a patent attorney in Washington, D.C., Vculek’s life balances family, farming and advocacy. As he steps into the NOA presidency, he brings a dedication to U.S. onion growers that promises a strong, forward-looking future for the industry.

Stronger roots mean stronger crops—and RootRx® delivers both. This advanced botanical extract formulation, powered by potassium and proprietary Redox Active Molecules, energizes root metabolism and activates beneficial soil biology to enhance water and nutrient uptake.

Our pure, microencapsulated calcium is high-quality, plant-available, and designed to move efficiently into your crop. Whether you’re focused on yield, quality, or long-term soil health, Mainstay® Calcium 2.0 is your foundation to season long performance and maximum return on every acre.

Puncturevine (Tribulus terrestris L.) is a summer annual broadleaf weed species. It is also called “goat head” or “caltrop.” It thrives in dry and hot growing conditions. It causes significant problems in agricultural production areas, home landscapes and gardens, as well as roadsides, railway yards and waste places.

Puncturevine usually emerges after onions are established. The weed grows close to the ground and forms dense mats at the base of onion plants. It competes with onions for growth resources, produces seed burs that stick to tractor tires and interferes with harvest operations.

Puncturevine produces yellow flowers with five petals, about half an inch wide. The seedpods of puncturevine turn gray and spiky when mature. The seeds are contained inside the spiky seed pods. The seeds remain viable in the soil for up to five years. A puncturevine plant may produce 200 to 5,000 seeds during a growing season. Usually, the seeds remain dormant in the first season and germinate in the next. The spiky seedpods often stick to shoes, tires and animal fur.

Reducing the soil seedbank of puncturevine can help control this weed long term. This can be achieved by removing the plants before they produce flowers or seeds, hoeing the plants to remove the taproot and regularly monitoring the infested areas. Herbicides that can provide control over puncturevine include products containing oryzalin, benefin or trifluralin for pre-emergence control and 2,4-D, dicamba and glyphosate for post-emergence control. Please refer to herbicide labels for use.

seed treatments provide early season disease and insect protection for young onion crops. Seed Dynamics applies the protectant to the seeds themselves, through a safe and controlled delivery. It works at the most critical time — during germination and seedling emergence — so your seeds can thrive, while fending o threats of early damage. Get a hero from Seed Dynamics , the Seed Preparation Professionals. Call us at 86 6.321.9747 or choose a dealer listed above. Visit our Website at SeedDynamics.com! When onion seed and seedcorn maggots threaten young crops, our heroes come prepared. FarMore FI500 and Spinosad/Lumiverd