Growing your business | Growing your industry

For more than 90 years CANEGROWERS has represented the interests of the sugarcane farmers of Queensland. Through times of challenge and opportunity, CANEGROWERS has helped family farms and the whole industry to grow and prosper.

CANEGROWERS is known and respected for its strong voice locally, nationally and internationally—the collective voice of many farmers has a powerful impact.

Editor: Robyn Devine

Advertising and Classifieds: Jane McGregor

Articles appearing in Australian Canegrower do not necessarily represent the policies or views of CANEGROWERS.

Published monthly by: CANEGROWERS, GPO Box 1032, Brisbane, Queensland 4001 Australia. ABN 94 089 992 969 Telephone: 07 3864 6444

Email: editor@canegrowers.com.au Website: www.canegrowers.com.au

Subscriptions

Yearly subscriptions for 12 hard copies (postage included)

• Within Australia: $190 inc GST

• Overseas (AUD): $290

12 Month Digital Subscription: $78 inc GST

Tully growers Roy and Mitchell Butcher are passionate about progression and growing cane

Photo credit: Renee Cluff Read more on page 24

CANEGROWERS is set to welcome more than 80 industry representatives from around the globe to Cairns for the World Association of Beet and Cane Growers (WABCG) Conference, taking place from 23 to 27 June.

As the host organisation, CANEGROWERS has taken the lead in coordinating the full program of events, offering attendees valuable opportunities for global collaboration and knowledge sharing.

A highlight of the week will be a fullday technical field trip on Thursday 26 June. Following two days of conference sessions, delegates will tour the Far North Queensland region to explore the diversity of Australian cane farming practices — many of which will be a first-time experience for international guests.

A fire broke out at the Marian Sugar Mill near Mackay, on Sunday 18 May, black smoke was seen rising from the top of the mill. The mill was evacuated around 3pm with all employees and contractors safely out of the premises when nine fire crews responded. The blaze was extinguished by 6pm. The cause is under investigation, but Mackay Sugar advised the fire would not impact on this year’s production.

The Australian Competition and Consumer Commission (ACCC) has unveiled a dedicated Small Business web page, delivering a one-stop resource designed to help start-ups, family-run operations and primary producers navigate their rights and obligations.

At its heart sits the Small Business Toolkit, offering clear, step-by-step guidance on key issues—such as unfair contract terms, a top ACCC enforcement priority.

Beyond the toolkit, visitors can learn how to report business-related disputes via the ACCC Infocentre, explore the Commission’s advocacy, education and enforcement initiatives, and access the latest news on regulatory developments.

A curated collection of industry Codes of Conduct and quick links to specialist ACCC resources ensure that whether you’re negotiating with suppliers or responding to customer complaints, support is just a click away.

Stay connected and empowered: bookmark the new Small Business page for updates tailored to your enterprise. For a deeper dive into how the ACCC champions small businesses, read “What We Can and Can’t Do for Small Business” on the ACCC site.

Learn more: accc.gov.au/business/ small-business

CANEGROWERS TRANSPORT AND WHS COMPLIANCE ROADSHOW CONCLUDES IN ROCKY POINT

On Tuesday 20 May, the final CANEGROWERS Transport and WHS Compliance Workshop was held at Woongoolba Public Hall in Rocky Point. Seventeen people attended, bringing the total number of participants across all ten workshops to over 250.

At the workshop, Mark Lalor from WHS Queensland emphasised the importance of informing farm visitors about potential hazards, ensuring that new employees receive proper training and keeping some form of written record documenting training and farm visitor inductions.

Representatives from the NHVR covered Chain of Responsibility, the Agricultural Notice and NHVR’s plans for the season. Here, the necessity of keeping vehicles wellmaintained was stressed with NHVR Safety and Compliance Officers likely to be out across the state during the crush.

Feedback from the roadshow was positive, with attendees reporting that the content was relevant to their businesses. Whilst this year’s roadshow has finished, CANEGROWERS remains committed to promoting safe practices in the industry and assisting growers with matters in this space.

Queensland’s 2025 sugarcane crush is officially underway, with harvesters firing up across the Tableland district on Thursday 22 May.

It marks the start of a new season that growers hope will bring better fortunes after a tough run last year.

Around 28.5 million tonnes of cane are expected to be cut and crushed across the 13 districts.

The crop is down slightly from last year, with recent widespread flooding across north Queensland causing major losses to plant cane, while prolonged cloudy weather also slowed growth in some districts.

Despite this, growers are hoping to turn the page on 2024, which was one of the most disrupted seasons in recent memory

Unseasonal rain, mill breakdowns and industrial action caused major delays that saw some districts harvesting into January – and around a million tonnes of cane left in the paddock.

“Growers are eternal optimists,” CANEGROWERS CEO Dan Galligan said. “They’ve done their part, growing the best crop they can under the conditions. Now we will be working together with the rest of the supply chain to make this season work.”

While last season’s industrial disputes have been resolved, the reality is, multiple difficult harvesting seasons have had a cumulative impact on the profitability of farmers, Mr Galligan said.

“In the brief break since the last harvesting season we’ve been in urgent talks with the sugar manufacturers, and while we’re seeing a real willingness to tackle the problems and get things back on track, there are no quick fixes, unfortunately.”

Workforce shortages are also creating challenges, skilled mill workers, harvester drivers and haulout crews are in short supply.

CANEGROWERS is working with local offices and the Queensland Farmers’ Federation to help address these issues.

“There’s huge potential in this industry,” Mr Galligan said. “But we won’t fully unlock it until we can consistently harvest the entire crop in most efficient and profitable time.”

With the first cane bins filling up, growers are crossing their fingers for dry weather, reliable mills, and a smooth run through the season.

A long-running push by CANEGROWERS for disaster funding reform has delivered another major win for Queensland cane farmers, with the State and Federal governments agreeing to broaden the definition of ‘primary producer’ under disaster assistance rules.

The change means farming families who rely on both on-farm and off-farm ag-related income – like harvesting or planting services – will no longer be locked out of disaster support. These growers will now be eligible for key assistance measures, including recovery grants, concessional loans, and freight subsidies.

Announcing the change at the 2025 FNQ Field Day in Mareeba on Thursday 29 May, Queensland Primary Industries Minister Tony Perrett said agriculture was “vital to every Australian,” adding: “When our producers suffer, we all do.”

CANEGROWERS CEO Dan Galligan joined local growers and ag industry leaders in Mareeba to welcome the news.

“This is a smart, sensible fix that brings disaster recovery support into line with how modern farms actually operate,” Mr Galligan said.

“We thank Minister Perrett for listening to growers and championing this reform, and we acknowledge the strong support from both the Queensland and Federal governments.”

The move follows sustained advocacy by CANEGROWERS , in partnership with the Queensland Farmers’ Federation, and comes after

widespread flooding devastated large swaths of North Queensland’s cane country earlier this year, especially around the Herbert River region.

“Many families rely on a mix of onfarm income and contracting work to stay viable – it’s never made sense to leave them out of disaster support,” Mr Galligan said.

The reform will be applied retrospectively to Queensland’s 2025 summer flooding events, meaning any farmers who were previously deemed ineligible under the Disaster Recovery Funding Arrangements (DRFA) should contact QRIDA on 1800 623 946 to find out what the amendments mean for them.

Over the past six months, CANEGROWERS has gone to bat for Queensland cane farmers, securing vital changes to disaster recovery rules:

DEC 2024

Extension of Grant Applications

The Queensland Government extended the deadline for disaster recovery grants after Cyclone Jasper – giving growers more time and certainty as they rebuilt.

FEB 2025

Replanting Costs

Now Covered

A joint State and Federal decision to include replanting costs in grant eligibility was a critical win for floodaffected farms.

MAR 2025

Grants Increased to $75,000

The maximum support available to primary producers was lifted – a vital boost for growers recovering from widespread flood damage.

MAY 2025

Broader Definition of ‘Primary Producer’ Farming families earning both on-farm and off-farm ag-related income – like harvesting or planting contracting – are now eligible for support.

“This is about making sure no grower falls through the cracks”

The reform adds to a growing list of tangible wins for cane growers in recent months.

Earlier this year, CANEGROWERS successfully secured the inclusion of replanting costs in disaster recovery grants – another first for the industry. The organisation also worked with government to deliver targeted relief for recent events, including extended application deadlines for Cyclone Jasper support and an increased

funding cap of $75,000 for growers hardest hit by the summer floods.

“These are meaningful, realworld outcomes that show what industry advocacy can achieve,” Mr Galligan said.

“We’ll continue working to ensure disaster support keeps pace with the way growers run their businesses, because when growers are backed, the whole community benefits.”

Soil health starts here. At Aztec Dynamics, we support smarter farming with organic fertilisers and drone services that build soil health and cut chemical use. Using trusted brands like Alltech and NTS, we deliver microbial and mineral nutrition to boost soil life and crop performance.

Our drones handle spraying, spreading and mapping - without compacting your soil - and we back it all with expert testing and agronomy support.

Why it matters:

Ÿ Stronger, more active soils

Ÿ Lower input costs

Ÿ Organic - certified solutions. Better soil. Better farming.

Queensland’s sugarcane growers have backed Owen Menkens to lead the industry through a pivotal period, reelecting the Burdekin grower for another three-year term as Chair of CANEGROWERS Queensland.

Mr Menkens was returned to the role by the grower-only Policy Council, which also elected Innisfail grower Joe Marano as Senior Vice Chair and Herbert River’s Steven Marbelli –a newcomer to the state board –as Vice Chair.

“This is a grassroots organisation, run by growers for growers,” Mr Menkens said. “To be re-elected by my peers is an incredible honour. It shows the trust we’ve built and reflects the important work we still have to do.”

The appointments cap off CANEGROWERS ’ triennial election process, which began in February when growers nominated for their local district boards. Each district board then nominated a representative to the Policy Council – one from each

mill area. The newly formed Council met in Brisbane at the end of May for its first meeting, where it elected the state board.

This bottom-up structure ensures the organisation remains fully accountable and representative, from paddock to policy, with every leadership role held by a grower elected by fellow growers.

Also elected to the state board were returning members Joseph Borg, Kevin Borg, and Michelle Fischer, alongside three new faces – Glenn Betteridge, Claude Santucci, and Steven Marbelli.

“The strength of this board lies in its mix of continuity and renewal,”

Mr Menkens said. “With experienced leaders like Joe Marano and Kevin Borg alongside committed new board members like Glenn, Claude and Steven, we’ve got the right team to move the industry forward.”

The Policy Council will now establish a series of industry committees to lead focused work on key priorities including mill performance, supply chain efficiency, sustainability, diversification, and grower profitability.

The board also welcomes new Policy Council members (pictured top left) Leah Russo (Herbert River), Charles Papale (Burdekin), Brett Leach (Mackay), and Peter McLennan (Isis) joining a number of returning councillors.

“We’ve significant challenges ahead, but just as many real opportunities. This grower-elected leadership team is well positioned to shape a strong, sustainable future for Queensland’s cane industry,” Mr Menkens said.

BY DAN GALLIGAN, CEO, CANEGROWERS

Natural disasters are a perennial drag on the success of our industry.

Here in Queensland, we’re particularly vulnerable to the volatile wet season, which can bring tropical cyclones, floods and monsoon lows – often right alongside droughts and bushfires.

A look through the history of our industry shows how successive natural disasters have steadily undermined both the quantity and quality of cane crops across the state.

For an industry like ours, that are so heavily reliant on consistent cane supply to keep mills running and income flowing into businesses and communities, the cumulative impact is devastating.

But the effect of natural disasters can’t be fully understood at just the macro scale. The impacts are far more profound at the individual family farm level.

Disasters hit the hip pocket hard, and the financial pain can last many months, even years, after the event.

The science tells us that the frequency and severity of these events is only going to increase.

So, we need policy that keeps pace, both with the scale and nature of these disasters, and with the needs of our modern industry.

As I outlined in this magazine a few months ago, it was with this dynamic in mind that CANEGROWERS joined with the Queensland Farmers’ Federation, QFVG and Cotton Australia to put forward a set of urgent policy reforms aimed at improving natural disaster recovery arrangements.

This week, the LNP State Government and the new Federal Government ticked off another reform on that list.

In addition to the expanded eligibility for disaster grants to fund crop replanting, the move to broaden the definition of a ‘primary producer’ is a profoundly important step forward.

I’ve seen first-hand the impact of restrictive guidelines on our industry.

Watching QRIDA staff in Ingham explain the rules to more than 100 growers earlier this year — many of whom were clearly eligible in practice but excluded on paper — was a powerful reminder of how broken the system was.

Despite being bona fide farmers, impacted by the disaster and clearly in need of assistance, they were turned away.

That should no longer be the case.

Thanks to this reform, many cane growers who are growing their businesses or entering the industry – particularly as harvesting contractors – will now be eligible for the support they need to get back on their feet.

We know so many of these farmers are saving to buy land, expanding their operations, and investing in the future.

And that’s exactly what our industry needs – not just recovery, but confidence to invest and grow.

That’s why this policy change matters. And that’s why the swift action by the LNP State Government and the Federal Labor Government deserves to be recognised and commended.

Brazil

India

Thailand

Speculators

Currency

Your Trusted Partner

Current as at 20 May 2025.

By Elliott Apel, QSL Assistant Manager Trading & Risk

A significant downpour in late April brought much-needed rain to Centre South Brazil after three consecutive months of below-average conditions. However, the wet weather also restricted early-season harvesting. According to the latest UNICA data, 34.3 million tonnes of cane had been harvested and 1.6 million tonnes of sugar produced by the end of April, with an average sugar mix of 45.3% − all significantly lower than last year’s figures.

Harvesting in India is virtually complete, with only four mills still operating into late April. Final production is on track to meet expectations of around 26 million tonnes of sugar. Attention will now gradually shift to the upcoming June-September monsoon season.

Early monsoon rains in Thailand have had a positive impact on the crop, prompting some forecasters to revise their outlook and increase the 2025/26 Season production forecast by 1.2-1.8 million tonnes of sugar.

Speculators continued to favour a net short position throughout April and into May. The Commitment of Traders report dated 13 May 2025 showed speculators holding a net short position of 45,615 lots.

The Australian dollar rallied strongly following the surprise announcement of widespread tariffs by US President Donald Trump. However, sentiment has since shifted after the US and China agreed to a temporary 90-day reduction of additional tariffs to allow for further trade negotiations. Markets now anticipate a short-term easing of tensions, although concerns remain about the longer-term outlook for US-China trade relations and potential disruptions to global import flows.

Neutral

Neutral

Neutral

The outlook ratings above are in relation to AUD/tonne sugar prices. A bullish outlook is considered positive. A bearish outlook is considered negative.

The highest grower-managed pricing levels achieved across all growing regions using QSL products to date (all gross price actual/tonne) are:

• 2025 Target Price = $735 / IFC $735 (Oct25)

• 2026 Target Price = $685 / IFC $690 (Jul26)

• 2027 Target Price = $650 / IFC $610 (Jul27)

• 2028 Target Price = $605

• 20 June 2025: Any 2025-Season Target Price Contract tonnage not priced by this date will automatically have its pricing window extended and roll costs may apply.

• 20 June 2025: Any unpriced tonnage allocated to the ICE 11 July 2025 contract through the Individual Futures Contract and/or Self-Managed Harvest Contract that is not rolled by this date will be priced by QSL at the next market opportunity.

As harvesters fire up across Queensland, CANEGROWERS is doubling down on what matters most – representing growers, driving results, and building a stronger future for our industry.

The CANEGROWERS Queensland levy for the 2025 Season has been set at 22.23 cents per tonne (ex GST) on all cane delivered to mills by members, capped at 100,000 tonnes.

This represents an increase on last year once again capped at CPI – a commitment to keeping downward pressure on the lever while maintaining strong advocacy and service delivery.

And the value is clear.

From securing better disaster relief and pushing for mill accountability, to investing in the next generation of cane farmers, CANEGROWERS is delivering real outcomes in every corner of the industry.

“Growers are being squeezed from every direction – costs, labour, weather, and mill performance,” Chairman Owen Menkens said.

“That’s why we’ve stepped up our efforts and fought hard for wins that make a difference on the ground.”

Among the key outcomes delivered in the past 12 months:

Conducting in-depth analysis of mill performance issues to help inform how to address season length

Disaster grants tripled, from $25,000 to $75,000

Delivering policy change to allow disaster recovery grants to cover the cost of replanting crops

Application windows extended, giving growers breathing room after a crisis

National biofuels feedstock strategy advocacy – pushing sugarcane into the clean energy future

NHVR freeboard approval, removing the burden of covering every road-transported load

Practical guides on WHS and load restraint – cutting red tape with clear, grower-friendly info.

“Advocacy is what we do best,” Mr Menkens said. “We make sure cane growers are heard in every room where

decisions are made – in councils, state parliaments, federal departments and even global forums.”

But it’s not just about government. With last season’s crushing delays leaving a million tonnes of cane uncut in the paddock, CANEGROWERS has been working closely with millers to ensure better planning, clearer commitments, and a harvest that runs on time.

“Too much cane was left behind last year,” Mr Menkens said. “We’re holding conversations that need to be had to ensure this season delivers for growers.”

Meanwhile, free crop insurance will again be included in 2025 membership –covering up to 100,000 tonnes* of cane for fire, hail and transport-related damage, at $35/tonne indemnity with a 50-tonne excess.

That’s not just peace of mind. That’s real protection when nature doesn’t play fair.

Looking to the future, CANEGROWERS is investing in people and knowledge to ensure a thriving, sustainable industry.

That includes:

The Next Ratoon mentoring program, connecting experienced growers with the next generation

Young grower tours to grow skills and networks

Curriculum-linked education in schools to share the sugarcane story with future generations

Practical workshops on WHS, transport, and compliance, delivered free in growing regions

Business resilience training, helping growers manage risk and strengthen operations

And the industry is coming together.

Events like Sugar Cubed 2025 –Australia’s only large-scale sugarcane event designed by growers, for

growers – are putting innovation, connection and opportunity in the spotlight.

Next month, CANEGROWERS will host the World Association of Beet and Cane Growers (WABCG) conference in Cairns, putting Queensland growers on the world stage.

Even at the Ekka, the cane industry has a strong voice – proudly telling our story to close to 10,000 visitors to the CANEGROWERS display last year.

From the paddock to parliament, the classroom to the boardroom, CANEGROWERS is working every day to protect, promote and grow this industry.

And it all starts with growers, standing together.

*Crop insurance will be charged on all tonnes over 100,000 delivered to the mill

BY OWEN MENKENS, Chair, CANEGROWERS

It’s been a busy time across the CANEGROWERS network lately, with elections held right across our cane-growing districts to decide who’ll represent local growers on their district boards.

Those new boards officially kicked off their three-year term on 1 May, and one of their first jobs was to nominate someone to sit on the CANEGROWERS Policy Council – the group that helps guide where we’re headed as an organisation.

That Council met on 26 May, and I was genuinely honoured to be elected Chair of CANEGROWERS Queensland for another three years.

It’s a big responsibility, and one I take seriously. Leading an organisation that’s been around for almost 100 years –built and run by growers – is a real privilege.

With that centenary just around the corner, it’s a good time to reflect on one of the things that makes this organisation so special – our deep roots.

This is a truly democratic organisation – one that’s shaped entirely by the people it represents.

That strength – growers standing together and speaking with one voice – has carried us through all kinds of ups and downs. And we need that unity now more than ever.

There’s a lot on our plate. Rising costs, mill issues, the STL insourcing mess, more red tape than ever, and a pretty unpredictable global sugar market.

None of it’s easy – but when we stay united and focused, we can keep pushing for the best outcomes for growers and our industry.

At the Council meeting, Joseph Marano from Innisfail was elected Senior Vice Chair, and Steven Marbelli from Herbert River – who’s new to the board – stepped into the Vice Chair role.

They’re joined by Michelle Fischer (Rocky Point), Joseph Borg (Mackay), Glenn Betteridge (Burdekin), Kevin Borg

(Plane Creek), and another newcomer, Claude Santucci from Tablelands.

Together, we make up the board that oversees CANEGROWERS Queensland’s governance and financial direction.

But it’s the Policy Council where the most important work happens. That’s where we set priorities and give direction to the exec team and staff.

Everyone around the table is a grower – a leader in their own district who has been elected by their peers.

That means the decisions being made come with real experience and accountability – and usually a good bit of healthy debate, too.

The Council also splits into four committees, which gives members the chance to really dig into the topics they know best – whether it’s trade, the environment, research or regulations. There’s always someone in the room who’s lived what we’re talking about.

That’s the power of CANEGROWERS – growers using their local experience to drive big-picture decisions for the whole industry.

It’s a model that’s worked for nearly a century, and I reckon it’s never been more important than it is now.

Thanks for the continued trust. I’m looking forward to working hard for growers across Queensland over the next three years.

If there’s anything you want to raise – or even just have a yarn – don’t hesitate to reach out.

And here’s hoping for a safe, smooth and profitable harvest this season.

13 June 2025

Now in its eighth year, Big Dry Friday has raised over $8 million to support rural and regional communities, delivering help where it’s needed most.

Find out more or donate

In light of the recent flood events impacting many cane-growing regions, the Morgans Foundation has donated to GIVIT NQ and the local SES NQ to further support those in need.

BY RENEE CLUFF

A value-adding venture to turn the tops and trash of sugarcane into renewable energy feedstock is gaining momentum.

Sugarcane

(Courtesy: Burdekin Renewable Fuels)

Burning sugarcane prior to harvest could soon become a practice of the past in the Burdekin, as support grows for a project to turn unused biomass into energy.

SKY Renewables, in collaboration with grower-led Burdekin Renewable Fuels (BRF), is spearheading a project to harvest the whole crop green and use the tops and trash as feedstock to produce renewable energy for the Asian market.

Founder and CEO of SKY Renewables, Simon Yim, said he began the background work on the initiative in 2017 when a visit to the Burdekin coincided with a growing demand for biomass in Asia.

“At the time, the Japanese were really crying out for an alternative to nuclear after the Fukushima meltdown in 2011 and they really wanted to be able to go to baseload renewable energy and using biomass pellets is one of the methods they prefer,” Mr Yim explained. “So, on one hand you have a situation where you are wasting the resources and on the other, a place which is crying out to get them at a high price. The most interesting thing was that nobody was doing it.

“The fact that they are burning the cane today means that if we can put the tops and trash to an alternative use without burning it, we are probably saving 3-million tonnes of carbon

dioxide emissions right off the gate. If the growers are burning it, it’s of zero value and what we are offering is around US$10 per green tonne of trash, so all of a sudden you can turn something you have burnt which is of zero value into a revenue stream.

“We are not here to change the sugarcane ecosystem; we are just adding value by utilising a valuable pool of waste where it is needed”

“Growers can still supply the cane to the mills; they can still earn whatever they’re earning in terms of sugar production. But instead of burning the field before harvest, what we’re advocating is that we harvest the whole crop. That would involve more bins, more runs to the mills but it’s all doable and at SKY Renewable’s cost.

“The other major reason for coming to the Burdekin is that it’s the most productive cane area in all of Queensland and the fact that it’s 100% irrigated means the production is stable and we need stable production to make sure the feedstock is there year in, year out.”

SKY Renewables has hired a Brazilian company to undertake a detailed feasibility study on changing harvesting and transporting practices. Mr Yim’s plan is to build a separation plant where the tops and trash would be separated from the billets using high-powered fans.

“We’ll send the billets to the mill by conveyer belt and build a pelleting plant or briquetting plant next door

As a lawyer for the first ten years of his career, Simon Yim worked in-house for the Bank of TokyoMitsubishi UFJ and China Light & Power in Hong Kong.

His second career decade saw him specialise in corporate mergers and acquisitions (M&As). He led M&As for GE’s industrial businesses across the Asia-Pacific, covering energy, oil and gas, aviation, healthcare, transportation, water technologies and general industrial.

Simon also worked for major US power business Southern Company as Business

where we can use the tops and trash to make pellets or briquettes,” he said.

“We have trialled the Burdekin tops and trash on an industrial scale with the most prominent pelleting equipment manufacturer in Europe. Briquettes are a similar process but it’s more of a loose structure compared with pellets and it’s much less expensive.”

SKY Renewables is in talks with the two largest power generation companies in Singapore where there is high demand for biomass pellets to

Development Director and China Regional Director. As Partner of the private equity firm The Longreach Group, he played a key role in the turnaround of EnTie Commercial Bank in Taiwan.

Prior to focusing on SKY Renewables, Simon was working in private equity for two firms including the British Lloyds Banking Group, based in Hong Kong. He advises Solaris Fund in Japan and US-based insurance brokerage firm Lockton Companies and has held board positions with Huadian Power International and the Shajiao C Power Plant JV in China.

replace the burning of coal, as well as biomethane gas made from briquettes through gasification and methanation.

“For Project Lion, we’re talking to power companies in Singapore that use LNG,” Mr Yim said. “LNG is hard to decarbonise and the only way recognised by the Singapore Government is to blend it with biomethane So, it would be used as a clean feedstock to generate renewable electricity through a combined cycle gas turbine (CCGT).

“The only competing feedstock of biomethane in Asia is residual from palm oil, which is controversial, and the supply is very fragmented. 95% of what’s being produced is going to Japan, so when you think about alternatives for Singapore or Japan, there really is nothing there.

“For project Flame we’re talking about pellets because another potential customer in Singapore only runs a coal-fired power plant and because of the carbon tax Singapore is introducing – it’s the highest in Asia –they are facing a very steep fine if they continue burning coal.

“But if they were to turn to biomass by burning pellets, not only do they avoid the carbon tax, they can actually generate carbon offsets which they can sell to the EU for example.”

The Burdekin only has enough biomass to supply one of these projects, and that’s in conjunction with adding fibre from a cover crop. “We are not just thinking about tops and trash, we are thinking about creating a unified fallow crop,” Mr Yim said. “We’re leaning on sunn hemp and we can use the whole crop as fibre for making pellets or briquettes.

“With the two combined, there would be enough to supply more than a million tonnes of pellets, which is exactly what our potential Singapore customer wants. Or, enough biomethane to support a 240MW CCGT to use biomethane exclusively and be generating 90% of the time.”

SKY Renewables is aiming for 100% supply uptake from Burdekin growers and is asking for 36 months of supply exclusivity. It’s also requesting them to set aside 20 cents per tonne to be deposited into an escrow account. “We cannot touch that money,” Mr Yim said. “All we are asking for is for growers to put skin in the game. At the end of 36 months, or before that if the project materialises, we turn that pool of money into equity. If it doesn’t happen, we’re going to return the money with interest.”

In return, SKY Renewables is committed to paying AUD$15/tonne for green trash and is also offering an option for growers to turn those proceeds into equity in the company, with a total 20% stake of the company set aside for growers. “My objective is to have our long-term interests aligned so we move forward together as one voice,” Mr Yim said.

Burdekin Renewable Fuels Chair and CANEGROWERS Burdekin Director, Greg Rossato, said supporting the proposal is a no-brainer.

“Simon Yim’s business experience in Asia is second to none, he has a large specialist team of highly qualified people, and he can reach into those massive Asian companies and get deals done,” Greg said. “He knows that end, we know our end so were melding together and it’s coming together right.

“We fully understand that harvester modifications will be done but Simon’s offering a net payment – growers don’t have to pay any increase in harvesting costs or logistics costs and the grower simply gets paid. Where else are we going to get a deal where we’re not paying for any of these changes or feasibility studies and then get a 20% equity if the project comes to fruition?

“He believes in it that much he is willing to risk a lot of money. I don’t know how much more you can de-risk a project for your growers.

“You’ve got to have farmers onboard so he’s doing it the right way. All we need to do is be supportive. We’re here to help in any way. BRF is doing that until we know either way whether it’s a goer or not.”

More than 100 Burdekin growers attended a town hall meeting held in early May to discuss the proposal. Over 60% signed up to the deal within the following 48 hours. Further meetings have since been held throughout the month of May.

As we move towards the processing of the sugarcane, it is worth noting that large sections of the Queensland sugar industry have endured through what has been one of the most intense wet seasons in recent memory. Our industry has more than 150 years of history and there is no doubt that the incidence and severity of natural disasters are increasing, with the impacts of the recent North Queensland floods through the Herbert, Burdekin and Tully regions. Growers, sugar manufacturers and governments must heed the experience of recent floods, and recalibrate our response to it, to secure the sugar industry’s future for another 150 years.

The flood damage in some regions, like the Herbert, has been severe. Tens of millions of dollars’ worth of cane has been lost across Queensland, particularly in and around Ingham. Widespread damage has been caused to our factories and our cane rail infrastructure. Many sections of rail track have been washed out and rail signals, bridges and rail level crossings need to be cleared and repaired.

The sugar manufacturing sector has been doing a remarkable job, with very little outside help, to ensure factory operations and the supporting rail freight infrastructure is up and running in time to begin manufacturing sugar in late May or early June. Large amounts of time that had been set aside for maintenance have been lost, and the progress of maintenance and repairs have been further slowed due to flooded and damaged roads creating supply chain disruptions for essential materials and equipment.

It is a race against time to be ready for the start of the season. Our sector is no stranger to challenges of this nature, and we aim to be up and running to ensure that money is put into the pockets of all locals who rely on sugar for their livelihoods.

ASH SALARDINI CHIEF EXECUTIVE OFFICER AUSTRALIAN SUGAR MANUFACTURERS

The 2025 season will be a challenging one, and there will be a need for participants in all sectors of our industry to have patience and understanding –this has not been a business-as-usual preparation for the production season for many manufacturers, and there will be hiccups and some things that will not go to plan. Understanding and collaboration across our industry will give us the best possible chance to keep the crush on track.

Queensland and Federal governments have done a first-class job responding to the floods and in working towards recovery, however, there have been blind spots in their response. One area that needs to be rectified is the Queensland Reconstruction Authority’s inability to fund disaster recovery efforts as it relates to the industry’s cane rail network.

Queensland’s cane rail networks carry around 30 million tonnes of harvested sugarcane from farms to factories each year. This represents a significant public good for Queensland because without this freight corridor, the harvested cane would need to be moved to factories by road. Moving the second largest freight task in Queensland, or parts of it, on the public road networks each year would create enormous congestion for many regional communities and a road maintenance bill beyond the scope of current state and local government road maintenance budgets.

Noting the cross-jurisdictional responsibility for recovery, the Queensland and Federal governments must make sure that appropriate changes to policy and legislation are made now to ensure that if and when the next natural disaster impacts on this critical infrastructure network, agencies are empowered to work with our industry to get it back up and running. The collective response to natural disasters will be one of the defining issues for the future of the sugar industry and the communities that rely on it.

BY RENEE CLUFF

The town of Tully has celebrated 100 years since its mill’s first crushing season.

There wouldn’t be a town without Tully Sugar mill, a fact acknowledged during the month of May as residents and sugar industry representatives came together to reflect on a century of mill history.

“The town was built specifically because the sugar mill was going to be placed here in the Tully area,” explained Rob Magarey, Chair of the Tully Mill Centenary Steering Committee.

“The town was first gazetted in 1924 and that was principally to provide staff and service people for the sugar mill which was then completed in 1925. So, Tully wouldn’t have been here unless it was for the sugar mill.

“It must have been a hive of activity to clear land, to clear blocks in the town for buildings and it very quickly was erected, and things went ahead.

“Pioneering families, particularly the Henry family, opened up the area, had permanent farms here and then others came along.”

Dr Magarey said it was an interesting journey to take a trip through the mill’s past.

“What’s come to the fore is that the basic processes of growing cane and milling haven’t really changed but changes have come from the technology that really has swept through the industry,” he said.

“For instance, the basics of how cane is crushed remains the same but, in the beginning, there was no monitoring or process control whereas now it’s heavily controlled through NIR and a range of other technologies to refine the system and maximise efficiency.”

Today, the COFCO-owned mill employs 250 permanent workers, with another 80 hired during the harvesting season. It remains the main employer in Tully, which according to the most recent census figures, has a population of around 2,400.

It seems pretty much everyone in town attended a range of events across ten days to mark the mill’s milestone.

More than 500 people attended the gala dinner, 200-plus were at a morning tea function, and an estimated 1,000 people took a tour around the mill onboard the Homebush locomotive, which had been loaned from Wilmar Sugar in the Herbert River district. Other events included cemetery tours to pay homage to sugar industry pioneers, an art display, pop-up historical display and a family fun day complete with a car and motorbike show and children’s activities such as jumping castles.

A commemorative book and a mural on the wall of the local supermarket were also created to mark the occasion.

The future of milling and farming was also a feature, through the Tully Sugar Centenary SRA Industry Field Day.

“It’s really been a community event, and a lot of hard-working committee members have all collaborated really well over the past two-and-a-half to three years to bring it to life,” said Dr Magarey. “Different parts of the industry have really come together and really made it a great celebration.”

The festivities followed the 100th birthday celebrations for the town last year.

Tully Sugar mill in 1925, courtesy Queensland State Library

From top to bottom:

A large mural was commissioned as part of the centenary celebration

The event included rides on the Homebush locomotive, which was borrowed from the Herbert River district *Terms and conditions apply It pays to plan ahead with Pursehouse Rural 5.0% Reward on your prepayment made before June 27th* Take advantage of Pursehouse Rural Prepayment Rewards

pursehouserural.com.au

However, it was not until he trialled Shield Systemic Insecticide from Sumitomo Chemical Australia two years ago, that he finally started winning the battle.

Far North Queensland canegrower Carlo Di Salvo has battled damage from canegrubs – the most significant pest in sugarcane –since he began growing the commodity in 1998 when the Tableland Sugar Mill began operating nearby.

Mr Di Salvo, whose father Sid started the business, now operates with his wife Chrissie, son Sebastian and daughter Livinia as C&C Di Salvo, growing sugarcane and citrus over 141 hectares at Arriga on the Atherton Tableland, 17kms west of Mareeba.

Facing the pressure of crop loss from canegrub damage, he was encouraged by an agronomist from Combined Rural

Traders (CRT) Mareeba to trial Shield (with its active ingredient, clothianidin) alongside a traditionally used product (imidacloprid) which is currently being phased out.

Two seven-hectare blocks of young cane were treated equally in late 2023. Within a few months, it was clear that Shield was the better performer.

“On the Shield block the cane stood up better to canegrubs, it was healthier, more vigorous and there were not as many gaps as the other block. Cane from the Shield block also cut better and had a

better weight which resulted in a better return. Cane on the other block fell over because the stools were attacked, it had lots of gaps, and the plants were not as strong. It turned out so badly, I ended up ploughing it out while the Shield block still looks good,” Mr Di Salvo said.

“I’ve seen some really bad damage from canegrubs over the years, especially in the blocks closer to the riverways where they seem to nest near the big trees. You can lose up to 80 per cent of the crop and it doesn’t return. No-one can afford to farm with an 80 per cent crop loss.”

Canegrubs which attack and eat sugarcane roots significantly impact on the crop’s ability to take up nutrients and water, therefore, reducing yield and profit. Beetles lay eggs in the soil during summer with the larvae hatching into grubs which eat roots off around late summer-early autumn.

“Damage would usually occur just after the wet season, but because it was in the root system, you couldn’t see it

until the plants fell over and by then it would be too late,” Mr Di Salvo said. Shield is now part of the program at C&C Di Salvo where it’s used once a year when the cane starts shooting back after harvest.

“To see healthier and heavier cane which gives you a better return is a reassurance. Shield is more expensive but, as I see it, it pays off in the long run.

“The result of extra weight and sugar per hectare covers that cost and you can return the crop, probably for about five years.

“It’s an option that shows good results and hopefully helps us fight canegrubs for a good while because there doesn’t look like any new chemicals are being released anytime soon for the control of canegrubs.”

The Di Salvos were among seven Queensland growers who took part in the trial comparing Shield to the traditional product, all achieving similar results.

Sumitomo Chemical Australia business development manager Jock Leys said a re-examination of Shield’s efficacy in sugarcane in recent years found it performed significantly better than the traditional product which came from same class of chemistry.

The price had been reduced by about 40 per cent to make it more viable for CANEGROWERS , he said.

BY RENEE CLUFF

Whether it’s managing a large corporate sugarcane enterprise or running the family farm, Tully District’s Roy Butcher is not one to sit still.

As a third-generation sugarcane grower, Roy Butcher has spent more than three decades honing his skills and knowledge across every facet of the industry. And he’s showing no signs of slowing down, with a recent new appointment only enhancing his passion to continue progressing.

“I’ve been in the industry through the lowest of the lows and the highest of the highs,” Roy reflected. “I’ve been through the droughts, the floods and also the good times.

“It’s been an educational journey; I’m always learning new things and new practices.”

In 2022, Roy took on the role of Farm Manager for Amstar Speciality Ingredients, which operates 1700 hectares of sugarcane land across seven farms south of Tully. It’s an investment by Global Mind Australia Pty Ltd, a member of TTC AgriS –a leading player in Vietnam’s sugar industry. Roy was familiar with the land, including the main farm, where he’d spent the previous decade working.

His son Mitchell oversees the harvesting side of the business and acts as manager, keeping the farms running smoothly when Roy

is overseas. As part of his role, Roy works closely with teams in Vietnam, Laos, and Cambodia to share his hands-on Australian farming experience, particularly in areas like mechanisation, soil health, and datadriven practices.

“Once we got involved in big farming, we really dived into new innovations and technology, and our partners overseas have shown a real hunger to learn,” Roy said. “They’re genuinely eager to see how we do things here –especially when it comes to investing in machinery and embracing innovation to lift productivity. That commitment to progress is central to the TTC AgriS vision. As the official John Deere dealer in Vietnam, the company is actively encouraging and investing in farmers to help them shift toward more productive, sustainable farming models.”

Roy’s role extends far beyond the paddocks of North Queensland –he serves as a bridge between Australian farming excellence and Southeast Asia’s growing agricultural sector. His visits to Vietnam go beyond technical consultancy; they foster enduring relationships and mutual understanding between farming communities and corporate partners across the region.

“They are family-orientated people even though it is a corporate company,” Roy said. “After my father died in 2022, they showed support and care well beyond anything I’ve ever experienced before in my career. They look after us, so we’ll do the same thing in return.

“Before I started in this role, I swore black and blue that I’d never step foot on a plane to go overseas, but we get treated as part of their family and watching them work with the people over there is basically the same thing –one big family that works together in the same direction.

“That’s how I try to treat the guys that work here on the farm – not as numbers, but as a family because I believe that if you treat people with kindness, they tend to go the extra mile to help you get to where you want to be.”

Roy is focused on numbers when it comes to precision farming. He has rate controls on the spray rig and fertiliser boxes, and yield monitors and SmartClean technology on the harvester, the latter which Mitchell explained monitors the harvest to allow for better control of primary extractor fan speed settings.

“It’s about trying to minimise losses,” Mitchell said. “It assists me in my decisions as operator and also helps us deliver a consistent product to the mill.”

The pair says the 1.9m row spacing also assists, and planting and harvesting are always in single rows.

“We don’t have any troubles with weed population because we’ve got the sticks per metre in the ground,” Roy said. “I look at the efficiency side of things and there’s 17% less travelling.

The harvester can walk slower still cutting the same tonnes per hectare, so it takes the wear off the high working gear and that sort of thing.

“It’s also a plus when it comes to laser levelling because the machine’s not bouncing over all the undulating country, it’s pretty much smooth sailing. We just give it a brush up every time we fallow because we try to minimise soil movement as best we can.”

All equipment is manufactured by John Deere to enable consistency and in turn, efficiency. Last year, Amstar bought a new harvester and three 6195M haulout tractors for their Australian operations. They’ve also extended and modernised sheds.

“They’ve invested to be here for the long-term,” Roy said. “They see a future

in us as well as the sugarcane industry in Australia overall.”

As part of his precision farming program, Roy also pays plenty of attention to soil health. He plants cover crops when the weather allows and always checks that the soil chemistry is balanced.

“We ensure that the health of the soil is balanced before we apply the nutrients and we seem to be making increased progress, even with the weather events we’ve been battling in the last two years,” he said. “We’re still faring significantly well with the amount of rainfall we’ve had.”

“We follow the Smartcane BMP practices and record all our fertiliser and chemical applications through JOC (John Deere Operations Centre) and we put that into the booklet.

At the end of it, they calculate the total N and P and we’ve been under budget every year since I’ve been running the farm.”

This year, he’ll be undertaking trials aimed at releasing locked up phosphorous in the soil. He’s also been working with Sugar Research Australia (SRA) on varieties that will cope with water inundation. After TC Jasper and this year’s North and Far North Tropical Low, parts of the main farm were five metres underwater. The lower country is always harvested first to ensure new cane is mature enough to survive the onslaught of the wet season, but Roy said the past two years have been particularly brutal.

“We’ve never endured damage like we have in the last two years”

“We’ve discovered that the varieties SRA recommends for floods actually didn’t succeed in the floods we’ve had,” he said.

“Some of the varieties that we didn’t think would work for the Tully district actually worked here on our farm and worked well and surprisingly survived the floodwaters better than expected.”

Of course, there are variances across the expanse of the land. The main farm is spread across an area measuring around 10 kilometres by three kilometres, which can also make feral pig control challenging. During my visit, we came across a pig casually

Top: Despite extensive drainage, low lying areas of the main farm are prone to flooding

Middle: Roy (left) and Mitchell (right) have a close bond on and off the farm

Bottom: Spray rigs fitted with rate controllers form part of a data-driven approach to farming

wandering down one of the headlands. They’re not the only trespassers, according to Roy.

“My biggest fear is that while we’re doing our job by helping control feral pigs, we accidentally shoot someone that shouldn’t be on the property,” he said. “That would be a hard pill to swallow to live with, let alone coming under the focus of the law.”

There are advantages to working across one large area, though. Harvested cane can be tipped off on one of only three drop-offs and there has been scope to re-design the land area to make longer rows, planting through blocks to minimise machines having to turn around in small paddocks or tight corners.

One of the corporation’s other farms is 38 kilometres away, so transporting equipment does become a problem. “We’re now looking to consolidate to reduce the need for travel, mainly due to transport restrictions because currently, we have to move on critical roads,” Roy explained. “Nearly one person’s wages is lost every time you’ve got to shift from this farm to the top farm.”

117,000 tonnes are expected to be cut from the corporation’s farms this year and the harvesting contract covers 1,465 hectares.

Roy’s family has a long history when it comes to harvesting expertise. His maternal grandfather started in the industry hand cutting cane, shoulder loading onto horse carts, and placing portable rails. He later became a shareholder of a group in Feluga which started mechanical harvesting in the area.

Roy’s parents, Roy and Sandra Butcher, were entrenched in the harvesting equipment industry from the 1970s well into the 2000s. Roy Senior, a diesel mechanic and panel beater, ran his own sawmill until joining his wife to become dealers of Don-Mizzi, Toft Don and AusToft and later, with Neville Toft machines under the Cameco brand.

“Mum and Dad were a one-stop-shop, they had the quality and quantity of parts available for all the customers,” Roy recalls. “It’s not like it is today waiting for parts all the time. They used to travel up and down the coast during the season. If there were people broken down in other districts Dad would just grab the parts, jump in the car and meet them on the road.

“Mum’s family own the farm at Feluga and when Grandfather passed away, Grandmother didn’t want the farm so they split the farm up between the two daughters, so we started farming ourselves in about 1983.

“I worked on the farm with Mum and Dad until I left school, got my mechanical apprenticeship and I was still working with them on weekends.

“My brother and I and our sons still run the farm today for Mum and Dad, so we’re now up to four generations on the farm. Both my kids, Mitchell and Ella, were babies running around in nappies going for rides in bin tractors. At three years of age Mitchell used to drive the controls on the bin tractor and that’s probably where he got hooked on being involved as well. Once he finished school he began binning out and now he’s driving harvesters.

“I did seven years in my trade and then decided I wanted to go into cane, so I

started binning out. My passion was to drive the harvester, and I did that for about 10 years. I then wanted to invest myself more into the farming side of things and after Cyclone Yasi an opportunity arose.

“Damien Rigato took me on in 2012, it was a fairly decent sized farm, around 23,000 tonnes of cane and bananas as well. Then they invested in more properties and we were also commercial billet planting. I became second in charge and when they sold, the new company (Amstar) offered me a position as farm manager.

Roy is appreciative of the advice and support he’s received along his journey, having been involved in trials with the Department of Primary Industries, SRA and Tully Cane Productivity Services Limited. He is, however, concerned about a lack of new extension staff coming through the ranks. “Agronomist Peter Reed, for instance, has 40 years or so of experience and is right across what trials have been done, so there is no risk of repetition,” he said.

“When you’ve lost that experience in the industry, you lose all that knowledge.”

There’s no risk of that on the Amstar farms, where cross-generational learning and mentorship are epitomised by Roy and Mitchell Butcher.

BY GARRY ROSEWARNE SRA GENERAL MANAGER VARIETY DEVELOPMENT

Supplied by Sugar Research Australia

After several months in the job, SRA’s new General Manager Variety Development, Garry Rosewarne, says he’s starting to appreciate the complexities of growing sugarcane and the challenges it raises for variety development.

Garry is a highly experienced plant breeder who has worked both in Australia and internationally throughout his career. He has managed a long list of R&D projects as well as leading successful plant breeding programs in wheat, lentils and field peas, all being jointly funded by the Grains R&D Corporation (GRDC). In this journey he has had experience in incorporating 21st century breeding technologies such as genomics and remote sensing which can dramatically improve the rate of genetic gain. He was appointed SRA General Manager –Variety Development in March.

Sugarcane breeding is tougher than in other crops like wheat but it is paying off for the industry and we’re seeing results.

The sheer size of sugarcane

The cane’s height, density and the amount of land needed to grow it makes planting, harvesting, in season crop management, and record keeping all particularly difficult.

No downtime between crops

In small grains, farmers typically sow in autumn and harvest in early summer, giving breeders five months off to analyse data, make selections, prepare for the next year of trials and even run nurseries over summer.

Sugarcane crops grow for 12-24 months before harvest, meaning breeders are planting trials at the same time as harvesting plant, first and second ratoon crops.

This cycle puts a significant handbrake on the program and dramatically slows genetic gains.

We breed for many traits

We breed for many traits making the process more complex than for most other crops:

tonnes of cane per hectare (TCH)

commercial cane sugar (CCS)

resistance to diseases (e.g. smut, Pachymetra , RSD, etc) and

agronomic traits (e.g. age of maturity, trash and flower characteristics).

Disease prevention is slow

To prevent disease, all cane going into trials must be cold soaked, hot water treated and grown in clean seed plots between different stages of the program.

Other crops such as cereals and pulses only require a simple seed dressing, either powder or liquid, that can be applied at sowing.

It takes time to build up planting material

One tonne of cane produces 10 tonnes. In comparison, pulses have a seed bulking rate in multiples of 20 to 40, cereals, 50-80, and canola well over 100. This impacts not only the breeding program, but also how soon varieties can be adopted by growers.

Sugarcane genetics are complicated

Sugarcane has a complex genome with a base number of chromosomes of 10, which can each have repetitions of 10 or more, creating a lot of redundancy in the genome.

Chromosomes can also be randomly lost, so that a final chromosome number can be anywhere between 100 and 110.

Wheat has a large genome, but these are arranged in 21 stable chromosomes, making any molecular breeding program relatively simple.

Despite these constraints, the Variety Development program has generated amazing genetic gains, thanks to a well-structured and informed multidisciplinary team.

The team is well qualified with outstanding scientific knowledge of high-level field operations, pathology, quantitative genetics, cytogenetics, remote sensing, tissue culture, data management, statistics and genomics.

In studying the rates of genetic gain achieved by the program, I have examined multiple lines of evidence:

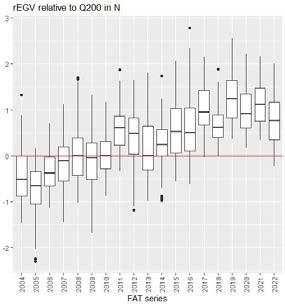

Tracking variety improvements

The relative economic genetic value (rEGV) is a selection index which is acknowledged by external reviewers as one of the most accurate used

1 shows how much better new varieties are performing compared to an old standard, Q200 (red line).

by breeders anywhere. It examines production values and economic costs associated with tonnes cane per hectare, CCS, fibre and resistance to important diseases.

In Figure 1, the consistent gains over time are shown by plotting the rEGV of the top 10 clones from the yield trialling system against a standard variety – Q200.

The left of the graph shows Q200, one of the best performing lines when released in 2004 but now completely outclassed by modern clones.

Of the 800 advanced clones in contemporary trials, more than 250 easily outperform Q208, another standard variety.

Breeders have many opportunities to select the next variety with a combination of suitable disease and agronomic traits and yield.

New varieties are outperforming older lines

The breeding program is derived from controlled trials and is therefore the most scientific data available. However, mill data is important, too.

A plant breeder must understand the main production environments

of an industry. Trials can then be set up across a vast landscape which captures all the regional constraints faced by growers.

However, sugar mill data captures statistics for every crop across a growing region.

The Variety Development program has generated amazing gains, thanks to the SRA breeding team

The 2023 mill data show which varieties are performing the best across the different regions.

Figure 2 calculates TCH for each variety graphed against the release year.

In all regions modern varieties are clearly trending upwards and outperforming older lines.

Figure 2 shows tonnes of cane per hectare from the 2023 mill data of the Central Region. Clones marked in orange dominate production – their collective contribution is more than 90 percent.

Figure 2 shows data from Central Region. The orange points show more than 90 percent of the 2023 crop. Varieties such as SRA21 and SRA9 are more than 20 percent higher yielding than older varieties such as Q208 and Q183.

Two cautionary notes

Examining mill data for crops within a five year release period (e.g. SRA21) has shown an overestimation of 5 percent in the plant crop of a number of varieties. This can be higher in poor ratooning crops such as Q253.

However, if the more recent releases limit long term yield losses to the 5 percent level, these results are very encouraging.

Misnaming varieties

Misdeclaration is unlikely to favour any one variety over another.

However, SRA’s fingerprinting technology provides opportunities to evaluate future variety accuracy.

Breeding progress comes not only from offensive breeding strategies targeting yield and sugar content, but also from defensive strategies targeting disease resistance.

SRA has actively bred for resistance to smut and Pachymetra. The increases in resistant germplasm can be seen in Figure 3

When smut came to Queensland in 2006, much of the breeding program was susceptible. However, more than 50 percent of varieties are now resistant.

This has cost yield gains since the sources of resistance came from poor yielding lines. Combining many thousands of good genes into a new resistant variety can only be achieved over many breeding cycles. Many of the good genes donated by an elite parent in a crossing can be lost, and it can take multiple breeding cycles to

levels

(yield) 15% over 10 years

million

Smut Resistance $810 million

Orange Rust $648 million

Pachymetra $324 million

Table 1 shows the value of defensive breeding strategies to industry compared to offensive breeding strategies.

recombine them, along with the newly introduced disease resistance.

However, defensive breeding is far more valuable to the industry than offensive breeding.

Table 1 shows the value of annual 1.5 percent yield improvements over 10 years which totals more than $240 million. However, the value of defensive breeding strategies incorporating smut resistance equals more than $800 million.

If it wasn’t for defensive breeding for smut and orange rust, there would be no Australian sugar industry today. Compare our industry with Papua New Guinea where cane yields are only 30-

40 tonnes per hectare. No sugarcane business in Australia would survive if yields were this low.

The breeding program – both for yield improvement and disease resistance traits – is making great progress and with the exciting new technologies now on the way, SRA will contribute much more to a successful and thriving sugar cane industry in the future.

ADVERTORIAL

Yellow crazy ants became a significant concern for local sugar cane farmers in 2012 when they were detected in sugar cane crops.

Because of the ants’ serious impact on crop vitality, managing yellow crazy ants soon became a key priority for the local cane farmers whose subsequent advocacy was instrumental in securing funding for the Wet Tropics Management Authority’s Yellow Crazy Ant Eradication Program.

Impacts of yellow crazy ants on crop yield

The economic impacts of yellow crazy ants can be significant as increased pest pressures reduce crop yields, leading to lower returns and higher costs for farmers.

Yellow crazy ants have been identified for causing crop stunting, a problem that was initially thought to be due to cane grubs. By nesting among the sugar cane stools, yellow crazy ants expose the root structure, which reduces soil moisture, impairing the plants’ ability to absorb nutrients, which in turn stunts growth.

The ants are also known for “farming” aphids and scale insects, protecting them in exchange for honeydew, a sugary substance the pests secrete. As a result, these secondary pests thrive and cause crop damage by feeding on sap, weakening plants and leading to reduced yields.

Furthermore, the excessive honeydew secreted by aphids and scale insects encourages the growth of sooty mould, a black fungus that coats plant leaves. This mould blocks sunlight, reducing photosynthesis and further harming plant health. In sugarcane, this also contributes to stunted growth and lower-quality crops.

Several strategies have been developed by WTMA, MSF Sugar, and CANEGROWERS to manage the risks of new and existing infestations, with the goal of mitigating the impacts of yellow crazy ants. These mitigation strategies include regular communication and updates on infestation areas with industry stakeholders.

WTMA’s Eradication Program Manager Lucy Karger said the partnerships forged with the sugar industry had been critical to the program’s ongoing success.

“Shared data and mapping harvester movements, via a locally developed traffic light system and washdown protocols, have significantly reduced the potential to spread ants from contaminated sites to clean areas,” Ms Karger said.

“This information, and cooperation from the industry, has been extremely valuable in helping WTMA make informed decisions in relation to survey and treatment efforts. With ongoing surveillance, treatment and community support, full eradication of yellow crazy ants in the Cairns region is achievable.”

The April showers were few and far between with only 136mm falling during the month; this was less than 40% of the monthly average.

Even though we had less rainfall it still didn’t feel like a month of sunshine as there were too many cloudy days. The ground is still very wet in the northern districts, and it will be a challenge to start cutting in some areas by 9 June.

We hope the month of May will be a good transition month for the crop as we started to see some arrowing of certain varieties midMay. Mossman coastal growers are due to start on 9 May, weather permitting, and the crop to be sent to MSF Mulgrave Mill will be 200,000 tonnes of cane.

This is likely to consist of ratooning cane from 2024 and the best standover cane.

SRA came to Mossman on 8 May to do some early testing of cane, stand-over and ratooning, for growers. Most samples indicated the cane was still in growth mode but there were cases where cane

was maturing as well. We hope this means that Mossman coastal growers will have a chance of getting a reasonable district average ccs for 2025, but we may not reach the 12.0 CCS of 2024.

The final offers for Mossman Mill were due to be submitted with the Liquidator by 6 May 2025. Mossman grower representatives met and interacted with a number of potential buyers of the mill, however, at the time of writing this article, growers remain uncertain of outcomes from the final offer process.

The Mossman Advisory Committee met for the third time on 29 May 2025.

The Mossman & District Show Society has undertaken to hold a Show Ball for the Douglas Shire in June as a celebration of rural industries and activities within the Shire. There will be many historical sugarcane industry items on display for what may be the last year of delivering Mossman sugarcane to a sugar mill.

seed sales—has made a lasting impact. We extend our sincere thanks and best wishes for his future endeavours.

The 2025 harvest season is officially underway!

The first bin was tipped at the Tableland Mill on 22 May, marking a strong start to what’s projected to be a solid season.

This year’s crop estimate stands at 880,000 tonnes, with the season expected to run for 26 weeks—wrapping up by the end of November.

As operations ramp up, growers are reminded to maintain high standards for pads and haulout

roads. A smooth, well-prepared surface not only enhances efficiency but also helps ensure the safety of everyone involved.

This month, we also bid farewell to Graham Cripps, Agronomist at the Tableland Mill, who has stepped down from his role. Graham’s dedication over the years—especially his recent work in establishing the clean seed plot and coordinating

The Cairns Region has recently experienced cooler and relatively dry conditions, which have been favourable for pre-planting activities.

Average maximum temperatures were around 30.4°C, with minimums near 23.1°C. Rainfall for April totalled 69.0 mm — well below the historical average of 108 mm. These conditions have enabled effective soil preparation and reduced the risk of waterlogging, with planting now underway across much of the district.

The 2025 Members Pre-Season Breakfast was recently held and well attended. The new Chair of

On the topic of the clean seed plot, it’s been encouraging to see strong uptake across the district. A number of clean seed varieties are still available, so if you haven’t yet placed an order, there’s still time. Contact the office for more information or to reserve your selection.

Here’s to a safe, productive, and successful season ahead!

The 2025 membership levy, combining the state and local district charges is: 59.65 cents per tonne (inclusive of GST) on all sugar cane supplied to the Tableland mill by all members during the 2025 crushing season.

CANEGROWERS Cairns Region, John Ferrando delivered an informative pre-season update, followed by a membership presentation from QCGO’s Matt Kealley.

A highlight of the morning was the Men’s Health Forum, pictured, organised by Next Ratoon Mentor Celiamaree Zarins. The session included a pre-recorded presentation by Dr Gavin Le Sueur from the Cairns GP Superclinic, and a talk from Men’s Health advocate Earl Nielson.

Despite the challenges of recent years, the 2025 season is off to a promising start. Growers are optimistic, supported by

favourable weather and ongoing investment by the local milling company. Crop estimates been returned, with initial forecasts for both Mulgrave and South Johnstone showing yields approximately 10% higher than the disappointing 2024 season.

The 2025 membership levy, combining the State and local district charges is: 55.91 cents per tonne (inclusive of GST) on all sugar cane supplied to Queensland mills by all members during the 2025 crushing season.

director Victor Guarrera for his service. Joseph Marano remains Chairman of the board.

Our representatives had a busy networking and advocacy month, attending the Sugar Cubed and ASSCT conferences as well as meeting with the Queensland Primary Industries Minister, Tony Perrett. Staff have also assisted growers with land valuation objections and disaster funding grants, while the Cassowary Coast Reef Smart Farming (CCRSF) extension team has been busy preparing growers for Smartcane BMP audits for both accreditations and reaccreditations. 92% of

More than 70 people attended CANEGROWERS

Innisfail’s Annual General Meeting in May, hearing about the challenges of the weather-marred 2024 season, which included 174 days of rain in the first 200 days of the year.

Members are looking forward to a more positive 2025 season, with a crop of 1.4-million tonnes estimated to be crushed and

Retiring, long-serving director Victor Guarrera and his wife Meg pictured with Chairman Joe Marano

South Johnstone Mill ready to begin crushing in mid-June, in accordance with Cane Supply Agreements.

Following elections earlier in the year, new board director Louis Fichera has been welcomed, while members and the board alike have expressed their gratitude to retiring, long-serving

cane land in the district is benchmarked and 71% is accredited.

CCRSF also attended the Tully Sugar Centenary SRA Industry Field Day, among other things promoting activities of the Johnstone Sugarcane Practice Change Program, which is funded through the Queensland Government’s Queensland Reef Water Quality Program.

The 2025 membership levy, combining the State and local district charges is: 53.80 cents per tonne (inclusive of GST) on all sugar cane supplied to South Johnstone Mill by all members during the 2025 crushing season.

Through May the cane continued to grow with only a couple of paddocks across the district are showing low signs of flowering.

This is a big contrast to season 2024, which had an almost complete covering of flowers in early April. Noticeable growth occurred in paddocks over the final two weeks of April and first week of May, even though most days over this period were cloudy and many recorded rain.

As a comparison, in 2024 for the first 130 days, it rained for 107 days with a total of 3556 mm, almost full flowers in the crop. In 2025 for the first 130 days, it rained for 88 days with a total of 3448mm, no flowers in the crop.

The crushing season for Tully district is due to commence in the first week of June, with crop estimates currently around 79 to 82 tonnes per hectare. If the estimates are correct, this should

give a total district crop size of between 2,330,000 and 2,410,000 tonnes through the rollers.

Final preparations are taking place both inside and outside the mill. New bridge girders for the Mullins bridge across the Tully River downstream of the highway are complete and have been lifted into place in the week of 19 May. Main bridge replacement across the Tully River, upstream of the highway has commenced with abutment piles been driven on the southern side of the river. Steam trials commenced in the week of 12 May.

Tully Sugar agronomist, Greg Shannon and Tully Cane Productivity Services Manager, Peter Sutherland held four meetings across the district in May. Meetings were held in El Arish, Lower Tully, Riversdale and Murray Upper, all supported by Jess Portch from SRA and CANEGROWERS Tully representatives.

The purpose was information sharing about topics such as varieties that are more likely to be suitable to your farm, soil type or subdistrict and varieties available for planting in season 2025.

A pre-season update and 2025 Local Variety Guide documents for the Tully Region were distributed to assist growers in planning for the next 12 months. The Local Variety Guide highlights awareness of Pachymetra sugarcane root rot and information on surveys conducted for Pachymetra since 2004. A list of varieties that show good or intermediate resistance are outlined on the guide.

Evidence of rat damage has been noted in some areas. Early control measures may be required. Make sure you check paddocks where there is permanent water or has a history of rat damage.

The Herbert River district, like all CANEGROWERS regions across Queensland, has commenced a new three-year term of board leadership.

At the first board meeting of the new term, Steven Marbelli was elected Chair, with Leah Russo elected as Deputy Chair. This leadership team brings a strong mix of experience and community engagement to the organisation.

The board also welcomed Brenden Accornero, a representative of the Young Growers group, as a new addition to the board. His

As the season draws near, the community needs to be vigilant on the movement of cane trains at road crossings and across the district in general. As the season progresses, there will be an increase in oversize vehicles utilising the road networks. Please be aware of the requirements for the movement of oversized vehicles.

membership portal provides up to date information tailored to your cane growing district. If you are uncertain about how to login to the Membership portal, please contact your local CANEGROWERS office for assistance.

The 2025 membership levy, combining the state and local district charges is: 43.84 cents per tonne (inclusive of GST) on all sugar cane supplied to Queensland mills by all members during the 2025 crushing season. This fee is inclusive of cane testing/auditing fees.

appointment signals the district’s commitment to fostering the next generation of cane industry leaders. At the same time, the board bid farewell to Chris Bosworth, acknowledging his many years of dedicated service and leadership. Chris’ contribution to the district and broader industry is sincerely appreciated.

In mid-May, CANEGROWERS