At SMS Equipment, we’re more than machines from trusted brands like Komatsu. No matter your project, we’re the people beside you— today and every day—bringing industry-leading technology and expertise to your job site.

Because the right partnership makes everything possible.

Turn to page 16 .

CONNECT WITH US @HeavyEquipGuide

WE’D LIKE TO HEAR FROM YOU

Do you have a job site story, innovation, or industry concern that our readers should know about? We’d like to hear from you.

Contact: Editor in Chief Kaitlyn Till at ktill@baumpub.com or 604-291-9900 ext. 330

EDITOR IN CHIEF

Kaitlyn Till ktill@baumpub.com 604-291-9900 ext. 330

DIRECTOR OF DIGITAL STRATEGY

Slone Fox sfox@baumpub.com 604-291-9900 ext. 335

SENIOR WRITER

Meghan Barton mbarton@baumpub.com 604-291-9900 ext. 305

ASSOCIATE EDITOR Stephanie Bontorin 604-291-9900 sbontorin@baumpub.com

VICE PRESIDENT OF SALES/ ASSOCIATE PUBLISHER

Sam Esmaili sam@baumpub.com 604-291-9900 ext. 110

ADVERTISING

PRODUCTION MANAGER

Tina Anderson tanderson@baumpub.com 604-291-9900 ext. 222

DESIGN & PRODUCTION

Morena Zanotto morena@baumpub.com 604-291-9900 ext. 325

PRESIDENT/PUBLISHER

Ken Singer ksinger@baumpub.com 604-291-9900 ext. 226

VICE PRESIDENT/CONTROLLER

Melvin Date Chong mdatechong@baumpub.com

FOUNDER

Engelbert J. Baum

Published by: Baum Publications Ltd.

124 - 2323 Boundary Road Vancouver, BC, Canada V5M 4V8

Tel: 604-291-9900

Toll-free: 1-888-286-3630 Fax: 604-291-1906 www.baumpub.com www.heavyequipmentguide.ca @HeavyEquipGuide

FOR ALL CIRCULATION INQUIRIES

Toll-free: 1-866-764-0227 email: heg@mysubscription.ca

Subscription: To subscribe, renew your subscription, or change your address or other information, go to: http://mysubscription.ca/heg/

Heavy Equipment Guide serves the Canadian engineered construction industry including: roadbuilding and maintenance; highways, bridges, tunnels; grading and excavating; earthmoving; crushing; trucking and hauling; underground utilities; trenching; concrete paving; asphalt paving; demolition; aggregates production; fleet maintenance; and asset security and management. The magazine is distributed to key industry personnel involved in these sectors.

Subscription Price: In Canada, CDN $91.00; Outside Canada, US$149. Heavy Equipment Guide is published eight times a year in January/ February, March, April, May/June, July/August, September, October, and November/December.

Heavy Equipment Guide accepts no responsibility or liability for reported claims made by manufacturers and/or distributors for products or services; the views and opinions expressed are those of the authors and not necessarily those of Baum Publications Ltd.

Copyright 2025, Baum Publications Ltd. No portion of this publication may be reproduced without permission of the publishers.

We acknowledge the financial support of the Government of Canada.

Printed on paper made of FSC®-certified and other controlled material. ISSN 1715-7013.

PUBLICATIONS MAIL AGREEMENT NO. 40069270

Return undeliverable Canadian addresses to: Circulation Dept., 8799 Highway 89, Alliston, ON L9R 1V1 email: heg@mysubscription.ca / Toll-free: 1-866-764-0227

Small operator contests and challenges have been a staple element of industry trade shows for years. World of Concrete, in particular, has been the venue for plenty of skillbased contests, including the always popular trowel challenges. But over the last six years or so, the operator competition has become something much bigger: it’s now a spectacle that is ripe for online engagement while celebrating the dedication and skill of operators.

The most prominent operator competition, and the one that established the trend, is Caterpillar’s Global Operator Challenge, which is now in its third cycle leading up to the final at CONEXPO-CON/AGG 2026. The Global Operator Challenge has brought together operators from around the world to celebrate their skill on the biggest stage in construction.

Over the last couple of years, the newly formed National Equipment League, sponsored by HD Hyundai Construction Equipment, has also established itself as a rising must-watch for equipment enthusiasts, and it is currently airing its third season.

This year, the AEM has partnered with the National Utility Contractors Association to form the National Equipment Operator Championships to be held at The Utility Expo in Kentucky, October 7–9. That competition will focus on celebrating the skills of operators working within the utility industry.

Operator challenges aren’t just limited to earthmoving machines. This summer Liebherr introduced its international competition, The Game of Cranes, to find the best crane operator in the world.

I’ve watched a few operator challenge events, and attended a few as well, and what always stands out is the camaraderie among the competitors, including in international competitions where the operators don’t necessarily speak the same language. It’s refreshing to watch the cross-cultural connection and the mutual support of a job well done.

But perhaps one of the most important uses for operator challenges is as a recruiting tool. This is where there is room for improvement. These challenges have largely been dominated by men even though the competitions are open to everyone.

It has been refreshing to see some women compete. The National Equipment League has had female competitors, and Cat

I’ve watched a few operator challenge events, and attended a few as well, and what always stands out is the camaraderie among the competitors.

has also hosted skills events for women at its facilities. But if these competitions are to act as a recruiting tool to attract more young people to the industry, they should further diversify who gets seen in the operator’s seat on the biggest stages.

Skill in equipment operation is gender-neutral, but this is a case where more competitions that specifically recruit women might be warranted given that men drastically outnumber women in this industry. That starting imbalance makes it inevitable that most of the competitors who make it to the final stages will be men.

Operator skills competitions are great fun to watch, and some of them stream online. I highly recommend checking out the talent on display, and, if you’re game, maybe you or someone from your organization will join in a future competition.

Kaitlyn Till Editor In Chief

ktill@baumpub.com

heavyequipmentguide.ca

On September 11, 2025, Associated Equipment Distributors (AED) issued the following statement:

Today, Prime Minister Carney announced the first five projects that his government would be referring to the Major Projects Office (MPO) for accelerated development. The Prime Minister announced that the five projects would be:

LNG Canada Phase 2, Kitimat, British Columbia; Darlington New Nuclear Project, Bowmanville, Ontario; Contrecœur Terminal Container Project, Contrecœur, Quebec; McIlvenna Bay Foran Copper Mine Project, East-Central Saskatchewan; and

Red Chris Mine expansion, Northwest British Columbia.

AED has consistently advocated for the Government of Canada to make a clear commitment to investing in large-scale infrastructure development. The announcement of these projects is a positive first step in expanding critical infrastructure to support trade, energy, and critical mineral development that will support the Canadian economy and Canadian workers.

AED’s President & CEO Brian McGuire applauded the announcement by Prime Minister Carney, highlighting that these projects will help support key industries and expand much-needed infrastructure capacity.

“Today’s announcement by Prime Minister Carney is an excellent first step in supporting project development and getting shovels in the ground faster across Canada,” McGuire said. “These projects will attract billions in investments, generate thousands of jobs, and help make the Canadian economy more prosperous and competitive by expanding Canada’s trade, energy, and mineral extraction capacities. While reducing project timelines is excellent, AED will continue to advocate for investments that ensure projects not only start but reach completion.”

AED will continue to advocate for the Government of Canada to invest in building new infrastructure across the country that expands Canada’s energy, trade, transport, housing, agriculture, and critical mineral capacity.

The construction industry’s largest and most anticipated construction trade show, CONEXPO-CON/AGG, is officially open for registration. Taking place March 3–7, 2026, in Las Vegas, the show brings together every major sector of the construction industry to explore the latest equipment, innovations, and technologies.

“CONEXPO-CON/AGG 2026 is more than a gathering — it’s the launchpad for the next era of construction,” said Dana Wuesthoff, show director. “This is where construction industry leaders, innovators, and visionaries converge to rewrite what’s possible. From groundbreaking technologies to lasting partnerships, every moment at the show is designed to inspire progress, spark new ideas, and propel the construction industry forward.”

Building on its legacy of innovation, show organizers say that CONEXPO-CON/AGG promises an event more expansive and dynamic than ever before. Attendees can look forward to exciting additions like the Ground Breakers keynote stage and specialized workshops.

“CONEXPO-CON/AGG is far more than an industry event — it’s the crucible where the future of construction is forged,” remarked Eric Sauvage, show chair and president & CEO at LBX Company. “For exhibitors, this is a rare and invaluable opportunity to connect directly with thousands of decision-makers, showcase state-of-the art products to an international audience and gain first-hand insight into the evolving needs of the marketplace.

“Here, the world’s leading innovators unveil their latest breakthroughs, create meaningful partnerships, and shape the direction of our industry for years to come. CONEXPO-CON/ AGG is truly an unrivaled platform to demonstrate cutting-edge technology, engage with the brightest minds, and build enduring momentum for lasting success,” continued Sauvage.

“Attending CONEXPO-CON/AGG provides valuable exposure to any potential new and improved safety-related solutions and resources that can be shared, applied, and implemented in our business,” said Spencer Johnson of Payne + Dolan, Inc., a design and construction services company based in Waukesha, WI.

“There is a wide array of equipment, manufacturers, products, technology, education, and people and the show is very large, allowing for ample opportunity to explore specific interests.”

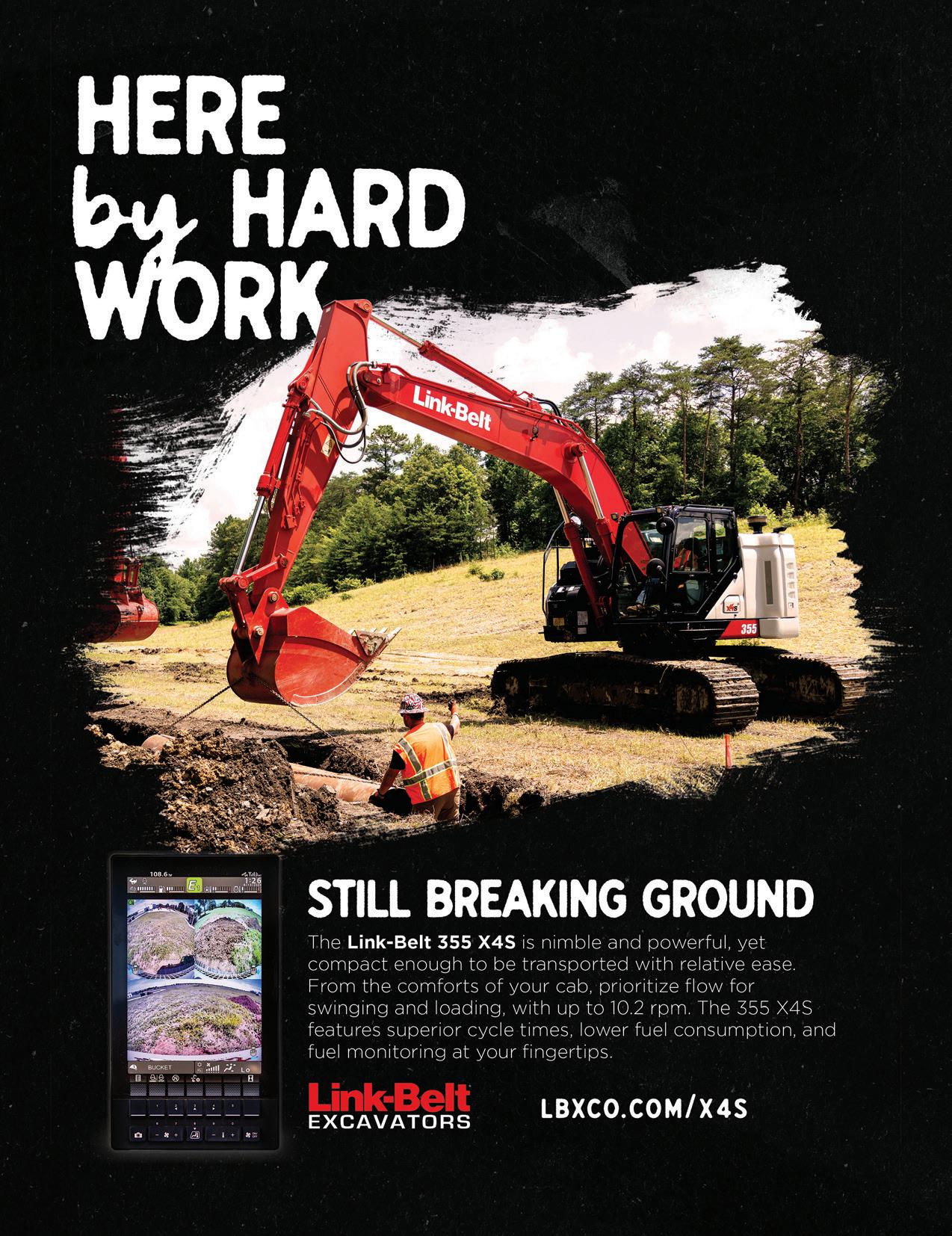

Calgary-based JT Equipment will offer rentals, sales, and support for Link-Belt Excavators across southern Alberta.

This partnership enables JT Equipment to offer a broader range of heavy equipment, catering to the diverse needs of the construction, forestry, landscaping, and municipal sectors in Alberta. The company’s inventory includes excavators, skid steers, loaders, dump trucks, telehandlers, woodchippers, and stump grinders.

“We look forward to working with the team at JT Equipment to grow our presence in the Calgary and the southern Alberta market,” said Kevin Roberts, LBX director of North American sales.

Matthew Cox, vice president of JT Equipment, said, “We’re proud to become the official Link-Belt Excavator dealer for southern Alberta. This partnership marks a significant milestone for our company, reflecting our commitment to providing top-quality equipment and service to our customers. Link-Belt’s reputation for innovation and reliability aligns perfectly with our values, and we’re excited to bring their world-class machines to our region.”

Look for Heavy Equipment Guide’s inaugural Excavators special issue this fall. In this issue we’ll dive deep into construction’s most iconic machine.

Terapro Construction will represent the Ammann product line, including soil and asphalt compactors and light compaction equipment. It will sell the machines directly to businesses and end-users and also offer them through its rental division. The agreement expands Ammann America’s distribution and service capabilities in Ontario and Quebec.

Finlay has named ProTrack as its new authorized dealer in British Columbia. This new partnership marks a significant step in Finlay’s expansion into Western Canada, leveraging ProTrack’s 25 years of experience in providing reliable equipment and exceptional contractor support. The new dealership will provide local sales, service, parts, and support for the full line of Finlay crushing, screening, and conveying equipment.

Power Curbers Companies has acquired Miller Formless Systems, a producer of mid-sized slipform machines based in McHenry, Illinois. The acquisition was finalized on August 29, 2025, marking a significant milestone in the continued growth of both organizations.

Miller Formless will continue to operate under its brand name. Power Curbers Companies says it remains committed to preserving the company’s presence while introducing operational efficiencies that will benefit contractors in the areas of machine delivery, parts availability, and after-sales support.

Together, Power Curbers, Power Pavers, Anvil American, and Miller Formless will now provide contractors with a comprehensive lineup of concrete paving solutions, from extruded curb machines to mainline highway pavers.

Raimondi Cranes, an Italian manufacturer of heavy lifting solutions, has entered into a definitive agreement to acquire key lifting businesses from the U.S.-based Terex Corporation.

Operating under the umbrella of Arada Industries, which is owned by Arada Group, Raimondi Cranes is set to acquire Terex Tower Cranes, Terex Self-Erecting Cranes, and Terex Rough Terrain Cranes, alongside its U.S.-based after-sales and service infrastructure.

The Toro Company, Ditch Witch’s parent company, has completed the sale of the Trencor business and the auger boring product line of the American Augers business. This sale will allow Ditch Witch and American Augers to strengthen its focus on horizontal directional drilling (HDD), a rapidly growing segment of the underground construction market supported by demand in the pipeline, water, and energy transmission sectors.

Under the Ditch Witch Division, American Augers will continue to design, manufacture, and distribute its line of horizontal directional drills, pumps, and fluid cleaning systems for complex infrastructure projects. As underground construction projects become more challenging, Ditch Witch’s renewed focus on HDD and trenchless technologies underscores its commitment to meeting the evolving needs of contractors worldwide.

The first two models in New Holland’s D-Series mini excavator line are the E42D and E50D. Designed for a variety of work sites and tasks, from municipal utility work to agricultural trenching to commercial landscaping, the D-Series delivers exceptional performance in tight quarters. With zero tail swing, long arm options, the choice of steel or rubber tracks, and a two-way or six-way blade with standard float function, these machines are flexible across industries and operating environments. They come equipped with dual auxiliary hydraulic lines and an optional third high-flow line for powering energy-intensive tools like mulchers with precise flow control through the cab’s interface.

The TL11R3 is the newest model in Takeuchi’s compact track loader portfolio. Electric-over-hydraulic controls on this 11,650-pound radial-lift machine enable precise operation while minimizing operator fatigue. Operators can switch between ISO and H joystick patterns, adjust sensitivity settings, and use a self-levelling feature for better load handling. Available in standard and high-flow configurations, the TL11R3’s high-flow option delivers up to 40 GPM for demanding attachments. Powered by a 107.3-hp engine that meets Tier 4 Final emissions standards, it offers a rated operating capacity of 2,735 pounds, 7,958 pounds of bucket breakout force, and 12.4 inches of ground clearance. Inside the cab, a suspension seat, touchscreen display, Bluetooth radio, and a 270-degree rear-view camera (standard on highflow models) enhance comfort and visibility.

Loftness Specialized Equipment has introduced the first auxiliary hydraulic cooler designed specifically to be compatible with Kubota’s new SVL97-3 compact track loader. The Cool Flow delivers up to 150,000 BTUs per hour of cooling capacity and mounts directly to the SVL97-3 roof with a custom low-profile bracket to reduce the risk of overhead contact. Two 14-inch fans, regulated by an automatic thermostat, ensure consistent cooling performance in demanding applications. Engineered for full hydraulic flow in either direction, the system supports a wide range of attachments. A heavy-duty steel frame enhances durability, while easy-access screens allow for simplified maintenance. The Cool Flow is suited to high-heat environments.

Hitachi Global Air Power has added the Sullair OFE1550 to its lineup of electric portable air compressors. This model delivers 1,550 cubic feet per minute at 125 PSI of Class 0 oil-free air and is designed for operations requiring high air purity. The OFE1550 features a Totally Enclosed Fan Cooled (TEFC) motor for reliable use in harsh environments, zero emissions, a Wye-Delta starter, and a smart auto-lubrication system. A 10-inch touchscreen controller supports ease of use, and the unit is engineered for manoeuvrability and simple maintenance.

Bid-Well’s new MT Series of material transport systems expands the company’s portfolio beyond paving machines. The first model, the MT Behemoth, is engineered to deliver powerful, precise material movement for bridge construction. At its core is a stationary power unit that serves as the central source of energy and operational control. This unit drives the machine’s travel, trolley movement, elevation adjustments, and any powered accessories, whether hydraulic or electric. The machine frame is constructed from ultra-high-strength weathering steel. The three transport trolleys housed within the material transport hanger frame are the primary carrying apparatus. Lift heights range from 20 to 100 feet with speeds up to 21 feet per minute. Maximum load is 7.5 tons (15,000 pounds). Longer configurations are available.

Articulated dump trucks (ADTs) are ready to adventure off-road for demanding hauling on rugged terrain in construction, mining, and quarrying applications. Steep slopes, ruts, mud, and water are no match for the robust ADTs from the ten manufacturers represented in this spec guide. Turn the page to learn how to select the right ADT for your job site, then check out the specs to explore the range of options available in North America.

BY KAITLYN TILL, EDITOR IN CHIEF

While the tasks of ADTs may seem simple (move material from point A to point B), the variables that go into selecting the right machine can have an outsize impact on the machine’s productivity, uptime, and longevity, all of which are significant to your bottom line. I asked industry experts to give their best advice for selecting an ADT, and here are their top tips.

Choosing the right size ADT, including pass matching with your wheel loaders and excavators, in addition to optimizing for distance travelled, ground conditions, and density of material, will maximize site productivity and improve the longevity of your equipment.

“For instance, a 25- to 30-ton ADT might be suitable for short hauls with a mid-size excavator, while a 35- to 40-ton model would be more appropriate for moving large volumes over long distances. It’s equally important to match the size of the excavator or wheel loader to the ADT,” says Bill Zak, wheel loader and ADT product manager at DEVELON.

Zak adds that properly partnering ADT options to site conditions is vital for longevity. This includes matching tire size, type, and width to the specific site conditions.

Brad Castle, product manager for articulated dump trucks and tracked carriers at Bell Equipment adds that correctly sizing the ADT will help fleet owners reduce

bottlenecks on site and reduce unnecessary idling time.

“Determine the number of passes required to fill the truck,” says Bruce Boebel, Komatsu’s director for construction products and service. “Selecting the right size bucket for your excavator or loader is important in helping eliminate partial loads and reduces unnecessary cycles.”

Tyler Smith, Volvo Construction Equipment’s product manager for articulated haulers, emphasizes the importance of matching ADT tires to your application.

“Tire manufacturers provide a rating called TMPH (ton miles per hour), which is the maximum recommended load the tires can carry at a particular speed. Tires need time to cool down, so if you’re doing long runs at high speeds, a rigid hauler might be a better match because its tires can dissipate heat faster. The tires on an articulated hauler are meant to take on rough terrain rather than nice, hard-packed roads. Another consideration is whether to use standard 29.5 tires or 875 metric tires, which are wider and can reduce ground pressure by distributing weight over a larger contact point to provide better flotation in poor conditions.”

He adds that if you haul sticky materials, you may want a hauler with a bed heating option, or if you haul abrasive materials, you might want to add a liner to extend the life of the bed.

Volume capacity will determine the size of ADT you need, and factory-fitted options like a spill guard, sideboard extensions, and tailgates can increase volume capacity.

“The most popular tailgate is an overhung configuration,” says Smith, “but if you’re hauling large rocks and are worried about them getting stuck, an underhung

2

version might be a better choice.”

An ejector truck configuration may be the best option in some conditions, according to Scott Thomas, market professional with Caterpillar. You should consider an ejector truck if you are hauling sticky materials, need to spread material while moving but reduce dozer work, your site has height restrictions or uneven terrain, you want to reduce carryback, or if you have limited support equipment.

Estimating the long-term ownership costs of an ADT, which can include fuel efficiency, routine maintenance, parts availability, and resale value, should be balanced against an attractive sticker price, says Boebel from Komatsu.

Colton Kreber, a John Deere Construction & Forestry product marketing manager, says that having the ability to manage fuel costs can be an advantage to any operation. Different drive modes will enable easy customization for both inexperienced and veteran operators for a variety of conditions.

“The power-to-weight ratio of an ADT has a huge impact on fuel consumption, which is the largest component of a machine’s hourly owning and operating cost,” says Castle from Bell. “An ideal power-to-weight ratio means fuel is not wasted on moving unnecessary weight.”

Todd James, sales representative for Liebherr, suggests you look at how much material the truck can carry in relation to its operating weight without compromising balance or stability. He notes that a tapered dump body design with a low loading edge for fast and efficient material discharge, especially when handling cohesive materials, will result in faster cycle times and improved efficiency on job sites.

4

Skilled operators are in high demand, and features that keep them comfortable and safe will help you retain your skilled employees.

“Since operators often spend long hours behind the wheel of an ADT, machine comfort should be a key part of your buying decision,” says Boebel. He recommends looking for trucks that offer supportive, adjustable seating, a low-vibration ride quality, and clear visibility.

Joe Hodges, product manager for HD Hyundai Construction Equipment North America, says to look for a spacious cab, intuitive controls, great visibility, and reduced noise levels.

Zak from DEVELON emphasizes on the importance of operator training. “A solid understanding of an ADT’s functions not only boosts productivity, but also helps prevent accidents that could shorten the machine’s lifespan,” he says.

“Well-trained operators also develop a better understanding of a machine’s limits and the consequences of exceeding rated capacities. This includes being aware of stability limits during dumping and avoiding quick, abrupt turns that can lead to rollovers, as well as understanding braking limitations when travelling downhill with a loaded dump body.”

Getting input from the whole team will help you select a machine that everyone is happy to work with, says Smith from Volvo. “Owners, fleet managers, operators, and service team members all have different considerations and preferences, and they all matter.”

3

Our experts agree that even the best-built machine will require unexpected service during its life.

“Following routine maintenance schedules is essential for extending the life of an ADT,” says Zak from DEVELON. “This includes daily lubrication and adhering to all key maintenance intervals recommended by the manufacturer in the Operation & Maintenance Manual.”

Routine maintenance for ADTs should also involve visual inspections of tires, the driveline, and structural members for any damage, as well as checking for leaks and abnormal sounds.

“Remember to adjust maintenance intervals for special conditions, such as extremely dusty environments, which may require more frequent air filter cleaning or specialized oils,” Zak adds.

James from Liebherr says that centralized service points, an automatically opening tailgate, and hydraulic system diagnostics help speed up routine tasks.

Boebel from Komatsu recommends considering whether the dealer offers responsive field service, easy access to parts, and technical support when you need it most. You should evaluate if your team can perform routine maintenance independently, or if you will need dealer assistance.

5

Kreber from John Deere says that inexperienced and experienced operators look for features designed to reduce fatigue and maximize performance, and those features can have added safety benefits.

“Auto dump brake, adjustable transmission retarder, and descent control provide another layer of safety for the operator,” he says. “Additionally, rollover protection prevents dumping when the ADT is at an unsafe dump angle.”

Zak from DEVELON points out that bad habits may pay off in the short term, but can result in dangerous operation and equipment degradation in the long run.

“While overloading ADTs might offer short-term gains, it ultimately leads to higher repair costs and a shorter machine life,” he says. “Overloading also negatively impacts tire life. It is crucial for operators and owners to understand and respect the machine’s rated capacities. For instance, exceeding stability limits during dumping or making quick, abrupt turns can contribute to rollovers. Similarly, understanding braking limitations, especially when descending hills with a loaded dump body, is critical to prevent runaway trucks.”

Boebel from Komatsu adds, “Look for models designed with operator protection, visibility, and machine stability in mind, especially when working on uneven terrain or in high-traffic areas. Key safety features include anti-slip surfaces, back-up alarms, visibility enhancements like wide-angle mirrors or cameras, and systems that help control traction and braking.” HEG

Liebherr’s ADT is engineered for productivity, durability, and performance in the most demanding off-road conditions. The TA 230 Litronic is the first model in the lineup and represents Liebherr’s entry into the ADT market. It combines high payload capacity, powerful driveline technology, and intelligent assistance systems to support safe, efficient haul operations across a variety of industries including construction, mining, and quarrying. Built with operator comfort, fuel efficiency, and serviceability in mind, the TA 230 is designed to perform across rugged terrain.

The Liebherr TA 230 Litronic is a 6x6 articulated dump truck designed to handle the toughest hauling tasks. It features a powerful 6-cylinder Liebherr engine to deliver high performance in rough terrain. Its unique drivetrain and active traction control system ensure optimal power distribution, while the spacious cab and intuitive operating system provide excellent operator comfort. Safety and efficiency are enhanced with hill start assist, downhill speed control, and a maintenance-friendly design.

with hydro-pneumatic spring cylinders, maintenance-free bearings External planetary axle with load-switchable differential lock, four-point suspension, maintenance-free bearings

Heaped payload capacity is SAE 2:1 without tailgate. Operating weights, payload capacities, and engine horsepower are rounded to the nearest whole number.

ic rollover protection, auto wait brake, push-to-start ignition, LED lighting, updated keypads, and an optional object detection system with multi-view camera. These upgrades aim to improve operational safety, ease of use, and throughput in high-volume environments.

The Caterpillar 730 EJ uses a push block to unload without raising the bed, reducing tip-over risk and sticky carryback. This helps maintain full capacity and saves 30 to 40 seconds per cycle on well-designed sites, boosting daily productivity. While spreading material on the move, dozer needs are reduced. Inside the cab, the nextgeneration 730 EJ upgrades the operator’s experience with a touchscreen pad, push-to-start ignition, operator ID, rollover protection, auto wait brake, overspeed protection via ARC, optional coaching, and better fuel efficiency.

It’s a big, heavy world out there — let Manitou do the heavy lifting for you. From compact telehandlers to rotating telehandlers and everything in between: if there’s a way to lift it, Manitou will help you handle the weight of the world.

These easy-to-use, reliable telehandlers have proven themselves around the world, on jobsites big and small. Put the durability of Manitou telehandlers to work for you

Learn more at Manitou.com.

John Deere currently offers four ADT models. This lineup offers a wide range of payload capacities and delivers the power and torque for exceptional power-to-weight ratios that allow operators to work efficiently. The full lineup features on-board diagnostics that help the operator monitor the health and productivity of their machine. In addition, smart features such as auto-differential lock, tire-pressure monitoring, and on-board payload weighing help boost productivity and uptime while helping to keep operating costs down.

The 460 P-Tier is powered by a new JD14 engine and comes equipped with John Deere’s Advanced Vision System. New automatic hydraulic valve lash adjusters reduce repair time by eliminating the need for valve lash maintenance and streamlining service processes. The new Advanced Vision System expands an operator’s field of view through new virtual mirrors. The view dynamically pans as the ADT articulates to give maximum visibility down the sides of the truck. This feature, combined with trajectory lines in the rear camera and a front-facing camera, allows the operator to easily manoeuvre the ADT. In addition, its user-friendly interface helps operators identify objects and view their surroundings in real time.

DEVELON offers two ADT models in North America. These trucks are designed for demanding hauling on construction sites, for road projects, and in mining and quarrying environments.

DEVELON ADTs feature a front-mounted turning ring coupled with a free-swinging rear tandem gear-driven bogie. This ensures maximum ground contact for smooth rides and optimal traction on rough and soft terrains. The trucks’ limited-slip differentials further enhance power transfer to the wheels with the best grip. A self-levelling front suspension is another key feature of DEVELON ADTs. The hydro-gas system provides enhanced shock absorption, contributing to a smoother ride and improved operator comfort.

DEVELON ADT cabs are designed for comfort, featuring air conditioning, heated air suspension seats, precise steering, good visibility, and low noise levels. The trucks are equipped with a vehicle control unit for displaying critical information on an in-cab monitor.

The DA45-5 is a 45-ton ADT designed for construction sites, quarries, and mining operations. It features an active payload measuring system for load optimization and productivity, displaying weight on an in-cab LCD screen. The DA45-5 boasts enhanced performance with a front-mounted turning ring, sloping rear frame, and free-swinging rear tandem bogie for constant six-wheel ground contact. Its hydro-gas, self-levelling front suspension ensures a smooth ride.

The Rokbak RA30 is built for versatility and efficiency. The fully independent suspension and wheel movement is provided by a double wishbone design. This is coupled with 4 x hydraulic dampers/coil over springs. Powered by a fuel-efficient engine, it delivers strong performance while keeping operating costs low. The RA30 features a user-friendly cab with excellent visibility, ergonomic controls, and advanced safety systems. Its high-performance transmission and all-wheel drive offer superior traction and control on challenging terrain.

Double wishbone design, 4 hydraulic dampers/coil over springs provide fully independent suspension

Four trailing links and a panhard rod locate the front axle giving a high roll centre

Heavy-duty axles with fully floating axle shafts and outboard planetary reduction gearing

Three axles in permanent all-wheel drive coupled to the frame by three rubber-bushed links

tion Control System (KTCS), which automatically manages inter-axle locking and braking for improved traction. K-ATOMiCS transmission technology and hydro-pneumatic suspension help deliver a smoother ride. Komtrax telematics is standard with no subscription fees for the life of the machine. Options include Komatsu Care programs, extended coverage, and a range of equipment and tire upgrades.

Engineered for productivity, the Komatsu HM400-5 articulated dump truck delivers high-capacity hauling and exceptional manoeuvrability on rugged terrain. The truck features a robust, low-maintenance design and a spacious cab carefully designed with a focus on operator comfort and visibility. Standard payload metering and Komtrax telematics help optimize fleet management, while a robust centre-tilting frame and long-travel suspension system provide exceptional stability and control.

tem for remote diagnostics and fleet management. These ADTs offer ergonomic cabs, simplified maintenance, and safety

manoeuvrability, a tight turning radius, and stability on rough terrain. Key features include a fuel-efficient Scania engine, smooth 6x6 drivetrain, advanced telematics, and an ergonomic, high-visibility cab. Easy-access service points reduce downtime, while optional features like an on-board weighing system and tailgate maximize payload control and productivity.

The Hydrema 922HM is a specialized variant within the 922G series. It is engineered specifically for sensitive terrain applications requiring minimal ground pressure. This articulated dump truck features extra-wide tires and elevated ground clearance, making it ideal for soft or environmentally sensitive job sites where traditional equipment would cause damage. Powered by a Cummins Stage 5 engine and equipped with advanced hydraulic systems featuring five synchronized pumps, the 922HM delivers excellent off-road performance. Features include oil-immersed disc brakes on all six wheels and a powerful retarder system for reliable operation in challenging conditions.l

ton of material moved.

Fitted with a progressive technology platform for ease of integration, the Bell B50E is successfully operating on fully autonomous and remote-controlled sites in North America.

B20E LGP 18 15

B25E 6x6 21

B30E 6x6 23 23

Pivoting walking beams with laminated rubber suspension blocks

Pivoting walking

Pivoting walking beams with laminated rubber suspension blocks

B35E 6x6

B40E 6x6

B45E 6x6

B45E

B50E

Active

Pivoting walking beams with laminated rubber suspension blocks

Pivoting walking beams with laminated rubber suspension blocks

Pivoting walking beams with laminated rubber suspension blocks

Trailing arm cradle supported by hydro-pneumatic suspension struts, with an additional lateral stabiliser

Pivoting walking beams with laminated rubber suspension blocks

Trailing arm cradle supported by hydro-pneumatic suspension struts, with an additional lateral stabiliser

BY MEGHAN BARTON, SENIOR EDITOR

At Tomlinson, change isn’t a challenge. It’s a competitive strategy.

While some construction companies are still debating the cost and complexity of going digital, Ottawa-based R.W. Tomlinson Limited has already embedded technology adoption into the DNA of its operations. With a fleet of over 700 machines reporting into Caterpillar’s VisionLink platform, a cloud-based telematics and productivity system, Tomlinson has full visibility into real-time operations across its construction, aggregates, and recycling businesses. With integrated dashboards at job sites and a workforce trained in telematics and data-driven decision-making, this third-generation, family-owned business has demonstrated a consistent commitment to digital transformation.

Ryan Downing, vice president of materials and operations, doesn’t describe Tomlinson as a tech company, but he might as well. Tomlinson has embedded AI functionality within its IT department, where AI specialists and a dedicated research analyst focus on applying intelligent tools to streamline operations. Their work includes developing chatbots for faster data access and exploring AI-based analysis of downtime reports.

“We embrace AI here. So yeah, we’re construction, but we’re a little bit more than that. We attract a lot of different talent in our market here because of our ability to change and adapt to that technology.”

This embrace of technology stems from leadership that doesn’t just accommodate innovation, they expect it.

Tomlinson is built on three core values. These principles, defined through internal sessions and field team feedback, shape how the company manages its people and how it evaluates new equipment and systems. For Downing, these values also explain why Tomlinson has been able to stay ahead of the tech curve.

The first core value highlights that Tomlinson is driven to push boundaries to deliver the best results possible. With the second core value in mind, the company is committed to its customers’ success. And Tomlinson’s growth mindset is focused on team and organizational development.

This includes leveraging platforms like VisionLink to turn job site data into decisions. “We’ve grown into it,” Downing says, noting that tools like Cat Grade and VisionLink didn’t just arrive; they were adopted with purpose.

The tone for embracing new tools and technologies is set by CEO Ron Tomlinson, whom Downing credits as a relentless champion for change.

We’re change-hungry here, but we also know that change is scary.

Ryan Downing Vice President of Materials and Operations, R.W. Tomlinson Limited

“Ron pushes us to find technology and to use that technology to make the business better,” Downing says. “Sometimes he’ll even go out and buy the tools before anyone else is on board, just because he knows they’re going to be good for the company.”

That mindset isn’t new. Ron’s father, Bill, who led the company through its second generation, had the same forward-thinking approach. And now, with weekly leadership meetings that include cross-departmental decision-making, Tomlinson treats technology adoption not as an isolated initiative, but as a shared operational priority.

A long-standing commitment to innovation laid the foundation, but a significant highway project, undertaken over 15 years ago, propelled Tomlinson into the next phase of technology adoption. GPS-based technology and 3D grading tools soon followed, becoming common across their fleet.

“We just felt like we were behind and we wanted to be ahead,” says Downing. The early goal was simple: improve accuracy and remove guesswork for field crews. Over time, the company has evolved its use of technology to address broader operational challenges like cost control, fuel efficiency, scheduling, and

asset management. With VisionLink, Tomlinson now monitors everything from real-time utilization and idle time to fuel-consumption metrics and site-wide productivity.

“A machine sitting, not running, is expensive. A machine sitting, running, but not working, is even more expensive,” says Downing. “VisionLink helps us understand those patterns and act on them.”

Within a few years, Downing says Tomlinson had acquired more surveying technology than any dedicated surveying company in Eastern Canada.

Change doesn’t always come easy in construction. Downing acknowledged the skepticism that can arise when introducing new systems, especially among experienced operators. But the company has learned to meet resistance with structure and support.

“We’re change-hungry here,” says Downing. “But we also know that change is scary.” Tomlinson doesn’t just roll out a new tool and expect it to work. The company understands the value in providing its team with the training, the calibration, and the time to become experts in the new tools.

Downing emphasizes that success only comes when users are fully engaged. “[Support] enables people to adopt the ability to change. We try to get people’s mindsets around the fact that [they] can change and [they will] be successful.”

That philosophy extends across the company. Operators are encouraged to make suggestions and test innovative solutions, while internal teams and field crews are supported by dealer expertise and in-house training. Downing acknowledges Caterpillar’s authorized dealer, Toromont Cat, for facilitating the smooth integration of new machines and VisionLink tools.

John Windle, machine sales rep for Toromont Cat, credits Tomlinson’s success with technology to its proactive approach and commitment to partnership. He describes how the company doesn’t hesitate to explore new tools and often challeng-

es the dealer to help make it happen. According to Windle, Tomlinson’s trust in its partners creates the kind of working relationship where ideas can be tested quickly, problems can be solved fast, and new systems have room to take hold.

VisionLink’s biggest impact at Tomlinson is how it helps the company turn raw data into actionable intelligence.

Inside the company’s quarries, for example, daily safety meetings begin with operators reviewing site dashboards that show utilization and idle time. “The guys have turned it into a bit of a competition,” says Downing. “They’re competing with other sites to see who can get the lowest idle time. That saves fuel, saves wear on the equipment, and makes everything last longer.”

On the logistics side, VisionLink enables direct communication between scales and loaders. Loaders know what product they are moving, how much they’ve moved, and which truck is waiting. The result? Faster load times, reduced wait times for customers, improved allocation of equipment across multiple business units, and better customer service.

Downing explains that Tomlinson’s integrated operations give them a unique advantage. “If that machine’s working at a quarry or if it’s working at our C&D facility, it doesn’t matter to me,” he says. “I want to know what it’s doing, how it’s doing it, and how it fits into the broader picture of what we’re doing from a construction or a materials or recycling standpoint.”

Tomlinson’s embrace of digital maturity goes beyond equipment and OEM platforms. The company has also made significant strides in building its own technology infrastructure and developing internal tools that solve real job site challenges.

One such tool is a mobile consumables inventory app that enables foremen to order job site materials through an interface that functions much like the Amazon app. Orders are routed internally and typically fulfilled by the next day, helping reduce

friction in site-level procurement.

To support this kind of tech-enabled workflow, Tomlinson employs in-house app developers tasked with building, customizing, and refining the digital tools that support operations. While the company occasionally collaborates with third-party developers, most of its core applications are designed in-house to better align with internal processes and allow for faster iteration.

That internal capability has helped the company refine solutions based on field feedback, maintain a higher degree of control over how technology is deployed, and accelerate adoption. It also lays the groundwork for smooth integration with platforms like VisionLink, ensuring that telematics from OEM systems can be leveraged effectively within Tomlinson’s broader tech ecosystem.

Growth at Tomlinson doesn’t just mean scaling operations. It means empowering people through smarter tools and training and building a workforce that’s ready for what comes next.

“You have to have the old-school construction mentality to be a construction company,” says Downing. But Tomlinson doesn’t just hire farm kids who know how to run equipment anymore. They also want the gamers, the people who understand tech, and the ones who want to sit in a chair and run equipment remotely.

Tomlinson’s investment in in-house apps, AI integration, and systems innovation attracts younger talent and keeps experienced workers engaged in continuous learning. This investment is supported by Caterpillar’s evolving technology ecosystem, including VisionLink’s interfaces and advanced assistive controls that make on-boarding easier for new hires and upskilling easier for seasoned pros.

The company has even collaborated with start-ups to build custom dispatching and consumables tracking apps that

support job site efficiency. Tomlinson co-developed a custom truck dispatching tool with the start-up company, Tread, transforming it into a fully integrated dispatch platform. The app uses minimal cell data to track hired trucks and GPS data to streamline payment workflows. This solution now supports real-time logistics visibility across job sites. And while some of that innovation is still maturing, Downing says it’s not about perfection, it’s about commitment.

“We’ll try anything that looks attractive. We’re not afraid to see it fail,” Downing says. Tomlinson will put new tools through all the rigours. “That’s part of a process to make sure that you have something that works at a really high level.”

Not every company is ready to (or needs to) adopt technology at Tomlinson’s pace. But for those on the fence, Downing has a clear message: construction technologies are ready. Are you? Just as important as adopting the tools, Downing underlines the need to commit to the process to achieve success. Technology isn’t necessarily the problem when things go wrong. It’s often a lack of training, integration, or follow-through. Without full commitment, proper training, and consistent use, he notes, even the best systems can be mistakenly blamed for failure.

“That’s why people may fail with it,” says Downing. “They’ll try it, they’ll make a mistake with it, they blame it on the tech, and then they move on.” He urges contractors to engage directly with equipment and technology partners to tailor solutions to meet their real job site needs.

At Tomlinson, embracing technology is essential. This mindset is built into the way they lead, the way they work, and the way they think about the future of construction. In an industry where operational insight and efficiency are now critical, that might just be the company’s greatest competitive edge. HEG

Hamm’s new G-Tier soil compactors, the HC 100i and HC 130i, have operating weights between 11 and 13 metric tons (25,832 and 29,745 pounds) and can be supplied with a smooth drum or a padfoot drum. They meet the EU Stage V and EPA Tier 4 Final exhaust emission standards.

Hamm says the new compactors, with a drum width of 2,140 mm (84.3 inches), deliver high centrifugal forces and linear loads. ECO mode allows users to drastically reduce their diesel consumption without compromising on compaction power. When ECO mode is engaged, the frequency and compaction forces remain consistently high even at a reduced engine speed, which not only saves fuel but also cuts CO2 emissions.

The machines achieve excellent gradeability and have triedand-tested three-point articulation that guarantees a high level of manoeuvrability, stability against overturning, and excep-

tional traction. The new compactors are powered by an 85-kW John Deere engine.

Various options are available for the new models, including compaction measurement with the Hamm Compaction Meter, a process data interface, padfoot shells, a powerful lighting package, and an automatic vibration system.

The working environment of the new compactors is designed to be ergonomic and can be customized with a range of options. These options include the ROPS cabin with heating and air conditioning functions, a tilting steering column, and a variety of types of seats designed to meet the different needs of operators.

Maintenance points are easy to access, making servicing the machines simple, which keeps downtime brief and ensures smooth operation.

THE ALL-NEW

Designed for construction, demolition and quarry applications, including underwater jobs, our comprehensive breaker line includes 12 models. Blue Diamond Breakers are compatible with excavators, mini-skid, skid steer and compact track loaders. Every one of our breakers features:

• Solid mono-block design; only 2 moving parts.

• Anti-blank firing to protect internal components.

• A unique poly case shell for vibration dampening.

• Interchangeable machine mounting brackets.

THERE’S SIMPLY NOTHING LIKE IT IN THE INDUSTRY.

Choose Blue Diamond –where all we do is elevate everything you do.

Ready to meet the most durable breaker in the industry? Visit us at www.bdabreakers.com!

ATTACHMENTS - IT’S ALL WE DO

BY KAITLYN TILL, EDITOR IN CHIEF

With better visibility, more technology features, easier-to-access maintenance points, and fewer points to regularly service, the forthcoming next-generation Cat 140 motor grader, previewed at bauma 2025, is designed to improve total cost of ownership, reduce fuel consumption, and keep the operator comfortable and aware of their surroundings.

Marina Makarova, regional product application specialist for Cat motor graders in Africa, the Middle East, Europe, and Central Asia, was on hand to give bauma visitors a tour of a pre-production model.

“The main focus was on improving the operating and maintenance efficiency. We tried to reduce fatigue for the operator, so that they would stay focused on the performance of the machine,” said Makarova, who began the tour by pointing out the most striking visual update.

The redesign starts with the front chassis, which is lower to improve the operator’s visibility, and the fuel tank has been integrated into the front chassis for optimized centre of gravity. The cab now has a hexagon shape, similar to Cat’s next-generation 120 motor grader, to give the operator better visibility to the moldboard.

Moving into the cab, operators will appreciate easy access to operating functions, the new 360-degree camera option, and diagnostic information all accessed via a 10-inch touchscreen. The comfortable new seat with ride indicator gives feedback to the operator on whether the seat suspension is appropriately adjusted to their weight. Cat has also updated its three-axis joystick controls, making steering, controlling the implement, and switching between forward and rear tools, easy. Once inside the cab, the benefit of the cab shape change from square to hexagonal was obvious — the view to the moldboard was excellent.

Mastless 3D grade control keeps the moldboard on target; according to Makarova, the mastless solution also improves

The updated Lever version of the 140 will also feature the new cab design, as well as the new technology, maintenance, and operator comfort features.

the motor grader’s range of motion for easier, more accurate grading on side slopes.

Makarova demonstrated easy access to service components, including oil and filter maintenance points. Cat has also updated the engine pre-cleaner to improve cooling capability which reduces fuel consumption. Maintenance activities can be tracked in VisionLink, which will remind technicians when preventive maintenance tasks need to be done.

Cat has also made access to the braking disc easier by changing it from an internal design to an external design so that the technician does not need to disassemble the transmission to troubleshoot it.

Makarova added that Cat has improved the robustness and penetration performance of the ripper. A new technology option on the 140 monitors tire slippage when the ripper is in use and adjusts the height of the ripper to compensate.

The new high-performance circle on the 140 is based on the slew bearing from the Cat 320 excavator. It is totally closed and sealed from the bottom, which reduces the number of routine adjustments needed to keep the circle tight and the number of movable wear parts that need to be replaced. With regular greasing the operator is good to go.

The new Cat 140 motor grader will go into production in Q1, 2026. HEG

CAT’S NEXT-GENERATION 140 MOTOR GRADER FEATURES A NEW HEXAGONAL CAB DESIGN FOR BETTER VISIBILITY TO THE MOLDBOARD.

THE NEW CLOSED, HIGH-PERFORMANCE CIRCLE ON THE CAT 140 MOTOR GRADER REQUIRES LESS ROUTINE MAINTENANCE THAN OPEN CIRCLES.

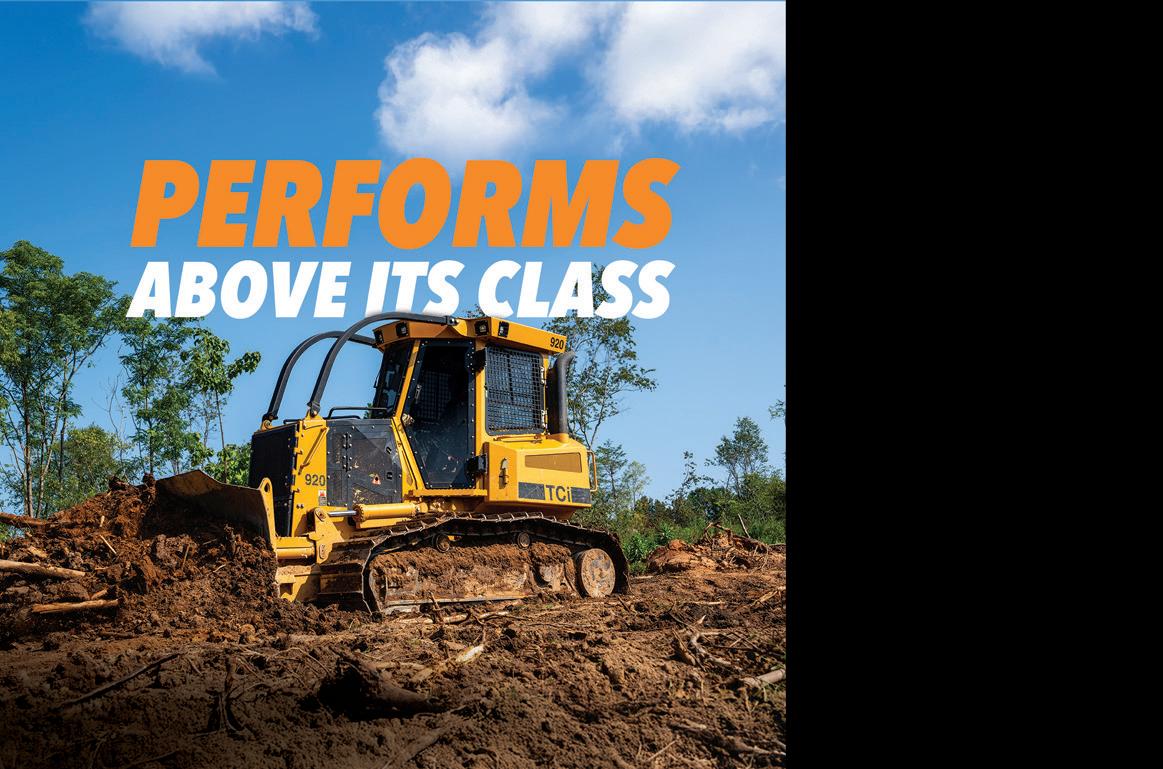

The 920 moves more, pushes harder, and finishes the job faster.

ESSENTIAL STEPS TO PROTECT YOUR ASSETS

As the weather begins to cool and the days become shorter, the time for equipment storage draws closer, providing the perfect opportunity to perform proper end-of-season maintenance on your roadbuilding, construc tion, and utility equipment to ensure your fleet is ready to hit the ground running come spring.

Making time for service tasks and repairs during the busy construction season is crucial for understanding your equipment’s mechanical condition, but not always possible. Proactive care in the off-season helps avoid unexpected downtime and costly repairs, keeping your machines operating at peak efficiency. Consider completing:

A full mechanical inspection: Check critical components like belts, hydraulic hoses, bearings, and brakes, paying special attention to worn items often overlooked during peak operations on aging equipment.

Tires and tracks checks: Maintain correct inflation, prevent flat spots, or track damage during storage by inspecting for cuts, punctures, wear, and proper inflation.

Scheduled service: While you should always follow the manufacturer’s suggested maintenance schedule, ensure you change engine and hydraulic oils, replace filters, inspect air intake systems, and keep grease points well-lubricated.

available and need to store your equipment outdoors, be sure to use breathable covers and inspect your machines regularly for any animal intrusion or fluid leaks.

Construction equipment is routinely exposed to dust, mud, and debris, elements that, if not properly addressed, can accelerate wear and create a breeding ground for corrosion. Implementing a cleaning process at the end of each season — including complete debris removal and a thorough washing of both exterior surfaces and undercarriages — is essential. These preventive measures help maintain equipment integrity, support optimal machine performance, and ensure equipment remains in peak condition while in storage, or for continued use throughout the winter months.

appropriate levels and adding fresh fuel and stabilizer to the fuel tanks. Run the engine for at least five minutes to allow the stabilizer to enter the rest of the fuel system. If you’re planning on storing your equipment for a while, most fuel stabilizers claim to keep gas good for up to 24 months. Alternatively, you can siphon the fuel out of the tank and run the machine until it’s dry. While this process takes time, it provides the comfort of adding fresh fuel come spring. However, if you plan on mov ing your machine at all, this wouldn’t be the best option. Depending on space availability, it is always preferred to store equipment indoors where it can be protected from the elements and minimize risk of animal interference. If you don’t have the space available and need to store your equip ment outdoors, be sure to use breathable covers and inspect your machines regularly for any animal intrusion or fluid leaks. You can check this by placing drip trays or cardboard underneath.

By completing these end-of-season maintenance steps, you safeguard your equipment investment and ensure your con struction and roadbuilding fleet is ready to perform reliably and efficiently when the next season begins.

PROPER CARE HELPS MAINTAIN EQUIPMENT INTEGRITY, SUPPORTS OPTIMAL MACHINE PERFORMANCE, AND ENSURES THAT EQUIPMENT REMAINS IN PEAK CONDITION WHILE IN STORAGE, OR FOR CONTINUED USE THROUGHOUT THE WINTER MONTHS.

CONSTRUCTION EQUIPMENT IS ROUTINELY EXPOSED TO DUST, MUD, AND DEBRIS, ELEMENTS THAT, IF NOT PROPERLY ADDRESSED, CAN ACCELERATE WEAR AND CREATE A BREEDING GROUND FOR CORROSION.

The new 109-hp 4TS Teleskid and 400T compact track loader (CTL) are the largest models in JCB’s compact track loader lineup. The new Teleskid model is a step up in size from the 3TS teleskid, a machine unique to JCB that combines the capability of a CTL with the extended reach of a small telehandler. Both machines deliver more horsepower and higher torque for operators tackling tougher jobs.

The new 4TS Teleskid reaches nearly two full feet higher than the 3TS. Featuring a 15-foot lift height and nearly 4,000 pounds rated operating capacity, the 4TS eliminates the need for a separate telehandler in many situations, providing a single machine that handles everything from grading and trenching to material handling and loading.

Its compact profile — 13,000 pounds SAE operating weight and 6 feet 10 inches in overall height — enables it to navigate tight spaces with ease while excelling in heavy-duty applications. The 4TS is suited to stacking, loading, and accessing hard-to-reach areas. Addressing feedback from 3TS owners, the 4TS is designed to run high-flow attachments even when the boom is fully extended, overcoming a key challenge and expanding its capabilities for complex job site operations.

The 4TS features a newly designed low-leak valve body that prevents boom drift, ensuring materials stay exactly where you need them, even when the boom is fully extended.

For demanding applications like forestry, snow removal, and land clearing, the 12,544-pound 400T delivers power and durability. Its redesigned chassis and expanded cooling pack eliminate the need for auxiliary coolers, ensuring optimal performance during extended high-flow operations. Delivering over 40 GPM of hydraulic flow at 4,000 PSI, the 400T powers flow-intensive attachments like drum mulchers with ease.

The G73 is an efficient grading solution for 30- to 50-hp compact track loaders and articulated wheel loaders. SharpGrade says that the G73 fills a long-standing gap for contractors requiring professional-grade accuracy on small, challenging job sites, while still retaining the capacity to grade open areas quickly. The attachment can also grade in reverse. Fully articulated with the wings closed, the G73 measures just 45.5 inches (1.15 m), yet opens to 73 inches (1.85 m) with large hydraulic side wings. Multiple hitch options are available. Rotation Sensor, IMU mounts, and external data ports are available to plug and play most 3D solutions, including GPS and LPS.

QuadGrade Power Pro, which allows the operator to control all functions directly from the touchscreen while in auto mode, is integrated with no wiring on the base machine, which SharpGrade says is an industry first. This plug and play solution is ideal for rental companies and large fleet operators with multiple machines.

The HDX Series Grapples, which includes both root grapples and grapple buckets, fits between Blue Diamond’s HD and Severe Duty Grapples. They are designed for midsize skid-steer loaders, CTLs, and tractors up to 75-hp.

The wide opening of the HDX Series Grapples allows the operator to grab bulkier items in one load. Uneven or awkward material is stable and secured by the independent acting top clamps with commercial-grade hydraulic cylinders for maximum clamping force.

FAE has entered the rotary cutter market with the new RCM/SSL attachment for 75- to 150-hp skid-steer and compact track loaders. It is engineered for the removal of underbrush and vegetation measuring up to 4 inches in diameter (up to 10 inches max intermittently). FAE says that it is also ideal wherever speed takes priority over final product size and when the control of discarded material is not a concern.

The attachment is equipped with N blades and will initially be available in the RCM/SSL-175 size. The RCM/SSL-200 version will be available at a later date.

The Ammann ARR 1575-2 is 23.6 inches (600 mm) wide with optional drum extensions up to 33.9 inches (860 mm). Dual eccentric shafts per drum and a two-stage vibratory system provide adjustable amplitude from 0.6 to 1.2 mm, centrifugal force from 34 to 72 kN, and a frequency of 40 hertz for compaction on various materials and layer thicknesses. Its oscillation mechanism and central steering joint maintain stability and ground contact. The remote control includes defined working and safety zones. The battery lasts for 16 hours and can be charged on board or can be removed for external charging. Maintenance-friendly features include a welded frame, wide-opening hoods, and ServiceLink telematics.

The Hamm HTC 15 features two 32-inch (810-mm) padfoot drums, and is ideal for cohesive soils. Its low centre of gravity reduces tipping risk. The infrared remote control operates with three sensors to maintain sightlines, and the transmission automatically stops if the operator’s line of visibility is lost. Weighing 1,456 kilograms (3,210 pounds), the roller is compact and easily transportable. Drum width extensions are included as standard, increasing versatility. Tip-over engine protection boosts safety, while straightforward access to service points supports routine maintenance. Its articulated design allows precise movement in confined trenches.

3

The Wacker Neuson RTD-SC4 has adjustable drum widths from 23.6 to 32 inches (600 to 820 mm) and a 19.8-hp Kohler KDW1003 diesel engine. Its asymmetric articulated frame reduces hoses and components by more than 30 percent, enhancing serviceability, and the transmission and exciter are designed for 1,000 hours of operation between maintenance. An automatic return to centre steering function minimizes constant adjustments during trench compaction. Radio remote control includes pre-tip alarms, tip-over shut-off, and proportional hydraulics for smoother operation. Optional COMPATEC compaction monitoring and EquipCare telematics provide compaction and maintenance data.

BY SAM ESMAILI, ASSOCIATE PUBLISHER

Sitting on a little more than 50 acres in the Emilia-Romagna region of Northern Italy is Magni Telescopic Handlers’ newly constructed, state-of-the-art facility where the company’s telehandlers are manufactured. These multi-tool, multi-application machines are distributed around the globe and utilized by a variety of industries.

This summer, Heavy Equipment Guide was fortunate enough to be invited to visit Magni’s headquarters. The facility, which was completed in May 2021, features almost 500,000 square feet of manufacturing, testing, storage, and office space. Carefully designed with sustainability and social responsibility in mind, the plant generates 1,000 megawatt-hours of solar energy every year, which meets about 25 percent of the facility’s overall energy needs. The trip certainly did not disappoint as I was introduced to the vibrant culture of this rapidly growing company and its more than 600 employees led by the founder, Mr. Riccardo Magni.

Although Magni Telescopic Handlers was founded in 2013, its roots go back to post-WW2 and Riccardo Magni’s father, Pietro Magni, who worked as a mechanic. The Magni family comes from the “Motor Valley” of Italy, the home of many well-recognized motoring brands, including Lamborghini, Maserati, Ferrari, and Ducati, but the Magni family had an agricultural background. Pietro wanted to pursue something more in line with his own personal passion: the automotive industry.

Pietro started by purchasing trucks and machinery that had been left behind by the U.S. and Allied forces after the war. He used the parts and components of these machines to build and repair tractors. This venture began to grow, and he applied his knowledge to developing parts and retrofitting tower cranes for a company in the area. He eventually decided to sell this company and create a new one. This was a turning point for the Magni family. In 1972, Pietro, along with his children, including Riccardo, founded the equipment company Fargh SpA in Castelfranco Emilia — where Magni Telescopic Handlers is headquartered today.

RTH 6.31 IS PART OF THE COMPANY’S EXPANSIVE ROTATING TELEHANDLER LINEUP, WHICH NOW INCLUDES 20 MODELS.

Pietro started developing hydraulic cranes of his own for Fargh SpA before creating the company’s first telehandler for a construction company in Modena, Italy, in 1980. At the time, telehandlers were not well known in the region. Unfortunately, in October 1981, Pietro Magni passed away. The leadership of the company then transitioned to Riccardo Magni.

Riccardo Magni had begun his career as a lawyer, but his passion, like his father’s, was in engineering mechanics and building machinery.

“My passion from the very beginning, from when I was very very young, was mechanics,” Magni said. “I was living in a family where we were building, fixing, and engineering every day. As a matter of fact, almost all the machines that we have now, I designed. I generally don’t design a machine that the market expects. I do just the opposite — I design the machine and I propose it to the market.”

Under the leadership of the younger Magni, the company moved away from manufacturing cranes and focused solely on the telehandler, which, at the time, had near-zero market share within the construction equipment space. Magni was fascinated by telehandlers because he saw that there was more diverse opportunity for them in the industrial market, and their versatility extended beyond the basic function of lifting loads.

In 1982, at age 29, Magni met with Manitou founder Marcel Braud and started a long relationship and collaboration between the two companies where he led the development of telehandlers for Manitou. In 1985, Manitou purchased 51 percent of Fargh SpA.

The Manitou-Fargh collaboration, which became the company Manitou Italy, continued for over 27 years until 2008 when Magni decided to part ways with the Manitou organization, no longer approving of the direction of the company.

His departure was finalized in 2009, and, after a three-year noncompete agreement expired, Magni, along with his four children, founded Magni Telescopic Handlers SRL in January 2013. Magni was looking to once again showcase the family’s

We wanted to make the highestperforming rotating machines, which weren’t common, using our knowledge. This was our competitive advantage.

Riccardo Magni

Founder & CEO, Magni Telescopic Handlers

extensive knowledge and experience in the telehandler space. He started by introducing two rotating telehandlers: the RTH 4.22 and the RTH 4.26.

“I wanted to show what we are able to do,” Magni said. “And I wanted to leave my children with our family business.”

By 2015, the new company offered 21 telehandler models across three product categories: Rotating Telehandlers (RTH), Heavy Lift Telehandlers (HTH), and Fixed Boom Telehandlers (TH). In 2016, Magni introduced the RTH 6.46 SH which held the title as the highest-reaching rotating telehandler until 2020, when Magni introduced the RTH 6.51 SH. The RTH 13.26, introduced in 2019, is still the highest-capacity rotating telehandler on the market.

“We wanted to make the highest-performing rotating machines, which weren’t common, using our knowledge. This was our competitive advantage,” said Magni.

EXHIBITS: JANUARY 20-22, 2026

EDUCATION: JANUARY 19-22, 2026

LAS VEGAS CONVENTION CENTER

Push limits. Smash barriers. Break boundaries. And when you’ve conquered all those obstacles? You discover your full capacity for greatness. World of Concrete delivers all the real-world solutions that will crush your challenges and take your expertise to new heights. Growth opportunities are everywhere, whether you’re getting hands-on with game-changing tools and tech or shaking hands with your future partners. Ready for maximum success? Nothing’s standing in your way.

ACHIEVE PEAK PERFORMANCE VIEW GLOBAL EVENTS

By the late 2010s, the company had turned its focus to expand ing globally by establishing subsidiaries in France, Germany, the U.K., Poland, Belgium, South Africa, the U.S., and two repre sentative offices in Southeast Asia and Central-South America. These subsidiaries were set up to support the network of over 200 dealers serving 63 markets worldwide. In Canada, Magni telehandlers are distributed through a dealer network that includes Stanmore Equipment and Cropac Equipment; with six dealers, Magni TH is able to cover Eastern and Western Canada.

But, impressively, major growth began to take shape in 2021. Starting that year, the company accelerated to levels it had not previously seen, while many in the industry were hard hit by COVID-19 pandemic challenges. Magni’s growth trend continued year-over-year until 2023 when the company tripled its revenues from three years earlier.

When I asked Magni how the company was able to sustain such growth during a time of challenges relating to parts and components shortages, which were widely felt during the COVID-19 pandemic, he replied, “We were lucky as our new facility was finalized and ready in May 2021. We had followed the market and could see the market changing rapidly, so we took advantage of our new facility and space by ordering a great number of parts early on.”

He also highlighted the company’s strong partnerships with its suppliers, which helped along the way, and are what he considers to be the Magni advantage. These include Liebherr (which supplies rotating components), as well as Deutz Engines, Volvo Penta Engines, SSAB High Strength Steel, Dana, and others.

“When it comes to winning points [with customers],” he said, “I would have to point to our cab: the shape, visibility, space, comfort, and touchscreen technology. It is also hermetically sealed for sound and dust insulation. We have a terrific cab. Now we see many competitors following our design, which is flattering. Currently we hold 115 patents.”

In 2025, Magni Telescopic Handlers’ full equipment lineup includes 20 RTH models, 16 TH models, 9 HTH models, and 8 THA models developed for agriculture.

While the company is best-known for its larger, high-reaching machines, at bauma 2025 Magni displayed its most compact telehandler, the recently introduced TH 3.6, which is equipped with a new compact cab that gives the operator total visibility. A 7-inch touchscreen with the Magni Combi Touch System

(MCTS) on-board software grants complete control of the machine for a unique user experience via icon-based navigation. In addition, the TH 3.6 is outfitted with Load Moment Indicator (LMI), a sophisticated and precise anti-tipping system that provides constant monitoring of the vehicle’s movement to avoid any kind of overloading.

He concluded the visit with his thoughts on the future and the direction of the company. “There are many things that we are doing,” said Magni. “For starters, we will be launching our first fully electric machines later this year. This is our entry into this space with four models including an electrified version of the TH 3.6. This will complement our dual-power offerings and will work well in certain applications.

“Though we are not so sure about a fully electric future, some of our customers have asked for this solution and we will provide [it to] them.”

After nearly 50 years of championing telehandlers around the world, Riccardo Magni would like to continue to lead and expand Magni’s footprint globally. When asked if he will wind down his career, he said, “I know this industry very well. Though I enjoy riding my motorcycles when I’m not running the business, I would very much like to stay involved. My son Carlo Magni, who is currently vice president of the company, is likely to take on more responsibility in the coming years.”

Magni telehandlers will be showcased at two North American trade shows, including at The ARA Show and CONEXPO-CON/ AGG, early in 2026. HEG

THE RIGHT EQUIPMENT HELPS YOU GET THE JOB DONE, BUT KNOWING HOW TO USE IT SAFELY KEEPS YOUR TEAM PROTECTED BY JUSTIN WHARTON

Aerial lifts are everywhere, and like any piece of heavy equipment, they come with their own unique risks. When you’re 100 feet in the air, there’s zero room for error. Electric shocks from power lines, severe weather, falls, and even tip-overs all threaten worker safety. But when used properly, they offer major benefits: saving time, reducing labour needs, and allowing quick set-up and repositioning.

That’s why choosing the right equipment and the right rental partner is critical. A provider who keeps pace with the latest safety standards and equipment advancements gives you access to the machines to keep your team productive and protected.

But equipment alone isn’t enough.

Busy job sites come with complex safety and compliance challenges. What you need is a partner who goes above and beyond by offering training, resources, and expert support to ensure your crew can operate safely and meet regulations. Because the right lift paired with the right expertise keeps your job productive, your team protected, and gives you the competitive edge you need to succeed.

Safety isn’t a one-time checkbox. It’s a daily commitment. No one wants to make that call after a job site accident that was completely preventable. Because the moment you hear “There’s been an incident,” everything changes. Projects halt, investigations begin, and families are forever affected. The impact doesn’t end with the accident. Morale takes a hit. Projects stall. Insurance costs rise. Your reputation is on the line.

Safety isn’t a one-time checkbox. It’s a daily commitment.

Properly trained workers can proactively identify, assess, and control potential hazards. They recognize warning signs: unstable ground conditions, overhead power lines, changing weather patterns, or equipment showing signs of wear. In many Canadian provinces, working at heights training is mandatory for anyone on construction sites using fall protection systems. This isn’t just regulatory compliance — it’s life-saving education.

Choose a rental partner who doesn’t just deliver the lift but also trains your team on how to use it safely and confidently. Classroom sessions build knowledge. Hands-on instruction builds habits. Pairing new workers with seasoned mentors is another effective way to reinforce safety best practices and establish accountability from day one.

Safety training goes beyond basic certification. A safety-first culture encourages openness, continuous improvement, and feedback. We practice daily “Take 10” sessions so crews can discuss concerns and specific hazards they’ll face that day. Toolbox talks are another way to keep safety conversations fresh and relevant. Create a space for workers to voice concerns, share experiences, and learn from each other.

Aerial lifts aren’t just becoming safer, they’re becoming smarter. Innovation in equipment design and updated ANSI safety regulations means we have access to valuable data on machine health and usage. We can even monitor operator behaviour to help identify when additional training may be needed.

Unexpected equipment failures can bring jobs to a halt or leave operators stranded. Advancements in load-sensing hydraulics and tilt alerts help prevent dangerous operations, like lifting with too much weight or working on unsafe slopes. And instead of relying solely on scheduled inspections, telematics can deliver immediate alerts when equipment issues arise.

But technology is only powerful when it’s put to good use. It’s not just about collecting data, it’s about using insights to make smarter decisions. It’s common to see the wrong equipment application on a job site, like using an articulating boom where a straight boom would be safer and more efficient, or deploying a large rough-terrain scissor lift when a smaller battery-powered model would get the job done with less cost and impact. These mismatches can create avoidable safety risks, reduce productivity, and drive up operating costs.

That’s why it’s so important to work with an experienced, professional equipment provider. The right partner will assess your project needs, understand the site conditions, and match each task with the most appropriate equipment, delivering safer, more efficient, and more cost-effective outcomes every time.