AUGIWORLD

Customize, Develop, Create

AUGI Members Reach Higher with Expanded Benefits

AUGI is introducing three new Membership levels that will bring you more benefits than ever before. Each level will bring you more content and expertise to share with fellow members, plus provide an expanded, more interactive website, publication access, and much more!

Basic members have access to:

• Forums

• HotNews (last 12 months)

• AUGIWORLD (last 12 months)

DUES: Free

Student members have access to:

• Forums

• HotNews (last 24 months)

• AUGIWORLD (last 24 months)

• AUGI Educational Offerings

DUES: $2/month or $20/year

Professional members have access to:

• Forums

• HotNews (full access)

• AUGIWORLD (full access and in print)

• AUGI Library

• ADN Standard Membership Offer

DUES: $5/month or $50/year

Small

Enhancements in Civil 3D

Establishing

Leaving Breadcrumbs: A Journey to Develop Traceable and Verifiable Drawing Content

The Quiet Power of DWG Archives

Behind every building, product, or piece of equipment is a record that design and engineering teams return to again and again: DWG archives that span years of design work. These drawings document the lifecycle of projects, from original concepts to asbuilt details, and they continue to carry weight long after the work is complete.

A facility upgrade may require archived drawings to meet the requirements of a permitting office. A hospital expansion depends on as-built floor plans to understand existing layouts. In manufacturing, equipment repairs often rely on part drawings

created years ago. Across industries, DWG archives serve as the thread that ties together design history, compliance records, and future updates.

WHY 2D STILL MATTERS

The growth of 3D modeling and BIM has transformed the design process, but 2D drawings remain the most widely used format for documentation. Floor plans, schematics, and permit drawings provide clarity that regulators, contractors, and fabricators expect. For compliance and communication, DWG remains the common language.

Cost and efficiency are also key factors. Not every project requires a full 3D workflow, and tasks such as plant layouts, schematics, or quick design iterations are often completed more efficiently in 2D. For organizations with decades of DWG archives, abandoning 2D entirely is neither practical nor economical. A dependable CAD system must respect this history while supporting both 2D and 3D workflows.

DWG FILE COMPATIBILITY AND DIGITAL CONTINUITY

An archive can only be useful if it is accessible. Drawings must open reliably, display accurately, and update without disruption. A file created fifteen years ago should be just as dependable and accessible today as it was the day it was created. DraftSight’s DWG compatibility provides that stability, giving organizations confidence that their archives remain usable.

For manufacturers, digital continuity means part designs remain available for service and repair. For architects and builders, it keeps drawings accessible for compliance reviews and renovation projects. Many industries also face regulations that require the retention of design documentation for years, sometimes even decades. Legacy DWG files may be required in legal disputes, intellectual property verification, or to meet contractual obligations. Reliable access protects organizations from delays, uncertainty, and costly rework.

BRIDGING 2D AND 3D WORKFLOWS

Design work today rarely happens in a single environment. Teams move between BIM, SOLIDWORKS, and other 3D platforms, while still depending on 2D drawings for permits, fabrication, and revisions. DraftSight supports this dual reality, keeping DWG workflows efficient alongside modern 3D tools.

This balance is especially important during project handoff. In construction, deliverables for permitting and turnover are still 2D drawings derived from BIM models. In manufacturing, service teams continue to rely on DWGs long after a product has left design. DraftSight ensures that documentation remains accurate and accessible, allowing approved work to continue supporting projects throughout their lifecycle.

DWG archives hold years of knowledge and preserve the integrity of past projects. More importantly, they continue to serve as trusted resources for the work underway today. With DraftSight, those archives remain accessible and reliable, ensuring that the designs of yesterday continue to support the projects of tomorrow.

DRAFTSIGHT LIVE: PREPARING FOR WHAT’S NEXT

This fall, the DraftSight LIVE virtual event will spotlight what’s next for 2D CAD, including the debut of DraftSight 2026. Sessions will highlight new features designed to streamline daily work, including improved reference management, customizable workspaces, and performance enhancements for large files. The event provides a first look at how DraftSight continues to evolve while maintaining dependable and efficient DWG workflows.

REGISTER TODAY TO RESERVE YOUR SPOT AND BE AMONG THE FIRST TO EXPERIENCE DRAFTSIGHT 2026.

Letter from the Editor

Ijust got back from Autodesk University 2025. I think I am overloaded with AI content. All-in-all it was a good event. Got to see some friends and of course AUGI staff and members!

This month we focus on customization.

Customization in software refers to modifying existing software tools to better meet specific user needs or project requirements. This can involve creating tailored features, tools, or add-ons that enhance functionality and improve efficiency in design and engineering processes.

This topic definitely resonates with me. We have so much customization in our set up at the office. Having things set up with customization as we do, it helps with the speed and ease of overall production.

Customization in software is essential for organizations seeking to optimize their processes. By tailoring applications to specific requirements, businesses can enhance productivity, improve security, and achieve better overall performance.

I hope each one of you can learn something valuable from our many, seasoned authors. Keep on CADomizing!

AUGIWORLD

www.augi.com

Editors

Editor-in-Chief

Todd Rogers - todd.rogers@augi.com

Copy Editor

Miranda Anderson - miranda.anderson@augi.com

Layout Editor

Tim Varnau - tim.varnau@augi.com

Content Managers

3ds Max - Brian Chapman

AutoCAD - Open

AutoCAD Architecture - Melinda Heavrin

BIM/CIM - Stephen Walz

BricsCAD - Craig Swearingen

Civil 3D - Shawn Herring

Electrical - Mark Behrens

Manufacturing - Kristina Youngblut

Revit Architecture - Jonathan Massaro

Revit MEP - Jason Peckovitch

Tech Manager - Mark Kiker

Inside Track - Rina Sahay

Advertising / Reprint Sales

Nancy Tanner - sales@augi.com

AUGI Executive Team

President

Eric DeLeon

Vice-President

Frank Mayfield

Treasurer

Todd Rogers

Secretary Kristina Youngblut

AUGI Board of Directors

Eric DeLeon

Chris Lindner

Frank Mayfield

Todd Rogers

Shelby Smith

Scott Wilcox

Kristina Youngblut

AUGI Advisory Board of Directors

Gil Cordle

Jason Peckovitch

Rina Sahay

Jeff Thomas III

Publication Information

AUGIWORLD magazine is a benefit of specific AUGI membership plans. Direct magazine subscriptions are not available. Please visit www.augi.com/account/register to join or upgrade your membership to receive AUGIWORLD magazine in print. To manage your AUGI membership and address, please visit www.augi. com/account. For all other magazine inquires please contact augiworld@augi.com

Published by:

AUGIWORLD is published by AUGI, Inc. AUGI makes no warranty for the use of its products and assumes no responsibility for any errors which may appear in this publication nor does it make a commitment to update the information contained herein.

AUGIWORLD is Copyright ©2025 AUGI. No information in this magazine may be reproduced without expressed written permission from AUGI.

All registered trademarks and trademarks included in this magazine are held by their respective companies. Every attempt was made to include all trademarks and registered trademarks where indicated by their companies.

AUGIWORLD (San Francisco, Calif.)

ISSN 2163-7547

Bright Ideas for a Bright Future

AUGIWORLD brings you the latest tips & tricks, tutorials, and other technical information to keep you on the leading edge of a bright future.

Many companies that switch to BricsCAD® need to port over their existing customizations. While customization can also cover the user interface, tool palettes, and CAD settings, we are going to take you through migrating your current AutoCAD® applications over to BricsCAD® and provide some thought leadership on planning along the way.

Let’s start with identifying some of the most popular AutoCAD® APIs. Top of the heap is ObjectARX® (AutoCAD® Runtime Extension), then .NET API, ActiveX, and then we will cap it off with Visual LISP (AutoLISP) (See Fig. 1). Now, let’s look at these one by one.

AUTOCAD .ARX

Converting an AutoCAD® ARX Application to BricsCAD involves porting your code to the BricsCAD Runtime Extension (BRX). BRX is designed to be source code compatible with ObjectARX. This means a significant portion of your existing codebase may function correctly without modification. The BricsCAD platform is highly extensible, supporting an advanced plugin architecture that enables third-party plugins to extend, interact with, and modify the behavior of the application. The BRX plugin architecture provides a .NET API for use by managed .NET plugins, and a C/C++ API for use by native C/C++ plugin modules. (See Fig. 2)

AUTOCAD.NET API

As mentioned, similar to ARX, .NET API involves porting your code to the BricsCAD Runtime

Extension (BRX). And just like ARX, a significant portion of your existing codebase may function correctly without modification.

For both ARX and .NET, there are some aspects to consider for a successful port.

Namespaces: (eg, ‘Autodesk.AutoCAD.Runtime’) should be replaced with (eg, ‘BricsCAD.Runtime’)

API Differences: While largely compatible, consult the BricsCAD API documentation for possible differences and their equivalents. Also, pay close attention to areas where your application interacts with specific AutoCAD features that might not have direct counterparts in BricsCAD. Specific functions or classes might have different names, parameters, or behavior between ObjectARX and BRX. Identify any external libraries or dependencies specific to AutoCAD and find suitable alternatives for BricsCAD.

Other aspects to consider may be dependencies, UI Elements, Dynamic Blocks, and Third-Party tools. Visit the BricsCAD API documentation for developer documentation and resources during your conversion process. (See Fig. 3)

Figure 1

Figure 3

BricsCAD

ACTIVEX

BricsCAD supports ActiveX automation in the PRO, BIM, Mechanical, and Ultimate editions. This compatibility allows you to control BricsCAD from external applications that act as automation controllers (e.g., applications incorporating VBA such as Microsoft Visual Basic). While BricsCAD supports ActiveX, ensure your application logic accounts for any differences between the BricsCAD and AutoCAD object models. Within BricsCAD, you can use VBA to edit and manipulate embedded ActiveX objects, including Microsoft® Word documents and Microsoft Excel charts contained in BricsCAD drawings.

VISUAL LISP/AUTOLISP

With LISP, you can use it to call BricsCAD commands, system variables, and dialog boxes. Most LISP code will load and run in BricsCAD without modification. LISP is similar to AutoLISP. LISP greatly extends the commands and functionality that are available in BricsCAD. As with ARX and .NET, there are some things to consider.

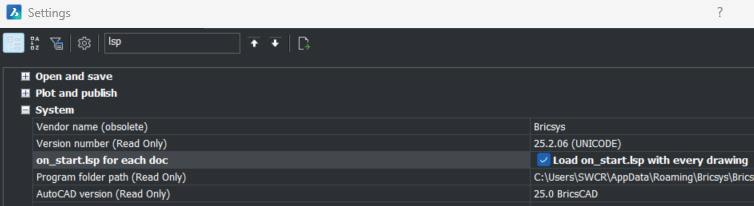

Rename the Automatic Launch Files: If you are using an ‘acad.lsp’, it should be renamed to ‘on_start.lsp’. Subsequently, if you are using an ‘acaddoc.lsp’, it should be renamed to ‘on_doc_load. lsp’. Note: It is not recommended to edit on_start_ default.lsp and on_doc_load_default.lsp. Instead, you should create two new files named on_start.lsp and on_doc_load.lsp. Don’t forget to also ensure your settings are correct. (See Fig. 4)

Support Folder Location: Typically, this would be ‘C:\program Files\BricsCAD V25 en_US\Support’. The exact path can be found by accessing (getvar “SUPPORTPATH”) at the BricsCAD command prompt.

Hard-Coded Paths: Check to see if any specific, hard-coded paths exist. Make sure that they are pointing to an area that is recognised. Remember, when you no longer need AutoCAD, these folders may not be found.

Encrypted VLX/FAS Files: BricsCAD is compatible with AutoCAD® AutoLISP, so it can load and run LSP files. However, the VLX and FAS file formats are AutoCAD-specific specific encrypted LISP files, and BricsCAD cannot load such files.

When the source code for an application is unavailable, rewriting the application becomes a potential solution, although it’s not always the best

Figure 4

approach. This situation can occur in a couple of common scenarios:

• Missing Documentation: Essential tools might lack documentation because a former employee who developed them has left the company.

• Third-Party Software: Vendors often protect the source code of their software.

In the case of third-party software, it is recommended to contact the vendor to request a version compatible with BricsCAD.

CONCLUSION

The more you know before you start, the better, which is why we highly encourage starting this process as early as possible. Once you have recompiled your code, with rocket-like speed and precision, BricsCAD

propels your team forward. Automate, customize. Leverage APIs, LISP, VBA, and BRX. Streamline workflows, boost productivity. Explore BricsCAD’s powerful development ecosystem. Innovate, optimize, achieve more, and blast off with the power of BricsCAD’s BRX. (See Fig. 5)

MORE ABOUT BRICSCAD

Bricsys® BricsCAD® is the true CAD alternative. We are the 2D and 3D CAD alternative that helps you switch smoothly, excel in the detail, and realize better value from day one. Not ready to buy? Download the free, 30-day trial of BricsCAD at Bricsys.com. Would you like free lessons? We have that available with Bricsys Learning. Ready to migrate to BricsCAD? Download the Migration Guide. The latest version of BricsCAD improves the tools and features users love, as well as new functionality and UI that supercharge productivity. Follow us today on LinkedIn and YouTube.

MORE ABOUT BRICSYS

Bricsys®, part of Hexagon®, is the global technology company that creates the BricsCAD family of computer-aided design (CAD) products and the Bricsys® 24/7 project collaboration platform. We are relentlessly committed to the success of our customers by offering cost-effective, missioncritical CAD software with industry-leading product support. Learn more at www.Bricsys.com.

Sir Grant is a part of the EMEA Bricsys team based in the UK. He has a strong client-facing background with the ability to adapt and focus across many disciplines and environments. Grant has a demonstrated history of working in the computer software industry, skilled in BricsCAD, AutoCAD, Production Management, Constructionbased cloud technologies, and Software Development. Grant is a seasoned conference speaker and presenter. In his personal time, he likes to BBQ & volunteer within his community. Additionally, Grant has recently discovered a passion for building intricate parts for his model trains.

Figure 5

Be a Connector

If you are reading this, you are probably a member of AUGI. AUGI exists to connect users to users. It has been doing that for thirty-five years. The connection points include online forums, publications, local and international meetings and more. By connecting user to user, AUGI has enable software users to get answers from the real world. From others who have figured out problems, workarounds and new tools. From those that had once been frustrated, but who now share their knowledge with others.

Chances are you have been connected by AUGI. You now have expanded resources and access to information that you did not have before. Someone probably provided you with an answer to your issues or told you where you might get an answer. That person is what I call a connector. I am a connector. You should be one too. I encourage you to become a connector, expand your connections or establish new connections. Getting connected to others helps everyone.

CONNECTING YOURSELF

It starts with you. You should be connecting with others. Take the initiative and open yourself up to others. Start asking questions. When you meet with others, ask them about their experiences and

share yours. Just the simple act of asking “How did you do that?” when someone tells you about what they have done can link you together with another person that may have a solution to your problems. The first step in becoming a connector is to step outside of your world and reach into someone else’s.

Connect at a vendor event. Don’t just sit there and listen, ask a question. Don’t stay quiet for the entire time, speak up. If you are skittish, keep it short. You don’t have to unload every issue that you have. Just pick one and ask if others have seen anything like it before. Start by talking to the vendors. Trust me, they are dying to talk to you.

Connect to a User Group. It may be at a user group meeting. If you don’t go to one, join one. When you are there, settle in until you feel more comfortable and then speak up. It may take a few meetings for you to see how the flow of the presentations and discussions go. But once you get in the flow, speak up from the audience. And don’t worry about presenting yourself perfectly. We have all been new to a group and a little shy about fitting in. Stop worrying and just say something. It may take a few meetings to feel comfortable talking, especially if you stumble a little the first time. Keep pressing on and get connected.

Connect with Individuals. Once you have connected with a vendor or a group, reach out to individuals. It may be at events still, but you should seek one-to-one connections. It might be over an event lunch break. If you sit at a table with others, introduce yourself and ask the person next to you where they work, what industry they serve, or how big their firm is. Just start a quick conversation. While I am at it, I suggest that you do not eat alone. Don’t grab the box lunch and sit in a corner. Go to a table that has others at it already and take an empty seat. And if you have trouble initiating conversations, then reply to what others say. If someone asks you a question, reply with your answer and then extend that conversation by asking them something.

Don’t forget to make contact with vendor staff and developers. They are always seeking new people to share resources and solutions. Some vendors are very sales focused, but they all usually share their knowledge. It is good to know multiple vendors. Software developers want input also. Tech events are great for sharing with developers. They need to know real world issues with their software and the needs of design teams. They enjoy hearing from you.

CONNECTING OTHERS

Now that you are linked to people by following the easy steps above (yeah, that was easy – like the JOIN command in AutoCAD). Now you should start connecting those you know to people they do not know. This is what I hope you all strive to do. Without any underlying expectation other than helping others, get folks talking to each other.

Some of you don’t have any trouble connecting. You speak up and get involved. You know people and they know you. That is great. You who are connected should then focus on being a connector for others. For those that have trouble associating with others, they may need a connector. Someone that can keep a conversation going or just offer introductions. You can be that connector and link people to people.

Start in your firm. Start networking the staff at your firm to each other. If the firm is large, there are a lot of people who do not know others at the firm. Start a small user group in the company and introduce staffers to others. If your company can pay for pizza, do it at lunch. If they won’t, then

do it during working hours, maybe a 30-minute meeting once a week. Keep it short and focused on productivity, not just chit chat. Share tips and tricks. Help folks learn new things.

Link up people who have had similar problems and know of a fix. I have been asked questions, and my response is “I know who knows that”, then I walk the person across the office and ask another staffer what they did when they had this problem. The person gives the answer and the two are soon discussing other things. They are now connected.

Move outside your firm. Bring together people you know to other people you know. If you have a friend at another firm that needs help, each out to another person in your network and introduce them. If you know a tech expert/blogger/writer/ speaker, introduce others to that person. The expert will enjoy the networking opportunity. Seek out those at events that seem to not be talking with many people. Go over and introduce yourself and then offer to introduce them to others. I have done this at Autodesk University many times.

Connect your firm to others. As you expand your connectivity, bring the knowledge and expertise back to your firm. I have a very large file of business cards (sounds kind of old school), that I tap into when needed. Use LinkedIn or other online communities to join folks together. And don’t forget AUGI. AUGI is always the best place to start for tech connection online and offline. Get Connected with AUGI by going to these links - https://www.augi. com/get-connected - https://forums.augi.com/ Mark Kiker has more than 30 years of hands-on experience with technology. He is fully versed in every area of management from deployment planning, installation, and configuration to training and strategic planning. As an internationally known speaker and writer, he was a returning speaker at

Autodesk University for twenty years. Mark has served as Draftsman, Principal Designer, CAD/BIM Manager, IT Director, CTO, CIO and AUGI Board President. He can be reached at mark.kiker@augi.com and would love to hear your questions, comments and perspectives.

DISCOVERING THE HIDDEN GEMS THAT WILL TRANSFORM YOUR WORKFLOW

You know that feeling when you get something new? It might be something ordinary or complex, anything really, but suddenly it makes your life easier, and you can’t imagine living without it. It could be a new mouse for your laptop, new clothes, a watch, running shoes, anything at all. In this article, I’ll try to highlight two small Dynamo for Civil 3D innovations that are part of the Civil 3D 2026.1 update. These innovations are quite small and hidden and are listed in the official documentation under two categories: bug fixes and smaller buckets of work—both of which sound rather unassuming at first glance and could easily be overlooked. And that’s exactly why I want to focus on them— because they can bring you tremendous value. We’ll explore what was fixed and what will become indispensable in your Dynamo graphs.

As infrastructure professionals, we often focus on the marquee features—the flashy new tools that grab headlines and dominate marketing materials. But sometimes, the most transformative changes are the quiet ones, the fixes and refinements that address real-world pain points we’ve learned to work around. Civil 3D 2026.1 includes several such improvements in Dynamo, that represent significant workflow enhancements for those who recognize their potential.

I’ve selected Dynamo nodes that relate to fundamental Civil 3D objects for our discussion – COGO Points and Feature lines. In the following sections, I’ll demonstrate how you can leverage these improvements in your daily project workflows, transforming routine tasks into streamlined, automated processes that save time and reduce errors. Let’s take it step by step.

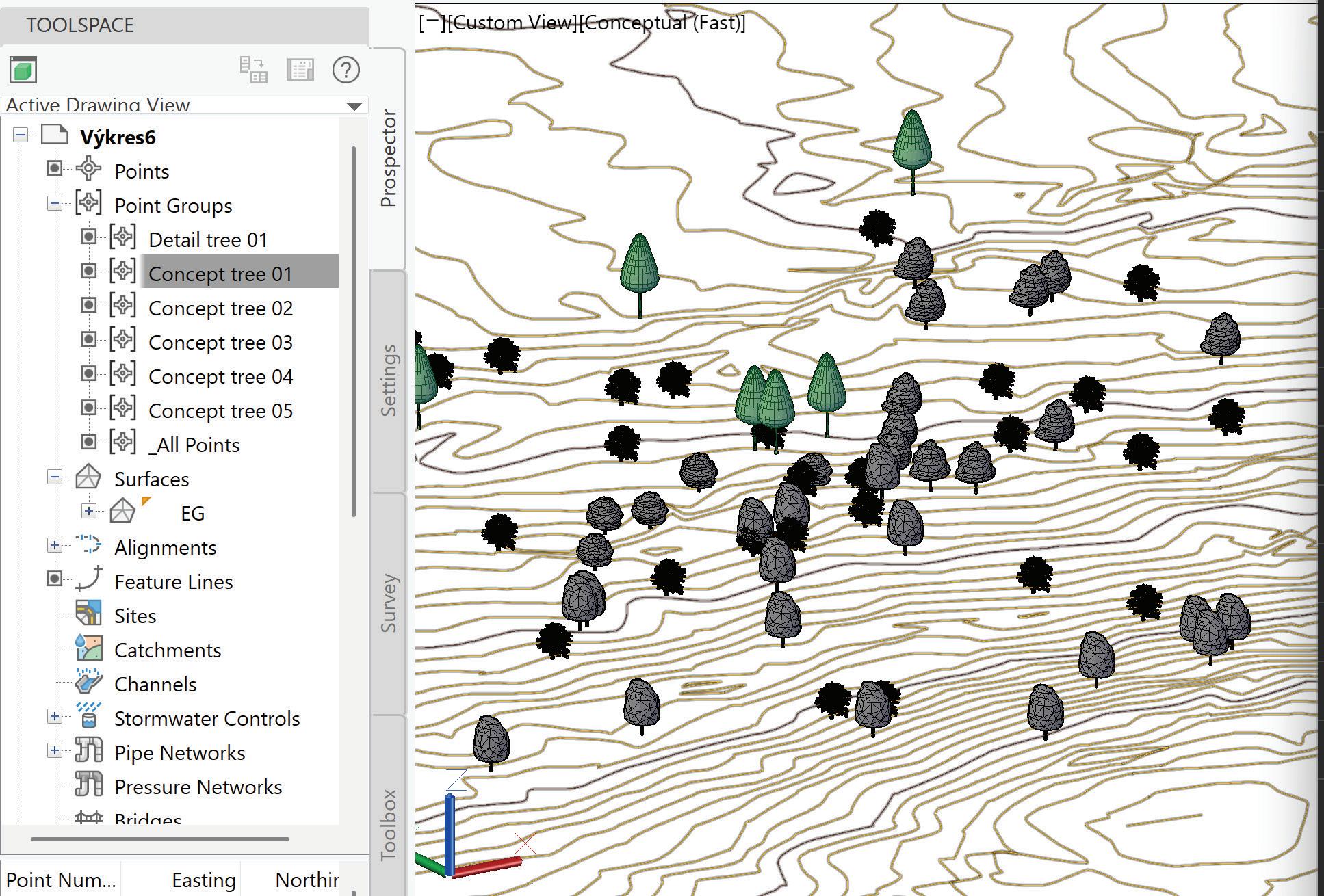

ENHANCEMENT #1: COGOPOINT. SETLABELSTYLE DEFAULT SETTING

Picture this scenario: you need to add large quantities of COGO points to various point groups, and you want the point style to automatically adapt based on the group assignment. The group and its style settings should control the display style, including the label style. This is fundamental Civil 3D behavior that many of us take for granted in manual workflows, but it has been surprisingly difficult to achieve programmatically through Dynamo.

Until now, the CogoPoint.SetLabelStyle node required explicit style assignment, preventing the natural inheritance behavior that makes point groups so powerful. This limitation prevented users from utilizing the full potential of Dynamo automation for truly automatic workflows.

The first improvement addresses the CogoPoint. SetLabelStyle node, which now allows setting the label style to <default>. This seemingly simple change is actually a fundamental prerequisite for allowing the point group to control the style, restoring the natural Civil 3D behavior we expect. This enhancement opens entirely new automation possibilities. We can now envision placing different types of points not just as 2D, but also as 3D elements with appropriate styles based on 2D, 3D or Multiview blocks inside them. These might

include traffic signs, railway posts, trees, or any other infrastructure elements that benefit from consistent, group-based styling (Figure 1).

Imagine you’re preparing several conceptual designs or studies for a large site, and part of your task is to place a substantial number of trees — of many different species — in varied, random arrangements for each variant. Doing this manually for hundreds of trees is time-consuming and prone to inconsistency.

Now you can build a fully automatic Dynamo workflow that:

• Imports species lists and placement rules

• Randomly generates and places COGO points for each tree

• Groups points automatically by species or intended design treatment

• Applies consistent, predefined styles to each group, ensuring clarity across all design variants

This way, you can quickly iterate multiple planting scenarios while maintaining accuracy and presentation quality directly within Civil 3D.

The key breakthrough is that these new points, created through Dynamo, will automatically adopt the display characteristics defined by their assigned point groups (Figure 2).

Figure 2: COGO_Points_Set Raw Description

The workflow here leverages classification based on raw description filtering, meaning new points added to point groups will self-organize and, most importantly, display correctly without manual intervention.

This approach scales beautifully. Whether you’re managing ten trees or hundreds, the automated classification and styling system handles the complexity while maintaining consistency across your project (Figure 3).

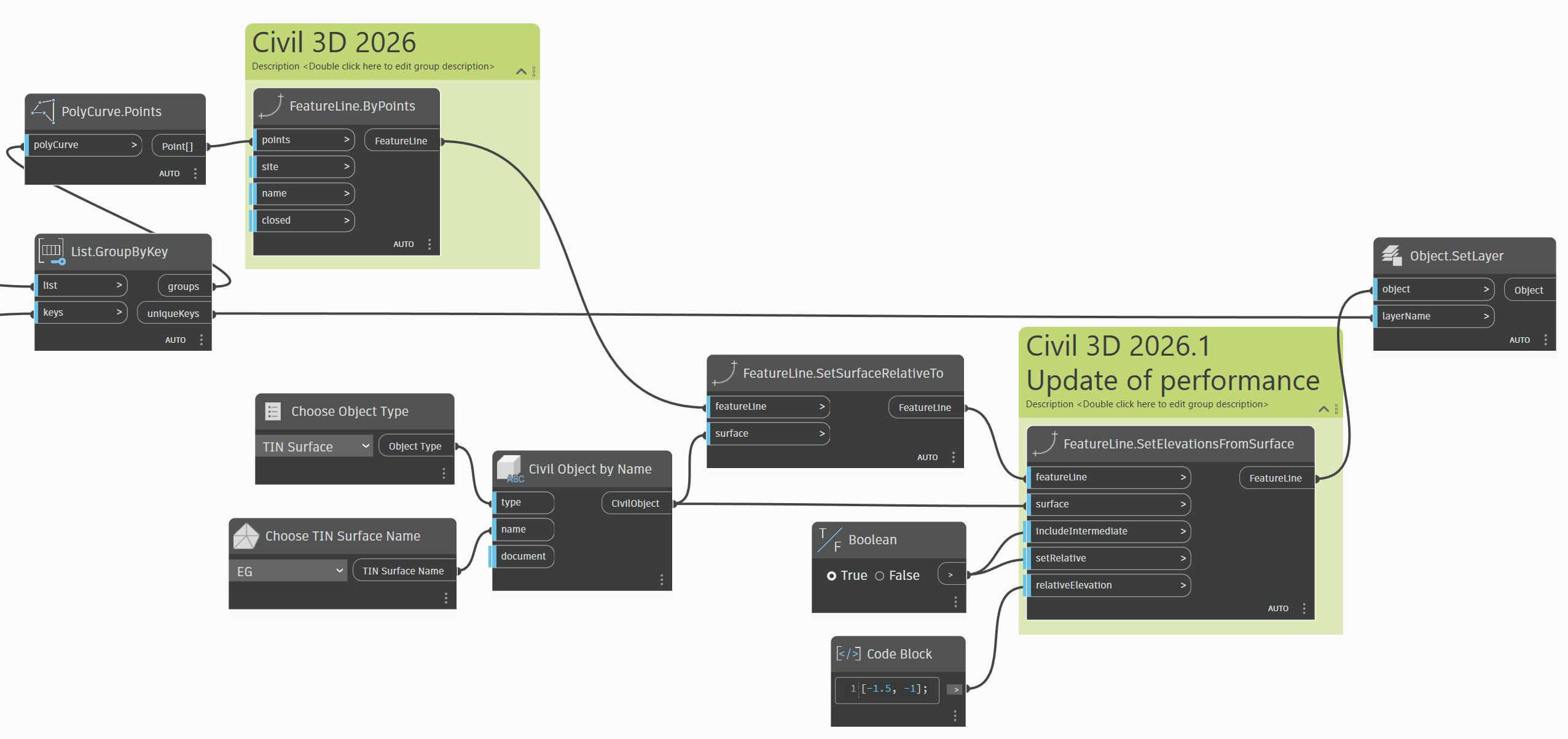

ENHANCEMENT #2: FEATURELINE NODES INCREASED PERFORMANCE

Moving to our second enhancement, we encounter improvements in the smaller buckets of work category—a humble classification that belies the significant impact these changes will have on daily workflows. The performance of the FeatureLine. SetElevationsFromSurface and FeatureLine. SetPointElevation nodes have been significantly improved.

Anyone who has worked with large datasets in Dynamo knows the frustration of long waiting for graph output. The previous performance limitations were repared very soon after first release in Civil 3D 2026. I want to give kudos to Zachri Jensen, Product Management Engineer for Dynamo at Autodesk, who responded very quickly to the Dynamo BIM forum and immediately began working on this update several months ago. He worked with my dataset, as well as other datasets from the Civil 3D community, to implement this important update.

This experience highlights why I encourage everyone to be active on user forums to get similar updates based on real project needs delivered very quickly. It’s crucial that our user community continues to grow and engage actively.

The Civil 3D and Dynamo communities have always been generous with knowledge sharing, and these improvements will undoubtedly spawn new techniques and best practices. I strongly encourage you to engage with user forums, attend technical sessions, and share your own discoveries as you explore these enhanced capabilities. Your active participation not only benefits your own projects but helps drive product development based on realworld requirements.

The most successful automation implementations often combine insights from multiple sources, adapting techniques from different disciplines and project types to create solutions tailored to specific workflow requirements.

As a practical example, here is a Dynamo script that imports polyline geometry from an XREF, converts it into feature lines, and then shifts these feature lines relative to the existing surface — streamlining what would otherwise be a tedious manual task, especially when dealing with a large number of objects (Figures 4-6.

LOWERING THE BARRIER TO AUTOMATION

For professionals hesitant about automation, these improvements offer compelling proof of concept

Figure 4: Polylines from Xref

opportunities. The enhanced nodes address familiar tasks using established Civil 3D concepts, reducing the learning curve and building confidence in automated approaches.

BUILDING MOMENTUM THROUGH EARLY WINS

In my own projects, I’ve seen excellent results building Dynamo graphs with these focused

improvements. Many of these successful graphs only became possible after a series of updates and incremental software enhancements that effectively strengthened the weakest links in the workflow chain. That’s why I’m glad to share this topic in this article, complete with real-world examples, in the hope of helping more teams adopt Dynamo for Civil 3D successfully and achieve the same gains in efficiency and consistency.

Figure 5: Set Featurelines Elevation

Figure 6: Featureline In Civil3D

CONCLUSION: SMALL CHANGES, TRANSFORMATIVE RESULTS

Like that new mouse or those running shoes I mentioned at the beginning, these Civil 3D 2026.1 Dynamo enhancements might seem modest at first glance. They’re categorized as bug fixes, not headline features. But for professionals who recognize their potential, they represent fundamental workflow improvements that will become indispensable parts of daily practice.

The CogoPoint.SetLabelStyle and CogoPoint. SetStyle default setting capability restores natural Civil 3D intelligence to automated workflows, enabling sophisticated point management systems that scale effortlessly from small projects to major infrastructure developments. The FeatureLine performance improvements remove timebased barriers to automation, making previously impractical workflows viable for production use.

Together, these enhancements lower the automation barrier for Civil 3D professionals while providing experienced Dynamo users with more powerful and reliable tools.

The next time you’re working through a repetitive task involving point placement or feature line elevation management, remember these quiet improvements waiting in your Civil 3D 2026.1. Like all the best tools, they’ll quickly become so integrated into your workflow that you’ll wonder how you ever managed without them.

Sometimes the most transformative changes are the ones we barely notice—until we can’t imagine working without them.

Lukas Drbohlav is a civil engineer who graduated from Czech Technical University specializing in water management and hydraulic structures. He began his career working on environmental construction projects including land reclamation, remediation, terrain modifications, and sewerage systems for 5 years, where he became passionate about Civil 3D starting with the 2009 version.

Currently serving as Services Manager for AEC Infrastructure EMEA at Graitec, an Autodesk Platinum Partner, he brings 8 years of experience in consulting and management roles. His expertise spans complex project delivery, team leadership, and developing innovative approaches to streamline design processes through technology integration. He enjoys helping others discover ways to simplify their work, which he has been doing for Graitec customers for the past 8 years.

With extensive field experience in infrastructure consulting, Lukas Drbohlav focuses on helping engineering teams optimize their workflows through strategic implementation of Autodesk solutions. His practical approach to problem-solving and deep understanding of project challenges makes him a trusted advisor for organizations looking to enhance their design efficiency and data management capabilities.

Contact Lukas Drbohlav at lukas.drbohlav@graitec.com or connect via LinkedIn at https://www.linkedin.com/in/ lukas-d-49558696/

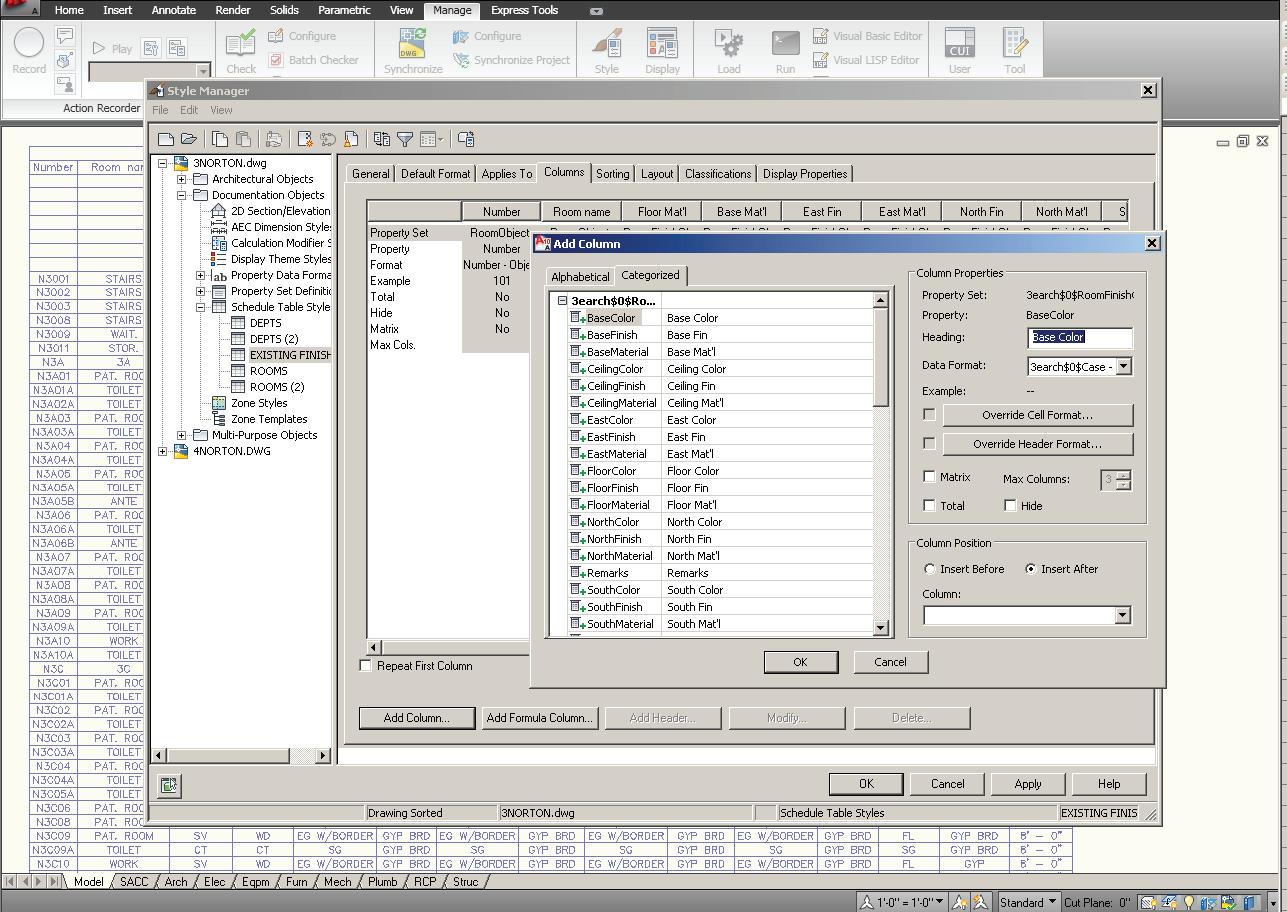

Customizing Schedule Tables in ACA

Schedules are tables you can customize and insert in drawings to list information about selected objects in your building model. Objects are made up of properties that contain data. Schedule tags provide an efficient tool of collecting the property data attached to the objects for display in a schedule table. You can create schedules with varying levels of detail by defining and attaching sets of properties to object styles or to individual objects and then extracting and displaying the data in a schedule table. You can produce basic schedule tables using the default tools provided with the software.

OVERVIEW

Before delving into schedule tables, it is important to understand some of the terminology associated with them. Here’s a little overview of some important terms that apply to creating and managing schedule tables.

• Schedule Tags - You can use project-based

or standard schedule tags in your drawings to graphically display the property data of an object. By linking the schedule tag to a property in a property set, you report property data of the object. When you anchor the tag to an object to which the property set is applied, the value of the property displays in the tag. The information in the tag is updated if the object or if the property changes.

• Schedule Tools – AutoCAD Architecture provides default tools for project-based and standard wall, door, and window schedules on the Scheduling tool palette and in the Content Browser. Selecting one of these tools that has a style, and other predefined properties allows you to quickly place a schedule table in your drawing.

• Schedule Styles - A schedule table style specifies the properties that can be included in a table for a particular object type. The style also controls the table formatting, such as text height and spacing, columns and headers.

AutoCAD Architecture

Display properties in the style control the visibility, layer, color, linetype, and linetype scale of table components.

• Property Sets - A property set is a user-definable group of related object properties. When you attach a property set to an object or a style, the property set becomes the container for the property data associated with the object. Property sets are specified using property set definitions.

• Property Set Definitions - A property set definition is a documentation object that specifies the characteristics of a group of properties that can be tracked with an object or style. Each property has a name, description, data type, data format and default value.

• Property Data Formats - A property data format is specified for each property definition within a property set definition to control how the data for that property displays in a schedule table, in a schedule tag or on the property palette. Property set definitions and schedule table styles use property data formats to control the display format of values for each property.

CREATING SCHEDULE TABLE STYLES

Schedule table styles are used to control the appearance and the content of schedule tables. A schedule table style for the type of schedule table you want to create must be contained in the drawing. When a schedule table style is copied into a drawing, data formats and property set definitions specified in the style are also copied. Property data formats and property set definitions will be discussed shortly.

Like many entities of ACA, schedule table styles are created and edited in the Style Manager under the Manage tab of the Ribbon. To create a new style, expand Documentation Objects, right-click on Schedule Table Styles and click new. Enter a name for the new style and hit enter. Next, you will edit the options for the schedule table style. The eight tabs you must choose from are as follows:

1. General is where you would add a description, if desired. You can also click on Notes and add a note and/or a reference document.

2. Default Format allows you to specify the format you want for your new schedule table style. This includes text appearance, matrix symbol and cell size.

3. Applies To allows you to specify which objects

you want the schedule table style to track. This could be as simple as a polyline or a door. This could also be several ACA objects, depending on what information you wish to include in your schedule table.

4. Columns allow you to add columns to represent properties that are reported in the schedule table style. You can also add column headings, edit column data and edit column placement in your style (see figure 1).

5. Sorting/Grouping allows you to specify the sort order of each row within the schedule table style. You can also group columns together with this feature and specify if you would like to display subtotals for the group.

6. Layout allows you to specify the format of the table title, the column headings and the matrix column headings.

7. Classifications allow you to assign a group of named properties to various objects. They assist in controlling how objects are displayed and scheduled.

8. Display Properties allows you to specify the visibility, line type, layer and other display properties of the schedule table style you are creating.

Once your style has been created, you can drag and drop it on to your tool palette for quick access. You can also add the schedule table to the Annotation Tab on the Ribbon by using the CUI. I highly recommend doing this if you plan to use your new schedule table style frequently.

PROPERTY DATA FORMATS AND PROPERTY SET DEFINITIONS

Before you create a schedule table, you will need to attach the property sets that are referenced in the schedule table style to the objects and object styles. These attached property sets become the containers for the data that will appear in your schedule table. A schedule table extracts the data from objects and displays it in the table. Data is not saved in the table itself.

A property set definition is a group of related properties of the objects and object styles to be reported in the schedule. Once attached to an object or its style, a property set becomes the container for the property data associated with the object. Values for properties are obtained directly from the object or are entered manually for the object or the style. Property set definitions are

created and edited in the Style Manager under the Manage tab of the Ribbon. To create a new property set definition, expand Documentation Objects, right-click Property Set Definitions and click new. Enter a name for the new definition and click enter. As with the Schedule Table Style, you will want to check which entities your new Definition Applies To. Now you will want to click on the Definition tab and add Property definitions as needed (see Figure 2). Click Apply and OK when you are finished. Property Set Definitions are added to objects through the property’s palette, extended data tab.

A property data format is applied to each definition within a property set definition. Property data formats are created and edited in the Style Manager under the Manage tab of the Ribbon. To create a new property data format, expand Documentation Objects, right-click Property Data Formats and click new. Enter a name for the new format and click enter. Now, you will want to click

on the Formatting tab. Here, you will need to specify how you wish for the formatting to appear. Fill in all information pertinent to the format you are creating. Click Apply and OK when you are finished.

INSERT A SCHEDULE TABLE

Begin by opening the Annotation tab of the Ribbon or opening your tool palette (depending on where you placed your new schedule table style) and selecting the Schedule Table you created. Next, select the objects you wish to include in the schedule table, or you can press enter to schedule an external drawing. Objects selected that are not of the type specified for the schedule table will automatically be filtered out of the drawing. Next, you will need to specify in the drawing area the insertion point for the upper-left corner of the schedule table and then specify the lower-right corner of the table, or you can press enter to scale the schedule table to the current drawing scale.

(See Figure 3)

Figure 2 – Define A Property Data Format

AutoCAD Architecture

Figure 3 – Annotation Ribbon

Figure 4 – Update Schedule Table

If your schedule table contains question marks in any of the cells, the property set definition that contains that property is not attached to an object or object style. If you have empty cells or dashes within cells, this indicates that the property set definition is attached but data is either not available or is not entered for that object or object style.

It is important to note that property data formats, property set definitions and schedule table styles cannot be changed through RefEdit. Changes made through RefEdit seem to work but the drawing will revert to the previous settings when saved back to the xref file. If you are using an xref file and need changes to be made to the schedule table, you will need to open the xref drawing directly and make changes there.

UPDATING A SCHEDULE TABLE

A schedule table will update changes automatically when the automatic update option is turned on. This option can be turned on by right clicking on the schedule table style on the tools palette and selecting properties. Under Selection you can choose to Add New Objects Automatically. If, however, the option is turned off, you can manually update a schedule table. To do this, select the schedule table, right click and click Update Schedule Table. Please note that when you select a schedule table in your drawing, the Schedule Table Tab appears in the ribbon. Updates and edits can be performed straight from the ribbon! (See Figure 4)

You can also add objects to or remove objects from a schedule table after it has been inserted in the drawing. All you have to do is select the schedule

table, right-click, and click Selection. Next click either Add or Remove, depending on which you want to do. You then select the objects in the drawing that you want to add to or remove from the table and press enter.

You can even add hyperlinks, notes and reference documents to the schedule table. Double-click on the schedule table and then on the Properties Palette, click on the Extended Data tab and expand Documentation. Now click on the icon next to hyperlink, notes or reference documents, depending on which one you wish to add.

CREATING A SCHEDULE TABLE IN A PROJECT

Schedule tables can contain information from external references and block references, which typically must exist in the same drawing as the schedule table. Schedule tables now optionally specify an external drawing, which is scheduled as if it were an external reference in the same drawing as the table. The advantage to this is that the graphics of the external drawing do not need to be generated in order to fill out the data in the table.

To begin, open the sheet to contain the schedule table. Now, open the tool palette that you want to use and select a Schedule Table tool. On the Properties palette, expand Basic General. Select a style and instead of selecting objects in the drawing, press Enter. Specify the insertion point of the schedule table and specify the size of the schedule table. A schedule table with no rows is inserted into the drawing. Select the empty table, right-click and select Properties. On the Properties palette, expand Advanced External Source. For

AutoCAD Architecture

Schedule External Drawing, select Yes. The External Drawing settings are displayed, with a list containing all drawings in the Views directory of the current project. Each drawing should correspond to a view defined in the project. If no project is active, the list contains all drawings in the last directory browsed. Select the view you want to schedule. If the desired external view drawing is not displayed in the list, select Browse and find it.

EXPORT A SCHEDULE TABLE

You can export the contents of a schedule table to a separate file, such as Microsoft Excel spreadsheet (XLS), Comma-separated values (CSV) and Tabdelimited text (TXT) files. In order to export to Microsoft Excel format, you must have Excel installed.

To begin, open the drawing file that includes the table you want to export. Select the schedule table and then click the Schedule Table tab, Modify panel, Export. The Export Schedule Table dialog box opens (see Figure 5). Select a file type to Save As. Enter a name for the file or click Browse to select

a file and click OK. The Format dialog box opens if you have selected an XLS file type for Save As Type. Now, convert the schedule values in the exported file by selecting Use Unformatted Decimal Value or Convert to Formatted Text. It is important to note that the format of values does not change in the drawing file. Selecting Convert to Formatted Text displays the architectural format (6’-0”) in Microsoft Excel. Click OK to format columns one at a time or select Apply to All Columns and click OK.

Melinda Heavrin is a CAD Coordinator & Facility Planner in Louisville, Kentucky. She has been using AutoCAD Architecture since release 2000. Melinda can be reached for comments and questions at melinda.heavrin@ nortonhealthcare.org.

Figure 5 – Export Schedule Table

AUGIWORLD brings you recent developments in Autodesk and related software items

Establishing CAD Standards –The Road to Success Is a Rocky One

CAD Standards

THE CHALLENGING ROAD TO ESTABLISHING STANDARDS

Setting up and implementing functional yet efficient CAD standards is a necessity for any organization.

The term “CAD standard” is often associated only with a document (CAD drawing), when the final product is just the tip of the iceberg. There is much planning and execution that must go on in the background to facilitate the process of consistently and correctly creating product support documentation.

The value of clear and accurate product documentation cannot be understated. The product produced by an organization not only represents its design capabilities, but it is also the face of the corporate brand. A key factor in the success of any product is the supporting documentation developed to support said product.

An organization needs to have a well-established and tested protocol in place to ensure that its

product documentation is accurate and consistent across its entire product line.

WORKING WITH THE GOOD, THE BAD, AND THE UGLY

Being a CAD designer for many years, I have reviewed and edited numerous CAD drawings. I quickly learned how to identify a quality document versus one that needs improvement.

As business grows, its customer base expands. Potential new customers will often contact current customers before doing business with an organization. The company’s reputation with existing customers can attract or repel a potential new customer.

An often-overlooked aspect of a product is its supporting documentation. This is the key to customer success. A customer’s maintenance department must rely on documentation supplied with a product. If the documentation is inaccurate, there is a likelihood of mistakes occurring and additional time being required to complete a task. This will complicate issues for said customers, as well as cutting into their productivity. This may seem like a minor detail, but it can (and often does) become a bigger issue.

OVERLOOKED DETAILS WILL COME BACK TO YOU

One might not think to give high priority to documentation concerns when there are “real” deadlines and issues impacting the shipment of a product. Certainly, you can clean up the documentation and red lines well enough to ship the product. What happens when you get multiple events happening in a tight time frame? The last

CAD Standards

thing being considered when a customer is pushing you is the quality of the drawings. Management wants you to ship and meet their timeline as a priority. They can then bill the customer and get the job on the books.

I have worked in the environment described above with previous employers. At the time, my functional duties only included CAD design, as there were many products to ship and a very tight schedule. A major concern raised with my manager at the time was reusing outdated design documents. Poor CAD work done once is bad, reusing it, even worse.

When the issue of standards was brought up, I was told that there was no necessity to investigate such. We were in the process of shipping ten machines to the same customer on a tight schedule and working sixty hours a week. I found ten different styles of CAD work and many inaccuracies, which should have been corrected long ago.

THE RESULT OF NOT ESTABLISHING STANDARDS

We got all ten machines shipped and billed, and management made their numbers as they wanted to. When there was a bit of time, I reapproached my manager about standards. He responded that it was a good idea to investigate the subject. I took some time and researched what protocols and policies were in place. There was nothing established that I could point to as a good start.

When I presented my findings, he took them to the bean counters for consideration. I was ready to start diving into the challenge. The process of developing standards and protocols was (and usually still is today) considered overhead.

That shut my efforts down, as overhead was not a money maker. No matter the amount of backup data I had, or case studies, no one saw the task as justified. I was back to using obsolete data and incorrect CAD data to work with upcoming designs. Fast forward a few years, and new management was established. There was an effort to establish some protocol and standard CAD design procedures. However, the approach was committee-based with at least ten people involved. There was some progress; we tried to establish goals and real milestones to shoot for. The effort ended up failing because of the number of people involved and their preferences in setting the milestones and goals. No clear definition of how to proceed was created.

We were back to square one and had charged many expensive overhead hours for ten-plus management-level people. This is where most organizations stop. No standards or protocols and still working the same as they did all along, with the same results.

THE END RESULT

The result of our efforts was predictable. No progress was made on the issue. When management saw the cost of the failed effort, they shut down any further efforts to pursue the development of standards, which were deemed a failure based on the prior efforts.

The use of inaccurate, obsolete data continued to be the norm for the department. As I was the CAD monkey for the group, my concerns were disregarded.

When I got a repeat machine design for an existing customer, I would typically use the legacy data from an old job. There would be minor updates and changes, as one would expect with any reissue of an old job. The changes, however “minor”, were timeconsuming because of poorly created drawings.

As this happened frequently, I got questioned as to why it took so long to reuse the existing data and just get it done. Non-CAD people do not see the

intricacies of working on a drawing, as it is not their task. I would usually end up doing the minimum work necessary and nothing more.

If I started a new project, I would also need to use legacy data as a base, as new work never included time to clean up documentation.

Many reorganizations later, we were still at the same place with no push for standards or protocols.

A PATH FORWARD

I would bet that the company is still without standards or established protocols for its documentation. For forward growth and successful business growth, this situation will need to change. Industry conditions have changed, and businesses must develop streamlined policies to stay competitive in the game.

This must be a living process, as CAD operators will be added or move to other positions, thus the task requirements will need to support these changes.

Too often, after the “team concept” is tried and fails, the task is abandoned because of the time and expense involved. Any process you attempt to sell to management will need to have solid backing. ROI will be what bean counters and management care about, as well as the time from implementation to when visible results are achieved

Management must see the value of investing in quality documentation, consistently created

CAD Standards

within the organization as a saleable asset for their customers. Some organizations will be easier to prove this point to than others. Do your research into the corporate mindset early and plan your attack around what points are of interest to management.

Have a solid plan, be ready to change it on the fly, and document everything, even the details that may seem unimportant (they are to someone in the process). With this plan of attack, you stand a much better chance of succeeding.

FINAL THOUGHTS

As my primary task was CAD design, I did much of my research on my own time. That may seem like wasted time to the average CAD operator. However, in the long run, my knowledge of the subject and my research into what worked helped me to work faster and more efficiently.

I can say that, even though my efforts were inconsequential at a corporate level, I am more efficient today as an individual, which I see as a win.

My current employer designs Automated Guided Vehicles (AGV’s) and test machines. I have worked with AutoCAD software for forty years, starting on version 1.4. Having been with my current employer for almost sixteen years and CAD manager by necessity for at least ten, I have seen their culture change many times in attempts to improve processes and become more efficient. CAD standards have become a high-profile topic recently. I am excited to share my process of implementing a user-friendly system of CAD standards with others.

by: Ted Vuong & Gus Leutermann

Big Nature Philosophy Guides Walmart Campus Design

LID and Big Nature at the core of the new Walmart Home Office campus stormwater treatment train.

KEY HIGHLIGHTS

• The campus features bioswales, rain gardens, and the Green Groove waterway to capture, treat and reuse stormwater, reducing reliance on conventional infrastructure.

• North and South Lakes serve as stormwater reservoirs, collecting runoffs and providing over 50 million gallons annually for irrigation and wildlife habitats.

• Low impact design elements like grass pavers and native plants minimize impervious surfaces and heat island effects, promoting sustainability.

The Walmart Home Office campus, located on 350-acres in Bentonville, Arkansas, prioritizes sustainability and responsible water management. Guided by the “Big Nature” philosophy, which recognizes every landscape as part of a larger ecological network, the campus design incorporates advanced stormwater management and treatment strategies to mimic natural, predevelopment hydrology and significantly reduces environmental impacts.

To support Walmart’s sustainability goals and improve stormwater quality, the campus utilizes a treatment train that layers multiple green infrastructure solutions. Key features include bioswales, rain gardens, and a centralized vegetated waterway called the “Green Groove.” The bioswales and rain gardens, located strategically throughout the campus, are designed to capture as well as clean stormwater before it enters the sewer systems. They also play a key part of the sustainable water management and serve as part of the efforts to control erosion on the campus.

“A key example of this regenerative approach is Walmart’s leadership in environmental sustainability — demonstrated through its stewardship of natural resources and efforts to minimize environmental impact,” said Seth Roy, group director, Home Office Campus Design and Construction at Walmart.

The civil engineering design included a drainage system to direct a substantial volume of stormwater through the Green Groove prior to discharge into the North and South Lakes, promoting natural pollutant filtration and decreasing the demand on conventional stormwater infrastructure. This approach also achieves significant cost savings by

minimizing the size and amount of conventional stormwater piping.

Together, these features efficiently manage stormwater, filter pollutants, provide non-potable water for reuse, and ensure water quality is maintained before it is either reintroduced to the campus or released into adjacent creeks. This integrated approach exemplifies Walmart’s core sustainability initiatives for water stewardship and sustainable infrastructure by advancing resilient, environmentally responsible water management at scale.

“The implementation of low impact design (LID), including bioswales along key roadways and active pedestrian corridors, effectively attenuates stormwater runoff and reduces infrastructure costs across the campus,” said Shaun Cessna, principal and team director in the Civil Engineering Group at Walter P Moore.

The Walmart Home Office campus master plan provides a holistic approach to water management, advancing both environmental responsibility and water resiliency for Walmart as well as the City of Bentonville. The city was forced to increase water rates by 100% in March 2025 due to increased

demand from new homes in concert with an existing infrastructure that loses 54% of its water due to leaks, according to a 2024 water rate study.

IMPORTANCE OF BIOSWALES

By providing storage, attenuating peak flows, and treating developed flows locally prior to entering the storm sewer system, the bioswales are a major contributor to the sustainable water management for the Walmart campus.

“The campus landscape incorporates native and drought-tolerant plants to reduce water usage, while advanced stormwater systems help manage runoff and improve water quality,” said Roy. “Features like bioswales, retention lakes, and the Razorback Greenway — a hiking and biking trail that runs through the campus and connects Town Branch Creek to Osage Park — reflect this integrated, eco-conscious design.”

Located along major roadways, the trail system, and drainage paths, these bioswales provide critical erosion control and stormwater management. Many of the paved areas on campus are designed to drain into bioswales, ensuring that every drop of water that lands on the campus, once it is properly treated, is reused as part of the irrigation system.

The bioswales help manage stormwater runoff, reduce infrastructure costs, provide local storage, and stormwater treatment before any water that lands on campus enters the storm sewer system for additional treatment. To further support operational efficiency, the bioswales and passthrough planters are designed for straightforward, low maintenance landscaping.

SUSTAINABILITY AND THE GREEN GROOVE

From a civil engineering perspective, it was critical to integrate the environment into the campus design to reduce the campus’s carbon footprint. A key component of Walmart’s commitment to sustainability is the Green Groove that runs through the heart of the campus and acts as a natural waterway alongside a bike and pedestrian trail.

The stormwater collection systems convey and discharge the pretreated runoff to the Green Groove vegetated waterway. The Green Groove was planned not only as the hike and bike extension of the Razorback Trail, connecting Town Branch Creek to Osage Park, but also to serve as the backbone of the campus stormwater conveyance and water quality treatment systems.

The Green Groove uses vegetation to control water flow while concurrently purifying the water for reuse in the campus irrigation system by linking to the North and South campus lakes that collect stormwater. The Green Groove actively treats, aerates, and polishes every drop of water by removing pollutants and debris before directing it to the campus lakes. Because the Green Groove utilizes the natural landscape — as part of the Big Nature philosophy — it ensures the stormwater on campus is effectively managed while also protecting the environment.

“The Green Groove allows for the connection of multiple stormwater treatments to not only activate, aerate, polish, and deliver naturally treated and clean stormwater, but deliver it free of sediment, excess nutrients, contaminants, and debris, to the campus lakes and streams that serve the outfalls from the lakes,” said Erica Valdez, senior associate in the Civil Engineering Group at Walter P Moore.

FUNCTIONAL USES OF LID

The Green Groove is a signature feature on the Walmart campus, exemplifying low impact development while reducing the need for

conventional conveyance infrastructure, and serving as a valuable campus amenity. Additional features include:

1. Bioswales: Enhance stormwater quality by filtering runoff, increasing time of concentration, and reducing downstream detention requirements. They effectively intercept and remove pollutants before water enters the storm sewer, detention system, and city infrastructure.

2. Lake Detention Design: Strategically located lakes maintain natural drainage patterns and accommodate runoff from surrounding communities. The South Lake utilizes an OPTISystem with real time data to optimize stormwater storage and release, increasing capacity to help downstream flooding.

3. Irrigation Design and Water Reuse:

Stormwater from the campus and adjacent roadways are directed to campus lakes for storage and reuse in landscape irrigation. This approach eliminates the need for city supplied water for irrigation, resulting in significant cost savings.

4. Landscaping: Extensive trees and plantings reduce the heat island effect, while mature trees relocated from the original site are preserved. Grass pavers are used throughout the campus to further reduce impervious cover.

ROLE OF THE NORTH & SOUTH LAKES

The North and South Lakes play a vital role in reducing potable water use on the campus. Both lakes also collect stormwater and are connected to the campus irrigation system, significantly decreasing Walmart’s reliance on the city’s potable water supply for irrigation purposes.

“The Walmart Home Office campus takes a proactive approach to stormwater management, incorporating bioswales and over 13 acres of lakes designed to filter pollutants, supply non-potable water, and improve water quality before it’s discharged,” said Roy. “These lakes are expected to provide more than 50 million gallons of water annually for smart irrigation, rainwater reuse, and supporting local wildlife habitats.”

Designing the stormwater system to create the treatment train upstream of the campus lakes allows for further reduction of costly and maintenance-intensive infrastructure, such as lake aeration, chemical and biological controls to control algae blooms, and dredging. The lakes were designed to allow for settlement of solids to improve the water quality of the downstream tributaries.

Because the North and South lakes are engineered water bodies designed to temporarily store and manage stormwater, this allows for the controlled release of developed flow from the campus via a weather-actuated gate at the South Lake. This gate facilitates water reuse and detention storage overlap, prevents downstream flooding, and minimizes the impact from the developed campus on natural waterways such as Town Branch Creek and Osage Creek.

The lakes’ wet bottoms and wetland planting allow for the final step in the water treatment train before being released into the creeks.

WATER AS A RESOURCE

A major component of the Walmart Home Office campus master plan was acting on the understanding of the importance of water as a resource. The need for planning for the most effective use of the water resources at the campus was an overarching goal.

This was accomplished by identifying the water resources to serve the campus, evaluating the risks from either too much or too little water, and planning for the management of the water resources on campus. Each provided the framework for understanding the cycle of water and how to provide mutually beneficial solutions for the campus, the community, and the environment.

“The foundation in engineering a more sustainable campus was understanding the site-specific water supply sources, demands, and stresses from the development and the community,” said Charlie Penland, managing principal and director of Business Development in the Infrastructure Group at Walter P Moore.

To help understand these, a series of water mapping and water balance analyses for the Original Home Office located approximately a mile away identified the feasible options for onsite water collection, storage, and reuse as well as providing the critical information needed for LID features.

“As a regenerative company, Walmart is committed to restoring what it takes and leaving the world better than it found it. In collaboration with its consultants, Walmart has thoughtfully developed a dynamic and cohesive campus plan designed to

inspire pride among associates, their families, and the Bentonville community,” said Roy.

Walter P Moore incorporated sustainable water management practices to ensure synergy between Walmart and the city of Bentonville in order to manage stormwater, reduce campus water usage, and improve the quality of water leaving the campus.

Ted Vuong, PE, LEED AP, ENV SP, is a managing principal at Walter P Moore. He can be reached at tvuong@ walterpmoore.com.

Gus Leutermann, PE, is a senior associate and senior civil engineer at Walter P Moore. He can be reached at gleutermann@walterpmoore. com.

Leaving Breadcrumbs: A Journey to Develop Traceable and Verifiable Drawing Content

INTRODUCTION

Where did that come from? Is that current? When did we receive that? If you’ve spent any amount of time working multiple datasets from varying sources within a DWG environment, these are likely familiar questions. Additionally, you likely understand how difficult it can be to verify and trace DWG content. In a large project involving multiple subcontractors, data sources,

and fluid data sets, I evaluated “out-of-the-box” options available in Civil 3D and developed a plan for curating traceable and verifiable drawing content. This article will review the options explored, including xdata, object data, and property set data.

A CLOSER LOOK AT THE PROBLEM

Many times, when working on large, long-duration projects, you receive many data sets over the course of several years. There are generally document

control processes in place that log receipt of data in a transmittal log and store it away for team use and records. That said, once that data is incorporated in a DWG base file, that tie is severed. This is not a problem for our GIS professionals, as metadata is a standard operating procedure for them, but it’s very rarely considered in CAD workflows. On smaller projects you can leverage multiple base files named and organized by provider, however, this is clunky and not feasible on a large scale. As an example, imagine you have base files made up of six surveyed segments spanning 40 miles, supplemented with publicly available data from four different sources. The client has provided their own data set of existing assets, and a subcontractor has provided pothole data (exposed utility data) for select locations along the project.

With all that in place, the following tasks and questions become difficult to navigate:

• Segment 5 has a new survey deliverable, and you must swap out the old one without removing data sets from other sources at that location.

• Does the segment 1 survey shown include the January data set?

• Is the watermain shown from survey?

• Where did that stream edge come from?

• What level of confidence do we have, SUE A, B, C?

To address each of those issues, a solution involving the attachment of metadata to each block, point, line, and polygon needs to be determined.

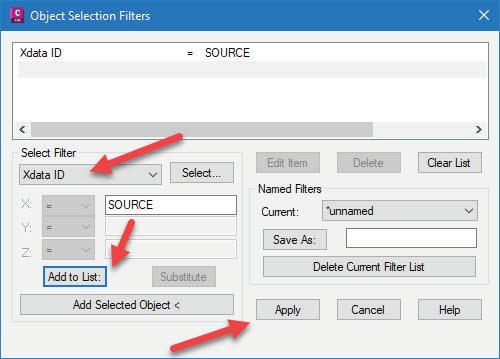

XDATA

Xdata facilitates the attachment of up to 16Kb of data to an individual object and its relatively difficult to break. The drawback is it is not very user-friendly for reasons mentioned later, and the objects it can attach to are limited. Out-of-the-box options for managing this data are also limited. On the Express Tools tab, you have options to “Attach Xdata” and “List Xdata” see figure A. Both options apply to a single object at a time. For querying, you can use the FILTER command and select objects by Application Name, but you need to know the Application Name see figure B. The Application is the container you create and name that contains the data. To gain the additional data management capabilities required to make this a feasible option you then need to go down the custom coding path or leverage third-party applications.

Figure A

Figure B

Figure C

OBJECT DATA

The most familiar option on the list for Civil 3D and Map 3D users is object data. Object data is added through object data tables. The tables can be created in CAD, assigned multiple attribute fields, and attached to multiple objects at once. See figure C for an example object data table. Object data can populate from GIS attributes and share as GIS attributes. For queries, there are advanced tools available in the Map Task Pane, making selection a breeze. See figure D for an example of this interface. Sounds great, right? The downside is the method is easily breakable and not particularly easy to look at holistically. To review the data within a drawing you either need to select object by object, use a thirdparty application, or delve into coding.

PROPERTY SET DATA

The last option to review is property set data. Property set data can be applied to objects through property set definitions. The definitions are created and managed through the Style Manager, where you can select the object type it applies to, define the fields, and choose if they are manual, automatic, or other. Once a definition is in a drawing, multiple objects can be selected and added through the

Extended Data Properties tab. For a holistic view of the data attached to objects in a drawing, you have several options: create a schedule, use the “EXPORTPROPERTYDATA” command, use the Autodesk Standardized Data Tool for Civil 3D, third-party applications, or leverage coding. As with all the options explored thus far, there is a downside here as well: queries. Objects cannot be easily quired without the use of third-party tools or coding.

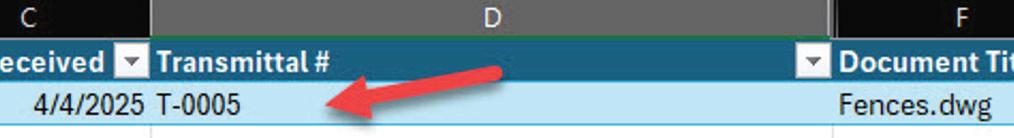

THE CHOSEN SOLUTION

Each of these solutions have their strengths and weaknesses. For my aforementioned use-case, property set data was my top pick. Going back to the problem of a severed tie, I worked with document controls to include a field for transmittal number in the existing transmittal log. See figure E. I then created a Source Data property set definition. This definition includes manual and automatic fields as show in figure F. When data is transmitted to document controls, the information is logged as it always has been, but it is also now given a unique identifier. That is then attached to the objects themselves before incorporation to the project base file see figure G. An individual object can now be selected and reviewed for the information within

Figure D

the fields but also traced back to the original log for additional information. A holistic look at all the data and its attribution can be facilitated by the means mentioned previously in this article. Further, exports of this data can be analyzed in Excel and/ or PowerBI. Additionally, a Dynamo script can be leveraged to select objects by their specific field. Once the data is selected, you can easily replace, edit, export and more.

CONCLUSION

The three methods reviewed are all viable and none are perfect — there isn’t a one-size-fits-all solution. That said, the method’s individual strengths might make one a better option than the other for your specific use case: Xdata’s durability to accidental destruction, object data’s out-of-the-box queries and GIS interoperability, and property sets export options and dynamic attribution. Now that we understand the options available for embedding metadata in DWG content, we can evaluate the best workflow based on our specific use case and implement a plan for curating traceable and verifiable drawing content!

Jacob Matuseski is the Oil and Gas Pipelines and Station CAD Lead within HDR’s Resources Business Group, a global leader in engineering, architecture, environmental and construction services. Jacob has been in the AEC industry for 15 years with 14 years of experience in the oil and gas industry. During this time, he has managed multidisciplinary teams of technicians and designers from project inception to as built. In Jacob’s current role, he is responsible for the development of CAD standards, understanding and utilizing client CAD standards, monitoring and forecasting design personnel workloads, technology advancement and implementation, and quality assurance. Jacob can be reached for questions or comments at Jacob. Matuseski@HDRinc.com or on LinkedIn.

Figure E

Figure F

Figure G