PRODUCT FEATURES

❱ RESTORATION PRODUCTS & SERVICES

❱ STRUCTURAL STEEL

❱ STEEL BUILDINGS

❱ GREEN ROOFS & WALLS

❱ APPLIANCES

❱ PLUMBING PRODUCTS

❱ RESIDENTIAL WINDOWS

❱ HARD SURFACE FLOORING

❱ PAINT & COATINGS

❱ RESTORATION PRODUCTS & SERVICES

❱ STRUCTURAL STEEL

❱ STEEL BUILDINGS

❱ GREEN ROOFS & WALLS

❱ APPLIANCES

❱ PLUMBING PRODUCTS

❱ RESIDENTIAL WINDOWS

❱ HARD SURFACE FLOORING

❱ PAINT & COATINGS

Prefabricated Precast Concrete Window & Wall Systems outperform other systems in:

· Pre-assembled, caulked, vapour air tested windows are installed in the panel at the precast concrete facility which provides improved quality assurance.

· The rapid installation allows the building enclosure to be completed sooner, giving the interior trades faster access to a more climate-controlled building and therefore ensuring the project is completed quickly and efficiently.

ADDED BENEFITS OF PREFABRICATED PRECAST CONCRETE WINDOW & WALL SYSTEMS:

• Provides significant improvements in terms of cost, schedule, quality, productivity, safety and the ability to reduce waste and increase client satisfaction with a quicker return on investment.

• An unlimited array of architectural designs, colours and textures are available including heightened durability and lower maintenance costs.

For more Information and Educational presentations check out Learn on Demand, a 24/7/365 Educational Platform. Visit cpci-learnondemand.com/

Visit www.cpci.ca/publications to download your free copies of the Structural Solutions Technical Guide and High Performing Precast Concrete Building Enclosures –Rain Control Technical Guide.

5

RAIC PERSPECTIVE

The 2025 RAIC International Prize – Climate Action.

6

SHAPING VANCOUVER’S SKYLINE

Sixty years of Musson Cattell Mackey Partnership’s bold architectural legacy.

9

PANE AND SIMPLE

Revolutionary styles and cutting-edge tech are transforming the residential window sector.

15

A BRUSH WITH VISION

Bold colours and breakthrough coatings reshaping 2025. 21

BACK TO THE FUTURE

The restoration sector is thriving as experts revive some of Canada’s most iconic buildings.

27

ALL UNDER CONTROL

The latest in appliance innovation is driving ultimate convenience, control, and energy efficiency.

PREPARE TO BE FLOORED

Elevating spaces with bold hard surface flooring and game-changing adhesive solutions.

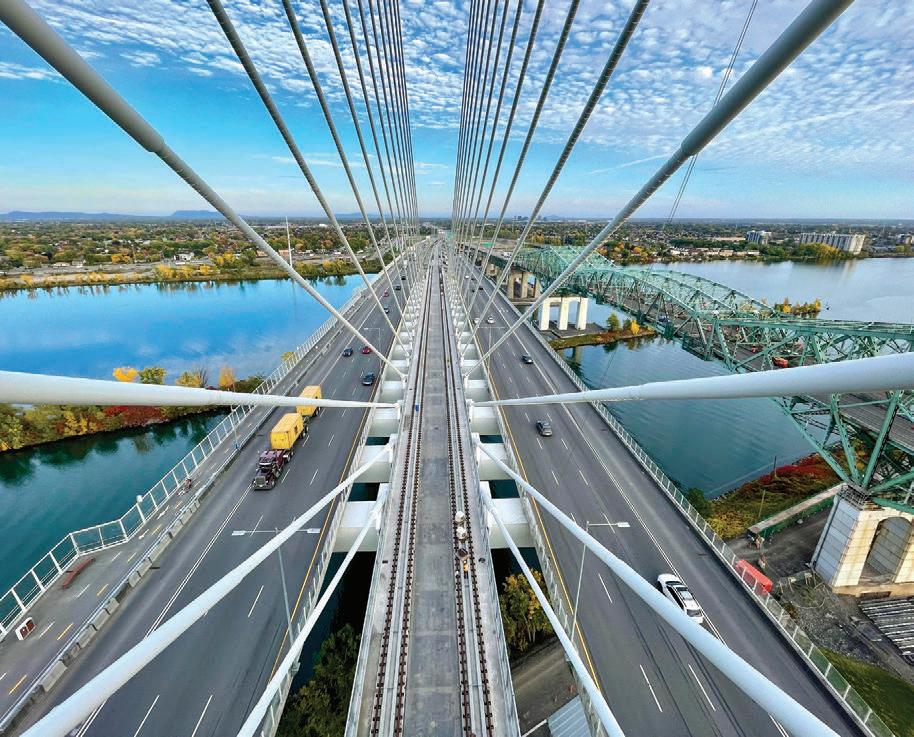

THE BACKBONE OF CONSTRUCTION

Advocacy and innovation are more essential than ever in driving structural steel’s growth.

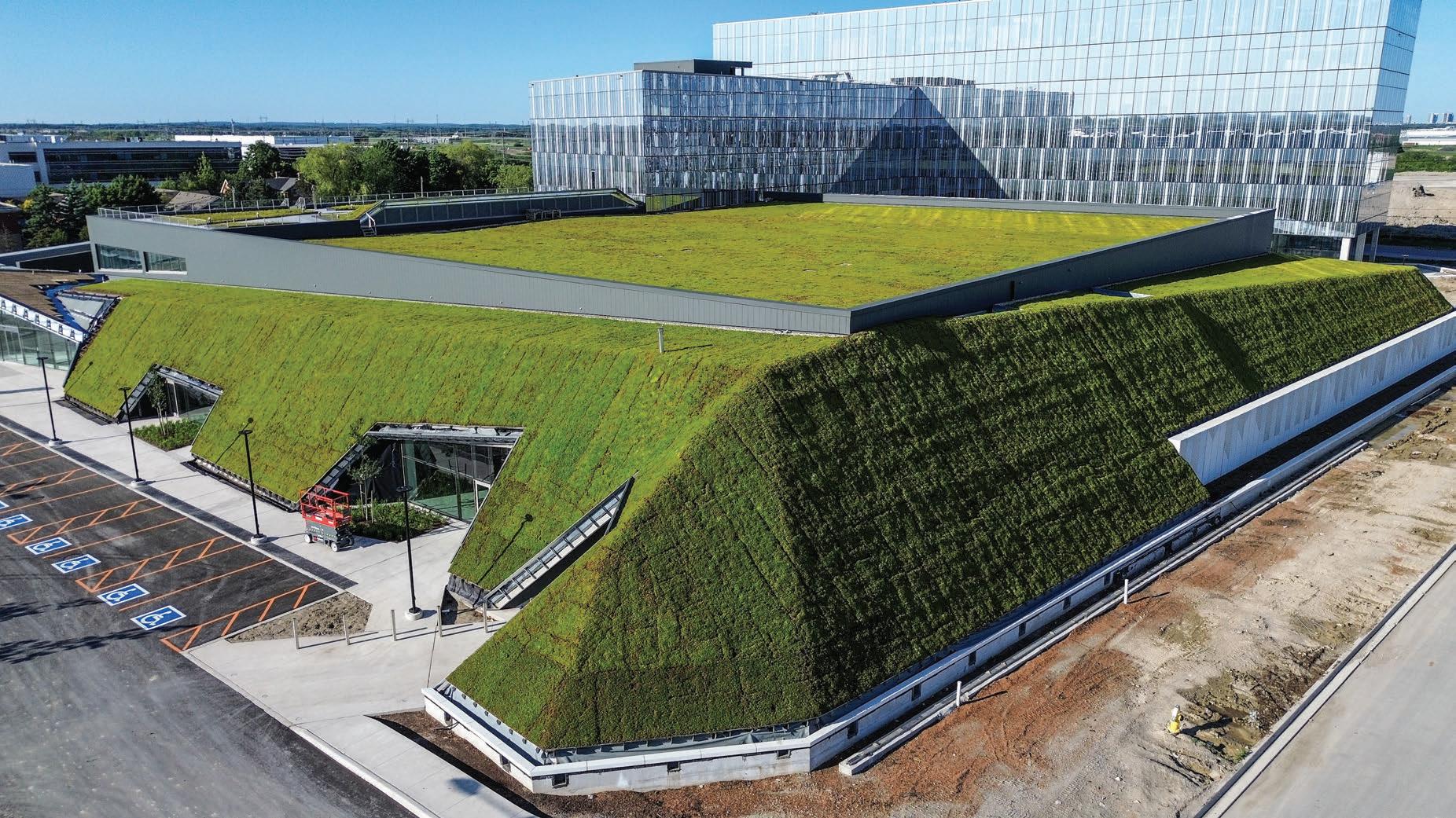

ROOTS

Green roofs and walls are sprouting change, transforming built environments everywhere.

While steel buildings thrived in 2024, this year’s looming tariffs create uncertainty.

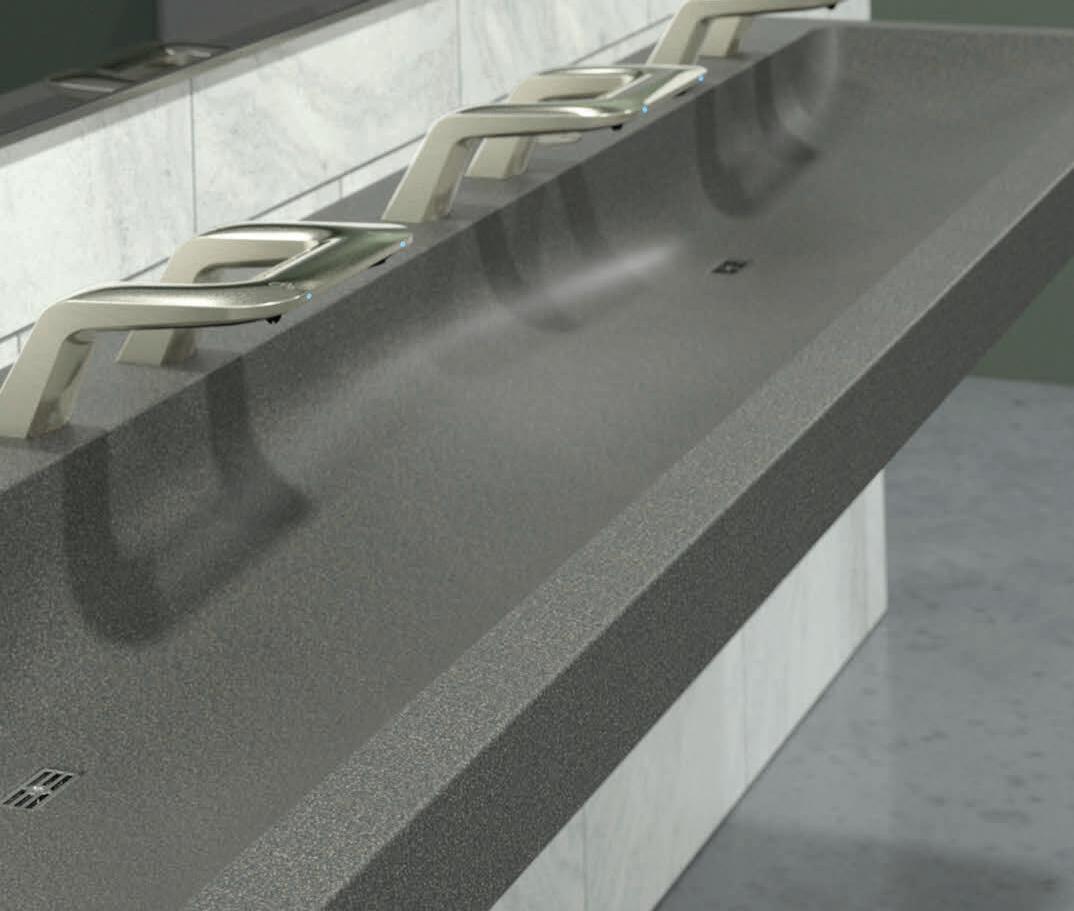

Smart, efficient plumbing options feature cutting-edge design and technology.

by AMANDA SHORE, m.arch, oaa, mraic RAIC Honours and Awards Manager

The RAIC International Prize, originally established in 2013 as the RAIC Moriyama Prize, was conceived based on the visionary ideals of Canadian architect Raymond Moriyama. He firmly believed that exceptional architecture possesses the power to transform society by embodying humanistic values such as social equality, respect, and inclusiveness. The prize recognizes architecture that creates environments contributing to the well-being of all people, aligning with these fundamental principles.

In 2023, the RAIC International Prize evolved to reflect the broader mission, vision, and values of the RAIC. This evolution introduced an annual thematic focus, emphasizing contemporary and critical issues in architecture. The inaugural theme in 2024, Indigenous Architecture, highlighted and celebrated Indigenous practitioners who integrate Indigenous knowledge and ways of knowing into the built and natural environments.

THE IMPORTANCE OF RECOGNIZING RAIC VALUES INTERNATIONALLY

The RAIC International Prize serves as a global platform to showcase Canadian architectural leadership and values, such as sustainability, inclusivity, and innovation. By engaging with international practitioners, the RAIC fosters cross-cultural dialogue and collaboration, enriching architectural discourse worldwide. These values are not only fundamental to Canadian architecture but also resonate globally, inspiring projects that prioritize the well-being of communities and the environment.

THE 2025 RAIC INTERNATIONAL PRIZE

Architecture plays a critical role in inspiring meaningful action on global climate issues. The RAIC International Prize’s 2025 theme, Climate Action, aims to spotlight an architect, practice, group, or project that exemplifies design excellence in addressing the climate crisis. This theme aligns with the RAIC’s broader climate action commitments, including its Climate Action Plan and strategic initiatives aimed at reducing the carbon footprint of the built environment.

The recipient will be chosen by a selection committee and will be announced at the RAIC Conference on Architecture, scheduled for June 1 to 4, 2025, in Montreal.

MEET THE 2025 SELECTION COMMITTEE

The 2025 selection committee, chaired by RAIC past president Jason Robbins, includes a distinguished group of design and industry professionals from around the globe. This diverse group reflects the international scope and ambition of the prize, ensuring a robust and insightful selection process.

■ Afaf Azzouz, senior manager in Deloitte’s sustainability and climate practice. She is a professional engineer, a Building Energy Modeling

Professional (BEMP), and has a master’s degree in sustainable engineering. She has also recently won four awards acknowledging her efforts, including from Clean50, Association of Energy Engineers, and the CaGBC.

■ Beatrice Galilee, an author, editor, curator, and founder of The World Around, a non-profit organization amplifying impactful global architecture and design. As a visiting lecturer at the Pratt Institute, Galilee’s work focuses on contemporary architecture and its future trajectory.

■ Dr. Harriet Harriss, a professor at Pratt Institute and former dean of its School of Architecture. An award-winning writer and educator, Dr. Harriss is renowned for her contributions to social justice and climate crisis pedagogy, as well as her interdisciplinary approaches informed by feminist and decolonization theories.

■ Mona Lemoine, registered architect and sustainability consultant with 25 years of experience focused on practice, advocacy, and education in the built environment. Lemoine is the chair of the RAIC Committee on Regenerative Environments (CORE), and co-chair of the RAIC’s Climate Action Plan (CAP) Steering Committee. She has served on several professional committees with the Canadian Green Building Council (CaGBC), US Green Building Council (USGBC), Canadian Mortgage and Housing Corporation, and the City of Vancouver.

■ Joanne Perdue, a leading voice in Canada’s green building movement for more than 30 years. A registered architect since 1991, her leadership and advocacy in green buildings and sustainability have been recognized through the CaGBC’s 2022 Lifetime Achievement Award, a USGBC LEED Fellow designation, and a Canada Clean50 award.

■ Jason Robbins, FRAIC, lead architect at AECOM Canada where he specializes in national defence and public safety projects. Throughout his career, Robbins has advocated for good design and architecture in our built environment. As RAIC past president, Robbins continues to support the RAIC’s vision of a strong architectural community that is empowered to create change and support its members in their pursuit of design excellence.

■ Whare Timu, a leading architect celebrated for his innovative approaches to Indigenous design and co-design practices. His portfolio includes culturally significant projects such as the University of Technology Sydney First Nations Residence and Te Manawataki o Te Papa Civic Square in Aotearoa New Zealand.

The RAIC International Prize continues to inspire architects and designers to create meaningful, impactful work that addresses urgent global challenges. By celebrating projects that embody its core values, the RAIC reinforces architecture’s capacity to lead societal transformation and shape a more equitable and sustainable future.

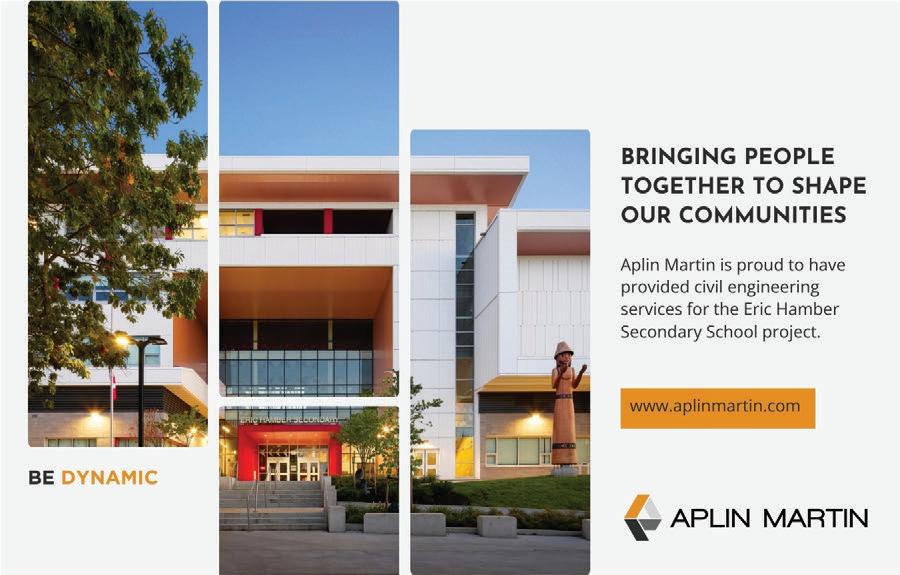

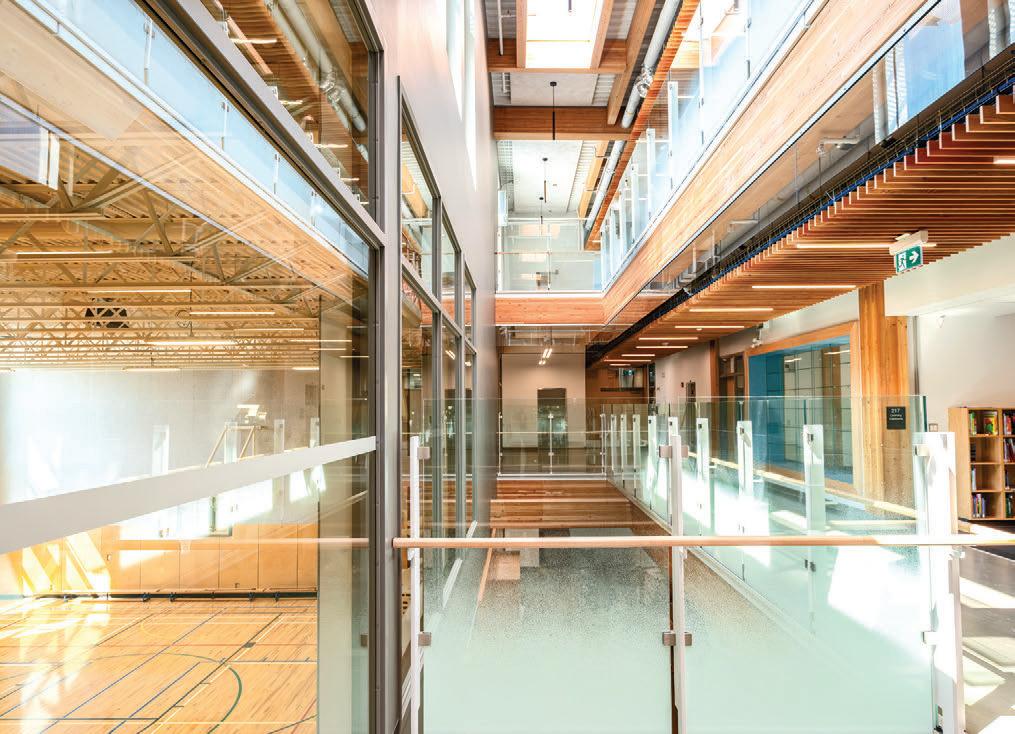

by NATALIE BRUCKNER | photography courtesy MUSSON CATTELL MACKEY PARTNERSHIP

If you find yourself at the corner of Burrard and Pender in downtown Vancouver, pause for a moment and take a 360-degree turn. What you’ll see is nothing short of a living timeline of architectural evolution – a showcase of Musson Cattell Mackey Partnership’s (MCM) profound impact on the city since its founding in 1965. From sleek commercial high-rises and thoughtfully planned residential spaces to transformative heritage renovations and ambitious master planning projects, MCM’s fingerprints are etched into Vancouver’s skyline, telling a story of innovation, adaptability, and a vision that has shaped the city’s identity over six decades.

Today, MCM is a driving force in Vancouver’s architectural landscape, with a team of more than 100 architects and designers shaping the city’s past, present, and future. Over the past 60 years, as Vancouver’s population has grown from 836,000 to more than 2.5 million, the firm has been a constant, crafting spaces that mirror the city’s evolution. Its portfolio includes iconic landmarks like the Vancouver Convention Centre West, the Vancouver Aquarium revitalization, and Canada Place, cementing its reputation for innovation, reliability, and enduring relationships.

The firm’s origins are intertwined with the city’s growth, mirroring the transformation of Vancouver itself. Founded by Frank Musson in 1965, MCM emerged in a good place at a good time. “Frank was originally the in-house architect for Dominion Construction, a company owned by the Bentall family. He left Dominion amicably to establish his architectural practice, and the Bentall family became one of the firm’s major clients. They remain one of our clients today,” says Mark Thompson, partner at MCM.

Renante Solivar, partner, notes that one of the core philosophies established by Musson was a hands-on approach to the practice. “He was very involved in projects, and that approach remains a central tenet of how we operate today,” adds Solivar. “From the very beginning, Frank understood that truly impactful design comes from close collaboration – not just with clients but also within the team itself. That philosophy continues to shape our work.”

All five partners at the firm are actively involved with clients and projects, working side by side in an open-plan space rather than behind closed-off doors, a rare commitment for a practice of MCM’s size. This balance between business management and hands-on architecture reflects a deliberate choice. “Personally, I became an architect to practice architecture, not just manage a business. We’ve structured our operations to balance business management with staying active in the creative and technical aspects of our work,” explains Thompson.

While MCM is well known for its work on large, complex projects, its ability to pivot into new areas – such as science and technology labs, and even interior design – while continuing to support core clients has helped it weather economic downturns like the dotcom bust. “That adaptability has been a hallmark of our practice. Today, we focus on a variety of projects, including mixed-use developments, retail, and high-rise residential work, evolving to meet the changing demands of our clients,” says Solivar.

Another defining decision for the firm was its choice to stay local. “We’re a 100-person firm based entirely in Vancouver, with no branch offices. We’ve consciously chosen to focus geographically on B.C. while diversifying our project types to remain resilient. This approach allows us to stay rooted in Vancouver, which is important to us,” explains Thompson. “We’re proud to be the largest 100 percent Vancouver-owned architectural firm. Being locally owned and operated strengthens our connection to Vancouver and its community.”

When it comes to projects, MCM takes a collaborative approach. “There are no egos here,” says Solivar, “which has allowed us to successfully build – not just design – so many complex, large-scale projects.” And with more than 400 projects completed, it’s difficult to select those that truly showcase the firm’s skill set.

The Bentall Centre stands out as a group of transformative first-class office towers that helped reshape Vancouver’s downtown. Canada Place, with its iconic cruise ship terminal, is another landmark project. Then there’s Electronic Arts’ headquarters in Burnaby, which marked MCM’s entry into the tech sector. The Vancouver Convention Centre West and the Paradox Hotel – formerly known as the Trump International Hotel – are also iconic, skyline-defining projects.

More recent work includes the King George Hub, The Stories at Broadway and Granville, 622 SW Marine Drive, 155 East 6th Street, and the ongoing master planning development in the Great Northern Way area – projects that are shaping the future of Vancouver.

While the standout iconic structures are certainly worth celebrating, MCM has been involved in countless lesser-known projects that have helped shape Vancouver over the years. One such project is 155 Water Street, which incorporates key heritage elements and holds special significance for both Solivar and Thompson. Anchored by two historic Gastown facades, with a new seven-storey building rising above Vancouver’s oldest neighbourhood, 155 Water Street blends modern office and retail spaces with preserved heritage. “Vancouver doesn’t have much heritage compared to older cities, so these buildings are even more precious,” says Thompson. “We’re finding ways to preserve entire heritage buildings – upgrading them for earthquake and fire safety while making them functional for modern use.”

In fact, this focus on restoration is central to MCM’s philosophy moving forward. “We’re seeing increasing opportunities with older buildings. Clients with aging Class B and Class A office buildings often ask how to keep them relevant. Renovation is a key focus, especially with land in limited supply. Over the next five to 10 years, we’ll likely see more of this as we find ways to modernize and preserve older structures rather than demolish them,” says Thompson.

MCM’s expertise in restoration is evident in projects like The Post on Georgia, the largest heritage revitalization in B.C., and the Vancouver Club’s renovation of its Class A heritage building. This project included restoring the existing east and west elevations in tandem with the development of an adjacent city park over a parking garage.

“We’re always mindful of what’s coming next and how different uses can be blended together,” explains Solivar. “For example, with the aging population, we’re currently exploring how medical facilities can be integrated into office or mixed-use developments.”

When it comes to MCM’s projects, there’s a little secret, a certain je ne sais quoi that ties them all together: a touch of whimsy. “Back in 2006, I worked on the Convention Centre and float plane terminal with Frank. He told me something that’s stuck with me ever since: ‘Most of our work is functional, and that’s essential, but great architecture leaves room for a little whimsy.’ He said it could be anything – a moment of wonder or a smile – that makes the project unforgettable; I always strive to carry that forward in my own work,” says Solivar. It may not always be obvious at first, but that hidden touch of whimsy is what makes each MCM project uniquely memorable and so very Vancouver. A

by ROBIN BRUNET

It’s a familiar refrain throughout the construction products sector, especially when it comes to residential windows: energy standards continue to drive product development, whether through meeting performance codes or developing an Environmental Product Declaration (EPD). Tracy Nadiger, VP of marketing at All Weather Group, which includes All Weather at Home (formerly All Weather Windows), summarizes the market as her company looks ahead to business this year: “In the past, advancements in technology tended to focus on the use of PVC over wood, but the focus now is on glass technology,” she says.

Specifically, Vacuum Insulating Glass (VIG) is beginning to establish a presence in the Canadian residential construction sector sooner than expected. Nadiger says a key entry point will be in the construction of net-zero homes. “From there, VIG could become more mainstream as developers seek to minimize the energy losses associated with traditional windows,” Nadiger says.

With R-values of up to R20, VIG has been credited with turning walls into windows. Essentially, a VIG unit consists of two lites of glass with micro support pillars in between, lined by a seal. The high vacuum

chamber is said to provide better thermal insulation than a brick wall or insulated glass and is also excellent at blocking noise, making vacuum glass especially attractive for urban areas. VIG units are also free of condensation, even in extreme cold

Nadiger cites another development to keep an eye on in 2025. “Low-E coatings continue to be driven by energy codes and Canada’s 2030 sustainability mandate, to the point we’re seeing coatings on three sides of window systems instead of two,” she says, referring to triple pane applications.

But Nadiger warns that both VIG and Low-E come with tradeoffs. “VIG is two to three times more expensive than standard window systems, plus the capillary tubes between the two glass panes are noticeable,” she says. As for Low-E coatings, “They significantly affect the transmission of light into a building. So developers will have to assess when and where these systems are a good investment. But both technologies are here to stay and will likely become more accessible in coming years, which is why we at All Weather at Home will be unveiling Low-E offerings in 2025, and possibly VIG units.”

Nadiger has another observation about the residential window industry in 2025: “I have no idea where this is going or if the effect will become

severe, but the demand for glass for solar panels is ramping up and taking away capacity from float glass for residential and commercial applications. Whether this will cause shortages remains to be seen, but it’s worth keeping track of.”

As of January, Innotech Windows + Doors was busy launching its line of EPDs. The company’s brand manager, Jessica Owen, says reaching this point “took 18 months of significant effort involving all of our departments and suppliers – but the result is worth it, as we now have EPDs that outperform the baseline.”

Innotech’s EPDs pertain to its Defender 76TS and Defender 88PH+ Windows and Doors Series. Developed in compliance with ISO 14025 and EN 15804:2012+A2:2019, the EPDs have been verified by the Athena Sustainable Materials Institute.

Innotech is also very much on top of Life Cycle Assessments (LCAs) as they become common vocabulary of developers, especially those in government projects. “For example, the City of Vancouver continues to lead the industry with requirements for embodied and operational carbon to meet zero emissions buildings targets, and we continue to be part of the discussion surrounding the need to balance embodied carbon with operational carbon,” Owen says.

EuroLine Windows. Genuine quality engineered for a lifetime of performance and comfort. Experience personalized service that values your unique vision, backed by a company with a proven reputation. Trusted by the most discerning homeowners and professionals. euroline-windows.com

Zhen Liu, owner of Silex Fibreglass Windows & Doors, champions the adoption of EPDs as a reflection of the construction industry’s growing commitment to transparency and sustainability.

“While EPDs haven’t directly increased our client base, they are increasingly required for large-scale commercial and institutional projects,” Liu notes. “These certifications demonstrate our environmental leadership and position us as a trusted partner in sustainable building initiatives.”

requirements, allowing architects to maintain their creative vision without compromising sustainability.

As the construction industry increasingly prioritizes environmentally responsible solutions, Silex’s fibreglass windows are emerging as the material of choice for projects that aim to combine design excellence with sustainability. “At Silex, we’re proud to offer products that not only meet the functional and aesthetic needs of modern architecture but also support the broader goal of reducing environmental impact,” Liu concludes.

Fibreglass windows are particularly well-suited for projects that demand both environmental responsibility and cutting-edge performance. “Fibreglass as a material inherently supports sustainable construction,” Liu explains. “Unlike aluminum, fibreglass requires significantly less energy to produce, and it doesn’t involve forestbased materials like wood. This allows us to market our products as having some of the lowest embodied energy in the industry.”

Beyond manufacturing benefits, fibreglass windows excel in operational performance. With a naturally high resistance to thermal transfer, they offer superior insulation, contributing to reduced heating and cooling demands in buildings. This not only enhances occupant comfort but also aligns with stringent energy efficiency targets, such as those required by LEED and other green building certification programs.

Durability is another critical advantage. Fibreglass windows resist warping, rotting, and corrosion, significantly extending their lifecycle compared to traditional materials. “When architects and developers choose fibreglass, they’re not only investing in a product that lasts longer, but also reducing long-term maintenance and material replacement costs,” Liu says.

Design flexibility is equally important for the architectural community. Fibreglass windows can be customized to meet aesthetic and structural

aluminum and fibreglass frames), and strength (a well-engineered fibreglass window delivers vastly superior strength characteristics compared to other windows, such as PVC, and provides greater sheer strength than PVC).

For the record, Inline also touts as a benefit that it is the only fully integrated fibreglass window and door manufacturer in Canada: “As a result, we have the distinct advantage of controlling all aspects of design, production, and quality. Beginning with the manufacturing of lineals using the pultrusion process, painting, to design and final assembly of windows and doors, our experienced team has gained the industry reputation for producing the best fibreglass windows and doors in the marketplace.”

Davyd Funk, president of Euroline Windows & Doors, says his company, a leading North American manufacturer of high-performance, custom-made windows and doors, reports that, “Since 2020 we’ve enjoyed an extremely productive relationship with Aluplast, a German company globally recognized for its innovation in product development.”

One product that made a splash upon its introduction in 2024 and is expected to grow even more in popularity is the energeto NEO tilt-and-turn window system, which boasts a Bauhaus-style minimalist design with rebates that are nearly half as narrow as those in other Aluplast systems.

Energeto NEO is replete with innovative Aluplast technologies, such as steel reinforcements replaced by Powerdur composite reinforcements, the technology of gluing the glass unit into the sash glazing rebate, and the option to fill the profile chambers with thermal insulation materials.

Of the tilt-and-turn functionality, Funk says, “We’ll be seeing an expansion of tilt-and-turn well into 2025 and beyond, especially in the multi-family residential sector. It’s ideal for developers who want to create a narrow, modern aesthetic, and German engineering ensures that these systems are durable over the long term.”

Cascadia Windows & Doors of Langley, B.C., is well known for creating high-performance fibreglass windows and cladding support systems. It recently became the first window manufacturer in the world to issue an EPD for its Universal Series Windows, Doors, and Window Wall, in accordance with the new Fenestration Assemblies Product Category Rule (PCR). This underscores the company’s commitment to transparency and the transition to high-performance building design.

The new PCR prescribes standardized rules and methods for calculating and reporting the environmental impacts of products, allowing for greater accuracy and consistency in evaluating a product’s lifecycle impacts, particularly in reporting embodied carbon impacts.

Michael Bousfield, technical director at Cascadia, points out that “In general there are two competing interests in construction with regards to windows: the requirement to meet stringent energy codes, especially in locations such as urban B.C., and the architectural desire for more glass in order to provide better views and boost property values.

In a similar vein, Inline Fibreglass Ltd.’s windows exhibit all the environmental benefits of pultruded fibreglass, along with stability (the material expands and contracts an incredible 800 percent less than vinyl), conductivity (fibreglass is less conductive than

“Cascadia has developed to the point where we accommodate both needs along with providing developers with product longevity – because as building codes become even more rigorous, it’s hardly acceptable to have a window with a 20-year service life compared to the 100-year lifespan of the surrounding wall.”

As for new products, Cascadia recently unveiled its new Juliet Balcony, which provides architects and designers a novel way to reduce thermal bridging associated with balconies, while still offering maximum ventilation for occupants.

“This system is compatible with the Universal Series inswing windows and doors, plus window wall, and custom sizes and configurations are available,” Bousfield says. The window and guardrail

components are assembled at the factory while the guardrail glass is installed onsite, from the interior of the building. “Best of all, the Juliet Balcony does not impact the window’s thermal performance,” Bousfield says. “It’s a fabulous product for any large opening window where you want to expand space but not construct a traditional balcony.”

Finally, Viewmax of Concord, Ontario, is another supplier dedicated to providing energy-saving

windows, curtain walls, and related products. One example is its P2 Passive Energy Saving System, designed for passive buildings to have extraordinary thermal insulation and condensation-free performance, while its noise reduction performance makes a a highly comfortable home environment. The integrative design with aluminum cladding protects the exterior window frame and wall contact surface from severe weather conditions. A

by NATALIE BRUCKNER

Every year, the world’s leading paint and coatings manufacturers unveil their colour of the year – a single or palette of shades chosen to capture the pulse of design and culture. But these selections are more than just a reflection of fleeting trends; they reveal deeper global currents, from shifts in consumer behaviour and technological innovation to the evolving relationship between people and their spaces. Informed by extensive research across fashion, architecture, nature, and technology, these colours tell stories of where we are and where we’re headed. With sustainability and innovation at the forefront, here’s what the experts are forecasting for this year.

At the Sansin Corporation, Ivory 21 emerges as a serene and sophisticated choice for 2025. This earthy, organic soft white, enriched with neutral undertones, elevates the natural beauty of wood grain while adding a bright, calming quality to any space.

“Ivory reflects a growing trend toward natural, translucent finishes that protect wood while celebrating its character,” says Sjoerd Bos, Sansin’s managing director. “It’s versatile enough to complement coastal tranquillity, Nordic minimalism, and even timeless traditional styles.”

The beauty of Ivory lies in its ability to transform surfaces, from ceilings and decks to siding and interiors. It’s equally at home creating a subtle elegance on its own or serving as a foundation for bold, contrasting hues. As Sansin colour specialist Adam Bartlett puts it, “Ivory is beautifully understated. It lets the wood’s unique tone shine through while offering endless creative possibilities.”

Whether enhancing the intricate grain of a wooden ceiling or providing durability to high-traffic exteriors, Ivory combines functionality with flair. Its soft, inviting tone promises to inspire architects and homeowners alike, proving that beauty and performance can go hand in hand. With Ivory, wood becomes naturally perfect.

Over at Benjamin Moore, their Colour Trend Collection for 2025 embodies a harmonious blend of familiarity and subtle vibrancy with 10 hues that project a comforting vision of colour on the horizon. The palette strikes a balance between grounding neutrals like Sea Salt CSP-95 and Paris Rain 1501, and deeper, moodier tones such as Ashwood Moss 1484 and Leather Saddle Brown 2100-20.

Cinnamon Slate 2113-40, the Colour of the Year, is a standout – a luxurious mid-tone fusion of plum and soft brown. This nuanced shade invites curiosity, encouraging exploration of its intricate undertones and fostering a sense of warmth and connection.

According to Sharon Grech, colour and design expert at Benjamin Moore Canada, this collection reflects a collective yearning for balance and reassurance, translated into restorative colours and soft, rounded palettes. This aligns with broader trends in architecture and furniture design, emphasizing organic shapes, layered textures, and the cherished items that make a space feel like home.

From creating harmony to serving as a versatile design tool, Benjamin Moore’s palette for 2025 highlights the emotional impact of colour. It provides designers and homeowners alike with options to craft environments that feel both personal and welcoming.

Meanwhile, the Pittsburgh Paints Company embraces bold expression with Purple Basil (DLX1046-7) as the Dulux Paints Colour of the Year. This rich, warm purple balances the calming qualities of blue with the vitality of red, symbolizing a new era of self-discovery and curated maximalism.

Ashley McCollum, marketing manager and global colour expert for Pittsburgh Paints Co., highlights the shade’s ability to inspire movement and adaptation, capturing the energy of nature, science, and virtual worlds. Complementary hues like Dark Green Velvet (DLX1136-7) and Bark (DLX1007-7) evoke nature, while Tarreyton (DLX1140-3) and Blue Calico (DLX1246-7) reflect the fusion of real and artificial spaces.

Sico paint takes inspiration from the night sky with Starry Night (6044-83) as its Colour of the Year. This deep purple blends warmth and energy, creating

dynamic spaces that foster connection. Paired with earthy tones like Pink Adobe (6073-31), Soft Shell Clam (6193-53), and Gray Area (6240-52), Starry Night mirrors the sky, land, and sea. McCollum recommends Sico Prestige paint for these transformative shades, offering a stain-and-scuff-resistant finish that uplifts every room with rich, expressive colour. Together, Dulux and Sico’s 2025 palettes invite homeowners to explore bold, dynamic choices in design.

At Sherwin-Williams, the 2025 Color Capsule of the Year celebrates the company’s 15th anniversary of announcing the Color of the Year. “Each year colour forecasting is complex and exciting. The Global Trendsight team drew inspiration this year from global influences and emerging design preferences to select a capsule that captures the spirit of the times and resonates with a broad audience,” explains Emily Kantz, colour marketing manager at Sherwin-Williams.

While many of the colours evoke a sense of nature – reflecting a growing trend among homeowners to bring the outdoors in – Kantz clarifies that the central theme is “vintage with a twist.” The capsule feels eclectic and reminiscent of the 1970s, which is making a comeback in design, with modern shades added to keep it fresh and fun.

One of Kantz’s favourite colour pairings is combining browns like Grounded SW 6089 with whites like Sunbleached SW 9585. “The combination feels elegant, yet restorative. It’s a softer take on the classic black-and-white pairing with a refreshing twist,” Kantz says. She recommends using this combination in master bedrooms for a luxurious yet comforting feel. Another unexpected pairing she loves is Rain Cloud SW 9639 and Chartreuse SW 0073, creating a fresh, light, and fun vibe, perfect for spaces like dining rooms or sitting rooms.

While colour inspires creativity, coatings themselves continue to evolve with performance-driven innovation. Cloverdale Paint continues to lead the way in architectural coatings with its cutting-edge Guardian Plus Interior 100 percent Acrylic Enamel line. This advanced family of coatings is designed to meet the high standards of architects and designers, offering exceptional scuff and burnish resistance, optimal washability, and four gloss options: Matte, Eggshell, Pearl, and Semi-Gloss. These coatings are low-VOC, non-yellowing, and ideal for residential, commercial, and institutional projects, balancing durability with reduced environmental impact and maintenance needs.

Cloverdale also introduces Rodeo (EX010) as its 2025 Colour of the Year. “Reflecting a growing desire to connect with nature in an increasingly technological world, Rodeo embodies calm and balance. Its earthy tones pair seamlessly with greens, terracottas, and soft creams, creating harmonious, nature-inspired interiors,” says Trish Picariello, colour consultant.

Picariello adds that advancements in smart lighting and sustainable design complement these trends, integrating technology that enhances natural lighting while reducing energy use. When paired with higher reflective value colours and strategically positioned surfaces, designers can achieve dynamic, eco-conscious spaces that connect people to the planet.

Meanwhile, the growing popularity of textured concrete opens doors for creativity, thanks to innovative solutions from companies like Nawkaw Corporation. Since 1988, Nawkaw Corporation has been at the forefront of architectural staining, developing, and applying innovative colour solutions for concrete and masonry. As textured concrete continues to emerge as a popular trend in modern design, Nawkaw’s expertise is shaping how this material is used to create visually dynamic surfaces.

Textured concrete offers a canvas for creativity, and Nawkaw’s hand-applied mineral stains enhance its versatility. Their skilled artisans use advanced techniques to mimic the look of materials like wood, metal, and leather, allowing for endless design possibilities. These finishes go beyond aesthetics, delivering durable and unique results tailored to each project.

By blending craftsmanship with decades of experience, Nawkaw helps designers and architects push the boundaries of what textured concrete can achieve. Whether it’s bold facades or intricate interior walls, their work highlights the potential of this innovative material in modern spaces.

Canadian innovation takes centre stage with Corkelite cork spray, a cutting-edge coating made from natural cork granules and water-based resins. According to experts at the company, this versatile solution enhances both energy efficiency and durability, making it a standout choice for modern construction and renovation projects. Achieving Class A certification in tunnel fire tests, Corkelite is the first product of its kind in Canada to meet this high safety standard.

Beyond fire resistance, Corkelite cork spray provides thermal and acoustic insulation, flexibility, and exceptional weather resistance, offering a blend of performance and aesthetic appeal.

Another leader in this realm is the Thermal Elite Pro paints that have been formulated to improve energy efficiency in buildings and reduce thermal absorption. The company states that this decreases the reliance on HVAC systems, contributing to energy savings and enhanced indoor comfort. Like cork spray, these paints are eco-friendly and easy to apply, providing a practical and sustainable solution for projects that combine aesthetics and functionality.

The company states that incorporating products like Corkelite’s cork spray and Thermal Elite Pro paints enables construction professionals in Canada to adopt safer, more efficient, and environmentally-friendly practices, aligning with current industry trends. A

Naturally Perfect™ high-performance wood protection for mass timber structures.

Finish your mass timber masterpiece with Sansin Precision Coat line of Factory Finishes. Sansin Precision Coat systems are designed to maintain the beauty, and integrity of mass timber during production, shipping and construction. This aquatic center in British Columbia is protected with Precision Coat KP-12 and Precision Coat SDF in Sansin’s 2025 Color of the Year – IVORY #21. Sansin’s waterborne coatings allow the mass timber to breathe; absorbing and releasing humidity naturally. Sansin’s IRIS® team can help to optimize the performance of your mass timber structure.

Urban or Rustic?

Neutral or Colourful?

Modern or Classic?

Find your Colour Narrative in our fullspectrum palette that captures more of the widely specified paint colours from across Canada, determined by our Customers and Colour Experts.

Precast concrete delivers faster construction, superior durability, and architectural versatility—ensuring developments are built to last in both structure and style. Build smarter, stronger, and faster with Stubbe’s Precast. Visit Stubbes.org to learn more.

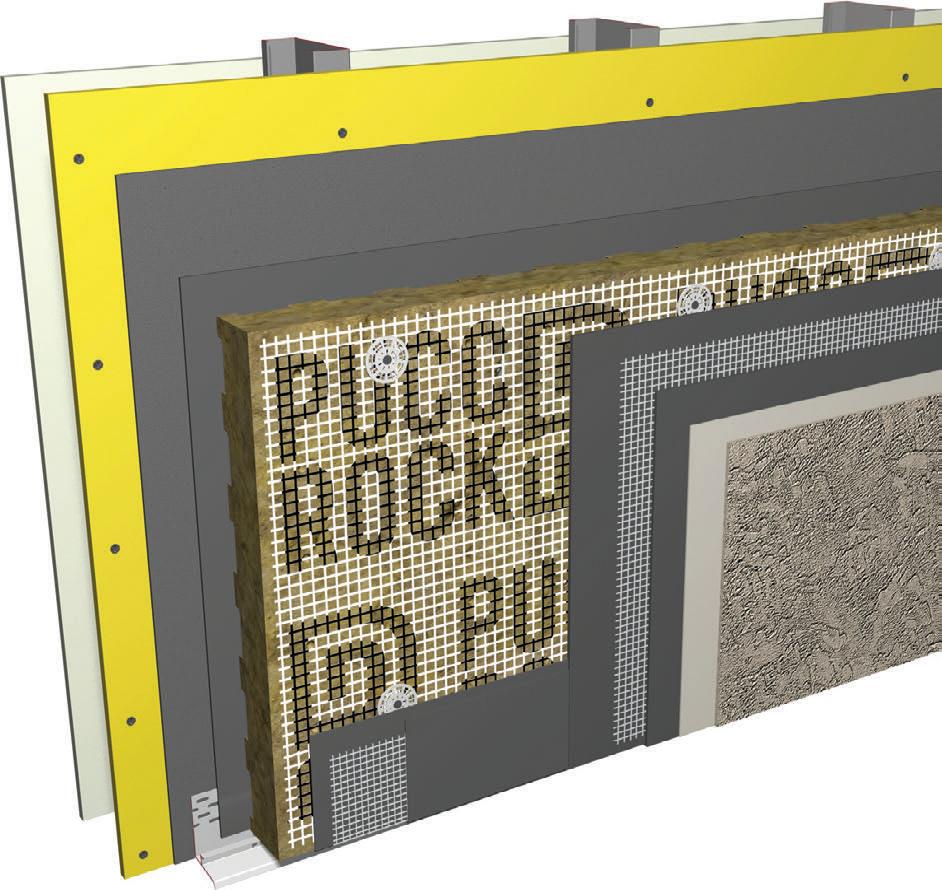

EvoBuildTM is the evolution of sustainable building materials designed to meet today’s sustainability targets.

With knowledgeable experts, science-backed data and sustainable product formulations, we’re able to work alongside you, offering unparalleled service from concept to completion.

EvoBuild™ Low Carbon Concrete is part of Heidelberg Materials’ Evolve™ Family of Products. Learn how these revolutionary products can help your project be part of a greener tomorrow.

The

restoration

by ROBIN BRUNET

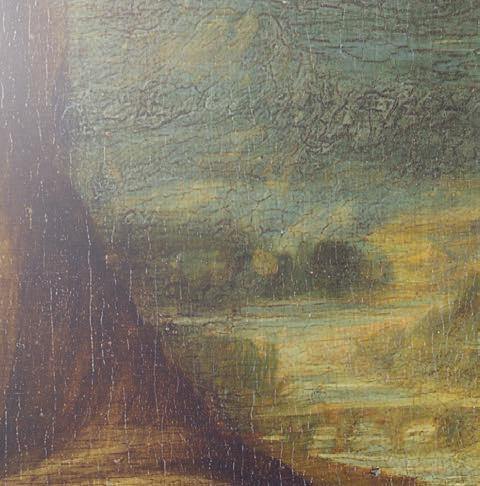

From professionals who carry out the work to those who supply the materials they require, the restoration sector is a perpetual source of brisk business, and product innovation.

In Canada, concrete and masonry restoration is prevalent from coast-tocoast, for projects both utilitarian (infrastructure) as well as of cultural significance – with Ottawa a hotbed of historic structures requiring rehabilitation.

Two examples: the National Capital Commission’s Lady Grey Wall and Escarpment project and the repurposing of the West Memorial Building, both of which rely on the products and expertise of Heidelberg Materials.

The West Memorial Building, constructed between 1954 and 1958, had never undergone major repairs or renovations until 2018, when EllisDon was tasked with securing its 20,000 square feet of usable space for the operations of the Supreme Court and Federal Courts.

Since then, the rehabilitation has involved reinforcing the building, replacing mechanical, electrical, and life-safety systems, and making

seismic upgrades. Structural work includes the completion of new shear walls, reinforcement of beams and columns, and installation of new slab toppings. Additionally, building envelope and heritage work has involved mortar replacement, stone repairs, window restoration, and new roofing.

“We are bound by security not to discuss certain aspects of this project, but we can disclose that we used lightweight concrete solutions for the floor slabs, with a total of 1,000 cubic metres being poured 100 cubic metres at a time. SCL concrete was used for the structural walls, and the sheer scope of work necessitated a vast array of mixing designs,” says Kevin Chevrier, Ottawa-based QC manager at Heidelberg Materials, who adds that the project is expected to wrap this summer.

The Lady Grey retaining wall, built between 1911 and 1913, reaches 10 metres at its highest point and spans 580 metres along the Ottawa River, from the National Gallery of Canada to Sussex Drive. The NCC is repairing the Lady Grey wall to protect its structural integrity, as parts of the wall began to collapse in 2020. This project is also scheduled for completion this summer.

The restoration work was extensive and included the installation of piles and shoring along the north section, demolition of the existing north section of the wall and railing system along Lady Grey Drive, installation of caissons, and the demolition and rebuild of the first 125 metres of the south wall section.

Heidelberg Materials is supplying over 3,000 cubic metres of evoBuild low-carbon concrete for the project. Specifically, the mix design for the wall sections, which represent the vast majority of the project, is ES435201V – evoBuild Silver Low Carbon 35 MPa Flowcrete. This evoBuild product offers more than a 50 percent reduction in the carbon footprint from the Canadian Ready-Mixed Concrete Industry-Wide 2017 baseline, resulting in a reduction of over 470,000 kg of carbon dioxide (CO2) for this wall restoration alone.

Matthew Atwill-Morin, president of Atwill-Morin, a Montreal-based stone masonry restoration specialist, reports that his organization has been particularly busy with restoration projects in the Maritimes lately. “That includes the restoration of the Carleton Martello Tower in Saint John, New Brunswick, which dates back to the War of 1812,” he says.

The second and final phase of this rehabilitation project focused on replacing the fire command post atop the tower. Maxim Construction deconstructed the command post. “We created pockets in the stone wall to accommodate granite blocks, allowing for the installation of steel beams to reconstruct the command post above,” says Atwill-Morin. “Once this phase is completed, we will return to work on the brick vault below.” Atwill-Morin’s team is expected to return to the site in late winter to reconstruct the stonework around the granite blocks once the beams have been installed.

Atwill-Morin has also been working on the restoration of the legendary Province House in Charlottetown, PEI, for the past two years, with completion expected at the end of 2025. Since the building should retain its significance both as a tourist attraction and a historical landmark, work crews have undertaken trenching of ancestral brick walls, the fabrication of openings in load-bearing masonry walls for the passage of mechanical conduits, the replacement of stone paving in interior corridors, and the installation of Wallace-type natural stone alongside the assembly of exterior staircases.

Yet another Maritimes project is the Cape Breton Regional Hospital, completed this year. The work has focused on the building envelope, including masonry solidification, repointing, spot brick replacement, and the installation of Helifix-type

world’s largest residential Passive House EnerPHit retrofit

helical anchors to stabilize the masonry. “Access to the work site was a challenge, and few local suppliers had the necessary equipment,” Atwill-Morin says. “We ended up using lifts and swing scaffolding, which was impressive for the locals.”

Atwill-Morin’s growth continues in the Toronto area, with major restoration projects, including the façade retention and conservation of the heritage building at 263-267 Adelaide St. West.

In the Ottawa region, masonry restoration projects for 2025 include the continuation of the building envelope restoration at the Supreme Court of Canada. Additionally, the Atwill-Morin structure team is working to bring the Place du Portage III federal building up to code by performing structural reinforcement and concrete restoration, including the addition of new shear walls to enhance the building’s resistance to lateral wind and seismic forces.

Huntsman Building Solutions’ status as a world-leading polyurethane spray foam company continued to benefit the restoration sector in 2024. Maxime Duzyk, the company’s senior global director, building science and engineering, says, “Many contractors and architects are adopting the D-Max wall assembly [which allows for the installation of spray foam insulation from the interior of a building while managing the thermal bridging of the studs and structure] in many of their projects – 10 in Quebec alone for 2024-25.”

Huntsman’s Coatlok Coatings, which can be applied to virtually any shape to create a monolithic containment barrier, was used to completely

insulate and waterproof the foundation of the Hillsdale Golf & Country Club in Mirabel, Quebec. As for Huntsman’s renowned Heatlok Soya HP (which leverages Honeywell’s Solstice liquid blowing agent technology and can be used for roofs, walls, subslabs, and other surfaces), it was applied as underslab insulation at the Rockwood Terrace nursing home in Durham, Ontario. “It was a revelation for the general contractor, who was not familiar with using spray foam for insulating under the slab,” Duzyk says. “The speed and simplicity of the installation resulted in time and cost savings, while improving the quality and durability of the assembly – all of this while protecting the building from radon.”

While Huntsman’s work in the residential, commercial, and industrial sectors is well known within construction circles, the company continues to promote awareness of its solutions via webinars and other media, showcasing how seamless insulation and air barriers reduce operational carbon, lead to high energy efficiency, and how sustainable spray foams are key to smart, sustainable residential retrofits.

Lafarge Canada Inc. continues to lead the way in providing materials and expertise for projects focused on durability, sustainability, and reducing CO2 emissions. For example, its parent company, Holcim, achieved a milestone in 2024 with the placement of North America’s first 99.2 percent clinker-free concrete pavement. This collaboration with Stoneway Concrete resulted in a 74.7 percent reduction in CO2 emissions compared to standard concrete.

Pierre Garant, marketing assistant manager at Lafarge Canada Inc., explains, “Our rehabilitation efforts often rely on the precision and customization offered by our BMQ Volumetric Trucks and specialized concrete products. These enable tailored mixes that ensure both durability and sustainability.”

BMQ Volumetric Trucks played a critical role in recent bridge repair projects in Quebec. For example, Ductal Ultra-High Performance Concrete was used to repair internal structural elements of a box girder bridge deck and for pier jacketing on a major bridge, restoring confinement and capacity while protecting against further deterioration.

*(CPCQA) CERTIFICATION PROGRAM BY PROCESS OFFERS KEY BENEFITS TO ARCHITECTS, CONTRACTORS, ENGINEERS, GOVERNMENT AUTHORITIES AND OWNERS.

Additionally, 2,000 cubic metres of Conventional 35 MPa self-consolidating concrete was used to repair columns and overhead box-girders on an elevated urban highway without necessitating prolonged closures. Rapid-strengthening solutions, like Chronomax LX, allowed for quick overnight repairs to minimize traffic disruptions.

Beyond bridgework, BMQ Solutions products such as Solhydflow THT, a high-temperature repair mortar, and Solhydcrete SCC-10, a high-performance self-consolidating concrete, have been instrumental in plant and bridge pier repairs, demonstrating their versatility across diverse applications.

Garant adds, “In addition to our concrete restoration work, we’re deeply committed to biodiversity. A standout example is the 12 Mile Creek Restoration in Pelham, Ontario, where Lafarge donated aggregate to address erosion and improve habitats for species like Brook Trout.”

Innovations in waste reduction also underscore Lafarge’s leadership in sustainable construction. By utilizing recycled aggregates, supplementary cementitious materials (SCMs), and solutions like ECOPact low-carbon concrete and Dynamax high-performance concrete, the company reduces the embodied energy of its materials while extending the service life of infrastructure.

Looking ahead to 2025, Garant says, “Our goals include advancing circular construction by increasing the recyclability of materials, further reducing embodied carbon, and participating in projects that push the boundaries of innovation.”

In infrastructure restoration, waterproofing is often a key component, which is why Xypex Chemical Corporation has become a global leader in crystalline waterproofing technology.

In November, Xypex announced that Concrete Waterproofing Manufacturing Pty. Ltd. (CWM), trading as Xypex Australia, which also includes CWM’s subsidiary XMS (Thailand), and National Concrete Solutions, will become wholly owned subsidiaries of Vancouver-based Xypex.

The new combined business will enhance operations and deliver quality products and solutions to customers. Presumably, it will also continue to undertake unique one-off projects, a case in point being a venture that Xypex recently highlighted as a showcase: using surface-applied waterproofing chemicals to penetrate the concrete substrate of the new pedestal supporting the 83-ton, 3,200-year-old statue of Ramses II stands, in Egypt’s Grand Egyptian Museum.

Since the pedestal is situated in a water pond, waterproofing crystalline technology was vital for the protection of the historic monument. Xypex Concentrate was chosen for its exceptional performance and proven track record, and the waterproofing of Ramses II’s pedestal is now considered permanent.

Meanwhile, Kryton International published an in-depth report last year titled Enhancing Concrete Durability and Reducing Carbon Footprint with Hard-Cem, referring to Kryton’s Integral Hardening Admixture that protects concrete against abrasion, erosion, chipping, and dusting. “In a recent study by ASTM C627 standards, a Robinson Floor Test was used to test the abrasion resistance of Hard-Cem,” the report states. “The test ran 273 kilogram [800 pound] steel wheels over Hard-Cem treated concrete and a control sample for 5,000 revolutions to note the impact. The Hard-Cem-treated concrete exhibited significantly less wear compared to the control sample.”

The report also notes that thanks to Hard-Cem, New Gold Inc.’s New Afton Mine in Kamloops has extended the life of its concrete infrastructure, avoiding at least two replacement cycles.

416.746.2479 | tklgroup.com

Kevin Yuers, VP of Product Development at Kryton, says, “Our normal experience is that Hard-Cem will double the lifespan of most concrete, thus preventing emissions to a significant degree. That’s why we continue to tell municipalities and other governments to ‘just fix it once’ by investing in the proper products, rather than trying to cut corners and having to repair infrastructure annually.” A Designing, consulting, manufacturing & installation of eco-friendly architectural and structural precast concrete

Specializing in Luxury Appliances for Residential and Commercial Developments

Contact: Michael Gnat | 416-635-4835 mgnat@midnorthern.com 45 Red Maple Rd. Richmond Hill, ON Learn more at midnorthern.com

INTEGRATION + CONNECTIVITY SLEEK

INTUITIVE PERFORMANCE + VIKING

THE NEXT GENERATION OF REVEALING NOW AT

The latest in appliance innovation is driving ultimate convenience, control, and energy efficiency

by LAURIE JONES

Appliances are no longer just functional; they’ve become statement pieces that bridge the gap between professionalgrade performance and the everyday needs of homeowners, offering a seamless blend of style and efficiency. To meet the demands of diverse lifestyles and design preferences, manufacturers and suppliers are stepping up with innovations that cater to every taste.

In 2024, Fisher & Paykel launched its Series 11 48-inch Professional Induction Range. This full induction range expands upon the brand’s cooking solutions to provide a new level of precision, power, and control with its ultra-responsive induction cooktop and two independently operated oven cavities.

Designed with professional cooking results in mind, this robust range combines specialized cooking functions, intuitive technology, and energy-efficient power. “Fisher & Paykel is proud to offer such a beautiful and comprehensively engineered induction range for this growing product category that represents, in many ways, the future of cooking,” says Sam Zalin, Fisher & Paykel’s VP of product management, U.S. “Drawing on decades of temperature engineering, this introduction ensures precise heat in a variety of forms.”

The 48-inch Professional Induction Range’s ceramic cooktop features six induction cooking zones for ample space and flexibility. Two of the zones can be paired to form Smart Zones that support larger cookware. While larger ranges typically require higher circuit capacity, The Series 11 48-inch Professional Induction Range can work with a 50A circuit, meeting U.S. electrical code standards. This means some homeowners won’t need special hardwiring for installation. With 15 oven functions in the main cavity, 11 in the secondary, and a handy food probe to help monitor progress, the Range delivers the ultimate cooking flexibility.

Euro-Line Appliances president Mark Eglington sees an appliance colour trend moving into matte black, mimicking what is happening in the auto industry. “Although 95 percent of sales is still with stainless steel, about four percent will be with the matte option. We have products coming out under the AEG brand that would be a matte black colour for the built-in product, with sizes ranging from 24- to 48-inches,” says Eglington.

He adds that Euro-Line will be offering a brand new 36-inch built-in wall oven from AEG this year that will have a matching built-in coffee machine, a warming drawer, and a couple other items surrounding it to create a matching portfolio. “We’re also seeing cooktops moving toward a matte black, scratch resistant style. Also available are glass cooktops and black porcelain enamel cooktops.”

Eglington explains the company took an opportunity during COVID to re-evaluate their line up and created a unified family portfolio aesthetic. “We matched up all the products across the board with each other. It’s turned into something that’s visually beautiful that features a dark, black, glossy glass with stainless steel assets. The design community has taken to it due to its minimalistic appearance, which means the designers can create a beautiful kitchen and not worry about appliances interrupting their vision for what the design and the flow should look like, because it’s all focused on the entry level products, even though it still comes from Europe – and because it’s held privately by us, there are no miscellaneous fees. We’re able to be highly competitive with the pricing in the market and the quality of the product comes out of factories that we’ve worked with for 30 years.”

Michael Gnat, director of commercial sales for Midnorthern Appliance (a division of The Brick Warehouse) says, “Trends in appliances continue to show a migration to induction cooking over gas as the alternative to traditional electric.

Manufacturers are not investing in new gas technology given several jurisdictions are pushing away from gas.” He explains several brands are introducing full surface induction cooktops. “These allow the user to place their pots anywhere they choose rather than being confined to designated cooking zones.”

Gnat notes there is also a higher demand for all black appliances versus stainless steel for market condominiums. “Even companies such as Wolf, Miele, Jenn Air, and Monogram are showing more black on their built-in cooking products. The use of cabinet panels on built-in refrigeration and dishwashers continues to be used in multi-unit residential applications. We are getting requests for freestanding stainless steel for purpose-built rental projects as developers and asset owners see a long-term advantage for replacement, should the need arise, that would not impact kitchen sizes.”

According to Canadian Appliance Source national flooring manager Alicia Harmon, white appliances are making a stunning comeback – and they’re better than ever. “While traditional textured white refrigerators and coil-top ranges still hold their well-earned place in the appliance world, a fresh new aesthetic is taking over.”

She notes today’s white appliances come with high-end features like bronze, black, platinum, and champagne hardware, sophisticated glass finishes, and cutting-edge technology – think illuminated knobs and cooktops, push-to-open connected wall ovens, AI cameras, and even tablets built into fridge doors.

“Reimagined cooking appliances are available in dual fuel, gas, electric, and induction options, making them perfect for every type of home chef,” she says. “For those who want even more tech, there are options to sync all of your appliances to your home’s Wi-Fi network.”

These updated classics combine sleek design with ultimate functionality. “Clients are loving the pristine, fingerprint-free look, while designers admire how they effortlessly blend timeless elegance with modern flair, transforming any home. With trusted brands like GE Café, Samsung, KitchenAid, Whirlpool, and LG Studio leading the charge, these aren’t your grandparent’s appliances anymore,” Harmon says.

Blair Bishop, regional sales manager at Middleby Residential Canada Brand says that Viking is taking a detour from the professional appliance space they created and entering the more contemporary design kitchen spaces with the debut of its new Viking RVL Collection. “With a fully integrated design, RVL seamlessly blends tradition with contemporary flair, showcasing unparalleled craftsmanship, innovative design and the cooking performance you expect from a true Viking product,” says Bishop.

The modern styling and innovative controls further revolutionize the home kitchen with a dynamic product offering including steam and convection ovens, cooktops, and warming drawers. “The RVL products have been reengineered to fit into cabinetry with industry leading small reveal tolerances and the ability to install products either vertically or horizontally,” says Bishop. The RVL Single and Double ovens utilize a two-speed convection system to evenly circulate air throughout the entire oven cavity along with the environmentally friendly Steam Clean feature that is perfect for light and medium cleaning and only takes 20 minutes.

The Viking RVL Single and Double ovens are the first Viking products with an all-in-one platform for connected cooking and a streamlined user interface outfitted in stunning black glass. The touch control screen allows for easy adjustment of the oven while the app provides seamless guided cooking, including over 200 recipes to make cooking as easy as it is delicious.

Along with the single and double ovens, there are additional new products that are part of the RVL built-in cooking product line. The 30-inch Steam Oven

brings a new dimension to culinary possibilities and the induction cooktops, offered in 30- and 36-inch sizes, redefine cooking efficiency, offering superior power, responsiveness and efficiency.

Behzad Joushan, key account manager, Trail Appliances’ multifamily builder sales division, notes artificial intelligence is making significant strides in the appliance world. “It’s exciting to see how manufacturers are leveraging this technology,” he says. “Smart washers and dryers use AI to detect weight and fabric type, automatically adjusting wash cycles for optimal performance. Beyond laundry, we’re seeing smart refrigerators that can track the items inside and suggest recipes, as well as ovens that learn your cooking preferences to perfect each meal. These advancements not only improve user convenience but also enhance energy efficiency and appliance longevity.”

He adds steam ovens are gaining popularity as a healthier cooking option. “They retain more nutrients and vitamins in food compared to traditional high-heat methods, reducing the need for added fats and oils. Additionally, steam cooking minimizes the formation of harmful compounds, making meals both delicious and nutritious. This trend aligns perfectly with the growing consumer focus on health and wellness, and it seems like they’re gaining traction in kitchens everywhere.”

Another trend worth noting is that built-in designs continue to lead. “We’ve noticed that the built-in aesthetic remains a top preference among consumers, maintaining its strong presence from previous years,” says Joushan. “This trend is all about creating a seamless and cohesive look in modern kitchens. Built-in appliances not only enhance the overall design but also save valuable space, making them a favourite for both new kitchen builds and renovations. The sleek, integrated appearance appeals to homeowners who appreciate both functionality and style.”

From customized coffee makers to smart appliances to AI technology, the home appliance market is constantly evolving. In keeping up with the fast-moving

trends, the team at TG Appliance Group Inc. offers a broad range of options for consumers. “In 2025, we will see change beyond the design freedom to integrate and fully customize your appliances, and more focus on the refinement of smart technology and connected appliances,” says Iris Brown, director of store merchandising and promotions. “We are now seeing several platforms that connect and control smart home appliances, from Amazon Alexa, Apple HomeKit, and Google Home with a large ecosystem of compatible devices, to exclusive appliance apps like Home Connect [Bosch & Thermador], SmartThings [Samsung], and ThinQ [LG]. These platforms vary in their features, supported devices, and user interfaces, offering remote control, smart assistance, and service diagnostics, and step-by-step recipes.”

Brown adds many ovens now include an air fry mode, harnessing the trend that offers healthier cooking with delicious crispy results of traditional baking/ roasting. “The convenience eliminates the need to switch between appliances and by combining two appliances into one, it frees up counter space. Electrolux and Frigidaire, GE, LG, Whirlpool, and Samsung ranges and ovens lead the market with air fry mode option.”

Sylvia McDonald, client relations representative at Midland Appliance, notes that one trend in the evolving landscape of kitchen design is capturing the attention of homeowners and interior designers alike: custom ranges that reflect unique styles and meet specific culinary needs. “European brands such as Officine Gullo, La Cornue, Ilve, and AGA all offer personalization where homeowners can choose from various finishes, colours, and materials to match every kitchen style.”

She adds these custom ranges are available in various sizes and offer features such as high output gas burners, griddles, French Tops, and induction burners.

“Each is built with high-quality materials and craftsmanship to ensure a higher standard of construction, leading to better performance and durability.”

As the demand for personalized home experiences continues to grow, the market for custom ranges is expected to expand. “Whether you’re a gourmet chef or an occasional cook, a custom range can transform your kitchen into a space that truly feels like home,” says McDonald. A

Diamond Polished Concrete is a unique, advanced flooring system that brings out the natural beauty of concrete, helps reduce maintenance costs and enhances the natural durability of concrete surfaces. The Tri-Con Diamond Polish System employs an innovative 7-step grinding and polishing process that utilizes progressively finer diamond grinding heads. This system also uses the most advanced penetrating sealer technology.

Tri-Con Concrete Finishing is an industry leader with more than 30 years experience in the concrete industry. We are a one-stop supplier capable of pouring new floors to exact specifications as well as restoring existing concrete surfaces with endless versatility. We guarantee that we deliver on time, on budget and on spec every time.

by LAURIE JONES

Hard surface flooring experts are stepping up their game, blending timeless elegance with modern functionality. From eco-friendly materials to cutting-edge innovations in installation, the latest trends are reshaping how designers and homeowners approach flooring. Whether it’s sleek and sustainable or effortlessly easy to install, these floors offer a perfect balance of beauty, durability, and practicality for the year ahead.

“Olympia Tile + Stone is committed to staying ahead of current trends, and this is perfectly showcased through two of our best-selling lines,” says Anila Bregasi, senior director of purchasing and product development. “Our large format tile sales continue to grow, and one of the best examples from Olympia’s portfolio is the Arkistone series. This comprehensive limestone replica collection is available in five colours and offered in a range of sizes, starting from 12-by-24-inch up to 48-by-48-inch. The versatility of the Arkistone series makes it ideal for both indoor and outdoor applications.”

Bregasi notes luxury stone replicas are not new, but they remain a prominent trend, and the Room series from Olympia is a great example, showcasing high-definition stone imitations in a six-millimetre thickness. “New designs are added annually, with

the catalog currently featuring 21 stone designs and 10 decor options. Sizes range from 24-by-24-inch to 48-by-110-inch, with various surface finishes available. The six-millimetre thickness ensures ease of installation on most interior floor and wall surfaces.”

For 2025, Ames Tile + Stone offers the Kerlite Easy line, the first certified and patented dry lay system for ceramic flooring. Made in Italy, Kerlite makes sustainable renovations fast and easy. “Our installation team found the Kerlite Easy system very easy to work with and install,” says Dave Griffith, project manager at Bridgewater Tile. “It was less labour intensive than a typical porcelain tile installation due to the fact the tiles are loose-laid and not bonded directly to the substrate with thin set.” He adds people can walk on the tiles immediately after installation.

Used for both residential and light commercial applications, a Kerlite Easy installation has an overall thickness of seven millimetres, making it useful to overlay existing surfaces and avoid costs of old tile removal. The Silent mat and Filler sealant used on the reverse side of Kerlite slabs provide a resistant, stable, and waterproof floor system. Weighing only 13 kg/m2, a new porcelain stoneware floor can be installed without adding significant weight to existing surfaces.

Installed without mortar thanks to the exclusive use of fibreglass-reinforced Kerlite slabs, the porcelain stoneware Easy flooring system is more durable than other traditional tile-laying systems and is

available in stone, concrete, marble, and solid colour options. They are also CO2 neutral and come with a 20-year warranty.

American Biltrite recently launched Abdefender, a revolutionary collection of rubber flooring and stair treads specifically designed to enhance safety in high-rise building emergency exit areas. With its exceptional fire-retardant properties and low smoke development, Abdefender sets a new standard in protective flooring solutions. Available in six versatile colours, this collection offers rubber tiles with a round profile and stair treads with integrated risers, either with or without visually impaired safety strips. Custom colours and stair treads are also available for larger orders, ensuring design flexibility without compromising safety.

“Safety and innovation are at the heart of everything we do,” says Jean-Pierre Benoit, corporate VP and general manager at American Biltrite. “With Abdefender, we are providing architects, engineers, and builders a dependable solution that prioritizes occupant protection in the most critical spaces, such as stairways and emergency exits. Designed to comply with stringent building codes in North America, Abdefender offers reliable fire and smoke safety for high-traffic areas.”

Abdefender is also Red List free, demonstrating its compliance with the Living Building Challenge Declare program. This certification underscores American Biltrite’s commitment to material transparency, toxic chemical avoidance, and simplifying material specification and project certification processes. From hospitals and schools to airports and residential towers, this collection is engineered to protect both people and buildings in case of an emergency, all while providing an elegant and durable flooring solution.

Forging a path in eco-friendly products, Shnier and Division 9 are committed to delivering sustainable tile solutions that balance style, performance, and

environmental responsibility. By partnering with forward-thinking suppliers, they prioritize eco-friendly manufacturing practices that reduce environmental impact, without sacrificing quality or design.

“Our brands – Richmond Tile & Stone and Division 9 Tile & Stone – place sustainability at the core of their product offerings. This approach is rooted in three key areas: economic responsibility,

social accountability, and environmental stewardship,” says Greg Vrantsis, product manager – ceramic tile at Gesco Industries LP. “We focus on sourcing innovative, sustainable products that make a meaningful difference, such as tiles with up to 45 percent recycled content, zero industrial wastewater discharge, a 99 percent internal process recycling rate, and over 95 percent of raw materials sourced locally – within a 500-mile radius – to reduce carbon emissions.”

Vrantsis explains the product selections include: Native Wood – a carbon-neutral wood-look that pays tribute to classic wood designs while offering a modern, sustainable alternative; Plaster 2.0 –the first fully carbon-neutral tile that blends artistic Venetian plaster styling with bold hues and versat ile formats; Area 51 – a sleek, minimalist urban concrete-look tile designed for residential and commercial spaces; and NetZero – a modern slatelook tile in neutral tones and practical sizes for any environment.

“From feature walls to high-traffic floors, Richmond Tile & Stone and Division 9 Tile & Stone tiles deliver beautiful, durable, and environmentally conscious solutions,” he says. “As Canada’s trusted leaders in floor and wall coverings, we continue to drive sustainability in the industry – one innovative collection at a time. We are proud to supply industry-leading brands, including AHF, Armstrong, Tier Element, HTMX, Aspecta, and many others. Our extensive portfolio includes a wide range of commercial floor coverings that deliver on performance, design, and sustainability.

Schluter-Systems, a leader in tile installation innovations, is excited to introduce its latest products: Schluter-Ditra-PS peel and stick uncoupling membrane and Schluter-Primer-PS, a brand-new primer specifically designed for use with Schluter peel and stick membranes. “Ditra-PS brings the benefits of the original Ditra membrane – the multi-tasking underlayment that provides uncoupling, load distribution, waterproofing, and vapour management for durable tile installations – to a convenient peel and stick format,” says Dale Kempster, director of standards and methods. “Ditra-PS features a pressure-sensitive adhesive on its underside that provides strong adhesion to a variety of substrates, including concrete, OSB, vinyl, laminate, and more. This new option eliminates the need for thin-set mortar to install the membrane, significantly reducing installation time, labour costs, and cleanup.”

Primer-PS is a ready-to-use topical primer designed specifically for Schluter’s peel and stick membranes. It optimizes adhesion by creating a uniform layer that strengthens the membrane’s bond to various substrates, ensuring a durable and reliable connection.

“With a quick drying time and easy one-coat application, Primer-PS simplifies the installation process while providing a strong, long-lasting bond,” Kempster explains. Ditra-PS is offered in both rolls and sheets and Primer-PS is available in one-quart and one-gallon formats, providing flexibility for various project sizes. Both products are now available, with detailed product information accessible through the Schluter-Systems website.

Custom Building Products, known for its innovation and commitment to quality manufacturing, offers a grout colour selector, enhancing the appearance of finished tile or stone installations to create a definite wow factor. Whether accenting or blending with the tile, Custom Building Products’ visualizer uses a variety of grout options to fit the installation’s unique needs, including: Fusion Pro for stain resistance; CEG and CEG-IG epoxy grouts for chemical resistance; Prism performance grout; and SimpleGrout pre-mixed grout, ready to use.

Choosing the best grout colour starts with selecting the tile for installation. Consider the characteristics of the tile and the desired finished look. Is the tile patterned or solid? Is it made of natural stone, ceramic, or glass? If it’s glass, is it transparent or opaque? Finally, think about whether you want the grout to stand out or blend with the tile. If the grout colour matches the tile, a solid hue will make the installation look larger, although

colour variation could break the look. But if the visible tile pattern has a contrasting grout, it will create a striking look. Mixing the grout tones with the coloured tile opens up a wide variety of design options.

At Maxxon, experts understand that acoustics are essential for creating quiet, comfortable living environments in multifamily buildings. Acoustic consultants work with developers, using science-backed processes, building code requirements, and years of experience to achieve the best results for building projects.

Maxxon-certified applicators undergo rigorous training to ensure top knowledge in installation techniques, code requirements, and the latest advancements in sound control technology.

Quality products are key to successful installations, and Maxxon Authorized Applicators have access to exclusive lines such as GypCrete, Commercial Pro, and Acousti-Mat. A

Unrivaled Service | Unparalleled Expertise | Bold Innovation

Why Galvanize?

✔ Maximum Protection

✔ Durability & Adaptability

✔ Longest Life Coating

✔ Best Return on Investment

✔ Eliminate Maintenance

Corbec Specializes in Galvanizing a Wide Range of Structures and Metal Products, Including: and more!

Buildings

Bridges

Galvanized Rebar

Towers & Electric Power Grids

Steel Structures

OEM Products

To Corbec What Matters Is:

▪ Galvanizing Better

▪ Quality & Innovation

▪ Expertise & Quality Assurance

▪ Service - Pre-During and After the Project

▪ Collaboration and Assistance to the Project Team

State-of-the-art Facilities

Hamilton | Montreal | Quebec | Halifax

Publishing with CSA, the first-ever Environmental Product Declarations (EPDs).

The first in Canada for Galvanized Steel

The first in North America for Galvanized Rebar

Environmental Product Declarations (EPDs)

EPDs are critical in assessing the environmental footprint of materials, assisting in making informed decisions and effects the scope for considerations and design for sustainable construction projects. Why EPDs Matter?

The Advantages of Using EPDs

▪ Leverage long-term cost savings

▪ Gain a competitive edge

▪ Reduce Environmental Footprints

▪ Enhanced Life Cycle Assessment

▪ Achieve Green Building Certifications

▪ and more

Utilizing EPDs in Your Project

▪ Material Selection

▪ Design Optimization

▪ Establish Clear Sustainable Targets

▪ Life Cycle Assessment

▪ Transparent Reporting

Advocacy and innovation are more essential than ever in driving structural steel’s growth

by ROBIN BRUNET

Given the ever-growing regulatory landscape, it seems every aspect of construction requires a strong advocate and lobby force behind it – a need keenly appreciated in the structural steel sector as 2025 unfolds.

The Canadian Institute of Steel Construction’s (CISC) vision as Canada’s voice for the steel construction industry is to provide leadership in sustainable design, construction efficiency, quality, and innovation. The CISC fosters dialogue, collaboration, and commerce among industry stakeholders, advancing the benefits of steel to consultants, builders, buyers, academia, and government.

In June, the CISC appointed Keanin Loomis as its new president and chief executive officer. Since then, the 95-year-old institute has become notably more active in promoting dialogue and collaboration. It has also responded swiftly to industry developments, such as in August when Ottawa announced 25 percent tariffs on Chinese steel, aluminum, and electric vehicles. The CISC praised the measure, stating it had “advocated to the Department of Finance that the government adopt this measure. In the coming days CISC will undertake an in-depth review of the specific products the Department of Finance proposes to subject to the tariffs and will offer additional feedback to the government where appropriate.”

The institute added that, “the government should establish ‘Fabricated in Canada’ requirements for the construction of all taxpayer-funded and supported manufacturing projects that contribute to the transition to a low-carbon economy, including EV and battery plants, to maximize the return on taxpayer investment.”

Loomis shared with Award magazine, “Advocacy is badly needed in our sector, right down to the granular level. In terms of getting our message out, this is a new era for us, and we see 2025 as a pivotal year for change.”