The only Australian made front. Made by Aussie farmers, for Aussie farmers.

HARVEST MORE FOR LESS WITH MIDWEST

The only Australian made front. Made by Aussie farmers, for Aussie farmers.

HARVEST MORE FOR LESS WITH MIDWEST

How

The only harvesting front designed and manufactured in Australia

High strength yet lightweight design

Smooth and consistent ground contour following

The most economical platform on the market

Limited electronics provides increased reliability and performance

No step smooth design behind the cutterbar means less crop loss

A good feature of the Midwest is the straight cut off the knife onto the belt, no obstructions means it feeds a lot better and you don’t lose heads.

BRAD GLOVER MIXED FARMING, HERMIDALE

Midwest draper platforms enable you to harvest more, for less. With extra wide platforms you can reduce harvest time and man hours, while superior performance features ensure you are harvesting as much as possible.

From 30ft through to 60ft we can supply a front to meet your harvesting needs.

Our three extra-wide sized platforms (50, 55 and 60ft) bring productivity and efficiency gains to optimise big combine performances and capacity in terms of tonnes/hour and hectares/hour; and most importantly reducing harvest costs per hectare or per tonne.

No other brand of grain harvesting platform can match these Midwest platforms for harvest width and performance features, and in turn deliver exceptional low cost of ownership value as a matched harvester/platform combination with the best resale value on the market..

No matter what size CTF System you operate with, Midwest now has a platform size to effectively operate in that production system.

The Midwest Durus range of platforms are the only grain harvest platforms in today’s market that are sized for all CTF Systems.

Currently we’re running four Midwest 60ft fronts. We’re stripping about 2500t a day, with the four machines travelling at 5-6km/hr and covering about 10ha/hr per machine. They’ve certainly got us hopping!

ADAM COLEMAN OODNADATTA FARMS, MOREE

Lightweight strong truss platform frames built to handle harsh harvesting conditions.

Working independently of the combine, Midwest’s patented Hoverpoint air ride adaptor has fantastic ground following in uneven or contoured country. The air ride adaptor ensures smooth movement in rough conditions and our unique float system utilises the laws of gravity without the need for electronics or ground sensors, guaranteeing quick real time response. The platform is mounted above the feeder house allowing the platform to sit 500mm closer to the cab than other brands, giving the best operator visibility on the market. This mounting gives us significant weight leverage benefits allowing us to build wider drapers without compromising the combine feeder house lift capacity.

Airbag cushioned platform ground wheels for smooth platform ground contour following. 60ft has four ground wheels, all others have two. This combination delivers accurate and smooth platform ground contour following and ride in the field, even in higher speed harvesting conditions.

Midwest’s strong but simple design and lightweight truss style platform frames are built to handle varied harvest and ground surface conditions.

Our renown high strength and lightweight design has been achieved by leveraging a one piece length of “superform” steel for the frame main back bone. The structure strength per kilogram of steel is nearly twice as strong as the usual 350 Grade high strength steels used in many applications.

Our widest 18.3m (60ft) platform weighs in at a very light 5180kgs.

Two front lights on the reel arms and two rear stubble lights above the ground wheels turn night into day. Reducing driver fatigue with clearer visibility for increased safety.

Our industry leading draper belts are puncture and tear resistant featuring reinforced cleats to give longer working life to the draper belts. The centre ‘V-Guide’ belt tracking facilitates ‘true’ alignment preventing premature wear and uneven stretching and enables the belts to be reversed if the front edge becomes damaged, effectively doubling draper life. With strong vulcanised drive rollers, positive draper drive is ensured at all times and features single point tensioning for quick and even belt tightening.

Large capacity 90mm carbon cog drive system for the efficient and high transfer of power from the combine to the platform. High capacity knife and feed drum drive train with field proven radial button clutch protection.

The superior dual timed knife enables high speed cutting in all crop types and conditions. Synchronised high power drives deliver minimal vibration and smooth operation through the carbon COG drive belts. The NO STEP smooth stainless steel surface behind the cutterbar ensures fast and even crop flow onto the draper belts minimising grain loss and giving perfect crop feed to the combine.

Midwest cutterbar gauge wheels are rolling skid wheels on the extremity of the cutting table right behind the knife enhancing the ground following performance. Low cutting conditions such as pulse crops, melon holes and roll over contour banks are no issue. The unique mud-scraper eliminates soil sticking in damp conditions.

Solid rubber tyres alleviate any flat tyre issues. Matched with Midwest’s patented centre lateral pivot ball and suspension system make dirt build-up a thing of the past.

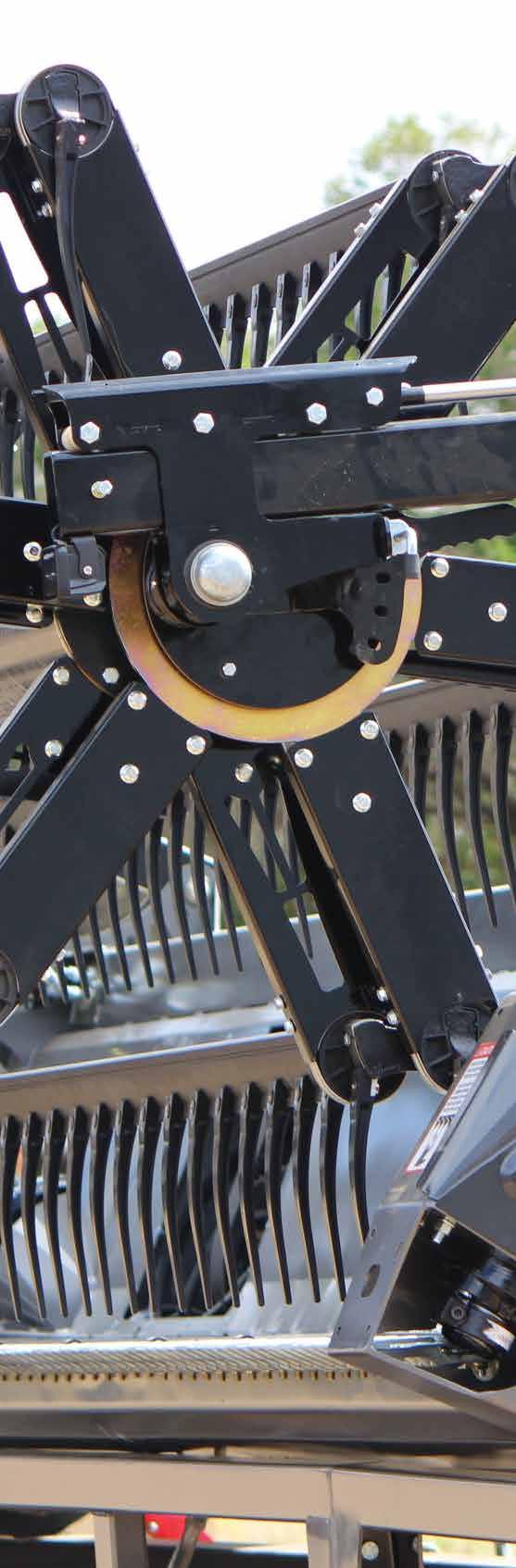

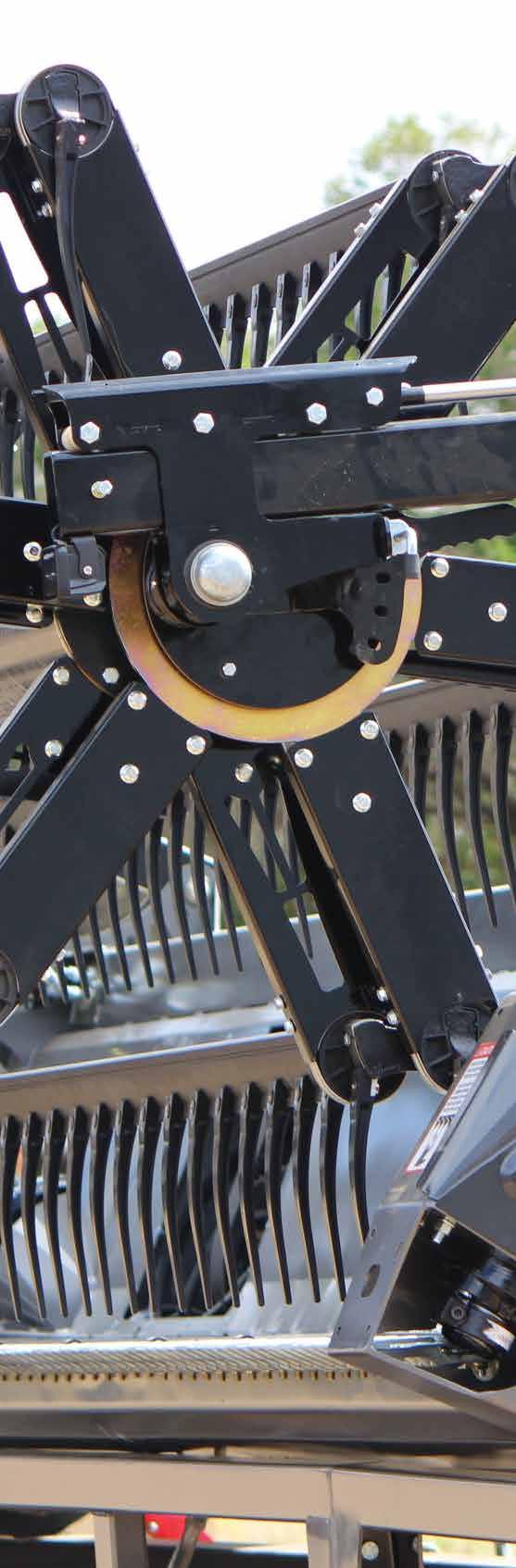

The Midwest Durus Premium platform features the largest diameter six bar pickup reel available on the market today giving greater crop reach and offers 20% to 44% more finger tines than competing brands.

The Midwest tine reel is designed specifically for Australia’s hard and fast harvesting conditions while ensuring superior functionality in varying crop types and yields.

Made from extruded aluminium the reel is lightweight and strong. The wide reel bar design acts as a bat reel enabling smooth crop lay down onto the draper mat for the ideal crop flow.

It features six reel bars instead of five, allowing significantly slower reel speeds preventing grain shatter and crop losses from the reel and at the knife.

The reel fingers are stronger to ensure they last you longer. Made from specially engineered nylon they are lightweight and highly durable. Featuring UV resistant properties and excellent abrasion resistance they are designed to withstand harsh harvesting conditions. These long life fingers offer the best crop engagement, gathering and recovery available on the market today.

The replaceable large reel bushes on aluminium extrusions are cost effective and simplistic in design, saving you time and money.

The reel offers an adjustable hydraulic relief valve to help minimise damage from accidental impacts in field. EXCLUSIVE MIDWEST SIX BAR REEL

The unique Midwest feed drum is positioned forward in the crop flow, guaranteeing aggressive force feeding in all crop types and conditions. The tapered drive ends provide smooth crop flow under the floating feed drum that is torque clutch protected featuring feeder reverse for dislodgement of foreign objects. Large capacity 410mm (16 inch) feed drum with flighting for positive and aggressive feeding of all crop types from the centre belt into the combine feeder house.

Add to the performance of the Midwest Durus Premium platform with various options to match your requirements:

Range of knife guards and sickles to suit crop types/ harvest conditions.

Outer Gauge Wheels (end) for further enhancing platform ground contour following, especially with low to ground crops.

Canola cross augers for direct cutting canola and enhancing crop feed onto the centre belt and centre feed drum to the harvester feeder house.

Engineered Highway certified Transporters especially for wide platform transporting and ease of maneuvering between fields and farms.

Tow Hitch on Transporter is a 40 or 50mm ring feeder and large seven (7) pin plug.

See option details over the page.

Manual Quick Change Sliding Deck giving versatility to windrow cereal crops, grasses and stubble.

Note: This options is only available when ordering a platform and is not available to be added on at a later date.

Fully integrated cross auger for no more dead spots, uneven or clumpy feeding.

Cutterbar wheels give instant ground following response right behind the knife. Ideal for contoured country and low cutting conditions.

2 finger 3” single cut

4 finger (long short)

General purpose. Sickle has 76mm centres. Limited cutting speed.

1 1/2 single cut guards

Designed specifically for pulse crops, will handle others. Used with standard sickle knife sections. 76mm centres on long points, 38mm centres between long and short points, half guard helps reduce crop shatter.

3 finger 2” double cut guards

50mm guards used with a double cut sickle bar on 2” centres. Ideal for higher speed cutting conditions. Attachable extensions available.

Weights are based on Durus Premium platforms with 6 bar pickup reel and floating adaptor. Weights may vary with different options and configurations.

Platform weights and dimensions

Platform features

Platform Specifications

Five bar pick up reel

bar pick up reel

Drive System

68 mm Carbon Cog Belt Drive

90mm Carbon Cog Belt Drive

Suspension / Adaptor

Literal Spring Adaptor

Vertical & Lateral Air-ride

Adaptor

Claas Combine hydraulic valving

The weights are harvest ready weights including oil, feed drums, adaptor and ground wheels. Refer to combine manufacturer sales and services literature for permissible loads and weights etc.

Ground Wheels Standard gas strut gauge wheels

airbag gauge wheels

Other Features

Single Right hand delivery windrow

LED Fore and aft lighting package

Cross Auger; price is subject to platform size

Midwest’s highway compliant custom built transporters are a convenient, reliable and safe way to move your draper platform. Our optional onboard toolboxes mean that everything is at your fingertips for in field servicing. Whether you operate harvest, forage or windrow platforms, Midwest’s specialised mounting kits mean all brands can be fitted to our transporters.

Midwest transporters have you covered no matter what width or model you have.

Standard features Optional features

• Highway compliant

• 40mm ring feeder tow eye

• Steel mud guards and Midwest mud flaps

• 850mm ball-race turntable

• LED lights & rotating beacon

• Oversize sign with flag holders

• 15” six stud wheels

• 50mm square axles

• Jockey wheel

• Platform tie-down points with turnbuckles

• Marine grade 2 PAC paint finish

• Electric brakes

• Spare tyre with mounts

• Toolboxes

• Platform mount kits

Toolbox options

By running 60ft fronts on our combines we cover more country in a day with less headers, slower speeds, less fatigue and lower fuel use resulting in lower cost of ownership.

WILSON MANAROO | WALGETT