Manutec embarked on a new project in 2014 with the aim of replacing all of our standard range of bearing fitted press wheels and discs with a completely new range of Zero Maintenance quick repair press wheels. Since 2014 we have been introducing different versions and now 95% of wheels sold are Zero Maintenance. Additionally nearly all of Manutec’s Australian made seeder manufacturers now fit AgriHubs as standard.

Manutec now has available five different press wheel and disc hub units. The new units are all repair by replacement, are non-greasable and require very little assembly. All new assemblies can now be purchased with a Zero Maintenance option. Additionally older wheels can also be replaced with the new Zero Maintenance option.

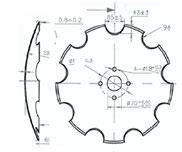

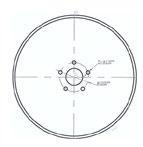

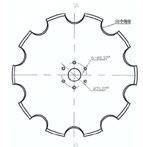

PCD available are 5x108, 5x98, 4x98 and 6x98 All units can be replaced by staff with very little technical training. The images on the right show the current range of Zero Maintenance hubs and wheels.

A range of opener and coulter discs is also now available to suit these AgriHubs in 5x108 and 5x98 PCDs.

Australian Manufacturers

Now using AgriHubs

Gason

Daybreak

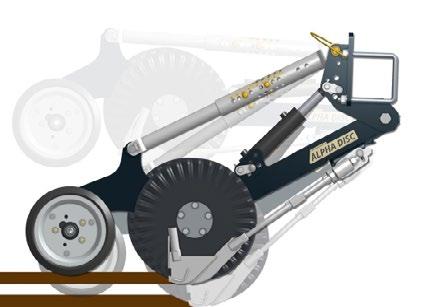

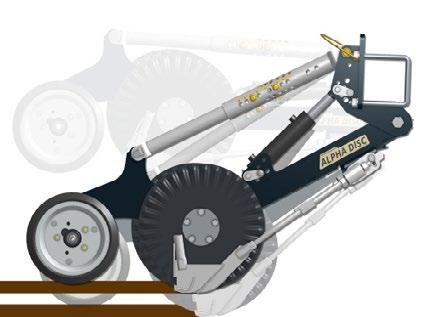

Alpha Disc

Multi Planter

Toowoomba Engineering

Horwood Bagshaw

Rootboot

Knuckeys

Gessner

Aftermarket

AgriHub replacment for older Press wheels

Horsch

Sow EZY

Horwood PSS

Morris C1 and C2

Flexi-Coil PD5700 and custom made to suit most machines

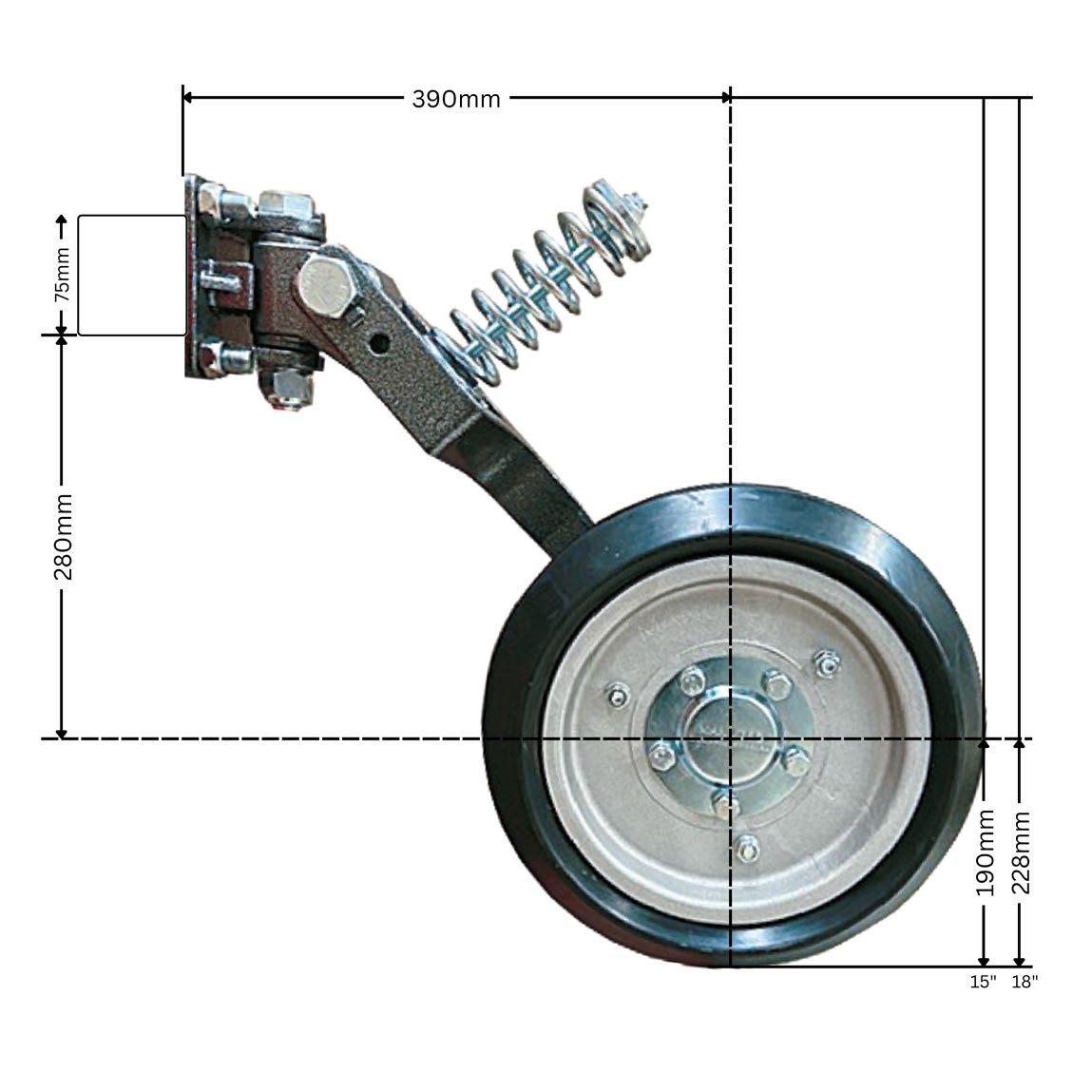

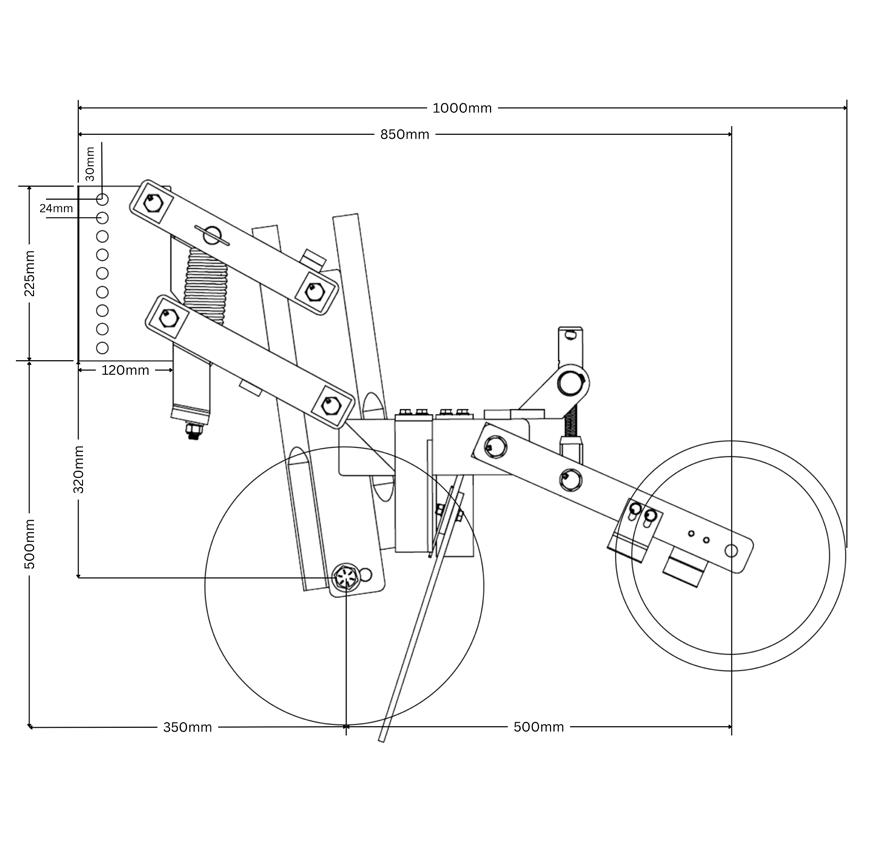

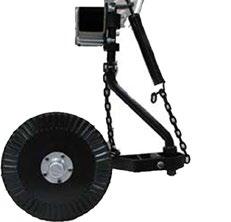

Walking Wheel Assemblies are a cost effective option that utilizes one single bracket and arm to run a pair of wheels offset fore and aft. They are available in swivel and fixed variants. Walking Wheels are mounted across the back of the machine either on the existing bar (space permitting) or on a new purpose built tool bar. Walking Wheels have adjustable axles and generally will suit spacings from 5” to 14”, higher spacing can be achieved however Manutec recommends that other options may be better considered. Walking Wheel Assemblies come standard fitted with AgriHub Press Wheels in either 15”, 16” or 18” Solid and Semi-Pneumatic Wheel profiles. If required variants are also available with Integral Hubs and HT Hubs, that use greasable taper roller bearings.

MOUNTING OPTIONS

Brackets to suit mounting to 3”, 4” or Diamond Bar. Depending on machine configuration and spacing units can be attached to existing rear toolbar, if not a new toolbar will need to be fitted. U-Bolts supplied. Extension Arms also available for fitting Toolbars. Generally for spacing of 9” or less a new toolbar will be required.

18” WHEELS vs 15” WHEELS

18” wheels are generally selected in situations where either extra ground clearance is desired by the customer or in extremely sticky soils where the bigger wheel will clean slightly better. The 18” wheels with their larger rolling diameter will have less wear and will also require less maintenance. The 18” wheels will however add extra weight and cost. For most situations the 15” wheels with AgriHubs are suitable.

SWIVEL vs FIXED

In the majority of situations swivel walking wheels will work best. In some situations fixed walking wheels are used. If you are considering fixed we recommend that you give us a call to discuss your situation.

OPTION 1

Zero Maintenance

Agri Hub (Repair by replacement)

OPTION 2

Greasable Integral Hub (Fully maintainable)

OPTION 3

Ford Hub/Holden HT Hub (Fully maintainable)

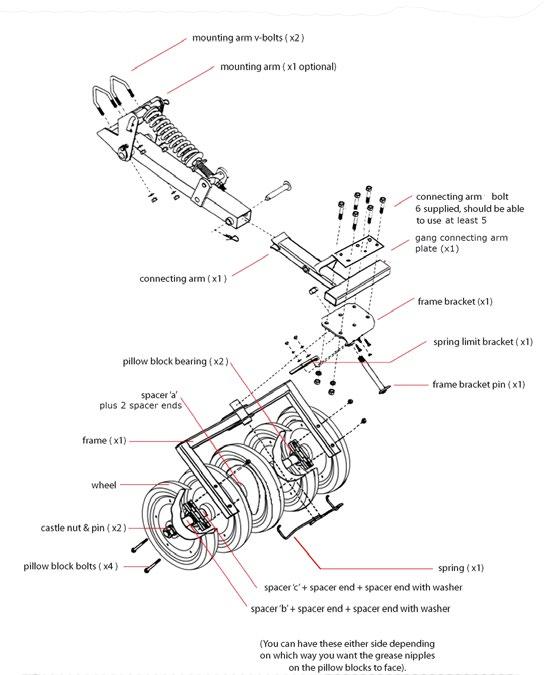

Gang Assemblies provide a simple and cost effective option. They are widely used when the ability to use either harrows or press wheels is required. If you already have a set of worn out gangs, then see the next page for our repair kits(gang conversions).

These gangs are easily configured for use with a number of popular quick release harrow/press wheel mounting arms. Gangs are often preferred due to the lower maintenance requirements, ie less bearings. Gangs work best with up and back sowing. We do not recommend gangs in areas with a lot of medium to large rocks.

Manutec gangs can be quickly removed when not required or for maintenance. All Manutec gangs use 18” wheels and all bearings are fully sealed non-greaseable Ag bearings. For long life we recommend solid and semi-solid tyres.

Mount Arm Gang Assembly

Ideal for use in applications where interchangeability with Harrows is required. 18” Wheels with Nylon Bush Centres used as standard. Gangs are available in 4,5,6,7,8,9 and 10 wheel configurations depending on the spacing width. Normally we like to limit sections to about 6 wheels.

Available in 7.2”, 9”, 10“ and 12” spacings as standard in a variety of wheel numbers. For other spacing widths contact Manutec for availability. Available in a range of tyre options. Manutec normally recommends a thicker tyre, either semi-solid or solid, especially if being used to dry sow.

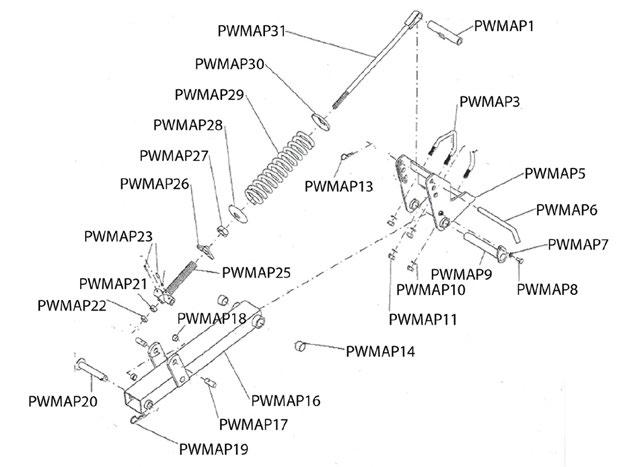

GANG MOUNTING ARM SPARE PARTS

Mounting Arm

Quick Release Mounting Arm, compatible for use with either Press Wheel Gangs or Harrows. A complete range of spare parts is available for all gang components.

Harrow Arm

3 or 4 Harrow Option

Quick release arm for connecting harrows to Mounting Arm.

NOTE:

1. Manutec Gang Frames and Arms are all double re-enforced

2. Manutec Wheel Spacers will never seize

3. Manutec stocks spares for all components

FLEXI-COIL 820 BOURGAULT

CASE PDX, MORRIS

EZEE-ON

If you are buying or already have a new or second hand Gang Assembly with either steel or poly wheels that either are not suited to your conditions or are simply worn out then Manutec Gang conversions offer a good solution. Simply unbolt the existing wheels and axles from the gang frames and replace with Manutec parts. Very popular for converting Flexi-Coil, Bourgault, Morris and Ezee-On gangs. This eliminates the problem of removing the existing wheels from the axles to replace them with new wheels, which on some gangs is a time consuming, expensive and sometimes an almost impossible task.

The Manutec kit provides new axles, spacers, bearings and wheels. Additionally the unique Manutec spacer system is guaranteed to never seize up, making future maintenance an easy task, extending the life of your gang by many years.

For tyre options see page 17, generally Manutec recommends semi-solid or solid tyres,unless being used in wet sticky soils for majority of the seeding (>90%). All Manutec Gangs use 18” wheels and all bearings used are fully sealed non-greasable Ag bearings.

Are you currently considering or already changed to split row or spread row seeding? If so Manutec has several tyre options to suit 3”,4” 4.5” width. These tyres are also suitable for sandy soils.

TO SUIT MORRIS MAXIM

JD1830 FLEXI-COIL 5000/5500

BOURGAULT 5810 & other compatible seeders

If you are buying or already have a new or second hand air hoe drill with rubber or steel wheels that either are not suited to your conditions or are simply worn out then Manutec Air Hoe Drill (AHD) Gang conversions and replacement tyres provide a good and economical solution.

Thinking of converting from 3” to 4” tyres/wheels? Talk to us about how we can do this for you.

Why choose a Manutec Air Hoe Drill conversion?

1. 18% Stronger Components

Manutec has increased the shaft size and bearings from 1.25” to 1.5”.

High quality PEER bearing & housings have been used.

2. Reduced Cost

Despite the increase in strength, the Manutec conversions are less expensive than the original OEM parts.

3. Reduced Ongoing Cost and Maintenance

Manutec utilises a split rim system and high durability cushion rubber tyres. All components available as spare parts and easily repairable. Axles are made from high quality Australian steel and bearings are all premium SKF-PEER brand.

4. Australian owned and operated for over 30 years

Replacement solid 21” tyres for John Deere 1820/1830, 22” tyres for Flexicoil and Bourgault air drills are also available.

MANUTEC is able to supply a range of aftermarket OEM products or alternative products. We can also rapidly prototype or re-engineer new press wheel, gauge wheel, planter wheel, tyre or disc products as replacement parts for OEM machinery. We can also supply press wheel and coulter parts to suit most Australian made farm machinery.

John Deere 1820/1830 Air Hoe Drill

Heavy Duty durable tyre as a replacement tyre for the John Deere 1820/1830 Air Hoe Drill Gang. Available in 3” and 4” width, Complete gang conversion kits also available.

Bourgault 5710/5810 Air Hoe Drill

Heavy duty 3” & 4” tyres are available to suit Bourgault 5710/5810 Air Hoe Drills and complete gang conversion kits.

Flexi-Coil 5000/5500 and Drill Gang Tyres

Heavy duty 3 & 4” tyre is available to suit Flexicoil 5000 Air Hoe Drill. Complete gang conversion kits also available.

John Deere 1860/1890 Gauge Wheels and Discs

To suit 1860, 1890 and Max Emerge with Mud Razor technology. Also available for AUSTIL,SIMPLICITY, SERAFIN and other machines.

ConservaPak and John Deere 1870

Wheels and tyres to suit ConservaPak machines and wheels to suit John Deere 1870. With a large range of tyre options.

Coulter Discs

A wide variety of coulter and disc opener discs are available to suit John Deere, John Shearer, Grizzly, Stubble King, Gason, Duncan, Sow Ezy, Austil, Daybreak, K-Line and most Australian made coulter assemblies.

Equalizer

Wheels to suit Equalizer machines. With a large range of tyre options.

Seed Hawk

Replacement wheels to suit Seed Hawk in a range of tyre profiles

DBS/AUSPLOUGH

A number of specialty tyres and wheels are available to suit DBS planters, fitted with split row or spread row boots.

If you have a press wheel, gauge wheel, closer wheel or disc on your machine that is not giving you the best result or that has operational limitations, give us a call to discuss what options may be available.

Horsch

Replacement Wheel, AgriHub and axles available to suit Horsch machines.

Flexi-Coil PD5700 Precision Hoe Drill

Replacement press wheels and axles/hubs are available to replace existing press wheels available in round, wedge and flat profiles

Bourgault 3320 Paralink Hoe Drill

Replacement press wheels and axles/hubs are available to replace existing press wheels available in round, wedge and flat profiles

Morris C1 and C2 Contour Drills

Replacement press wheels are available to replace existing press wheels available in round, wedge and flat profiles

Flexi-Coil Gangs (ST820)

7.2”, 9”, 10”and 12” gangs and gang conversions are available. The conversions are also suitable for Bourgalt, Morris and EzeeOn bars. The gangs can be fitted to any machines with a 4” x 4” (100mm x 100mm) frame size. Wide tyres are also available to suit split/spread row seeding and other spacing widths also available.

Air Hoe Drill Replacement Gangs

Manutec has developed a gang conversion system to retrofit to the following Air Hoe Drills:

Morris Maxim

Flexi Coil 5000

John Deere 1820/1830

Bourgault 5710/5810

The Manutec system replaces all wheels, plus axles, bearings and spacers.

If you have an issue with reliability or performance of an existing part and are looking for an alternative part, please contact us. Most OEM wheels with standard bearings can be converted to Zero Maintenance AgriHubs.

ORIGINAL

HORWOOD BAGSHAW

15” PSS Press wheels and tyres - AgriHub/ Integral Hub

AF GASON

15” & 18” Press wheels and tyres - AgriHub/ Integral Hub

MULTI-PLANTER

18” Press wheels and tyres - AgriHub/ Integral Hub

JOHN SHEARER

15” Press wheels and tyres - AgriHub/ Integral Hub

15” Disc Opener Discs

KNUCKEYS

18” Press wheels and tyres - AgriHub/ Integral Hub

18” Coulter Discs

SOW-EZY

15” & 16” Press wheels and tyres

15” Disc opener discs, hubs and scrapers

AUSTIL/SIMPLICITY

15” Press wheels and tyres

16” Gauge wheels and hubs

20” and 22” Opener Discs and hubs

DAYBREAK

15” Press wheels and tyres

18” & 24” Gauge wheels

24“ and 26” Opener Discs

GESSNER

15”, 16” and 18” Press wheels and tyres - AgriHub/ Integral Hub

ALPHADISC

13” and 16” Press wheels, tyres and AgriHubs

18” Alpha Discs and AgriHubs

MOOSE INDUSTRIES

15” Press wheels and tyres - AgriHub/ Integral Hub

18” Coulter Discs

ROOT BOOT

15” Press wheels and tyres -AgriHub (5x98)

20” Discs and AgriHubs (5x98)

TOOWOOMBA ENGINEERING

18” Press wheels and tyres - AgriHub/ Integral Hub

AFTERMARKET

JOHN DEERE 1820/1830 AIR HOE DRILL (TYRE ONLY)

Solid | 100mm | Wide Flat | Flat 21” Diameter

Solid | 80mm | Wide Flat | Flat 21” Diameter

FLEXICOIL 5000/BOURGAULT 5810 (TYRE ONLY)

Solid | 100mm | Wide Flat | Flat 22” Diameter

Solid | 80mm | Wide Flat | Flat 22” Diameter

DBS - AUSPLOUGH (TYRE ONLY)

A range of tyres and wheels now available to suit DBS see page 18. Specifically to suit split and spread row seeding.

JOHN DEERE 1860/1890/SERAFIN (Spoked Gauge Wheels)

Solid | 103mm | Wide Gauge - In built scraper | 16” Diameter

Solid | 110mm | Wide Gauge - In built scraper | 16” Diameter

Solid | 80mm | Narrow Gauge - In built scraper | 16” Diameter

Solid | 10mm and 25mm | Closer Wheels | 10” Diameter

See also Plain Discs to suit 1860/1890 on page 15

REPLACEMENT PARALLELOGRAM WHEELS

• JD 1870

• Equalizer

• Seed Hawk

• Bourgault 3320 Paralink

• HORSCH (Requires AgriHub conversion)

• Morris C1 and C2 Contour Drills (AgriHub also available)

• Flexi-Coil PD5700 Precision Hoe Drill (AgriHub also available)

JOHN DEERE 1730/MAX EMERGE (RIM & TYRE)

Semi Pneumatic | 115mm | Wide Gauge Wheel | 16” Diameter

JOHN DEERE 1870/CONSERVAPAK (RIM & TYRE)

Large range of 15” and 16” wheels and tyres available.

GANG CONVERSIONS

Flexi-Coil | Bourgault | Morris | Ezee-on

AIR HOE DRILL GANG CONVERSIONS

John Deere, Flexi-Coil, Bourgault and Morris

EQUALIZER

15” Press Wheels

HORSCH

16” Press wheels Replacement AgriHub conversion

K-LINE SPEED TILLER

CD22SCDISH6MM | Replacement Discs | 22” and 24” Diameter

A full listing of our range of aftermarket parts is available at www.manutec.com.au

Manutec now has a full range of wheels to suit all major makes of parallelogram/ precision seeders. Additionally conversions are also available for most machines to our Zero Maintenance hub system.

TO SUIT (and compatible models)

• HORWOOD BAGSHAW PSS

• BOURGAULT 5320/3420 (8)

• JOHN DEERE 1870

• MORRIS C1/C2 (8)

Tyre and wheel options

• DBS

• GASON

• GESSNER (8)

• KNUCKEYS

• SEED HAWK (8)

• EQUALIZER

• FLEXICOIL 5700 (8)

• HORSCH (8)

16PW120RDSP/SS/SF 120mm ROUND (1) (6) 16PW120WGSP/SS/SF 120mm WEDGE (1) (6)

16PW120FLSP/SS 120mm FLAT (2)

16PW140RDSP/SS 140mm ROUND (2) 16PW120VESP/SS 120mm VEE (1) 16PW120PRSP/SS 120mm PAIRED- ROW (2) 11PW115RDSS 115mm ROUND (3) 12PW140RDSP 140mm ROUND (3)

11PW50WGSF 50mm WEDGE (3)

13PW145FWSF/SP/SS/100 145mm WINGED (3)

15PW80WGSF/SP 80mm WEDGE (4) (5)

15PW80WGSS/SD 80mm WEDGE (4) (5)

15PW80FLSP 80mm FLAT (4) (5)

15PW75RDSP 75mm ROUND (4) (5)

15PW100FLSF/SP/SS/SD 100mm FLAT (4) (5)

15PW110WGSP/SD 110mm WEDGE (4) (5)

16PW100RDSP/SS 100mm ROUND (4) (5)

18PW55WGSP/SS/SD 55mm WEDGE (7)

18PW80WGSF/SP/SS/SD 80mm WEDGE (7)

18PW55FLSP/SS/SD 55mm FLAT (7)

18PW100FLSF/SP/SS/SD 100mm FLAT (7)

16PW80WCSP/SD 80mm WEDGE (4)

16PW70VCSP/SD 70mm DOME (4)

13PW125FWSS 125mm WINGED (3)

13PW100RDSS-80 100mm ROUND (3)

13PW90WGSP/SS 90mm WEDGE (3)

13PW75FWSP 75mm FLAT (3)

17PW120RDSS/SD 120mm ROUND (2)

Notes

(1) PD5700, SEEDHAWK, 5320/3420, 1870, C1/C2, HORSCH, GESSNER (16”) (2) PD5700, SEEDHAWK, 5320/3420, C1/C2, HORSCH (3) DBS, SEEDSTORM (4) PSS,1870, EQUALIZER, CONSERVAPAK, GASON (15”) (5) CAN BE USED ALSO ON PD5700, SEEDHAWK, 5320/3420, 1870, C1/C2 HORSCH PLEASE CALL (6) DONT USE SF (HIFLEX) ON HIGH PRESSURE SEEDERS (7) KNUCKEYS/MULTIFARM/TOOWOOMBA ENG/GASON/GESSNER (18”) (8) FOR MIXED WET DRY SEEDING WE RECOMMEND THE SS (HIGH DURABILITY) TYRES

* GASON USES BOTH 15” AND 18” WHEELS / * GESSNER USES BOTH 16” AND 18” WHEELS

Swivel Arm Assemblies are designed to be mounted on a low tool bar across the back of the machine. This can be done on either a fixed tool bar or an adjustable toolbar. Sections can be quite long if necessary as the assembly weight is low. The light/medium version can be used with 15” and 16” wheels and the heavy duty version can be used with 15”, 16” and 18” wheels.

A range of mounting options are available for this type of assembly. The simplest option is to build a new fixed toolbar off of the existing rear frame of the machine. Mounting Arms are available if a removable solution is required, however this will add cost. Manutec carries a complete range of spare parts for all products and most parts can be shipped within 24 hours of ordering.

Swivel Arm Assemblies are designed to be mounted either on the rear frame of a machine or on a false bar mounted off the rear frame. Swivel Arm assemblies can be used in conjunction with walking wheels or individually as a single independent assembly. These units provide a good heavy duty assembly with a high ground clearance. The fixed arm variant is for those customers that do not require the swivel capability and want a single independent wheel. Seed tube mounting plates are fitted to the swivel variants.

Single Swivel Arm Assembly (15” and 18” Wheels)

Used either in conjunction with walking wheels or individually as singles. Seed tubes are available as an option.

Twin Fixed Spacing Swivel

Arm Assembly (15” and 18” Wheels)

Used on machines with fixed spacing where spacing adjustment is not required. Seed Tubes are available as an additional option.

Twin fixed Spacing Fixed Arm (No Swivel)

Used on machines with fixed spacing where swivel action (turning) is not requred often used on tight spacings.

Single Fixed Arm Assembly (No swivel) (15” and 18” Wheels) Fixed (No Swivel Variant) Single Walking Wheel. For customers that do not require the swivel capability.

The twin heavy duty coulter can be fitted with 16”, 18” and 20” coulter discs. It is capable of over 300lbs of pressure and can be set up from 9” to 16” spacings.

The single heavy duty coulter can be fitted with 16”, 18” and 20” coulter discs. It is capable of over 300lbs of pressure.

The Manutec range of heavy duty coulter assemblies has been designed primarily for cutting through heavier trash loads. They can be fitted to either the existing bar (including diamond bar) or a new tool bar using 3” or 4” Ubolts. The twin coulters can be configured from 9” out to 16” spacings.

Coulter discs are fitted to the Coulter using either a Zero Maintenance AgriHub or a Cast Iron Hub, fitted with a 40mm Round Axle, LM Tapered Automotive Roller Bearings and Triple Marine Seals. An additional layer of protection is provided with a Galvanised Steel Over-cap.

The Coulter discs are high grade hardened and heat treated high tensile steel. Brackets and Arms are made using fabricated steel components. Swivel joints are ball bearings fitted with both an internal and external seal. Disc sizes available are 16”, 18” and 20”. The complete range of disc options are available on page 14.

The different shapes will keep the discs rotation speed high providing higher cutting speeds and clay removal. They each have varying levels of throw and soil disturbance. Please call for advice.

The durability of tines, with the precision and trash flow of discs, the iPaddock Alpha Disc is the disc seeder for farmers who prefer tines! Instant upgrade option for John Deere 1890, Tobin Bullet, Seed Hawk, Serafin, Morris Contour and similar toolbars. Please note, if you have hard ground, it is essential to have a heavy bar for the narrow row spacing (187.5mm) dual row option.

The unique dual row iPaddock Alpha disc units offer a low cost, low maintenance precision seeding option for high productivity and narrow row spacings, and will retrofit directly onto 4”, 6” or 8” toolbars including John Deere 1890 model disc seeders, at close to half the price of other disc seeding row units. Other popular toolbars for retrofitting with iPaddock discs include the Tobin Bullet, Morris Contour, Serafin and DBS. For not much more than the cost of rebuilding your John Deere disc seeder units, you can now fit an all-new set of iPaddock discs for years of trouble free operation, while doing a better job of planting your crop, year in, year out.

Each row on the iPaddock Alpha disc has a custom designed rippled disc governed by a load bearing press wheel to accurately place seeds into a firm, well-shaped furrow, without the big issues of mud blockages common on gauge wheel disc seeders. The standard dual row iPaddock units have 2 discs spaced at 187.5mm (7.5”), which dramatically lowers the cost of achieving narrow row spacings for improved yields and weed competition. The unique iPaddock Alpha disc dual row system also means every disc can be mounted on a single rank, eliminating the serious issue of the rear row backfilling the front row, as happens with conventional multiple rank seeders. This also greatly simplifies pipe checking and maintenance. No more grovelling around under the machine in the dirt!

Seeding with discs can increase productivity by 50% with the same size machine, but other disc seeders are notorious for reliability and chemical issues in Australian conditions. iPaddock Alpha Disc is the solution to these issues. Australian designed by iPaddock‘s Mic Fels, the iPaddock Alpha Disc is the first true broadacre, no maintenance precision disc seeder. Compatible with most 4” (100mm), 6” (150mm) and 8” (200mm) toolbars.

Single disc systems typically use an even number of Left and Right hand units to balance side draft, with Left units on the Left and Right units on the right side of the toolbar. This creates a “toe-in” effect which helps machine tracking. At 187.5mm row spacings you will need 2.67 Standard Dual units per metre width. This equates to 24 units (12L, 12R) for 9m/48 rows; 32 units (16L, 16R) for 12m/64 rows; 48 units (24L, 24R) for 18m/96 rows. Contact us for advice on other configurations.

A full range of spare parts is available

Any Manutec discs that have a 5x108 stud pattern can now be used with zero maintenance AgriHubs. Some discs are also available in a 5x98 pattern to suit SKF AgriHubs Double Bevel Plain

22” K-Line 4 x 137mm 5mm & 6mm

22” 13 Wave 5x108mm 6mm

24” K-Line 4x137mm 8mm

26” 13 Wave 5x108mm 6mm

28” Grizzly 6x185mm 6mm

28” Grizzly 6x185mm 8mm

28” - 40x40SQ 10mm

30” - 6x205mm 10mm

30” - 8x292mm 10mm

15” Suits Sow-Ezy/Duncan 6 x 90mm 4mm

15” Stubbleking/Shearer 6 x 76.2mm 4mm & 6mm

18” GVI 5 x 108mm 5mm

18” JD 1860/1890 4 x 111.5mm 5mm

18”

20”

20”

15” Suits Sow-Ezy/Duncan

18” ALPHA DISC 5 x 108mm 8mm 4mm & 5mm

OEM DISCS

• K-LINE

• GRIZZLY

• DAYBREAK

• GASON

• DUNCAN

• ROOT BOOT

• JOHN DEERE 1860/1890 (Disc hubs, seals, bearings, caps & scrapers also available)

• SOW EZY (Disc hubs, seals, bearings, caps & scrapers also available)

• AUSTIL (Disc hubs, seals, bearings, caps & scrapers also available)

• STUBBLE KING

• JOHN SHEARER

• ALPHA DISC

For the full range of aftermarket products for other manufacturers visit ww.manutec.com.au

For other OEM machines or coulters please call or visit www.manutec.com.au for latest products.

The Manutec Double Disc Opener (DDO) system is designed to deliver consistent, high-speed sowing performance across a wide range of conditions. Each opener is mounted on an independent parallelogram, allowing for individual row movement. If one unit encounters an obstruction, it lifts independently while the rest remain engaged, keeping the machine stable and working effectively.

The parallelogram system maintains constant down pressure—independent of the weight of your seed drill—ensuring uniform sowing depth, regardless of how full the drill is with seed or fertiliser. In most applications, no ground opener is required ahead of the disc, although Manutec’s Triple Disc System can be used where additional ground penetration is needed.

Designed for versatility, the DDO system is suitable for high-stubble conditions and can cut through small branches and twigs. Unlike traditional tyne seeders, the Manutec DDO allows for faster sowing speeds, reduced horsepower requirements, and excellent seed placement—helped by an integrated seed firmer, mud scraper, and a precision press wheel depth adjuster.

Whether retrofitted to an existing bar or installed on a new toolbar, Manutec’s DDO system provides a lightweight, low-cost, and highly adaptable sowing solution.

Downforce: Up to 300 lb via adjustable spring (heavier spring available)

Max. Parallelogram Travel: 150mm

Sowing Speed: 10–16 km/h

Stubble Handling: Cuts through wheat stubble up to 8 t/Ha

Row Spacing (Single): as narrow as 180 mm (7”)

Row Spacing (Staggered): even tighter spacings possible

Mounting Options: Suits standard and diamond (Shearer) bars

Press Wheel Options: Multiple profiles to suit varying soil types and finish preferences

The Manutec range of adjustable Double Disc Openers comes standard with a 13” diameter press wheel fitted with a high durability 48mm tyre and an extreme ag bearing. A range of different 13” and 15” wheel options are available that provide different tyre profiles to suit a range of different soil and seed types. Each Double Disc Opener has a leading scalloped disc and a trailing plain disc. Double plain disc is also an option if required. Each disc is fitted with an Zero Maintenance AgriHub. To enquire about different wheel or disc options please contact Manutec.

Adjustable – No Arm

Suits: A wide range of adjustable mounting arms

Adjustable – Drop

Suits: 3” Tool Bar (75mm)

Item Code: DDO-ADJ-D-3

Suits: 4” Tool Bar (100mm)

Item Code: DDO-ADJ-D-4

Adjustable – Standard

Suits: 3” Tool Bar (75mm)

Item Code: DDO-ADJ-S-3

Suits: 4” Tool Bar (100mm)

Adjustable – 4” Bar

Suits: 4” (100mm) Tool Bar

Item Code: DDO-ADJ-MP-4

Adjustable – Extra Long

Suits: 3” Tool Bar (75mm)

Item Code: DDO-ADJ-L-3

Suits: 4” Tool Bar (100mm)

Adjustable – Diamond Bar

Suits: 3” (75mm) Shearer/ Diamond Tool Bar

Item Code: DDO-ADJ-SH

15” TYRES

WEDGE

FLAT

DOME/VEE

SP, 55mm

SP, 80mm

SF, 80mm

SP, 110mm

SD, 55mm

SD, 80mm

SS, 80mm

SD, 110mm

SS, 150mm

SS, 150mm

16” TYRES

WEDGE

SD, 80mm

SP, 80mm

18” TYRES

WED GE

SP, 55mm

SP/SF, 80mm

SD, 55mm

SS, 55mm

SD, 80mm

SS, 80mm

SP, 110mm

SD, 110mm

SP, 55mm

SP, 80mm

SP/SF,100mm

SD/SS, 55mm

SD, 100mm

SS, 100mm

SP, 140mm

SS, 140mm

DOME/VEE

FLAT

SD, 70mm

SP, 70mm

SP, 55mm

SD, 70mm

SP, 55mm

SP/SF, 100mm

SP, 120mm

SD, 55mm

SS, 55mm

SD, 100mm

SS, 100mm

SD, 120mm

ROUND

SP, 75mm

SD, 90mm

- Used in rugged country with excessive rocks

- Gives longer tyre life (less wear), Dry Seeding

- Allows for a greater range of setup parameters

- Good behind Disc Openers in hard to close soils

- Takes greater pressure

Restrictions: Require Mud Scrapers in Sticky Soils & Less Shock

Absorption

- Used in areas of high abrasion

- Gives longer tyre life (less wear), Dry Seeding

- Takes greater pressure

- Allows for a greater range of setup parameters

- Gives better “cleanability” than solid

- Good on Gangs and behind disc openers

Restrictions: Require Mud Scrapers in Very Sticky Soils

ROUND

SS, 100mm

SF/SP, 100mm

FLAT RIBBED

SD, 100mm

- Used in Sticky/Clay Soils

- Good mud shedding

- Better Fuel Economy (Less Drag) in heavy conditions

- Faster Tractor Speeds (Time efficiency) in heavy conditions

Restrictions:

- Expect 10% - 20% per annum tyre replacement over life of tyres

- Tyre Wear may be greater if used for high percentages of dry sowing

- Used in very sticky soils

- Used on parallelograms

- 24 x 7 seeding in wet conditions

- No scrapers required

Restrictions:

No dry seeding or hard rocky soils

Why 15”, 16” or 18” ?

- Ground/Trash Clearance

- Assembly Type/Tyne Type

- Maintenance (Bearings/Seals)

- Machine Set-Up/Clearances

- Depth/Pressure Control

- Roll Through - Mud Shedding

- Tyre wear rate

- Turn Rate

HIGH SIDEWALL

WEDGE/VEE

80mm SP

120mm SP

80mm SS

120mm SS

120mm Vee SS ROUND

AFTERMARKET OEM TYRES

JD/FX/BG (AIR HOE DRILLS)

80mm JD1830

100mm JD1830

80mm FX/BG

GAUGE

GAUGE

100mm FX/BG DBS

SP

SP

SS

SS

FLAT

80mm SP

120mm SP

120mm PR SP

80mm SS

120mm SS

120mm PR SS

OEM tyres also available for most Australian made air seeders

• AUSTIL

• MULTIFARM

• HORWOOD BAGSHAW PSS

• TOOWOOMBA ENGINEERING

• ROOT BOOT

• DAY BREAK

• KNUCKEYS

• GASON

145mm WINGED SF/SP

50mm FLAT SF

75mm FLAT SP

135mm ROUND SP

115mm ROUND SS

GAUGE LIP

SD, 110mm

SD, 100mm

SP, 125mm

PLANTER WHEEL TYRES

TAPERED

SD, 35mm

SD, 115mm

SD, 110mm

SP, 110mm

SD, 110mm (Scraper)

FLAT 12”/13”

SP, 50mm

SP/SS, 75mm

SP, 25mm

SP/SS, 70mm

SS, 90 mm

13” /75mm FLAT SP/SS

16” /70mm FLAT SP/SS

16”/60mm WAVE SP/SS

GAUGE BANKED

SD, 115m

DOME 10”/13”

SD, 10mm

SD, 25mm

SP, 100mm

CONSERVAPAK

70mm VEE SP/SS

80mm WEDGE SP/SS

90mm R OUND SF/SP/SS

GAUGE MUD RAZOR

SD, 80mm

SD, 103mm

SD, 110mm

ROUND 12”/13”

SD, 25mm

SD, 48mm

A farmer in SA contacted us after seeing one of our spoked Mud Razor gauge wheels. The brief was: Could we do the same thing on a John Deere 1860/1890 Single Disc Opener to help reduce the plugging problem in sticky soils? We worked closely with the customer to get the ideal dimensions and ease of fitment. This resulted in the rapid development of both a 3” and 4” replacement Mud Razor gauge wheel with spokes and inbuilt disc, ready for the next seeding season.

The seeding conditions around Clermont in Queensland are quite unique. The soils are extremely sticky when wet and they are also very susceptible to pressure. Too much pressure and the clays seal over forming an almost impervious layer for the seed to grow through. As a result the farmers like to use a low pressure tyre and they need the tyre to be as flexible as possible. After a request from a farmer we developed the new Hi-Flex low pressure tyre in around 4 weeks. These are now being extensively used by other farmers in the Clermont area.

A customer in Clare came in to see us having a few issues with their seeder clogging up with mud around the press wheel. We designed a new press wheel tyre that could be fitted onto the existing rims that improved the mud clearance around the tyre by over 200%. Additionally we then used a rubber compound that had a proven ability to flex and self-clean without needing a scraper.

A farmer in NSW had recently fitted two new wings on to an existing parallelogram. The new wings had been supplied with Manutec press wheels and the remainder of the old machine was fitted with a different brand. After the first 30 minutes of seeding the driver got out to check the machine and de-plug the mud from the machine as was the usual practice. The entire centre section was totally plugged, the new wings were clean. The customer rang to tell us he was leaving immediately to drive to Adelaide and collect all the wheels needed to retrofit the remainder of the machine. He collected the wheels the following morning and professed he had no idea, the wheels could be so different. He had been putting up with this issue for ten years!

The brief from a Moree based customer was to build a lightweight replacement gauge wheel that could be run on the John Deere MaxEmerge planters, that could discharge the mud from between the disc and the wheel and prevent “plugging”. We obtained samples and photographs and key measurements from the customer and then developed concept drawings as to how the new wheel could fit into the MaxEmerge system. This proved to be a very challenging task as the clearances on fitting parts is very tight and the MaxEmerge componentry is very lightweight so weight is a key issue. A spoked alloy wheel was designed to keep the weight down and also to provide the space for the mud to flow through. Additionally we developed a unique tyre that was able to provide mud shedding flex on the rise and a hardened rubber face against the disc that would reduce the smearing problem.

The brief was pretty simple, the fitted tyres are wearing out too quick, help! After the 3rd phone call from 3 different farmers, we arranged for a sample of the existing tyre/wheel and then we re-engineered a new tyre that would be able to be retrofitted to the existing rim and that would give a significant improvement in durability. This project was fast tracked because all 3 farmers were waiting for the tyres to be able to start seeding. From start to finish this project took about 2 months. We also now do a similar version of these to suit Bourgault and Flex-Coil air hoe drills. These tyres are available in 3” and 4” widths.

The brief was, the existing tyres are building up too much and giving the wrong pressure profile, we need help quickly to get our crops in this (2014) season. The soils in this particular part of Alberta are very sticky and very sensitive to pressure. After considering the options we were able to come up with a quick fix solution and airfreight 200 new wheels to Canada from Adelaide in less than two weeks. We then worked with the farmers to develop an even better solution over the next few months and built a complete new wheel designed to suit their conditions ready to use for the 2015 seeding season. The wheel is a 100mm round soft tyre with high sidewalls. From start to finish this project took about 12 months, however we were able to provide an interim solution in under two weeks.

15” & 18” AGRI-HUB PRESS WHEELS (ZERO MAINTENANCE

HUBS) SH VERSION WITH FITTED STUB AXLE

- 15” or 18” Alloy two piece split rim (actual rim diameter = 285mm and 385mm)

- 15”, 16” or 18” Tyre fitted PCD 4x98, 5x98, 5x108 (varies with code)

- Agri-Hub and Nuts/Bolts (Axle fitted)

- Agri-Hub Cover Plate

- Absolute Zero Maintenance and minimal assembly

-Designed to attach directly to an arm

- multi stud pattern 1, 4x98mm, 5x98mm

- multi stud pattern 2, 5x108mm, 5x114mm

15” & 18” INTEGRAL PRESS WHEELS

- 15” or 18” Alloy two piece split rim (actual rim diameter = 285mm and 385mm)

- 15”, 16” or 18” Tyre fitted (varies with code)

- Type A LM Bearing Set, Heavy Duty Seal, Dust Cap and Clips

15”, 16” & 18” HT & FORD PATTERN PRESS WHEELS

- 15” or 18” Alloy two piece split rim (actual rim diameter = 285mm and 385mm)

- 15”, 16” or 18” Tyre fitted (varies with code)

- Multi stud pattern, 5x108mm (HT), 5x114mm (Ford)

HUB OPTIONS: Narrow HT Hub, Ford, AgriHub, Standard HT, 5203 Hub, Zero Maintenance options.

STUB AXLE OPTIONS: 6”, 7”, 8”, 10”, rounded axles, 9” square axles, double ended axles and 16mm 5/8” bolted axles . Made to Order.

10“, 12” & 13” PLANTER PRESS WHEELS

Manutec planter press wheels come in a variety of types, including:

- 13 “ Alloy two piece 5x108mm HT Pattern split rim (actual rim diameter 245mm) (OPTION 1)

- 16mm(5/8”) fitted bearing (OPTION 2)

- 13” Tyre fitted (varies with code)

- 10” Solid Rubber, 12” Nylon

HUB OPTIONS: Narrow HT Hub, Ford, AgriHub, Standard HT, 5203 Hub 16mm 5/8” bearing, Zero Maintenance options.

13” DBS COMPATABLE PRESS WHEELS

- 11”, 12” and 13” tyres available in 50mm, 75mm, 115mm, 135mm and 145mm wide tyres.

- Two piece alloy split rim

- Extreme Ag 5/8” /16mm bearing

- Rubber cheeks

- Options to suit split row/spread row seeding

- Tyres also compatible with DBS plastic rims

15” & 18” NYLON BUSH PRESS WHEELS

Master Guide: All /ANB Wheels come standard with the following:

- 15” or 18” Alloy two piece split rim (actual rim diameter = 285mm and 385mm)

- 15”, 16” or 18” Tyre fitted (varies with code)

- 25mm (15”) or 32mm (18”) Nylon Bush fitted CAUTION: Normally due to increased wear, rates on gangs, only thick tyres are used

15” & 18” SEALED BEARING PRESS WHEELS

Master Guide: All /ASB Wheels come standard with the following:

- 15” or 18” Alloy two piece split rim (actual rim diameter = 285mm and 385mm)

- 15”, 16” or 18” Tyre fitted (varies with code)

- 2 x 6205 -2RS (25mm Bore) Bearings Fitted CENTRE OPTIONS: ConservaPak (6205-2RS), GASON (6305-2RS), DUNCAN (6305-2RS)

15” FLANGE BEARING WHEELS

Master Guide: All Wheels come standard with the following:

- 15” Alloy two piece split rim (actual rim diameter = 285mm)

- 15” or 16” Tyre fitted (varies with code) Flange options: 4 Bolt Round or Square

15” & 16” JD1870 WHEELS AND CONSERVAPAK WHEELS PRE 2019 VERSION

Master Guide: All wheels come standard with the following:

- 15” Alloy two piece split rim (actual rim diameter = 285mm)

- 15” or 16” Tyre fitted (varies with code)

- 25mm Sealed Bearings fitted, seals fitted, bushes supplied

- Will fit directly into existing yoke of JD1870

16” SPOKED GAUGE WHEELS

- Spoked gauge wheels to suit John Deere, Serafin and AUSTIL machines, plus any compatible machines

- Fitted with Manutec’s exclusive Mud Razor Tyres

- Reduce plugging and mud build up on discs with the combination spoked rim and inbuilt scraper

- Extreme AG 5/8” -16mm bearings

15” & 16” JD1870 WHEELS AND CONSERVAPAK WHEELS

POST 2019 VERSION (ALSO SUITS EQUALIZER)

Master Guide: All wheels come standard with the following:

- 15” Alloy two piece split rim (actual rim diameter = 285mm)

- 15” or 16” Tyre fitted (varies with code)

- 5203 Sealed Bearings fitted, bushes supplied, seal guards supplied

- Will fit directly into existing yoke of JD1870 and Equalizer

- Can be fitted to original Conservapak (please call)

16” PARALLELOGRAM WHEELS

- 16” Diameter multi pattern Ford/HT wheels (Seedhawk, Morris, Bourgault, Flexi-coil, John Deere precision seed drills)

- Wide profile tyres with high sidewalls

- Flat, round, wedge shape tyres and vee

- Split rim with interchangeable tyres

- Suits Morris C1/C2, Bourgault, Flexicoil & Seed Hawk

-AgriHub conversion also available

The Manutec Inframe assembly puts the wheel in as close as possible to the sowing tyne without having the shock and vibration issues of a tyne mounted assembly. The inframe assembly also has the added bonus of being able to have a secondary seed tube attached to the assembly so that the seed tube can be positioned just in front of the press wheel so the depth of seed is governed by the press wheel. This method of seed placement works best with small seeds and is particularly beneficial where inconsistent seed depth or too greater seed depth is a problem. Manutec does two different variants of seed tubes one for small seeds and an adjustable version for medium and large seeds.

WHEEL OPTIONS

All assemblies come standard with Zero Maintenance AgriHubs. A range of wheel size and tyre options are available on page 17. These are also available with fully maintainable Integral Hub press wheels (taper roller bearings) if required.

WHEN ORDERING IN-FRAME ASSEMBLIES

Dimensions of tyne, working height of machine and frame spacing will be required to determine best configuration for each machine. Give us a call and we will get the required information from you.

In-Frame Mounted Assembly (15”, 16” & 18”)

Ideal for small seed applications and where necessity exists to use the press wheel to govern the depth of seed, or for use when breakout precludes use of tyne mounted assembly. Not recommended in high trash environments unless coulters are also fitted.

Features

• Suits 3”, 4” or Diamond Mount on most Tool Bars

• Swivel and seed boot combination gives greater tracking accuracy

• A range of seed tube options is available to suit this assembly, giving greater accuracy for seed depth placement

• Each unit acts independently

• Large Range of Wheel and Tyre Options to suit all conditions

• 15”, 16” and 18” wheel Sizes available

• AgriHub (Zero Maintenance) wheels

OPTION 1

OPTION 2

Greasable Integral Hub (Fully maintainable)

Zero Maintenance Agri Hub (Repair by replacement) OPTION 3

Ford Hub/Holden HT Hub (Fully maintainable)

The Manutec range of light and medium coulter assemblies has been designed primarily for cutting weeds (melons, wireweed) and light stubble. They can be fitted to either the existing bar (including diamond bar) or a new tool bar using 3” or 4” Ubolts. A low mount option is available for combines. The twin coulters can be configured from 7” out to 16” spacings.

Coulter discs are fitted to the Coulter using a Cast Iron Hub, fitted with a 40mm Round Axle, LM Tapered Automotive Roller Bearings and Triple Marine Seals. An additional layer of protection is provided with a Galvanised Steel Over-cap.

The Coulter discs are high grade hardened and heat treated high tensile steel. Brackets and Arms are a variety of cast steel and fabricated steel components. Swivel joints are a combination of nylon bushes and ball bearings. Disc sizes available are 16”, 18” and 20”.

Disc Coulter

All twin coulters have an off vertical angle applied to the disc, this assists with keeping discs sharp and clean. Spacings from 6” to 15” are available

Twin Disc Coulter (Set Back)

All twin coulters have an off vertical angle applied to the disc, this assists with keeping discs sharp and clean. Spacings from 6” to 15” are available

Manutec tyne mounted assemblies come standard with Zero Maintenance AgriHub press wheels. Available in fixed, adjustable and semi- adjustable variants. The semi-adjustable variant has been specifically designed to allow for double shooting. Available in variants to suit straight edge on tynes or curved flat on tynes. For other tyne variants, call for advice on suitability. When ordering specify tyne type and dimensions. Fully Maintainable Integral Hub press wheels (taper roller bearing) also also available

Adjustable Tyne Mounted Assembly (C-Tyne)

Fully Adjustable, two adjustment points, ideal for non-standard C-tyne set-up, 15” or 16” wheels recommended, however 18” wheels can also be fitted.

Adjustable Tyne Mounted Assembly (Edge Tyne)

Fully Adjustable, two adjustment points, ideal for non standard edge on tyne set-up, 15” or 16” wheels recommended, however 18” wheels can also be fitted.

Fixed Tyne Mounted Assembly (C-Tyne)

Non adjustable ideal for standard C-Tyne set-up, 15” or 16” wheels recommended. Wide throat design.

Semi-Adjustable Tyne Mounted Assembly

Ideal for standard tynes where some pressure adjustment is required. Incorporates wider throat for large pipes and double shooting. Models to suit edge on and flat on tynes. 15” or 16” wheels recommended however 18”wheels can also be fitted.

Please note: Tyne Mounts are not recommended in areas of high breakout or high trash loads

Greasable Integral Hub (Fully maintainable)

OPTION 1 Zero Maintenance Agri Hub (Repair by replacement) OPTION 3 Ford Hub/Holden HT Hub (Fully maintainable) OPTION 2

Manutec has produced the MUD RAZOR range of disc opener gauge wheels that are specifically designed to significantly reduce and in most cases eliminate mud “plugging”. The MUD RAZOR also increases the cutting efficiency of the disc by keeping it clean of mud and other build up

The MUD RAZOR scraper is incorporated into the tyre face which minimises the internal clutter and allows any loose mud or residue to flow through the spokes in the wheel. All Manutec Mud Razor Gauge Wheels are fited with Zero Maintenance, quick repair hubs with sealed for life bearings.

Gauge wheels also available to suit older NDF and Daybreak disc seeders.

A replacement square drive seed distributor is now available. Internal plastic/nylon parts are available as a separate item to repair similar units.

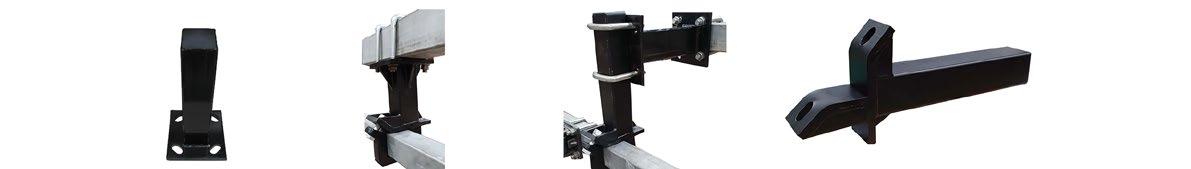

Manutec carries a large range of toolbar extension arms and plates that allow a number of options to be considered when attaching a new toolbar to the front or rear of any seeder machine.

Standard Extension Arms (Ubolts)

Standard Extension Arms are available in 200mm, 350mm and 700mm lengths. Plates are also available to allow custom lengths to be made. Standard Extensions Arms are available with either 3” or 4” ubolts.

Clamp Extension Arms (Clamp + Ubolt)

Clamp Extension Arms are used where narrow spacings or when all single wheel press wheels are being fitted. Clamp Extension Arms are available in 100mm and 220mm lengths.

Drop Arms

The clamp extension arms and the standard extension arms can also be used as drop arms.

Shackle Plates

We have also developed a range of shackle plates that allow 3” and 4” RHS to be connected without the need for plates. Additionally a 350mm ubolt drop arm and 400mm clamp drop arm are available.

Manutec supplies many Australian manufacturers of agriculture trailers and farm machinery with trailer parts. Manutec is able to supply a complete range of parts. Axles and stubs can be made to order from quality Australian made steel. Fast turn around times can also be achieved for breakdown work. Additionally Manutec has the machining capability to make studs/axles up to 110mm in diameter. Manutec supplies parts for the following types of trailers.

- Utility stock trailers, single, dual and tandem up to 4.5 tonne (road legal)

- Mobile feder bins - Comb trailers

- Marine trailers - Mobile ramps

- Hay trailers

PARTS SUPPORTED INCLUDE

MUDGUARDS