URSA

Ursa is the architectural partnership of Luís Ribeiro da Silva and Margarida Quintã. They conceive of architecture as a form of knowledge and its practice as the identification, formulation, and resolution of problems affecting the human condition. If you are interested in discussing this idea or any others, you are welcome to visit their studio at Rua Eng. Carlos Amarante 149, 4250–090 Porto, Portugal, or you can write to them at ursa@ursa.com.pt.

PHILIP URSPRUNG

Philip Ursprung is Professor of the History of Art and Architecture at ETH Zurich, specializing on contemporary art and architecture. His most recent publication is Values and Surfaces: Art, Economy,Architecture (2025). With the exhibition Neighbours he represented Switzerland with Karin Sander at the 18th Architecture Biennale Venice (2023).

MARIANA SIRACUSA

Mariana Siracusa is an Argentinian scholar based in Milan. She is the founder of SPAZIO, an independent platform for critical reflection, speculation and discussion on architecture. Her current research focuses on the history of real estate schemes in Milan.

On a late spring afternoon, I visited the construction site on Rua Roberto Ivens with Luís Ribeiro da Silva and Margarida Quintã from URSA. It was getting dark, and a few halogen spotlights illuminated the interior. The façade facing the street, with its clear concrete grid, was already complete. Thanks to the concrete panels inserted at half the height of each floor, it immediately stands out from the neighboring buildings. Inside, the brick walls were finished. I followed the elegantly curved entrance hall of one of the apartments. I saw the curves of the partition walls, intertwined like entrails to save space for a generous living area facing the street. I moved among the muscular, oblique concrete supports at the rear. Perhaps it was the time of twilight and the dramatic lighting, but I experienced the building as a stage for a play. It was easy to imagine how everyday life would soon unfold here.

I enjoy visiting construction sites. The shell of a building reveals the idea behind the construction before the atmosphere emerges. It shows that architecture is a process and the result of countless acts of craftsmanship and individual decisions, of trials, errors, and corrections. Nowhere else is the work that goes into a building more evident. Once the surfaces are finished and the colors, glass panes, and built-in furniture are in place, the building is transformed from an active subject to a more passive object.

Perhaps it was precisely this rawness that made me realize that URSA, here on Rua Roberto Ivens, articulates a fundamental tension that has characterized architecture since industrialization. It is the tension between the system, i.e., the relationship between elements, and the form, i.e., the shape of objects. The system is, if you will, connected to the realm of machines, to repetition, mechanics, norms. Form, on the other hand, stems from the specificity of the human body, its singularity, its organic metabolism, and its transience. The connection between abstract and anthropomorphic spaces is, between the processual and the monumental is, of course, not a new theme in the history of architecture. But neither is it dated, because it cannot be resolved. What distinguishes the famous Porto School is not so much a specific style or a formal repertoire but its ability to continually revisit this tension between system and form. URSA has designed four breathtaking apartments that will provide their residents with a beautiful home for many years to come. It has also made an original and productive contribution to an architectural conversation. It keeps the tension between system and form alive. And it keeps the discipline of architecture going.

CONVERSATION WITH MARIANA SIRACUSA

This text is the transcription of the conversation held with Mariana Siracusa on the occasion of her visit to the construction site on Rua Roberto Ivens in August 2023. Mariana is the founder of the Milan based architecture gallery and bookstore Spazio, and a long-time friend of Luís and Margarida.

“EVERYTHING

IS POURED ON-SITE”

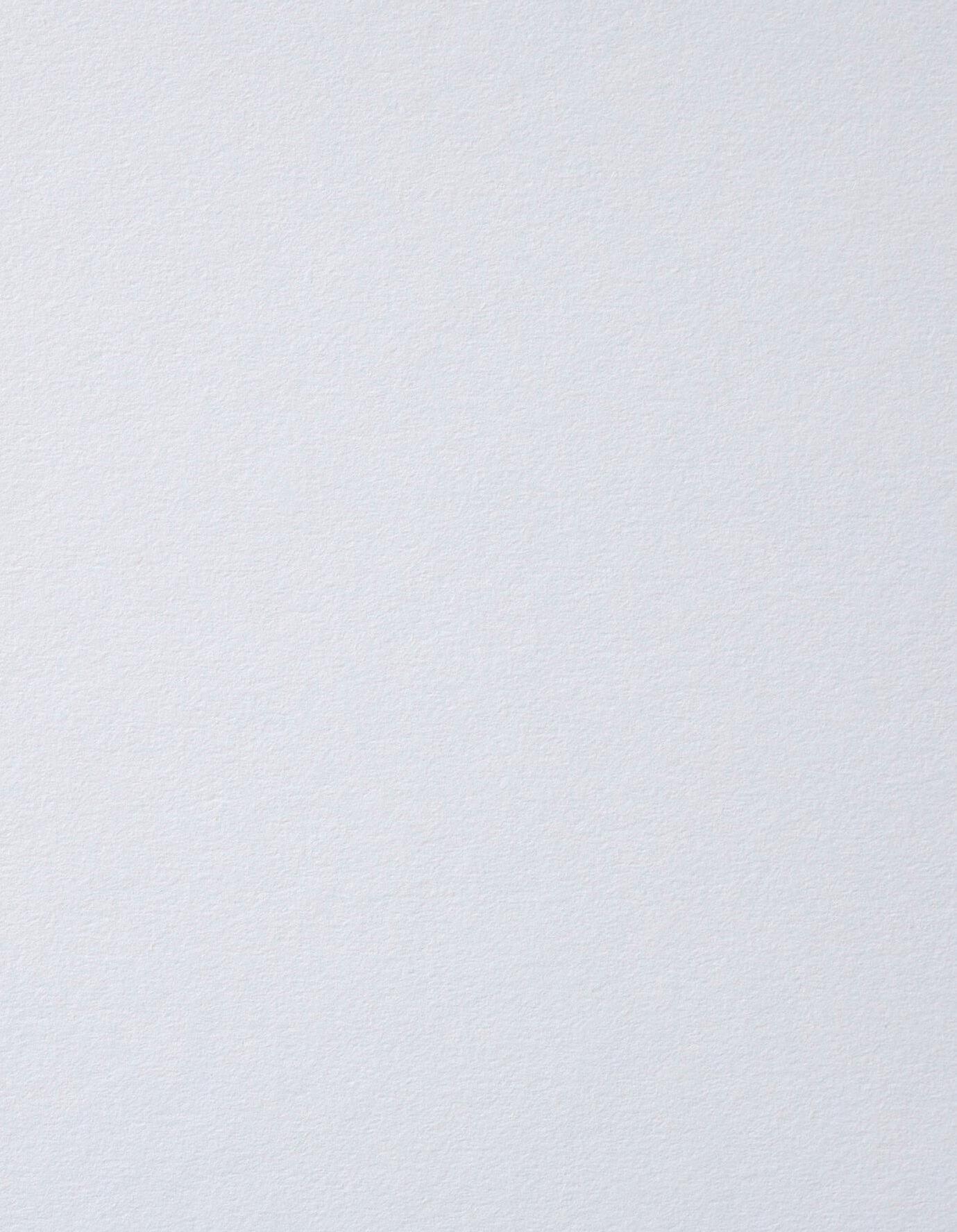

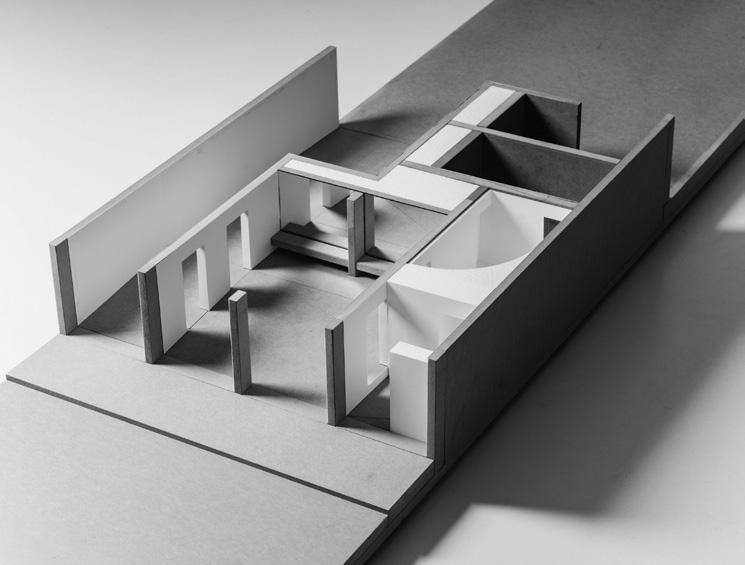

Mariana Siracusa (MS): Ah! I knew that you liked working with big models, but I did not expect to enter your construction site and find one this large! Which scale is it, 1:20?

Luís Ribeiro da Silva (LRS:): It is, and we brought it here because it is quite a useful tool for the construction team, making the project much more tangible. It also helps us make decisions about how to build the building. For example, this model was particularly useful during the concrete works, because all the formwork masons and concrete workers could clearly see the connections between the different elements of the facades, the divisions between the different pours, and how the geometry of the shell accommodates all these transitions.

MS: Because the facades were poured onsite?

Margarida Quintã (MQ): Yes, everything was poured on-site. A lot of people ask us if the facade elements are precast because the concrete is so smooth, but everything was poured here, even these very slender parapets were cast here on-site.

MS: And is it because it’s cheaper to do it this way?

LRS: I guess it’s because it’s Portugal… and yes, in the end it’s cheaper to do it like this. You see, this cast-in-place concrete technology is well developed here, whereas precast technology is not that

well developed. Besides, in this case the concrete elements of the facades —pillars and slabs— are actually structural, and to build a structural facade out of precast elements would be far more difficult to do in Portugal.

MQ: You see, more often than not, precast concrete elements in facades do not carry any load, they are mostly used as cladding, and then the actual structural elements are behind, or elsewhere. And then there are of course other context related issues like the question of thermal insulation, which in some geographies determines that the structure should not be exposed to the weather, but in our climate it is perfectly reasonable to expose the structure like we do, and then to work out all the thermal breaks from the interior. But going back to the point, in our building all the vertical loads are carried by the two facades, by the staircase and elevator shaft, and by a single pillar in the interior, so for us it was only natural to make everything out of cast-inplace concrete.

MS: So the facades literally hold the building in place?

LRS: Yes, quite literally.

STRUCTURAL SQUARES

MS: And I see that outside you also have a mock-up of the oblique supports of the rear facade, what’s behind it?

MQ: You mean, what’s behind the construction of the mock-up, or what’s behind the construction of the rear facade?

MS: Well, both.

LRS: You see, because we had to align our building with the facades of the neighboring buildings, the two sides of our building footprint had to have different depths:

on this side the building is around 15m deep, whereas on that side the building is around 19m deep. So from the start it was mandatory that we worked with these two facade planes. Then all the heights of this rear facade are determined by the heights of the front facade, where our building continues the height alignments of these same neighboring buildings. This being said, we had initially planned to make the facade pillars go straight down to the ground, like they go in the front facade, but once the clients saw the model they thought they would have little space to maneuver their cars here in the back of the plot. And for that reason we had to recede the structure, and we did so by means of these elements that we call “esquadros”, or structural squares.

MQ: And then the mock-up was important because this somewhat faceted geometry of the basis of the pillar was quite demanding in terms of execution. You see, we could not converge the reinforcement steel of these two lines of force in a single point, and so we deflected the oblique one into this tiny slanted surface, much like our Brazilian forefathers used to do.

LRS: Again, with cast-in-place concrete you only get one chance to make it right, and because the geometry of these squares is rather intricate, their construction is very challenging: the construction of the formwork, the fixation of the steel reinforcement, the vibration of the concrete and etcetera, every step requires utmost precision and skill. As a matter of fact, we could only achieve this standard of quality in the concrete works because we are lucky enough to be working with the best people in the business of cast-in-place concrete in Portugal today, a company named Matriz. They have a truly outstanding team, so passionate, always striving to ameliorate the construction solutions at every step of the way. For instance, if the rainwater water spouts ended up embedded in the

reinforced concrete slabs, it’s because the construction manager, Eng. Corte Real, proposed that we would do so, when our initial solution was in fact far less refined.

MQ: It is truly a great privilege to be working with Matriz, yes, and we owe them much.

“WE ARE BUILDING ON THE BEACH”

MS: This question of the structure of the building reminds me of a video that you posted on your social media at the beginning of the construction works where a number of men are climbing a sort of rebar column while digging it into the soil, it looked like an impromptu dance!

MQ: Yes, that was funny. The question here is that the soil is extremely sandy, because we are building so close to the beach. And for that reason we had to adopt a deep foundation solution, more precisely a bored (cast-in-place) pile solution. Those rebar columns that you see in the video are the reinforcement of the piles’ concrete, which is injected into the soil at the same time that the drill bit comes out of the hole. And because the soil is so sandy, each of those piles had to be bored to a depth of 12 meters.

LRS: A little anecdote: during the pandemic, the truck driver of the construction company got sick and he couldn’t come to work. But at that time, the brick walls were being laid, and sand was needed to make the mortar. So the construction foreman, Mr. Horácio Santos, just decided to dig a hole on the ground, no deeper than one to two meters deep, and he sourced the sand he needed from there, from the land beneath his feet! I guess it’s no exaggeration to say that we are building on the beach.

FLOOR PLANS

MS: It is clear that you have put a lot of thought and rigor into the execution of these facades, and I am wondering how they relate to the layout of the interior spaces?

LRS: Well, there are different relations in play here, but perhaps the most decisive one is that a four-partite structural facade is just very convenient to arrange the layouts of the three-bedroom apartments, which are the basis of the program.

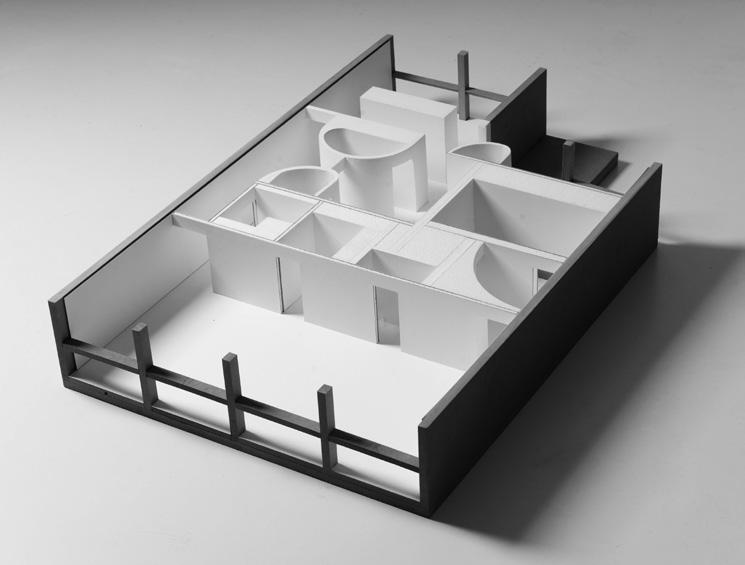

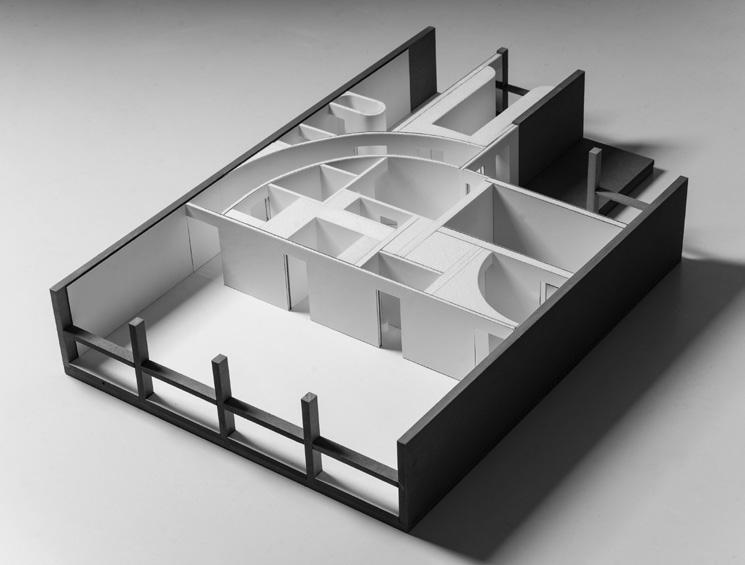

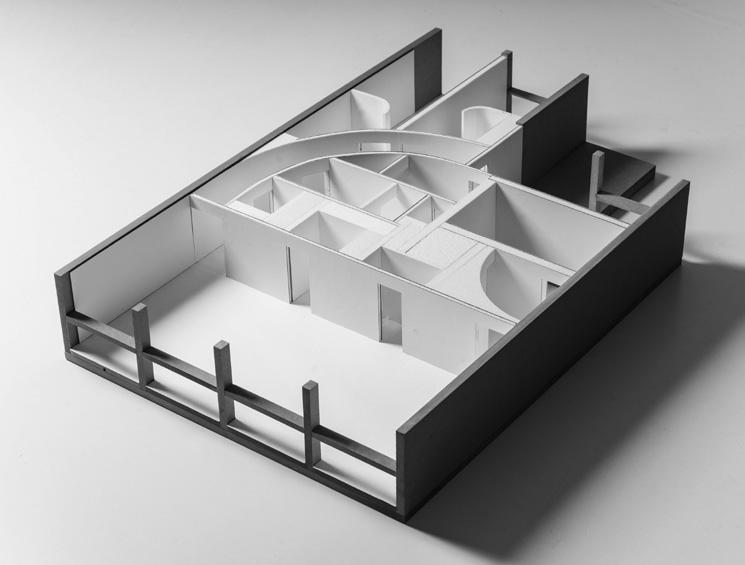

MQ: Perhaps this is easier to explain if we take one of the model floors out?

MS: Sure.

LRS: You see, because this rear facade is facing east and it has rising sun, it was only natural to orient the bedrooms towards this inner courtyard. So we decided to lay two bedrooms perpendicular to the facade here, on the deepest side of the building, taking two modules of the four-partite facade; and then here on the shallowest side of the building we laid out the third (en suite) room, parallel to the facade, taking the two remaining modules.

MQ: Besides, because we are working with a plot width of nearly 12 meters —11 meters and 80 centimeters to be precise— a fourpartite structure results in spans of nearly 3 meters wide, which have minimal deflections, and are just very easy to do.

LRS: Then the layout of the ground floor also benefited from a four-partite structure, let us see this in the model’s ground floor. So, we needed to take one module to allow the cars to pass through to the back of the plot, another module for a garbage room on the street side —which here in Matosinhos is mandatory— and at least another two modules to make a relatively generous entrance to the building. So as you can see, for us the modulation of the

structure is absolutely inextricable from the layout of the different spaces.

MS: I see.

MQ: And then there are also some important implications between the layouts of the ground floor and the apartments. For instance, we wanted every apartment to have a large living room facing the street, occupying the full width of the plot. And then, we also wanted these living rooms to have the circulation on the edges; which is to say, we wanted the entrance from the lobby on one end of the living room, and the access to the private spaces of the apartment on the other end of living room. With this premise it only made sense to place the vertical accesses adjacent to one of the sides of the plot, and such side would have to be the same as the garbage room’s on the ground floor — or otherwise there would be a conflict with the cars’ passage. Then at that point we had to decide on which side to locate the vertical accesses, and we chose the one which resulted in the shorter corridor for the rooms. And then we only had to go back to the ground floor, and design it accordingly.

MS: So the layouts of the ground floor and of the apartments are absolutely interdependent?

MQ: They are, absolutely.

MS: And you were just commenting on the importance of the living rooms, are they similar in all four apartments? But the apartments’ typologies are different, right?

LRS: Yes, exactly. There is a three-bedroom apartment on the first and second floors, a two-bedroom apartment on the third floor, and a one-bedroom on the fourth floor, all with the same floor area.

MQ: Let us dismantle the model so we can see the apartments side by side.

FEATURED WORK

ROBERTO IVENS BUILDING MATOSINHOS, PORTUGAL

2019-2024

Office ursa

Client RI727

Gross floor area

1080 sqm

Architecture ursa

Luís Ribeiro da Silva

Margarida Quintã

Paulo Pires Teixeira

Structural Engineer Iperforma

Paulo Marinho

Hydraulics Engineer Iperforma

Pedro Pinho

Electrical and Telecommunications Engineer

Auditene

Pedro Lopes

Mechanical Engineer

Auditene

Vitor Naldinho

Fire Safety Consultant

Exactusensu

Thermal Comfort and Acoustics Consultant

Adriana Pinho

Construction Management

Matriz

João Paulo Corte-Real

Reinforced Concrete Structures Manager

Matriz

Horácio Santos

Finishing Manager

Matriz

David Silva

Heating and Ventilation Systems

Leonardo Machado

Facades

Jofebar. Panoramah!

Metalworks

JHS Oliveiras

Marbleworks

Africa Stone

C.G.Lobo

Carpenter Campinho Arantes

Cabinet maker

Fernando Marques

Images

© Paulo Catrica

SPECIAL THANKS

Afonso Quintã

António Flor

Daniel Quintã

Eurico Almeida

Joana Matos

Joana Rocha

Luísa Baptista

António Morais

Mariana Siracusa

Paulo Catrica

Philip Ursprung

Pina Ferreira

Rute Moreira

PUBLICATION

DATA INFORMATION

COLLECTION

AMAG LONG BOOKS

VOLUME

LB 39

TITLE

URSA

roberto ivens building

ISBN 978-989-36626-1-8

PUBLICATION

DATE

December 2025

EDITOR-IN-CHIEF AND GENERAL MANAGER

Ana Leal

EDITORIAL TEAM

Ana Leal, architect

Filipa Figueiredo Ferreira, designer

João Soares, architect

Inês Rompante, designer

PRINTING

Graficamares

LEGAL

DEPOSIT

480255/21

RUN NUMBER

1000 numbered copies

PUBLISHER AND OWNER

AMAG publisher

VAT NUMBER 513 818 367

CONTACTS

hello@amagpublisher.com www.amagpublisher.com

Sílvio Saldanha /1000

LONG BOOKS COLLECTION

LB 01 DAVID ADJAYE mole house

LB 02 NICHOLAS BURNS guimarães chapel

LB 03 DAVID ADJAYE the webster

LB 04 CARVALHO ARAÚJO casa na caniçada

LB 05 ANDRÉ CAMPOS | JOANA MENDES centro coordenador de transportes

LB 06 ANDRÉ CAMPOS | JOANA MENDES

PEDRO GUEDES DE OLIVEIRA fábrica em barcelos

LB 07 DAVID ADJAYE winter park library & events center

LB 08 DAVID ADJAYE 130 william tower

LB 09 BRANDENBERGER

KLOTER ARCHITECTS community hall laufenburg

LB 10 BRANDENBERGER

KLOTER ARCHITECTS school pfeffingen

LB 11 BRANDENBERGER

KLOTER ARCHITECTS double kindergarten rüti

LB 12 BRANDENBERGER

KLOTER ARCHITECTS school aarwangen

LB 13 BRANDENBERGER

KLOTER ARCHITECTS school birrwil

LB 14 ANGELO CANDALEPAS the castle

LB 15 PAUL MURDOCH ARCHITECTS

flight 93 national memorial

LB 16 ÁLVARO SIZA monte da lapa volume l

LB 17 SO – IL amant

LB 18 AFF spore initiative

LB 19 LYNCH ARCHITECTS n2

LB 20 VIANA DE LIMA casa das marinhas

LB 21 SPASM parikrama house

LB 22 JOSEP FERRANDO social center

LB 23 SJB 19 waterloo Street

LB 24 KENGO KUMA cam

LB 25 TOMOAKI UNO terabe guest house

LB 26 AM2 Arquitectos | ARENAS & ASOCIADOS | NOARQ halo

LB 27 LYNCH ARCHITECTS westminster coroner’s court

LB 28 CHRIST & GANTENBEIN swiss national museum

LB 29 CAMILO REBELO côa museum

LB 30 CAMILO REBELO ovo

LB 31 CAMILO REBELO mim

LB 32 NICOLA BAVIERA apartment house urdorf

LB 33 VINCENT VAN DUYSEN casa m

LB 34 EDUARDO SOUTO DE MOURA vaticano chapel

LB 35 EDUARDO SOUTO DE MOURA casa de braga

LB 36 CAMILO REBELO promise

LB 37 LUÍSA PENHA duas portas

LB 38 ÁLVARO SIZA fundação gramaxo

LB 39 URSA roberto ivens building, is the thirty-nineth title from LONG BOOKS COLLECTION.

AMAG LONG BOOKS COLLECTION brings together a unique selection of projects that establish new paradigms in architecture.

With a contemporary and timeless conceptual graphic language, the 1000 numbered copies of each LONG BOOK will document works with different scales and formal contexts that extend the boundaries of architectural expression.