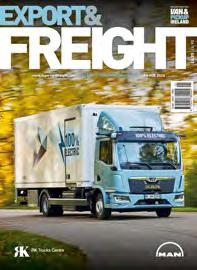

As we say goodbye to 2025, and head down the road into 2026 the transport and logistics sector is in a state of transition.

And while our industry is changing rapidly, with new technology and the move towards more sustainable operations, it is still grounded by the same fundamentals that have always driven it forward - reliability, resilience and adaptability.

With emissions targets tightening and customers demanding greener supply chains, operators will increasingly focus on practical decarbonisation - from the wider adoption of electric and alternativefuel vehicles to smarter route planning and load optimisation.

Technology has a huge part to play in all of this, and no doubt AI will have a significant role in the transport companies of the future.

None of us know exactly what 2026 will bring but we are confident whatever challenges lie in the year ahead the professionals who work in this industry will meet them head-on and adapt to still get the goods delivered on time.

What we can predict is that Export & Freight will be here to keep you as up to date as possible with what’s happening across the industry –both through this magazine and via our weekly newsletter.

In this issue we have the latest industry news, columns from our industry experts as well as features on Tyres and on Servicing and Winter Maintenance. We also have a special focus feature on Terberg MPM, as this Hillsborough based company looks confidently towards the future.

We hope you enjoy reading this issue, and if you have any news or stories for our next issue please get in touch.

Austin Lynch Editor

Email: austin@4squaremedia.net

EXPORT & FREIGHT SUBSCRIPTIONS, 4 SM (NI) Ltd

Email: accounts@4squaremedia.net

Web: www.exportandfreight.com

RHA appoints Brian Beattie as new Manager of Northern Ireland Affairs Page 4

DAF XD and XF Electric elected ‘International Truck of the Year 2026’ Page 6

In a blink of an eye: Scania Autonomous Trucks help Red Bull Athlete Matt Jones complete a World First Page 12

Transaid challenges riders to take on Isle of Wight adventure Page 48

MAN Financial Services UK Marks One Year with TRATON Financial Services – A Year of Growth, Partnership and Progress Page 58

Josh Fenton, Policy Manager Trade, Customs and Borders, Logistics UK Page 20

Martin Reid, RHA Policy Director for Scotland, Wales and NI Page 22 Court Reports Page 50

John McMahon Page 60-61

Servicing and Winter Maintenance Page 23-27

Terberg MPM - Building for the Future Page 34-46 Focus on Winter Tyres Page 51-56

Ford Ranger PHEV - Built Tough Page 64-65

Naming ceremony of Stena Futura takes place in Belfast Page 66-67

Email: helen@4squaremedia.net

The RHA (Road Haulage Association) is pleased to announce the appointment of Brian Beattie as its new Manager of Northern Ireland Affairs, starting in March 2026.

In his new role, Brian will lead the association’s engagement across Northern Irelandstrengthening relationships with members, decision-makers,

industry partners and local stakeholders. He’ll also be a key member of the wider RHA team. Brian is a highly respected leader in the Northern Ireland transport and logistics community, with more than 25 years’ senior operational experience at McCulla (Ireland) Ltd.

During his time as Director of Operations, Brian played a central role in the growth and management of the company.

Commenting on the appointment, RHA MD Richard Smith said: “I’m delighted to welcome Brian to the team. Brian brings invaluable

experience across our sector, and he’s acutely aware of what’s required of businesses operating in, and trading with Northern Ireland. His knowledge of the local business community, and standing within our industry will further enhance the support we provide to members in the region.”

Brian Beattie said: “I’m pleased to be joining the RHA team in 2026, a crucial time for our key sector in Northern Ireland. “There are some big challenges and opportunities ahead. I look

Two leading commercial equipment suppliers have joined forces to provide one of Europe’s foremost tour logistics specialists with a consignment of mega event trailers.

McGuinness, based in Dublin, is one of Ireland’s longest-established and most trusted tour logistics specialists. The company travels across Europe with major artists, bands and production crews, transporting the full scope of touring equipment - lighting, staging, audio systems, backline, and technical infrastructure - safely and precisely from venue to venue.

Joining the fast-expanding McGuinness fleet and supplied by Ireland’s premier Renault truck dealer, Setanta Vehicle Sales, are 10 Krone Dry Liner steel bodies trailers and 10 brand-new Renault 4x2 T-High trucks.

“Our reputation is built on reliability,” says Mick Dillon, Fleet Manager for McGuinness.

“Touring is unforgiving - every load-in and load-out is time-critical, and our trucks often move overnight to ensure the next show is ready to build when the crew arrives.

We handle everything from delicate audio gear to high-value staging systems, so the equipment we run has to be robust, secure and absolutely dependable. For us, the right trailer specification isn’t a luxury - it’s essential

to meet the demanding schedules and loading requirements of modern touring.”

In this regard, the high cube mega trailers are steel bodied with steel rear doors and come with a bespoke ramp carrier, insulated roof and, for flexible loading, Krone’s multipoint keyhole system. All steel parts are shot-blasted prior to priming and then finished with Krone’s KTL powder coating paint process. A 10-year guarantee against corrosion perforation is provided as standard.

Setanta Vehicle Sales, based in Dublin,

forward to playing my part, working with colleagues and collaborating with trusted partners to deliver for members and our industry.”

supplies a wide range of trucks and trailers for a variety of sector requirements and says the company, has a strong commercial relationship with Krone Trailer UK.

“There is always a strong demand for Krone event trailers,” says John McCann, Head of Trailer Sales for Setanta, “driven largely by their reputation for providing high quality equipment, tailored to the requirements of the job. Moreover, the Krone team understand what is required, and for this particular customer, they were able to respond quickly to a tight delivery schedule.”

“McGuinness is part of the live entertainment world,” adds Mick Dillon, “and in touring, there is simply no margin for error. Whether it’s an arena, stadium or festival site, our job is to ensure that every piece of production equipment arrives exactly when it’s needed and in perfect condition.

“Once the show ends, we’re straight into a highly coordinated breakdown and overnight move to the next city. Our drivers and crews are among the best in the industry, but they can only perform at that level with equipment that’s equally reliable. Keeping a major tour moving night after night demands nothing less.”

With decades of experience on the road, says the company, McGuinness has built a reputation for delivering complex multi-truck tours with absolute reliability, seamless coordination and industry-leading attention to detail.

DAF’s New Generation XD and XF Electric trucks have been awarded ‘International Truck of the Year 2026’.

Harald Seidel, president of DAF Trucks, received the most prestigious award in the truck industry during an award ceremony at the Solutrans exhibition in Lyon, France. It is the third win for DAF in five years, after the New Generation XF/XG/XG+ and XD became ‘International Truck of the Year’ in 2022 and 2023. In line with the rules of the International Truck of the Year (IToY) organisation, the title is awarded annually to the vehicle introduced in the previous 12 months that has made the greatest contribution to road transport efficiency. The assessment covers a range of criteria, including technological innovation, comfort, safety, drivability, energy efficiency, environmental performance and Total Cost of Ownership (TCO). Praised for exceptional efficiency

The jury of 23 leading commercial vehicle journalists from across Europe praised DAF’s XD and XF Electric truck series for their

exceptional energy efficiency, refined yet powerful driveline, and advanced technical architecture. Furthermore, the award-winning vehicles were recognised for their long driving ranges, advantageous LFP battery technology, and superior driver comfort.

“During extensive test drives, jury members praised the XD and XF Electric for the perfection of their drivelines and the almost imperceptible gear changes. The modular vehicle concept, offering a wide choice of battery and axle configurations provide operators an exceptional flexibility”, commented

Florian Engel, chairman of the International Truck of the Year jury.

“With the new XD and XF Electric, DAF Trucks demonstrates that the combination of a central electric motor and a traditional rear axle can be at least as energy-efficient as a driveline with an e-axle. Moreover, this DAF configuration provides perfect weight distribution, enabling virtually all use cases to be covered by a single technical platform.”

Zero emission range up to over 500 kilometres

The XD and XF Electric trucks are powered by PACCAR’s advanced

At the annual Fleet Transport Awards, the DAF XD with powerful yet economic PACCAR PX-7 engine was crowned ‘Irish Distribution Truck of the Year 2026’ in the medium duty rigid class. This marks yet another award for the New Generation DAF truck series, whose extensive lineup has claimed multiple accolades across Europe in recent months.

The prestigious Fleet Transport Awards ceremony, held at the Johnstown Estate Hotel in County Meath, just outside Dublin, welcomed over 650 guests from across the Irish transport industry. The awards jury, made up of commercial vehicle editors, transport professionals, operators and drivers, undertook detailed assessments of each nominated vehicle, evaluating performance, efficiency, safety, driver comfort and ease of operation.

‘Something special’

“After only a few seconds behind the wheel of the DAF XD the driver will realise that this truck is special”, stated the jury. “To start with: the 6.7 litre PACCAR PX-7 engine with the PowerLine eight-speed automated transmission offers refinement not found previously in this vehicle

class. The truck is a pleasure to drive and the full-width 2.5-metre cab gives the sense of a much bigger truck, even in the day cab format. The XD also offers impressive safety benefits from a new engine brake that delivers up to 300 hp.”

‘Class-leading’

“Of increasing importance in the urban distribution segment is visibility. DAF XD’s direct vision addresses this issue in a highly practical manner with the class-leading forward view. The view is further enhanced by DAF’s well-designed digital camera system, especially thanks to the DAF Corner View, which provides an excellent view of the area directly in front of the co-driver’s side of the truck. Also important is the ease of access for multi-drop drivers. Certainly, the DAF XD sets

EX-D1 and EX-D2 e-motors, delivering outputs from 170 kW (230 hp) to 350 kW (480 hp). With modular battery packs ranging from 210 to 525 kWh, the 4x2 and 6x2 tractor and rigid vehicles offer zero-emission ranges of over 500 kilometres on a single charge, and even over 1,000 kilometres per day thought optimal charging planning.

DAF’s XD and XF Electric trucks are designed for both city and regional distribution and long distance applications, combining excellent aerodynamics with a low cab position, ultra-low window belt-lines, and advanced digital camera systems for superior safety and visibility.

‘A moment of pride’

“Winning the International Truck of the Year 2026 with our XD and XF Electric models is a moment of pride for all DAF employees”, said DAF president Harald Seidel. “This recognition underlines our commitment to drive the future of zero-emission transport through innovation, quality and sustainability. We are thrilled that the jury of leading commercial vehicle journalists acknowledges the vehicles’ efficiency, safety and exceptional driver comfort. Receiving the most prestigious award in the truck industry is another recognition of the hard work of the entire DAF organisation to deliver first class products and services to our customers.”

a number of new benchmarks in this sector.”

The DAF XD is a new-generation distribution and vocational truck that stands out in safety, efficiency, and driver comfort. It offers a wide range of powertrain options, including fuelefficient PACCAR MX-11 diesel engines and advanced fully electric PACCAR EX-D1 and EX-D2 motors. The XD is available in multiple chassis configurations – 4x2, 6x2, 6x4, 8x2, 8x4, and even 10x4 for heavy-duty applications – providing tailored solutions for all transport needs. Cab variants include the Day Cab, Sleeper Cab, and Sleeper High Cab, each designed to maximize visibility and ergonomics, while offering first class comfort for drivers.

The latest versions of our award-winning New Generation DAF series come with a full suite of innovations that benefit robust construction and municipal applications. Driveline and aerodynamic improvements optimise fuel efficiency and increase durability. And a much richer specification takes safety and comfort to another level. Discover how DAF Transport Efficiency can power the success of your operations.

Manfreight has expanded its warehousing capacity in Northern Ireland with the £9m acquisition of a 100,000sq ft ambient facility in Belfast Harbour, supported by Danske Bank UK. The new site forms a key part of the company’s strategy to grow its BRCGS-accredited warehousing network across the UK and Ireland, strengthening Manfreight’s ability to provide fast, scalable, and fully integrated storage and distribution solutions to customers across multiple sectors.

Located less than four minutes from the major ferry terminals and only two minutes from the motorway network, the new facility offers a strategic connection between sea freight and road distribution, enabling highly efficient onward movement of goods. With over 12,000 standard / 15,000 Euro pallet spaces and the capacity to process more than 1,050 pallets per day, the site has been designed around flow, throughput, and operational agility. Turnaround times of under 30 minutes ensure high-volume capacity even during peak demand.

The Duncrue Street facility integrates seamlessly with Manfreight’s state-of-the-art chilled warehouse in Belfast Harbour and its temperature-controlled operation in Skelmersdale, creating a unified, three-site warehousing network across the UK and Ireland. This connected approach allows customers to access ambient, chilled, and temperature-controlled storage within one vertically managed supply chain, supported

by Manfreight’s own fleet of 330+ trucks and 550+ trailers.

Digital visibility sits at the heart of the operation. End-to-end tracking and data integration provide customers with a continuous line of information from collection to storage to final delivery - a capability increasingly demanded by modern FMCG,

food, pharmaceutical, retail, and manufacturing supply chains.

Speaking on the acquisition, Chris Slowey, Managing Director of Manfreight, said: “The key to our success is our ability to combine speed to market with scalability and highly bespoke levels of service. This facility gives us even greater control of our distribution, transportation,

and storage operationsensuring we can maintain one continuous line of data for our customers. We are grateful to Danske Bank for supporting this next step in our journey.”

Danske Bank’s Mark Brown added: “Manfreight is an ambitious local business that continues to invest in its end-to-end logistics offering. We are pleased to support its growth strategy and look forward to seeing the business expand further.”

With this latest development, Manfreight continues to build one of the UK and Ireland’s most advanced warehousing and logistics networks - combining ambient and temperature-controlled capacity with cutting-edge technology, strategic location, and sustainable design principles.

If you have any questions or would like to discuss how this facility can support your requirements or to request a copy of the brochure, please contact Manfreight by emailing warehousing@manfreight.eu

Why push air when you have a load to pull? The Volvo FH Aero increases your energy efficiency thanks to its aerodynamic cab. Designed to reduce your fuel costs, extend your range and minimise your environmental footprint. The Camera Monitoring System replaces side mirrors, opens your visual field, and further streamlines the cab. Your efficiency. Extended.

Contact your Volvo Trucks local dealer or visit volvotrucks.co.uk

The UKWA (UK Warehousing Association), the organisation working for a better future for warehousing, is looking to attract more members.

There are currently over 1,000 UKWA members across the UK but the organisation is seeking to increase its membership spread and are particularly looking for more members here in Northern Ireland.

Clare Bottle is the Chief Executive of UKWA, the leading trade body for the UK warehousing sector, offering support, insights, and advocacy.

Through UKWA Clare is working ‘for a better future for warehousing’

“Among our objectives at UKWA we want to make sure our young people recognise the career opportunities in warehousing. We want to ensure our members are embracing the green revolution, so our warehouses become increasingly sustainable. And we work very hard consolidating the reputation of the logistics industry with policy-makers and the public” comments Clare Bottle.

Talking to Export & Freight from a hotel in Slough – Clare explains that while a lot of her role is on the road they have their head office in Market Harborough, Leicestershire.

The Chief Executive says this is a great location as warehousing in big in the East Midlands. UKWA used to have its head office in London, as at that time the trade body felt it was important to be close to Government and policy makers. But they closed this after the COVID pandemic.

However they felt it was important to have somewhere the team could get together, and having this office has also made it possible to take on an apprentice.

Clare has been with UKWA for the past four and a half years, and before joining the trade body she worked for Coca-Cola Europacific Partners where she was Associate Director of Warehousing.

Clare explains she enjoyed working for Coke but was head-hunted by UKWA and when she realised what the new position was, she decided ‘I’d like to do that’.

Asked about how the membership works – and is it the person, or the organisation who joins; Clare explains UKWA membership is for companies – not individuals… and members are divided into two categories – full members and associate members.

An example of a full member is a company that operates warehousing – leasing forklift trucks, having a property and being involved in warehouse operations, either as a thirdparty logistics provider (3PL) or as the warehousing department within a larger retail or manufacturing business. Associate members will have some kind of goods or services that they want to sell to the full members e.g. warehouse management systems, forklift trucks or HR services.

“Any business that is involved in warehousing we would really welcome them.

We’re trying to grow our

membership at the moment. We are the Voice of Warehousing’. Turning to this part of the UK, Clare said membership is small in Northern Ireland at the moment but it is growing. Some multinational UKWA members like Amazon, DHL Supply Chain, DSV and GXO have operations in Northern Ireland alongside local businesses already in membership, including Jenkins, Montgomery Distribution, TST Group and Woodside Distribution.

Becoming a member…

To become a member of UKWA you can join on the website (www.ukwa.org.uk), or you can contact one of the team.

“Lisa on my team is the best person to contact – she looks after our full members. She’s been with the organisation longer than me and she knows everybody

“We will do a credit check, and ask for copies of insurance – just some basic checks on companies before they join the organisation.

Regarding the cost of membership – it depends on how much covered space you have – annual subscriptions range from £721 up to £3,166 for the biggest members.

As Clare and UKWA work to attract more members, Clare explains the benefits of membership are broken down into four central pillars: Benefits of membership – four pillars

Talk about Warehousing – we are the Voice of Warehousing.

“We talk about warehousing because people simply don’t talk about warehousing enough.

“We talk to the public, the media, policy makers and MPs to ensure warehousing is part of the national dialogue – which gives us a stronger voice.

Raise Standards – members can benefit from coming along to UKWA events to pick-up new ideas. Through working with experts and academics UKWA recently introduced the first ever globally recognized qualification for warehouse managers.

“There has never been a recognized qualification to be

a warehouse manager - we had that written from scratch by experts a few years ago. The course is run in England at the moment – but can also be accessed via online modules.

Those who complete the full course and pass the exams get a qualification issued by Chartered Institute of Logistics and Transport.

“So that’s one of the ways of raising standards” comments Clare Bottle.

Build Community – making people feel like they are part of something valuable and important. This includes running events and roadshows and conferences – it’s all about networking. UKWA also works hard to build its online community, with a new improved website and active presence on LinkedIn too.

Help Our Members – members can contact us with any queries about warehousing or if they’re simply looking for warehouse space.

Explaining a bit more about how UKWA target and act on certain topics, Clare explained that back in 2022 they were getting queries about members putting solar panels on warehouse roof tops. In response to this they did some research into this topic, so they are now able to give advice and guidance to members.

And this ultimately led to them publishing a ‘Solar Toolkit’ – for which they received some moral support from central government (although sadly no funding).

“And now we are hearing a lot of enquires from members about the storage of batteries for electric vehicles – companies having to store batteries for EVs as part of the supply chain.

“There’s a lot of electrification going on as we decarbonize our economy and the insurance rules about how we are supposed to store batteries are a bit of a mess – so that’s yet another opportunity where UKWA can be seen stepping up to help our members.

“If you want to be part of this journey, please join the UK Warehousing Association”

We’re proving electric trucks work in the real world. With millions of electric miles already covered, we have the proof to back our promises. Experience you can rely on. Expertise you can trust.

renault-trucks.co.uk

Scan the QR code to watch our Zeroing In electromobility series

In a story of man vs motor, Scania’s autonomously driven trucks gave Red Bull Athlete and mountain biker, Matt Jones, the opportunity to become the first person to jump through two moving trucks.

This world first, completed at an airfield close to Scania’s home in Södertälje, Sweden, was a true test of both innovation and precision, as both the rider and the trucks needed to be in perfect sync for the jump to happen safely.

Having originally sketched the idea down in a notepad, Matt chose to use Scania’s selfdriving trucks, as the accuracy and dependability of this cutting-edge AI-based technology, would guarantee Matt with the window of less than a second to make the jump.

Speaking about the challenge, Peter Hafmar, Head of Autonomous Solutions at Scania, says: “What an incredible feat and world first to be involved with. It was a real team effort from the Scania and Red Bull teams, with months of working together to make Matt’s ‘impossible’ vision a reality.

“You need to remember; he has just a blink of an eye to make this jump. With no margin for error, the team had to be so precise and calculated throughout. Thanks to our autonomous trucks, we could create a window of opportunity needed for Matt to do this kind of jump.

Seeing first-hand the precision and safety that Scania’s autonomous trucks and technology has brought to this challenge fills us with immense pride.

“Transport is a cornerstone of our daily lives, and with that comes the responsibility to make sure goods arrive to the right person or company in the most safe and efficient way. This feat gives everyone a glimpse of what

autonomous technology is capable of – delivering precision and safety that you can count on.”

Red Bull Athlete Matt Jones said: “I tried to turn my brain off and become autonomous, I had full faith in the technology and maths. I was completely locked in staring at the road ahead with the trucks in my peripheral vision, knowing that they were going to cross over each other and reveal the gap I was going to jump through.

“When I got halfway up the ramp and the trucks had initially gone past each other, I felt huge adrenaline because I could see the target on the other side. I instantly went from feeling numb to being flooded with adrenaline, it was nothing like I’ve experienced before.

“After completing the jump I experienced so many emotions. I had a sense of relief, pride and accomplishment in myself, but also so much appreciation and respect for the Red Bull

team and Scania to make all of this possible.”

After months of meticulous planning, technical and physical rehearsals and safety checks to prepare, this feat saw the Scania, Red Bull and PlusAI teams collaborate and share their creativity, engineering expertise and determination to turn an ‘impossible’ vision into a reality.

Scania is already revolutionising transport, with its focus of driving the shift towards sustainable transport systems that creates a world of mobility that is better for business, society and the environment. Autonomous vehicle technology is ready to and will play an active role in redefining safety, operational efficiency and minimising the environmental impact. This technology is no longer just an idea for the future. Scania’s autonomous mining trucks have been operating in Rio Tinto’s mine in Australia since 2018, and have been available to commercially buy since 2024. That is just the beginning. Self-driving technology will soon be moving onto highways, enabling hub-to-hub freight transport.

In fact, Scania is already actively testing on European roads, in partnership with the Silicon Valley based company PlusAI.

Scania’s world-class trucks and in-house software capabilities, paired with PlusAI’s cutting edge AI-based technology will deliver safe, scalable and factory-built autonomous solutions for the road.

Find out more about Scania’s autonomous technology here: scania.com/autonomous

In the fast-paced world of transportation and logistics, risk is an unavoidable reality. From fleet accidents to cargo damage and liability claims, the financial impact of unforeseen events can be devastating.

This is where an insurance broker becomes an indispensable partner—providing expertise, cost efficiency, and peace of mind for businesses navigating complex risk landscapes.

Transportation insurance is not a one-sizefits-all solution. Brokers bring deep industry knowledge, understanding the nuances of motor fleet coverage, goods-in-transit policies, and liability protection, alongside many other covers. Unlike direct insurers, brokers work for the client—not the insurance company—ensuring that coverage is tailored to operational needs. Their ability to interpret policy wording, negotiate terms, and identify gaps in protection can make the difference between a minor setback and a major financial loss – a vital service for any business.

Managing insurance costs is a priority for every transportation business. Large brokers such as Dickson Group leverage their broad market access and negotiating power to secure competitive premiums without sacrificing coverage quality. They understand how factors like fleet size, driver training programs, and telematics data influence pricing, and they use this insight to position clients favourably with insurers. In many cases, brokers can also advise on risk management strategies that reduce claims— and, in turn, lower long-term insurance costs.

We all understand that claims are one of the most influential factors upon premium rating. Ensuring that claims are reported early helps give insurers confidence and proactively management of claims can help reduce premiums.

Dickson Group’s Claims Director and its dedicated claims team work on behalf of their clients to ensure that claims are dealt with quickly and professionally.

Not every broker can cope with the challenges of transportation companies who are

based in Northern Ireland, but also have Republic-based business operations.

For ROI elements of the client’s business, Dickson Group will engage with its sister company Dickson & Wilson Insurance Brokers based in Monaghan, to coordinate the insurances. In practical terms, this means Dickson & Wilson negotiate with Dublin and Europeanbased insurers for the client’s ROI-based risk, whilst Dickson Group in N.I. deal with the NI and GB-based insurers.

An independent broker like Dickson Group is not tied to any single insurer, and act as an agent of their clients, the policyholders. Which means their recommendations are unbiased and client-focused. This independence allows them to compare multiple providers, ensuring businesses receive the best combination of coverage and price. For transportation companies, where margins are tight and risks are high, this impartiality is critical. It guarantees that decisions are driven by client needs, not insurer incentives.

Transportation is a local and regional business at its core. Having a broker with offices across Northern Ireland, and who understands the local market, regulations, and road conditions, adds significant value.

A local broker can respond quickly when incidents occur, provide face-to-face support, and build relationships that go beyond transactional interactions. In times of crisis—such as an accident or cargo loss—this proximity ensures faster claims handling and personalised service.

Ultimately, an insurance broker is more than a policy provider—they are a strategic advisor. By aligning coverage with business goals, helping manage risk, and ensuring compliance, brokers enable transportation companies to operate confidently and focus on growth. In an industry where every mile carries risk, having the right broker on your side is not just smart—it’s essential.

We know that a penny at the pump can make a real impact on your costs. We deal with over 150 insurers, giving you the peace of mind that you have the best insurance cover at the best price for your business.

Whether it’s for your vehicles, your premises, your employees or the goods you transport, we have the expertise to create a tailor-made insurance programme specific to you.

As well as core insurances such as motor, employers’ liability and property, talk to us about cover for cyber insurance, warehouse legal liability, or legal advice immediately following an accident.

MAN Truck & Bus has further strengthened its electric truck line-up with the introduction of the 12-tonne MAN eTGL, now available in a configuration specifically designed for refrigerated box bodies. The new variant was unveiled at the Solutrans 2025 exhibition in Lyon in mid-November and marks an important step in extending zeroemission transport into temperature-controlled urban and regional distribution.

The refrigerated eTGL enables locally emission-free and exceptionally quiet delivery of temperature-sensitive goods, including food and pharmaceuticals. A dedicated high-voltage interface allows the refrigeration unit to draw power directly from the vehicle’s electrical system, offering an efficient and weight-optimised

solution without the need for a separate power source. With this addition, MAN’s all-electric refrigerated logistics portfolio now spans vehicles from 12 to 42 tonnes.

The eTGL is equipped with two battery packs providing

a usable capacity of 160 kWh, delivering a range of up to 310 kilometres depending on body configuration and operating conditions. Fast-charging capability allows the batteries to be recharged from 10 to 80 per cent in around 35 minutes, enabling operators to make effective use of loading or rest breaks and extending the potential daily range to as much as 600 kilometres.

Friedrich Baumann, Member of the Executive Board for Sales & Customer Solutions at MAN Truck & Bus, said the new model significantly broadens the scope of MAN’s lightweight electric trucks. Together with the eTGX and eTGS, the manufacturer now offers a

comprehensive zero-emission solution for temperature-controlled logistics, from inner-city distribution through to long-distance transport. Like its heavier electric counterparts, the eTGL benefits from recent efficiency upgrades across the MAN eTruck range. Improvements to auxiliary systems, enhanced waste heat utilisation and refined driving functions deliver an approximate ten per cent increase in range. As a result, the latest eTGX variants can now achieve up to 570 kilometres in articulated form and up to 870 kilometres as a solo chassis with box body, depending on specification.

Based on MAN’s established 12-tonne

diesel chassis, the eTGL offers a payload of up to 6.6 tonnes, a 4,500 mm wheelbase and body lengths ranging from 6,200 to 7,300 mm. Low-entry cab access with a single step makes it particularly well suited to multi-drop urban distribution. A fully digital 12.3-inch display provides drivers with real-time information on charge status, range and energy consumption. The vehicle shares its electric drivetrain architecture with the heavier eTGX and eTGS models, including MAN-developed battery packs produced at the company’s Nuremberg facility. Each pack delivers 80 kWh of usable capacity, while propulsion comes from a centrally mounted 285 hp electric motor paired with a two-speed gearbox. MAN’s modular battery concept, designed specifically for commercial vehicle applications, allows a wide variety of chassis and body combinations.

This flexibility enables fully electric operation across a broad spectrum of transport tasks, from long-haul and construction applications to refuse collection and now deep-freeze supermarket distribution. In real-world operation, MAN’s electric trucks have already demonstrated strong efficiency and reliability. Around 400 eTGX and eTGS vehicles have accumulated more than nine million kilometres in customer service within their first year, recording an average energy consumption of approximately 93 kWh per 100 kilometres.

Supporting the vehicle range is MAN’s 360-degree eMobility Consulting service, which is also available to eTGL customers. This includes tailored analysis of vehicle deployment, route planning and charging infrastructure requirements, with particular focus on the specific demands of refrigerated logistics. At Solutrans, the eTGL formed part of MAN Truck & Bus’s wider zero-emission showcase, alongside the eTGX, eTGS and the hydrogen

combustion-engine hTGX, winner of the Truck Innovation Award 2025. The stand also featured expert presentations and

consultancy sessions, underlining MAN’s commitment to supporting operators through the transition to electric mobility.

In a market where every penny counts, UK and Northern Irish truck fleets are understandably focused on tyres that offer dependable mileage and good value. Yet the very option that can deliver both - quality retreads - continues to be overlooked.

In a recent survey of more than 700 UK-based commercial vehicle fleets, Continental Tyres found that the results painted a revealing picture of operator priorities. More than half of respondents (56.7%) selected mileage performance as one of the most important criteria when choosing tyres. While similar numbers (56.3%) highlighted the retail price. Other key decision points were damage resistance (51.6%) and wholelife ownership costs (50.2%). These are practical, operationally driven considerations, no surprise in a fiercely competitive industry where tyres represent significant cost. However, additional data from the same survey showed that two-thirds of fleets (66.9%) exclusively fit new tyres. For many operators, the hesitation stems from perceived issues with quality, as 62.5% of respondents believe retreads may not have the quality of new tyres, while 46% question their durability. These findings underline Continental’s determination to combat the misinformation and misconceptions around retreads. Pete

Robb, Marketing Director at Continental Tyres, points out that fleets are actively seeking tyres that offer value for money, precisely the area where retreads excel. He describes retreads as a “sweet spot” for many businesses, thanks to their lower purchase price and like-for-like mileage capabilities compared to an equivalent new tyre. Yet a historic reluctance persists, pushing fleets towards cheaper new tyres that may be single-use products and may not deliver the same operational benefits as high-quality retreads from a renowned manufacturer.

A retread tyre can have a lower retail price than its new equivalent, immediately reducing running costs. High-quality retreads may then be regrooved, extending their overall service life, and in many cases, the casing can be retreaded a second, sometimes third, time. Over the tyre’s lifetime, this can translate into hundreds of thousands of miles.

The sustainability benefits are equally significant. With hundreds of truck tyres replaced every day across the UK and Northern Ireland, the environmental burden of disposal is considerable. In a typical retread, up to 85% of the tyre uses recycled or renewable materials, and the process can save up to 55kg of waste per tyre in production.

Retread manufacturers invest heavily in research, development and engineering to ensure the final product meets stringent regulations. All retread tyre manufacturers must comply with the UN’s ECE Regulation 109, which ensures performance, dimensions and tyre wall markings are equivalent to those of a new tyre. Within Continental’s own operations, ContiLifeCycle plants, where ContiRe and Bandvulc tyres are produced, adhere to ISO auditing criteria, ensuring consistently high production standards. Modern retreads aren’t a compromise. Businesses are too often missing out on reducing their operating costs and enhancing their environmental credentials because of a perception that remanufactured tyres are inferior, when in fact, they offer a compelling blend of performance, cost efficiency and sustainability.

To find out more, please visit: ContiLifeCycle Continental Tyres

Josh Fenton

Manager

From 1 January 2026 all carriers, logistics firms and traders moving goods between Great Britain and Northern Ireland, as well as GB to the EU, will need to comply with Import Control System 2 (ICS2) - the EU’s upgraded customs security and safety programme.

ICS2 replaces the EU’s Import Control System, and requires more detailed data submissions on all goods entering the EU prior to their arrival. As part of this process, ICS NI, currently used for the movement of goods from GB to NI, will also transition to the mandatory requirements of ICS2 from 31 December 2025. From this point, ICS NI will no longer be an option. The new system requires logistics companies to submit an Entry Summary Declaration (ENS) when moving goods between GB and NI, GB and the EU, and countries outside of the EU into NI. ENS must be submitted no later than two hours before the goods arrive in NI or the EU. ICS2 marks a considerable change in the requirements for companies operating across the supply chain, and readiness is essential. Please be aware that those who do not comply with ICS2 requirements will have their goods stopped and delayed at EU customs borders, with the potential for these goods not to be cleared, and sanctions imposed for failure to comply. However, a perceived lack of readiness in the system, visibility and clarity over requirements have given logistics businesses cause for concern while preparing for compliance and may put further pressure on small to medium enterprises (SMEs) - something which we at Logistics UK are maintaining awareness of with officials to speed a resolution.

ICS2 spells out new data requirements that need to be understood in order to ensure supply chain readiness – more specifically, the descriptions of goods, which need to be more detailed, and the commodity code, previously four digits, which will now need to be provided in six digits.

The descriptions of goods must be clear, concise and specific, to clarify what the goods are. To this end, descriptors cannot feature ‘stop words’ which are determined by the EU. It has published a list of words that would be considered too vague. Examples of these words include accessories, animals, cleaning products, and clothes. If these words are included in the ENS, it will be automatically rejected. For example, labelling goods as ‘jewellery’ would not be acceptable, but labelling these goods as ‘women’s gold jewellery’ would provide the necessary clarification, and would be accepted. This guidance will be continuously updated and iterated by the EU.

One major challenge associated with getting prepared for ICS2 has been the readiness of the IT system. There have been reports of system outages and disruptions, and since the system is maintained by the EU, and not a UK-based authority, operators have reported challenges in communicating issues as and when they arise. For busy periods of the year, like the festive season, hauliers cannot afford outages and the complete stoppage of goods. Logistics UK is calling for contingency plans to be mapped out and communicated to the industry before the 31 December 2025 deadline to ensure goods continue to move in case of a widespread systems failure. This should be done both for ICS2, but also for the Trader Support Service (TSS) for those transporting goods between GB and NI. In some instances, businesses have already reported they have had to revert to ICS NI where outages have prevented them from using ICS2.

It is therefore essential to ensure the system is fully operational when it is formally brought in, to keep trade flowing between countries.

Another major challenge for ICS2 is the potential impact on groupage operators and the pallet network model. Groupage allows multiple small consignments, often lowvalue and time-sensitive, to move at speed through shared transport and hauliers often lack contact with consignors or consignees.

The sector makes up a huge portion of the movement of goods from GB to NI, with the majority of hauliers being small to medium enterprises where any disruption can have a significant impact on their businesses.

One solution Logistics UK has been pressing government for is a Trusted Hauliers Scheme to be put in place to ease difficulties with the Windsor Framework and now the ICS2. As a periodical review of hauliers, it would allow groupage operators more time to secure all the information required and enable hauliers to maintain speed.

With the deadline of ICS2 compliance looming, logistics businesses must do all they can to prepare and to reduce any potential disruption. In a similar vein, those overseeing the effective rollout of the system must listen to industry concerns and respond accordingly, to ensure it adequately aligns with the needs of the entire supply chain. Logistics businesses operate on razor-thin margins and cannot afford any further impacts on their operational efficiency and profitability. The system that is brought in must be tried, tested and fit for purpose – and if all else fails, there must be a contingency plan to ensure trade is not halted.

For more information about the organisation and its work, please visit logistics.org.uk

The sustainable option for businesses who want to help the environment.

Fuelled by years of early investment and leadership in the field of renewable energy, Texaco HVO Renewable Diesel is lower in carbon and burns cleaner than regular diesel. Its high cetane count enhances engine performance and gives a smoother delivery that performs well in both cold and warm climates. As a drop-in fuel with a chemical makeup that’s the same as regular petroleum-based diesel, no engine or infrastructure changes are needed.

Why Texaco HVO Renewable Diesel is the better choice:

100% renewable and sustainable

Up to 90% less greenhouse gas emissions compared to regular diesel

Chemically the same as petroleum-based diesel

Burns cleaner with a lower carbon footprint

Provides higher engine performance

Performs in cold and warm climates

Cost-competitive

More reliable than electric vehicles

Significantly lower greenhouse gases than hybrid and electric vehicles

Guaranteed performance

In September 2025, Lord Murphy published his independent review of the Windsor Framework. It is a pretty comprehensive and sizeable document with more than eighty recommendations.

At the start of November, Lord Murphy met with the NI Economy Committee to go over his findings and our new Policy Lead for Trade and Borders, Alastair Gunn, joined Ally Hobson of Montgomery Group, Mark Tait of Target Transport, and myself in following Lord Murphy in giving evidence to the Committee. Some of Lord Murphy’s findings aligned with what members have been telling us and the fact that Ally and Mark could give real life examples of where the Trader Support Service (TSS) is hampering rather than supporting the sector. RHA’s long standing request for a “trusted haulier” scheme has also been picked up by Lord Murphy and was reported to the committee as a recommendation. This would allow hauliers to prove they have met requisite standards and allow the authorities to pursue the serially non- compliant and the ones who deliberately put in incorrect information to reduce admin and cost.

Our main ask is for “Risk” to be moved to the point of sale. This would make sense as once an item is sold you know its end destination. If sold goods are going to ROI and therefore the EU, then customs processes would apply. If they are sold and will be remaining in NI or heading back to GB, then we believe customs

processes should not apply.

Currently, almost all goods (excepting retail or food) are automatically deemed “at risk” and must go through full customs requirements, even when just going into stock.

Our position throughout the past four or years has remained consistent, as have our asks of Westminster. Moving risk to the point of sale removes the need for huge parts of the NI supply chain to go through the red lane.

As stated at the Committee last week, this is no ‘silver bullet’ but it

would make a marked difference to the day to day running of NI PLC. The Committee heard from our members that it is easier to move goods through Dublin from GB to NI than it is to move goods directly GB to NI as the movements through Dublin can be done with one customs entry, one package, one press of a button, unlike the multitude (NIRMS, Non-NIRMS, UKIMS, API etc) required when using the direct GB to NI route. The Chair of the Committee. Phillip Brett MLA, thanked RHA, “throughout the entire process

you have being willing to stand up and speak about the issues…. from a business point of view these arrangements do not work.”

There were times at the beginning when we were the lone voice but many organisations such as FSB have started to raise concerns from their members. The Committee have subsequently written back to us to say that they have quested a briefing from HMRC’s Windsor Framework NI Stakeholder Engagement Team and also that they will be writing to the Secretary of State for NI to indicate support for a Trusted Hauliers Scheme, reform of the Duty Reimbursement Scheme, to indicate concern about unlawful movements and seeking a study of the effects, seeking commentary on moving risk to the point of sale and confirmation that this will all be fed into the UK/EU reset talks.

RHA held an event at the House of Lords at the end of November with Lord Murphy and several other Peers to discuss his report and for our members to relate their real time experiences of moving goods from GB to NI. We will also be asking for support from the House of Lords in pushing the discussion forward for moving risk to the point of sale. Keep an eye out for that report in the next issue of Export and Freight.

As winter tightens its grip across the UK and Europe, the importance of proactive servicing and seasonal maintenance becomes impossible to ignore.

Shorter days, dropping temperatures and often treacherous road conditions place unprecedented strain on commercial vehicles, making reliable performance not just a matter of efficiency, but of safety, compliance and continuity for operators working to keep goods moving through the colder months.

For fleet managers and owneroperators alike, winter presents a unique set of challenges. From cold starts and reduced battery efficiency to the increased risk of component

wear, corrosion and fluid failure, the hidden impacts of sub-zero conditions can quickly escalate into costly downtime if not properly addressed.

A comprehensive servicing regime, tailored specifically for winter operation, is therefore essential in safeguarding vehicle reliability and protecting bottom-line profitability.

This feature explores the critical role that winter maintenance plays in ensuring fleet resilience, examining best practice approaches to preventative servicing and the key checks

that should form part of any cold-weather preparation plan. From coolant strength and brake performance to tyre condition, lighting systems and driver awareness, every element contributes to keeping vehicles roadworthy when conditions are at their most unforgiving.

In a sector where missed deliveries and unexpected breakdowns can have farreaching consequences across supply chains, investing in scheduled inspections and structured maintenance programmes offers more than

peace of mind; it provides a strategic advantage. Technological advances, predictive diagnostics and smarter servicing schedules are now enabling operators to stay one step ahead, minimising risk while maximising uptime throughout the winter season.

As the transport industry continues to balance operational pressures with tightening regulations and sustainability targets, winter maintenance remains a cornerstone of effective fleet management.

As we start the New Year, there’s a renewed emphasis at SWS on the all-important supply of consumables for the workshop, without any loss of our focus on workshop fit out and the supply of equipment.

SWS have been working with commercial vehicle workshops across the whole of Ireland for over 50 years. Alongside all the changes that technology has introduced, the need for a supplier that understands the challenges faced everyday has never been greater.

That’s exactly where SWS fit in – combining an in-depth understanding of what it

takes to run the workshop with product knowledge that has been accumulated as a result of the experience. And it doesn’t just stay as knowledge. Backing up the advice is a stockholding at their Irish distribution centre that has the customer as a priority.

If you’re starting the year conscious that your workshop has got to be overhauled, but not sure where to go for honest, open advice

give SWS a call. With our years of experience we can give you the best advice that will result in a cost-effective solution that best suits your business and your individual needs.

Remember, it doesn’t stop at supply – the comprehensive packages offered are all-inclusive of training, maintenance and certification. This is all backed up by some of the best names in the industry – Stertil Koni, VL Test Systems, Samoa, Majorlift; to name but a few. However, it’s quite likely that your workshop is all up to date, everything functioning as it should and apart from some regular maintenance (don’t forget SWS) all the boxes are ticked. That is except for one (important) thing – all those items that are needed every day, every week and every month. If that’s the case – we’ve got your back. SWS

understand the pain that running out of the most basic items – like cable ties, can cause. It’s why the stock holding is so large. If you need it, SWS want to be able to supply it. To make accessing these basic products easier SWS are rolling out an all-new publication – The Workshop Essential. And this does exactly what the title says – it’s full of all those every-day, essential lines. If a copy hasn’t crossed your desk yet – give SWS a shout. They’ll be glad to get one to you and to discuss the options available to ensure you’ve always got the best quality products that you need, when you need them.

Five winter-readiness essentials to keep Ireland’s fleets moving

Irish fleet operators know that winter rarely arrives in a predictable way, with sudden cold snaps, coastal moisture, heavy rain and salt exposure all putting extra strain on vehicles. Whether maintenance is handled in-house or through a trusted workshop partner, making sure the right winter checks are carried out is essential for maximising uptime.

Diesel Technic provides a wide range of spare parts to keep fleets dependable through the toughest months.

Here are five critical areas to prioritise for reliable winter running:

1. FUEL FILTRATION & WATER SEPARATION

Ireland’s damp climate raises the risk of water contamination in diesel. Combined with low temperatures, this can lead to waxing, blocked

filters and hard starting. Fuel filters, seals and water separators should be checked and replaced as needed.

2. COOLING SYSTEM & ANTIFREEZE PROTECTION

Fluctuating temperatures and shorter journeys can expose weaknesses in the cooling system. Radiators, pumps, hoses, thermostats and clamps should all be inspected, and coolant concentrations verified to ensure adequate freeze protection.

3.

Cold weather increases electrical load, particularly for vehicles operating at night or on rural routes. Alternators, starters, wiring and connectors should be tested to ensure reliable cranking and charging performance.

Road salt and constant moisture—

especially on coastal or motorway routes - accelerate corrosion across braking and suspension components. Brake lines, hoses, valves, chambers and chassis mounts should be carefully inspected for early signs of wear or damage.

Fog, rain and frosty mornings make effective heating and demisting essential. Blower motors, resistors, sensors and HVAC

components should be checked, and it Is good practice to run the A/C periodically to maintain compressor lubrication.

Diesel Technic provides a comprehensive range of quality-assured spare parts across all key winter-maintenance systems, helping workshops and fleet operators reduce downtime and keep vehicles moving through the toughest conditions.

Its dedicated Parts Specialists also offer technical support via the Help Desk: www.parts-specialists.com/en/helpdesk

Renault Trucks has just unveiled new versions of the Renault Trucks E-Tech T: the Renault Trucks E-Tech T 585 and the Renault Trucks E-Tech T 780, which can travel up to 600 km on a single charge.

Designed to meet hauliers’ specific needs, the Renault Trucks E-Tech T 780 is focused on range and the Renault Trucks E-Tech T 585 on payload, while the Renault Trucks E-Tech T 540 4x2 remains dedicated to regional distribution.

The increased range of the Renault Trucks E-Tech T 780 and T 585 has been achieved by integrating an electric axle. The E-axle enables all parts of the powertrain – electric motors and transmission – to be grouped together at the vehicle’s rear. This architecture frees

up space between the side members to accommodate additional battery packs.

These new models are fitted with highenergy-density NCA (Nickel, Cobalt, Aluminium) lithium-ion batteries, with a specific L-shape design to fit neatly in the new layout. Renault Trucks guarantees their performance up to 8 years or 1 million kilometres.

The Renault Trucks E-Tech T 585, which carries 585 kWh of battery capacity, can travel up to 460 km* on a single

charge, while offering the highest payload in this vehicle range.

With 780 kWh of capacity, the Renault Trucks E-Tech T 780 achieves a range of 600 km* and is designed for hauliers looking above all for maximum range.

To get the most out of stops, both models are compatible with charging stations equipped with the ultra-fast Megawatt Charging System (MCS), up to 720 kW. These stations can provide up to 350 km of range in a 45-minute driver’s rest break.

They can also be charged at a depot using the standard CCS (up to 350 kW). Alongside these developments, Renault Trucks is upgrading its current model, the Renault Trucks E-Tech T 540 4x2, which will now be able to travel up to 450 km on a single charge.

Designed for long distances, the Renault Trucks 6x2 tractor versions E-Tech T 585 and T 780 provide optimal driving comfort, and thanks to their rear axle, these new models’ manoeuvrability is comparable with that of a 4x2 tractor version. This lightweight, steerable and liftable axle protects tyres during return trips at low load.

To guarantee the performance and profitability of its electric vehicles, Renault Trucks provides a full range of connected and predictive services:

The Optifleet fleet management solution, with its various modules, enables route planning, real-time vehicle tracking, performance analysis, and charging management, for simplified planning and monitoring.

The Serenity Pack, a specific electromobility contract, ensures optimal use of electric trucks through enhanced tracking and personalised assistance provided by Renault Trucks experts during the first year of operation.

The Driver App enables drivers to monitor charging status and remotely prepare

their vehicle (pre-conditioning of the cab and batteries), so as to guarantee optimal availability before each assignment.

Finally, the Renault Trucks E-Tech Programme consultancy service provides transport operators with access to electromobility experts and advanced tools (fleet and route analysis, site energy capacity assessment, range and CO2 savings simulations, etc.) to build a bespoke decarbonisation strategy.

These three new models will be produced at the plant in Bourg-en-Bresse, where vehicles in the electric heavy-duty range –Renault Trucks E-Tech T and Renault Trucks E-Tech C – have been assembled since late 2023. They are available to order now.

Renault Trucks is expanding its electric range with the Renault Trucks E-Tech D14, a 14-tonne vehicle designed for city-centre distribution rounds. Compact and agile, it joins the electric medium-duty range developed by Renault Trucks, which now provides solutions fit for all urban applications, from 14 to 28 tonnes.

With a 2.39-metre-wide chassis, a 3.8-metre wheelbase and a turning radius under 7.3 metres, the Renault Trucks E-Tech D14 is the most compact and manoeuvrable vehicle in the manufacturer’s electric range. It stands out as the ideal solution for deliveries in dense urban environments where space is limited. Its low load bed height makes it easier to perform repeated tasks, whether they involve dry or refrigerated goods distribution. With a payload of 6.7 tonnes, it achieves an excellent trade-off between carrying capacity and agility.

And the Renault Trucks E-Tech D14 is the only truck in its category to feature full air suspension, both at the front and rear, providing optimal driving comfort in urban environments. Range to meet the city’s needs and simplified charging Fitted with four LFP batteries

providing a combined capacity of 176 kWh, the Renault Trucks E-Tech D14 offers a range of up to 220 km on a single charge, comfortably covering the needs of a full day’s distribution work in town. It is also the only 14-tonne vehicle to feature a 43 kW AC on-board charger, to enable charging at alternatingcurrent stations, which are widely available and easy to install.

The Renault Trucks E-Tech D14 is paired with a set of connected services designed to make operators’ day-to-day work easier. Drivers and fleet managers can remotely monitor charging data using the Driver App and plan their routes with the Optifleet Mission module, which come as standard. With the optional module Optifleet Charge, they can remotely

control battery charging status and optimise charging cycles to maximise vehicle availability.

Going a step further, the Serenity Pack – a specific electromobility contract – provides enhanced tracking and personalised assistance by Renault Trucks experts during the first year of operation, to guarantee optimal use of the electric truck.

Finally, the Renault Trucks E-Tech Programme consultancy service provides transport operators with access to electromobility experts and advanced tools (fleet and route analysis, site energy capacity assessment, range and CO2 savings simulations, etc.) to build a bespoke decarbonisation strategy.

The Renault Trucks E-Tech D14 is available to order and is produced at the plant in Blainville-sur-Orne, France – a European leader in electric truck manufacturing.

With this new model, the Renault Trucks electric distribution range is now available in 14, 16, 18 and 28 tonnes, making it another part of a comprehensive electromobility solution offering that ranges from 3.5-tonne to 44-tonne.

Over the past two years, Transbridge Freight Services has been on a mission—driving innovation, strengthening resilience, and raising the bar for what a modern logistics partner can deliver. From helping clients shrink their carbon footprint to tackling the rising challenges of cyber security, they’ve been reshaping how the supply chain can be protected, optimised, and future-ready.

We caught up with Director, Brian Anderton to give us an inside look at their progress - and a glimpse into their ambitious plans through 2026 - he answered some of the key questions shaping the next chapter of their journey

Q1. WHAT ARE THE KEY EXPECTATIONS FROM YOUR CLIENTS HEADING INTO 2026?

Historically the main asks of any Transport Service provider were to provide a reliable door to door service at the best price possible. Over the last 2 years a lot more focus, particularly from our larger Global clients, has been centred on reducing our carbon footprint and subsequently our client’s scope 3 Emissions. The other hot topic, particularly in the last year has been Supply Chain and Cyber Security.

Q2. TAKING CO2 REDUCTION FIRST, WHAT IMPROVEMENTS HAVE TRANS-BRIDGE FREIGHT SERVICES MADE IN THE LAST 12 MONTHS TO SATISFY YOUR CLIENTS ESG EXPECTATIONS?

If you recall you featured our first fully electric powered Temperature Controlled Trailer in Export & Freight in June 2024, our fleet replacement

plan is now underway with these trailers as the default asset, with more added in 2025 and further builds planned for 2026. We also gained accreditation of ISO14001:2015 Certification which involved a major gap analysis of our energy use and how best we could reduce that. One of our highest energy intensive resources

is the constant heating and cooling our Pharmaceutical Warehouses. Our obligations under the regulation of the MHRA and client contractual agreements is that we maintain a warehouse and transit environment for the Healthcare and Medicinal products that have strict temperature conditions. Both Cold Chain and Ambient products that patients rely upon to arrive with its efficacy intact. To reduce this high energy demand we have just completed installation of Solar Panels at our Antrim facility with Manchester to follow suit by Q3 2026. Working closely with our approved supplier Solmatix Ltd these panels provide a significant reduction in electricity consumption and in turn a valuable reduction in CO2.

Q3. MOVING ONTO SUPPLY CHAIN AND CYBER SECURITY, CAN YOU EXPAND ON WHAT YOUR ROLE AS THE TRANSPORT PROVIDER HAS HERE?

Taking Cyber Security first, I think the whole world is starting to understand the huge impact a Cyber Attack can impact all of our daily lives, whether that be through direct public facing services such as Banking or Communication channels or secondary impacts such as consumer

interruption. There have been some really high-profile examples recently such as Marks and Spencer, Jaguar Land Rover and the NHS to name just a few that were pretty much paralysed at the hands of Cyber Criminals resulting in wide reaching commercial damage and Millions of Pounds in losses. It is no secret that Cyber Criminals see the Supply Chain as a prime target to create disruption and mayhem, particularly in key areas such as Healthcare. Albeit we are a relatively small cog in a much bigger machine we don’t take lightly our responsibility in terms of protecting not only our Data and Systems but also that of our highprofile client portfolio. A recent minor incident prompted us to significantly update our IT security and working practices to reflect the risks we know of today. Mobile Phones, Internet and Social Media exposure, remote working and innocent everyday devices that connect to the outside world all pose risk of attack. We have invested heavily in external expertise and technology to not only protect as best we can but to also train our teams to be aware of the length these unsavoury individuals will go to, to bring our business to a grinding halt. Our primary responsibility is to protect

our ability to function and in turn maintain the key supply chain that our customers entrust to us. The big challenge is keeping pace with the evolution of the threat. Product Integrity is one of key the pillars upon which our customer relationships are built, and load security is a key component of protecting product integrity. The GB to Northern Ireland post Brexit process also demands a higher level of visibility and security. We have partnered with Northern Ireland based, Block Chain specialist, Ubloquity Ltd to provide a sophisticated yet practical solution to provide transparent data in tandem with a highly secure vehicle locking system.

The smart locks that we have invested in are of Military Grade and are independent of the truck itself. The locks contain Communication Sims that not only give pinpoint accuracy as to its location, but also communicates via a dashboard to our operations team. From this central panel we can see the status of the lock, the log of events, and have the option to attach documentation electronically that can be shared securely with all interested parties, including Border Force, HMRC, Shipping Companies and Clients. The locks can be opened by RFID Card

and remotely and most important they can be deployed to any vehicle of our choosing. The provision of complete Block Chain visibility increases our value-added security that this perilous modern digital world demands.

Communication and collaboration with all interested parties is key. Its important to note that threats don’t just arise from the criminal world. Hostile Governments and Regimes also see Cyber Attack as a very sophisticated and effective weapon. Paralysing Supply Chains, particularly in critical sectors could have a devastating impact on the entire nation.

We will be exhibiting again at the Making and Distributing Pharmaceuticals event in April 2026 where we will be hosting a Q&A Panel with some key experts on this subject from different industry sectors. Our Social Media platforms will be promoting this event in the coming months for anyone want to join the conversation.

sales@transbridgefreight.co.uk

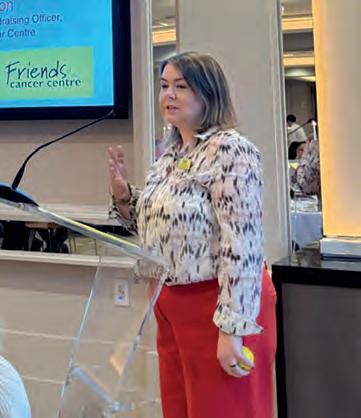

The Merchant Hotel in Belfast was once again the venue for the annual Logistics UK lunch, which was held at the start of November.

The event was hosted by Jemma James, Digital Development Director, Logistics UK and attended by representatives of the local transport and logistics industry and their guests. In her address Jemma James welcomed ‘members, colleagues and friends’ to the lunch, telling the audience, “You are the people that literally keep Northern Ireland moving”.

“Our sector is the heartbeat of this economy. More than 6,000 logistics businesses operate here, employing almost 70,000 people – that’s around 8% of Northern

Ireland’s total workforce.”

“Every household, business and public service depends on all of you in this room whether its food on supermarket shelves, medicines in hospitals or parts for advanced manufacturingnothing moves without logistics.

“This is a chance to celebrate all of you and everything you do, but also to look ahead.

Ms. James continued saying she understands the challenges the local industry faces – trade friction, rising costs, constrained infrastructure, decarbonisation, skills shortages. And yet despite all these pressures, the industry here in Northern Ireland continues to deliver.

“Logistics UK have been working hard over the past 12 months with the Northern Ireland Executive and the UK Government to make sure they recognize this industry’s contribution. This includes simpler,

more efficient GB and NI trade backed by improved Windsor Framework processes, and fighting for a fair decarbonisation transition with realistic timeframes including investment in charging and refueling infrastructure.

Ms. James also said how Logistics UK are supporting the next generation through the ‘Generation Logistics Campaign’. Currently backed by over 40 businesses this campaign aims to increase positive sentiment about careers in logistics among 13-24 year olds.

Concluding her address Ms James said, “Thank you – you are the voice, the strength and the heartbeat of this organisation”

Jemma James then introduced Maire Clare Reid, Chair of the Northern Ireland Freight Council to say a few words.

Describing logistics as ‘One of Northern Ireland’s most dynamic

and resilient industries’, Marie Claire said; “Today isn’t about statistics and regulations – it’s about people: people who plan, drive, load, repair, dispatch and deliver. People who have worked through disruption, uncertainty and endless change – yet still find a way to make sure everything gets where it needs to go.

“As someone who has spent their life in logistics, I’ve seen first-hand just how much this industry contributes to the everyday life of Northern Ireland. We underpin every sector from agrifoods to retail to construction.

Maire Claire highlighted how the Freight Council collaborates with government to bring about practical solutions to industry issues.

She gave an example of how during Storm Eowyn ‘supply chains were disrupted, roads were closed and operations across the country were stretched.

“Through Logistics UK Northern Ireland Freight Council we gathered direct feedback from our members on the ground and presented the evidence to the Dept. of Infrastructure. As a result a temporary relaxation of driver’s hours rules was granted to help our industry recover

quickly and safely. That was a clear example of collaboration between industry and government.

“The Freight Council continues to engage in several issues that matter deeply to our members and the wider industry

“The more people understand what logistics delivers, literally and

figuratively, the more influence we have in shaping the policy and public perception to our industry. The world around us is changing, but the Northern Ireland logistics sector has shown time and again we can evolve, adapt and we can lead.

Following a delicious lunch guests

were entertained by the fabulous comedian, author and playwright Nuala McKeever and after this a charity raffle, in aid of Friends of the Cancer Centre – took place. A show of hands confirmed the preference of the audience was to keep this annual fixture at the start of November for next year.

With a brand-new, state-of-the-art facility in one of Ireland’s most strategically placed business locations, a healthy order book and a highly skilled and motivated team, Terberg MPM is a company firmly on the move.

A subsidiary of the Terberg Special Vehicles division - part of the internationally respected, family-owned Royal Terberg Group - Terberg MPM Ireland delivers world-class specialist vehicle solutions to the transport, construction and fire and rescue sectors. Since its establishment in 2010, the business has grown from a start-up operating out of the McCluskey family garage in Hillsborough into a 30-strong operation based in an impressive new 1,650m² facility alongside the main A1 Belfast–Dublin corridor.

On Thursday, 9th October, Terberg MPM Ireland officially opened its new state-of-the-art facility in Hillsborough. The opening ceremony was attended by MPM employees, customers, the Extended Board of Directors and members of the Terberg family.

Speaking at the official opening of the new headquarters in October 2025, Managing Director Mark McCluskey talked about the company’s journey to date. “This new facility means growth for the team. It provides space for new staff to join, more opportunities to

develop, and a workplace designed with the future in mind. It’s an exciting time for everyone.”

He said he often gets asked what MPM stands for? MPM stands for ‘McCluskey Plant and Machinery’, and when he and

his wife established the business the plan was to be brokers and consultants for people buying and selling machinery; to work less hours, to carry no stock, to employ no people and continue to work from the office at home…. “How do you think that’s going” he asked his guests. The turning point for the business came when a chance conversation with industry contacts Richard Woodings led to an informal meeting over the family breakfast table - and ultimately, to MPM becoming the authorised Terberg distributor for Ireland. What began as a small partnership has since evolved into a long-term collaboration and a significant market presence, with Alaistair, one of the original visitors, now serving as a director of Terberg MPM.

Terberg MPM is the sole distributor for Terberg products across Ireland, supplying the full RT, YT and DT tractor ranges.

RT Series (4x4 RoRo Tractors): Built for demanding port and industrial environments, with robust driveline technology ideal for steep ramps and heavy-duty operations.

YT Series (Distribution Tractors): Favoured by major retail chains including Tesco and Asda, with diesel options and growing demand for the electric YT variant—six of which are currently operating in Ireland.

DT Series (Low-Entry Distribution Tractors): Designed for multi-drop operations, with a low-entry cab that reduces driver fatigue during frequent stops.

As the Terberg brand accelerates its electric transition, the RT253EV— Terberg’s first all-electric 4x4 RoRo tractor—is nearing production.

Recent nationwide roadshows generated strong customer interest ahead of market launch in 2026, with deliveries expected early 2027. In addition to new tractors, Terberg MPM provides high-quality refurbished Terberg vehicles.

“These trucks are built to last. The vehicles can be reconditioned and refurbished by our engineers

thereby extending its service life by up to ten years,” Mark explains. The company also maintains an extensive rental fleet, offering both short- and long-term solutions across Ireland, supported by full maintenance packages.

“Whether it’s for a short period, such as while a customer’s truck is being repaired or for a longer period of time our rental fleet is there and can be delivered to any location in Ireland whenever it’s needed” said Mark McCIuskey.

Terberg MPM now works with many of Ireland’s leading transport operators. Recent highlights

include supplying Stena Line in Belfast with RT223 RoRo tractors to support routes to Cairnryan, Liverpool and Heysham. Guinness in Dublin has also added three electric YT tractors to its fleet. Other major names such as Manfreight continue to rely on Terberg MPM for specialist vehicle support.

Beyond transport tractors, the company operates a Fire and Rescue division supplying PPE and right-hand-drive fire engines for export markets. Through its online retail platform, The Fuel Tank Shop, Terberg MPM also supplies steel, plastic and mobile fuel storage solutions from top manufacturers including Western Global, Tuffa and Cemo.

OUR SERVICES INCLUDE:

Commercial Vehicle Accident Repairs

From vans and pickups to HGV cabs and fleet vehicleswe handle repairs of all sizes with precision.

Advanced Bodyshop & Paint System

State-of-the-art facilities delivering factory-finish results on all makes and models.

Panel Work, Chassis Alignment & Structural Repairs

Expert technicians ensuring your vehicles return to full safety and performance standards.

Fleet Support & Priority Turnaround

We know downtime impacts delivery schedules - our priority services help keep your fleet running efficiently.

Insurance-Approved Repair Centre

We deal directly with your insurer for a seamless, stress-free process.

Courtesy Vehicles Available

Stay operational while repairs are underway.

In transport and logistics, time is everything. When a vehicle comes off the road, it costs you - in schedules, in service levels, and in reputation.