INTHE MIX

EDITORIAL

Editor

Stephen Holmes

stephen@x3dmedia.com

+44 (0)20 3384 5297

Managing Editor

Greg Corke

greg@x3dmedia.com

+44 (0)20 3355 7312

Consulting Editor

Jessica Twentyman jtwentyman@gmail.com

Consulting Editor

Martyn Day martyn@x3dmedia.com

+44 (0)7525 701 542

Staff Writer

Gabrielle Brown gabrielle@x3dmedia.com

DESIGN/PRODUCTION

Design/Production

Greg Corke

greg@x3dmedia.com

+44 (0)20 3355 7312

ADVERTISING

Group Media Director

Tony Baksh tony@x3dmedia.com

+44 (0)20 3355 7313

Deputy Advertising Manager

Steve King steve@x3dmedia.com

+44 (0)20 3355 7314

US Sales Director

Denise Greaves denise@x3dmedia.com

+1 857 400 7713

SUBSCRIPTIONS

Circulation Manager

Alan Cleveland alan@x3dmedia.com

+44 (0)20 3355 7311

ACCOUNTS

Accounts Manager

Charlotte Taibi charlotte@x3dmedia.com

Financial Controller

Samantha Todescato-Rutland sam@chalfen.com

ABOUT

DEVELOP3D is published by

X3DMedia 19 Leyden Street

London E1 7LE, UK

T. +44 (0)20 3355 7310

F. +44 (0)20 3355 7319

© 2025 X3DMedia Ltd

All rights reserved. Reproduction in whole or part without prior permission from the publisher is prohibited. All trademarks acknowledged Opinions expressed in articles are those of the author and not of X3DMedia. X3DMedia cannot accept responsibility for errors in articles or advertisements within the magazine

Following a festive season marked by traditional overindulgence, it feels almost sacrilegious to start looking at food and drink again. Yet here we are, waistbands straining but ready to gorge ourselves on products that bring e ciency and style to kitchens. They include novel frozen desserts without waste; gourmet co ee without fa ; and customised chocolates that bring a touch of branding to restaurant tables. Our cover story shows the power of good design for reinventing a brand and keeping it hot and fresh, with its look at Kenwood UK’s new range of small kitchen appliances designed for modern living. The Go Collection sees Kenwood take a step beyond the traditional big-bowl stand mixers that I remember my grandmother using. This is a punchy new range of functional compact designs ready to slice, dice and mix with e ciency and good looks, before being stored neatly away.

For dessert, there’s ColdSnap’s design for single-portion iced desserts and drinks – think Nespresso, but for luxury ice cream or frozen margaritas. You might be quick to dismiss the idea (I know I was, until the third portion of delicious bourbon ice cream), but ColdSnap can boast some serious sustainability credentials, too, by removing the need for freezing a product right until the point of serving with a clever design that removes the need for cleaning.

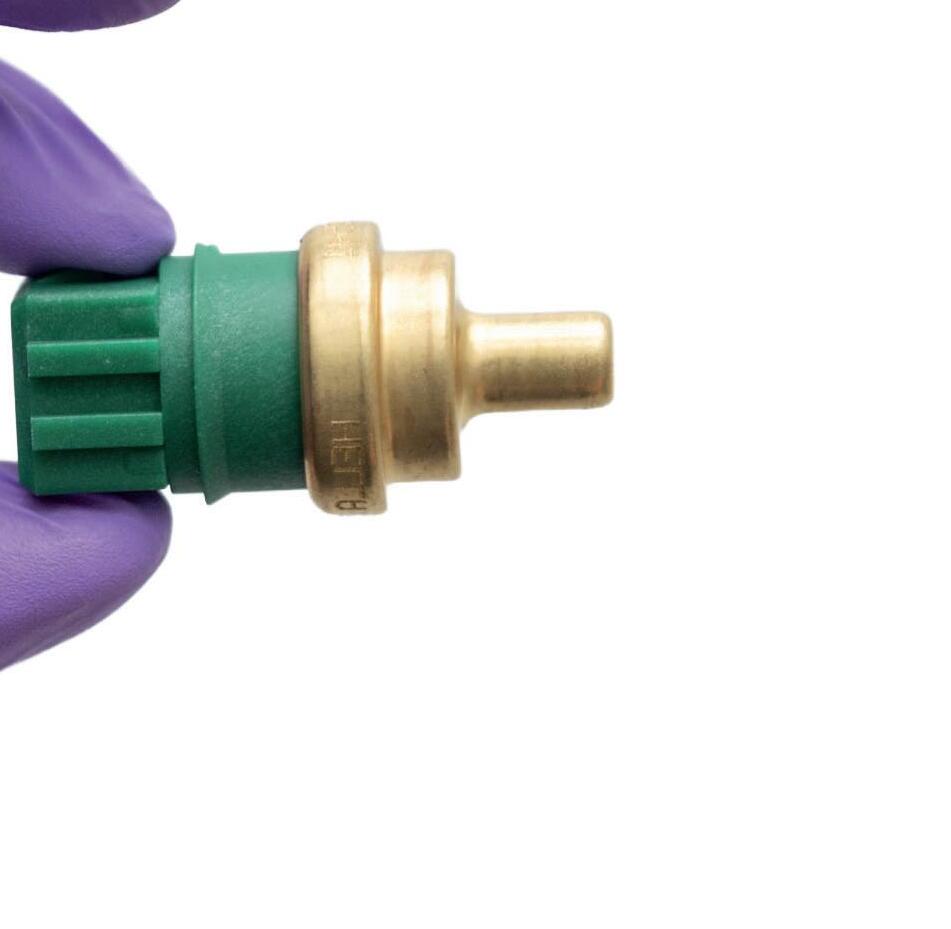

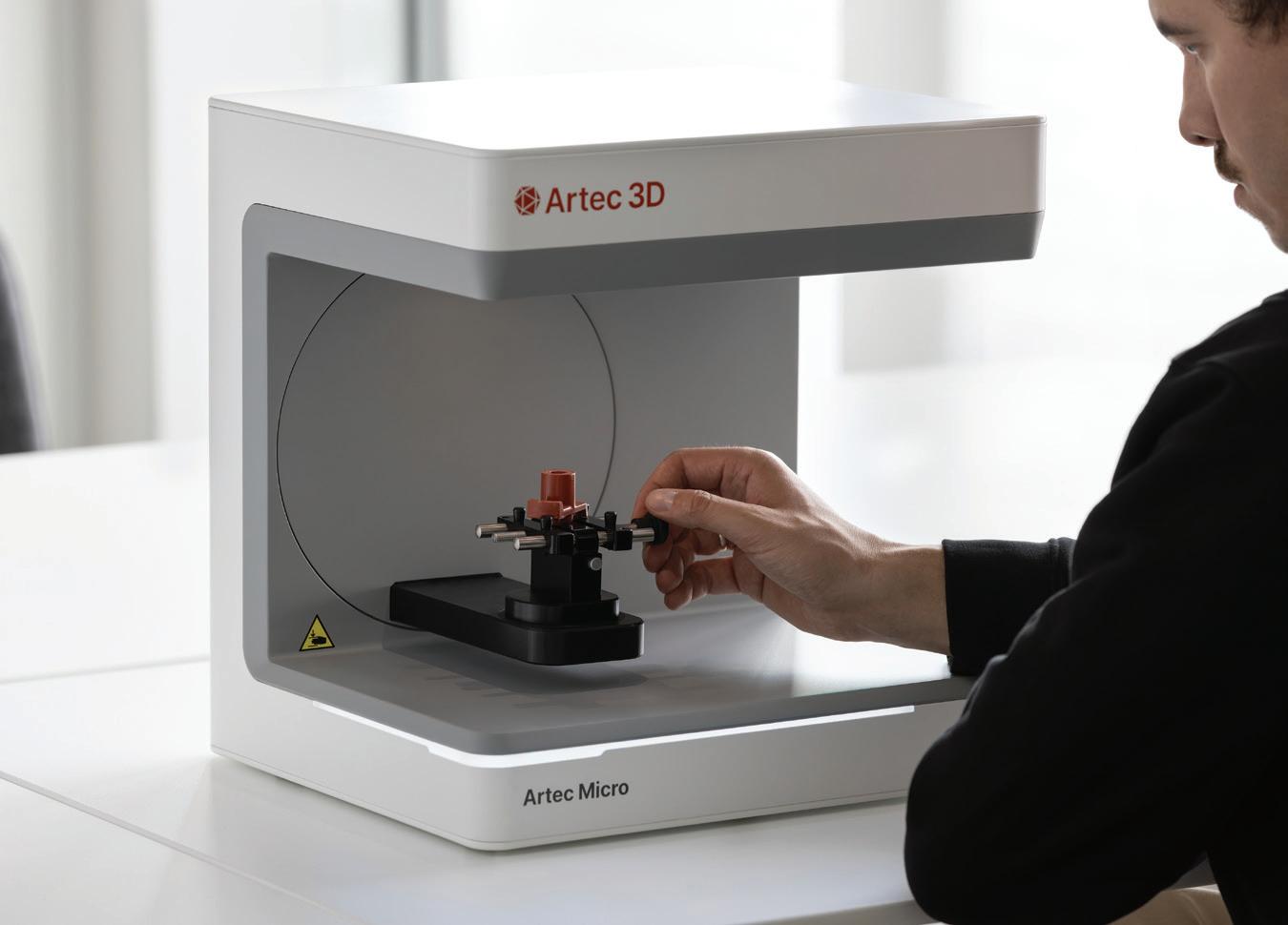

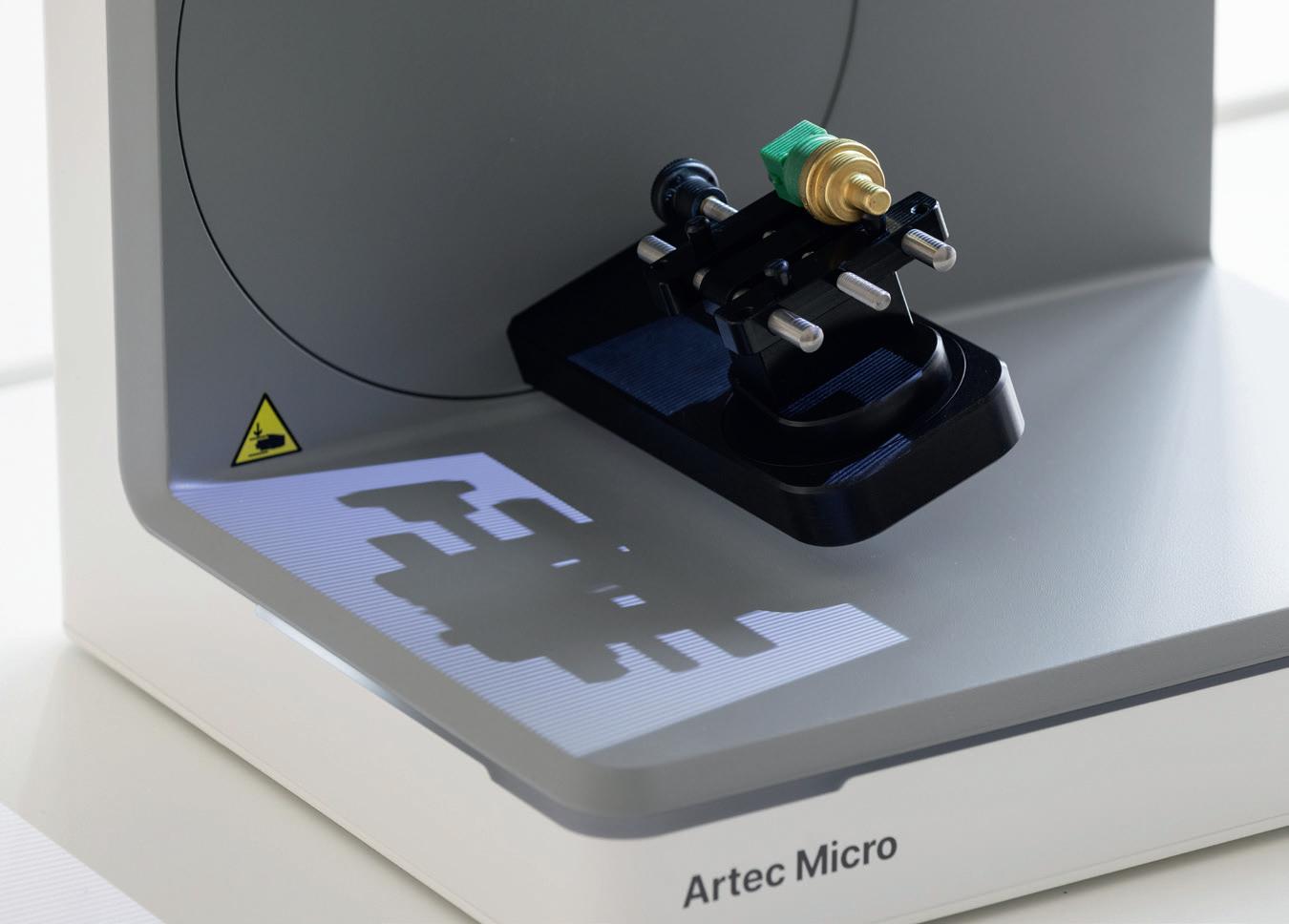

Beyond the kitchen, we bring you our round-up of pen display tablets for designers and engineers; a look at how Solid Edge is evolving, with its inclusion in Siemens Digital Industries Designcenter platform; plus, there’s a review of the Artec Micro II 3D Scanner, a desktop unit for small item data capture.

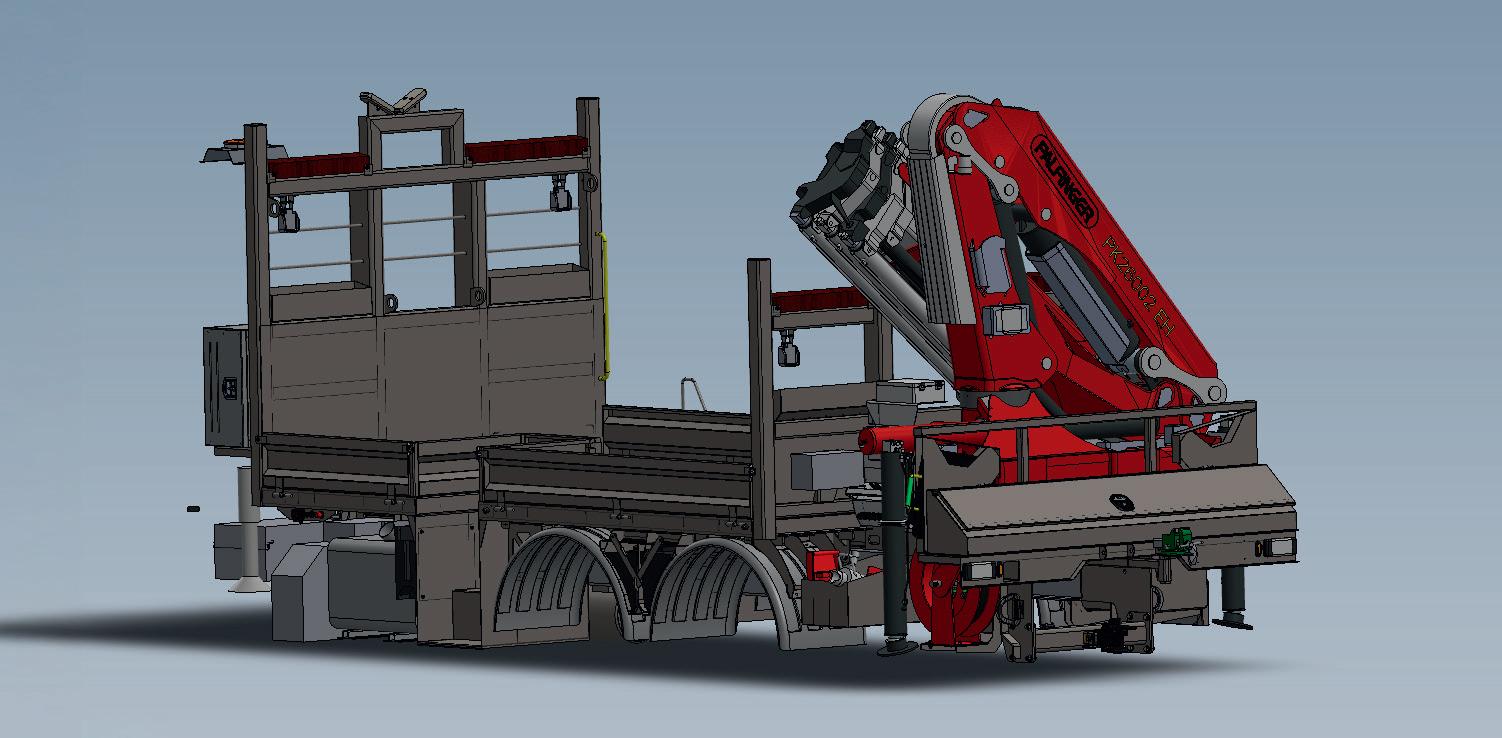

We are also delighted to welcome new writer Gabrielle Brown to the team and have immediately packed her o to learn how Epson is putting textile printers into the hands of student designers, enabling them to learn more about rapid prototyping of designs and textures.

If you’ve still room after all this à la carte extravagance, then remember to book yourself an advanced seat at DEVELOP3D LIVE. This will take place in Coventry, UK on 25 March 2026, and we promise you plenty more tasty treats at our in-person conference and exhibition.

Stephen Holmes Editor, DEVELOP3D

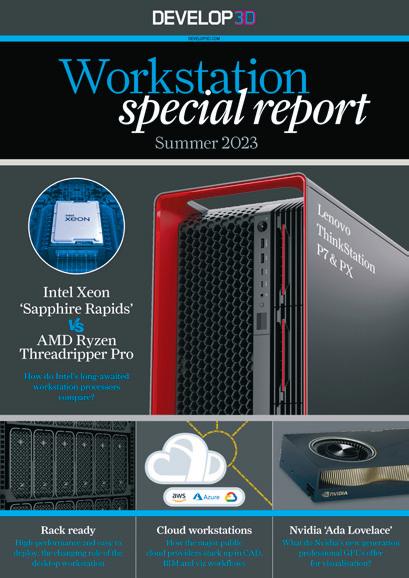

NEWS

Nvidia and Synopsys expand partnership, Catia gets AI agents and new browser version, PTC sells off Thingworx and Kepware, and more

FEATURES

Comment: SJ on the challenges of laser beam shaping

Comment: Christina Rebel on legacy workflows

Visual Design Guide: Ooni Koda 2 Pro pizza oven

COVER STORY MIXING IT UP AT KENWOOD

Unity: Smoothing the path to real-time experiences

Q&A: Siemens Designcenter Solid Edge

Event report: Five takeaways from Formnext 2025

Fine brew: Designing the Fellow Aiden coffee maker

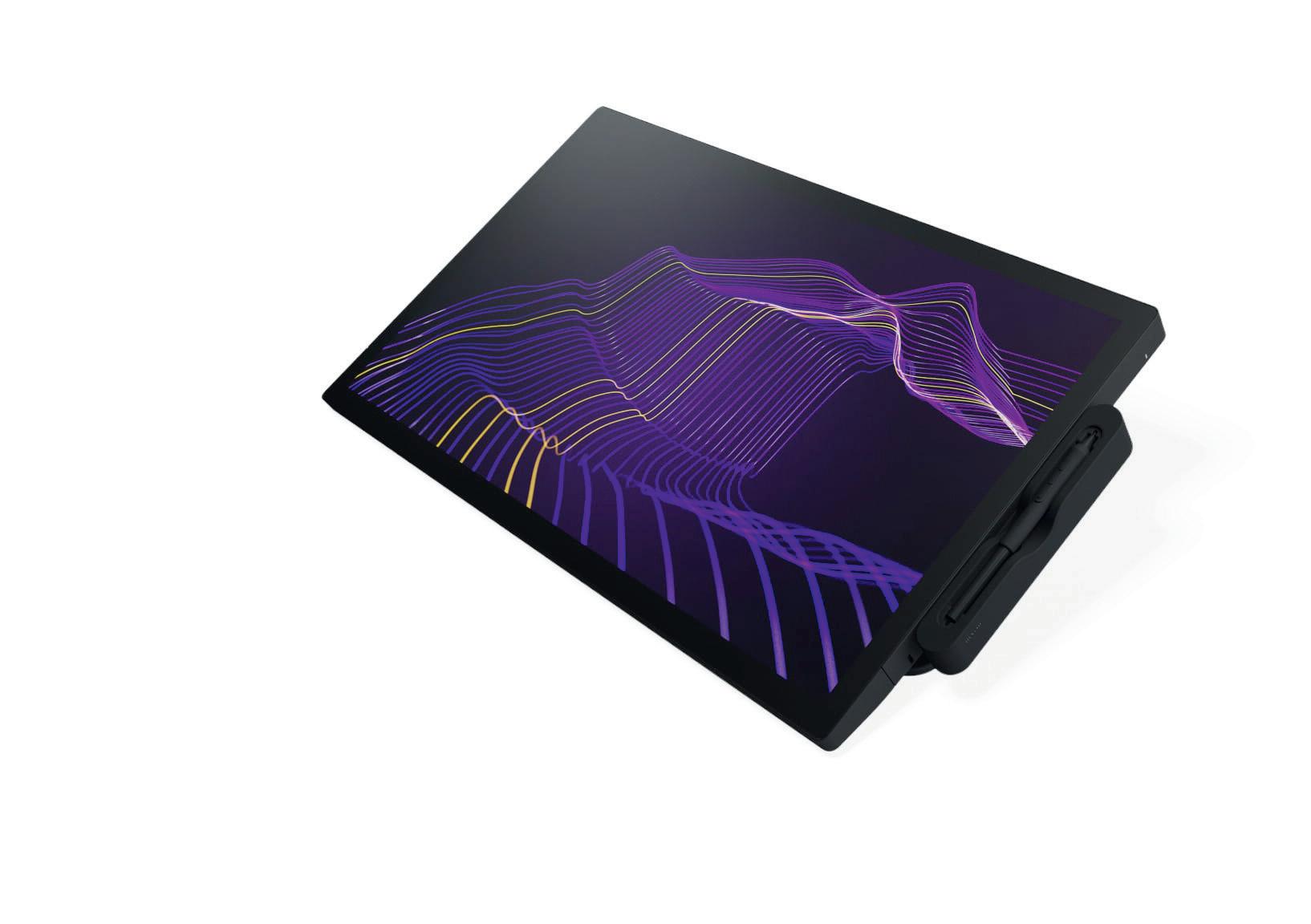

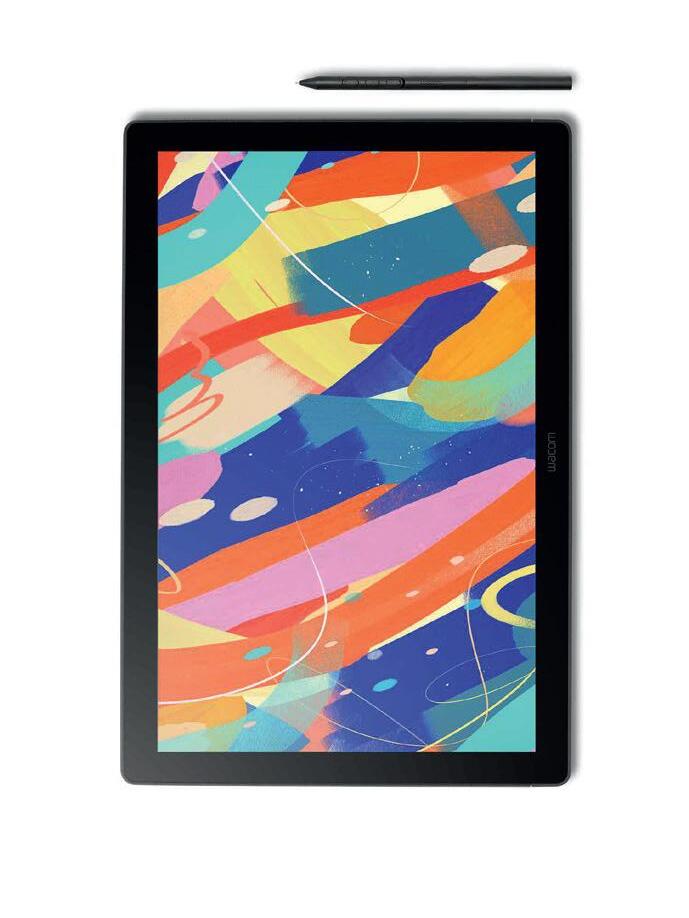

Product round-up: Pen display and graphics tablets

Chocolate factory: 3D-printed moulds for custom treats

Ice cream dream: ColdSnap’s frozen dessert maker

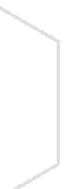

Waimea gets versatile with Driveworks CPQ

Behind the scenes at Epson’s Textile Academy

In the Fold: Bringing home Reformer Pilates

Manufacturing at the speed of innovation at Shapeways

REVIEW

Artec Micro II scanner

THE LAST WORD

As technology vendors chase military contracts, our favourite design and engineering tools are increasingly used to create products that destroy rather than improve human lives, writes Stephen Holmes

NVIDIA AND SYNOPSYS TEAM UP ON DESIGN AND ENGINEERING

Nvidia and Synopsys have announced a new multiyear collaboration around design and engineering, which spans Nvidia CUDA accelerated computing, agentic and physical AI and digital twin technology.

According to executives from the two companies, the expanded partnership will integrate the strengths of Nvidia’s AI and accelerated computing with Synopsys’ engineering solutions – including Ansys – to deliver capabilities “enabling R&D teams to design, simulate and verify intelligent products with greater precision, speed and at lower cost”.

In addition, Nvidia has invested $2 billion in Synopsys common stock at a purchase price of just under $415 per share.

Joint projects that have been announced so far include accelerating Synopsys

applications using Nvidia CUDA-X libraries and AI physics technologies, as well as building on the existing AI collaboration to enable agentic AI workflows by integrating Synopsys AgentEngineer technology with the Nvidia agentic AI technology stack. The latter will enable autonomous design capabilities for electronic design automation (EDA) and simulation and analysis workflows.

Digital twin technologies are also high on the agenda, with the companies targeting the next generation of virtual design, testing and validation using Nvidia Omniverse, Cosmos and other technologies. Synopsys and Nvidia also plan to make accelerated engineering solutions accessible to engineering teams of all sizes by enabling cloud access for GPU-accelerated engineering solutions. www.nvidia.com

Catia introduces AI agents and browser version

At the recent launch of Catia R2026x, executives focused on today’s need for speed, support for complex designs and the wider goal of providing customers who use its software with “complete experiences”.

To tackle these challenges, Catia is leaning heavily into enabling advanced virtual twins – not just for 3D design and engineering, but also for full factory use.

At the launch, Catia CEO Olivier Sappin chose to concentrate on tangible tools for present-day users and the slow creep towards cloud-based CAD, unveiling a wide range of updates and performance improvements. For example, the launch of Dassault Systèmes‘ Virtual Companions in CATIA – based on the same Aura technology launched for Solidworks earlier in 2025 – gives users of cloud-based

3DExperience Catia access to a chatbot for in-context guidance.

A particular highlight was the announcement of Catia in the browser, offering many of the system’s native tools within the same user interface, but with the benefit of a no-install approach. www.3ds.com

Materialise boosts its CO-AM platform

Materialise has introduced three tailored solutions for its CO-AM (Cloudbased Orchestration for Additive Manufacturing) platform, first announced in May 2022.

The new offerings – CO-AM Professional, CO-AM NPI and CO-AM Enterprise – are powered by CO-AM Brix, a new low-code, node-based automation technology, and by CO-AM Build Platform, a cloud-based, visual editor for build and platform preparation.

The company also announced that its Next-Generation Build Processors now feature a fully open, modular framework. www.materialise.com

Formlabs expands Tough Resin family

Formlabs has announced two new Tough SLA materials for its Form 4 3D printers as it builds out its materials offering for prototyping and end use parts.

Tough 1000 Resin is described as the “toughest and most ductile” material in the new line-up, rivalling HDPE.

Tough 2000 Resin, meanwhile, is classed as the strongest and stiffest material, not unlike ABS. Both materials can withstand harsh environments, impact and repeated wear and deliver a dark, matte surface finish that maintains details well. www.formlabs.com

CDS releases Cognitive Design 2.0

Cognitive Design Systems (CDS) has released Cognitive Design 2.0, the latest version of its AI-powered engineering platform.

This platform combines generative design and simulation capabilities for rapid exploration of structural part concepts, with manufacturing process constraints provided for 3D printing, casting, machining, moulding and forging.

According to CDS executives, the advancements contained in the latest release have been designed with a view to enabling engineers to unlock, test and validate manufacturable, high-performance designs at record speed, while working together in one collaborative environment. www.cognitive-design-systems.com

Nvidia and Synopsys are taking their partnership to the next level

Catia is leaning heavily into enabling advanced virtual twins

HP EXPANDS PORTFOLIO WITH IF 600HT FILAMENT 3D PRINTER

HP AM is expanding its industrial manufacturing portfolio with the launch of the HP IF 600HT filament 3D printer.

The move is designed to open up new applications in new markets for HP. The first system in this range, the HP Industrial Filament 3D Printer 600 High Temperature (HP IF 600HT), is a modular system designed for printing high temperature and engineered filaments and will be available in the first half of 2026.

A second system, the HP Industrial Filament 3D Printer (HP IF 1000 XL), is intended for producing large quality parts and will emerge in the second half of 2026.

According to HP executives, by bringing HP reliability and deep application expertise to the high-performance filament market, customers in industrial sectors such as aerospace, oil and gas, medical, automotive, railway and education will be able to produce highvalue, production-grade applications.

“The new portfolio broadens HP’s ability to serve diverse industrial needs, from engineering and high-temperature materials to precision components and large-format production parts, enabling customers to lower their cost per part and accelerate time to market,” said a spokesperson.

“Built on an open materials platform and supported by HP’s global service network, HP Industrial Filament 3D printer solutions give manufacturers the flexibility to innovate with a wide range of polymers and scale into new applications while maintaining industrial-grade performance.”

also announced the strengthening of its Metal Jet ecosystem with new material qualifications and industry collaborations.

Continuum Powders and INDO-MIM have qualified OptiPowder Ni718 for use on the HP Metal Jet S100, to achieve sintered components with over 98% density, consistent hardness (74-79 HR15N) and precise carbon control.

In collaboration with Continuum Powders and Tecnalia, HP AM is also advancing the development of OptiPowder M247LC, a low-carbon, nickel-based superalloy designed for high-temperature applications where strength and corrosion resistance are essential.

Once qualified, the framework will expand to include other high-performance nickel specialty alloys, with the goal of advancing binder jet technology. www.hp.com

ROUND UP

The BSI has published its latest update to the UK’s national framework for engineering design, drawing practices and geometrical tolerancing, comprising the standard, a technical product specification and documentation (BS 8888:2025) www.bsigroup.com

Comsol now boasts greater simulation solver performance and extended multi-GPU capabilities for acoustic simulations, thanks to Nvidia GPU connectivity in its Multiphysics 6.4 release, which introduces Nvidia CUDA direct sparse solver and Nvidia cuDSS www.comsol.com

Scan Computers has been named as a new authorised partner for Solidworks. This will enable Scan to add to its portfolio licenses for Solidworks 3D CAD, 3DExperience Solidworks and DraftSight 2D CAD, and add value by integrating these software products with its workstations www.scan.co.uk

PTC sells off Thingworx and Kepware products

PTC has announced it has sold its Thingworx and Kepware products to global asset management firm TPG, in a move that marks the departure of Internet of Things (IoT) and industrial connectivity technologies from the company's portfolio.

According to PTC CEO Neil Barua, the decision will enable PTC to focus on its core CAD and PLM offerings, as well as further development of its AI capabilities and SaaS products.

“With our resources and investments concentrated in these areas, we are confident we can help our customers address their most pressing challenges by enabling them to fully leverage the value of their product data and to transform each stage of the product lifecycle,” Barua said.

PTC acquired ThingWorx in 2013 for $112 million and Kepware in 2015 for $100 million. The decision to sell off these software products suggests a significant shift away from previous CEO Jim Heppelmann’s vision for the Boston-based company. www.ptc.com

The IoT party's over at PTC as the company opts to focus on core CAD and PLM products

Backed by Stratasys and built on technology acquired from iSquared, BASF’s Forward AM and Nexa3D, the iAM Marketplace has launched as a new hardware-agnostic sales platform for polymer 3D printing materials and post-processing consumables www.i-am-marketplace.com

Womp has announced that it is introducing an enterprise licensing option for its browserbased platform in order to enable more teams to adopt its organic form solid modelling tools and generative AI capabilities, along with its Womp 3D printing services www.womp.com

HP

HP AM is betting big on industrial filaments with its new 3D printers

STRATASYS INVESTS IN TRITONE FOR METALS & CERAMIC TECH

Siemens' Simcenter X gets updated

Siemens Digital Industries has launched Simcenter X Advanced, its latest update to Simcenter X, a scalable, software-as-a-service engineering simulation suite designed to reduce IT complexity and support greater flexibility and collaboration. This update provides engineers with universal access to CFD, systems, mechanical simulation and multidisciplinary design analysis and optimisation (MDAO). Optimisation studies are boosted with AIaugmented design exploration techniques and a chat feature for documentation support and set-up guidance. www.siemens.com

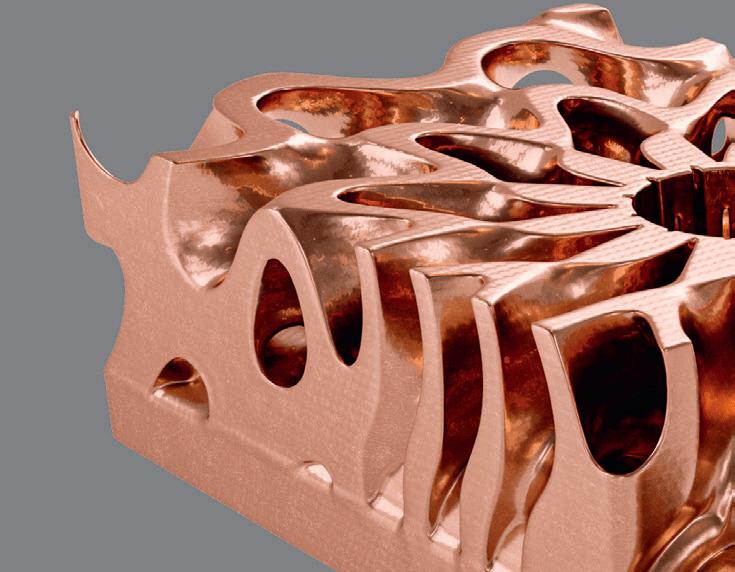

Stratasys is to invest in metals 3D printing company Tritone Technologies as it looks to expand beyond polymers and into other areas of additive manufacturing.

The agreement brings cutting-edge, industrial-scale, production-grade metal and ceramic technologies to Stratasys’s offering, advancing the company’s position as a comprehensive, end-to-end provider of a broad range of additive manufacturing solutions.

Tritone’s metal and ceramic offering is geared toward serial production, which Stratasys executives say aligns with the wider industry trend to deploy 3D printing for manufacturing at scale.

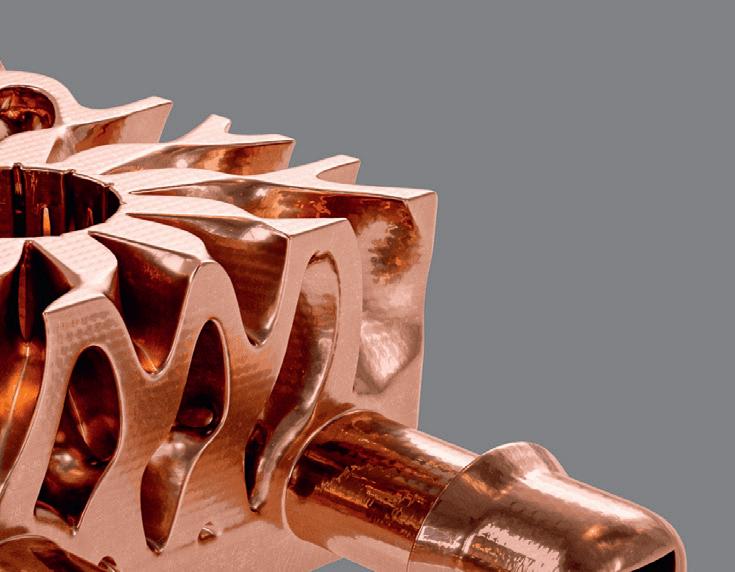

At the heart of Tritone’s innovation lies its MoldJet technology, a powder-free additive manufacturing process that redefines how metal and ceramic parts are created.

Designed for industrial production, MoldJet combines precision with speed, enabling the creation of complex geometries that meet high mechanical and density standards.

The technology enables users to switch between a wide range of metal alloys and ceramics, producing parts of different shapes and applications within the same batch, as well as offering the advantages of reduced downtime and maximum productivity. www.stratasys.com

Renishaw launches new build processor tech

Renishaw has launched its Next-Generation Build Processor (NxG BP), developed in collaboration with Materialise. This strengthens the integration between Renishaw’s RenAM LPBF metal AM systems and Materialise Magics. According to Renishaw executives, NxG BP is intended for ‘power users’ who manage a wide variety of part types and need functionality beyond that provided in Renishaw’s QuantAM software. The new processor enables direct export of job files from Magics to Renishaw machines using the QuantAM file format, eliminating manual file handling, reducing errors and saving valuable preparation time.

A key innovation is its ‘Swim Lane’ feature, which intelligently distributes laser scanning across defined regions of a build platform. By preventing interference between lasers and managing overlap for full fusion, the

system enhances part quality and consistency while reducing build times. Customers also benefit from integration with nTop implicit modelling workflows, for easier handling of complex geometries. www.renishaw.com

and efficient metal AM production

Altair refreshes its Hyperworks tool

Altair has updated HyperWorks 2026 with advances in AI, highperformance computing and multiphysics integration. Integration of multiphysics simulation allows engineers to analyse complex interactions such as thermal-fluid or electromagnetic-structural systems with greater accuracy. New workflows support e-motor optimisation, battery safety studies and high-temperature analyses. www.altair.com

V-Ray for Blender supports MacOS

Chaos has released its latest V-Ray for Blender update, adding support for macOS and giving users access to AIpowered tools.

New features support image enhancement, material generation and upscaling, which the company claims will make it faster and easier for users to craft high-quality renders.

A new AI Enhancer adds details and realism to supporting elements, such as foliage, human figures and terrain, as well as finetune specific objects. This aims to reduce the need for tedious and time-consuming rework.

The AI Material Generator tool, meanwhile, transforms images of real-world surfaces into render-ready, PBR material with all the necessary maps provided. www.chaos.com

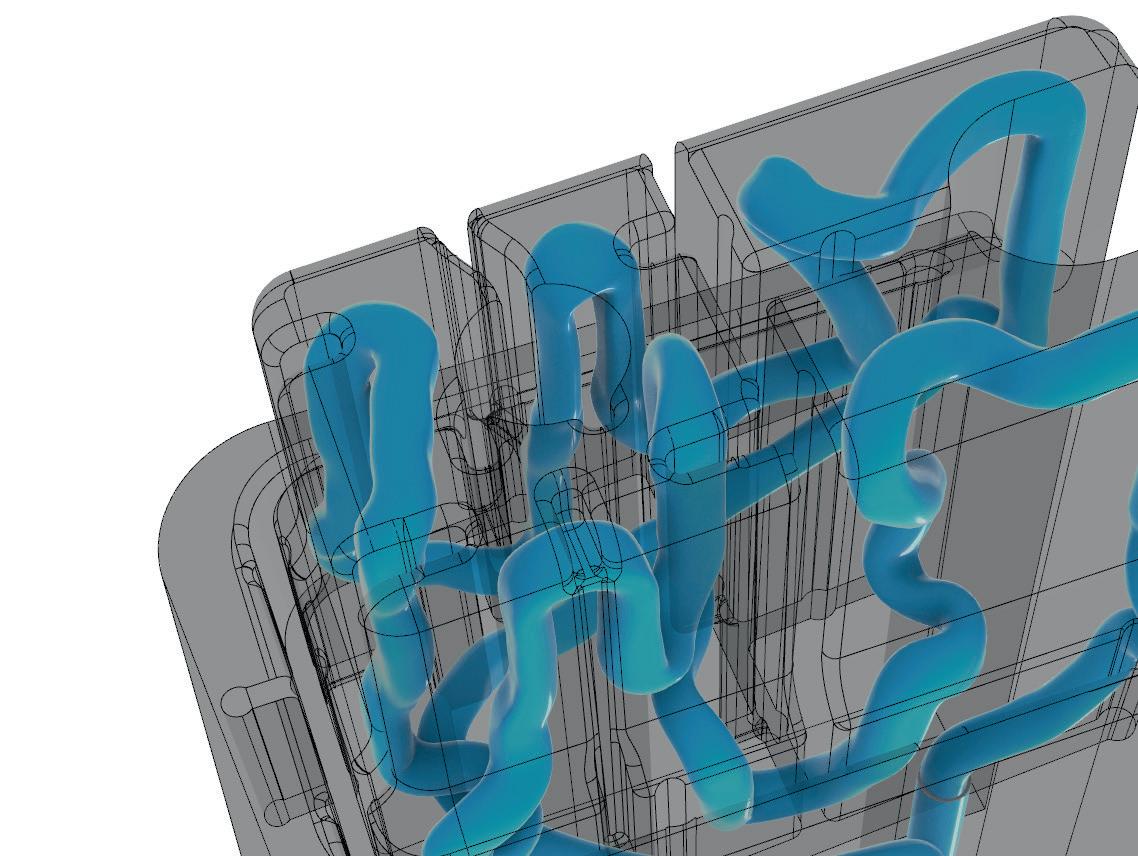

Tritone's MoldJet tech enables manufacturers to produce parts such as this copper heat exchanger

Renishaw machines offer users consistent, repeatable

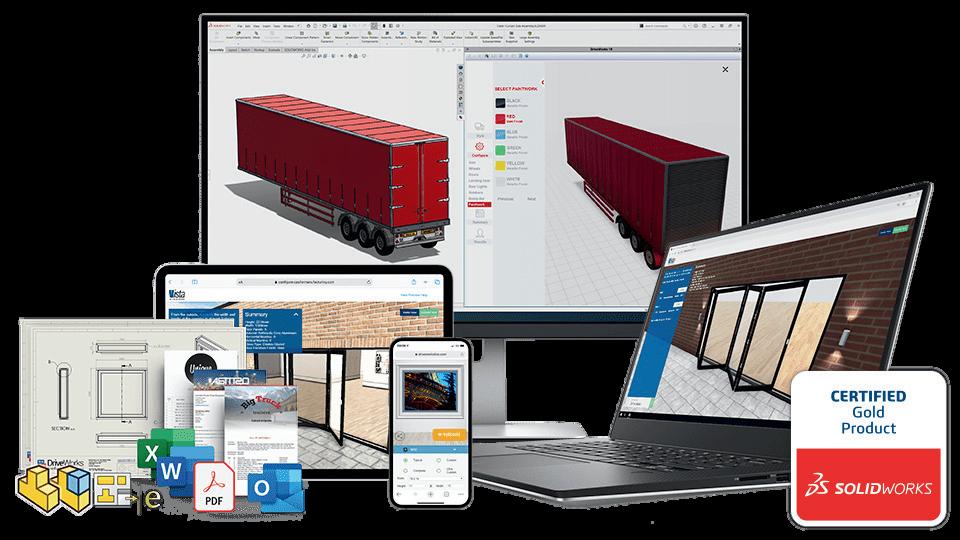

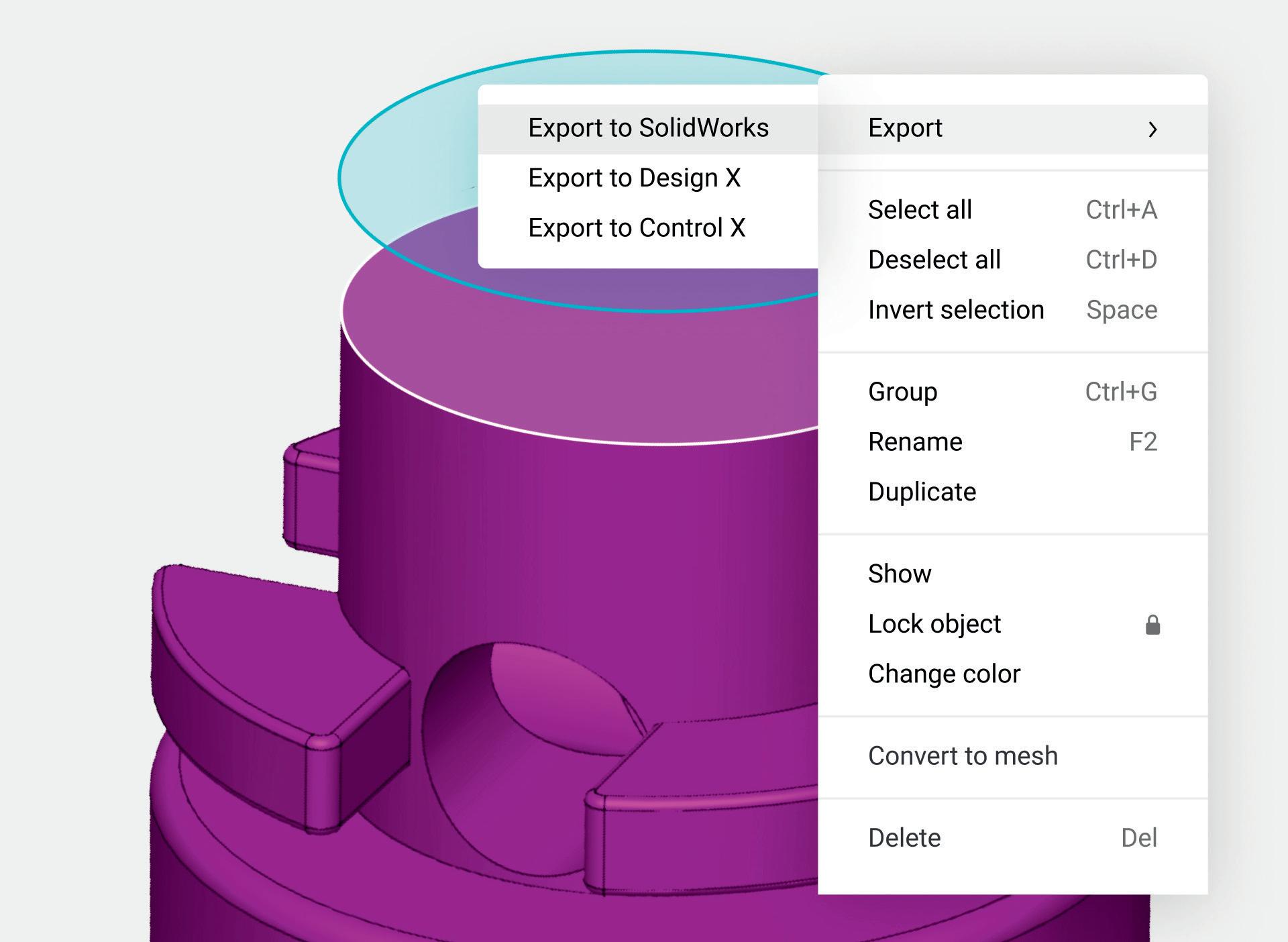

Design Automation for SOLIDWORKS®

Automatically create order-specific SOLIDWORKS parts, assemblies, and drawings, so you can focus on the engineering work that matters most.

Start your 30-day FREE trial at www.driveworks.co.uk. No credit card required.

Powerful features, simple setup and maintenance

DriveWorks Solo is the powerful rulesbased SOLIDWORKS automation add-in that enables engineers to quickly configure and generate variations of models inside SOLIDWORKS.

Setting up DriveWorks is simple. Capture the parameters you change manually in SOLIDWORKS, then create a user interface and build rules to control how the captured parameters are updated.

Once DriveWorks is set up, you can run it over and over again to automatically create custom SOLIDWORKS parts, assemblies, and drawings.

Reduce engineering time

Customers using DriveWorks have cut their design engineering time for custom products by up to 95%.

Simple no-code setup

Forget expensive implementation and maintenance. Set up, maintain, and use DriveWorks in-house.

Flexible and scalable

Trade-in DriveWorks Solo and upgrade to DriveWorks Pro for enterprise-wide design automation and CPQ.

Beam shaping laser technology in 3D printing has

much to recommend it,

writes

Growing up as a small child in a Caribbean household that had more people in it than seats at the dining table, the kitchen was the epicenter of the home in which my large, extended family gathered.

It’s been a long time since I’ve been home and longer still since I’ve tasted traditionally made coconut breads, but I still remember the clouds of flour in the air and my infinite curiosity as I asked my grandmother how we made bread without a recipe card. She would always say to mix the ingredients until it “feels right” or to bake the bread “until it tells you it’s ready”. I must have spent hours in front of her oven, watching and waiting with a furrow in my brows.

Fast forward 25 years and I’m spending hours in front of a laser powder bed fusion (LPBF) window, watching once again, with a furrow in my brows, and still unable to tell if what I’m baking is ready.

STIRRING THE POT

In my opinion, laser powder bed fusion (LPBF) isn’t an expensive process. However, the material testing, validation cycles, the building of material allowables, databases and the like – that’s expensive.

One reason is the abundance of samples requiring testing. For example, to build a statistically significant data set for Metallic Materials Properties Development and Standardization (MMPDS), you need at least 100 samples. Of those 100 samples, at least 10 have to come from different lots/heats to establish reliable A-basis and B-basis allowables. For those unfamiliar with the LPBF “oven”, that’s like saying you need to bake 100 loaves of bread with the same brand of flour, but the loaves need to come from at least 10 different ovens.

For those who spent their time during the Covid pandemic perfecting sourdough, that may not sound too intimidating. But for LPBF, we often have to develop the cooking

process as well – a complicated design of experiments where we have the ability to alter over 100 processing parameters until we achieve something that “feels right”.

Some parameter sets are great for lasing bulk material. Others are optimised for specific features like thin walls, lattices or overhangs. And for each parameter set you use, for each variation in the process – be that laser speed, laser power, layer thickness, hatch distance or scanning strategy – you have to qualify material for that specific set.

In short, there’s a lot going on in our kitchen, but I don’t mean to overwhelm you. Many of these parameter sets are well established, especially those supported as defaults by AM machine manufacturers.

But in 2025, when beam shaping technology hit its first powder bed, our efforts to produce ‘loaves’ that are fluffy on the inside and perfectly crispy on the outside suddenly seemed in peril.

FRYING PAN TO FIRE

Most of the research, development and qualification of LPBF and its subsequent parameter sets has been achieved using a standard Gaussian laser beam – a single, focused point of high-intensity energy (anywhere from 500W and 1kW).

But the new beam shaping lasers – or ‘doughnut lasers’ – work differently, spreading energy across a central spot and outer ring. Dynamic beam shaping offers six indices where you can start at the standard Gaussian beam and change the shape of the ‘doughnut’ in the blink of an eye, allowing you to switch quickly from lasing bulk material to fine features. The result is better throughput, higher productivity gains and (theoretically) faster print times, which should drive down per-part costs.

But if I have six indices and multiple parameters per index, does that mean I need 100 samples from 10 different machines for each index for a total of 600 samples minimum?

columnist SJ, but it complicates how we test samples and we’re probably going to need better software to keep track

When beam shaping technology hit its first powder bed, our efforts to produce ‘loaves’ that are fluffy on the inside and perfectly crispy on the outside suddenly seemed in peril

As an industry, we’re still arguing over the proper qualification path for multilaser systems. How will we ever come to a consensus when it’s now 12 laser systems with each laser having six different indices? The complexity of this problem simply isn’t discussed enough.

I’m concerned that beam shaping will set back manufacturing readiness levels and the perception of technological maturity. I also feel that it could have drastic impacts on qualification frameworks. Does currently available software even support assigning and managing all those new parameters within the print file? And if not, what AI/ ML-powered software will we need to better understand and qualify these build files?

(Thinking about this, if a software evolution brings about the death of the .stl file and the rise of the implicit, then you can count me as being all-in on beam shaping.)

For now, however, the worries keep multiplying as quickly as the parameter sets. The furrow in my brow is as deep as the Grand Canyon.

One thing remains the same: I just want to bake good bread. In other words, I want to make parts using robust, reliable and repeatable processes. Whichever laser produces the best ‘bread’, then I’m all for it.

ABOUT THE AUTHOR: SJ is a metal additive engineer, aka THEE Hottie of Metal Printing. SJ’s work involves providing additive manufacturing solutions and 3D printing of metal parts to help create a decarbonised world

What are legacy engineering workflows costing your business? In 2026, it’s time to do the maths and throw off the shackles of outdated methods that get in the way of true collaboration, writes Christina Rebel of CAD Rooms

There’s a question we should ask as engineers, but for some reason, we seldom do. How much time does your average CAD user actually spend designing, versus chasing file versions, waiting for supplier feedback or wrestling with legacy systems?

Over the past nine months, I’ve been investigating this issue across the space, automotive and industrial sectors whilst building CAD Rooms.

Honestly, the numbers make for grim reading. They represent a productivity crisis that most engineering organisations have simply accepted as “the way things are”. What does this look like? It looks like supplier review bottlenecks, where STEP files (and frequent updates to STEP files) need to be sent to third-party suppliers, accompanied by painfully long email threads containing annotated screenshots.

It looks like version control nightmares, in which files are given names like this: final_v3_REALLY_FINAL_actuallyfinal.SLDPRT.

I’m not even joking. This is how teams with brilliant engineers and sophisticated products manage their most valuable intellectual property. Software developers solved this problem 15 years ago with Git, which introduces version control, branching and merge capabilities, yet mechanical engineering is still living in 2010.

At the other extreme, it looks like the legacy PLM trap, where companies spend €2-€3 million annually on enterprise PLM systems that require six clicks just to check out a file. These systems were architected for a different era, when engineering teams sat in the same building, designs changed monthly rather than daily, and ‘collaboration’ meant occasionally sending a drawing to manufacturing. These PLM systems may excel at compliance and audit trails, but they’re spectacularly poor at enabling the rapid iteration of modern product development demands.

Finally, it looks like living in a state of licence lock-in. Consider the economics: a 25-person engineering firm typically spends €1.25 million per year on CAD licences alone. That’s €50,000 per seat. But most of that capacity sits idle whilst suppliers wait for “view access”. In the meantime, you’ve got engineers who can’t work because a file is checked out, suppliers who can’t provide feedback because they can’t afford a licence, and project managers who can’t review designs because they’re not in the CAD seat pool.

The traditional licensing model assumes scarcity – that software is expensive to distribute and access should be restricted. But we’re now in 2026. Browser technology can now render complex assemblies natively. The technical barriers have fallen; only the business model remains.

MORE MODERN METHODS

At Boston University, the rocket team shows what’s possible when you remove these constraints. They’re developing a liquid-fuelled rocket engine – by no means a simple engineering task. By going digitalfirst with browser-based collaboration, they’ve cut development time significantly while working as a distributed team.

The key to their success? They treat collaboration as a first-class requirement, not an afterthought.

Suppliers can review designs in real-time. Version control is automatic. Approval workflows aren’t gated by expensive licences. The tools get out of the way and let the engineering happen.

There are plenty of practical strategies that teams can implement now if they want to emulate this kind of success without needing to rip out their entire toolchain. They should:

• Separate editing from viewing. Not everyone needs a full CAD licence. Browser-based viewers can handle 95% of review workflows at a fraction of the cost.

Software developers solved the version control problem 15 years ago with Git and its branching and merging capabilities, yet mechanical engineering is still living in 2010

• Implement proper version control. If your engineers are manually managing file versions, you’re haemorrhaging productivity. Cloudbased PDM systems with automatic version tracking eliminate this overhead entirely.

• Rethink supplier collaboration. Give external partners the access they need without the friction of heavyweight tools. The delays you eliminate pay for themselves within weeks.

• Audit actual licence utilisation. You’re probably paying for capacity you don’t use, while creating artificial bottlenecks because you don’t have enough licences for review workflows.

The engineering software industry has sold us the idea that more features and higher prices equal better outcomes.

But the real measure of a tool’s value is simple: does it enable your team to iterate faster, collaborate better and deliver products that work? Everything else is just overhead.

ABOUT THE AUTHOR: Christina Rebel is CEO of CAD Rooms and Wikifactory, where she leads the development of cloud-based collaboration solutions for distributed engineering teams. Her focus is on bringing modern, accessible collaboration tools to engineering teams developing everything from electric vehicles to space tech. www.cadrooms.com

VISUAL DESIGN GUIDE OONI KODA 2 PRO

» Ooni’s latest addition to its outdoor oven range o ers a larger cooking area, better heat retention and a patented ‘tapered flame’ for an even smarter way to cook restaurant-style pizza in your own back garden

TAPERED FLAME

Fuelled by propane, the G2 Gas Technology twin burners in the Koda 2 Pro create a flame of exactly the right size to deliver 420% better heat distribution compared to the Koda 16. The result? Perfectly cooked pizza in just 60 seconds

SMARTER COOKING

The front-mounted digital temperature display provides real-time ambient temperature readings, while an included food probe reads directly to your smart phone via a Bluetooth-enabled app

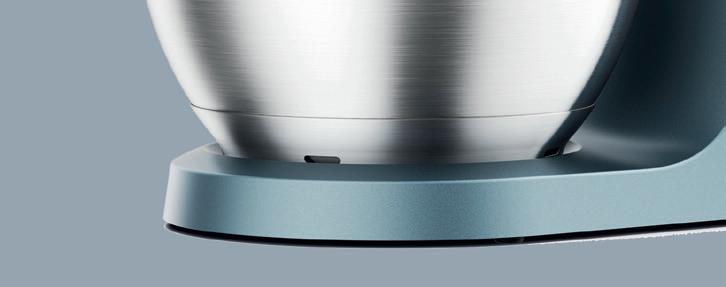

IN THE MIX

» As living spaces shrink and cooking habits change, Kenwood UK took the bold step of creating a new product range to meet modern needs. Stephen Holmes steps into the kitchen with the Go Collection to hear how its designers achieved the right blend of ingredients

The Kenwood Go Collection was designed to blend into the space and style of modern kitchens

K1

enwood UK’s newest range of small kitchen appliances evolved from an updated understanding of how many of us choose to live now, according to the brand’s design director, Samuele Meda. In particular, we’re opting for more compact living spaces and moving home more often. “Like me – I’ve moved nine times, and every time, the kitchen is smaller,” Meda laughs.

He’s speaking to DEVELOP3D from Kenwood UK’s designoffi ces in Havant, Hampshire. Meda is a design veteran, having worked for brands including Electrolux, AEG and Dometic in Sweden, before spending almost five years at Kenwood in the UK More recently, he moved back to Italy, where he now oversees the design process from De’Longhi's HQ, the Italian kitchen appliance company that acquired Kenwood back in 2001.

Given the deep roots of Kenwood’s stand mixers in traditional British kitchens, it is unusual for a brand like this to undertake a pure, ‘clean sheet’ design exercise. The Go Collection was born to answer an unmet need, rather than update current models or compete with rivals. And the devices in this range demonstrate a distinct shift away from the classic Kenwood appliances of old.

Kenwood’s award-winning stand mixers, food processors and blenders remain much-coveted worktop kitchen appliances among those serious about cooking – but observations about how Gen Z approaches food prep indicated a clear need for simpler, more convenient tools. After all, feature-laden machines with attachments to tackle almost every conceivable task can be daunting for some users. The idea of having to unpack and plug in another device and identify the right attachmentsisoffputting, let alone having to clean and repack everything once the work is done. Faced with a task like chopping an onion, many home cooks will opt instead for a knife and chopping board.

“So your competitor is not actually another food processor,” says Meda. “It’s something that the user at

home finds much more convenient and easier.”

Smaller kitchens, often in apartments, also mean smaller work surfaces and storage spaces. With that in mind, the overriding goal for the Go Collection was compact products, ready to work and so intuitive that users don’t need to read an instruction manual.

The impact that Dyson’s hair care range has made on the beauty appliances market also influenced Meda’s thinking. “When I gave my wife a Dyson hair dryer as a present, she loved it, right? But years before that desirable hair dryer, I would never have given one to my wife as a Christmas present,” he observes.

That was the challenge he issued his team, he continues. “Would you ever give your partner a food processor as a present? We have to create a product that is desirable –and I believe that we can make a blender or a hand mixer or a food processor that is desirable.”

The result is minimalist products wrapped in matte, mellow tones of grey blues and clay reds. They represent a stark contrast from the chrome, stainless steel and black shiny plastic that we’re all more used to seeing. The stand mixer, hand mixer and food processor work straight out of the drawer or off the shelf. The few removable attachments stow away neatly in clever covers or nooks in the design, in order to save customers the chore of having to search through drawers.

Customers clearly approve of this approach, because the Go Collection has been a resounding hit both with users and reviewers.

THE BEST INGREDIENTS

The starting point for the Go Collection was uncertainty, at least internally at Kenwood. Many on the team were not convinced that a move into a younger, more compact and more affordable range would suit the company’s market positioning. But when the green light was finally given, a team of six designers headed by Meda got to work.

The first week involved a classic design sprint – purely pen and paper sketching, idea generation and concepting.

● 1 The Kenwood stand mixer is a brand staple, but its Go Collection update is simpler to use, easier to store and brings a pop of colour to kitchens

‘‘ Your competitor is not actually another food processor. It is something that the user at home finds much more convenient and easier Samuele Meda

“You’re in the phase where everything’s acceptable, right? We don’t need to restrict ourselves from giving crazy opinions and we work collaboratively. So the entire team is working together, not one designer,” says Meda.

At the end of the first week, three concept ideas were chosen. “There is no personal judgment. It’s not about ‘because we didn’t pick your concept, you’re not a good designer’. It is simply that we picked the best ideas and we really wanted to arrive at a maximum of three ideas.”

Week Two focused on identifying the best designs, involving two or three days of building out concepts in 3D CAD using Siemens NX. Other digital tools came into play for adding core technologies such as motors and switches to the designs, using Siemens’ PLM software Teamcenter and STEP files from supplier libraries.

The use of Siemens NX comes in part from Meda’s experience working as a designer for Electrolux in Sweden and the need to communicate closely with engineering teams, especially when it comes to electronics.

“Because we use the same CAD, we can all work on the same model. They understand you. You understand them. It’s a much more collaborative process,” says Meda. While he accepts that a software like NX can present a steep learning curve for many new designers, it’s justified by the results – closing the gap between designers and engineers, the reduction in waste and the preservation of design intent.

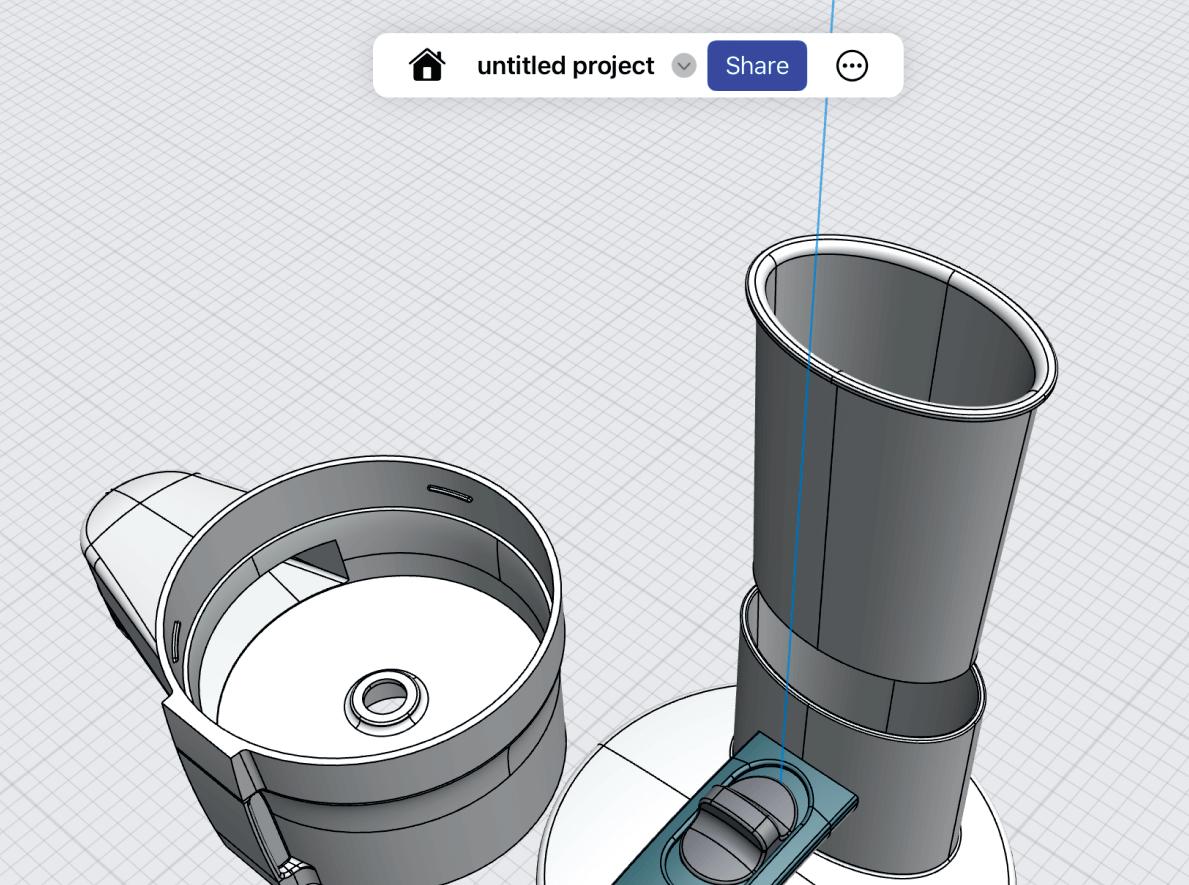

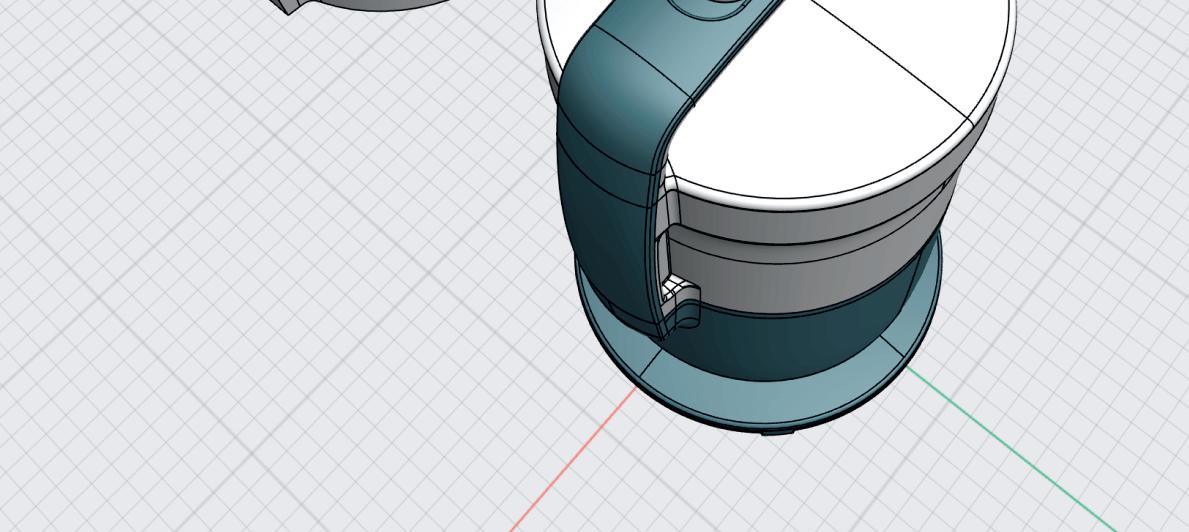

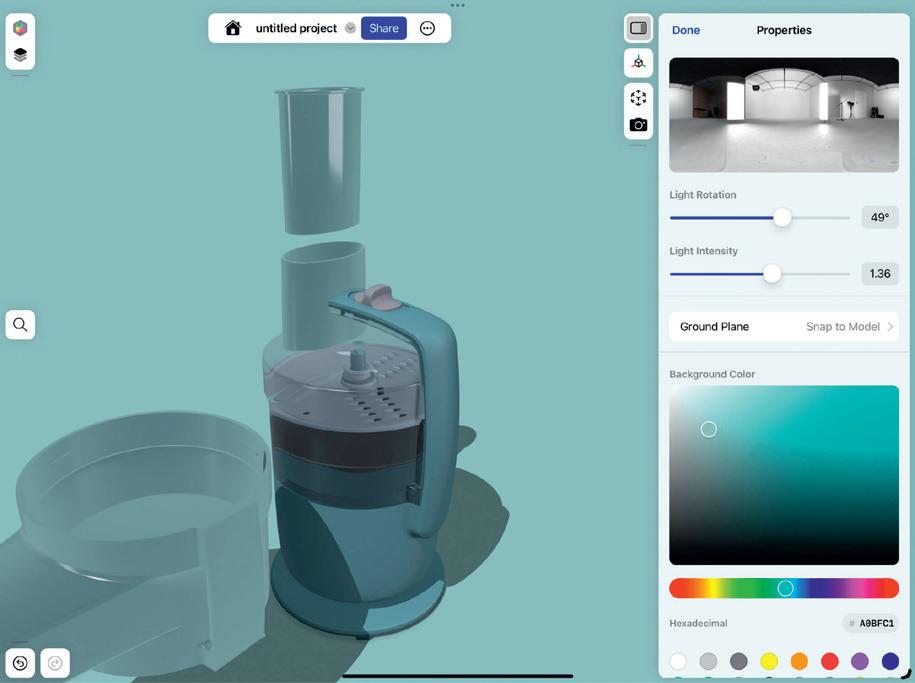

Meda has also adopted Shapr3D as his main, personal CAD tool. This originates from him always travelling and needing to open a 3D CAD file on his iPad and sketch over or annotate a quick screenshot using the Apple Pencil. Over time, the Shapr3D package has taken on even more purpose in Kenwood’s workflow.

For the MultiPro Go food processor, Meda prototyped various positions of handles and buttons using Shapr3D, creating several concept variations with different styles of buttons for the user interface. Flying through concepts allowed him to test out multiple options and look at prototypes the next day.

The goal was to keep the design under 30cm tall, in order to allow the device to be stored in a deep kitchen drawer. Since the engineering team advised that only 35cm was possible, Meda’s iPad was brought to the meeting table, where he quickly edited the design in front of the team to show how the feed tube could be integrated in the top of the bowl. This gave the engineers the confidence to see that the design was possible and convinced them to try it out.

Whereas modifying a model in another CAD might take 10 minutes or more, and might confine the user to a desktop, this method proved effective in quickly conveying ideas visually, because everyone could get around a screen.

THE RIGHT TOOLS

Meda’s role is predominantly to give design direction to the team, and Shapr3D allows him to do this not only through sketches, but also by going into CAD models and being able to understand the limitations of dimensions or maybe even an undercut, he says.

“But it’s also fun, because I can open the file, I can visualise [the product], I can play with colour, material and finish. I can now use it with Apple Vision Pro. So, it’s this prototyping and collaboration dialogue between myself and my team.”

The use of Shapr3D is growing among the wider Kenwood design team, especially in the concepting stages to get into 3D modelling much faster. The knock-on effect of being able to 3D print prototypes and assess renders in XR for CMF is also welcome.

Kenwood’s design base in Havant offers a full workshop for prototyping, with all the 3D printers, CNC milling machine and spray booths needed to build rapid prototypes in-house. Yet it’s the use of the Apple headsets linked to Shapr3D that is having perhaps the biggest impact on how Kenwood’s team designs products.

“The CMF is something that [historically] we didn’t consider at the beginning. It was mainly shape, because we were used to having a 3D print or milled-out block of

●

● 2 Kenwood design director Samuele Meda uses Shapr3D to help guide design workflows, regardless of his location

3 Shapr3D offers designers the ability to quickly render models to explore CMF options

foam. And when you get that, of course, the CMF is not there, just a grey blob,” he explains.

“With the Vision Pro and Shapr3D, you can also simulate colours, material and finish – much better than just a form. We’ve learnt to design from the beginning with CMF in mind, and not just, ‘Oh, beautiful shape. Now, which colour do we pick?’”

This process has not diluted the team’s use of Siemens NX, he stresses. Instead, it has enhanced it, such is the speed with which a model can be exported as a STEP file, and then quickly pushed through Shapr3D into the Vision Pro headsets to quickly render and add colours, textures and materials.

With four Apple Vision Pro headsets in the UK office, team members can all get around a product virtually, testing out multiple models with colours, or even different features like dials or buttons. Now that he’s based in Italy, Meda can join in reviews securely from De’Longhi’s offices or even while on the move, with the session driven by a team member in the UK.

“Of course, it will never look [precisely] like the real one,” he admits, “but you’re making decisions and choices based on something that you can actually see now!”

COMPREHENSIVE CMF

For the Go collection, some colour, materials and finish (CMF) inspiration came from the likes of modern audio equipment, explains Meda. In that sector, the huge visual presence of old hi-fi set-ups has been replaced by WiFi-enabled smart speakers that blend into their surroundings more seamlessly.

“We wanted to apply a similar approach to our appliances, so you can have a nice piece of decoration in your kitchen and it doesn’t look like an appliance, both from a styling point of view, but also to make it more desirable and more an object that you want, not necessarily because you need that object.”

Because of this, the CMF was tailored to fit into modern kitchen environments with muted colours and matte finishes. To develop these, final CAD models were taken into Luxion KeyShot, allowing the team to create still and

animated renders and drop them into different pre-built kitchen models, complete with colours, textures and lighting – allowing the team to quickly place the appliance in a variety of homes reflecting different styles and tastes.

Kenwood UK also invested in a powerful workstation for the studio, enabling the team to run KeyShot renders, “very, very fast, especially for videos”, says Meda. “You can imagine – there are lots of frames to be rendered.”

While final decisions are always made using what Meda calls a ‘hi-res’ physical model, built by hand for each colourway in De’Longhi’s main model shop in Italy, before being shipped to the UK, getting to this final decision is accelerated not only by renders, but by testing colours physically at an earlier stage.

Using the Swedish NCS system for standardised colours based on human vision (an approach Meda brought with him from his time at Electrolux), three shades of each colour were picked before a local supplier matched the NCS colour and provided it as a paint in a spray can. This proved to be a straightforward, cheap and pretty accurate means of testing colours on 3D models, as opposed to taking bets on a paper swatch or calibrated monitor.

“The swatch is nice, but when you maybe apply the colour to a kettle, maybe it doesn’t work, maybe it’s too much, it’s too dark, it’s too light, because it’s how it reflects the light.”

The final hi-res models are beautifully realistic and accurate in every facet, but given the time it takes to achieve this effect and then ship them across Europe, a 3D-printed prototype sprayed quickly with a rattle can in the workshop can help avoid lengthy errors.

Kenwood uses an external visualisation specialist for its final marketing materials, meaning that the requests and edits from its marketing team don’t eat into valuable design time. The agency in question also uses KeyShot, helping to maintain the link between teams by standardising on software choices.

Keeping the blend of software tight knit has proven effective for Kenwood’s design team, helping it react quickly to a new market opportunity and reinforcing its identity as an innovative kitchen brand for modern living. www.kenwoodworld.com

‘‘ We’ve learnt these days to design from the beginning with CMF in mind, and not just, ‘Oh, beautiful shape. Now which colour do we pick?’ Samuele Meda ’’

Kenwood UK’s blend of quick sketches, CAD modelling with Shapr3D and 3D-printed prototypes helps the team develop stylish products faster

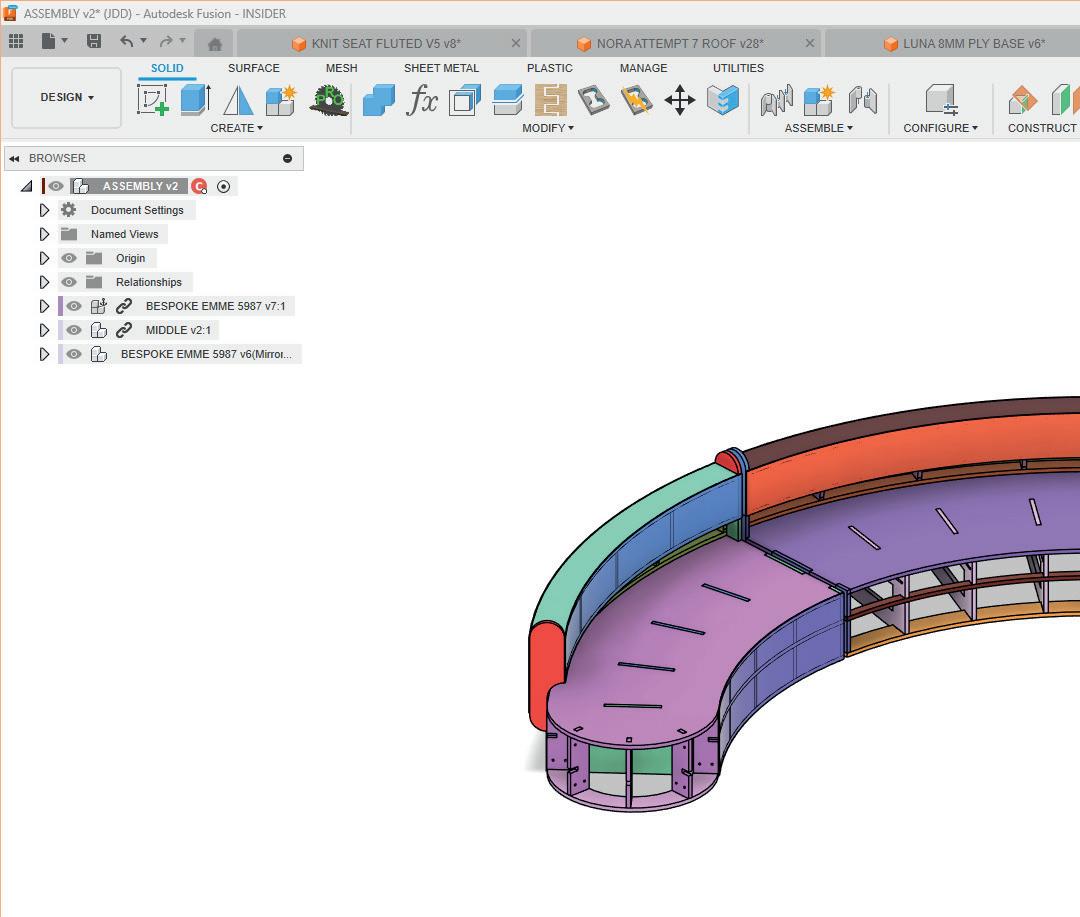

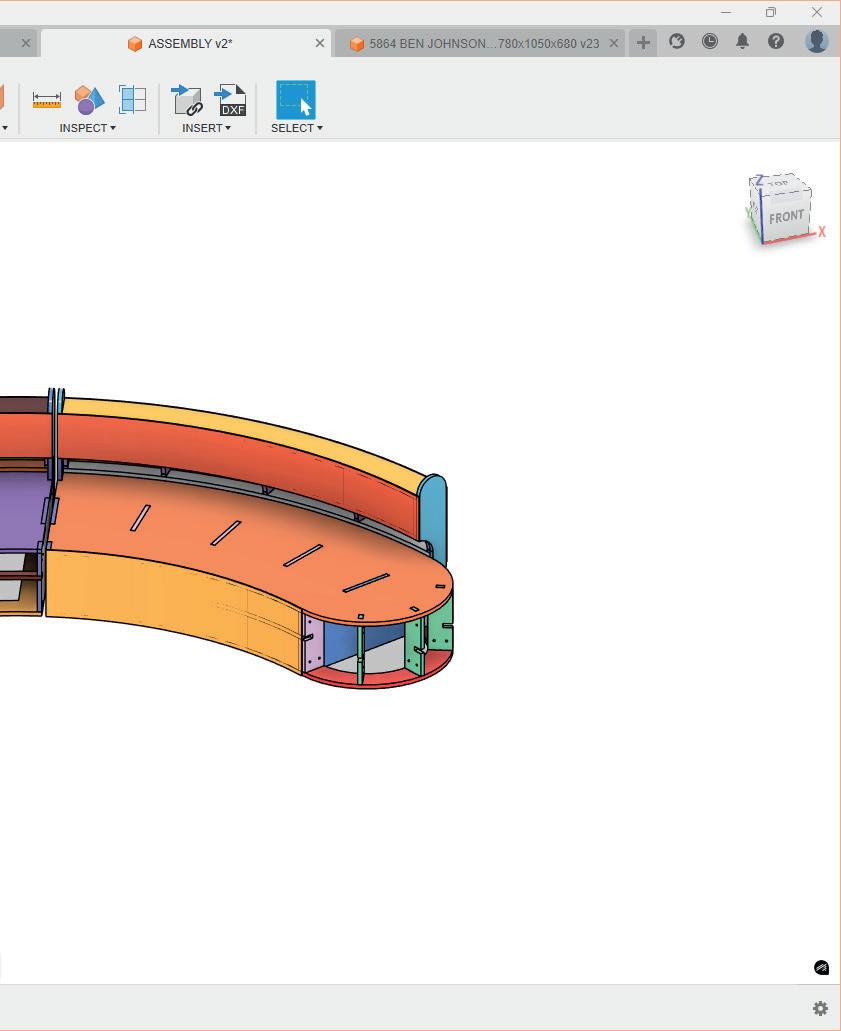

JDD Sets a New Standard in Office Furniture

Fiifteen years ago, Joint Design Direction (JDD) began when two long-time friends, James Mercy and Joe Duffell, reconnected over a drink during the Christmas holidays. They first met in secondary school when they were 11 years old. After they studied design at separate universities, they both pursued careers in the design industry, albeit in different roles. That one evening catch-up was fortuitous. James and Joe decided to combine their experiences and embark on their own furniture design journey. Without any external funding, they scraped together some money to get started. Their first launch pad was at the famous 100% Design (now Design London) trade show in London, where they showcased JDD in an area for new companies. At their stand, James and Joe met the architects furnishing Google’s headquarters in Europe, West Asia, and Africa. They were having issues sourcing certain products, such as high-back

sofas, and asked JDD if they could help. Of course, it was an immediate yes. James and Joe said yes to everything and, “we’d figure it out later,” James says.

“Our passion was for design, but we didn’t even know we were going to go into office furniture design before that,” James says. “It gave us the direction to where we are today.”

JDD now boasts more than 30 standard products, from privacy pods to sofa dens, seating, banquettes, and a brand-new sleep pod. With all design and manufacturing based in the UK, they provide both their standard products and customized versions to companies around the world. The business is booming with more than 90 employees; a full-scale design and manufacturing facility at their headquarters in Dudley, England (the home of the Peaky Blinders); and showrooms in Birmingham, London, Glasgow, and Dubai. To keep up with new demands and grow the business even further, they recently adopted

Forthedesignofournewrestpod, Fusionwasparticularlyhelpful.During prototyping,wemightneedtoadjust thedesigntomakesomethingwider tofitordeterminethestandardization ofthemattress.Parametricmodeling cameinhandy.It’saclickofabutton ratherthanredrawingthewholething

CharlieAdlem,Production Designer,JDD

Autodesk Fusion to help bring beautiful and functional furniture solutions to life even more quickly and efficiently.

Moving over to Fusion for furniture design

A combination of factors led the JDD team to Fusion. Their designs were becoming more complex, and their manufacturing capability was growing rapidly. A year ago, they started using Fusion and haven’t looked back. Now their entire design-to-manufacturing workflow is optimized and already making a huge difference.

“Clients might want different widths, depths, or heights for the products, and that’s easily done with the parametric modeling in Fusion,” says Charlie Adlem, production designer, JDD.

On the design side, Henry, product designer at JDD, has also moved over to Fusion. Previously, he was modeling in 3ds Max and testing with OnShape. When he needed to share a CAD file with Charlie or George Hopkins, production designer, JDD, he provided either STEP files or just 2D drawings.

“It really made sense for me to move into the same software with Fusion because now we can just share the documents and models,” Henry says. “When you share a STEP file, you lose all the history, notes, and little nuances because you’re just exporting it as a dumb file. Then Charlie and George would have to rework it, and there was a lot of unnecessary

back-and-forth communication. Now everything is there in one place. I’ve only started using Fusion, but it’s really sped up the process already.”

they can just open it up on a tablet or a phone. It makes the process much faster.”

Looking forward

Ease-of-use reigns supreme

to push the boundaries of frame making and

For JDD, Fusion’s ease-of-use is, well, easily their favorite aspect of using it. Plus, it provides the opportunity to push the boundaries of frame making and accuracy.

“I’ve used other software in the past, like SolidWorks and Rhino, and they seem so complicated compared to Fusion,” Charlie says. “The user interface and icons are easy to use. The tools in Fusion are easy to pick up, and there are loads of tutorials online.”

JDD has also discovered new ways to collaborate—even down to the factory floor. “Before we’d have to do drawings for the wood mill and the person assembling it,” George says. “But now we share the file link, and

JDD’s current design focus is on wellness, whether it’s for the workplace or the public sector, such as libraries, universities, and more. Since the successful launch of their new Yume Rest Pod and Nita, the JDD team is dreaming up even more ideas to bring wellness to those environments. As they scale the company and these latest designs, they have a strong foundation with Fusion.

to pick up, and there are universities, and more. Since the

Yume Rest Pod and Nita, the JDD team is dreaming up even more ideas to bring wellness with Fusion.

“It’s all about the end using Fusion is making an impact for them,” James says. “My

“It’s all about the team’s workflow at the end of the day, and using Fusion is making an impact for them,” James says. “My positives are their positives. As long as things make their jobs easier or more efficient and enjoyable, then that’s a win for me. If using Fusion helps them, it helps the company.”

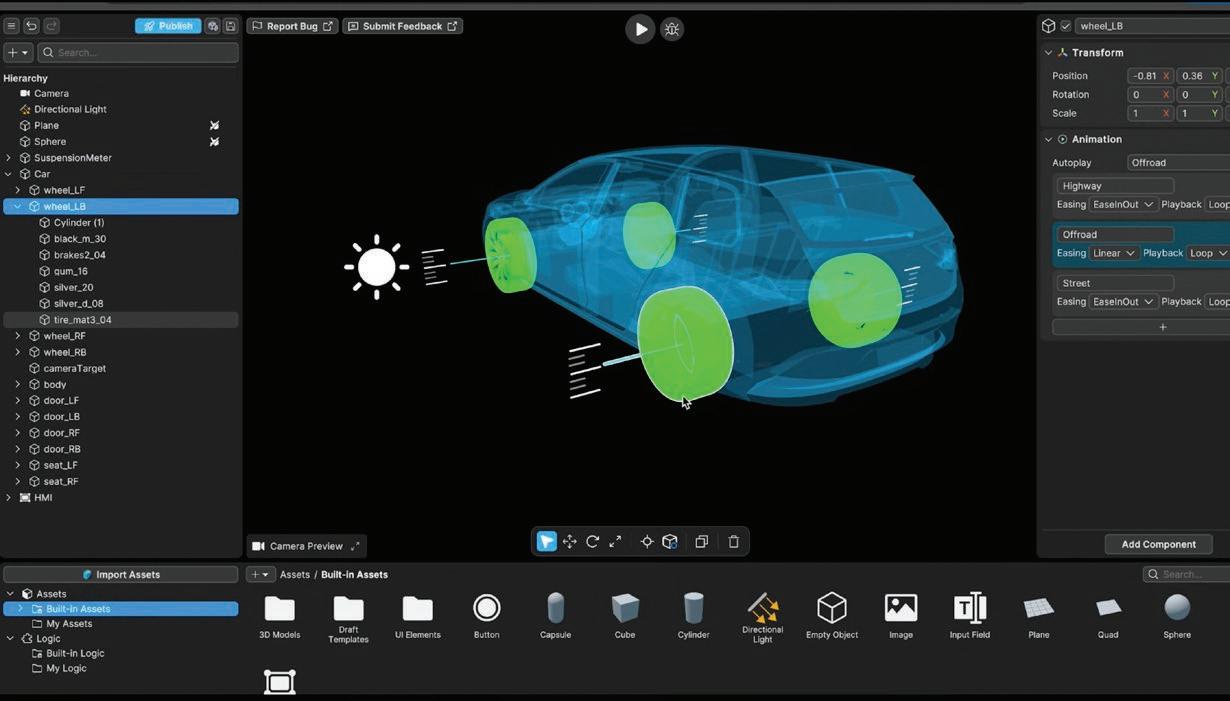

SMOOTHING THE PATH

» With no-code workflows and streamlined data pipelines, Unity is looking to simplify how firms build, share, and scale interactive 3D experiences, writes Greg Corke

Creating interactive 3D experiences has long been regarded as the domain of technical specialists — coders, game developers, and those skilled in customising real-time engines like Unreal and Unity. In product design, manufacturing, automotive and AEC, this technical barrier has stalled countless ideas before they could become usable tools. Sarah Lash, GM & SVP of Industry at Unity, calls this “POC purgatory” — the place where promising ideas never progress beyond the initial proof of concept.

“I’ve had conversations with people that go like, ‘Yeah, we’ve got 60 requests for projects in queue, and we have enough bandwidth to do five of them,” she says. But there’s an obstacle that affects many more firms, “If they don’t have a C# developer, how are they getting started?”

Unity Studio, now out in beta, aims to change that dynamic, offering an intuitive, web-based platform designed to let “anyone” create interactive 3D experiences without having to write a single line of code.

In its simplest form, this could be an interactive 3D viewer where users click elements in a CAD or BIM model to reveal more information, or a web-based product configurator where customers choose options, colours, and materials and see the 3D model update in real time.

Unity Studio can also be used to power training applications that animate 3D models to guide engineers through servicing procedures, collaborative design review tools, giving non-CAD users real-time access to large models, or construction-sequence simulations that help contractors visualise each stage of a build.

Unity Studio is essentially a cut down version of Unity Editor, the main workspace where users create, organise, and manage 3D applications, including games. However, unlike the full Editor, Unity Studio runs in a browser and is built around a simple, drag-and-drop visual interface. “It gives the ability to start something in a Unity-like environment, whether you’re a designer, a trainer, or project manager, and help bring some of those ideas to life,” says Lash.

Unity Studio features a visual scripting system called Logic that lets users add behaviours and interactivity to an experience, instead of having to write code. It can be used to trigger actions based on events (such as when a user clicks a button or selects an object), control animations, adjust scene lighting or combine multiple actions to create more complex behaviours.

Applications created in Unity Studio can either serve as a launchpad for further development in the full Unity Editor or be published straight away.

Lash recalls an example where a training subject-matter expert from a large printing company used Unity Studio

to create an immersive 3D animated training environment to show users how to replace the industrial cartridges — a process that was previously explained using PowerPoint.

Another example includes an automotive company, where a designer with no prior Unity experience created a prototype of a Human-Machine Interface (HMI) for a car. The goal was to visualise the suspension travel of each tyre. Taking a sketch from collaborative design platform Figma and an optimised wireframe CAD model of the car, the designer added simple animations to demonstrate the movement.

Unity Studio seems like an obvious fit for smaller firms that may never have considered creating their own 3D experiences. But, as Lash points out, even the most forward-thinking organisations can have thousands of architects yet only a handful with the necessary C# skills.

This is true at BMW, where Markus Herbig, XR IT specialist admits that Unity Studio has created significant interest within the company, from both CAD users and project managers. “There’s a lot of people that don’t know how to handle a game engine, they don’t know how to programme C# or even C++, so Unity Studio gives us a huge benefit on creating new concepts, especially on the HMI side.

“If you have an idea, you just go to Unity Studio, you create it, and you can share it directly with somebody who maybe has some more influence,” he says. In other words, it’s about communicating ideas clearly to help decide which are worth pursuing.

With Unity Studio it’s also very easy to publish content, as Daniel Reichert, director, Unity Studio explains, “You don’t have to worry anymore about build settings or where do I host this?” he says. “You just click one button, you get a URL, and you can send it via email, via Teams or via Slack, to anyone in your company to check out the project.”

Unity is already working on new features, and there are plans to add real time collaboration. “This will enable multiple people to work on the same problem at the same time,” says Reichert. “In combination with commenting, this brings workflows that you know from the web browser, from tools like Figma, directly to the 3D editing world.”

AI powered capabilities are also on the horizon. The software already allows users to take a basic scene and upscale to make it look like a high-end render. While this is standard fare in many 3D applications these days, Unity is also working on a feature to generate logic dynamically —a capability that could, in practice, deliver substantial productivity gains.

At present, Unity Studio only allows applications to be published to the web, whereas the full Unity Editor lets you publish for Mac, Windows, mobile and XR

‘‘ Unity’s latest initiatives with Unity Studio, Asset Manager, and its expanding automation pipeline signal a clear shift in how interactive 3D experiences can be conceived, created, and shared ’’

PATH TO REAL TIME

platforms. Expanded support isn’t on the roadmap yet, but as Lash told DEVELOP3D, it is something currently under discussion.

ALL ABOUT THE ASSETS

For more advanced users, there’s Unity Industry, a suite of tools for developing and managing industrial applications across sectors such as manufacturing and AEC.

One of the biggest challenges facing any firm wishing to develop 3D experiences is access to data. “A lot of times [assets] are locked in silos or in different departments, or you need access to that type of [software] product in order to open a BIM model,” says Lash.

“We can only scale on the creation side if everybody’s working from the same foundation. We can only bring that to life if we know where all of that data lives.”

In Unity Industry this is handled by two tools – Unity Asset Transformer (formerly known as Pixyz Plugin) and Unity Asset Manager.

Unity Asset Transformer can ingest over 70 different file types, turning complex heavy CAD, BIM, 3D, reality modelling and other file types into lightweight meshes. Users have full control over mesh size and quality, so data can be optimised to maintain performance in different real time experiences on different target devices, across mobile, desktop, and XR.

Meanwhile, Asset Manager is a cloud-based digital asset management (DAM) system that stores all of this data and makes it discoverable for anybody across the business so it

can easily be brought into Unity Editor or Unity Studio.

“What could take weeks of converting these file types and having to email them back and forth and then check you’re working on the right version, is now happening in seconds and minutes,” says Lash. “Engineers, designers, internal partners, they can all work from the same live asset now. The more centralised they are, the more you can do with them, long term.”

Japan-based construction company Obayashi has built an entire 3D collaborative application, Connectia, around this workflow, transforming complex CAD, BIM, and point cloud datasets into ‘ready-to-use’ assets. Asset Manager automatically handles the data conversion and version control, eliminating the need for manual conversion.

BMW has also recently turned to Asset Manager and Asset Transformer to overcome the persistent challenges it faces when managing and accessing the digital assets critical to developing virtual experiences. The Unity tools form the backbone to BMW’s 3DMine, a comprehensive 3D asset management platform designed to streamline access by centralised data in a private cloud environment.

As Markus Herbig describes, the process of building virtual experiences was like “chasing a ghost” with teams constantly asking “what assets do we have? Where do we get the car from?”

“You’re kind of lost in this huge maze, and you don’t know where they are. You don’t see the assets,” he says. This lack of visibility made it difficult for BMW’s creators to efficiently find and utilise the necessary resources,

Unity Studio is an intuitive, web-based platform designed to let “anyone” create interactive 3D experiences without having to write a single line of code

often repeating the same processes again and again.

“[With 3DMine] each use case gets the right data in the right format at the right time,” he says.

DATA PREP – PUSH / PULL

Unity has been working to bring more automation to file optimisation and delivery, helping ensure that users have access to the right data at the right time.

A new tool called Pipeline Automation allows users to connect the Asset Manager to Product Lifecycle Management (PLM) systems like Siemens TeamCenter, or PTC Windchill, and other data sources, and create automations based on events, schedules or API calls.

Unity’s roadmap for pipeline automation focuses on giving users the flexibility to build pipelines however they want — whether through custom scripts, rule-based tools in the editor, or in the future AI.

“You can retrieve your CAD data from a PLM system and Pipeline Automation automatically converts this CAD data into usable real time 3D data, so it can be used downstream in real time 3D applications,” says Simon Nagel, staff solution architect, Industry at Unity. “Pipeline Automation can make sure that changes in the PLM system are automatically brought through.”

At the recent Unity Industry Summit in Barcelona, Matthew Sutton, senior manager of EMEA solutions engineering at Unity, shared an example of a Skid Loader Assembly model built in Solidworks. Changing the number of teeth in the bucket assembly and syncing it with the PLM system automatically triggers a pipeline automation, allowing Unity to retrieve the updated files and prepare the data for the Unity runtime. Importantly, the system can be set up to manage complex assemblies and their dependent sub-assemblies and parts.

THE BIG MODEL CHALLENGE

For viewing huge datasets, such as those used in automotive or digital twin applications, Unity applies 3D Data Streaming - not to be confused with pixel streaming, where graphics are processed in the cloud and the pixels are then streamed to an end point.

With Unity’s 3D Data Streaming the client device intelligently fetches only the necessary portions of 3D assets, such as specific levels of detail, textures, or regions of a model required for the current view. Everything is handled automatically - no manual data prep is required.

Biopharmaceutical company AstraZeneca is using the technology to review a colossal factory model with 437 million polygons and 1.3 million parts in XR on an untethered Meta Quest 3 headset.

“It’s possible to zoom in, take a look at a specific detail, and data streaming will just load the high-quality version of this completely automatically,” says Nagel.

A TIME FOR REFLECTION

Back in 2019, Unity launched Unity Reflect, a commercial design-review tool for AEC built around Revit and other CAD/BIM applications such as Rhino and SketchUp.

What made Unity Reflect stand out was its unusually deep integration with Revit — deeper than the standard Revit API allowed — enabled through a close partnership with Autodesk. This meant BIM models could be synced in real time, complete with both geometry and metadata.

The product showed real promise, but development slowed, and Unity Reflect was eventually retired a few

years later. Even so, many of the design / review workflows it championed still live on.

Today, they continue through the Unity Industry Viewer Template, which helps users of Unity Industry build custom, cloud-connected collaborative viewers for exploring and sharing 3D models in real time. The template provides development teams with an optimised foundation for streaming assets directly from Asset Manager and enabling multi-user collaboration across desktop, mobile, and XR.

At the recent Unity Unite conference, Unity demonstrated how Asset Manager can serve as a collaborative hub for large AEC models, including those from Revit and Navisworks. The key takeaways: massive BIM datasets can be instantly shared with multiple stakeholders, streamed into a web browser for viewing and annotation on modest hardware, all while preserving access to the rich metadata normally locked inside the original authoring tools.

CONCLUSION

Unity’s latest initiatives with Unity Studio, Asset Manager, and its expanding automation pipeline signal a clear shift in how interactive 3D experiences can be conceived, created, and shared. By lowering the barrier to entry and streamlining access to data, Unity is opening the door for far more people to participate in building, or contributing to the development of, real-time 3D applications.

But accessibility alone won’t guarantee adoption. Unity still must overcome long-held perceptions. For many firms, game engines remain associated with complexity, specialist skills, and steep learning curves. In the AEC sector, Unity Reflect once provided an accessible on-ramp into deeper customisation; without it, Unity will need to work harder to show that its tools aren’t just for developers.

Pricing will also be a key factor. While final details have not been confirmed, Lash told DEVELOP3D that Unity Studio will cost significantly less than Unity Industry, which starts just under $5,000. The package will likely include the full Asset Manager capabilities, but only selected features of Asset Transformer.

Looking ahead, AI-powered capabilities such as dynamically generated logic could play a crucial role in simplifying customisation even more and further reducing the skill threshold. If Unity can pair these advances with clearer messaging and industry-specific guidance, it has a genuine opportunity to reshape how real-time 3D is adopted across manufacturing, automotive, and AEC — not just by experts, but by anyone with an idea worth exploring. www.unity.com/industry

‘‘ Unity Studio features a visual scripting system called Logic that lets users add behaviours and interactivity to an experience, instead of having to write code ’’

Unity Studio concept of a Human-Machine Interface (HMI) for a car that visualises the suspension travel of each tyre

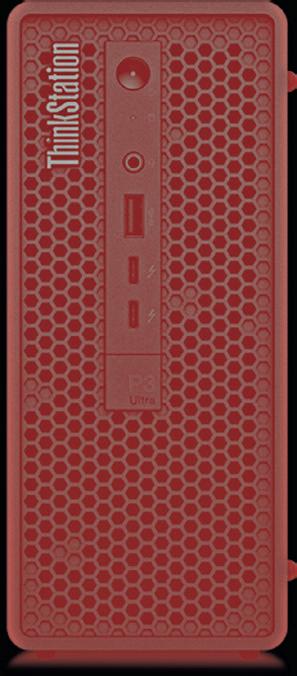

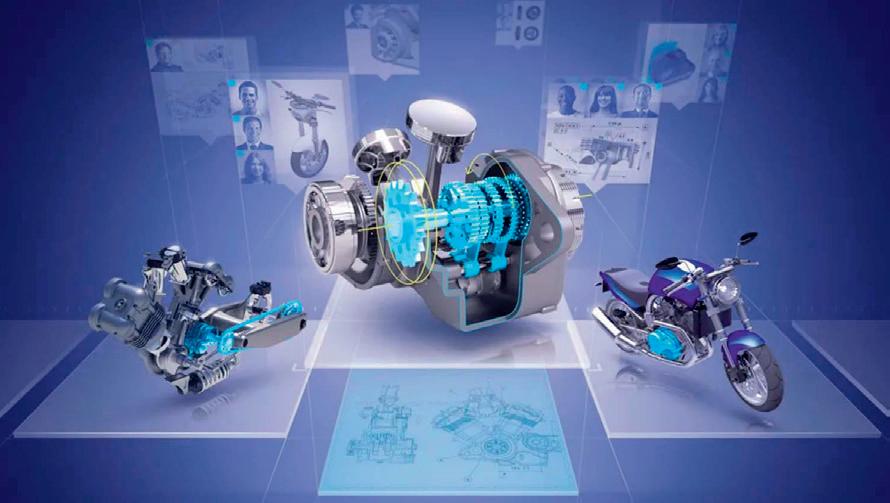

Q+A DESIGNCENTER SOLID EDGE 2026

» Changes are afoot in Siemens’ Designcenter ecosystem and Solid Edge has a new name – Designcenter Solid Edge 2026. We spoke to Dan Staples, VP of R&D for mainstream engineering, about the first release under the new title

Q: Siemens Digital Industries has been making some updates within Designcenter – can you tell us a bit more?

Dan Staples: Absolutely; Solid Edge has a new name –Designcenter Solid Edge 2026 – and that change signals something bigger. It’s now part of the Designcenter suite, which brings together NX and Solid Edge under one unified ecosystem.

This suite is built on our Parasolid kernel and is designed to deliver performance, flexibility and intelligent automation across the entire design process.

Q: What improvements has this new name brought with it?

Dan Staples: This year’s release is all about adapting to how engineers work today. Whether they’re on the desktop, in the cloud, or somewhere in between, Designcenter Solid Edge 2026 supports hybrid workflows that are fast, secure and collaborative.

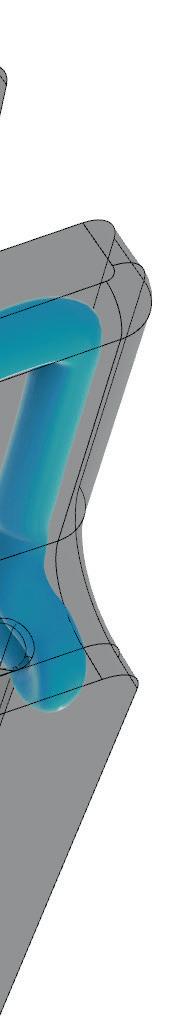

Dan Staples: For managing large assemblies, features like smarter display configurations, reusable exploded views and enhanced Part Copy streamline the process. Associative mirroring reduces rework and keeps everything aligned, while new configuration tools make it easier to toggle visual elements without altering geometry.

In manufacturing, we’ve added etching on bends and curves, automatic flange trimming and thin wall creation tools. These reduce manual steps and improve accuracy, making it easier for engineers to move from design to production. The Tab and Slot command also simplifies the creation of interlocking components, improving alignment and manufacturability.

Q: There’s also the new immersive Walkthrough command, how do you see that helping in a design workflow?

‘‘

AI is deeply embedded and it’s all about helping engineers work smarter, not harder. For example, Magnetic Snap Assembly uses AI to automatically detect and apply the correct constraints when placing components, making assembly up to nine times more efficient.

We’ve also introduced AI features like powered automatic drawing generation, automated revision tracking and a new Copilot that’s always available to answer questions and guide users in real time. The goal is to help maintain momentum without interruptions.

Dan Staples: Walkthrough lets the user move around a part or assembly like in a video game with a keyboard and mouse or Xbox controller. It’s perfect for design reviews and presentations, and the flythrough paths can be recorded for animations or exported to KeyShot for high-quality visuals.

Q: Which AI feature stands out to you the most?

Dan Staples: AI drawing automation is a game changer. It streamlines what has traditionally been a very manual process and is one of the most impactful AI features in Designcenter Solid Edge 2026.

This tool uses artificial intelligence to create 2D drawings that are already 70% to 80% complete as soon as the process begins. It intelligently places views, applies dimensions and selects templates based on design context and standards, significantly reducing set-up time. Engineers can still make adjustments, but the heavy lifting is already done, making documentation faster, more consistent and less tedious.

Even with the revision tracking – AI supports intelligent symbol placement and hole table generation – it’s not just automation. It’s guidance, precision and speed built into every step of the design process.

Q: What non-AI improvements have been added?

This means you can quickly create dynamic walkthroughs of your assemblies, helping colleagues or customers see your

This means you can quickly create dynamic walkthroughs of your assemblies, helping colleagues or customers see your work in action.

Q: Customisation and control were mentioned at launch a few times; which users

Q: Customisation and control were mentioned at launch a few times; which elements do you think users will appreciate most?

Dan Staples: From the new Dark Theme (which was a hit during beta testing) to cloud-synced preferences and flexible licensing, users now have more control over their workspace and tools than ever before.

This year’s release is all about adapting to how engineers work today, whether on the desktop, in the cloud, or somewhere in between Dan Staples ’’ animations

These preferences now follow users across devices via the cloud and the AI Copilot helps adjust settings on the fly.

Q: You mentioned flexible licensing, how is this evolving?

Q: You mentioned flexible licensing, how is this evolving?

with users’ needs, so instead of committing to every add-on up front, they can use tokens to

Dan Staples: With Value-Based Licensing, teams can unlock advanced capabilities using tokens, giving them fl exibility without long-term commitments. It’s a scalable toolkit that grows with users’ needs, so instead of committing to every add-on up front, they can use tokens to unlock advanced capabilities on demand.

Think of it as a flexible toolkit with the freedom to explore powerful options without a long-term commitment, all while keeping budgets predictable.

freedom to explore powerful options without a

www.sw.siemens.com

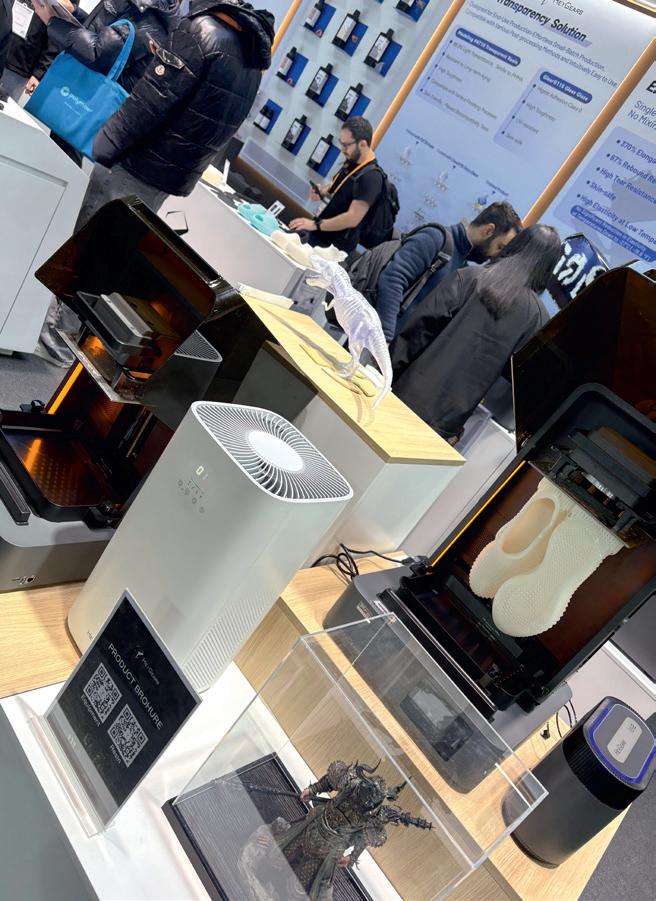

5 KEY TAKEAWAYS FROM FORMNEXT

» The highlights of this year’s edition of the world’s most important additive manufacturing tradeshow went way beyond the printers themselves, says Stephen Holmes, who braved the hustle and bustle of the November 2025 Frankfurt show in order to share his impressions with DEVELOP3D readers

1LET’S GET NICHE

Users need specific functions from their additive systems, and hardware suppliers have finally cottoned on to that fact.

Tailoring machines to application needs and materials is now the way to go.

At Formnext 2025, attendees were exposed to some excellent use cases focusing on specific materials and uses. Take, for example, a liquid silicone 3D printer from RLP (Rapid Liquid Print), which produces parts with overhangs and smooth surfaces from a tank of gel. As 3D printing increasingly shifts into the manufacturing of end-use parts, repeatability and qualification are becoming far more important. That, in turn, makes single-focus solutions more desirable over machines offering ‘jackof-all-trades’ flexibility.

2SMALL IS MIGHTY

There’s never been a better time to upgrade your workshop, with many brands now offering tidy, capable and cost-effective desktop equipment.

Bambu Labs arguably demonstrated the most electric presence across all four exhibition halls at Formnext. Its technicolour, double-decker stand was a hive of activity as makers, professionals and representatives of rival brands swung by to see what all the fuss was about.

Meanwhile, Fibreseeker was also attracting attention. Its desktop reimagining of Anisoprint’s continuous fibre 3D printing combined with its sub-$3k opening price is unlike anything we’ve seen before. Professionals should probably wait until production reaches some maturity and the company irons out any kinks, but there have been no shortage of people willing to throw money at the company’s crowdfunding campaign, which had topped $2 million at the time of writing.

● 1 Rapid Fusion’s LFAM Cerberus provides AM and CNC manufacturing capabilities in a shipping container

● 2 HeyGears had some interesting SLA technology and a wide range of materials on show at Formnext

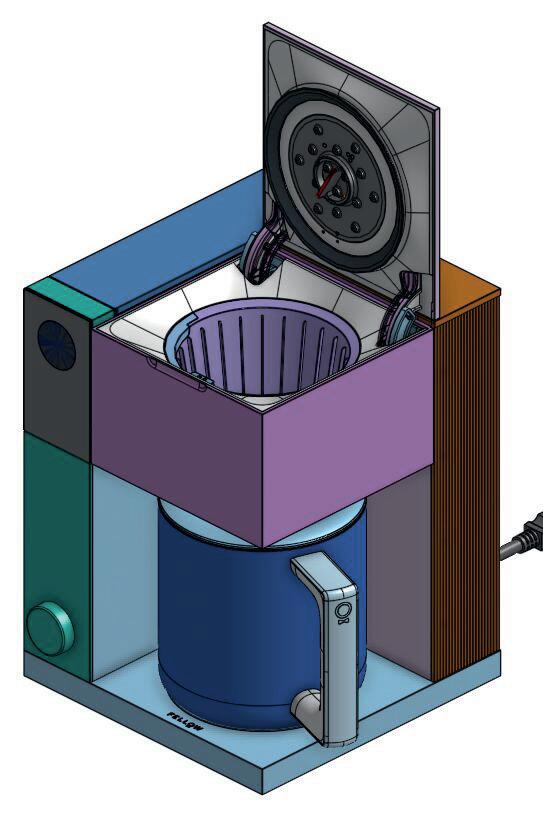

● 3 Genic’s software uses AI to automatically generate optimal conformal cooling channels for tooling

● 4 A catamaran built on an LFAM 3D printer drew many attendees to Caracol’s stand

●

5 The Nikon SLM NXG platform enables manufacturers to go big with metal 3D printing 1

Another eye-catcher was HeyGears, with its SLA technology and wide array of engineering materials (including some particularly nice clear resins and elastomers). This already looks like a solid option for users confident in taking a punt on SLA technology without local support.

Rapid Fusion, meanwhile, chose Formnext as the venue to unveil its military-focused LFAM Cerberus unit for containerised manufacturing, involving both AM and CNC methods. This supports distributed production out in the field, and in the harshest and most remote environments, with all the necessary kit neatly packaged into a standard shipping container and ready to print just 25 minutes after set-down.

Similarly, additive software companies are just as keenly aware that the one-size-fits-all solutions of the past often lack finesse. At Formnext 2025, Dyndrite and Materialise both announced dialled-in, system-specific build processors that offer customers better results straight off the printer. We can expect more targeted solutions like these in 2026 and beyond.

A key theme is that all three brands hail from Asia and are quickly making their mark in elsewhere in the world with their speed, quality and materials geared for product development.

There’s still hope for Western brands, though. The Formlabs and Prusa Research booths were thronged with attendees, looking to check out either Formlabs’ new Tough Materials or an eight-material, multitool upgrade to the Prusa Core One. But don’t be surprised if your next workshop 3D printer comes from a brand that doesn’t share the storied histories of these more familiar names.

3

SOFTWARE EASES ADOPTION

Dig past the hardware and there was plenty of software suppliers at Formnext, too, all eager to make an impact in the additive world. Designled tools like Nureo are looking to optimise industrial elements where AM can be used, such as conformal cooling channels in tooling and factory line cages that flip over products. Traditionally, these can be a pain to model and optimise, but Nureo can rapidly generate models that are ready to be printed and put to work on production lines.

Genic’s AI-generated conformal cooling software focuses on developing the best cooling channels for 3D-printed injection moulding tooling, boasting some impressive results for both reducing cooling times and reducing shrinkage, all with a few simple clicks, freeing up time for engineers to go and be more productive elsewhere.

4OLD DOGS HAVE NEW TRICKS

It’s a sign of a maturing industry that product roadmaps are settling down a little, with existing technologies receiving minor tweaks in the interests of productivity and betterquality end results.

This work is moving the industry away from the sci-fi wonder surrounding AM and closer to the heart of the matter: industrial equipment. Attendees got straightforward answers to questions like, “What does it cost?” That’s a big difference from previous years, where requests for even ballpark figures elicited evasive responses. On some stands, there were actual stats available, relating to machine and material CO2 footprints. Some vendors didn’t even bring machines. Carbon’s stand, for example, was singularly focused on real-life user applications that are already hard at work today, creating products that range from footwear to wheelchair covers. This highlights a growing awareness that AM is much more than just a machine and is best applied as part of a holistic solution.

Large-format additive manufacturing (LFAM) has fascinated me for years, but 2025 marked the point at which a growing number of established companies began to show off a more significant number and range of real-world applications. Full boat hulls, giant audio speakers and body panels for trains were all up for discussion, with brands like Caracol and Cead offering visitors the chance to literally climb aboard products built using their technology. Seeing massive robotic arms at work is no longer the novelty it once was, yet there were still plenty of eye-catching developments to see at Formnext, such as a bungalow-sized orange LFAM cell from Moi Composites that outputs continuous fibre thermoset composites. With new developments and applications continually emerging, there’s still plenty of ceiling for LFAM to grow into.

Renishaw’s RenAM 3D printers are a great example of how software upgrades are making tried-and-tested models more efficient, producing better quality output and improving uptime.

Renishaw’s new Libertas software improves surface finish and reduces the need for supports, while a new build processor developed with Materialise adds support for nTop implicit modelling and makes the platform attractive for new and existing customers alike.

5PRECISION COUNTS

There’s a battle underway in metals 3D printing and it’s a battle in which size very definitely matters. It’s all well and good to 3D print, in a single build, a massive rocket engine that contains multiple channels, vents, pipework and nozzles – but just how clean and fine are the details and how long does it take to produce?

Added smartness could be the answer, in the form of more lasers and sensors. These feature in monster machines like the BLT S1025 and the massive, high-throughput Nikon SLM NXG platform, but adding more melt points to build chambers can create issues. Either way, the company that can best balance high throughput and fine details without trade-offs stands to win big.