Mary C. Gannon • Editor-in-Chief

Mary C. Gannon • Editor-in-Chief

ANYONE THAT SAYS AMERICAN MANUFACTURING IS DEAD has not been paying attention. As a Greater Clevelander, I know well how many small, medium and large manufacturing facilities dot our landscape. The same goes for the entire country, really. The east and west coasts are home to high-tech advanced manufacturing, and you can’t drive through most cities in the Midwest without seeing hundreds of plants of some kind.

That being said, in the past 40 to 50 years, we’ve come to rely on a global supply chain and have outsourced a lot to far-flung countries because shipping and costs were affordable and easy. With so many concerns brought on by Covid-19 and tariffs, however, many manufacturers are looking to bring their production closer to their customers. So, what does this mean for American production?

According to a recent press release from AMT – The Association for Manufacturing Technology, U.S. manufacturing continues to grow stronger through new opportunities and technological innovations. AMT said that the 2025 USA Reshoring Survey, conducted among 500 U.S. manufacturers in collaboration with the Reshoring Initiative and Regions Recruiting, indicated that a larger and better-trained skilled workforce would motivate OEMs to reshore 30% of what they currently import — a greater motivator than lower taxes or tariffs, deregulation, or a decrease in value of the U.S. dollar.

The top three reasons given for reshoring were locating manufacturing near engineering (45%), reducing freight and duty costs (45%), and avoiding geopolitical risk (38%). Proximity to customer markets was the next most cited reason for reshoring (35%).

“The 2025 Reshoring Survey found that 43% of contract manufacturers have already reshored work for customers or are actively fulfilling reshoring orders, while another 16% are currently quoting reshoring projects,” said Harry Moser, founder and president of the Reshoring Initiative.

The survey results reveal that many manufacturers are considering the collaborative benefits of locating manufacturing near engineering and placing high value on the quicker delivery enabled by localization strategies.

It does seem this notion is true. I wrote earlier this month about ContiTech’s new hose manufacturing facility. Although not in the U.S., its location in Aquascalientes, Mexico was done for two main reasons: for access to a highly skilled workforce and to commit further to its mission of “in the region, for the region.” ContiTech also just announced plans to expand and update its Mount Pleasant, Iowa, facility as well, with expanded manufacturing operations which will strengthen production capabilities across its hose and belt businesses.

Likewise, Rockwell Automation just announced plans to build a new manufacturing site in Wisconsin. The project is part of a $2 billion investment in plants, digital infrastructure, and talent and has the potential to be Rockwell’s largest manufacturing campus globally. In a press release, the company said this move reinforces Rockwell’s long-term commitment to American manufacturing and to the skilled workforce that drives production and innovation. “It will integrate the latest in Rockwell’s production technologies, including AI and analytics tools, to increase efficiency and precision, while providing team members with access

to advanced tools and training. I’m excited to see our highly skilled workforce maximize the potential of this site,” said Bob Buttermore, chief supply chain officer at Rockwell Automation. “This investment reflects our confidence in our teams that deliver excellence every day.”

Many American companies are expanding their production capabilities to better meet the needs of customers within the region. For example, HydraForce can source hydraulic reservoirs locally and offer a custom solution with their in-stock valves for modular power pack units much faster than before, said David Kraft, marketing manager. Additionally, HydraForce has opened a new automated assembly and test line for compact hydraulics in Lincolnshire, Ill., to custom design systems rather than simply import them. The company has basically localized everything except for electronic systems and is assembling, building, machining, and testing locally.

These are just three examples of companies investing back into North American manufacturing, and there’s more like them every day. But as noted above, the people building the products, running the machines, and designing the systems are critical. We need to keep investing in a skilled American workforce, both on the engineering and manufacturing side. FPW

Mary C. Gannon • Editor-in-Chief mgannon@wtwhmedia.com linkedin.com/in/marygannonramsak

Persevering against the odds: how Rachel Granville found her place in engineering

Electrical controls engineer Rachel Granville is helping shape the future of Alkon’s manufacturing processes.

Industrial decarbonization with digital hydraulics

Improved hydraulic system efficiency and emissions reductions come with new digital technologies.

Learn the basics of industrial fluid power maintenance

Daily, weekly, and monthly checklists are crucial to maintenance programs.

EDITORIAL

VP, Editorial Director

Paul J. Heney pheney@wtwhmedia.com

Editor-in-Chief

Mary Gannon mgannon@wtwhmedia.com

Technology Editor Ken Korane kkorane@wtwhmedia.com

Senior Editor

Rachael Pasini rpasini@wtwhmedia.com

Contributing Editor Josh Cosford

Contributing Editor Carl Dyke

Contributing Writer Robert Sheaf rjsheaf@cfc-solar.com

www.nfpa.com

VP, Creative Services

Matthew Claney mclaney@wtwhmedia.com

Art Director, FPW

Erica Naftolowitz enaftolowitz@wtwhmedia.com

Art Director, FPW Digital Eric Summers esummers@wtwhmedia.com

Director, Audience Growth

Rick Ellis rellis@wtwhmedia.com

Audience Growth Manager Angela Tanner atanner@wtwhmedia.com

PRODUCTION SERVICES

Customer Service Manager Stephanie Hulett shulett@wtwhmedia.com

Customer Service Representative Tracy Powers tpowers@wtwhmedia.com

Customer Service Representative JoAnn Martin jmartin@wtwhmedia.com

Customer Service Representative Renee Massey-Linston renee@wtwhmedia.com

Customer Service Representative Trinidy Longgood tlonggood@wtwhmedia.com

Ph: 888.543.2447 • Fax: 888.543.2447

FLUID POWER WORLD does not pass judgment on subjects of controversy nor enter into dispute with or between any individuals or organizations. FLUID POWER WORLD is also an independent forum for the expression of opinions relevant to industry issues. Letters to the editor and by-lined articles express the views of the author and not necessarily of the publisher or the publication. Every effort is made to provide accurate information; however, publisher assumes no responsibility for accuracy of submitted advertising and editorial information. Non-commissioned articles and news releases cannot be acknowledged. Unsolicited materials cannot be returned nor will this organization assume responsibility for their care.

FLUID POWER WORLD does not endorse any products, programs or services of advertisers or editorial contributors. Copyright© 2025 by WTWH Media, LLC. No part of this publication may be reproduced in any form or by any means, electronic or mechanical, or by recording, or by any information storage or retrieval system, without written permission from the publisher.

VP, Operations

Virginia Goulding vgoulding@wtwhmedia.com

Digital Marketing Manager Taylor Meade tmeade@wtwhmedia.com

SALES

Ryan Ashdown 216-316-6691 rashdown@wtwhmedia.com

Jami Brownlee 224.760.1055 jbrownlee@wtwhmedia.com

Mary Ann Cooke 781.710.4659 mcooke@wtwhmedia.com

Jim Powers 312.925.7793 jpowers@wtwhmedia.com

Judy Pinsel 630.538.2638 jpinsel@wtwhmedia.com

LEADERSHIP

CEO Matt Logan mlogan@wtwhmedia.com

Co-Founders Scott McCafferty Mike Emich

SUBSCRIPTION RATES: Free and controlled circulation to qualified subscribers. Nonqualified persons may subscribe at the following rates: U.S. and possessions: 1 year: $125; 2 years: $200; 3 years: $275; Canadian and foreign, 1 year: $195; only US funds are accepted. Single copies $15 each. Subscriptions are prepaid, and check or money orders only.

SUBSCRIBER SERVICES: To order a subscription please visit our web site at www.fluidpowerworld.com

FLUID POWER WORLD (ISSN 2375-3641) is published six times a year: in February, April, June, August, October, and December by WTWH Media, LLC; 1111 Superior Ave., Suite 2600, Cleveland, Ohio 44114. Periodicals postage paid at Cleveland, OH & additional mailing offices.

POSTMASTER: Send address changes to: Fluid Power World, 1111 Superior Ave., Suite 2600, Cleveland, OH 44114

Josh Cosford • Contributing Editor

THANKSGIVING IS OVER, and now we're in that weird pocket of reduced productivity until January, when we've finally digested six weeks' worth of holiday feast. Sure, we get by and look busy, which explains why I get more walk-in cold calls during this period than the rest of the year combined. It’s not that I don’t appreciate the poinsettias and butter cookies, but I’ve got stuff to do before our Christmas shutdown, so maybe read the room and see yourself out after my sixth deadpan response of, "Oh wow … crazy."

Productivity is essential; we all chase our profitability growth targets to convince corporate stakeholders to keep those Christmas bonuses flowing, and to procrastinate one more year on our artificial intelligence Kaisan event. Indeed, the promise of shorter workweeks resulting from increased productivity has always been the carrot on a stick promised to workers for the adoption of production lines, automation, computers, and now, artificial intelligence.

I don't know about you, but I'm writing this in my office on a Friday, and I don't have the following Monday off. So, is AI really the answer this time or just another broken promise? If you listen to the doomsayers, it appears you're going to get that extra time off work, but not in the way you hoped. I'm sure you've seen or heard some of the modelling data from McKinsey & Company predicting that 30% of all current work could be automated by 2030, with a further 5% of jobs being replaced by AI altogether.

I don’t know about you, but I’m just not buying it. I’ve been around factories, machinery, automation, Industry 4.0, and the talk of the promised land for a long time, and the roadblocks aren't what you think they are. The technology exists, yes, and some companies are bet-

FIGURE 1

ter at adopting automation and AI than others. The problem is that many experts forget that 98% of businesses and corporations are "small," and that nearly 50% of the workforce receives pay stubs from them.

Small factories, fluid power distributors, hose shops, and service outfits don't just lack the knowledge to implement AI; they also lack the financial resources to undertake grand projects in which robots build, maintain, and configure flexible workstations or machinery. The time and money redirected from management and operational cash flow would bury the company before any such AI advantage was realized.

Sure, mega-cap companies like Amazon and Apple can afford the entire departments required to implement these cutting-edge technologies, and that’s perfectly fine, because we’re happy to get our protein powder delivered for free on a Sunday through our Prime

membership. But when your best customer comes in with a goofy hose and fitting, how will AI help you find that old adapter we had sitting on the test stand that will get said customer out of a jam?

What McKinsey et al forget is how much humans like doing human things. We like faceto-face meetings, solving problems, helping others and feeling valued. When a small business owner is pressed with taking out a $250k business loan so AI and automation can replace one human, it's not much of a business case unless the ROI is clear. And that's the problem – it's not. Just like Big Data, artificial intelligence has, so far, been little more than a party trick to replace your Google search. To prove my point, look at my actual ChatGPT chats from just the past few days (Figure 1), which I’m not embarrassed to share.

I'm not so short-sighted as to believe AI won't replace many jobs with information technology or art, which we already know it has. I'm trying to convince my son to ditch his aspirations as a computer animator, and you definitely don’t want to start that paralegal career. But we've still got 30 years before an Optimus robot will be good enough to build a hydraulic power unit. So stop doomscrolling, book those Christmas luncheons and enjoy work and life like you have for the past three decades. FPW

Josh Cosford • Contributing Editor jcosford@higginson.ca linkedin.com/in/joshcosford

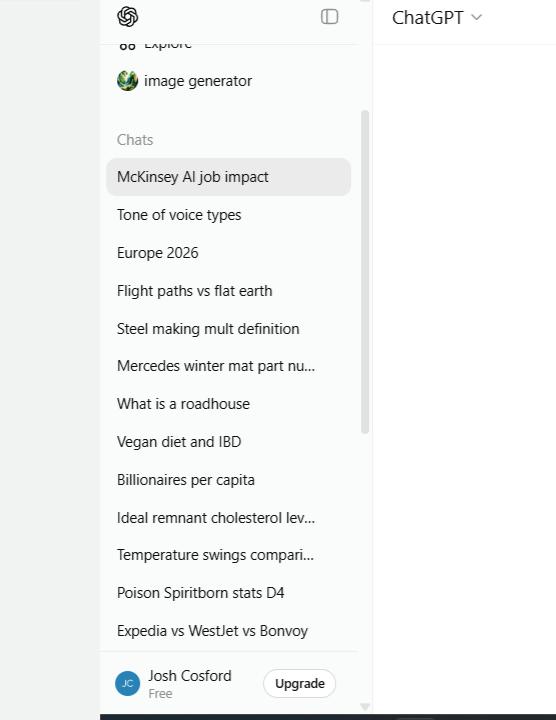

MOST OF THE ARTICLES I WRITE are assigned to me by super-editor Mary Gannon, and this article on strain gauges is no different. Oddly enough, I helped our Amtec Hydraclamp division technician assemble and test high-pressure spring clamps just yesterday, which we tested using a strain gauge. These clamps are 5, 10 and 15-tonne (yes, metric tonnes, not imperial tons) spring clamps and hydraulic release devices used to tension bolts for various applications. These clamps use disc springs so powerful that 450 bar (6,500 psi) is required to release clamping tension.

Without a strain gauge to help us adjust the preload of the retainer cap, we'd have no idea what the actual clamping output is, which would be unsafe for our customer's application should the force be inadequate. As the term implies, these sensors measure the strain applied to a given material. Strain gauges use a conducting material such as thin wire or foil applied to a flexible membrane and arranged in a grid pattern.

As the conducting material stretches or compresses, its electrical resistance changes and does so proportionally to the deformation of the material. The resulting change in resistance is measured, processed and interpreted into a force or pressure measurement, such as pounds or newtons. Strain gauge sensors must be calibrated because there is no direct and linear conversion between unrelated units such as Ohms and physical force.

There is also an intermediate circuit between the strain gauge and the electrical output, which is the interestingly named Wheatstone bridge. Named from — and I can't make this up — Sir Charles Wheatstone, who improved and promoted an existing concept. It consists of a quadrant of resistors wired in a series-parallel bridge circuit that improves the sensitivity and accuracy of the strain gauge.

Finally, the bridge output is amplified and converted into a voltage, current, or digital sig-

nal that represents the force or hydraulic pressure in the sensor. Strain gauges are used in load cells, like my above example, but also in most hydraulic transducers, so an industry standard output signal is typically 0-5 V, 0-10 V, 4-20 mA or some form of digital signal transmitting within a network.

Strain gauges are also used to measure torque, where simply being placed upon a shaft is sensitive enough to measure how much the shaft deforms under torque. Even the strongest forged steel twists helically as torque is applied, so sensors added to the shafts of pumps or

motors (or intermediate devices) can detect torque spikes or measure actual motor output. Strain gauges play a crucial role in fluid power systems by providing accurate and realtime measurements of pressure and force. Their integration into pressure transducers, load cells, and torque measurement systems enhances operational safety, efficiency, and longevity. By leveraging strain gauge technology, engineers can optimize system performance while helping to diagnose any potential cause of failure. And before you ask, manufacturers produce load cells with outputs in both tonnes and tons. FPW

By Mary C. Gannon • Editor-in-Chief

Editor’s Note: This article originally ran in our August 2025 issue, but critical details were omitted. We are running this article again with additional information about Innas’ modern transformer technology.

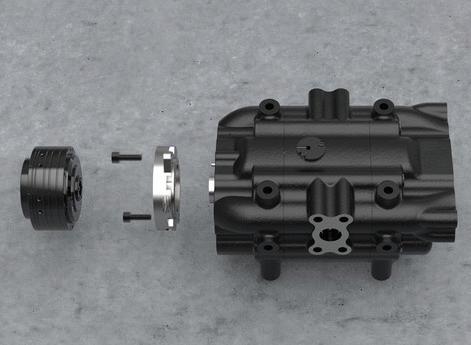

Peter Achten, CEO of Innas BV, had the idea for a hydraulic transformer but the concept didn't take off because hydraulic pumps of the day could not work with the technology.

The concept has now gained real traction with the development of the Innas’ floating cup displacement principle, which now serves as the foundation for both high-efficiency pumps and motors, as well as Innas’s new generation of hydraulic transformers.

The Floating Cup principle features cup-like cylinders which are carried and supported by a rotating barrel plate. The cups are hydrostatically balanced: they ‘float’ on the barrel plate. Each cup is paired with a piston having a ball shaped piston crown. The piston crown has a cavity. The dimensions of the cavity are chosen so that the expansion of the piston crown equals the expansion of the cup.

The ball-shaped piston crown has the same outer diameter as the inner cylinder of the cup. The resulting sealing line is always perpendicular to the main axis of the cup, irrespective of the tilt position of the piston. Consequently, the radial pressure load on the cup is equal in all directions. The cup is therefore completely balanced and does not create a hydrostatic load on the piston, which minimizes friction and wear.

The cups are floating, but the pistons have no chance to move. They are press fitted into the rotor, onto the main shaft. The oil column creates a hydrostatic force on the piston, having the same tilted position as the cup. The shaft torque is created by the radial components of these piston forces. The conversion of hydraulic power to mechanical output power is direct:

there are no moving interfaces or linkages. As a result, there are also no principle losses.

Now that the floating cup concept is proven for hydraulic pumps, the company has now made its hydraulic transformer available, highlighting it at bauma 2025 in Munich, primarily for autonomous machines.

“The transformer was always the goal,” said Achten, “but the industry wasn't ready. We had to first introduce a new displacement principle.

“When you want to control a cylinder, it is moving back and forth, and it stops and goes, stops and goes. And when it moves, it often moves with maximum load, you want to use a displacement principle like a pump or transformer to move this cylinder. Ideally, this pump should be running at zero rpm to start with the maximum load. And no pump principle could do this at the moment. When we designed the transformer in 1996 and built one, I knew

that we had to design a new principle and that became the floating cup.”

Achten said that with the hydraulic industry being so conservative, taking a completely new approach can be challenging. Thus, they first had to develop the floating cup principle up to a point where it was brought into the market, and now that is up and running, it was time to return to the transformer design.

“Now we have a transformer which can be operated with speed at a very high efficiency, with low positions, low noise levels, and can handle these high pressures of startup conditions without any problems. We built this into an application at a field test run, and now we're going to move into a very interesting domain of autonomous control,” Achten said.

Traditional combined hydraulic transformers (CHTs) paired two pump/motors. These designs, dating back to the 1970s and 1980s, rely on

mechanically coupled hydrostatic units to convert and control hydraulic power. Typically, one unit is variable and the other fixed, with pressure and flow ratios determined by their respective displacements. These systems tend to be difficult to control, bulky, inefficient, and mechanically complex. They require multiple rotating groups, complex valve coordination, and cannot achieve truly continuous variability. Because each pump/ motor contributes its own inefficiencies, the overall system efficiency is low, compounded further during regenerative operation. CHTs also struggle with compactness and smooth operation at low speeds, limiting their practical adoption despite their potential energy-saving promise.

Innas’s new IHT design replaces these dual-unit arrangements with a single, three-port rotating group. Instead of varying the swash plate angle to control displacement, the IHT varies the angular position of a rotating port plate. This changes the timing of the high-, low-, and loadpressure ports relative to the piston motion, continuously adjusting the effective displacement without altering geometry. The result is a compact, continuously variable transformer capable of both transforming and regenerating energy across the full pressure range of a Common Pressure Rail (CPR) system. The IHT can achieve the same transformation ratios as a dual-unit CHT while using roughly half the total displacement. When paired with Innas’ floating cup principle, it maintains high efficiency, smooth low-speed operation, and reduced noise and vibration — addressing key shortcomings of previous transformer designs. Achten noted that the IHT simplifies hydraulic transformation from a mechanically coupled dual-machine system into an elegant, single-unit device optimized for modern CPR-based hydraulics.

Traditional hydraulic systems often waste significant energy due to throttling losses in valves, unnecessary fluid recirculation, and poor load matching. The hydraulic transformer addresses these inefficiencies. Because it is a closed-loop system, the transformer minimizes throttling and bypass losses common in open-circuit valve systems. Additionally, with adaptive lead matching, the system continuously adjusts output

pressure and flow to meet real-time load demands, improving energy utilization. And finally, it has regenerative capability. Overrunning loads can drive the transformer in reverse, recovering energy and feeding it back into the primary circuit or into an accumulator for reuse.

In lab and simulation tests, Innas reports overall system efficiency gains of up to 50% when replacing conventional valve-controlled systems with transformer-based architectures.

Innas’ hydraulic transformer is compatible with many digital control architectures, such as electronic swashplate control, sensor-driven feedback loops, and programmable logic integration.

These capabilities make the hydraulic transformer suited for modern applications demanding high performance, precision, and energy efficiency such as mobile off-highway machinery, industrial automation, and hybrid and electric drives.

With the transformer, Achten says it gives machine builders a retrofit or quick-change system to move from an internal combustion enginedriven pump to an electric-driven easily and even at the last minute. Because everything is connected, you cannot just take away one component because those structures would fall apart. What Innas has to offer is a system to deliver energy and low emissions with the highest efficiency and the lowest cost.

“We’ve opened hydraulics to a new world. We are running into a world where we have been limited by our technology for a number of decades and we have failed to innovate to a large extent,” Achten said. “What we're trying to do is move hydraulics in the same direction as what electric drives have been doing for many years already. We’re creating smart hydraulics, and extremely efficient for our customers and our industry.”

Innas BV innas.com

Ron Marshall • Contributing Editor

A

, was used to solving problems. But this summer, his compressed air system was giving him a run for his money. Temperatures in the compressor room were soaring. Alarms were sounding. One of the rotary screw compressors had already shut down twice due to high temperature. Production was stalling, tools were sluggish, and downtime was starting to bite into the bottom line.

Chuck had his maintenance team clean filters and check oil levels, but the problems persisted. He knew this wasn’t just a maintenance issue — it was a system issue.

That’s when he decided to call in a compressed air auditor.

The auditor arrived quietly, tools in hand, and began the inspection with a walkthrough of the compressor room. Almost immediately, the issue became clear: ambient temperatures inside the room were topping 95° F, and the compressors were pulling in their own hot exhaust air, a recipe for overheating.

“These machines are designed to run with internal temperatures up to 220° F,” the auditor explained. “But when they’re ingesting hot, recirculated air, they can’t cool themselves. Eventually, they shut down to protect from damage.”

With Chuck’s approval, the auditor developed a focused plan. The team cleaned the oil coolers and replaced the air filters and separators. The compressor oil, an off-brand blend, was swapped out for the manufacturer’s specified lubricant that could withstand high thermal stress without breaking down.

Ventilation was next. The auditor used smoke sticks and temperature probes to show how hot discharge air was being pulled back into the intake. Chuck hadn’t realized how much this was sabotaging his system. They rerouted the exhaust air outdoors and installed ducting and fans to bring in cooler outside air. The dryer system also needed attention. The

existing unit couldn’t handle the higher inlet temperatures caused by the heat. A properly sized dryer was installed to ensure consistent dew points and protect downstream equipment.

Finally, the auditor left Chuck with a simple preventive maintenance plan: clean and inspect coolers in spring, change oil and filters regularly, sample for oil quality, and check airflow paths for blockages.

Within a few days, the transformation was obvious.

The compressors stopped tripping, discharge temperatures stabilized, and production returned to normal. Energy consumption even dipped slightly, thanks to the improved cool-

ing and airflow. Chuck felt like he’d regained control.

Standing in the now-cooler compressor room, Chuck shook his head and smiled. “Sometimes you need a fresh pair of eyes,” he said to his lead technician. “I should’ve called in help weeks ago.”

The lesson? Even experienced plant managers like Chuck benefit from bringing in a compressed air auditor when system problems go beyond the basics. With the right insights, a few practical fixes can prevent costly shutdowns, boost efficiency, and keep operations humming — even in the heat of summer. FPW

By Micah Statler • Director of Industrial Technologies, Advanced Technology Services

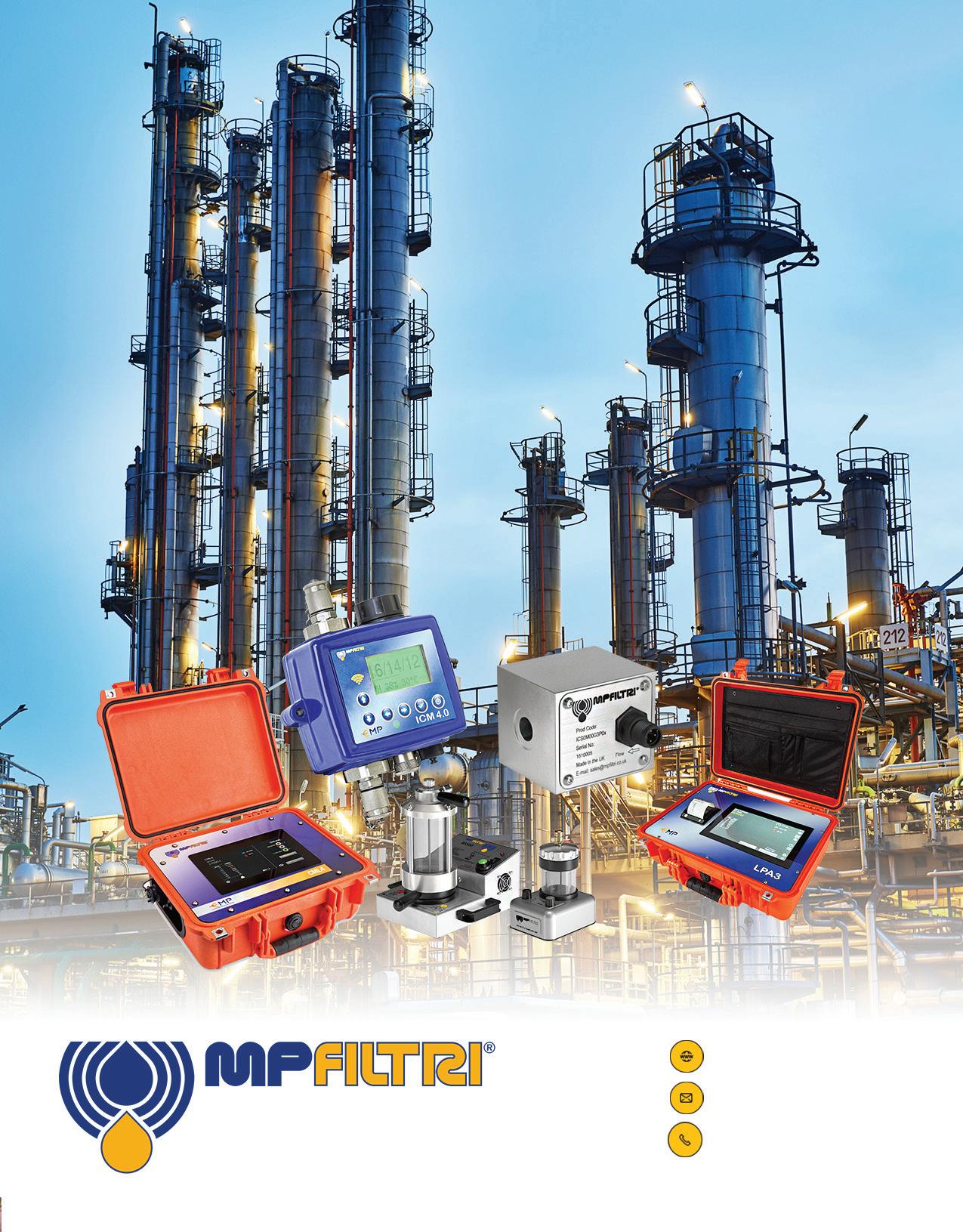

manufacturing and heavy industries, the fusion of traditional hydraulics with advanced digital technologies is redefining what’s possible in industrial automation. Smart hydraulics — systems augmented with sensors, IoT connectivity, and predictive analytics — are emerging as vital components for modern, data-driven operations. These intelligent systems promise improved performance, minimized downtime, and significant gains in operational efficiency across diverse industrial applications. Hydraulics have long been a cornerstone

of heavy machinery and industrial equipment, providing unmatched power density and precision control in applications ranging from metal stamping to injection molding. But traditional hydraulic systems often face challenges like energy inefficiency, unplanned maintenance, and limited adaptability.

Industry 4.0, characterized by interconnected systems, real-time data sharing, and advanced automation, is transforming these limitations into opportunities. By embedding smart technologies into hydraulic systems, manufacturers can now achieve levels

of responsiveness and efficiency that were previously unattainable.

At the heart of smart hydraulics lies the integration of sensors and IoT-enabled components. Pressure transducers, temperature sensors, flow meters, and position sensors continuously monitor system performance and send real-time data to centralized control systems.

This connectivity allows operators to:

• Track critical parameters like oil temperature, fluid levels, and pressure fluctuations.

• Detect anomalies early to avoid catastrophic failures.

• Adjust performance dynamically based on load conditions or production requirements.

For example, IoT-enabled hydraulic presses can automatically adapt to varying workloads, improving cycle times and reducing energy waste. In mobile applications, such as construction or mining equipment, intelligent hydraulics can optimize performance in changing environments, extending machine life and increasing productivity.

One of the most powerful advantages of smart hydraulics is predictive maintenance. Traditional maintenance schedules rely on fixed intervals or reactive servicing after failures occur, often leading to unnecessary downtime or costly repairs.

Predictive maintenance uses data analytics and machine learning algorithms to anticipate potential issues before they escalate. Key benefits include:

• Minimized downtime: Early detection of wear in hydraulic pumps, valves, or actuators allows for planned servicing during scheduled downtime.

• Extended equipment life: Monitoring oil contamination or temperature spikes prevents long-term damage to sensitive components.

• Cost savings: Companies avoid the high costs associated with emergency repairs and lost production time.

Traditional hydraulic systems are notorious for energy losses, especially in applications with highly variable load requirements. Intelligent systems address this through features like variable speed pump drives and load-sensing controls.

Smart hydraulics can automatically adjust flow and pressure based on real-time demand, ensuring energy is only used where and when it’s needed. This not only improves system efficiency but also supports sustainability goals by reducing overall power consumption and CO₂ emissions.

Additionally, advanced control algorithms allow for smoother, more precise motion control — critical for industries like robotics, aerospace, and automotive manufacturing where accuracy is paramount.

Smart hydraulic technologies are finding applications across a wide range of industries:

• Manufacturing : Intelligent hydraulic presses optimize force application for metal

forming, reducing waste and improving quality control.

• Construction: Connected hydraulic systems in excavators and loaders enable real-time performance monitoring and remote diagnostics, keeping machines operational longer in demanding environments.

• Agriculture: Precision farming equipment benefits from intelligent hydraulics that deliver just the right amount of power for planting, harvesting, and soil preparation.

• Energy Sector: Offshore drilling platforms and wind turbines use smart hydraulics to monitor and maintain critical systems under harsh conditions.

As the industrial landscape evolves, the shift to smart hydraulic systems isn’t just a trend — it’s a necessity. Manufacturers are under increasing pressure to improve uptime, reduce costs, and deliver sustainable solutions. Intelligent hydraulics address all three, offering a path to more resilient and adaptable operations.

Moreover, the ability to integrate these systems with existing digital infrastructures means companies can leverage the full potential of Industry 4.0 without overhauling their entire machinery fleets.

Smart hydraulics represent the next evolutionary step in industrial automation. By combining the raw power of traditional hydraulic systems with advanced sensors, IoT connectivity, and predictive analytics, industries can unlock new levels of efficiency, reliability, and performance.

In a world where downtime is costly and sustainability is critical, intelligent hydraulic systems aren’t just an upgrade — they’re a game changer. For companies ready to embrace Industry 4.0, investing in smart hydraulics is a strategic move toward a smarter, greener, and more productive future. FPW

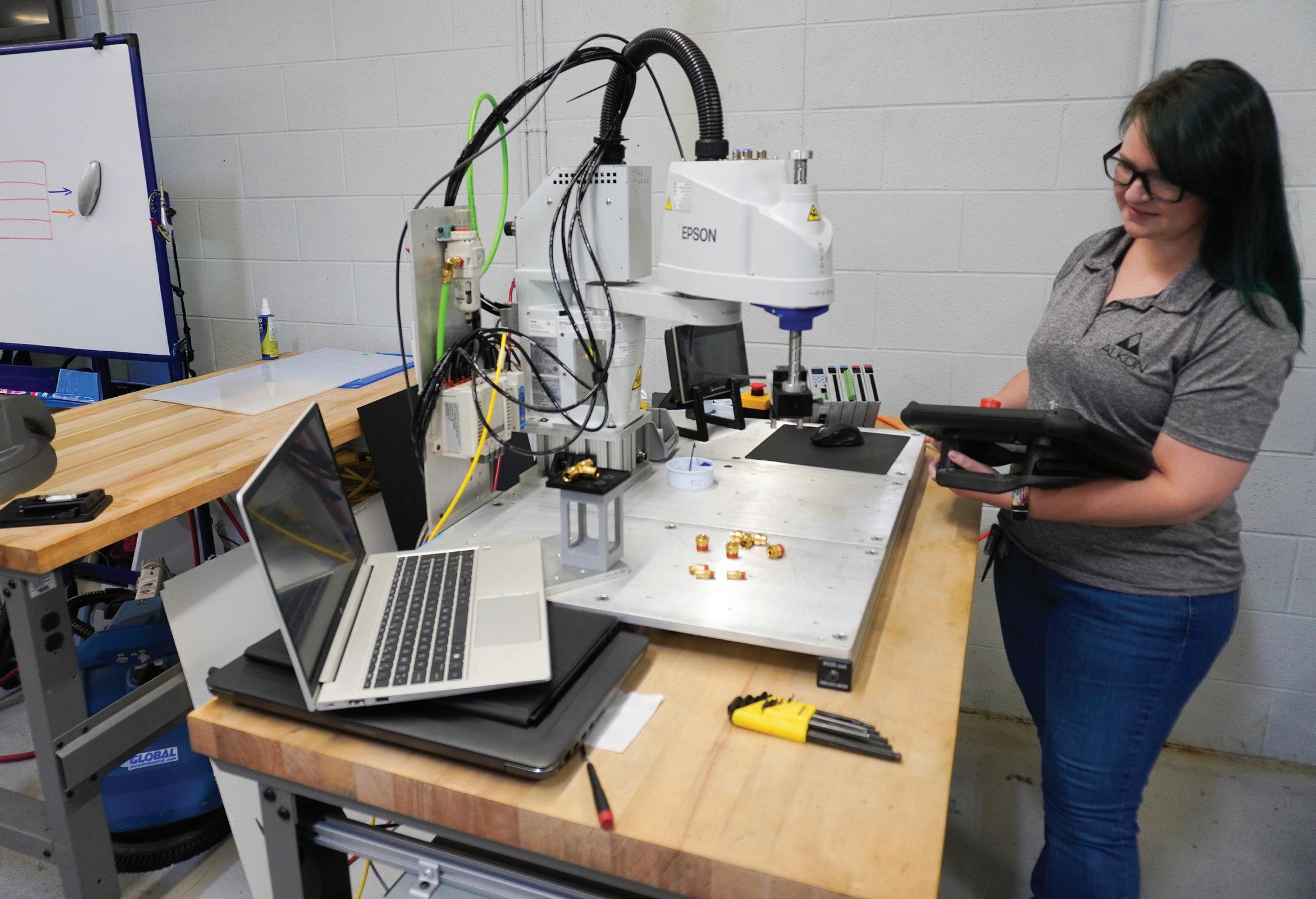

Electrical controls engineer Rachel Granville was discouraged from her engineering degree at the start of her college years, but now she’s helping shape the future of Alkon Corp.’s manufacturing processes.

By Mary C. Gannon, Editor-in-Chief

Rachel Granville was told by more than one professor that she didn’t belong in their classrooms while she pursued her degree in engineering at the University of Toledo. She was among a handful of young women in the freshman class who entered the computer science engineering program. By the time graduation rolled around, she was just one of two women engineers from that group.

“I grew up in rural Ohio. I decided to go to engineering school about four hours away from where I grew up. And when I say rural Ohio, I mean rural Ohio,” she said. “Along the way, you are met with teachers and even classmates that don't think you belong there, and unfortunately, we're in a time and place where they will speak out about that. I've had teachers tell me I don't belong in their classroom, and thankfully, I was able to persevere. I still met some wonderful people along the way.”

Granville had followed in her older brother’s footsteps, who graduated with a mechanical engineering degree just as she was entering college as a computer science engineering student. She entered computer science engineering because she wanted to be on the programming side of things but soon realized she wanted to see the tangible output of her work, so switched to electrical engineering, where she could have the best of both worlds.

“I like to see things with my hands, watch them work, and switching from computer science to electrical allows me to see the programming actually kind of happen. I do robot PLC and HMR programming, along with machinery design,” she said.

Before she switched to electrical engineering, she was questioning whether engineering was the right choice for her but her mentor at her co-op helped guide her.

Despite this discouragement, Granville attributes her co-op program through the University of Toledo with the reason she followed through on her dream. “The co-op is without a doubt, what's making engineers, engineers. Those three semesters of required internships give so much practical knowledge of how the real world works. You're given the fundamentals of engineering whenever you go to engineering school, but those co-ops allow you to mold yourself into what kind of engineer you want to be.”

She also met her now-husband at the time, and he, as well as her family back home, continued to encourage her path. “My husband, my family and friends, and my mentors that I met through my first internship, really are who pushed me to be like, yes, this is what I want to do with my life. I have a passion for this. I want to continue with it,” she said.

The University of Toledo’s engineering degree is a five-year program due to three

semester co-op requirements. But Granville participated in a fourth co-op, which led to her first job after graduation. She worked there for six years, and then after some management changes, went on a job hunt. That’s when she landed at Alkon, where she had the opportunity to work on both older and newer technologies.

“Alkon was looking to bring someone in house that had machinery knowledge and was willing to take on the task of not only designing new machines but dealing with some older machines as well. Outdated equipment is everywhere,” she said. “The fact that they were ready to tackle new projects and upgrade equipment and then use my troubleshooting skills to upgrade existing older equipment was kind of a good sign that Alkon was the place for me to be.”

Granville has been the lead engineer helping to upgrade existing machinery and move Alkon along in its automation projects. She primarily works on the systems that machine and assemble Alkon’s fittings, valves, cylinders, and other products. She also is designing more automated testing systems. “We have certain standards that different products must meet,” she said. “We have been pushing more towards automating some of those tests and then inline assembly testing to make sure all components are damage-free. In the process, we've upgraded some existing machines with vision systems that take pictures of every part and verify quality.

“We are also designing new machines, whether we're going to end up making those machines in house and using our mechanical engineer and our maintenance guys to build the machines, or working with an outside company. We're constantly testing and verifying new methods of assembling these parts,” she continued. “Then we also conduct a lot of 3D printing to verify different fixturing and tooling. I've kind of became the keeper of the 3D printer. We use it to test out different fixturing before we put it in a process, so that we know by the time it makes it into a machine that it's verified and it's going to work, which will save us downtime.”

Granville has been with Alkon for about

GRANVILLE WORKS ON ALKON'S ENGINEERING SANDBOX TEST STATION. HERE SHE TESTS A NEW GRIPPING TECHNOLOGY WITH ITS CURRENT ROBOT, TO TEST DIFFERENT 3D PRINTED GRIPPERS WITH DIFFERENT SIZED PARTS.

four-and-half-years and is grateful for the diversity at the company. Although she’s the only female engineer there, women hold roles in operations management, as supervisors, and elsewhere throughout the company. “Women are in every step of the ladder here at Alkon, and seeing that, being emboldened by that, has been great. It can be daunting coming into a building, especially whenever you're new, to earn respect. It has been fabulous at Alkon.”

Being in a more rural area means that there aren’t many opportunities to mentor young women interested in engineering, she said, but Alkon does offer a co-op program. “We have had several co-op students along the way. I have had a couple who I've worked to ensure that they are seeing all sides of what engineering is going to be like in the real world,” she said. “They're given projects. They're able to stray away from those projects and learn about other proj-

ects that are going on, even if it might not be their projects. We really encourage the curiosity of learning.”

She noted that as we move into a more digital world, many people assume anything automated is done with AI. “But as we grow and as we progress in technology, you must have the knowledge to keep up with the old technology, too,” she said. “We are seeing a bigger decline of people not understanding or realizing that older machinery exists and that there is specialty knowledge that's needed to keep up with those machines.”

She added that she still doesn’t think the number of young women pursuing engineering is where it should be but there seems to be a shift in growth. “I think the biggest change has actually been the

switch from STEM to STEAM. It’s a phenomenal thing in my book, adding the arts in there. I know there are a lot of people who feel as though the arts aren't part of engineering, but really it is.

“Having gone through engineering school, I feel like there is an engineering career for anybody, especially if you have that creative side in you. For example, looking from a machine from the outside in, you have to get creative and think what design aspects are needed to make this machine work,” she said.

“But in reality, we don't even think about things like how the screen interface is going to work with operators being colorblind for example. Being inclusive on touchscreens that use physical buttons, making sure fonts and colors are easily seen — this is something that's lacking in a lot of the engineering world. Bringing that creative aspect into it is what helps with inclusivity within the engineering world.

“I myself am an avid crafter,” Granville concluded. “You don't realize how many artsy things go into the engineering side of things, but then when you really look at it, the people who are doing knitting design, crochet design, sewing designs, they're all engineers at heart as well. They are using all of the same tools that an engineer would use to create these very creative works of art.” FPW

With new components, systems, and architectures, hydraulic system efficiency can be increased by 50%, with a one-third reduction in emissions as well.

By Alessandro Carmona, President, Industrial division, Danfoss Power Solutions

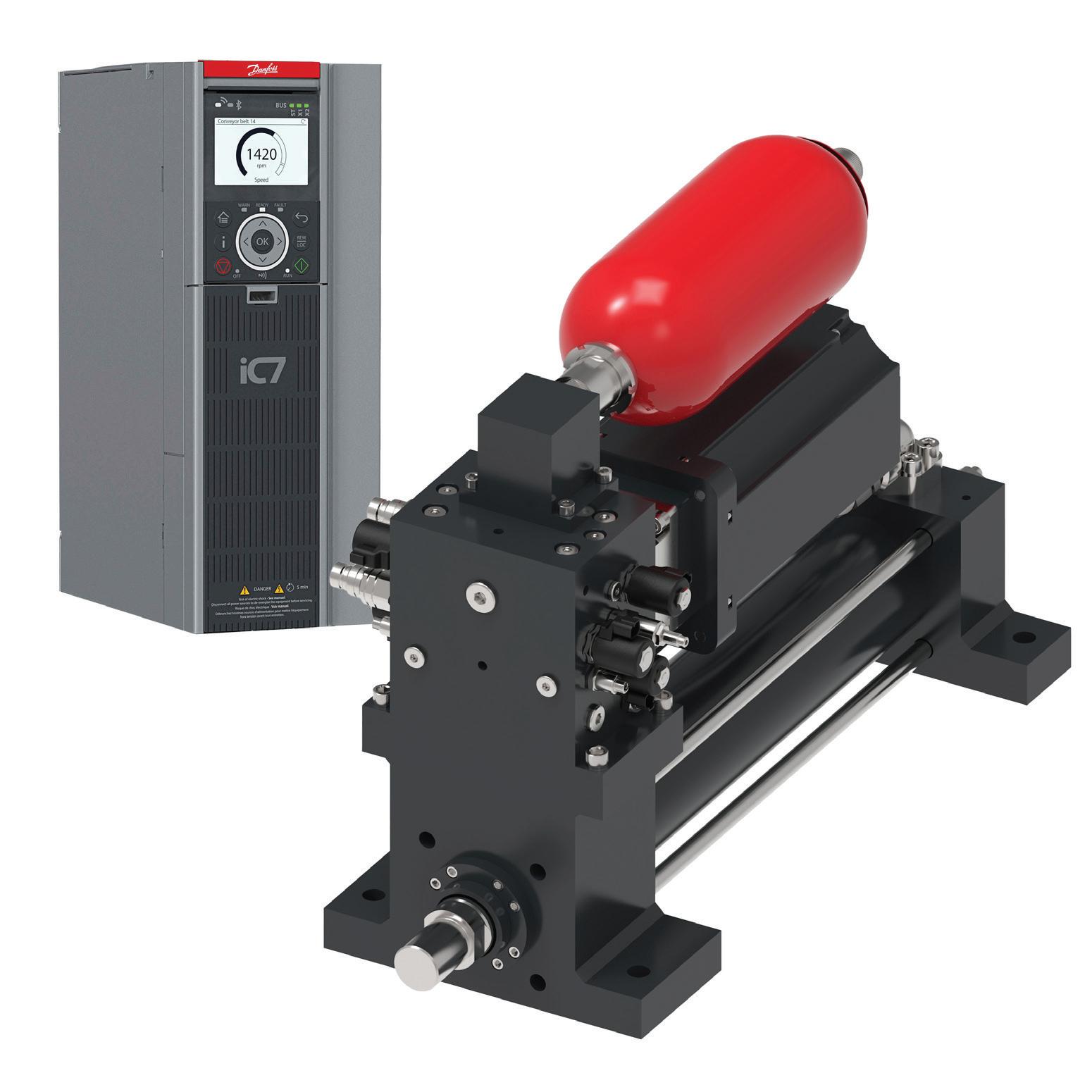

DECARBONIZING INDUSTRIAL HYDRAULICS IS POSSIBLE BY REDUCING ENERGY CONSUMPTION THROUGH DIGITAL HYDRAULICS SOLUTIONS.

SECTOR produced nearly 950 Mt of carbon dioxide emissions in 2023, according to the International Energy Agency. Meanwhile, a paper to be presented at IFK 20261 estimates that emissions from fluid power machinery amount to about 1,844 Mt of CO₂ per year — nearly two times the emissions of global aviation and 5% of global energyrelated emissions. Even more startling is that over 40% of fluid power machinery emissions (~767 Mt) are related to transmission losses. Useful work accounts for approximately 613 Mt of emissions, while electric/combustion losses account for 464 Mt of emissions.

The good news is we have the opportunity to create a significant impact, particu-

larly in industrial hydraulics. Decarbonizing fluid power is possible by reducing energy consumption through what’s known as digital hydraulics. With new components, systems, and architectures, we can increase efficiency by 50% and reduce emissions by one-third. In fact, innovation and efficiency step improvements in industrial applications are essential for developing sustainable and competitive machinery. Let’s take a look at how this is possible.

But first, a word about electrification. It’s no secret that electric machinery is much more efficient than hydraulic machinery. So, if we simply electrify, don’t we eliminate a good portion of those transmission

INDUCTION MOTOR SOLUTIONS UPGRADE TRADITIONAL ARCHITECTURES BY PROVIDING SPEED ON DEMAND VIA AN OPEN-LOOP CONTROL SYSTEMS COMPRISED OF A HYDRAULIC PUMP, AN ASYNCHRONOUS INDUCTION MOTOR, AND A VSD TO MATCH.

losses and, thereby, emissions? While on some applications this is possible, even preferable, in many industrial applications it’s not feasible to replace fluid power. In sectors such as discrete and process manufacturing, primary metals, marine and offshore, energy, and others, fluid power is indispensable due to characteristics not achievable with electric transmission: high power and force density, flexibility and comparatively low weight, inherent safety and robustness, and precise control of high-powered movement.

That’s not to say that all industrial sectors will retain fluid power. Rotary actuation applications and those sectors with lower power/force requirements can and are moving to electric drives. Robotics and automation is a good example. But for sectors and applications where fluid power will remain the best technical and commercial fit, the industry has a responsibility to deliver the best, most efficient solutions. We need to fully leverage opportunities from digitalization and electrification, and that’s where digital hydraulics plays a key role.

Variable speed drives (VSDs) have long been touted as a solution to increasing efficiency in industrial hydraulic applications. But digital hydraulics encompasses more than adding a VSD to a machine. Digital hydraulics entails controlling the speed of the motor and pump with a new system architecture. A variable speed-on-demand electric motor is coupled with a fixed- or variable-displacement hydraulic pump, and the motor and pump speed are used to directly control flow and/or pressure and ultimately the force and speed/position of an actuator. That’s in contrast to the conventional setup — a fixed speed electric motor coupled with a fixed- or variable-displacement hydraulic pump alongside pressure-, flow-, and directional-control valves

— where the pump displacement and valves control pressure and flow.

The conventional setup always runs at the rated speed, either 1,500 or 1,800 rotations per minute (rpm), depending on the region. Excess hydraulic oil flow is sent to the tank via a bypass or relief valve. In a digital hydraulic setup, the VSD is programmed to match the load requirements of the current duty cycle, thus eliminating energy waste. The pump and motor run and stop as needed, delivering power on demand, with a speed range of zero to 2,800 rpm. There is no or very limited excess flow. In comparison to the baseline conventional setup, the digital hydraulic setup lowers energy consumption by up to 70%, depending on the machine duty cycle.

Energy efficiency is the key benefit of digital hydraulics. Reducing energy usage significantly lowers operating costs, which results in a quick return on investment. Improved efficiency also reduces heat generation, which often allows downsizing or even elimination of oil coolers. At a minimum, it can help reduce the amount of hydraulic oil required and tank size of the tanks, thereby extending the life of the oil and seals.

Variable speed also enables the pump to be downsized, which reduces costs. Because the system can use the full motor speed range (up to 3,600 rpm) rather than running at a fixed rpm, it reduces the pump displacement requirement without changing the maximum available oil flow, shrinking the machine’s overall footprint. Pump downsizing opens the same possibility for the motor. A pump with a smaller displacement requires less torque to deliver the same pressure. Meanwhile, variable speed enables utilization of the high overload capability of electric motors to deal with the short high-torque portion of the machine duty cycle. Both of these characteristics allow selection of a smaller motor size, further improving total cost of ownership and decreasing power unit size.

DECENTRALIZED ARCHITECTURES ARE BETTER FIT FOR ELECTROHYDRAULIC ACTUATORS. EHAS HAVE LOWER OIL VOLUMES AND A LOWER RISK OF LEAKAGE AND ALSO REQUIRE LESS SPACE, OFFER QUICK SETUP AND COMMISSIONING, AND HAVE LOWER MAINTENANCE REQUIREMENTS.

Noise reduction is another significant benefit of digital hydraulics. Varying the electric motor and pump speed to match the duty cycle reduces constant noise, which helps protect operators’ hearing and meets more stringent noise regulations.

Digging deeper into what the technology looks like, there are several means for building digital hydraulic systems for industrial applications. At Danfoss, we classify them into three types: induction motor solutions, servo motor solutions, and electrohydraulic actuators.

Induction motor solutions upgrade traditional architectures by providing speed on demand. These open-loop control systems comprise a hydraulic pump — generally a piston pump — an asynchronous induc-

tion motor, and a VSD to match. These solutions may be available as pump-motors or hydraulic power units (HPUs).

Servo motor solutions are where we start to see new machine architectures, providing pressure and flow on demand as well as closed-loop control. The hydraulic pump is typically an internal gear pump or piston pump, while the motor is a permanent magnet synchronous motor (PMSM) paired with a servo motor VSD.

In addition to hardware, both system types require P/Q (pressure and flow control) and application software, enabling the proper dynamic and controllability. Induction motor solutions are for low dynamic and control requirements and are generally offered in low-, medium-, and highpower ranges. Servo motor solutions are for high dynamic and control requirements and are generally offered in low- and

accumulator, and VSD plus software. EHAs are best for machines in which most functions are electrified — in other words, there’s no HPU — and for isolated functions where the HPU is not close by or an HPU is serving only one cylinder. They also work well in applications with high sensitivity to oil leakage, such as food processing.

Compared to traditional centralized hydraulic circuits, EHAs have lower oil volumes and a lower risk of leakage. They require less space, offer quick setup and commissioning, and have lower maintenance requirements. Compared to electromechanical actuators, EHAs offer higher power density and force capabilities.

for a load cell for force measurement, and they are resistant to external shocks and vibrations.

Fluid power is changing, moving to efficient solutions and architectures that are closely linked to electrical actuation and digitalization. We need to build new competencies at component manufacturers, OEMs, and end users, and we need stronger collaboration between industry and academia to accomplish the changes necessary to reduce emissions. An initiative called Industry-Science Dialog in Europe is bringing together indus-

Digital hydraulics represents a significant advancement in industrial applications, offering solutions that meet the demand for efficiency improvement and emissions reduction, and enabling competitive decarbonization. The integration of digital control and power on demand into fluid power systems will play a critical role in shaping industrial operations now and into the future. FPW

Danfoss danfoss.com

Ball

Self-cleaning

40

Standard

Having daily, weekly, and monthly checklists helps you keep on top of things like filter maintenance and more.

By Josh Cosford, Contributing Editor

MAINTENANCE

VERYONE THINKS THEY KNOW MAINTENANCE and believes they're successfully running maintenance programs in their factory. This isn't my first time around the rodeo, because despite my occasional and intentional confusion of metaphors, I know what hides within industrial fluid power systems, and it’s not pretty. I’ve been in hundreds of factories and observed machines ranging from Michelin Star kitchen level of clean to “how is this burger joint still in business?” level of nasty.

KEEP AN EYE ON YOUR COMPRESSED AIR SYSTEMS AND DRYER BY ADDING THEM TO YOUR MAINTENANCE LISTS.

Hydraulic and pneumatic systems are both unique energy transmission systems, each with its own maintenance concerns relative to electrical and mechanical systems, despite the high level of overlap. Fluid power uses compressed oil and air to transmit force from a (typically) central source to the actuators on or at the machine, where they can perform work to transform raw materials into semi-finished goods.

Unlike in mechanical and electrical systems, fluid power components are sensitive to contamination. I'm not suggesting you should cut the bottom from an hourglass and drain its contents over a sprocket, but considering that oil and air circulate

through the internals of every pump, compressor, valve, and actuator, the potential for damage and wear is significant. For this reason, filtration is the front line of protection for every fluid power system and is critical to every maintenance program.

Filters reside in many locations throughout fluid power systems, and you may see three to six or more on each machine, depending on the medium and complexity. An air compressor alone, for example, may use up to four filters to ensure clean, highquality air is distributed downstream to the machine or tool locations.

Industrial environments are rarely cleanroom quality, especially where metalwork is concerned. Industrial fallout, in the form of oil or coolant vapor, combines with various forms of particulate to create an environment more abrasive than a drunk

Filters reside in many locations throughout fluid power systems, and you may see three to six or more on each machine, depending on the medium and complexity.

step-uncle. Additionally, centralized HVAC systems are rare in manufacturing plants, so expect that dust will find its way into every nook and/or cranny of your air preparation system.

Because compressors may cost many tens of thousands of dollars, be sure to

schedule the replacement of intake air filters at least annually in the best-case scenario, although semi-annual swaps are more appropriate in especially nefarious factories. These filters run the gamut in construction material from paper to foam and metal mesh to even synthetic HEPA media for cleanroom-quality areas.

The compressed air that the compressor has compressed then enters the main line filter, which is a large assembly appropriate for full flow and allows downstream nodes to receive clean air. High-quality versions offer bypass indicators to signal an element change, although inexpensive versions may require periodic replacement, piggybacked with other scheduled maintenance activities.

Depending on your plant layout and accoutrement, the presence of an air dryer

FRLs are common throughout pneumatic distribution systems, and they’re usually recommended at each workstation leg of the circuit. KEEP

should be noted and added to the maintenance list. They may sometimes equip preand post-filters, or even non-traditional equipment like coalescing filters. Regardless, a clean air dryer works better than a

contaminated air dryer, so be sure to add its filter servicing to your schedule. Additionally, compressors and refrigerant-style air dryers may have filters to protect the heat exchangers from clogging should grime build up on their cooling fins. Although a quick visual inspection easily identifies foam or paper elements requiring replacement, it’s a great idea to change or clean these frequently. Any buildup of industrial fallout can reduce airflow across the cooler, resulting in overheating of the compressor or dryer. Furthermore, desiccant air dryers may require the replacement of the desiccant material, which is best handled before you realize water is contaminating your machines and tools.

Any good maintenance plan begins with a schedule, as there are tasks to be completed daily, weekly, monthly and longer. No task is too small, because even something as small as an oil leak could lead to thousands of dollars in damage if a power unit or air compressor runs dry.

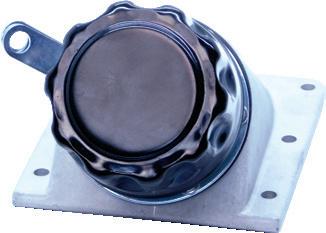

FRLs are common throughout pneumatic distribution systems, and they’re usually recommended at each workstation leg of the circuit. The Filter Regulator Lubricator ensures each station has the appropriate work pressure while filtering out both water and particles before it adds drops of lubricant to satisfy the needs of tools, valves and actuators. Their filters use a cyclonic separation method in addition to metal mesh or sintered bronze elements. Although these elements can be replaced, they can also be cleaned, in many cases.

Comparatively, hydraulic filtration systems are maintained less like the method lube shops use to convince you to purchase the replacement cabin filter, "What's that? If I don't replace the slightly dusty filter with the little boxwood leaf stuck in the pleat, I'll be inhaling cyanide gas before I get to the Dunkin's down the street?" No joke, one factory service center I booked my car into had an animation on their waiting area TV showing dirty air blowing through a clogged filter like a cartoon sloth’s bad breath animation. In reality, a clogged filter traps more subsequent particles, not fewer. But I digress.

Hydraulic filters have (or should have) gauges to signal maintenance staff when a filter is close to becoming clogged. These bypass indicators can be pressure gauges, transducers, pop-up indicators or warning lights. Depending on the manufacturer, they may signal their warning when the filter is around two-thirds clogged, providing plenty of time before the bypass check valve opens, which essentially dumps fluid straight through the element.

Filters are most commonly installed in and around the hydraulic power unit, and will be located in the tank top, inline to the return port, the primary pressure line or occasionally within special components, such as a servo/proportional valve stack or hydraulic manifold. The best filters are synthetic media with high beta ratios (efficiency) and low micron ratings. If you can upgrade your paper or cellulose elements to synthetic, do so, but just check to ensure you’re not creating excessive, flow-related back pressure due to the increased flow restriction of finer media.

No matter the filter type or location, it's best to stock a year's worth of spare elements. Besides being handy for your scheduled PMs, having them on hand for emergencies could be a lifesaver when a hydraulic pump implodes or you experience an unexpected influx of contamination. And don’t play guesswork; keep all the appropriate part numbers for replacements with the machine and service manuals. Filters and elements from older machines may have seen their filters replaced with crossover brands, so don’t leave these details buried in Doug’s skull, because he’s retiring in six months anyway.

Most of the fluid power maintenance missives I write regarding maintenance are related to filtration because it's the most critical component. Preventing the failure of your equipment trumps all other tactics, including predictive maintenance. Nevertheless, I rarely discuss the administrative tactics plants use to plan, schedule, and execute a successful fluid power maintenance program.

Any good maintenance plan begins with a schedule, as there are tasks to be completed daily, weekly, monthly, and longer. No task is too small, because even something as small as an oil leak could lead to thousands of dollars in damage if a power unit or air compressor runs dry. Here is a simplified breakdown of the daily, weekly and monthly tasks your maintenance team should perform on your fluid power machinery:

• Check fluid levels in the hydraulic reservoirs and compressor case

• Inspect power units, compressors and lines for oil or coolant leaks

• Listen for unusual noises or air leaks

• Observe any and all pressure gauges on regulators, power units and filter elements

• Drain the water from all air filter bowls with manual drains

• Inspect the breather caps and filter baskets on power units

• Check all hydraulic hoses and air lines for bulges and kinks

FRLS SHOULD BE CHECKED REGULARLY. THE BOWL FILTER SHOULD BE CLEANED, FILTER ELEMENTS REPLACED WHEN CLOGGED, AND LUBRICATOR OIL LEVELS SHOULD BE CHECKED.

• Verify that the pressure settings of all pressure valves is correct and adjust as necessary

• Inspect the air compressor intake filters

• Inspect the auto-drain style separators

• Sample and test the hydraulic oil of one of the power units (on a six-month rotation)

• Perform cycle counts on spare components in stock

• Inspect accumulators and confirm precharge pressure

• Perform a heat map on fluid power machinery

• Inspect and test pneumatic safety valves and lockout valves

• Perform leak detection audits using leak detection kits

The above schedule is a rough guide, and your actual requirements will depend upon the type and quantity of machinery in your plant. Also, reference and adhere to OEM maintenance guidelines and adjust schedules based on their requirements. Also, consider that harsh operating environments could accelerate the tasks in the

above schedule.

From a maintenance management perspective, some fundamental strategies are helpful to ensure your plant runs smoothly. Although it's not talked about, the principles of maintenance are just as important here as they are for excavators or highway line painting machines.

Although it starts with a great team, every good team is beaten by a poor system. Being clear with the millwrights and mechanics that their maintenance schedule is non-negotiable eliminates any opportunity for surprises or pushback; "Oh, you mean I had to do my weekly checks this week?” Without discipline in the maintenance schedule, you're just putting out fires while preventing nothing.

Sometimes unplanned maintenance results in backlogs, which then turn into bottlenecks. Ensure bureaucracy doesn't hinder repairs and unplanned maintenance. Awaiting on your plant manager to approve a replacement pump on a process-critical line contradicts lean manufacturing principles, especially when a pump replacement is the only possible solution. Reduce any such potential bottlenecks by giving the

appropriate personnel authority to make decisions, thereby minimizing decisionmaking handoffs.

Finally, find the time to upskill your maintenance team. I understand you can't just have your junior mechanics rewiring your control panel, but every plant needs more than one "fluid power guy." With more people trained on more machines, you don't have to work around the silos of technical ability and experience. Everyone should be able to replace a hydraulic cylinder or ISO subplate pneumatic valve, so when one mechanic is busy, there is no gatekeeping or backlog.

Finally, this article primarily discussed old-school methods and considerations for industrial fluid power maintenance, while entirely ignoring Industry 4.0 predictive maintenance advancements. Even if you've implemented smart factory technology into your plant, your awareness of exactly what these technologies are trying to achieve with collecting, analyzing and broadcasting data is clear when you consider the advice of this article. FPW

Edited by Mary C. Gannon • Editor-in-Chief

REGISTRATION IS OPEN FOR NFPA’S ADVANCED HYDRAULICS CONFERENCE , taking place March 4–5, 2026 in Las Vegas during CONEXPO-CON/AGG. Experts will present on the latest hydraulic technologies and applications.

This conference is a separate event from other CONEXPO-CON/AGG educational sessions. To attend, participants must first register for CONEXPO-CON/AGG (or already have an exhibitor badge). Then you may purchase your NFPA Conference pass. Registration is $100 for one day and $150 for two days. Subscribers to the NFPA’s Fluid Power Forum Plus will receive a 50% discount on registration. Sessions are as follows:

• Increased Runtime for Battery-Electric Excavators with Digital Hydraulics, by Chris Williamson, Danfoss Power Solutions

• Unlocking Digital Transformation: Why Strategic Ecosystem Partnerships are Essential to Delivering Risk-Reduced, High-Value Digital Services, by Adam Livesay, Elevāt and Russ Schneidewind, Bosch Rexroth

• Smart Hybrid Architectures for Off-Highway Machines: Standard Components, Smarter Controls, by Barun Acharya, Parker Hannifin

• How OEMs and Equipment Manufacturers Can Tap into System Sntegrators to Design and Optimize Their Machines’ Hydraulic, Electric, and Control Systems, by DJ O'Konek, Nott Co.

• Optimization and Validation of eHydraulic System Performance on a Battery-Electric Backhoe Loader, by Simon Nielsen, Danfoss Power Solutions

• Using 3D Finite Element Analysis to Increase Performance in Shaft Seals for Hydraulic Pump Applications, by Dr. Nino Dakov, Trelleborg Sealing Solutions

• Hydraulic Data from the Heart of the Circuit: Pump Output Digitization, by Mark Preissig, Casappa

• Comparison of Two Electric Linear Actuation Technologies: ElectroMechanical Actuation and Electro-Hydrostatic Actuation, by Dale Vanderlaan, Parker Hannifin

• Unlocking the Power of Practical AI in Mid-Market Manufacturing and Distribution, by Ken Baker, Bailey International

• Hydraulic System Efficiency Optimization Leveraging Quasistatic & Dynamic Models, by Chad Larish and Aaron Jagoda, Danfoss Power Solutions

• Variable Flow with Fixed Displacement Pump, by Andrea Rimondi, Marzocchi Pumps

• Steer By Wire: An Enabling Technology for Autonomy and Automation, presented by David Schulte P.E., Parker Hannifin

• Lowering Total Cost of Ownership, by Dr. Rhishkesh Gokhale, Evonik Oil Additives

• eHydraulic Building Blocks: Inverters, Components, and ApplicationSpecific Systems, by Joe Budden, Danfoss Power Solutions

• How Mechatronics Integration Ease the Adoption of Electrification, by Benjamin L’Hénoret, Poclain

• Tuesday will wrap up with a panel discussion led by Eric Lanke and a reception for Fluid Power Forum PLUS Subscribers.

Visit nfpa.com for complete session descriptions and to register. FPW

gives you on demand access to recorded webinars and training videos focused on real-world fluid power topics. You can learn from certified instructors who cover hydraulics, pneumatics, contamination control, energy savings, pumps, valves, troubleshooting, and safety. Sessions are designed to be practical, with explanations that help you connect theory to daily tasks and projects.

The library works well as a flexible study aid. Use it to review key concepts before a certification exam, refresh a skill you have not used

recently, or train a new team member. Videos can be watched in short bursts or in longer sessions, which makes it easy to fit learning into a busy schedule. Because content is organized by topic, you can quickly find the material that matches your immediate needs.

For a deeper learning path, pair the videos with other IFPS resources. Animated Circuits help you visualize sequence of operation and flow paths for hydraulic and pneumatic systems, while online training modules provide structured, self-paced coursework for

specific roles. Together, these tools support consistent training, improve safety awareness, and help teams standardize best practices across the shop floor and the field.

Visit ifps.org to learn more. FPW

“Been a huge fan for a few years now and will continue to be for years to come. Your work is unparalleled. I appreciate that you do not spare details when modeling components and systems. ”

- Troy T

“LunchBox Sessions is the best thing since sliced bread. Definitely will learn a bunch at a very small investment.”

- Bill M.

“The most concise and modern approach to maintenance teaching I have experienced.”

-Kody H.