+ wire Kraków + wire Southeast Asia

WireCo has reimagined crane hoist technology with its triple-core CASAR Lazerlift rope. Its team brought Lazerlift from initial concept to a rope that sets new benchmarks for strength, flexibility and durability in multi-layer crane hoisting applications. Below, Timothy Klein, senior principal engineer - structures and fabrication, WireCo WorldGroup, shares how the R&D process worked.

WJI: When did the idea for this cable design first surface, and what sparked it?

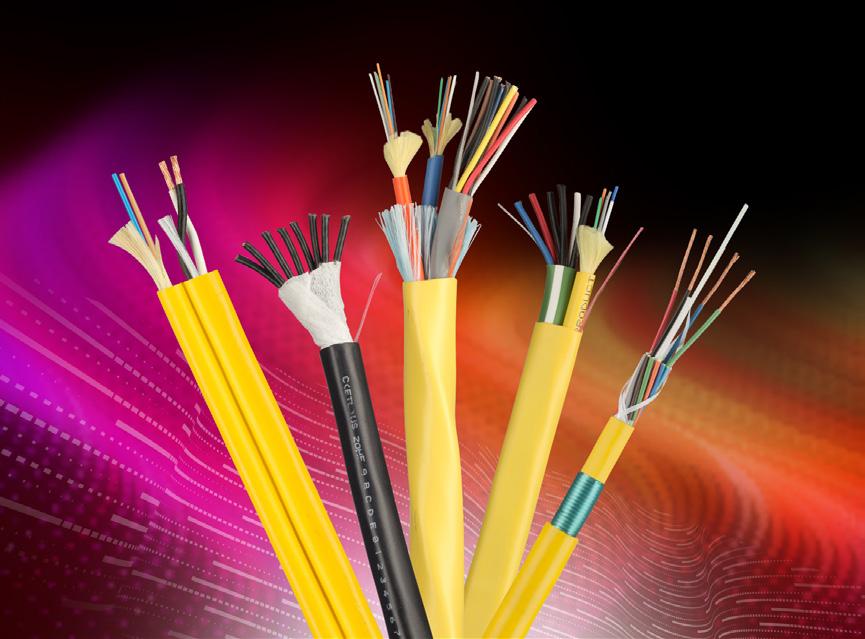

Klein: The lifting industry has been moving toward heavier loads, greater lifting heights and more compact crane designs, all of which put increasing demands on wire ropes. Traditional rotation-resistant ropes often struggled to deliver the combination of strength, flexibility, and crush resistance required for multi-layer spooling applications on modern hoisting systems. In these setups, ropes are subjected to extreme radial pressures and friction forces as they wind and unwind over multiple layers on the drum. Standard constructions can deform under these crushing loads, which leads to accelerated wear, loss of strength, and inconsistent spooling behavior. WireCo’s CASAR Lazerlift was developed specifically to overcome these limitations. Its 16-outer strand construction and advanced rotation-resistant design provide outstanding crush resistance, while maintaining the flexibility and abrasion resistance necessary for smooth, efficient operation. The result is a rope that combines superior tensile strength with long-term durability, ideal for cranes operating in demanding, multilayer hoisting environments.

WJI: When your team began the research, what did your early steps look like—did you focus more on lab work, computer modeling, or jump right into field trials?

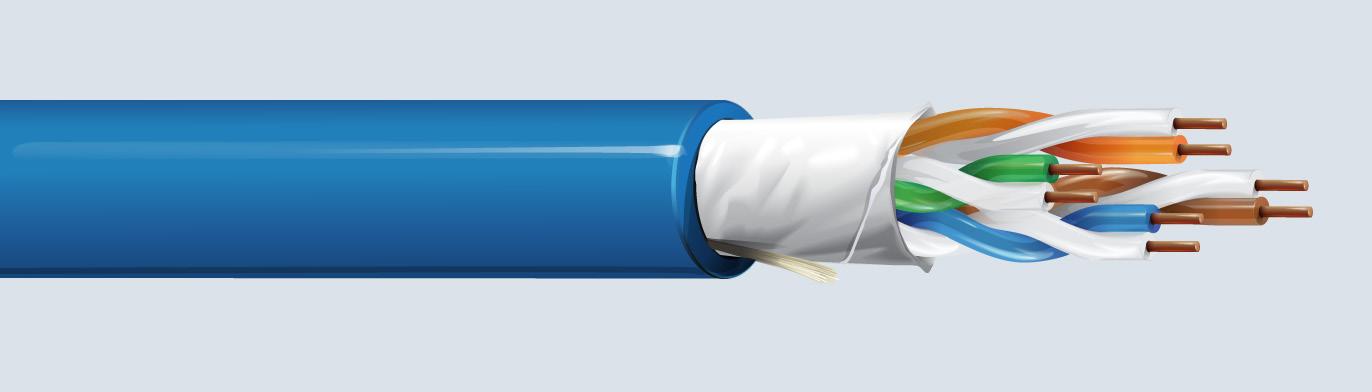

Klein: The development of Lazerlift began as a concept sketched by hand, an idea grounded in decades of wire rope engineering experience. From that initial drawing, the team transitioned quickly to computer modeling using our internal rope design software. This allowed engi-

neers to simulate rope geometry, balance rotational behavior, and optimize strand configurations for the strength and crush resistance needed in multi-layer spooling applications. Once the digital models demonstrated promising results, the project advanced to production trials within CASAR’s stranding and closing mills. These trials were critical in fine-tuning manufacturing parameters and validating the consistency of the rope structure at full production scale. Only after the design and production performance met internal benchmarks did the team initiate field trials with OEM crane partners. This deliberate, phased approach ensured that Lazerlift entered real-world testing as a fully validated product, not a prototype, ready to demonstrate its superior durability, spooling behavior, and MBF (Minimum Breaking Force) in demanding lifting environments.

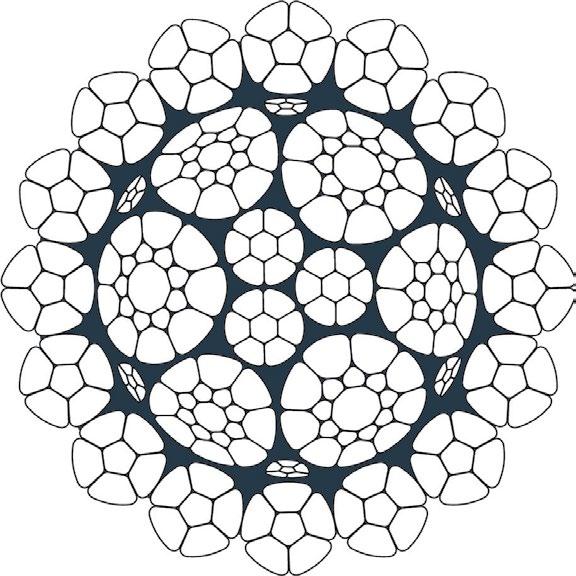

WJI: What made you settle on that triple core design and higher wire count—was it something that evolved through testing, or did you know from the start that was the direction to go?

Klein: From the beginning, the team recognized that the core design would be central to achieving Lazerlift’s performance goals. In multi-layer hoist applications, the rope core must maintain dimensional stability under extreme compressive forces while resisting internal wear. To meet these demands, Lazerlift was built around a high-density stranded core specifically engineered for multi-layer crane hoisting. This core structure features a double parallel lay design, which minimizes internal nicking between wires and strands, one of the leading causes of premature fatigue in conventional rope constructions. The result is a rope that maintains its shape and integrity through repeated bending and crushing cycles on multilayer drums. The triple-core configuration also plays a key role in achieving Lazerlift’s Cat. 1 rotation-resistant performance (RCN 23-1). This means the rope exhibits exceptionally low rotation under load, even at long lifting heights, without compromising tensile strength or flexibility. It is suitable for multi-layer spooling and performs best in Lang’s lay execution, while also available in both ordinary and Lang’s lay, right-hand or left-hand configurations, and in galvanized or ungalvanized options to suit diverse

operating conditions. In short, the final design wasn’t an accident of testing but a deliberate evolution of CASAR’s experience: a core geometry carefully optimized to balance strength, rotation control, and fatigue resistance, the three factors most critical to rope longevity in modern crane systems.

WJI: How did experiences from bench trials or realworld crane use shape your final product? Did operator feedback or field data push you to make specific changes?

Klein: During development, extensive internal cycle testing played a key role in refining Lazerlift’s final configuration. By running the rope through repeated loading and bending cycles on in-house test machines, the engineering team was able to analyze performance under simulated real-world hoisting conditions. These controlled trials helped optimize strand geometry, balance and tension to maximize overall rope efficiency and durability. While

the fundamental design concept proved sound from the start, minor refinements were made as testing progressed. Adjustments such as tighter diameter control and optimized wire grade selection improved uniformity and long-term stability without altering the core structural principles. By the time Lazerlift entered field trials with OEM crane partners, these refinements had already been incorporated, ensuring that the product performed consistently across different applications and maintained its superior crush resistance and flexibility in multi-layer spooling environments. Testing also verified Lazerlift’s reliable performance across a wide operating temperature range, from −50 °C to +75 °C.

WJI: Did you measure Lazerlift against industry requirements or mostly use your own standards for tests like breaking force, durability, and rotation resistance?

Klein: Yes. Lazerlift was developed to fully comply with global industry standards, including ISO, ASTM, and EN specifications that govern wire rope performance, testing, and safety requirements. Meeting these benchmarks ensures the rope’s reliability and consistency across international markets. In addition to those external benchmarks, the design team applied WireCo’s internal engineering and quality system metrics to establish the testing parameters for Lazerlift. The product was also measured against the stringent specifications of Load Handling Equipment (LHE)

manufacturers, which represent some of the toughest operational requirements in the lifting industry. By aligning Lazerlift’s performance with both regulatory standards and OEM expectations, WireCo ensured that the rope would perform consistently in demanding crane and hoisting applications worldwide..

WJI: In developing Lazerlift, did you work with crane manufacturers or on-site engineers? Was their input a big part of your design process?

Klein: Yes. Collaboration with crane manufacturers and on-site engineering teams played an important role throughout the development of Lazerlift. Their feedback was instrumental in validating how the rope performed under real-world conditions and across different crane types and configurations. The input from OEM partners helped confirm that Lazerlift delivers excellent spooling behavior on multi-layer drums, a key factor in maintaining efficiency and safety in long-fall hoisting applications. Consistent, smooth spooling reduces localized stress and wear, allowing operators to achieve longer rope life and more reliable lifting performance. By working directly with manufacturers during testing and early deployment, the design team ensured that Lazerlift not only met laboratory and internal performance targets but also satisfied the operational expectations of those using the product in demanding field environments.

WJI: What else of note was a factor in your R&D that is not covered above?

Klein: An important part of Lazerlift’s development was the extensive field testing conducted in both Europe and the United States. These trials provided WireCo’s engineering team with valuable performance data and direct customer feedback across a range of operating environments. Testing under different load conditions, drum configurations, and climate variations allowed engineers to validate that Lazerlift performs consistently in diverse applications. The results confirmed that the rope’s rotation-resistant construction and triple core design maintained stability and longevity even in the most demanding hoisting operations. The insights gained from these international field trials helped finetune production parameters and reinforced confidence in Lazerlift’s readiness for global deployment.