ENABLING SUSTAINABILITY IN PULP & PAPER MILLS’ ENTIRE LIFECYCLE

Welcome to the November-December issue of Pulp Paper & Logistics, the final issue of 2025. The magazine and its on-line equivalent continues to incorporate Green Packaging International, which features news and developments in fibre-based packaging, and as a key end-product for our industry is increasingly taking market share from plastics.

As mentioned in the last issue, readers’ opinions of PPL’s editorial content have been incorporated into our media schedule for 2026.

It’s always interesting at this time of the year to gather the subject preferences of readers and find that many have asked for coverage of similar activities.

It was also a pleasant surprise to learn that soon after releasing the 2026 schedule on 9 November enquiries have been coming in quickly. This can only be seen as a positive endorsement of PPL and the industry it serves.

And it continues to grow. As outlined in our media pack, global reader registrations now exceed 25,700. There are a further 3,900 individuals who wish to receive both PPL and access to the Green Packaging International section in a pdf format.

Looking forward to the January-February 2026 issue we are planning to feature: felts and inspection systems, mill automation upgrades, packaging paper machines, and biomass power.

Contributions should be sent by email to arrive no later than 20 January at pulppaperlogistics@virginmedia.com

It remains for me to wish all PPL’s readers the compliments of the season.

Vince Maynard, Publisher and Editorial Director

John Nutting Tel: +44 (0) 1732 868071

+44 (0) 7860 221486 Email: johnnutting47@gmail.com

Vince Maynard

Tralee, Hillcrest Road, Edenbridge, Kent, TN8 6JS, UK

Tel: +44 (0) 1732 505724

Mobile: +44 (0) 7747 002286

Email: pulppaperlogistics@virginmedia.com Email: pulppaperlogistics@outlook.com

David Young

+44 (0) 1737 551687

+44 (0) 7785 796826

Anthony Wiffen Tel: +44 (0) 1460 261011 Mobile: +44 (0) 7851 612799 Email: anton_print_1@mac.com

Financial support offered through the UK Government’s ‘Supercharger’ scheme – which is open to energy-intensive installations in specified sectors, including papermaking – is being increased.

The Government has accepted that the high cost of electricity in the UK is a huge problem for energy intensive manufacturing when exposed to imports from countries with lower energy costs. The initiative follows extensive input and evidence from the

Confederation of Paper Industries (CPI) and its members, to stress the importance of competitive energy costs in the face of international competition.

The change means that UK paper mills in the Supercharger scheme will have the rebate received for charges related to network costs increased from 60 to 90 percent, and more in line with the costs faced by competitors, such as in Germany.

Chief executive of the CPI Alex Veitch commented: “This policy

Users of Sappi Europe’s Magno Web range of papers are now able reduce their Scope 3 indirect emissions related to the purchase of goods and services, with the range’s production being fully-established at the Kirkniemi Mill in Lohja, Finland. Following investments in renewable energy and clean electricity, Magno Web benefits from Kirkniemi’s decarbonised operations without compromising quality or performance, and represents a 58 percent reduction in carbon footprint compared to its previous production location. Magno Web is a high-quality coated paper range used in publishing, advertising, and premium print applications. Sappi Europe says it is valued for consistent image reproduction, balanced brightness and opacity, with a choice of gloss or silk finishes that meet customer demands for both performance and versatility.

In 2023, the Kirkniemi Mill converted to renewable biomass energy, cutting Scope 1 (direct) emissions from its operations by 90 percent. With ‘clean’ electricity now supplying the site, Scope 2 (indirect) emissions have also been eliminated, making Kirkniemi a benchmark in sustainable paper production.

The Kirkniemi Mill’s transformation is among almost 80 projects outlined in Sappi Europe’s 2020-2025 decarbonisation roadmap, which contribute significantly to Sappi’s

2030 science-based targets.

“Sappi Europe’s decarbonisation journey underwent a massive acceleration from 2020 onwards.

We’re proud to have greatly surpassed our 2025 targets for CO 2 emission reductions, despite challenging economic conditions,” says Sarah Price, Sappi Europe’s director of sustainability. “For us, this is much broader than emissions; it’s about investing now for long-term positive change and enabling our customers to do the same.”

decision is a welcome step in the right direction, following detailed discussions with government to make the case for support. Looking ahead, our members need government to set us on a course toward internationally competitive energy prices to keep and grow jobs and manufacturing in the UK.

“However, while the Supercharger scheme supports parts of the paper sector, we still see urgency in addressing energy costs faced by all UK industry.”

l UPM will cease paper production at the Kaukas mill in Finland before the end of 2025 with the closure of the PM1 line and will shift its coated mechanical paper production to the Rauma mill. Following the closure, UPM’s coated mechanical paper production capacity will be reduced by 300,000 tonnes a year. UPM’s pulp, sawn timber and biofuels production and R&D activities at UPM Kaukas will continue.

l Third-quarter sales at Smurfit Westrock topped US$8 billion with net profit of $245 million. Adjusted EBITDA was $1.3bn, giving a margin of 16.3 percent. “The North American mill system demonstrated a strong operational performance in the quarter. Our corrugated operations continue to focus on value over volume and exiting uneconomic business,” said chief executive Tony Smurfit.

US-based Graphic Packaging started up its recycled paperboard mill at Waco, Texas in October with the expectation that it would reach full capacity in the next year to year-and-a-half.

Chief executive Michael Doss revealed that the new mill would be the “world’s most efficient producer of recycled paperboard”, as results for the third quarter were posted at US$2.19 billion, down 1 percent on the same period last year.

Net profit was also down, by 16 percent to US$142 million.

Commenting on the Waco mill, Doss said: “I am pleased to announce that our Waco, Texas recycled paperboard manufacturing facility produced its first commercially saleable rolls in October, well ahead of plan. I congratulate our team and our contractors for their exceptional work. I also want to thank the Waco community, Governor Abbott, and the state of Texas for their steadfast support.

“We expect to reach full production in 12 to 18 months. Waco will be the world’s most efficient producer of recycled paperboard, with the highestquality available anywhere outside of our own Kalamazoo, Michigan, facility. This marks the completion of our Vision 2025 transformation, and we now turn our full attention to our Vision 2030 priorities: innovation, execution, reaching investment grade, and returning cash to stockholders.”

Multinational paper group Lucart has acquired Cartindustria Eurocarta, one of Europe’s leading independent converters in the professional hygiene tissue market. The value of the deal was not revealed.

Best known for tissue brands such as Lucart Professional, Tenderly, and Tutto, Italy-based Lucart said the agreement strengthens the role of both companies as key players in the professional tissue paper market, adding that it marks a significant step in enhancing the Lucart Group’s presence in the away-from-home (AFH) segment.

Cartindustria Eurocarta converts about 40,000 tonnes of tissue products with sales last year of €78.5 million. It is said to be the largest independent European converter specialising in hygiene and cleaning products

Francesco Pasquini, chief executive of Lucart: “Cartindustria Eurocarta is the ideal partner to continue our group’s growth”

and services for away-fromhome use. Its headquarters and production facility in Porcari is

adjacent to the Lucart site.

Francesco Pasquini, chief executive of Lucart, said: “A longstanding customer of our semifinished products, Cartindustria Eurocarta is the ideal partner to continue our group’s growth strategy in the AFH channel. Its production flexibility and customer-centric approach align with Lucart’s value proposition, enabling us to more comprehensively meet the needs of the European professional market.”

Paolo Agati, founder and chairman of Cartindustria Eurocarta, added: “Lucart’s entry into our corporate structure marks a pivotal milestone for our company. This strategic move ensures continuity, sustainability, and strength in the growth journey we have undertaken over the past decade, enhancing our ability to compete on a European scale.”

l The management of forests and biodiversity was at the centre of discussions during COP30 held during November at Belém in northern Brazil’s Amazon region, the world’s largest tropical forest and a crucial carbon sink. The Amazon’s role in stabilising the global climate mirrors that of Europe’s managed forests, underlining the paper and pulp industry’s shared commitment to preserve these vital ecosystems. This commitment was further strengthened by the work of the Tropical Forever Forest Facility (TFFF), a global initiative supporting the transition toward a lowcarbon, circular bioeconomy. TFFF promotes sustainable forest management in tropical regions, strengthens local value creation, and supports innovation in fibre-based products that replace fossilbased alternatives.

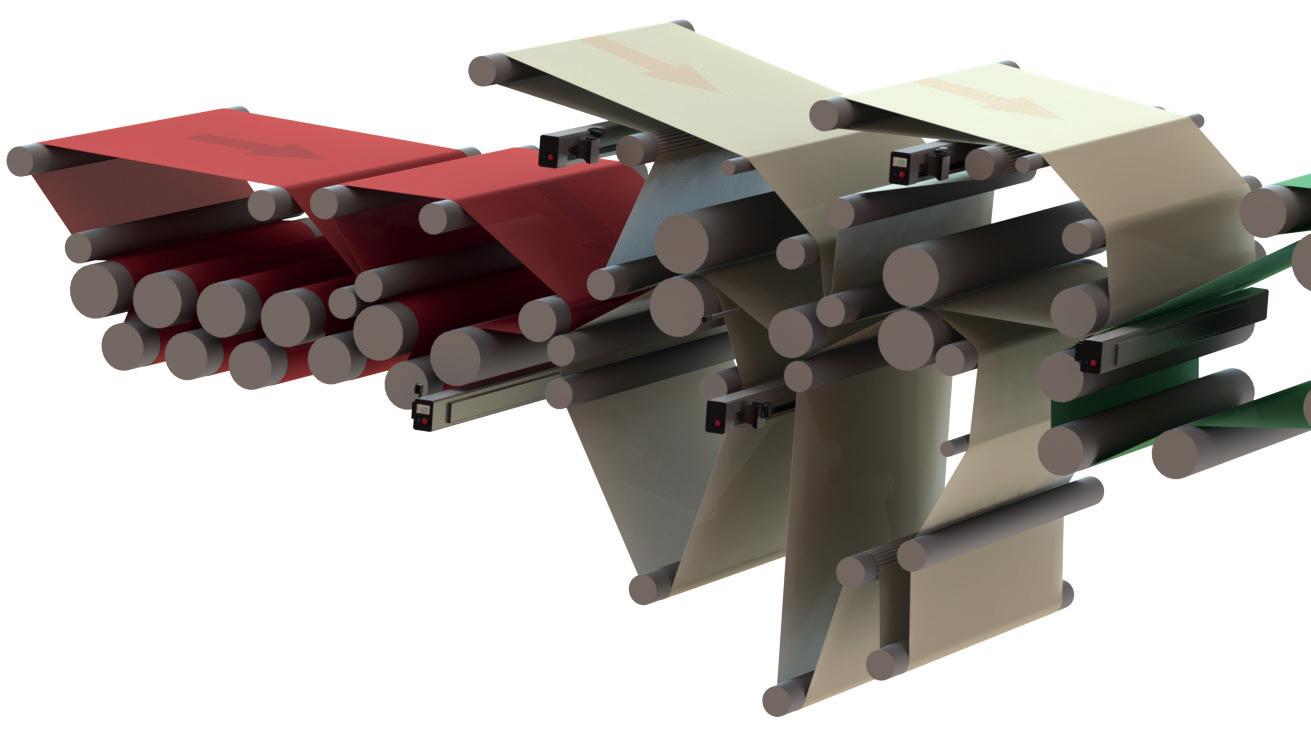

Executives of Eren Holdings, owners of the Shotton Mill in the UK, hosted delegates from the Sheet Plant Association (SPA) in September following the SPA’s 112th conference, held this year in nearby Chester.

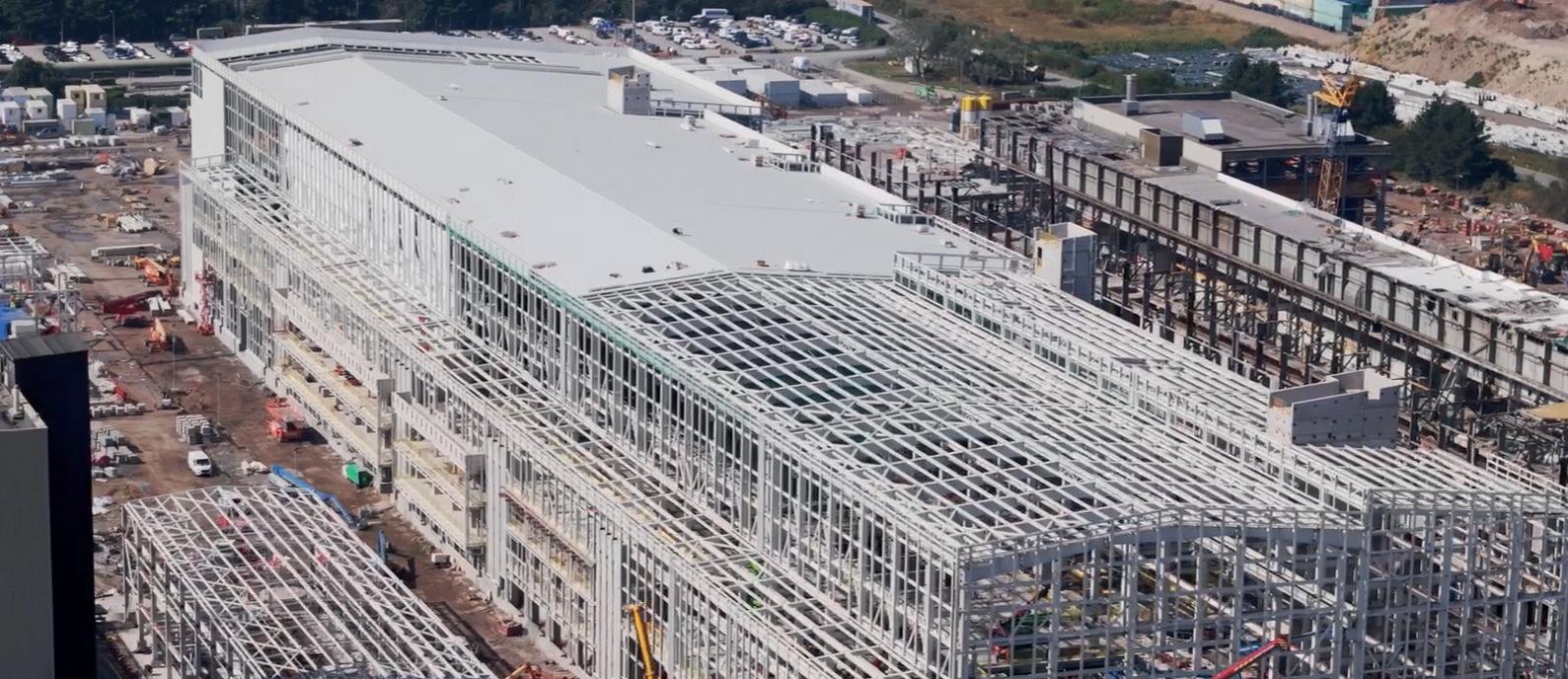

The visit provided SPA members with a behind-the-scenes look at the progress of the Shotton Mill’s £1 billion investments.

The SPA co-ordinates action in matters affecting the corrugated packaging industry, and the wider paper industry. It co-operates with associations having similar aims

and objectives in the UK, Europe and the USA and works with these associations to keep members informed about regulatory and legislative developments impacting the corrugated sheet plant industry.

The tour began with general manager Dan Johnson highlighting vital infrastructure, including a new effluent treatment plant (ETP), a combined heat and power (CHP) plant, and the significant logistics that are managing the build.

In the mill’s project headquarters, delegates were updated on the project’s progress,

with attention given to the plans for the Valmet containerboard machine, which is the centrepiece of the development.

Management from Eren Holding who attended included Hamdullah Eren, chairman of Modern Karton, and Dr Sabri Cimen, chief executive of Eren Paper and Shotton Mill Ltd.

Dr Cimen commented:

“This project is about much more than just scale; it’s about setting a new global benchmark for sustainable

A ‘first-of-its-kind’ adherence and clinical packaging facility has been opened at Dublin Airport by Smurfit Westrock.

With an investment of more than €40 million, the site which will provide packaging for clinical trials and regulated pharmaceutical packaging.

Speaking at the opening, Tony Smurfit, chief executive of Smurfit Westrock, said: “We are immensely proud of this groundbreaking and beautifully designed new plant. The

packaging solutions which are designed and manufactured here will contribute significantly to the next generation of life-

saving medicines.”

Smurfit Westrock has similar facilities at Kunshan in China and at Mebane in North Carolina, USA.

paper manufacturing. We are immensely proud to be building this technologically advanced facility right here in North Wales, continuing the region’s rich industrial heritage and securing the UK’s future as a leader in the circular economy.”

When complete in 2026, the Shotton Mill will have capacity to produce 750,000 tonnes of containerboard a year, using 100 percent recycled fibre and advanced, low-carbon energy technology.

l In what is seen as an aim by China to suppress imports of dry-milled pulp, its government said in October that it would call on recycled pulp importers to specify whether the material was milled using dry or wet processing methods. US observers are wondering how China will carry out site inspections to ensure that dry-milled pulp, which is regarded as potentially more contaminated, is compliant. Prices of OCC, a key feedstock, dropped as a result. News in brief

UPM will be sourcing raw material wood products from Versowood, Finland’s largest private producer and processor of sawn timber, following the agreement of a partnership between the two Finnish companies.

High-quality pulpwood and sawmill by-products will be shipped to UPM from Versowood, enabling UPM to strengthen wood supplies for its pulp mills in the tight Finnish wood market. UPM will in turn supply Versowood’s sawmills with logs acquired through UPM’s own wood sourcing operations.

“Through this long-term

partnership with Finland’s largest private producer and processor of sawn timber, we will significantly strengthen the availability of pulpwood and wood chips for UPM’s pulp mills in Finland. At the same time, the processing of valuable Finnish logs into highquality sawn timber will continue in a company that focuses on

the further processing of sawn products,” says Petri Hakanen, senior vice president at UPM Fibres Finland Operations.

“The agreement we have now signed is a natural continuation of our long-term cooperation with Versowood.”

As part of the agreement, UPM will sell its Korkeakoski

sawmill, at Juupajoki in Finland, to Versowood and receive a minority shareholding in the company in return. The Korkeakoski sawmill has produced annually 350,000 cubic metres of highquality pine sawn timber for the domestic market and for export. After the agreement is set up, UPM will have three sawmills in Lappeenranta, Pori and Pietarsaari, and the company will still be one of Finland’s biggest producers of sawn timber. The agreement is subject to regulatory approvals, including approval by the Finnish Competition and Consumer Authority, which are expected to completed by the end of 2025.

The world’s first mechanised paper mill has been reopened for visitor tours for the first time since it was devastated by a fire nearly four years ago.

The Frogmore Paper Mill at Hemel Hempstead in the UK was where the first Fourdrinier machine was installed in 1803. The mill, one of several in the area, was run by a number of operators until 2000 when the British Paper Company handed it to the Apsley Paper Trail charity which preserved its importance for future generations.

The site suffered significant fire damage due to arson in January 2022, leading to its closure and demolition of the visitor centre. Since then staff, volunteers and supporters have worked to restore and rebuild the facility.

Following the first ‘hard hat’ tour in October, visitors are guided twice-weekly around the mill as it

continues to recover and evolve, enabling the viewing of the historic paper making machinery and taking in demonstrations of paper making by hand and machine.

The Frogmore Mill site dates from at least the 13th century when it was named in a charter of Ashridge Monastery and used for corn milling, and later as a fulling mill. It was converted to paper making in 1774.

By 1803 the mill was acquired by the brothers Henry and Sealy Fourdrinier, important stationers in London, who installed the world’s first mechanised papermaking machine. The machine was perfected by engineer Bryan Donkin from Nicolas-Louis Robert’s design – the first Fourdrinier type prototype. Donkin installed several other similar improved machines in the area.

Mechanisation brought increased consumption of raw materials and

the supply of rags was insufficient, prompting investigation into alternative fibre sources. Esparto grass from desert regions was of particular significance, imported into the North of England as productive use of return trips for ships exporting coal and then transported by rail to Hemel Hempstead.

John Dickinson and Co leased Frogmore Mill and the nearby Two

Canadian tissue and paper maker Cascades has sold its Flexible Packaging business at its Mississauga mill in Ontario to Five Star Holding for C$31 million.

Flexible Packaging produces printed flexible plastic packaging and films and was the only such operation within Cascades, which will retain ownership of the site.

Quebec-based Cascades said the sale reflected its commitment to continuously advance its operations, commercial approach

and business model, in order to deliver the most value to its customers. The deal includes a supply agreement between to ensure the continued production and supply of the flexible film that is used by Cascades’ Tissue and Packaging businesses.

Hugues Simon, chief executive at Cascades, said that the decision would allow the company, “to reduce our debt and support the optimisation of our operational platform to grow our strategic sectors. We are

pleased to have found in Five Star a buyer committed to maintaining and developing the plant’s activities”.

Simon added: “We wish to thank our colleagues at Cascades Flexible Packaging for their contribution and look forward to continuing our collaboration with them as a one of their customers.”

Sales at Cascades Inc in the three months to the end of September were C$1.24 billion, up by 3 percent compared with

Waters Mill to prepare esparto half stuff for their other mills for 10 years from 1877, after which trials of pulp production from a variety of vegetable fibres including bamboo, esparto and wood had been explored at Frogmore.

In 1890 Herbert Sanguinetti started the British Paper Company for recycling used paper. Initially, one machine produced paper and lightweight board for printers and laminators. In 1907 a second machine (known today as Fourdrinier No2) was installed under the direction of Cecil Sanguinetti, Herbert’s third son, who largely controlled the destiny of the mill until his death in 1962 aged 90.

The mill can now be visited on guided ‘hard hat’ tours, offered twice weekly on Wednesdays and Thursdays. Numbers are limited, so tickets should be booked in advance at www. frogmorepapermill.org.uk

the same quarter last year. Based in in Houston, Texas, Five Star manufactures and designs a broad range of flexible packaging, printed films, and sustainability programmes focused on pet care, food & beverage, and consumer & industrial markets.

Vital components for a pulp mill expansion in Uruguay have been delivered and transported successfully to a construction site near the Punta Pereira private terminal.

The massive components – described as “critically oversized” – which are part of a deaeration tower, were handled by international logistics specialist deugro, in collaboration with dteq Transport Engineering Solutions.

The shipment included one unit measuring 10.9 x 10.4 x 10.2 metres and weighing 56 tonnes, another at 34.7 x 9.4 x 9.1 metres weighing even more at 140 tonnes and finally the heaviest weighing 150 tonnes and measuring 18.8 x 9.2 x 9.1 metres.

All three components had been shipped from the manufacturer in China by a heavy lift vessel from the Port of Taicang to the Punta Pereira terminal, north west of the capital Montevideo.

The US$1.9-billion Montes del Plata pulp mill, adjacent to the terminal, has been operating there since 2013, producing more than 1.3 million tons of plantation-based pulp a year.

The biggest challenge of the project was the on-carriage from the vessel discharge from the port to the laydown area, despite being at a distance of just two kilometres.

This involved a number of tight turns, extremely close buildings and street furniture along the route. To ensure a safe and effective transport against these restrictions, as well as the delivery of all components on time and

according to budget, meticulous preparation and planning with measurements to the nearest centimetre were required.

Engineers at dtec were commissioned by deugro to conduct a road survey, which determined the dimensional limits and corresponding maximum technically-feasible cargo dimensions and transport envelops that could be safely and efficiently moved across the infrastructure –from the port to the laydown area. This way, it was possible to ensure from the outset that the client’s cargo could be delivered without the need for modifications and without extensive transport management measures along the route, reducing time and costs.

“One of the challenging aspects of the project was the need to transport the cargo units through confined areas in the project site,” said Irene Gonzalez, transport engineer at dteq Transport Engineering Solutions. “dteq worked very closely with deugro Uruguay to gather all the information needed to develop transport solutions and swept path analyses needed in order to ensure a safe transport to the final place of rest on site.

“This allowed us to work on horizontal and vertical swept path simulations, in which we were able to identify potential clashes with existing buildings and road furniture ahead of the transport so that they could be removed prior to execution. Ultimately, all transports went smoothly and were moved with a minimum clearance of 100mm.”

Thanks to the precise calculations and

analyses, the cargo components were safely moved to the laydown area at the construction site, without major transport management measures along the route, apart from the removal of a few lamp posts.

“This allowed the oversized cargo units to be transported at their maximum dimensions, significantly reducing subsequent assembly costs, while avoiding having to choose between modifying or downsizing the cargo units and removing buildings along the transport corridor – resulting in further substantial cost savings,” said Nicolas Gomez, country manager for deugro Uruguay.

Another challenge was the width and length of the largest component, which to meet the required safety and industry standards, called for side-by-side axle lines. This equipment is not readily available in Uruguay, and importing would have significantly increased costs.

To address this, the truck was substituted with a self-propelled modular transporter (SPMT), enabling the components to be loaded onto shorter equipment. To guide the cargo units from the vessel to the construction site – along all critical intersections and bottlenecks –project managers from deugro were on-site to coordinate and supervise all of the operations.

“The close and excellent collaboration with the client, dteq and all partners involved, along with the precise project preparation and execution, ensured that all cargo components were delivered safely and on time,” concluded Gomez.

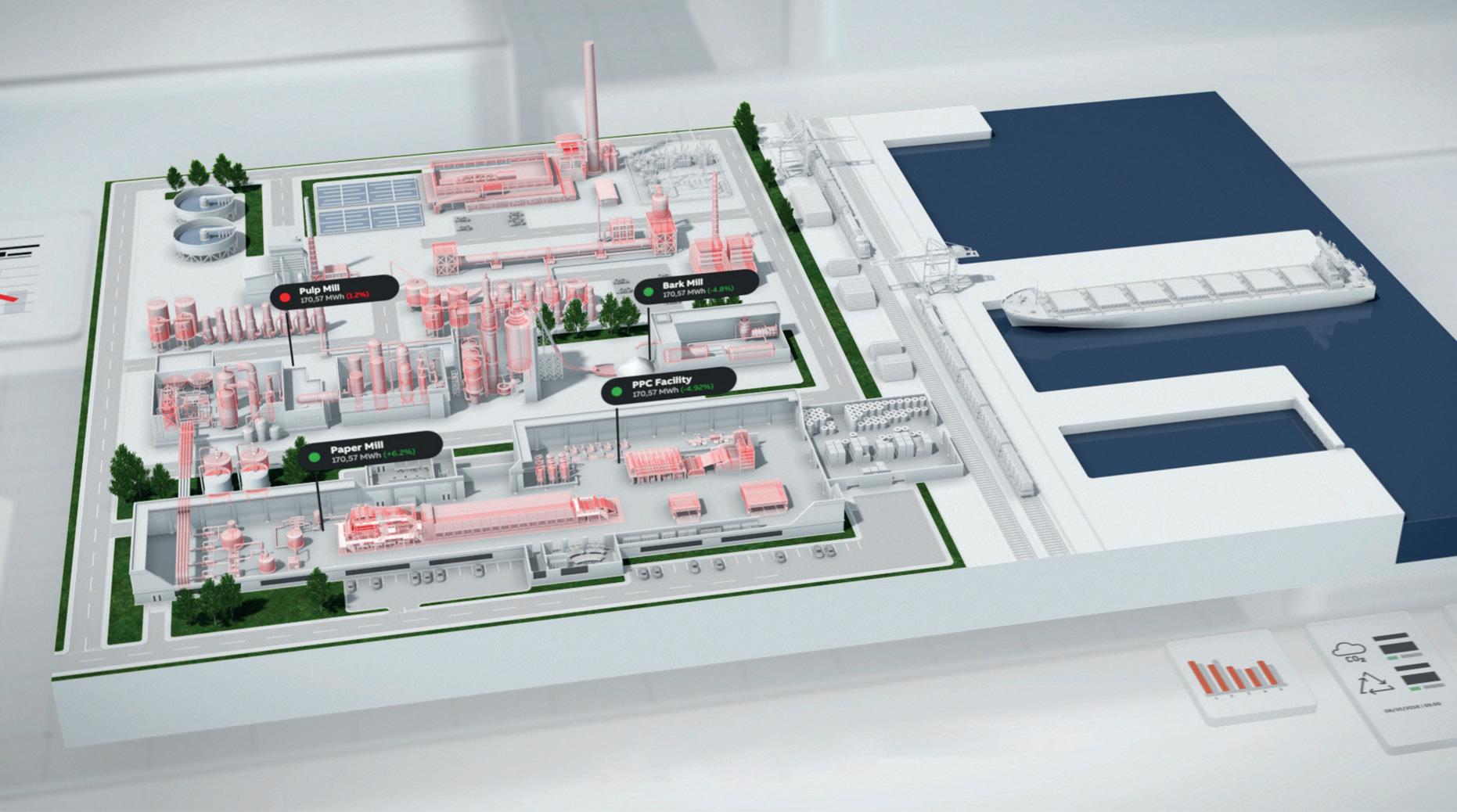

Improved cybersecurity in pulp and paper mills is enabling the integration of operational and information technology systems to unlock real-time data flow, enhanced operational visibility, accelerated decision-making, and the adoption of artificial intelligence. PPL reports

In the pulp and paper industry, operational technology (OT) systems that control and automate physical industrial operations have traditionally been isolated from information technology (IT) systems that manage data and enterprise-level functions. This separation was largely driven by cybersecurity concerns, leading to

strict controls on OT networks and limiting their ability to connect with broader IT infrastructure.

However, this division has hindered the ability to achieve critical automation advancements.

Integrating OT and IT systems enable continuous data flow, unlocking full operational visibility, accelerating decision-making, and allowing for proactive problem-

solving. It also lays the foundation for AI-driven process automation, which depends on secure, realtime access to external data to deliver real-time monitoring, predictive maintenance, and adaptive control.

This shift is accelerating the development of systems that support secure IT/OT convergence, prompting leading DCS

providers like Valmet to design solutions with cybersecurity and connectivity as foundational elements.

“Modern distributed control systems must now enable open yet secure communication across all levels of the automation architecture – bridging OT and IT environments – while protecting critical assets and data. The

Integrating OT and IT systems enable continuous data flow, unlocking full operational visibility, accelerating decision-making, and allowing for proactive problem-solving

objective is to advance toward intelligent automation that enhances operational efficiency, increases asset utilisation, and delivers tangible cost savings across the production landscape,” says Taavi Veltheim, manager of global solution management for distributed control systems (DCS) at Valmet.

Valmet is a leading worldwide provider of process technologies, automation systems, and services for the pulp, paper, and

and software used to control, monitor, and automate physical industrial processes. These systems are critical for ensuring the safe, efficient, and continuous operation of equipment such as pumps, compressors, reactors, valves, and other machinery commonly found in pulp and paper mills.

However, automation systems have traditionally functioned as isolated, highly secured environments: effectively digital fortresses with strict controls preventing any external data exchange. While this architecture provided strong protection against cyber threats, it also created a major limitation: no digital data could enter or exit the OT network.

Without this connectivity, linking production systems with business technologies such as analytics tools, cloud platforms, and enterprise resource planning (ERP) systems was not possible. However, connecting these environments delivers tremendous benefits by enabling continuous data flow, delivering end-to-end operational insight and allowing organisations to identify patterns, address problems proactively, and make better, faster decisions.

models and external insights while enforcing strict data protection measures to safeguard their competitive knowledge and ensure responsible AI deployment.

With AI-driven tools set to transform process automation, the emphasis is shifting to the distributed control systems (DCS) that serve as a foundational component of OT, providing the essential control infrastructure that enables safe, stable, and efficient operation of continuous industrial processes.

In the pulp and paper industry, distributed control systems (DCS) are used to oversee and optimise key stages such as pulping, bleaching, washing, drying, and finishing. These processes require tight control of variables like chemical dosing, steam usage, pressure, and moisture content to ensure consistent product quality. By coordinating these functions in real time, DCS help maintain consistent product quality, improve process efficiency, and reduce the risk of human error.

energy sectors. The company’s automation and flow control offerings further extend their reach into a wide range of other process industries. With headquarters in Espoo, Finland, Valmet has more than 220 years of experience in the industrial sector.

According to Veltheim, operational technology (OT) systems in pulp and paper manufacturing encompass the hardware

AI-driven tools also require access to external information for effective implementation within closed, automated systems. These systems must securely exchange data beyond their immediate environment to harness the full potential of artificial intelligence, particularly generative AI.

With generative AI, even a single well-crafted prompt has the potential to expose sensitive intellectual property such as proprietary processes or datasets. Therefore, organisations must strike a careful balance between enabling access to pre-trained

“Digitalisation initiatives have pushed DCS towards higher levels of connectivity and automation,” says Veltheim. “Today, DCS are expected to provide open and secure connectivity at all levels, including between operational and information systems.”

However, this shift introduces a new layer of complexity: securing the convergence point where data from physical operations intersects with enterprise IT systems. This is where modern distributed control systems play a pivotal role.

Cybersecure by design

To meet these challenges, Valmet has launched the newest generation of its DNA distributed control system from the very first

lines of code to deliver cutting edge cybersecurity, user interface, data storage and management, and other advanced features.

Introduced in 2024, Valmet DNAe takes a modern and proactive approach to cybersecurity, enabling companies to effectively prevent and respond to evolving cyber threats.

Valmet DNAe was built with IT/ OT convergence in mind, offering seamless connectivity from sensors to the cloud using edge technology and industrial-standard interfaces. The integration enables enhanced digital intelligence, paving the way for AI-powered tools at every level.

According to David Ding, OT cybersecurity engineer at Valmet, “DNAe is engineered with security at its foundation, empowering customers to stay ahead of cyber threats as OT environments become more interconnected and complex.”

Valmet approached the task by adopting the cybersecurity philosophy known as ‘security by design’. This school of thought emphasises incorporating security measures from the very beginning of a product’s development cycle, rather than adding them later in response to threats. Valmet DNAe’s product development process was validated with the Security Development Lifecycle Assurance (SDLA) certification in 2020. Valmet DNAe cybersecurity is also externally certified according to ISO 27001 and IEC 62443 standards.

Valmet recently reached a significant milestone in industrial cybersecurity by becoming the first fully web-based system to receive the ISASecure System Security Assurance (SSA) Security Level 1 certificate. The external assessment conducted by Exida, a product-certification and

knowledge company specialising in automation system safety, alarm management, cybersecurity, and availability, ensured that Valmet DNAe meets the strict security requirements and levels specified in the ISA/IEC 62443-3-3 standard.

At the core of the Valmet DNAe Distributed Control System is the Trusted Information Framework (TIF), which serves as the backbone for communication and data management. Built upon the TIF foundation, Valmet DNAe architecture includes measures such as role-based access control, authentication, encryption, endpoint protection and comprehensive audit trails.

Valmet DNAe incorporates endpoint protection measures such as system hardening, antivirus software and application whitelisting to reduce the risk of malware, unauthorised access and system compromise.

Encryption protocols, access controls, and VPN tunneling are used to secure data transmissions by encrypting communications and restricting access to authorised users, protecting sensitive information from interception or tampering. These measures support secure

remote access, enabling approved personnel to monitor, operate, and maintain mill systems from any location while preserving the confidentiality and integrity of all communications.

For IT teams, Valmet DNAe provides centralised user management and Active Directory (AD) integration, enabling role-based access control and authentication. Additionally, the system offers authorisation, audit trails, secure communication, encryption mechanisms, content-signed software, and comprehensive logging.

IT security integration helps security teams stay alert to potential threats. If needed, Valmet DNAe can deliver intrusion detection and prevention mechanisms to monitor network traffic and detect potential security breaches in real time. Centralised log management enables comprehensive analysis of security events, facilitating timely response and mitigation measures.

To support enterpriselevel visibility, Valmet DNAe integrates with customers’ Security Information and Event Management (SIEM) solutions,

providing valuable information to Security Operations Center (SOC) teams. Customers are supported by extensive Valmet Cybersecurity Services.

The future is now The integration of operational and information systems today depends on systems that can provide secure, real-time communication across multiple layers of an organisation’s infrastructure. Distributed control systems serve as critical enablers, tasked not only with managing process operations but also with ensuring secure data exchange between the plant floor and enterprise systems.

The growing reliance on AI tools and remote connectivity adds urgency to this shift. Ensuring that such technologies can be deployed safely and effectively in pulp and paper manufacturing requires a foundational approach to cybersecurity – one that is embedded into system architecture rather than added as an afterthought.

For more information about Valmet’s process automation systems, go to www.valmet.com/ dnae

Stop collecting paper samples!

Improve your press section efficiency! SmartScan™ contactless sensor accurately measures paper web dryness after the press section 24 hours a day, 7 days a week. Using a proprietary microwave technology, it is developed to overcome the typical limits of the NIR (near-infrared) sensors. SmartScan™ is available both for fixed point positions or traversing web scan. To save hundred of thousands of Euros in energy costs, stop collecting samples, choose the safe accuracy of SmartScan™ technology.

Cristini S.p.A. Diagnostic Systems Via Bombardieri, 5 – 24020 Fiorano al Serio (BG) Italy Tel +39 035 715 111 Fax + 39 035 711 451 email diagnostic.systems@cristini.it website www.cristini.com

Optimisation and automation are increasingly working across process islands in mills using new software tools, as explained by Wilson Monteiro* and Sanjit Shewale* from ABB

Running a pulp or paper mill has always been a balancing act. Fibre, water, energy, and chemicals all flow through tightly linked processes where a small disturbance in one area can ripple across the entire operation. If papermaking is a high-wire act, then optimisation and automation are the safety net, helping mills keep their footing

while conditions shift beneath them.

Today, these technologies are no longer nice-to-have tools for incremental efficiency. They are the backbone of quality improvement across an industry under pressure. From aging infrastructure and workforce turnover to rising operational complexity and customer demand for tighter tolerances, mills are

discovering that traditional ways of managing quality are no longer enough. To succeed, they need sharper visibility, faster feedback loops, and the ability to make better decisions in real time.

Turning noise into insight

For decades, many mills relied on manual testing and operator intuition to keep production on spec. But judging quality by a

handful of lab samples is like trying to understand a novel by reading only a few pages. Critical variations across the sheet or shifts in process conditions were easily missed, leading to costly rework or scrap.

Automation changes that equation. By embedding advanced sensors, data models, and closedloop controls directly into the process, mills can monitor quality

at a scale and frequency that human testing simply cannot match. Variations that once took hours or days to uncover now trigger near-instant alerts and corrective actions. The result is less waste, more consistent output, and a foundation for continuous improvement.

Of course, data alone doesn’t solve the problem. In a modern pulp mill, streams of information pour in from every unit of operation. Without the right tools, it can feel less like clarity and more like standing in a hurricane of numbers. What sets today’s optimisation systems apart is their ability to filter, interpret, and transform raw data into actionable insight.

Advanced process control, for example, can stabilise notoriously complex operations such as lime kilns or recovery boilers. These are environments where sensors often struggle, and variables interact in non-linear ways. By applying predictive models and optimisation algorithms, mills can reduce chemical use, improve product uniformity, and extend equipment life, all while keeping safety risks in check. In paper production, automated quality testing has had a similar effect. By capturing ten times more data points per reel than manual methods, automated systems can paint a detailed picture of strength, basis weight, and fibre orientation across the sheet. This ‘full-canvas view’ empowers operators to make on-the-fly adjustments that prevent off-spec rolls, while also uncovering opportunities to reduce basis weight or additive use without sacrificing performance.

But the real frontier for quality improvement lies in breaking down the walls between individual processes. Mills have historically managed operations in silos with a digester here, bleaching there and machines downstream. Each department is optimised within its own boundaries, often at the expense of the mill as a whole.

That’s why the launch of new mill-wide optimisation software, such as ABB Ability Plant Optimizer for Pulp Mills, marks such an important shift. By linking production planning with real-time operations, these systems turn a patchwork of local decisions into a coordinated strategy. They track material flows and quality-critical variables across every unit, making it possible to trace a deviation back to its root cause instead of just treating the symptoms downstream.

It’s less like patching leaks in a

pipeline one at a time and more like controlling the entire flow from the source. When every stage of production is connected and coordinated, mills can manage quality as a continuous process rather than a series of isolated fixes.

Agility in an age of uncertainty

Quality today is about maintaining high-specification standards as conditions shift. Mills face volatile fibre supply, rising energy costs, unexpected equipment upsets, and fluctuating customer demand. In this environment, static planning falls short.

Dynamic optimisation tools are helping mills to move beyond reactive firefighting toward proactive, scenario-based decision-making. By modelling alternative production plans, simulating shutdown and startup strategies, or identifying bottlenecks before they bite, mills can adapt without compromising

quality. The ability to calculate optimum setpoints and production rates on demand, or even continuously, helps balance throughput, cost, and resource use within the existing asset base. This agility is not just about efficiency. It builds resilience at a time when many mills are grappling with retiring experts and fewer experienced operators on the floor. Optimisation software acts as a digital mentor, embedding best practices and providing decision support that keeps newer teams working with greater confidence and consistency.

The pulp and paper industry may be centuries old, but its future will be written in real-time data and automated control. The winners will be the mills that see quality not as a checkpoint at the end of the line, but as a thread woven

through every stage of production. Optimisation and automation are making that vision practical. They allow mills to reduce waste, extend equipment life, and make better use of raw materials. More importantly, they give producers the confidence to meet higher customer expectations without

driving up costs.

In a market where packaging strength, tissue softness, or pulp purity can make or break customer relationships, consistent quality is the key to securing trust and long-term growth. And like craftsmen who sharpen their tools before shaping the product, mills

that invest in smarter processes today will be better equipped to produce the quality their markets demand tomorrow.

*At ABB, Wilson Monteiro is Global Business Line Manager for Pulp and Paper and Sanjit Shewale is Division Head of Digital (www. global.abb)

The leading Nordic professional event for the forest-based bioeconomy, as well as the pulp and paper industry, is coming again in spring 2026!

Pulp & Beyond brings together the latest innovations, products, services, technologies, and key industry professionals from Finland and around the world.

Popular conference and excursion packages are also on the way, along with much more – stay tuned for more details!

Secure your company’s spot at the event

Hanna Mårtensson, Salesmanager +358 40 565 1433

hanna.martensson@messukeskus.com

As the industry moves toward intelligent, self-optimising operations, advanced process control is a critical driver in the transformation. Daniel Schuck* explains how it is an enabler of stabilising and improving process performance

In the modern pulp and paper industry, operational excellence is no longer measured by output alone. Today, it’s defined by a mill’s ability to deliver consistent quality, control costs and meet ambitious environmental goals; all while navigating increasingly complex production environments.

Rising energy and raw material costs, stricter sustainability mandates and the accelerating pace of digital transformation are reshaping how mills operate. To stay competitive, they must push closer to process limits without compromising stability or efficiency.

This is where Advanced Process Control (APC) steps in, not just as an optimisation tool, but as a strategic technology that improves overall plant performance and works as the starting point for plants’ digital transformation.

Strategic benefits of Advanced Process Control

Stabilising plant performance

Process variability is one of the most significant challenges in pulp and paper operations.

Fluctuations in variables such as Kappa number, brightness, steam pressure and chemical dosing can lead to inefficiencies and quality deviations. APC systems continuously monitor and adjust

these variables, ensuring stable operation even under dynamic conditions.

Enhancing product quality

Consistent product quality is essential for customer satisfaction and market competitiveness. APC enables mills to maintain tighter control over specifications, reducing the risk of off-spec production.

Increasing throughput and productivity

By stabilising operations and minimising downtime, APC allows mills to operate closer to their maximum capacity. Recent internal case studies show production increases of up to 4 percent and productivity gains of up to 10 percent, achieved without major capital investments.

Reducing operational costs

Cost savings are realised through multiple channels:

l Chemical reduction: Better control minimises overuse.

l Energy efficiency: Optimised boiler and steam systems reduce fuel consumption. A more stable process can also reduce steam consumption.

l Water savings: APC minimises unnecessary water usage in washing and paper machines.

Improving mill availability

Unplanned shutdowns and

interlocks can be costly. APC systems include slowdown mechanisms that proactively adjust production in response to process disturbances, helping avoid interlocks and maintain uptime.

Reducing operator workload

Controlling complex variables is cognitively demanding. APC reduces the need for manual setpoint adjustments, allowing operators to focus on higher-value tasks.

Supporting sustainability goals

Environmental performance is increasingly tied to business success. APC contributes to sustainability by:

l Reducing emissions through optimised combustion and waste treatment.

l Lowering water usage with efficient process control.

l Improving energy efficiency by balancing steam and energy flows.

Andritz APC: When APC meets expertise and transparency

To help mills realise the full potential of APC, Andritz offers Andritz APC (Advanced Process Control), a supervisory process management system that acts as an automated expert operator. Andritz APC autonomously optimises process areas based

on cost and value, outperforming even the most experienced human operators.

Key features of Andritz APC:

l Multivariable, predictive and adaptive control.

l Glass-box architecture with embedded documentation.

l Native-language communication for operator guidance.

l Low-code development environment for fast deployment, built-in Andritz know-how via ready-to-use APC Libraries

Andritz APC is designed to be transparent, collaborative and scalable. Unlike black-box solutions, it provides clear logic and communicates directly with operators about strategy shifts, constraints and operational goals.

Flexible deployment:

l Complete solutions for defined scopes.

l ROI-guaranteed implementations.

l Integration with instruments, upgraded controls and Operator Training Simulators.

l Compatibility with DCS and Digital Twin environments.

Low-code customisation

Andritz APC is designed for flexibility. Customers can deploy and adapt the system using a

low-code environment, enabling faster implementation and easier scaling.

Andritz APC measurable values

The benefits of Advanced Process Control are not just theoretical: they’re measurable. Across multiple deployments, Andritz APC has consistently delivered tangible improvements in performance, cost-efficiency and sustainability.

The table overleaf summarises the range of improvements observed in Andritz ’s case studies applications.

APC optimises production by controlling inventory near the process and uses automatic PID tuning to keep loops stable and responsive across all production levels.

Cost reduction

Qualtiy loss reduction

Mill availability

Productivity increase

Operator action reduction

Emission reduction

Water usage reduction

Energy efficiency

These estimations in the chart reflect the flexibility and scalability of Andritz APC across different milling environments and process areas. Whether the goal is to reduce emissions, improve product consistency, or increase throughput, it delivers measurable value quickly and reliably.

Enhancing fibreline stability for a leading global pulp producer

A global leader in hardwood pulp production, renowned for its commitment to sustainability, innovation and operational excellence, faced a persistent challenge: frequent fibreline shutdowns were disrupting productivity and driving up production losses.

The challenge

The mill needed to stabilise fibreline operations to reduce variability, improve reliability and recover lost output. Despite having advanced infrastructure, the root causes of instability were difficult to pinpoint and resolve using traditional control methods.

The solution

Andritz deployed a comprehensive

APC strategy tailored to the mill’s needs. This included:

l In-depth equipment diagnostics and alarm integration,

l Advanced tuning of 47 control loops,

l Implementation of eight digital solutions to enhance process reliability. These interventions were designed not only to correct immediate issues but also to build a more resilient and self-correcting control environment.

results

The impact was both immediate and measurable:

l 94 percent of operational stability was achieved in the fibreline area.

l 60 percent reduction in the standard deviation of critical

Stabilised variables allow for tighter specs.

Control of complex variables.

Slowdown mechanisms prevent interlocks.

Reduced cognitive load on operators.

Automated setpoint management.

Optimised combustion and waste treatment.

Efficient combustion and washing control.

Boiler and steam system optimisation, as well as consumption optimisation

parameters, such as washer basin dilution – thanks to mesh adjustments and improved control logic.

l 54 percent reduction in product variability, contributing to more consistent quality and reduced waste.

By addressing the root causes of instability and automating complex control tasks, the mill significantly improved its operational reliability, demonstrating the transformative power of APC when paired with deep process expertise.

an enabler of the autonomous plant

From process stability to full operational autonomy

Advanced Process Control is more than a performance tool; it’s the

foundation of the autonomous mill. When integrated with Distributed Control Systems (DCS) and Digital Twins, solutions like Andritz APC enable real-time simulation, predictive maintenance and closed-loop optimisation. This convergence of technologies empowers mills to operate with greater agility, intelligence and resilience.

By continuously adapting to process changes, Andritz APC minimises variability, reduces manual intervention and enhances decision-making across all process areas. The result? Tangible improvements in production efficiency, product quality, cost control and environmental performance.

As the industry moves toward intelligent, self-optimising operations, APC will be a critical transformation driver. Andritz is proud to lead this evolution by delivering measurable value through transparent and collaborative approach with expert-driven solutions that help mills’ operations reach their full potential.

* Daniel Schuck is Vice-President Automation & Digitalization, Digital Products & Solutions at Andritz

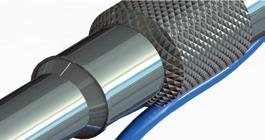

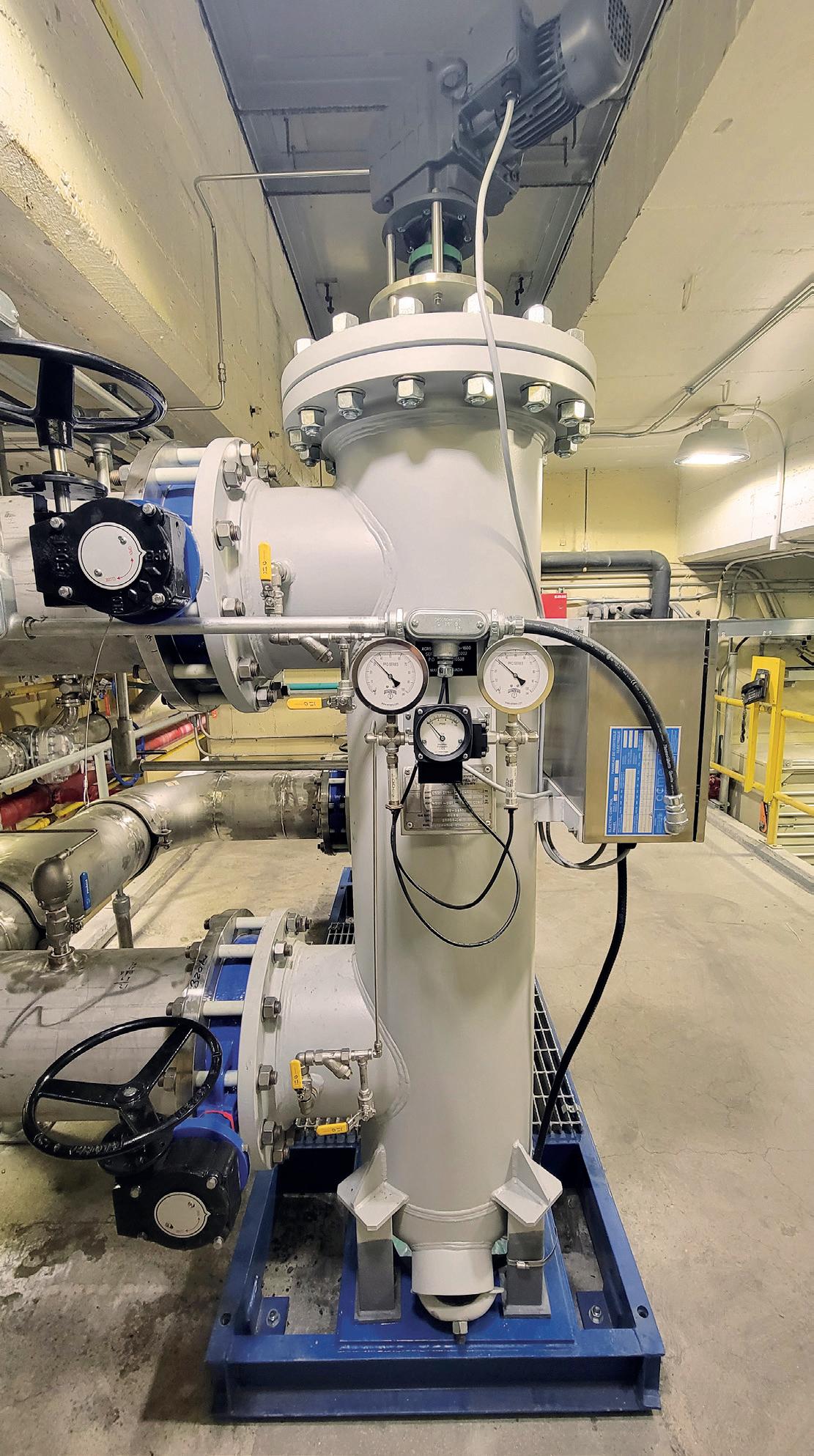

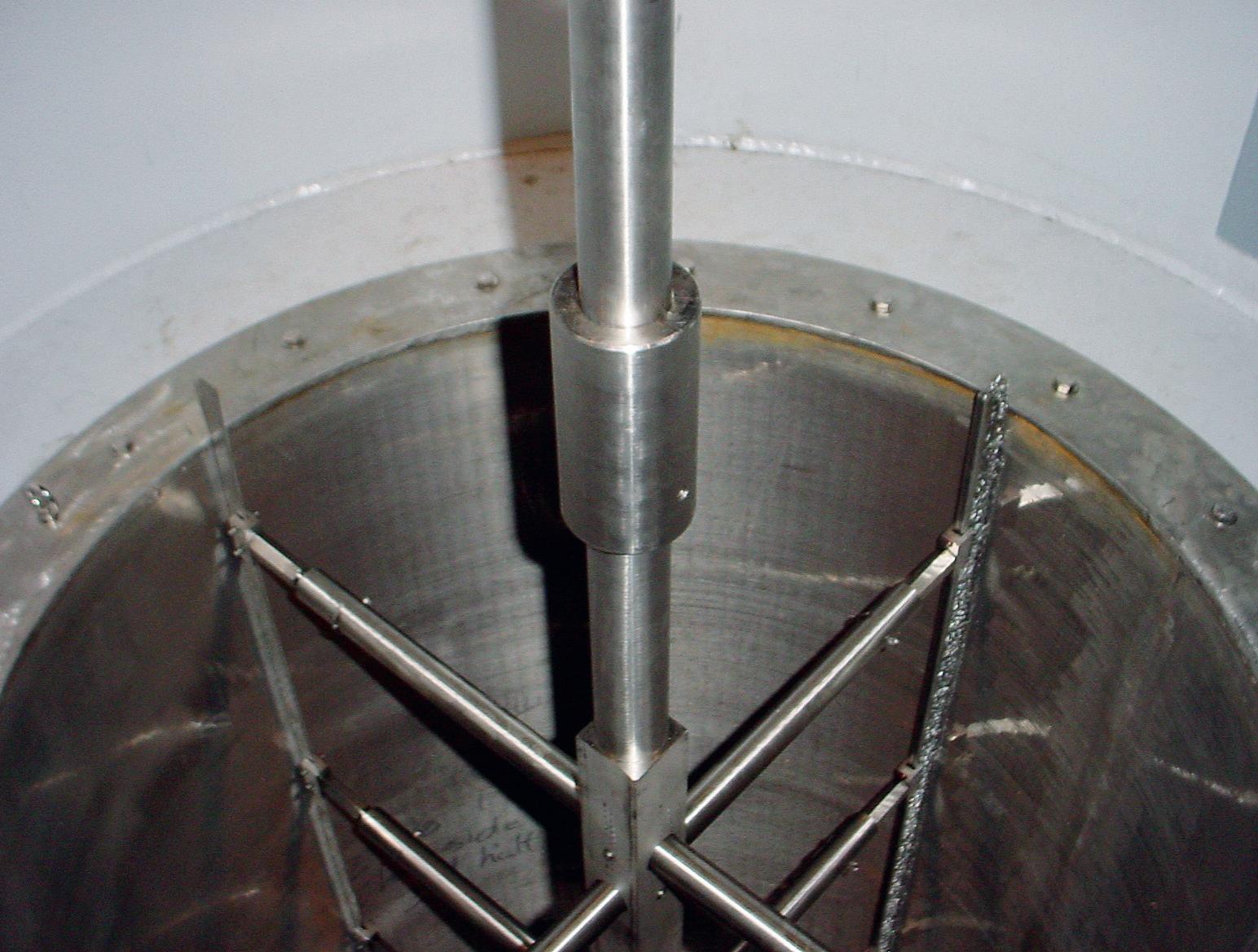

An international strainer expert helps industry professionals take advantage of scraper strainer technology, explains how it compares to traditional choices, and provides guidance on selection and installation. PPL reports

Pulp and paper mill engineers are responsible for keeping complex production systems running efficiently –balancing process reliability, product quality, and regulatory compliance, often under intense operational demands. They oversee everything from fibre preparation and chemical recovery to waste-water treatment and environmental discharge.

In this high-pressure environment, water quality plays a critical role. That is why advanced filtration technologies, particularly automatic scraper strainers, are essential. These systems help protect downstream equipment, minimise maintenance disruptions, and ensure consistent water purity – all crucial for maintaining uptime and meeting environmental standards in a mill that runs 24/7.

Pulp and paper mill engineers depend on industrial strainers to separate unwanted suspended solids from liquids and slurries. Strainers are commonly used in white-water applications to remove clumps of fibres and in black liquor straining before being sent to the burner. Strainers may also be used in the treatment of waste-water, seawater, or removal of debris from process and cooling tower water.

In the industry, pulp and paper mill engineers are often involved in specifying strainers, particularly

Strainers are used in the treatment of waste-water or removal of debris from process and cooling tower water

in applications that require bid specs or system-level design decisions. In this endeavour, automatic scraper strainers offer numerous advantages over traditional choices such as backwash filters and basket strainers.

Backwash strainers and manual basket strainers are widely accepted technologies and are often the default option during specification. However, conventional strainer designs can present reliability challenges and require frequent maintenance, particularly in applications where large debris or high volumes of suspended solids are present.

In contrast, automatic scraper strainers – cleaning the screen through direct mechanical contact using brushes and blades – are less commonly known. Many pulp and paper mill engineers are unaware that self-cleaning systems utilising mechanical brushes are available. These mechanical scraper systems offer a simpler design, eliminate the need for auxiliary piping or external water sources, and provide a more robust and adaptable operational profile.

“Automatic scraper strainers are frequently overlooked due to limited familiarity, leading to default specifications of

backwash or basket strainers – even in scenarios where a scraper strainer would offer superior performance,” explains Philippe Ellison, project manager at Acme Engineering Products, a North American manufacturer of industrial self-cleaning strainers. This common oversight can result in reduced efficiency, higher maintenance requirements, and subpar system protection. Ellison offers the following guide to help pulp and paper mill engineers understand the advantages of scraper strainers versus traditional filters. The guide highlights key advantages, ideal uses, and selection basics to

help engineers specify the right solution with confidence.

Selecting the appropriate strainer begins with understanding the application’s process requirements, including the type and size of solids, solid loading, and what needs to be filtered.

Strainer sizing involves balancing flow rate, particle size, and solid concentration. Higher solid loading requires a larger filtration area and vessel size. As flow rate and particle concentration increase, so must the strainer’s capacity. Proper data on particle size distribution and operational conditions is critical for accurate equipment selection and sizing as well.

According to Ellison, pulp and paper mill engineers may specify the wrong type of strainer if they lack detailed information about the operating conditions.

“For example, backwash strainers are sometimes specified in applications where the solids are large, sticky, or difficult to remove – conditions that backwash systems struggle to manage effectively. In these cases, scraper strainers are the better option, as their mechanical cleaning action is specifically designed to handle challenging debris,” explains Ellison.

Oversizing backwash strainers can also reduce cleaning efficiency. Contrary to assumptions, bigger is not always better. Correct flow rate and pressure data are essential for designing effective backwash systems.

In addition, no fluid processing or filtration system remains static. Treatment conditions continually change due to variable factors such as pressure, particle size, solids loading, and even the presence of sticky biologicals.

“Flow rate and the amount

Scraper strainers are available in materials such as Monel, D2205, SD2507, and even fibre-reinforced plastic (FRP) as in this example

of suspended solids in a fluid can vary significantly based on production demands, equipment in use, time of day, day of the week, and even seasonal conditions,” explains Ellison.

“A properly selected strainer must be able to handle the full range of operating conditions to ensure consistent and reliable performance.”

Basket strainers are manual

filters used to remove large solids or debris from a fluid stream, typically in water or process piping systems. They consist of a pressure vessel housing that contains a perforated or meshlined basket. The basket acts as a screen to capture and retain particulates while allowing the fluid to pass through.

In water filtration applications, basket strainers are used to remove coarse materials such as leaves, sand, rust, scale, and

other solids that may be present in the water. This helps protect downstream equipment such as pumps, valves, meters, and more sensitive filters from clogging or damage.

In continuous flow processes that cannot be shut down for cleaning purposes, duplex basket strainers are often installed. This type of strainer employs two distinct chambers that function independently. When one chamber needs cleaning, the flow is seamlessly diverted to the alternate chamber, enabling the removal and cleaning of the first basket.

Cleaning is a messy, laborious process that involves equalising pressure between the baskets, diverting flow to the off-line chamber, opening the cover, manually removing the clogged basket, and cleaning it before refitting the basket, ensuring the seal, and tightening the fasteners. If an operator fails to adequately clean the basket strainers for any reason, both strainers can become clogged at the same time. This can result in quality issues or unexpected downtime until the problem is resolved. For many processors, this can occur simply due to having too few personnel to keep basket strainers clean, along with their other duties.

Backwash filters are used in water filtration systems to remove suspended solids, sediment, and other particulate matter from water. They are designed to operate continuously with minimal manual intervention by automatically cleaning themselves through a backwashing process. In normal operation, dirty fluid flows through the filtration screen, trapping suspended solids, allowing the effluent to

pass through the outlet. Over time, these trapped particles accumulate and begin to restrict flow, increasing the pressure drop across the strainer.

To restore performance, the backwash process is initiated. During backwashing, the drain valve opens, causing a reverse in flow across the section of the screen which is isolated by the backwash cleaning mechanism openings. This dislodges the accumulated solids, which are then pulled into the backwash cleaning mechanism and flushed out through a drain. Once the filtration screen is clean, the system returns to normal filtration mode.

Pulp and paper mill engineers are generally most familiar with backwash systems, which often leads to their default specification even in cases where scraper technology would offer a more effective solution. This tendency to standardise around known

designs can result in missed opportunities for performance and efficiency improvements.

Backwash filters rely on a substantial amount of flow and constant pressure, which can compromise reliability if not always available. “Backwash units do not operate well in backwash mode below 30 psi. To compensate, some utilise complex, pressure-inducing tactics, but these do not always resolve the issue,” says Ellison.

Additionally, conventional backwash units are not designed to effectively remove larger or irregularly shaped solids.

“Backwash systems are only recommended when filtration requirements are below 50 microns and solid loading is low,” says Ellison.

Backwashing is not ideal for removing large solids from the screen elements. The problem is that the backwash arm must be quite close to the screen

to function properly, and that prevents the passing of larger particles.

Backwash systems are also more complex and require additional control valves, instrumentation, and sometimes external water sources. Scraper strainers eliminate these needs and operate more flexibly through programmable control panels.

Acme Engineering offers a backwash filtration system that stands apart from conventional designs. A key distinguishing feature of Acme’s backwash filters is that they do not require an external source of cleaning water. Instead, they utilise the system’s own process fluid for cleaning, which simplifies installation and reduces water consumption. Additionally, these filters are engineered to operate effectively at lower differential pressures, enhancing system efficiency and extending component life.

Another notable advantage is

the internal cleaning mechanism: the suction arm assembly rotates during backwash cycles, while the filter screen itself remains stationary. This design minimises wear on the screen and maintains structural integrity over time.

Acme is the only manufacturer that produces automatic filtration equipment that can be converted between Backwash and Scraper easily in the field. The filtration housings are designed to accommodate both cleaning mechanisms, allowing operators to switch one for another if the wrong type was specified.

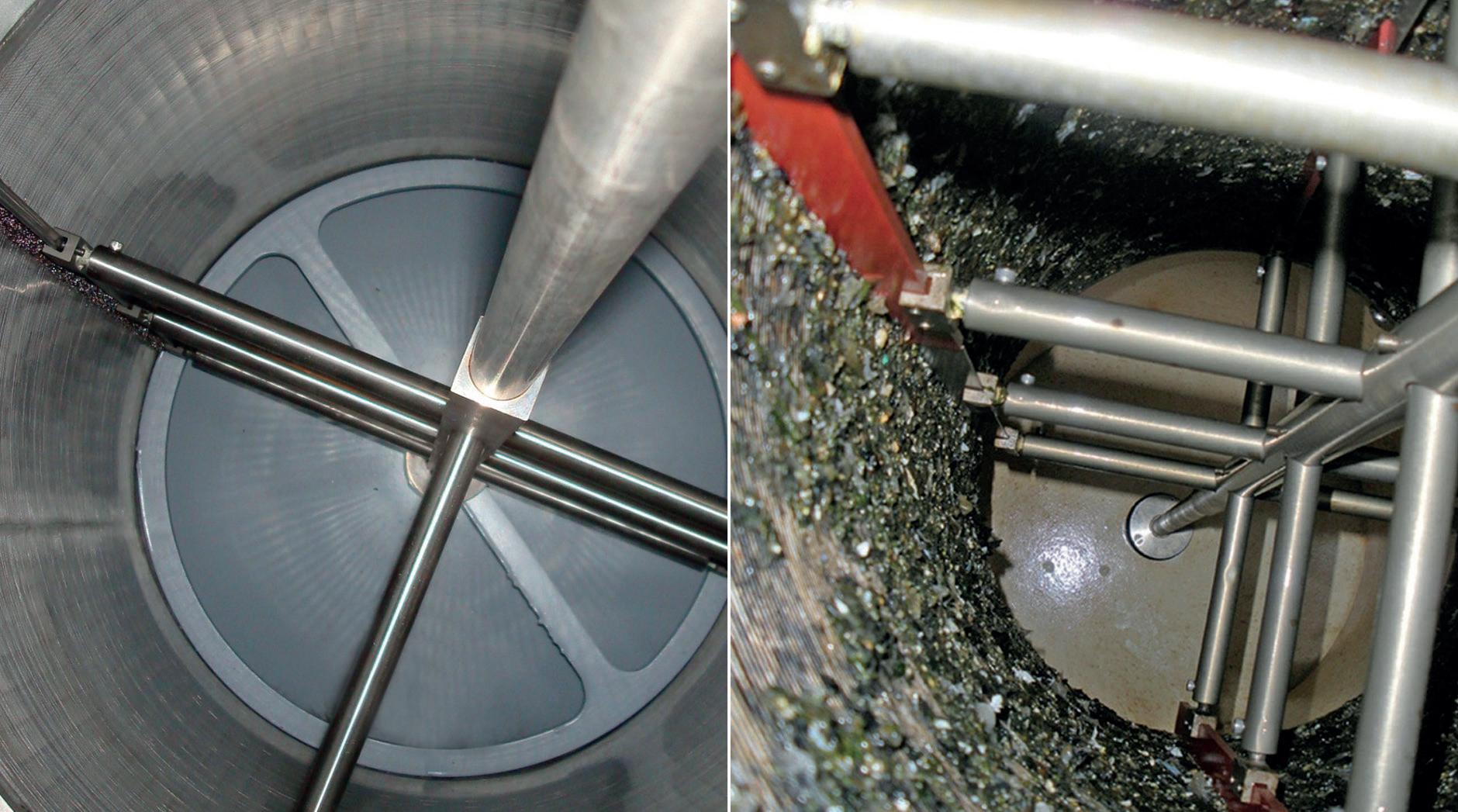

Automatic scraper strainers are a viable alternative to backwash systems in many scenarios. Unlike backwash strainers, scraper strainers do not rely on a pressurised backwash to remove solids from the screen. Instead, blades and brushes provide more reliable cleaning under varying conditions.

The automatic scraper strainer from Acme, for example, is a motorised unit designed to continuously remove both large and fine suspended solids. This process is managed by a fullyautomatic control system.

These scraper strainers are offered with three screen types, with their selection based on the specific application. Reverseformed wedge wire screens are the standard choice, valued for their durability and compatibility with brush cleaning systems. For applications requiring finer filtration, multilayer sintered metal mesh screens are recommended. In fibrous processes such as those in the pulp and paper industry, perforated screens with round holes provide optimum performance.

Four blades/brushes rotate at 8 rpm, resulting in a cleaning rate of 32 strokes per minute. The scraper brushes get into wedge-wire slots and dislodge resistant particulates and solids. This approach enables the scraper strainers to resist clogging and fouling when faced with large solids and high solids concentration. It ensures a complete cleaning and is very effective against organic matter ‘biofouling’.

Scraper strainers allow the solids to accumulate at the bottom of the vessel, where the blowdown valve will open periodically to clear them out. Blowdown occurs only at the end of the intermittent scraping cycle when a valve is opened for a few seconds to remove solids from the collector area. Liquid loss is well below 1 percent of total flow. If additional pressure is required to clean the screen, Acme Engineering can add an inexpensive trash pump to the blowdown line to assist in

removing the solids from the strainer sump.

“Since the solids are small, a little trash pump can pressurise the blowdown line to evacuate solids from the strainer,” says Ellison.

For applications with high solids loading that are prone to clogging, a macerator can be installed upstream of the automated scraper strainer to break down large solids into smaller fragments. This combination of proven technologies is already in use for some of the most demanding and debris-laden straining applications.

While standard carbon steel or stainless steel construction is suitable for typical applications, corrosive environments such as those involving seawater, erosive slurries, or aggressive chemicals can rapidly degrade conventional equipment. This deterioration can create risks related to safety, quality, and regulatory compliance, as well as cause production downtime due to the need for premature replacement of strainer components.

When the chemical properties and temperature of the process fluid raise concerns about

daily. The process is messy and undesirable, making it a task operators are often unwilling to carry out.

The frequency of part replacement often depends on the severity of the conditions and how often cleaning is required for the application.

material compatibility, automated scraper strainers are available in other materials such as Monel, D2205, SD2507, and even fibrereinforced plastic (FRP). The internal mechanism and wetted components can be manufactured from super duplex or similar highperformance steels.

Cost comparison

Manual basket strainers are the lowest-cost option but require frequent operator intervention. Scraper strainers are a midpriced solution and operate automatically. Backwash strainers are typically the most expensive due to system complexity, additional control valves, instrumentation, and sometimes external water sources.

According to Ellison, the costbenefit ratio of scraper strainers should factor into reduced infrastructure requirements, wear item replacement costs, and ongoing maintenance.

For example, a single, automated scraper strainer can replace multiple manual basket strainers as well as the associated piping. Basket strainers require regular maintenance, with manual models requiring cleaning several times

“While scraper strainers contain a few more wear components, such as brushes and blades, these parts are relatively inexpensive. In contrast, backwash systems can feature fewer wear parts but require more costly replacements. Over time, the maintenance expenses for both systems tend to balance out,” says Ellison.

Pulp and paper mill engineers face increasing pressure to deliver systems that are not only highperforming and cost-effective but are also reliable and have low maintenance needs. The adoption of advanced scraper strainer technology represents a significant opportunity to meet these demands.

By offering a mechanically robust, self-cleaning design that functions effectively in a broad range of operating conditions, automatic scraper strainers provide tangible advantages over traditional basket and backwash filters, particularly in high-solids or variable-load applications.

“As engineers become more familiar with scraper technology’s capabilities, supported by application data, installation success stories, and performance metrics, they are more likely to consider it a primary option in system design,” says Ellison.

More information from www. acmeprod.com or by mail at Acme Engineering Prod Inc, Trimex Building, Route 11, POB 460 PMB 10, Mooers, New York 12958, USA. Tel: 1 518 236 5659. Email: phil@ acmeprod.com

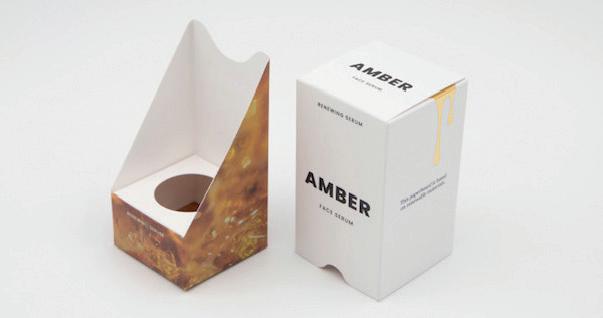

An extended food packaging portfolio has been launched by Mondi. The range includes solid board and digital printing following the acquisition of Schumacher Packaging, widening Mondi’s ability to serve customers across Europe.

The expansion enables Mondi to support customers in meeting evolving consumer expectations, EU regulations and the growing demand for sustainable, convenient and stand-out packaging.

Mondi’s extended offering addresses the most important trends shaping the food packaging industry. These include

Examples from Mondi’s new food packaging portfolio

lightweighting and smaller serving portions – optimised material use, smaller packs and lighter, high-performance fibre-based materials.

Other trends are: retail ready packaging (RRP) and point-of-

sale displays that improve brand recognition, enhance shelf visibility and ensure efficiency in packing and replenishment processes, as well as sustainability – packaging designed to be 100 percent renewable or recyclable,

Holmen’s premium Invercote Touch, the latest in the Invercote range, is aimed at brands that want to create packaging products with a natural look and feel. To showcase its possibilities, Holmen has created a product sample shaped like a flower. It’s a combination of design and special effects – and shows off the paperboard’s tactile qualities to best effect.

“We wanted to demonstrate what can be achieved with Invercote Touch,” said Maria Blohm, project manager for print and product at Holmen.

“We created this piece as a limited edition sample to spark inspiration. The outer box and the flower within prove that with our paperboard, you have the freedom to create beyond expectations.”

The paperboard flower sample is aimed at showcasing

Holmen’s Invercote Touch product sample shaped like a flower shows off digital print and tactile effects

Invercote Touch’s versatility, demonstrating its qualities for bending, folding and printing. To create it, Holmen collaborated with Gothenburg-based designer Mikael Selin, renowned for his

bold use of colours and patterns.

“We wanted to make an impact with an unboxing experience that customers would want to keep,” explained Selin.

“Something that sparks the

in line with EU directives such as the PPWR, supporting circularity and meeting the packaging eco-design requirements for retailers’ private-label brands and manufacturers’ own brands.

“The food sector is undergoing rapid change, with sustainability targets, EU legislation and shifting consumer behaviours all driving new requirements for packaging. By expanding our portfolio, we can help customers respond to these trends with lighter, more sustainable products that are optimised for shelf appeal,” said Paulus Goëss, operations chief for corrugated products at Mondi.

More information from www. mondigroup.com

imagination and pushes the limits of what can be done with paperboard. It sounds cheesy, but we wanted to think outside the box. And then we came up with the flower.”

To bring the design to life requires advanced construction techniques, so Holmen worked with Ink ‘n’ Art, specialists in digital printing and converting, and Copenhagen-based foil and embossing experts Dreyer Kliché.

“The collaboration was essential,” Blohm continued. “Because this was a limited edition, we wanted to print it digitally. Digital printing is more efficient for smaller runs, and we wanted to show that Invercote Touch works great with digital printing too. We also included vibrant printing and striking foils, alongside showcasing the natural material without effects.”

More information from www. holmen.com

The global packaging market was valued at US$1.2 trillion in 2025, says a report from Smithers, with generative AI (GenAI) emerging as a major driver of growth, creativity, and efficiency across the sector.

The research for Packaging Innovations & Empack highlights how AI is transforming packaging design, production, and supply chain processes, enabling brands to launch products faster, reduce costs and respond more effectively to shifting consumer demand.

“Every decade brings a new technology that reshapes the way we work – from the personal computer to the internet, mobile devices and the cloud,” said Josh Brooks, divisional director for packaging at Easyfairs. “Now it’s AI. Global investment in AI infrastructure is expected to reach $2 trillion in 2026 and the potential for packaging is immense. From creating personalised designs to optimising production lines, AI gives the industry the chance to rethink how we design, produce and deliver packaging at scale.”

The Smithers report details how GenAI is already lowering barriers for creativity, driving rapid growth in personalised and virtual content and generating versatile packaging formats on demand. Brands can launch products with greater confidence, guided by deeper insights into consumer preferences, while reducing the time and cost of experimental trials. Integration with digital printing, finishing and automated forming machines, combined with intelligent packaging, could transform supply chain management and customer communication.

Smarter AI-driven systems are also improving stock management, efficiency and waste reduction. Rising SKU numbers, shorter runs and increasing demand for customisation are driving flexible packaging lines, while e-commerce is using AI to create custom-sized packaging for individual deliveries. Robotics and collaborative robots enhance line flexibility without slowing production, while predictive AI helps mitigate operational risks.

The report highlights further innovations, including ‘right-sizing’ packaging to cut

costs and improve sustainability, rapid line reconfiguration for complex shapes and microfulfilment centres enabling 24-hour delivery. Real-time data enables companies to respond instantly to changing demand, promotions, or weather events, while self-learning AI supports a fully circular economy.

Generative AI is also transforming the creative process itself. Bespoke graphics can be generated on demand, enabling rapid prototyping and customisation, while AI agents adjust designs in response to market trends and consumer feedback. By 2025, AI is being applied across text, code, images, video and 3D content, with outputs expected to outperform professional designers and developers by 2030, marking a step-change in productivity and creativity across packaging.

The full impact of GenAI across the packaging supply chain can be explored at Packaging Innovations & Empack 2026, being held at the NEC, Birmingham, from 11-12 February 2026.

More information from www. packagingbirmingham.com

Innovative banana box packaging that is lighter while maintaining strength and sustainability has been developed by Mondi in collaboration with partners throughout the value chain.

The project began when Mondi’s technical team for containerboard explored a simple, but ambitious question during a customer visit in Latin America: Could the standard banana box be made lighter and more sustainable without compromising strength?

What followed was an international collaboration between Mondi, trading partner Europcell, Ecuadorian banana exporter Incarpalm and a leading European importer. Together, the teams redesigned the structure and paper composition of the traditional banana box, testing a range of options to balance durability, weight and humidity resistance.

The new design combines ProVantage SmartKraft Brown, known for its high strength and protective qualities, with ProVantage Frescoflute, a semi-chemical fluting that

enhances firmness in lightweight packaging boxes. The result is a box made with around 40 percent recycled fibre and up to 10 percent less weight than the previous design, helping to lower emissions during transport without compromising fruit protection.

To validate performance under real-world conditions, a full-scale production trial took

place in Ecuador in the summer of 2024. Bananas packed in the new boxes were shipped to Europe in a 33-day journey, with sensors monitoring humidity and temperature. Despite humidity levels of up to 100 percent, the boxes maintained their integrity throughout transit. More information from www.mondigroup.com

Stora Enso is growing its portfolio of premium packaging materials with the launch of Ensovelvet, a uncoated solid bleached sulphate (SBS) board with velvet-like smoothness on both sides. It has been developed for luxury applications such as cosmetics, perfumes and other premium consumer goods.

Designed to meet demand for natural and renewable designs in luxury packaging, Ensovelvet offers a combination of a natural uncoated surface, excellent stiffness and reliable folding

performance. This bright, premium SBS board is said to provide an enhanced sensory experience while ensuring excellent printability. It is particularly well-

suited for cosmetics packaging, perfumes and other high-end applications where touch and appearance are equally important.

Ensovelvet complements Stora

Enso’s flagship Ensocoat board, together forming a complete SBS carton range for brand owners and converters seeking versatility across coated and uncoated applications. Both boards are recyclable, supporting the shift towards circular packaging systems. The absence of coating in Ensovelvet also means fewer materials are needed in production, resulting in a reduced carbon footprint while maintaining the performance expected from premium packaging materials.

More information from www. storaenso.com

One of Turkey’s leading exporters of fresh fruits and vegetables, Özler Tarım and paper maker Mondi have reduced food waste with innovative, recyclable packaging, thereby improving sustainability and production efficiency and providing fresh, quality produce for global markets.

Özler Tarım has operations based in Adana, from where it supplies produce to a network of global markets, including Japan, Canada, the United States, the UK, Europe and East Asia. With a commitment to freshness and sustainability, Özler Tarım has consistently invested in innovation to ensure its produce reaches consumers in optimum condition.

However, one challenge remained: protecting sensitive fresh produce during long and often unpredictable sea freight journeys. Variations in temperature, humidity and the risk of packaging collapse during stacking and transit had the potential to result in food waste, product loss and operational inefficiencies. To address this, Özler Tarım turned to Mondi, the company’s long-time packaging supplier.

Together, Özler Tarım and Mondi worked to redesign the packaging, with performance and sustainability in mind. The goal was to create packaging that could endure the physical stress of international shipping while supporting Özler Tarım’s environmentally-responsible business practices.

The result was a robust, doublewall corrugated design that is 100 percent recyclable, strong enough to withstand stacking pressure and sea freight conditions, and compact enough to improve storage and logistics. With its flat-stackable design, the new packaging also streamlines production and shipping processes, contributing directly to a 15 percent increase in capacity at Özler Tarım’s Adana facility. More importantly, the design helped eliminate common issues like box collapse and damage-related claims, reinforcing the company’s reputation for reliability in its export markets.

Mehtap İncesöz, planning & supply chain manager at Özler Tarım, explained: “The packaging’s durability has made a noticeable difference, withstanding the humidity and movement of long

sea voyages. It ensures that our produce arrives undamaged, which not only preserves product quality, but also reflects the integrity of our brand. The positive feedback we’ve received from our clients overseas has been very rewarding.”