CAROLYN JACKSON CHIEF EDITOR

CAROLYN JACKSON CHIEF EDITOR

Food safety and quality issues can impact any food manufacturer, no matter how big or small.

Of the 95 food recalls coordinated by FSANZ in its latest report on 2024, undeclared allergens remained the leading cause of recalls, mostly due to labelling errors, with milk and gluten the most commonly involved allergens. Microbial contamination and foreign matter were other leading reasons for recalls and ‘mixed and processed foods’ was the most frequently recalled product category.

As we all know, food recalls are expensive with direct costs sometimes in the millions and indirect costs, such as brand reputation damage, being a bit harder to quantify.

In order to get off to a great start in 2026, we take a look at foreign body inspection systems as a food safety measure; UV light technology for poultry applications; and supply chain efficiency to improve worker safety.

We also take a closer look at a new dairy manufacturing facility recently opened in Dandenong South, Victoria, which has been built specifically for adding value to cheese in all its forms, including vegan. The Pure Dairy facility has been a vision of founder and chairman Adrian Josephson for nearly a decade, so it was interesting to talk to him further about all its features and benefits for our food facility design feature. Read more on page 10.

Wishing you all a very prosperous and safe 2026!

We welcome submissions from the food industry across Australia and New Zealand that will be considered for possible inclusion in the bi-monthly print publication and our daily web page. If you have a story you think would be of interest, please send an email to wnift@wfmedia.com.au.

Westwick-Farrow Media is committed to using environmentally responsible print services to produce our publications. This edition is printed on a paper made with a mixture of materials from PEFC-certified forests and recycled materials and made from elemental chlorine free bleached pulp with is PEFC certified from sustainably managed sources. It is delivered in a totally degradable plastic wrapper.

Westwick-Farrow Media A.B.N. 22 152 305 336 www.wfmedia.com.au

Head Office Unit 5, 6-8 Byfield Street, North Ryde Locked Bag 2226, North Ryde BC NSW 1670 Ph: +61 2 9168 2500

Editor: Carolyn Jackson wnift@wfmedia.com.au

Publishing Director/MD: Janice Williams

Art Director/Production Manager: Linda Klobusiak

Circulation: Alex Dalland circulation@wfmedia.com.au

Copy Control: Ashna Mehta copy@wfmedia.com.au

Advertising Sales Manager: Kerrie Robinson Ph: 0400 886 311 krobinson@wfmedia.com.au

If you have any queries regarding our privacy policy please email privacy@wfmedia.com.au

Printed by Ive Group

Print Post Approved PP100007395 ISSN No. 1039-8414

NOTICE:

All material published in this magazine is published in good faith and every care is taken to accurately relay information provided to us. Readers are advised by the publishers to ensure that all necessary safety devices and precautions are installed and safe working procedures adopted before the use of any equipment found or purchased through the information we provide. Further, all performance criteria was provided by the representative company concerned and any dispute should be referred to them. Information indicating that products are made in Australia or New Zealand is supplied by the source company. Westwick-Farrow Pty Ltd does not quantify the amount of local content or the accuracy of the statement made by the source.

Aquaculture Stewardship Council (ASC) has announced that Humpty Doo Barramundi, based in the Northern Territory, has achieved ASC certification. This is said to be the first time an Australian barramundi farm has met the globally recognised ASC standards for responsible aquaculture.

To meet ASC standards, farms undergo a rigorous third-party assessment, where they must demonstrate a comprehensive commitment to responsible farming that protects the environment, safeguards fish welfare, and supports the wellbeing of surrounding communities. This includes maintaining excellent water quality, minimising waste, protecting local biodiversity, social, welfare and health management practices. Farms are also required to show full traceability of feed and engage transparently with local stakeholders.

“We are proud to be the first Australian barramundi farm to achieve ASC certification,” said Dan Richards, owner and CEO Humpty Doo. “Strong environmental practice and high-quality aquaculture have guided our family business for more than 30 years and this certification confirms that our approach meets the world’s most trusted benchmark for responsible farming.”

Humpty Doo Barramundi’s saltwater wetland wastewater treatment system is a cornerstone of the farm’s commitment to sustainable practice and is one way that it ensures it meets ASC standards. Designed to mimic the natural tidal and mangrove environments in which barramundi thrive, the system recirculates and treats water through a closed loop wetland network, resulting in low impact to natural waterways while transforming nutrients into plant and algal growth for onsite use rather than pollution. This naturebased solution is designed to support fish health, production efficiency and ecosystem protection.

Australia’s Food and Beverage Accelerator is providing $740,000 matched co-investment to SeaStock Pty Ltd to help accelerate the commercialisation of clean-label ingredients designed as alternatives to synthetic additives.

SeaStock specialises in onshore algae cultivation and compound extraction. The funding will help with the development and certification of its RUBY SEA naturally derived red pigment (R-Phycoerythrin (R-PE)) extracted from sustainably cultivated Asparagopsis algae.

FaBA Director Dr Chris Downs said the project’s “approach to developing clean-label, functional ingredients aligns strongly with FaBA’s mission to accelerate the growth of Australia’s food and beverage manufacturing sector through science-led commercialisation”.

The FaBA-backed project will enable SeaStock to progress key research and development stages, including:

• Safe and scalable extraction of food-grade R-PE pigment (RUBY SEA)

• Identification and evaluation of commercially viable co-products

• Generation of data to support Food Standards Australia New Zealand (FSANZ) and international regulatory approval

• Bench-scale to pilot-scale production to facilitate material transfer agreements and early customer validation.

SeaStock Co-Founder and Managing Director Tom Puddy said: “This support from FaBA will accelerate our ability to deliver high-purity, naturally derived functional ingredients for the food and beverage sector.”

The project supports SeaStock’s broader mission to lead in the production and extraction of algae-based compounds that replace synthetic additives with sustainable, high-performance alternatives.

“By replacing synthetic additives with natural compounds, SeaStock has the potential to help shape a more sustainable and health-conscious future for consumers,” Downs said.

Barry Callebaut, manufacturer of chocolate and cocoa solutions, and Planet A Foods, the German food-tech innovator behind the ChoViva chocolate alternative without cocoa, have announced a commercial long-term partnership.

“Through this partnership with Planet A Foods, Barry Callebaut is embracing technology to open further avenues for growth while enhancing our resiliency to today’s cocoa-market volatility. We are excited about the collaboration with Planet A Foods to shape the future of chocolate solutions together with our customers,” said Christian Hansen, Head of Global Strategy at Barry Callebaut.

The partnership has been established to help meet the growing customer demand for sustainable chocolate solutions without cocoa while reaffirming that traditional cocoa remains at the heart of Barry Callebaut’s business and will continue to play a central role in its future.

“This partnership marks a key milestone in diversifying our portfolio and capturing the exciting opportunities in chocolate alternatives without cocoa,” said Dries Roekaerts, President Customer Experience at Barry Callebaut. “These non-cocoa innovations are not meant to replace traditional chocolate but to complement it, expanding our portfolio to meet growing customer and consumer demand. Together with Planet A Foods, we can scale the production of irresistible chocolate-like creations that broaden choice without compromising on taste, quality and our commitment to the planet.”

ChoViva is an ingredient made from locally available crops, such as sunflower seeds, which is designed to deliver a chocolate-like taste. For Planet A Foods, the partnership will help to drive innovation on its platform technology and help to establish itself as a future sustainable food ingredients leader.

The companies trading as Yume Food Australia (The Yume App Pty Ltd and The Yume App Holdings Pty Ltd) appointed Teneo Financial Advisory Australia (Teneo) as liquidators on 18 November 2025.

Founded in 2015 as a social enterprise dedicated to reducing manufactured food waste, Yume Food Australia operates a digital trading platform that enables major food manufacturers to sell surplus products. The platform is designed to generate additional revenue for manufacturers by reducing food disposal, while also streamlining the process for donating unsold food to relief organisations.

Since its founding, Yume has:

Wine industry products and technologies provider Enartis has announced the signing of a preliminary agreement to acquire 100% of Parsec, an Italian designer and manufacturer of integrated control systems for the wine sector.

The integration of the two companies will allow it to provide technological solutions for the complete and smart management of winemaking processes — combining the advantages of oenological solutions with automated process management, from grape reception to bottling, on a single platform.

Samuele Benelli, Chief Executive Officer of Enartis, said, “Today, we are laying the groundwork to unite not just two companies, but two families that share the same culture of customer service and the same passion for excellence and innovation. The extraordinary expertise of the Parsec team, combined with our global presence, will create incredible potential.”

Since 2008, Enartis has had branches in Australia and New Zealand.

• returned $30 million to Australian businesses and manufacturers;

• redistributed 11.5 million kg of quality food;

• avoided 44 million kg of CO2 emissions; and

• saved 2.5 billion litres of embedded water by reducing food waste.

“Yume has developed an impressive technology platform which provides a national market for food manufacturers to sell product that otherwise may have been disposed. Over the past decade, Yume has established a national network of buyers and sellers, creating a secondary food market that’s become an established and valuable part of many manufacturers’ supply chains,” said Rebecca Gill from Teneo.

“This is an attractive opportunity for a prospective buyer to leverage the 10 years of investment into this platform, as well as the relationships and network Yume has built.”

The liquidators are inviting expressions of interest from buyers across food, logistics, ESG, retail and technology, and will be exploring all strategic opportunities to complete a transaction in the near term.

Giuseppe Floridia, Chief Executive Officer of Parsec, who will continue in his role, said: “The combination of Parsec and Enartis allows for the integration of scientific knowledge with control and process management technology, offering the market tools for an ever more measurable and sustainable quality of wine.”

The agreement is subject to the completion of the procedure required by Italian law.

Pure Foods Tasmania (PFT) has completed its acquisition of Australian artisanal ice cream and gelato brand Elato Ice Cream (Elato). Furthermore, one of the founders of Elato has been appointed to lead PFT’s new ice cream division (previously The Cashew Creamery, which was 100% plant-based).

Founded by Roz Kaldor-Aroni and Benni Aroni, Elato started out small but is now manufacturing dairy ice creams that are sold to over 630 stores across Australia, including cinemas and supermarkets. The ice creams have been designed to be minimally processed, with a focus on taste, texture, less sugar and chemical-free ingredients — for example, using egg yolk instead of chemical emulsifiers.

Kaldor-Aroni has been appointed as the General Manager of PFT’s new ice cream division, which merges Elato and The Cashew Creamery to form a multi-brand platform in the dairy and plant-based frozen desserts category. She will be responsible for driving sales, new product development and brand growth, as well as maximising the use of PFT’s manufacturing assets and managing its contract packing operations.

The Victorian Government is backing an international food manufacturer to establish its first Australian production facility in the Wimmera region, Western Victoria.

Farm Frites Australia is establishing its $300m facility in Dooen to manufacture frozen chips using Australian produce, with a capacity to process up to 250,000 tonnes of potatoes every year once fully operational.

The frozen chips, fries and other potato-based products will then be supplied to takeaways, pubs, clubs and fast-food restaurants including KFC and Hungry Jacks right across Australia.

The 24-hour production facility, located next to the Wimmera Intermodal Freight Hub, is expected to create 250 new local jobs, support Australian farmers, and provide training and career opportunities for students in the region.

The new food processing facility was granted planning permit approval under the Labor Government’s Development Facilitation Program, which expedites planning decisions for eligible projects that will inject investment into the Victorian economy — creating new jobs and promoting economic growth.

Minister for Economic Growth and Jobs Danny Pearson said: “This is a huge investment that will see hundreds of jobs created for local workers, driving revenue for the Wimmera and right across the state.

“We’re proudly backing companies to invest in advanced manufacturing because we know it is key to unlocking economic growth and creating more opportunities for all Victorians.”

Farm Frites Australia General Manager Kieran Prestidge said: “Farm Frites Australia is delighted to have chosen Dooen — and the Wimmera — for our first Australian production facility and our $300 million investment in Victorian jobs, Australian farmers and local manufacturing.

“Dooen is perfectly located between the best growing regions in Australia and has excellent road and rail links, which will help us put more Australian produce on plates and tables all around the country.”

The plant is expected to be operational in 2027.

Carolyn Jackson

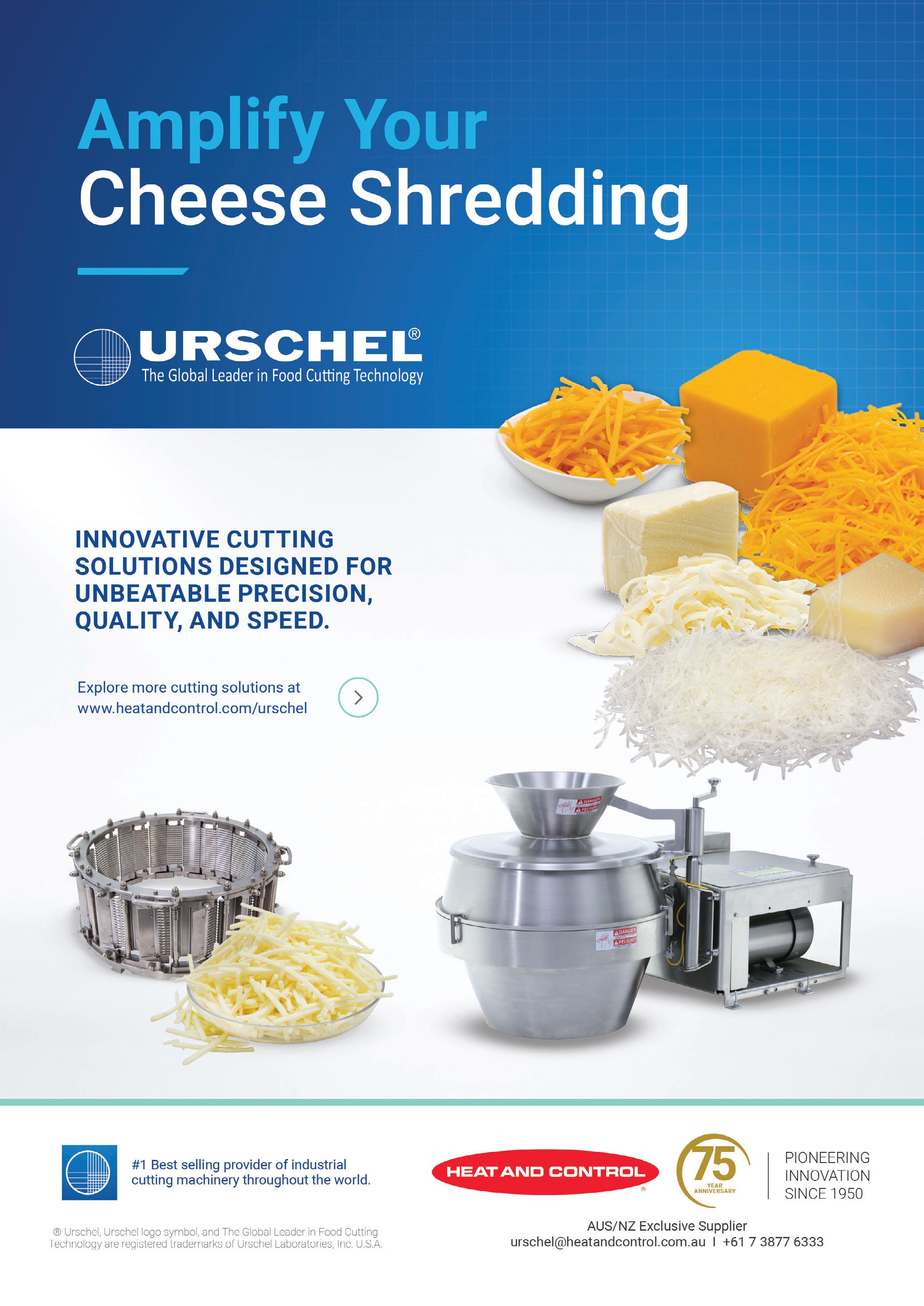

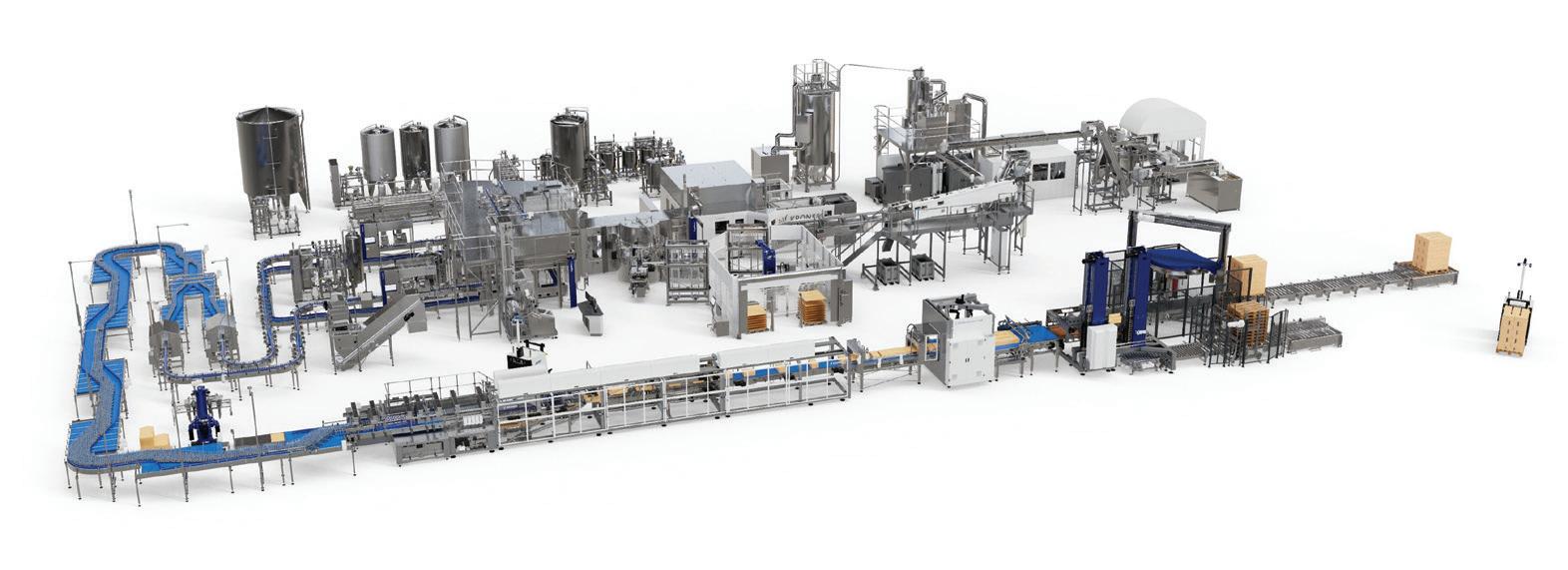

Pure Dairy’s dairy manufacturing facility in Dandenong South, Victoria has been a vision of founder and chairman Adrian Josephson for nearly a decade.

“In my younger years, I’d be travelling the world, selling Australian cheeses to the largest cheese converters in Europe and the US. Even then, I knew one day I needed to build something like this here in Australia,” he said at the opening of the new facility in October 2025.

The 13,000 m2 factory was years in the making, shaped by meticulous planning with Josephson overseeing every detail — from the HVAC systems in the production rooms and the drain layout to the colour of the epoxy flooring. He notes that the scale of stainless steel required represented a significant investment. With around 80% of the building requiring full-time refrigeration, every inch of roof space has been fitted with solar panels, delivering energy savings of approximately 35%.

All the full-scale processing equipment required for the factory was bought after careful consideration from leading suppliers such as Natec in Germany and Australia; Marchant Schmidt in Wisconsin, USA; Weber in Germany; and Propak Industries in Australia for its bagging machine.

“We’ve bought the world’s best equipment to see us out for the next 20 years. Our shredder, for example, is currently running at around 6 tonnes/hour with probably half the labour requirements, but it’s built for more than that,” Josephson said.

“From slicing, shredding and grating to shaving and packaging, the factory uses state-of-the-art modern technology that is highly automated to provide consistent-quality, valueadded cheese products.

“We built this site for growth in our own branded business; it’s built for export, it is built for retail, which we are not doing today, and this site is also built to offer contract manufacturing services.”

Geographically located in the south-east region of Melbourne with close access to rail, road and shipping networks, this cheese conversion factory has been built specifically for adding value to cheese in all its forms, including premium blends and vegan options. >

From slicing, shredding and grating to shaving and packaging, the factory uses state-of-the-art modern technology that is highly automated to provide consistentquality, value-added cheese products.

“Having state-of-the-art equipment and capacity backed by our capability enables us to work with anyone who wants to procure value-added cheese across Australia and the globe,” said Daniel Adlerstein, Chief Growth Officer at Pure Dairy, who has been tasked with growing the business.

The advantage of using all this high-tech processing equipment is that it enables the business to provide “flexibility with size, dimension of thickness, weight and shape of cheese products. We also have flexibility to provide bespoke packaging formats, from small retail packs to large custom foodservice size packs.

“Australia currently has a lack of capability to ‘innovate at pace’ so that’s what we are providing to the market. We are offering small guy service with big guy capability,” Adlerstein said.

In the near future, the business is planning to make use of the new manufacturing facility’s capacity by working

with all the local retailers, and QSR (quick service restaurants) and global priorities are also a key focus.

“Our kit enables us to produce highly customised blends so we can supply uniform product throughout the pack; the same mix ratio, the same feel, the same structure of every shred, regardless of what cheese we are using, and that’s a game changer,” Adlerstein said.

Some of the innovative requests coming their way are for different types of snacks and different formats from the traditional cheese cubes and sticks. “Whether it’s

cheese with crackers, cheese with meat or with nuts, lots of opportunities are coming up and with a variety of cheeses. It’s not just cheddar cheese in a pack, it could be parmesan in a pack with dates, or spicy cheese with jalapeños or salami sticks. The retailers are looking for these quick protein options in a pack,” Josephson said.

After many years in the planning and development, Josephson’s vision for a local cheese conversion factory has now been brought to reality.

“We are there now; we are now manufacturing!”

Do you have a design story to share? Please email wnift@wfmedia.com.au if you'd like to contribute.

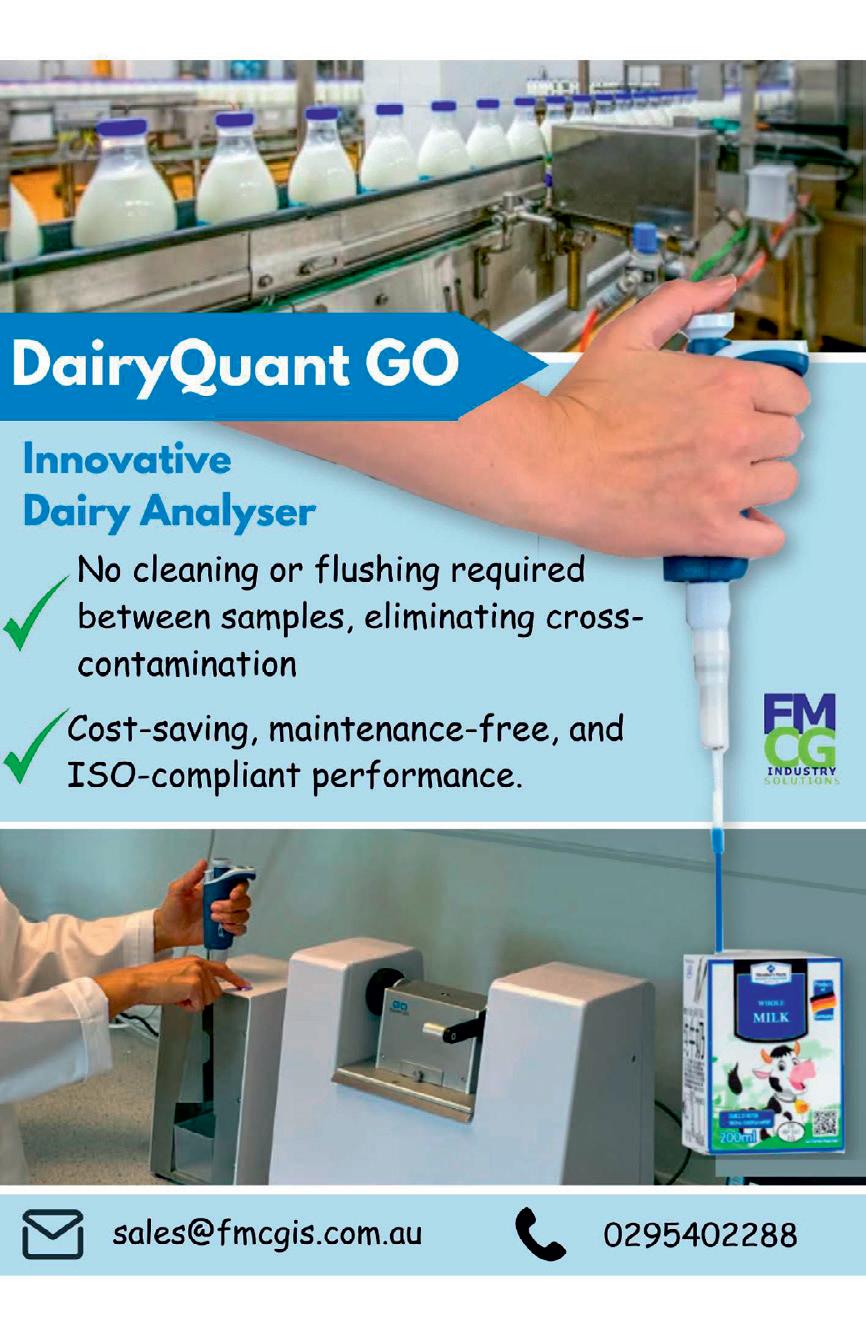

In Australia, dairy products with high protein and no added sugar are on trend. High-protein milk has grown at an average rate of 8.7% in the last five years, with new yoghurt and flavoured milk product launches over this time taking the most advantage of the trend. Functional ingredients in dairy for the over-60s is predicted to be the next big trend across Asia–Pacific.

(Source: www.euromonitor.com)

The cheese market in Australia and New Zealand is projected to reach nearly 527.46 KMT by 2034. The growth is mainly driven by the increased consumption of cheese in restaurants and the foodservice industry, but the good old cheeseboard is still on trend for entertaining.

(Source: www.researchandmarkets.com)

Plant-based dairy has experienced strong growth in Australia, growing at a rate of 5.2% in 2025, a faster rate than the overall dairy industry.

(Source: www.euromonitor.com)

Weight loss medications have marked a turning point for food consumption, which presents both a disruption and an opportunity for the food industry.

(Source: www.rabobank.com.au)

One example is Lactalis USA, which recently released its :ratio Pro-Fiber dairy snack formulated to be suitable for those on GLP-1 medication. The product is designed to meet the demand for the ‘nutrient rich’ trend, with 20 g protein, 10 g fibre and no added sugar.

(Source:www.lactalisamericangroup.com)

The Norco ice cream factory was left decimated by the devastating 2022 Lismore floods, and the uncertainty that surrounded its future proved that it was far more than just a factory to the town and people of Lismore. After an 18-month flood recovery process that cost more than $100m, the factory resumed operations in late 2023.

Norco’s reopened Lismore ice cream factory has now produced over 34 million litres of ice cream — enough to fill more than 13 Olympic swimming pools or, if scooped and lined up, to stretch all the way from Sydney to Los Angeles with plenty left over to share.

Beyond the sweet stats, over the past two years, the factory has also delivered almost $50 million worth of economic activity to the Lismore region via local jobs, supplier partnerships and ongoing operations; a testament to the resilience and strength of the community.

Norco CEO Michael Hampson said: “We are incredibly proud that in just two years, our operation has been able to repay the community — via economic contribution — more than the value of the government funding that initially helped us get back up and running.

“And that is especially why we wanted this milestone to be a community celebration,” he said.

To mark the occasion, Norco hosted a community celebration on 21 November on the front steps of the factory at 120 Union Street, Lismore. Locals enjoyed Cape Byron ice creams — recently ranked Australia’s best branded vanilla ice cream by CHOICE — along with cow-themed face painting and family-friendly games.

“This celebration was about recognising the strength and spirit of the Lismore community, and especially on National Agriculture Day, honouring our producers who work tirelessly to deliver Australia’s best-tasting dairy,” Hampson said.

“We’re immensely proud of what we’ve achieved together over the past two years and wanted to thank the community for their unwavering support.”

Established in Byron Bay in 1895, Norco is a 100% Australian farmer-owned dairy co-operative with 281 active members on 188 dairy farms in northern New South Wales and South East Queensland. Annual milk production is over 200 million litres.

NOSHOK developed a custom solution for a large butter processing manufacturer which included tank level and line pressure measurement sanitary transmitters.

Precise measurement and 3A sanitary equipment are crucial in the processing of anhydrous milk fat (AMF). The NOSHOK sanitary pressure transmitters provided unique design and technology benefits resulting in reliable measurement in the AMF production process.

AMF is manufactured from fresh butter or cream and must contain at least pure 99.8% milk fat and no additives. Codex Alimentarius standard CODEX STAN 280-1973 defines anhydrous milkfat, milkfat, anhydrous butteroil and butteroil as “fatty products derived exclusively from milk and/or products obtained from milk by means of processes which result in almost total removal of water and non-fat solids”.

AMF processing generally involves continuous flow direct from cream/milk and/or from reworked butter. During this process, there are many stages which require critical tank level and pressure measurements.

When the cream is being made into butter, buttermilk is extracted out of the process. This leaves butter which is approximately 80% fat. The butter is then melted and held in a tank.

NOSHOK’s 3A approved 204 Series Intelligent Silo & Tank Level Sanitary Pressure Transmitters were installed on the buttermilk tank and the raw melted butter tank, which allowed easy programming and range adjustment without test pressure via onboard display. These transmitters provide an accuracy 0.1% of adjusted span and 10:1 turn down, as well as a 360° rotatable display for ease of reading in multiple configurations.

The product is then pumped from the holding tank to a separator which removes any excess water/buttermilk. The butteroil that is left is approximately 99.5% fat. After a final vacuum treatment, the final product, AMF, will be in the oil tank at 99.8% fat.

NOSHOK’s 254 Series Intelligent Pressure & Level Transmitters were installed in the balance tanks and CIP tanks, as well as monitoring various line pressures in the process.

The large butter manufacturing company chose NOSHOK products due to several design and technology advantages, including reduced potential for damage, minimised temperature/ position error, and greater rangeability reducing required inventory.

The sanitary transmitters are designed with flush diaphragm technology that uses a compact, robust diaphragm with matching substrate to minimise the amount of fill fluid and reduce potential for damage. The instrument’s diaphragms are laser welded and helium leak tested, and sensors are positioned close to the media to provide active temperature compensation at the point of measurement to minimise temperature and position error. These sensors also provide local indication of process temperature. No reference pressure is required for range adjustment. Linearisation can also be made for various tank shapes.

The transmitter’s polished stainless steel housing is suitable for hygienic applications and harsh, aggressive ambient conditions. HART protocol is available.

AMS Instrumentation & Calibration Pty Ltd www.ams-ic.com.au

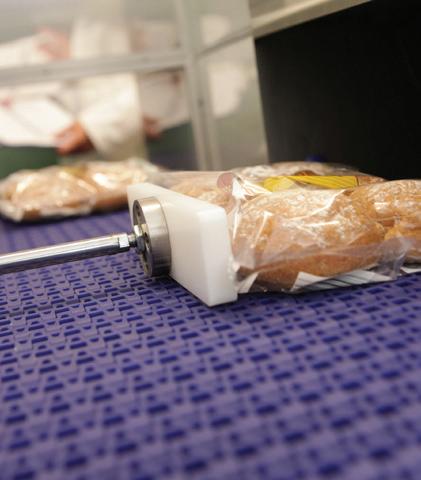

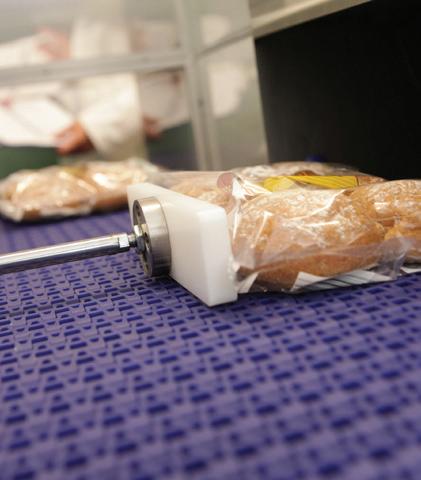

Designed for food service outlets, Saputo Dairy Australia (SDA) recently launched its Australian-made Individually Quick Frozen (IQF) shredded mozzarella into market under its Fred Walker brand.

The IQF process snap-freezes each individual piece of freshly made mozzarella in just three minutes, before the product is packed and stored frozen until it’s ready for use.

This approach is designed to lock in taste and texture while providing flexibility and convenience for users of the product.

With a 365-day frozen shelf life and the ability to use it straight from the freezer or thawed, the product is suitable for regional venues and pizza restaurants across the country.

Zoey Saunders, SDA’s General Manager, Marketing & Food Service, said the product is a direct response to what our customers have been asking for, which is a high-quality, Australian-made mozzarella that’s easy to use and store.

“We’ve tested it extensively, including directly with customers through in-store cook-ups, and the feedback has been overwhelmingly positive. It performs beautifully in both gas and woodfire ovens, whether used frozen or thawed.”

Dairy and plant-based food and beverage producers have long faced a dual challenge: delivering safe, high-quality products while working towards system optimisation and sustainability goals. Thermal processing, particularly ultra-high temperature (UHT) treatment, is one of the most energy-intensive steps in a food or dairy factory.

The traditional UHT infusion system exacerbates this problem, as steam is typically used once and then released, thereby wasting its heat potential. Companies committed to energy efficiency — both for the sake of sustainability targets and their bottom line — face an ongoing challenge: how to maintain product integrity and safety while making this core process more efficient and climate-friendly.

A customer in the nutritional beverages processing sector was seeking a more sustainable way to produce beverages using more energyefficient methods. The company has measurable goals related to its carbon footprint and was looking for ways to lower gas consumption.

Across a typical facility, thermal processes such as UHT, evaporation and pasteurisation account for 60–70% of total energy consumption, often relying on fossil-fuel boilers, which increase operating costs and carbon emissions.

A closed-loop approach

SPX FLOW has developed the SteamRecycle system to transform steam from a single-use resource into a recyclable, closed, energyrecovery loop. This electrification technology integrates directly with infusion UHT systems, and is designed to enable the recovery and re-use of 100% of the steam used during treatment.

While testing the SteamRecycle, the customer no longer needed continuous fossil fuel resources for thermal heating in the infusion UHT system. During use, steam is 100% reused to provide a greener energy solution.

When implementing the system, paired with infusion UHT systems, there was minimal chemical change at the exact needed bacteria kill-rate, without sacrificing quality. The processor reported no change in the product’s quality, including shelf life, colour, viscosity or any other properties.

The system works by recirculating vapours from the flash chamber back into the infusion vessel, effectively replacing the continuous need for fresh boiler steam once the process has started. This single-step change has reduced fuel use, cut water demand and eliminated the constant reliance on fossil-fuel boilers for steam generation.

By integrating SteamRecycle into its UHT lines, the beverage processor achieved measurable results, turning sustainability targets into tangible operational benefits while upholding product quality.

Features of the system include:

• Emissions reduction: the system eliminates continuous steam demand, which can help to lower annual carbon dioxide (CO2) emissions by more than 1000 tons per year for a single UHT line (at a capacity of 12,000 LPH running 6000 hours per year).

• Efficiency gains: with a coefficient of performance (COP) of nearly 4, the system is designed to deliver almost four times as much energy as the electricity it consumes.

• Resource conservation: the closed-loop system reduces water circulation requirements, reducing water use by up to 33 m3/h. This successful application of SteamRecycle demonstrates that sustainability can go hand-in-hand with operational efficiency and profitability, preparing plants for integration with renewable electricity grids and boosting competitiveness in an environmentally conscious market.

An Australian study has revealed that sustainably grown and milled flour can reduce food supply-chain emissions by between 22 and 77%, offering food manufacturers a ready-made solution to meet new Scope 3 climate reporting requirements.

The Reimagining Bread life-cycle analysis, a collaboration between Wholegrain Milling Co., Certified Sustainable, Deakin University, and artisan bakeries Rustica (Melbourne) and Infinity (Sydney), tracked greenhouse gas emissions from paddock to plate. It found that flour choice alone can be a decisive factor in lowering a company’s overall carbon footprint.

“Flour may seem humble, but for food companies facing mandatory climate reporting, it’s a lever that delivers measurable, auditable emissions reductions,” said Ash Truscott, Sustainability and Market Development Manager at Wholegrain Milling Co. “We’ve shown it’s possible to turn sustainability ambition into data-backed performance.”

The research analysed every stage of the bread supply chain, from grain production and milling to baking, using data independently audited and modelled under the Greenhouse Gas Protocol and National Greenhouse and Energy Reporting (NGER) framework.

Key findings include:

• 77% lower emissions from Certified Sustainable grain compared with conventional benchmarks (71.9 kg CO2e vs 315 kg CO2e per tonne).

• 55% reduction at the flour-milling stage (222–227 kg CO2e vs 495 kg CO2e international benchmark).

• 22–26% reduction at the bakery level through process efficiencies and verified inputs.

• These verified reductions span Scope 1 (direct fuel use), Scope 2

“By rethinking the raw ingredients behind everyday staples like bread, the study shows that small shifts in sourcing and process can translate into major emissions savings at scale.

(electricity) and Scope 3 (upstream and downstream activities), producing the first auditable dataset for flour’s role in food-sector decarbonisation.

“The farming process is the reason these grains are low carbon,” said Marg Will of Certified Sustainable. “Our partner farms have implemented regenerative and sustainable practices that improve soil and ecosystem health using fewer chemical fertilisers, which are energy-intensive to produce, and reducing tilling, which means less diesel fuel use. This combination improves soil carbon, cuts emissions at their source, and produces high-quality, mineralrich wheat with a lower carbon footprint and no chemical residues.”

The findings demonstrate that sustainability gains can be achieved across the entire food ecosystem from farms and mills through to bakery shelves. By rethinking the raw ingredients behind everyday staples like bread, the study shows that small shifts in sourcing and process can translate into major emissions savings at scale. For retailers and food manufacturers under pressure to substantiate climate claims, this represents a rare opportunity: a proven way to cut

emissions within existing product lines using verified, ready-to-report data.

Beyond corporate sustainability metrics, the research highlights a broader transformation underway in Australia’s food system; one where ingredient choices are directly linked to climate performance. Participating bakeries achieved not only reduced emissions but also operational efficiencies such as lower waste and improved energy tracking, proving that environmental and commercial outcomes can align.

“Supermarkets and food majors have ambitious net zero targets but limited levers inside the store walls,” Truscott said. “Switching to sustainable flour provides verifiable Scope 3 reductions at scale and tangible proof of progress to regulators, investors and consumers alike.”

The study reframes flour, one of the world’s simplest ingredients, as a strategic climate solution. By providing field-level, auditable data across every stage of production, it establishes a new benchmark for transparency in food manufacturing. For consumers, that means the bread on their table can now be part of a measurable, science-backed sustainability story.

“Sustainable flour isn’t just about better bread, it’s about better business data,” Truscott said. “It gives procurement teams credible, auditable information that feeds directly into ESG disclosures.”

As food and agriculture move into an era of verified sustainability, Reimagining Bread proves that even the smallest of ingredients can unlock deep emissions cuts across entire supply chains. By quantifying flour’s climate impact with field-level precision, the study provides both a blueprint and a benchmark for manufacturers, retailers and policymakers seeking credible, data-driven pathways to net zero. It’s a reminder that meaningful climate action doesn’t always start with sweeping reforms; sometimes, it begins with something as simple as flour.

The GEA GSI 260 skid is a new generation of separators for the beverage industry. With Kinetic Edge Design, the machine features a direct drive, resource-saving features and modular adaptability.

The optimised bowl and disc geometry is designed to increase the clarification area. This enables the skid to separate even ultrafine particles with high efficiency.

The Twin Hydrohermetic replaces conventional seals with two water barriers and a CO2 gap. This is designed to keep oxygen intake below 5 ppb to protect beer flavour and shelf life. The hygienic skid design facilitates cleaning and shortens commissioning time.

The synchronous direct drive is designed to achieve a higher efficiency than flat-belt systems and to run more quietly in a compact design. The entire drive unit can be replaced as a module, reducing downtime.

Overall service time is estimated to be around 6 h shorter compared to other drive concepts, although the exact figure depends on installation and location.

To address water and energy in beverage production, the GEA Centrifuge Water Saving Unit can be used to cut freshwater use by up to 99.9%, while the EngyVac system can help to reduce air resistance in the bowl and lower drive energy. Even without additional modules, the machine is designed to reduce water consumption through its sensor control.

The skid is operated with GEA X-Control and will be able to be linked to the GEA InsightPartner Separation KPIs dashboard in the future.

The machine is suitable for a variety of applications, from medium-sized and large breweries to wine, juice and tea producers, as well as manufacturers of plant-based beverages. GEA Group www.gea.com

Purearth Foods has become the first beverage manufacturer in Australia and New Zealand to deploy a software-led uninterruptible power supply (UPS) model. The project has delivered a fully managed service via Schneider’s Secure Power as a Service (SPaaS) model that is designed to help energyintensive businesses enhance resilience, reduce capital costs and improve operational focus.

Facing end-of-service-life challenges with its existing UPS assets, Purearth Foods required a solution that could modernise infrastructure while improving operational resilience and cash flow flexibility. Following a comprehensive technical review, Schneider Electric proposed its SPaaS model — an outcomes-based service that shifts responsibility for monitoring, maintenance and lifecycle management to Schneider Electric experts.

“Partnering with Schneider Electric has enabled us to modernise our critical power infrastructure sustainably while staying focused on our core operations,” said Simon Cousins, Maintenance Manager at Purearth Foods. “The SPaaS solution was chosen for its flexibility, operational benefits, and alignment with our focus on production efficiency. Having Schneider manage our UPS systems gives us confidence in uptime, reliability and efficiency across our production lines.”

Purearth Foods’ deployment shows how flexible, service-led power solutions can strengthen continuity in essential sectors like beverage production, supporting supply chain reliability, operational resilience and sustainability. By shifting from CapEx to OpEx, the company is enabling long-term, sustainable investment in industrial operations, reducing waste and improving energy efficiency across its production network.

“This deployment shows how we can apply smart, serviceled infrastructure in highly demanding production environments like beverage manufacturing,” said Segaran Narayanan, Vice President, Services & Safety, Schneider Electric. “By combining technology, data and tailored service delivery, we’re helping our partners like Purearth Foods shift from reactive maintenance to long-term operational resilience with sustainability built in from the start.”

For the beverage maker, this proactive, data-driven approach has improved uptime, reduced the operational burden on internal teams, and enabled cost-effective modernisation without large capital outlays.

Schneider Electric www.se.com/au

Flir, a Teledyne Technologies company, has introduced the iXX-Series of next-generation app-enabled thermal cameras that are designed for inspection tasks across many asset condition monitoring tasks, building inspection and other applications.

Built on Flir’s new ACE platform, the series combines the power of apps with a thermography inspection tool, enabling scalable, intuitive and connected condition monitoring.

Notably, direct integration with Flir Assetlink browser-based software automatically connects Flir radiometric images to an asset hierarchy structure, to help improve workflows and deliver critical insights for the user.

The intuitive, app-guided workflows are designed to enable maintenance workers of any skill level to undertake secure inspections.

FLIR Systems Australia Pty Ltd www.flir.com.au

Mettler-Toledo Product Inspection has released the X3 Series of bulk flow X-ray inspection systems, designed to deliver physical contamination detection, precision waste reduction and simplified operation. Consisting of the X13 and X53 models, the series offers hygienic design, streamlined usability and the advanced performance required by agriculture, confectionery and dried food producers worldwide.

Designed for bulk food applications, the system has been developed for unpackaged, loose-flow, bulk products on conveyors. Both systems in the series can detect contaminants as small as 0.3–0.4 mm (depending on application and contaminant material), protecting equipment, preventing recalls and supporting compliance with global safety standards. Typical applications include dried, fresh or frozen fruits and vegetables; nuts; pulses; root vegetables such as carrots and potatoes; confectionery; and cereals.

Reject options include a 30-nozzle air blast for pinpoint removal of contaminants in smaller products, or a 6-flap pusher reject for the removal of contamination in larger produce. With reject devices positioned above the product, they are less likely to become blocked or clogged with product debris, thereby maintaining performance and supporting hygienic handling.

With throughput rates of up to 5000 kg/h, both systems include tool-free belt and guide removal to simplify cleaning routines.

The X13 combines powerful detection with an affordable price point. Equipped with HiGain+ detector technology and ContamPlus software, it delivers sharp imaging and detection of physical contaminants such as metal, glass, calcified bone and stone in a large variety of bulk flow applications, regardless of consistency or format.

As the premium solution from the range, the X53 is engineered for manufacturers who handle the most complex bulk products and require high-level accuracy. It builds on the X13 and integrates HiGain+ DE (Dual Energy) detector technology and AMD (Advanced Material Discrimination) Pro software to deliver an additional layer of analytical intelligence. By processing two energy spectrums simultaneously, the X53 can differentiate between materials with similar densities, such as bone and product, allowing it to detect challenging low-density contaminants that single-energy systems may miss. It also introduces enhanced traceability and automation features, including product validation routines, self-checking performance verification and a fully lockable inspection tunnel for secure operation.

Both models feature front-open conveyor access and tool-free removal of key components. Options such as belt scrapers, water-cleaning systems and removable guide rails make sanitation fast and effective, while integrated cable management reduces clutter. Each system is available with a choice of ingress protection ratings up to IP69, providing flexibility to suit different hygiene standards and cleaning regimes.

Mettler-Toledo Ltd

www.mt.com

LEVEL indiCation

leVel GauGeS

WATER monitorinG

GERmAN expertiSe & quality

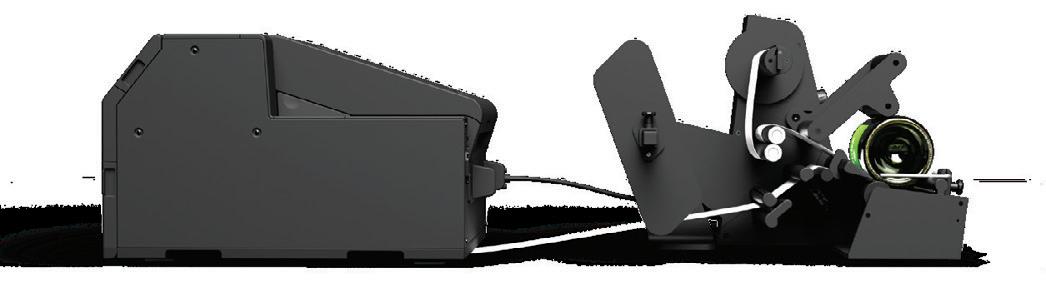

Krones Ingeniq is a fully automated, data-driven PET filling line for non-carbonated water. Rated at 100,000 bph, it has been designed to meet user demands with modular components, AI-driven automation and integrated service agreements.

The system consists of modular and standardised components that use robotics and artificial intelligence in a design that reduces the overall complexity of the line layout. It consists of three components: the line itself; digital access through Krones Connect and Secure; and Lifecycle Alliance where Krones assumes responsibility for output and life cycle with a modularised service agreement.

The digital automation architecture makes it possible to connect individual machines within a line network and maximise automation: from in-house preform manufacture to high-speed filling of non-carbonated water on the ErgoBloc L right through to autonomous material supply logistics and sustainable packaging solutions.

Krones (Thailand) Co Ltd www.krones.co.th

The McCrometer MCC014 Wafer-Cone flow meter is designed to provide good accuracy and repeatability in a space-saving unit that is easy to install. Suitable for tight-space installations and retrofits, it requires almost no maintenance and is designed to reduce lifecycle costs with its long life.

The flow meter uses the same principles as the V-Cone and its self-conditioning means little or no upstream or downstream piping runs are required. With a flangeless design, it can be used for small line size processes.

Other features include: the element is easily replaced to accommodate changing flow conditions; recalibration is not required; there are no moving parts to maintain; and the unit is designed to combine good flexibility with high performance.

It is suitable for applications in food & beverage, as well as water & wastewater, chemicals, plastics, pharmaceuticals, district HVAC, textile, power and oil/gas production. AMS Instrumentation & Calibration Pty Ltd www.ams-ic.com.au

Tru-Gard has released Tru-Gard Flex, a patented barrier system designed to provide impact protection in environments where people and property are at risk of impact.

The barrier system combines the strength of steel with engineered flexibility, allowing controlled deflection on impact. It features a maximum flex zone of 90 mm, enabling it to absorb and dissipate impact energy before returning to its original position. This approach helps reduce damage to vehicles, barriers and surrounding infrastructure.

It is suitable for use in warehouses, distribution centres and loading bays, including facilities and factories where vehicle movement, pedestrian safety and asset protection are critical considerations. Typical applications include protecting walkways and workstations, racking and production zones, preventing machinery impacts, and reducing accidental damage from forklifts, pallet movement and delivery vehicles.

The system has been designed to offer all of the benefits of the traditional Tru-Gard steel barrier system, including high-visibility options, impact protection and modular configurations to suit different hazard types, while providing an innovative alternative to impact management.

As with all Tru-Gard products, Tru-Gard Flex is designed and manufactured in New Zealand and supplied direct from the manufacturer. Tru-Gard Ltd www.tru-gard.com

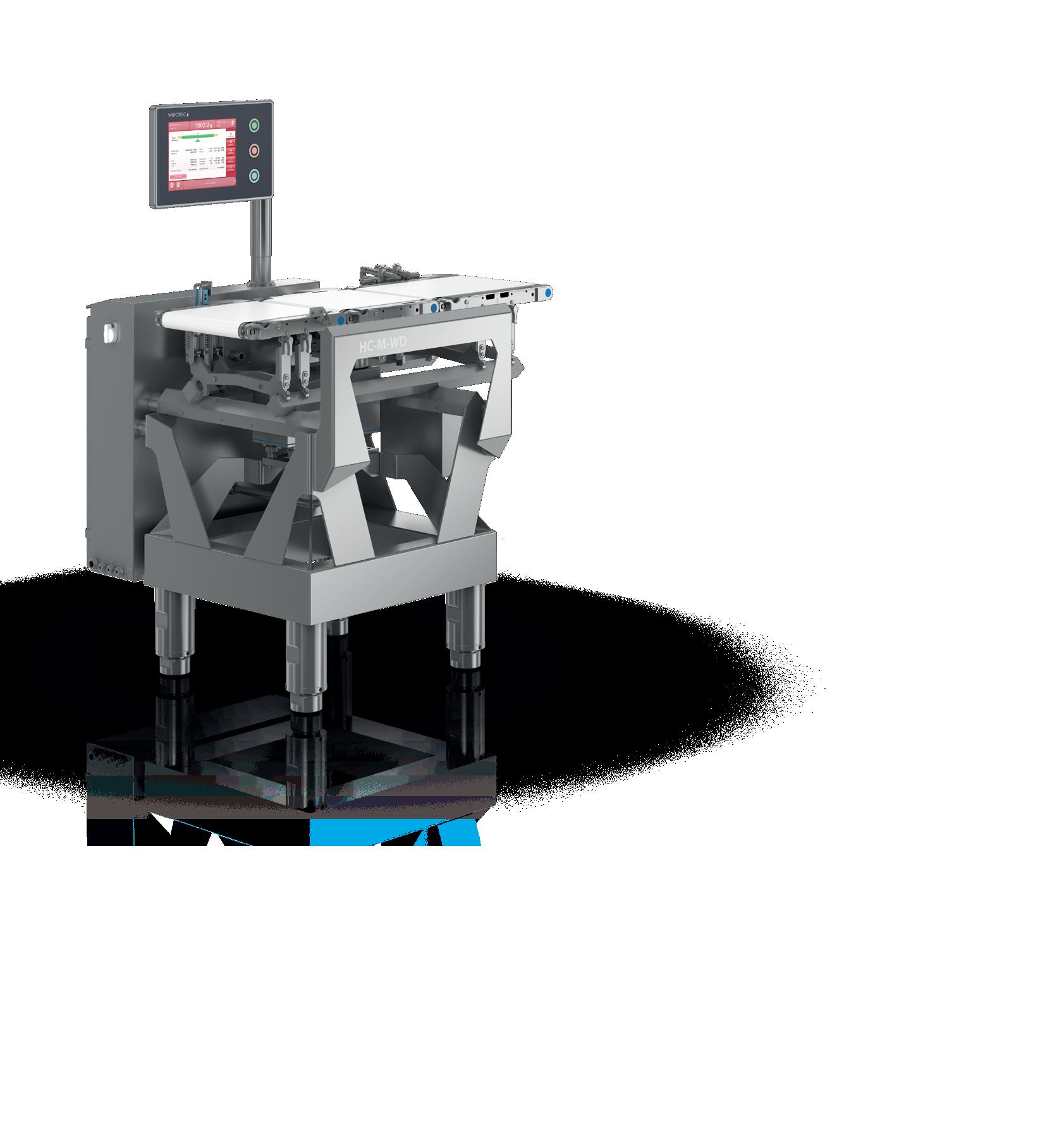

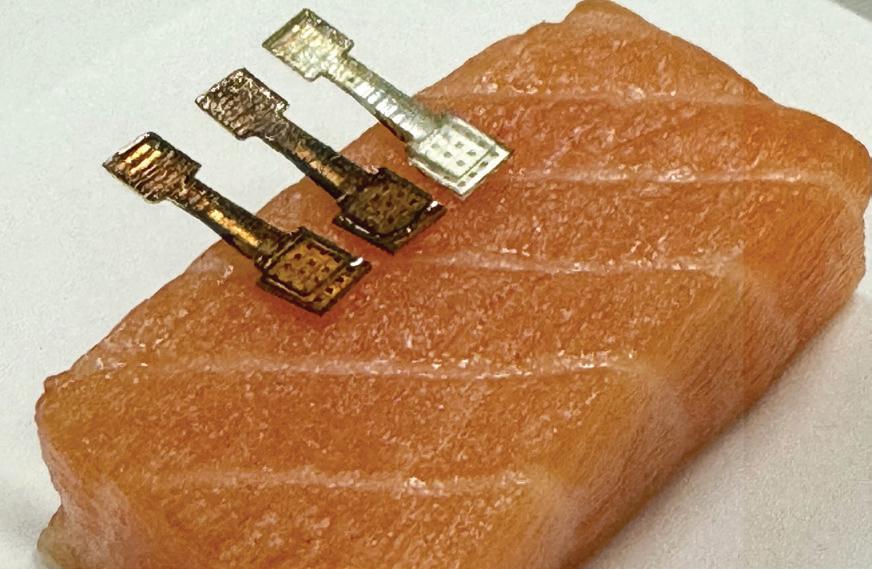

Foreign body contamination remains a recurring issue in the food industry and is consistently identified as a leading cause of product recalls. Based on aggregated analyses from food safety authorities and industry bodies, physical contaminants are responsible for an estimated 10 to 15% of global food recalls. In infant nutrition, where products are consumed by highly vulnerable groups, the acceptable risk threshold is extremely low.

Powdered products such as infant formula and milk powder are particularly sensitive. Multiple processing and packaging steps, combined with high-throughput production, increase the likelihood of unintended material entering the product stream. For this reason, manufacturers increasingly rely on end-ofline inspection systems as part of their overall food safety strategy.

Infant nutrition, where regulatory oversight and consumer expectations regarding food safety are especially high, requires consistent control measures throughout production. In addition to ingredient sourcing and process controls, inspection of finished, packaged products forms part of the quality assurance approach. This includes verification that products are free from foreign bodies before distribution.

An organic infant nutrition and baby food producer, Bellamy’s Organic, certified for the Australian and international markets, distributes its products in several regions, including Asia. At its production site in Braeside, Victoria, X-ray inspection systems inspect 800 g milk powder cans. This technology is commonly used in the food sector because it enables detection of both metallic and certain non-metallic contaminants, including plastics, rubber and dense organic materials, even in sealed packaging. Some of the inspected products include additional plastic components, such as caps and enclosed scoops. These elements increase inspection complexity and require careful system configuration to ensure reliable detection without excessive false rejects.

At Bellamy’s Organic, the inspection process is designed to minimise the X-ray path through the product, a standard principle in X-ray inspection. The system in use, a SC-S 4000 by German product safety specialist Wipotec, is configured with a horizontal beam orientation, often referred to as a sideview arrangement. This set-up can be advantageous for cylindrical containers like milk powder cans, which typically have a flat or slightly curved base, enabling more uniform inspection conditions.

However, inspection systems must not only detect contaminants but also handle products in a controlled and repeatable manner. Chain conveyors are used to transport cans through the inspection area and to remove rejected products from the main line. Smooth rejection is particularly relevant for rigid containers, where deformation could create additional quality issues. And as in many food production facilities, Bellamy’s Organic operates under space constraints, so the system had to be adapted to the available layout, including flexible positioning of the human–machine interface. Such adaptations can improve operator access and visibility, which in turn supports correct system use and consistent application of inspection criteria.

From a food safety perspective, equipment durability and consistency are also relevant. Inspection systems are often expected to operate over many years, and stable performance reduces the risk of undetected failures. The SC-S 4000 system at Bellamy’s Organic was originally installed in 2017 and continues to operate as part of the production process.

The Bellamy’s Organic example illustrates how X-ray inspection systems are applied as part of a broader food safety framework. These systems do not replace upstream preventive measures, such as supplier qualification, maintenance programs or hygiene controls. Instead, they serve as a final verification step before products enter the supply chain. In infant nutrition, where recalls can lead to significant financial and reputational consequences, foreign body inspection supports the overarching goal of risk reduction. As regulatory expectations continue to rise globally, inspection technology is increasingly viewed as a standard component of responsible food production rather than a differentiating feature.

More information on the topic can be found at www.wipotec. com/au/x-ray-and-vision or by emailing info.au@wipotec.com

Wipotec Australia Pty Ltd www.wipotec.com/au

Eriez has introduced a program to help food, pharmaceutical and packaging users upgrade their legacy Xtreme Metal Detectors using the PrecisionGuard X8-C Upgrade Kit. The program is designed to quickly modernise existing systems, providing enhanced sensitivity, smart connectivity and intuitive operation without the need for a complete system replacement.

Designed as a direct ‘drop-in’ retrofit for installed Xtreme Metal Detectors, the kit features the same shell dimensions and footprint to facilitate fast, seamless set-up. By replacing only the electronics and user interface, operators can continue using their existing sensing head, conveyor and reject device while gaining advanced performance, data integration and user control.

With a capacity to extend metal detector lifespan by seven to 10 years, the kit introduces features such as: large capacitive touchscreen interface with intuitive controls; high-speed processor; 304 stainless steel construction rated for IP69 washdown conditions (optional 316 SS available); and built-in web user interface technology (replaces SMART Link) with optional Wi-Fi bridge.

Eriez Magnetics Pty Ltd www.eriez.com

Camfil Australia has confirmed that its compact V-Bank air filter, Opakfil ES, has successfully maintained its Works with WELL designation. This program, developed by the International WELL Building Institute (IWBI), recognises products that align with WELL strategies based on IWBI licensing criteria. By achieving the Works with WELL trademarks, companies can demonstrate their commitment to advancing products and solutions that support human health and wellbeing.

Opakfil ES continues to meet stringent performance criteria, including: high energy efficiency, as it’s designed to minimise energy consumption, contributing to sustainable building operations; low pressure drop, ensuring efficient airflow and reducing strain on HVAC systems; and high dust-holding capacity, extending filter life and reducing maintenance needs. Compliant with ISO 16890, it is available in ePM1 and ePM10 efficiencies, ensuring effective particulate filtration.

These features make the air filter suitable for applications where air quality and energy efficiency are important.

Camfil is now working to further expand its range of WELL-certified solutions.

Camfil Australia Pty Ltd www.camfil.com.au

www.cbsfoodtech.com.au

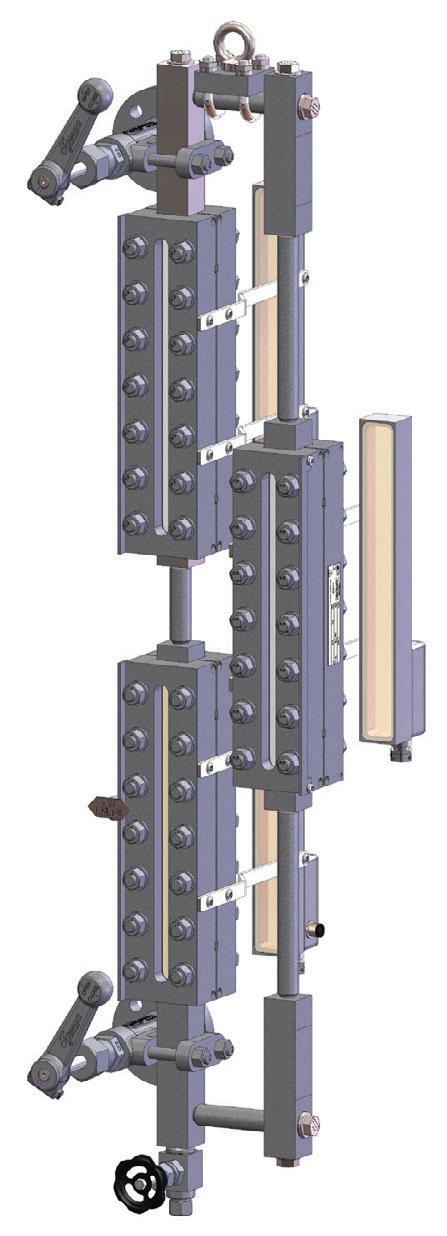

When two large wine tanks at the Destilaria Levira distillery in Portugal burst in 2023, over 2 million litres of wine was released, creating a river of red wine in the streets. Local emergency teams responded quickly to divert the flow of wine into nearby fields (preventing contamination of a local river), but extensive clean-up and repairs were required — with the distillery footing the bill.

This incident highlights the risks of overfill or overspill, which can have a major impact on wineries.

Not only does overspill result in costly product losses as well as additional wastewater treatment costs, labour and maintenance costs — it also exposes the winery to environmental or regulatory risk, as the wine may contaminate local water systems,” said Darryl Blackeby, Regional Sales Manager (SA/WA) of ifm efector (provider of specialist monitoring solutions, including sensors, controllers, software and other digital solutions).

Yet overspill/overfill is easily preventable. By replacing manual monitoring methods with innovative tech solutions, wineries can protect against overspill/overfill and achieve more efficient, sustainable production.

“Manually operated mechanical switches are not a reliable means to prevent overfill. By deploying electronic level switches, meters and sensors, wineries can automate the monitoring of their tanks and pump systems, ensuring that fill rates remain within a safe range,” Blackeby said.

Addressing the cost to install these solutions and automate level monitoring processes, Blackeby said that the return on investment is swift.

“The cost associated with overfill — ranging from wasted product to cleanup costs — will generally outweigh the investment required to install the technology. It only takes one spill to justify the use of these simple monitoring solutions,” he said.

ifm’s hygienic radar level sensors are designed to provide precise, remote level detection, even in tanks as high as 15 m. Equipped with IO-link technology and highquality displays, these sensor devices display tank levels digitally and in real time. The sensors are designed to be installed quickly and easily, even in small wineries.

In a recent example, the sensors were used in an installation for the Steinhauser distillery — a family-owned distillery founded in Germany in 1828 — to support the production of wines and spirits. “The advantage for us is that we no longer have to measure manually but can monitor the process remotely,” said the Steinhauser team.

Unlike flush pressure sensors that use hydrostatic measurement, radar level sensors do not have issues with deposits building up on the measuring cell, which can interfere with accurate readings. They’re also not affected by the extra pressure that builds up in the tank during fermentation, which can impact pressure-based measurement

“By

replacing manual monitoring methods with innovative tech solutions, wineries can protect against overspill/overfill and achieve more efficient, sustainable production.

methods. Additionally, these sensors use smart algorithms to ignore the effects of agitators moving inside the tank during filling.

The level sensors can be coupled with hygienic pressure sensors from the ifm range, as well as its flow meters, for a complete monitoring solution.

“With these devices, winemakers always know how much wine is entering each tank or vessel, and whether there is a pressure fluctuation in any of the tanks, potentially contributing to a tank breach,” Blackeby said.

The data collected by ifm sensors prompts early action, ensuring proper equipment function is maintained and faults are prevented, in turn reducing costly downtime and protecting product quality.

Wineries that collect and analyse their sensor data will benefit from the insights it yields, enabling them to optimise processes, workflows and maintenance schedules.

“In this way, our solutions equip wineries to future-proof their operations, helping them streamline their processes, reduce waste, optimise their resources and cut costs,” Blackeby said.

Widespread bird flu outbreaks worldwide underscore the urgent need for scalable, sustainable disinfection solutions to curb viral transmission in poultry environments and safeguard global food supply chains and public health.

The Silanna UV ultraviolet LED is designed to inactivate multiple H5N1 avian influenza virus strains within seconds, according to recent research by scientists at the University of Siena. The research showed strong viral reduction of up to 99.999% with Silanna’s 235 nm Far Ultraviolet C (UVC) LEDs.

Avian flu has not only disrupted agricultural markets but also food production. Earlier this year, H5N1 outbreaks hit global egg production, leading to shortages and sharp price increases. The virus’s ability to infect humans and other animals has heightened concerns worldwide.

The University of Siena revealed the research results for the product developed by Australian company Silanna during MEDICA 2025, a medical trade fair in Düsseldorf, Germany, at the end of November 2025. The presentation highlighted the Far-UVC LEDs’ strong antiviral performance and the broader implications for FarUVC technology in health, safety and sanitation.

Unlike traditional 254 nm mercury lamps, far-UVC light (200–240 nm) is considered biologically safe within regulatory limits. It cannot penetrate the outer layers of skin or eyes, enabling continuous disinfection in occupied spaces such as hatcheries, food-processing facilities and clinical environments. Researchers also suggest microbes are less likely to develop resistance to farUVC than to conventional antibiotics.

The University of Siena’s Department of Molecular and Developmental Medicine oversaw the joint research, conducted at a Biosafety Level 3 (BSL-3) laboratory in Italy in 2025. The test results confirmed that 235 nm LED irradiation achieves multi-log (up to 99.999%) viral reduction within seconds. These findings position farUVC LEDs as a possible next-generation biosecurity solution, reducing viral contamination risks in industrial and public health settings.

Microlise, a provider of transport technology solutions, has announced a new contract with Geraldton Fishermen’s Cooperative (GFC), which is claimed to be the world’s largest rock lobster processor and exporter.

Under the partnership, Microlise will support GFC with its delivery management, fleet visibility and safety, and health and compliance technology to help raise performance across every stage of the lobster supply chain.

Luke Olsen, Managing Director — APAC at Microlise, said, “We’re proud to partner with GFC to support such a unique and critical supply chain. By combining our AI-enabled Driver safety systems and advanced planning and optimisation tools with GFC’s deep industry expertise, we can help deliver measurable improvements in safety, efficiency and product quality, directly benefiting their members and customers.”

Michael May, GFC Supply Chain General Manager, said: “Our challenges in delivering maximum value to our members include long transport distances, keeping lobsters in top condition, managing driver safety and responding to the dynamic nature of our industry. Microlise helps us address all of these with a single, integrated system.”

Microlise’s Driver Excellence, AI Driver Distraction Cameras, Planning and Optimisation and Delivery Management solutions, including Electronic Proof of Delivery, are designed to help digitalise and streamline GFC’s planning operations while providing deeper insights and real-time visibility across the supply chain.

The solutions also place a strong focus on driver safety, enabling real-time monitoring of every load in transit, maintaining product quality and reducing transport incidents to ensure safer operations and smoother handovers.

“Safety is a foundation of this investment,” May said. “Protecting our drivers and our members’ product is non-negotiable for us, and Microlise helps raise the bar across the board.”

Looking ahead, GFC is also exploring digital traceability and additional technologies to further modernise its operations and strengthen returns for its members.

Headquartered in the UK with offices in Australia, Microlise has a range of modular, end-to-end transport technology solutions which have been used by more than 2500 companies worldwide, including Woolworths, Coles, Foodstuffs South Island, Foodstuffs North Island, Tesco (UK) and Waitrose (UK). Microlise www.microlise.com/au

New Zealand food metal detector manufacturer Fortress Technology understands the challenges of inspecting for metal contaminants on food processing lines. This includes the link between automation and why metal remains the biggest and most likely contaminant risk encountered in food processing and packing facilities.

When it comes to HACCP (Hazard Analysis and Critical Control Points) inspection machine choices, the options can seem overwhelming. Yet, metal detection remains a critical CCP, as metal can be introduced at any phase of production, from cutting meat, filleting fish, grinding spices or mixing dry and wet ingredients. A metal detection system is normally the first line of defence.

Calculating the true cost of a food recall is challenging, as no incident is the same as the next. Variables include the scale of distribution, the number of customers affected, the stage in the supply chain where the item is recalled, any fines or penalties incurred, and the drain on resources and business interruption at the production plant.

Supply chain transparency and the speed in which the source of a metal contaminant is pinpointed is imperative and can minimise the damage to brand reputation.

When considering an investment in food metal detectors, select technology that reflects the most prevalent contaminant risks. It is equally important to investigate

the long-term service costs and upgrade options. A locally based machinery supplier with strong R&D capabilities and experience can be invaluable.

Five key inspection strategies

1. Select inspection equipment with built-in record keeping

Look for systems that will track and record rejects, tests and settings. This type of software facilitates the documenting of potential product risks and helps to narrow the timeframe during which a problem can go undetected. Detailed records can be invaluable during investigations, helping clarify what happened and when, while also reducing how much suspect product must be discarded or recalled.

2. Choose the correct reject system

The type of reject device used will depend on multiple factors, including pack size, weight and shape, whether the product is free-flowing or packaged, the factory layout, size and floor space, as well as line pitch, speed and belt width of the conveyor.

3. Test machine performance automatically

If a fault with the reject system means that a contaminant is detected but not rejected, the line should stop automatically until the situation is resolved. Both detector performance and fail-safe capabilities should be tested regularly, ideally complemented with an automated test system like Halo Automatic Testing. This helps to increase the frequency and quality of verifications while also removing the risk of human error and workplace injury at critical control points — ultimately ensuring compliance with industry standards.

4. Watch for false rejects

Be sure that when a line stops because of detected metal, there is really an issue to address. Technologies like simultaneous multi-frequency enables producers of conductive products like meat, dairy and prepared foods to combine maximum detection sensitivity with minimal false rejects.

5. Ask about sustainability and product lifecycle compatibility

The longevity of an inspection system is heavily influenced by build quality. Some of the earliest analog Fortress Technology food metal detectors installed nearly 30 years ago continue to operate today. As part of the Fortress Never Obsolete commitment, they have been upgraded over time with efficient digital features. Long-term compatibility and upgrade paths should play a key role in the equipment selection process.

If, at high filling capacities, beverages slosh out of the bottle, levels of efficiency and hygiene suffer. KHS prevents this by drawing up extensive calculations.

If beverage filling is to be safe with little loss, physics comes into play.

Given the rotation speed and change in direction, especially at the transition from the transfer star to the closure system, high levels of centrifugal force act on the content of the containers. This can cause liquid to slosh out of the bottle. This may only comprise a few drops of spillage at a time — but with up to 90,000 fills an hour, the amount of product lost soon mounts up.

Another issue is hygiene. It’s not hard to imagine that on the one hand, sloshed sugary beverages soil container necks and closures, with mould even being formed in some cases. On the other, the machine is also contaminated. This in turn increases cleaning requirements and takes up valuable production time.

In order to counter this, KHS development engineer Dominik Weirich has been drawing up CFD calculations since 2013.

“Ever higher filling outputs mean that the technology’s reaching its physical limits, so that we also have to take liquid sloshing

into account when designing the machine,” Weirich said.

Data collected from the simulations he carries out form the basis here.

“First, we take a look at the geometric parameters of the beverage containers themselves: here, we investigate the impact the bottle shape, fill height and neck diameter have. This is done in close consultation with our Bottles & Shapes experts, especially in conjunction with new line projects, when changes are made to the geometry or the bottle weight is reduced, for example. Second, we have the physical parameters of the machines. These depend on the capacity, machine pitch and diameter of the stars. Adjustments can be made here relatively easily. Adapting the containers, however, is usually an iterative and more extensive process.”

As a rule, it can be said that the larger the product surface and the closer the beverage is to the bottle mouth, the more likely the liquid is to slosh. This interaction of the various factors requires calculations to be made that are then included in both the design engineering and the offers for the machinery. Weirich has already performed about 850 of these simulations — with this number continuing to rise.

Bürkert Fluid Control Systems honored by GEA in the category “Innovation” “Supplier of the Year Award” for fluidics specialist

Fluidics specialist Bürkert Fluid Control Systems has a partnership with the GEA Group that goes back more than two decades. In November 2025, GEA honoured Bürkert with its “Supplier of the Year Award” in the category “Innovation”. The award ceremony took place on 19 November in Amsterdam.

DAX-listed technology group GEA has honoured Bürkert Fluid Control Systems with the “Supplier of the Year Award” 2025 in the category “Innovation”, an award that GEA presents annually to a particularly innovative partner. It recognises the close partnership and the outstanding performance of Bürkert. The award ceremony took place on 19 November, 2025 as part of the Annual Supplier Summit, an exclusive event for suppliers in Amsterdam. Representatives from Bürkert were there to accept the award in person.

The award recognises Bürkert’s proactive cost optimisation initiatives in the area of total cost of ownership, and the support it has given GEA in developing new applications, such as the New Food test centres in the USA and Germany.

“Something that was particularly highlighted was Bürkert’s strategic direction, which ideally complements GEA’s long-term goals and future plans”, said Denis Cougnet,

Bürkert’s Corporate Key Account Manager for the GEA Group. Both companies pursue similar priorities such as innovation, efficiency and sustainability — an ideal basis for successfully continuing to collaborate and develop the partnership.

Bürkert CSO Roman Gaida stated: “Working closely with our customers and partners is at the heart of everything we do. Our strategic direction with a focus on digital services, automation, sustainability and a regenerative economy provides us with the right foundation for this. In these areas especially, we want to set new standards together with key customers like GEA. The Award shows that our strategic direction is keeping us on the right course. It confirms that we are consistently pursuing the goals we have set and successfully achieving them.”

Markus Bendisch, Director of Corporate Key Account Management at Bürkert, added: “We are delighted to receive this award: it underscores our innovative strength and our commitment to sustainable and partnership-based collaboration.”

A long-standing partnership and joint innovations

Bürkert and GEA share a long-standing partnership in which the fluidics specialist

provides the GEA Group with a wide portfolio of process and solenoid valves, plus tailored system solutions.

In addition to product quality and delivery reliability, Bürkert has ensured impressive results through its global production capacity based on a “local for local” principle in China, India and the USA, as well as its engineering expertise in system solutions. Another factor in the success story is the close collaboration that takes place within the framework of Corporate Key Account Management, which supports GEA worldwide.

The “Award” is not only a recognition of Bürkert’s past achievements, but also a mandate for the future, and confirms the strength of the partnership with GEA.

“This honour shows us the importance of consistently pursuing the path we have taken and continuing to provide solutions that help our customers make their processes more efficient and sustainable”, said Markus Bendisch in summary.

Burkert Fluid Control Systems www.burkert.com.au

Terry Smagh, Senior Vice President and General Manager, Asia Pacific and Japan at Infor*

Over the past few years, Australia has faced harsher fire seasons, unprecedented flooding and longer droughts.

In 2024, major floods in Western Australia forced freight trucks to take detours of over 2000 kilometres, delaying the delivery of basic supplies to remote communities. Last year, Ex-Cyclone Alfred caused the temporary shutdown of distribution centres in Brisbane, leading to produce spoilage and empty supermarket shelves. Add rising geopolitical instability, persistent labour shortages and increasing cyber threats into the mix, and the pressure on food and beverage organisations only continues to intensify. These disruptions can slow or freeze operations, affecting throughput, quality, shelf life, revenue and profitability.

In the face of these challenges, visibility has never been more crucial.

Spoilage and demand shifts can make or break margins, so knowing what’s happening and where is critical. Yet, according to our latest research, 61% of food and beverage organisations have limited visibility over parts of their supply chain, and only 7% of global supply chain leaders have achieved full multi-tier transparency, according to the World Economic Forum.

Despite growing awareness of supply chain fragility, it is clear that many food and beverage organisations operate with blind spots. Visibility might extend to immediate suppliers or logistics partners, but further up or downstream data often becomes patchy or out of date, making it hard to spot bottlenecks, quality issues or emerging

risks. This leads to missed production targets, wasted stock and downstream delays that damage both margins and customer trust.

Furthermore, visibility challenges do not only exist for entities and processes that are outside an organisation. They can also be present between different departments within the same company.

Interviewees in a recent study, commissioned by Forrester Consulting on behalf of Infor, describe how siloed operations and manual processes can drain warehouse and logistics productivity.

Food and beverage organisations need to build resilience,

To do so, visibility needs to be granular, real time and actionable. That means connecting siloed systems and integrating partner data while investing in smarter technology that goes deeper than surface insights, to help teams respond with speed and confidence.

Responding to sudden disruption — be it extreme weather, supply shocks or shifting regulations — requires greater visibility alongside increased agility. That’s why the most productive food and beverage organisations are leaning on technology, specifically intelligent automation, to make faster, more informed decisions while easing pressure on overstretched teams.

Here’s five tools helping them do it:

1. Generative artificial intelligence (GenAI) generates scenario-based simulations to help planners respond to forecast fluctuations with speed and precision.

2. Augmented intelligence delivers real-time recommendations based on live operational data, guiding better decisions before disruption hits.

3. Integrated shelf-life optimisation manages stock levels by product or location, helping prevent waste by aligning production and distribution with expiry thresholds.

4. Advanced visualisation tools support bi-directional track and trace, product recalls and general supply chain management.

5. Robotic process automation (RPA) automates time-consuming admin tasks such as invoice matching and order entry, freeing teams to focus on higher-value work.

Together, these tools streamline operations and reduce manual error while enabling a more proactive response, keeping organisations one step ahead, even when the unexpected hits.

Smarter decisions start with stronger data foundations

To make fast, confident decisions, food and beverage organisations need a single source of truth and integrated analytics. When systems are unified, insights are no longer buried in spreadsheets or siloed across departments. Instead, teams can access real-time operational data that helps them anticipate issues, identify inefficiencies and spot trends, so they can act with precision. With the right tools, leaner teams can do more — accelerating output and reducing manual errors, all while improving responsiveness. In an unpredictable world, this kind of data-driven clarity is how the most productive food and beverage organisations stand out.

“Despite growing awareness of supply chain fragility, it is clear that many food and beverage organisations operate with blind spots. Visibility might extend to immediate suppliers or logistics partners, but further up or downstream data often becomes patchy or out of date, making it hard to spot bottlenecks, quality issues or emerging risks.

This clarity is especially important in an industry under increasing pressure from both rising consumer expectations and a shrinking talent pool. As ESG regulations, traceability standards and food safety mandates become more demanding, centralised data ensures organisations can respond quickly and demonstrate compliance without adding to the administrative burden.

Ongoing disruption isn’t going anywhere, but with the right technology, food and beverage organisations don’t have to stay on the back foot. From automation to agility, the right approach to digital transformation is helping food and beverage organisations go from increasing complexity to greater clarity, building resilience while driving real, measurable results.

Now is the time to act.

*Terry Smagh is Senior Vice President & General Manager, Asia Pacific and Japan at Infor. In his role, Terry is passionate about driving SaaS adoption and growth across the fastest-growing region for Infor, and helping customers derive quick value from their business transformation and technology investments. He is a seasoned sales executive and revenue growth leader with more than 20 years of Asia Pacific experience across enterprise software sales in the digital transformation space, spanning industries such as retail, finance and insurance.

Dematic has expanded its automated guided vehicle (AGV) portfolio with the launch of the Reach Truck Series (RTS) 120. Designed for high-bay, single-selective racking environments, the series combines reach truck functionality with the benefits of driverless automation. It is designed to deliver consistent high-bay handling with precision and safety, making it a versatile solution for both new facilities and existing sites.