2025 National Manufacturing Summit Wrap-Up >>>

Weld Australia Calls for Support to Expand ‘Buddy Up Program’ >>>

2025 National Manufacturing Summit Wrap-Up >>>

Weld Australia Calls for Support to Expand ‘Buddy Up Program’ >>>

WELD AUSTRALIA

NATIONAL OFFICE

PO Box 197, Macquarie Park BC NSW 1670 1800 189 900 office@weldaustralia.com.au weldaustralia.com.au

Geoff Crittenden

Chief Executive Officer 1800 189 900 office@weldaustralia.com.au

TRAINING

Guy Brooks, General Manager, Training Operations 0488 743 322 training@weldaustralia.com.au

MARKETING

Michelle Tagliapietra, Executive General Manager, Sales & Marketing 0437 106 726 events@weldaustralia.com.au

MEMBERSHIP

David Choudry, Membership Manager 0417 878 104 membership@weldaustralia.com.au

QUALIFICATION & CERTIFICATION

Luke Nicholls, General Manager, Qualification & Certification 0487 487 985 qnc@weldaustralia.com.au

ENGINEERING

Simon Doe, Director, Engineering 0490 384 406 engineering@weldaustralia.com.au

NEW SOUTH WALES

Ashkan Abdibastami, Welding Engineer 0456 850 315 a.abdibastami@weldaustralia.com.au

VICTORIA, TASMANIA & SOUTH AUSTRALIA

Victor Blain, General Manager, Engineering – VIC, TAS, SA & WA 0409 823 991 v.blain@weldaustralia.com.au

QUEENSLAND & NORTHERN TERRITORY

Ross O’Bryan, General Manager, Engineering – QLD, ACT, NSW, NT 0491 491 888 r.obryan@weldaustralia.com.au

WESTERN AUSTRALIA

Lucas Bendo-Watson, Business Development Manager 0492 982 284 l.bendo-watson@weldaustralia.com.au

Australia’s manufacturing sector stands at a critical juncture. On the one hand, the federal government’s Future Made in Australia agenda signals renewed ambition and unprecedented investment. On the other, global headwinds, energy insecurity, and unfair overseas competition continue to erode our domestic industrial base. The 2025 Weld Australia National Manufacturing Summit made one thing crystal clear: we are running out of time to turn policy intent into meaningful, coordinated action.

Hosted by Weld Australia in Sydney in late July, the Summit brought together leaders from across industry, unions, academia, and all levels of government. The energy in the room was palpable, driven by a shared understanding that Australia must make more valueadded things, and must make them here.

But the challenge is no longer about convincing people of the value of manufacturing. It’s about implementation. How do we create long-term policy certainty, unlock investment, and build the skills base needed to meet this moment? How do we prevent a flood of dumped steel and imported infrastructure from undermining

our ambitions? And how do we seize the opportunity presented by the renewable energy transition to revitalise Australian industry?

These were the questions at the heart of this year’s Summit, and they must now be answered through coordinated, practical action.

One of the most promising themes to emerge from the Summit was the alignment between the renewable energy transition and industrial renewal.

Australia will need to manufacture over 6,000 wind towers and thousands of kilometres of transmission infrastructure over the next decade. This isn’t just an environmental imperative. It’s an industrial opportunity. We can either build these assets here or import them from subsidised overseas suppliers.

The economic case for local manufacturing is compelling. As Tim Ayres, Federal Minister for Industry and Innovation, pointed out, Australian structural steel and fabrication businesses stand to benefit enormously if procurement policy and investment settings are designed to favour local capability. The government’s

$1 billion Green Iron Investment Fund and $500 million Innovation Fund for clean energy manufacturing are welcome steps. But to make the most of these initiatives, we need stronger, enforceable local content requirements—something Weld Australia has long advocated for.

Government investment is vital, but without coordinated procurement policies that require local industry participation, we risk simply subsidising demand for imports. We need to ensure that every dollar spent on the energy transition supports sovereign capability and good local jobs.

Australia’s manufacturing sector is being eroded by a flood of low-cost, non-compliant imports that do not meet Australian Standards. These products undercut local manufacturers on price, not quality, creating an uneven playing field that threatens jobs, investment, and sovereign capability.

At the Summit, this issue emerged as one of the most urgent challenges facing Australian industry. While local fabricators are held to rigorous safety and quality standards, overseas suppliers can bypass these obligations and win contracts on cost alone. The result is a race to the bottom in price, with local manufacturers squeezed out of public and private sector projects.

Steel once destined for the United States is being redirected to Australia following the introduction of stronger trade protections in the US. Without similar measures here, Australia has become a dumping ground for cheap imports, accelerating the decline of a sector already under immense pressure.

But as several speakers pointed out, this is not a matter of scarcity. It’s a matter of will. Australia is one of the wealthiest countries in the world. We have the financial capacity, the workforce, and the public support to invest in a future made locally. What’s lacking is a commitment to the policy and economic reform needed to make it happen.

The warning was clear: without decisive intervention, Australia stands to lose its industrial base. And once lost, it may never return.

To realise the full potential of a revitalised manufacturing sector, we must strengthen the foundational enablers that support long-term industrial capability.

A level playing field is essential for the survival of Australian manufacturing. Right now, it doesn’t exist. Local fabricators who invest in quality, safety, training and certification are competing with offshore suppliers that

often ignore Australian Standards and flood the market with substandard, low-cost imports.

Multiple speakers at the Summit reinforced the need for enforceable standards, backed by independent verification and consistent national procurement practices. Australia cannot afford to continue rewarding non-compliance, particularly when our own manufacturers are being penalised for doing the right thing.

The Canadian model, presented at the Summit by Doug Luciani and Jim Stanford, provides a powerful case study. By embedding compliance within public procurement policy and mandating alignment with Canadian codes and standards, Canada has created a procurement ecosystem that supports domestic capability. A similar framework, tailored for Australian Standards such as AS/NZS ISO 3834 and AS/NZS 5131, would go a long way toward restoring fairness and certainty for local manufacturers.

Industry cannot plan for the future when government policy shifts with every election cycle. Long-term investment requires long-term certainty.

While recent government announcements, including the Future Made in Australia plan and National Reconstruction Fund, are steps in the right direction, we need clear, consistent signals about the direction of industrial policy. Alignment across the state and federal governments is essential to ensure manufacturing is not just part of our past, but a central pillar of our future.

The creation of manufacturing hubs, innovation precincts, and centres of excellence must be accompanied by a broader national strategy that articulates our industrial priorities, coordinates investment across the supply chain, and ensures accountability for outcomes. Australian governments must implement enforceable local content

mandates for government-funded projects.

Australian manufacturing is not asking for protectionism. It is asking for predictability. With the right policy foundations, manufacturers will invest in new technologies, expand their operations, and create secure, full-time jobs in every corner of the country.

3. Secure, Affordable Energy Supply

Energy is the lifeblood of manufacturing. When gas and electricity prices spike, production slows, jobs are lost, and investment dries up. Unfortunately, as new research from The Australia Institute confirms, Australia’s domestic energy settings, particularly on the east coast, have left manufacturers dangerously exposed.

The unrestricted export of gas has driven up domestic prices while failing to guarantee local supply. Manufacturers are now paying global prices for energy extracted onshore, often with little recourse or transparency. At the same time, our transition to renewables is being hampered by a lack of grid infrastructure and uncertainty around pricing.

The message from the Summit was clear: we need an energy system that works for Australians, not just exporters. That includes:

• Implementing a domestic gas reservation policy

• Capping uncontracted gas exports during periods of shortage

• Reforming the National Electricity Market to break the price-setting power of gas generators

• Accelerating investment in renewable generation and transmission, with industrial customers in mind

Without secure, affordable energy, Australia cannot sustain—or grow—its manufacturing base.

4. Skills and Workforce Strategy

A future made in Australia will only be possible with

a workforce trained in Australia. The manufacturing sector is already facing critical shortages in skilled trades, particularly in welding, fabrication, and advanced production. The transition to renewables, the push for sovereign capability, and the growth of advanced manufacturing will only increase demand.

The Summit highlighted the importance of innovative, inclusive approaches to workforce development. Programs like Corrections Victoria’s Centre of Excellence for Welding show what is possible when industry, education and social reform intersect. By training prisoner learners to ISO 9606 standards using both augmented reality and hands-on methods, the program is producing skilled, motivated workers ready for meaningful employment.

But this effort needs to be scaled nationally. Australia must invest in TAFE, develop consistent national training pathways, and build programs that attract young people into manufacturing. A national workforce strategy, aligned with industry needs and future growth areas, is essential to ensure we have the right skills in the right places at the right time.

Throughout the Summit, there was a growing sense of urgency. The Australian manufacturing sector has been in decline for decades. We are now at the point where we risk losing critical capability altogether.

We cannot afford another five or ten years of policy drift. If we fail to act now, we will not have the industrial base we need to support the energy transition, national resilience, or economic sovereignty.

This is not just a manufacturing issue. It is a national interest issue. Manufacturing creates secure, full-time jobs. It supports regional economies. It drives productivity and innovation. And, in an increasingly volatile global landscape, it is the key to economic resilience.

To rebuild a thriving, competitive and future-focused manufacturing sector in Australia, Weld Australia believes the following actions must be prioritised:

1. Ensure compliance and fair competition by:

• Introducing mandatory independent certification for all fabricated products modelled on Canada’s approach to ensure they meet AS/NZS ISO 3834 and AS/NZS 5131, reducing the flood of substandard offshore materials and restoring a level playing field.

• Strengthening Australia’s anti-dumping protections, especially in the face of global steel oversupply redirected from markets like the United States into Australia.

2. Provide policy leadership and long-term investment certainty by coordinating policy across

all levels of government to deliver clear, stable, and consistent industrial strategy, giving manufacturers confidence to make long-term investments in equipment, technology, and workforce.

3. Secure an affordable and reliable energy supply by:

• Implementing a domestic gas reservation policy to ensure manufacturers have access to reasonably priced energy, particularly on Australia’s east coast.

• Capping uncontracted gas exports and reform pricing mechanisms to stop local manufacturers from being exposed to volatile international gas markets.

• Accelerating investment in renewables and transmission infrastructure, with pricing models that reflect the needs of energy-intensive industries and provide long-term price certainty.

4. Leverage the renewable energy transition to stimulate local manufacturing through enforceable local content rules, strategic investment, and guaranteed supply chain participation.

5. Expand skills and workforce initiatives, including TAFE funding, manufacturing centres of excellence, and programs like Corrections Victoria’s welder training.

As I said at the Summit, we are staring into an industrial abyss. But right beside it is a once-in-a-generation opportunity. The only question now is whether we have the courage, vision, and political resolve to seize the opportunity before it’s too late.

Geoff Crittenden CEO, Weld Australia

Following the Summit, The Australia Institute released research reveals that gas exports have led to the tripling of wholesale east coast gas prices and doubling of electricity prices, since exports began in 2015.

The Australian and Queensland governments’ decisions in 2010 to allow large-scale exporting of Australian gas from Queensland exposed Australians to high global prices, ending decades of abundant, low-cost gas for Australians, leading to higher energy bills, gas shortages and manufacturing closures. Gas price increases due to excessive exports have also caused electricity prices to rise because gas power stations often set electricity prices.

“When you get your next energy bill, blame the gas industry and your governments for opening the gas export floodgates despite being warned it would drive up energy bills for Australians,” said Mark Ogge, Principal Adviser at The Australia Institute.

“Gas exports have led to manufacturing closures in Australia. Gas exporters manufacture nothing except gas shortages and higher energy bills for Australians. The kindest interpretation of the Australian and Queensland governments’ role in allowing gas export corporations to brutally price-gouge Australians over the last decade is that they are weak and gullible. Arguably, they are complicit.”

“Allowing new gas projects doesn’t solve the problem. We have tripled gas production in a decade, and we still have rolling shortages and high prices. New gas projects just mean more gas is exported and result in net-zero additional gas for Australians, unless we cut exports. The only way to fix this mess and reduce Australian energy bills is to cut exports and divert the gas to Australians.”

According to Geoff Crittenden, CEO of Weld Australia, “Gas exports have exposed Australian manufacturers to high global gas prices and are also driving up electricity costs, hitting manufacturers with a double blow, making it almost impossible to compete with subsidised imports.”

“It beggars belief that for the last decade, Australian governments have allowed LNG producers to export surplus uncontracted gas to the global spot market while Australian manufacturers are unable to secure gas at reasonable terms and prices. It needs to be fixed now.”

The research was launched at a press conference in Canberra, with speakers:

• Senator David Pocock, Independent Senator for the ACT

• Dr Monique Ryan MP, Independent Member for Kooyong

• Geoff Crittenden, Chief Executive Officer, Weld Australia

• Mark Ogge, Principal Advisor, the Australia Institute

• Cassandra Goldie, CEO of the Australian Council of Social Service

‘Total madness’: Senator David Pocock slams net-zero review, published by The Australian

Independent ACT Senator calls gas export system a scam, published by SBS News

Pocock and Ryan want exporters to divert uncontracted gas for domestic use, published by The Guardian

‘Steam out their ears’: Australians fired up about gas exports, published by The Australian Financial Review

DOWNLOAD A COPY OF THE REPORT >> READ THE MEDIA RELEASE >> WATCH THE PRESS CONFERENCE >>

Hosted by Weld Australia, the 2025 National Manufacturing Summit saw a diverse group of stakeholders come together on 23 and 24 July at the Shangri-La in Sydney. With the theme of Manufacturing Australia’s Future: Local Strength, Global Impact, the Summit delved into the unique opportunity to revitalise Australia’s industrial base, ensuring that it not only survives but thrives in the forthcoming decades.

Discussions at the 2025 National Manufacturing Summit focused on revitalising Australian manufacturing by addressing overseas competition, strengthening local capability, and leveraging strategic opportunities, particularly in the renewable energy sector. Key themes included:

Compliance and Fair Competition: A strong focus was placed on the urgent need to address the influx of non-compliant, low-cost imported steel and fabricated components. The presentation by Canadian expert Doug Luciani (President and CEO, CWB Group) demonstrated a proven international model that ensures compliance with national standards. This framework was well received by federal and state government representatives, prompting active discussion on how a similar compliance mandate could be adapted for the Australian context.

Renewable Energy Opportunities: The Summit highlighted the significant manufacturing potential tied to Australia’s energy transition. From wind tower fabrication to transmission infrastructure, discussions centred on the need to secure sovereign capability and reduce dependency on overseas suppliers, particularly as global supply chains become more volatile.

Policy Leadership and Long-Term Investment: Speakers reinforced the importance of clear, coordinated policy that supports domestic manufacturing through consistent regulation, strong procurement settings,

and strategic investment. NSW and federal leaders emphasised the power of government procurement to drive demand, de-risk private investment, and ensure long-term sector stability.

Skills, Inclusion and Workforce Strategy: Equipping a future manufacturing workforce emerged as a central theme. Programs like Corrections Victoria’s VET Centre of Excellence model were recognised for their dual social and economic benefits, delivering globally certified training while reintegrating secondchance workers into the labour market. Broader support for skills development is critical.

Structural and Economic Reform: The prevailing economic narratives were challenged, with speakers arguing that Australia has both the wealth and public support to invest in a future made locally. There were calls for practical reforms to energy pricing, export policy, and taxation, designed to create a level playing field for domestic manufacturers.

Building on Momentum: There is a shared recognition that time is running out. With increased dumping of foreign steel into Australia, global competition intensifying, and local capacity under pressure, attendees agreed that immediate action is needed. Encouragingly, there was also a sense of alignment across jurisdictions, and a willingness to move from rhetoric to implementation.

WITH THANKS TO OUR SPONSORS

In his address to the 2025 National Manufacturing Summit, the Hon Anoulack Chanthivong, New South Wales Minister for Better Regulation and Fair Trading, Minister for Industry and Trade, Minister for Innovation, Science and Technology, Minister for Building, and Minister for Corrections delivered passionate and pragmatic call for renewed focus on the role of manufacturing in the New South Wales economy.

Acknowledging the state’s proud manufacturing history, and the challenges it faces, the Minister laid out a clear vision for how government can enable a strong, sustainable, and resilient future for the sector.

While factors such as globalisation, complex supply chains, and offshore competition have contributed to the declining trend in manufacturing, the Minister made it clear that complacency is not an option.

“We can lay down our tools—or we can pick up new ones,” he said, referring to the transformative potential of innovation, data, robotics, and advanced design and prototyping to reshape how manufacturing is done.

NSW already accounts for one-third of Australia’s manufacturing output and manufacturing employs one in every fifteen workers across the state. To protect and grow this contribution, Chanthivong called for policy clarity and long-term commitment, particularly in areas such as:

• Procurement reform: Using government purchasing power to avoid the ‘valley of death’ for local manufacturers and stimulate investment across entire supply chains

• Manufacturing Centres of Excellence: Building on the success of TAFE-based hubs in the Hunter and beyond

• Innovation and commercialisation: Backing new initiatives such as the NSW Industry Policy, the NSW Trade and Investment Strategy and the NSW Innovation Blueprint

Chanthivong acknowledged that while Australia has no shortage of innovative ideas, it must become far better at commercialising them domestically. “We want great ideas to stay here, and we want Australians to reap the benefits,” he said.

The Minister closed by affirming that the NSW Government sees manufacturing as a critical pillar of the state’s economic future. “We have a responsibility and obligation to ensure manufacturing isn’t just part of our past, but a core part of our future.”

In one of the most provocative and compelling sessions of the Summit, Richard Denniss (Executive Director, The Australia Institute) challenged the audience to rethink the stories we tell ourselves about what Australia can and cannot afford.

With trademark wit and piercing economic insight, Denniss critiqued the prevailing political narrative that claims investment in skills, R&D, and energy reform for manufacturing is too costly. Denniss argued that the claim Australia cannot afford to invest in skills, research, or energy reform is not grounded in economic reality. It’s simply a matter of political priorities.

Denniss argued that Australia is among the wealthiest nations on earth—its GDP on par with Russia’s— and regularly spends billions on projects like nuclear submarines, inland rail, and dams without formal business cases or public scrutiny. “If it’s a priority, we can always afford it,” he noted, referencing how political will, rather than fiscal constraint, shapes national investment decisions.

He pointed to the $10 billion annually spent subsidising the fossil fuel industry as a glaring contradiction in a country committed to net zero emissions, while also refusing to adequately invest in clean energy or training for manufacturing. “Economics 101: tax things you want less of, subsidise things you want more of,” he said.

At the heart of Denniss’ address was a call to stop pretending manufacturing support is unaffordable. He reminded attendees that:

• Public support for manufacturing is consistently high

• Manufacturing employs around 1 million Australians, compared to 20,000 in the gas sector

• Manufacturing workers pay $20 billion in income tax annually, vastly more than the gas industry contributes via the PRRT (Petroleum Resource Rent Tax), which brings in only $1 billion

Denniss ridiculed claims that the gas industry is the ‘backbone of the economy,’ noting that over half of Australia’s exported gas is given away so cheaply that countries like Japan are able to re-export it at a profit. Meanwhile, domestic manufacturers face soaring energy prices, with gas prices rising over 300% since 2015.

To reverse this situation and genuinely support a “Future Made in Australia,” Denniss proposed a simple plan:

• Reserve domestic gas supply: As the world’s largest gas exporter, Australia should ensure local manufacturers have access to affordable gas.

• Stop giving gas away for free: Tax offshore gas properly and redirect revenue into strategic investment.

• Rebalance subsidies and taxes: Use economic levers to incentivise the industries Australians actually want to grow like manufacturing.

“If we’re serious about revitalising manufacturing, we need to stop pretending it’s too expensive, and start acting like it matters,” said Denniss.

In a keynote address that set the tone for the 2025 National Manufacturing Summit, the Hon Tim Ayres, Federal Minister for Industry and Innovation, and Minister for Science outlined the Federal Government’s bold industrial policy agenda and reaffirmed its commitment to revitalising Australian manufacturing as a national priority.

Ayres made it clear: the decline in Australia’s manufacturing base over recent decades has coincided with weakening national productivity, and it’s time to reverse the trend.

Ayres positioned manufacturing as essential to Australia’s innovation ecosystem, noting that globally-facing manufacturers have historically played a disproportionate role in driving productivity and investment. He cited McKinsey research that demonstrates how highly productive firms lift the performance of the entire economy.

Central to his remarks was the Federal Government’s Future Made in Australia plan, which will see $22.7 billion invested over the next decade to reindustrialise the economy, drive clean energy manufacturing, and secure sovereign capabilities. Ayres highlighted new initiatives including:

• A $1 billion Green Iron Investment Fund to capitalise on Australia’s iron ore advantage

• $3 billion for green metals production

• A $500 million Innovation Fund to boost domestic manufacturing of wind towers and clean energy infrastructure

• Stronger anti-dumping protections to safeguard domestic industries

• $1 billion in zero-interest loans to help firms scale up and seize export opportunities

He also touched on strategic investments in steelproducing regions like Whyalla, Newcastle, Wollongong and the Hunter, emphasising their critical role in producing low-emissions, high-value iron and steel products for both domestic and international markets.

Ayres painted a vision of an Australia that leads—not follows—when it comes to industrial capability, clean energy technology, and strategic value chain participation. He described the current economic environment as both volatile and full of opportunity, urging collaboration across sectors to build resilience and secure the nation’s future.

His message was underscored by urgency: “Taking action now is always better than more costly action later. Or worse, not being able to act at all, because it is too late.”

Looking ahead to the upcoming national economic reform roundtable, Ayres invited Summit participants to contribute their ideas and voices to shape longterm reform priorities. His speech made clear that manufacturing is not only back on the national agenda— it’s at the heart of Australia’s future prosperity.

Rebecca McPhee, Deputy Secretary of Investment NSW, kicked off the session, reinforcing the NSW Government’s commitment to revitalising local manufacturing, a sector that contributes $46 billion to the economy. Despite significant growth (3.2% in 2023–2024), McPhee acknowledged ongoing challenges such as high input costs, international competition, and a small domestic market. The NSW Industry Policy, which integrates multiple government strategies, aims to prioritise areas of local leadership, resilience, and workforce development.

Dr Jens Goennemann, Managing Director of AMGC, emphasised that Australia must view manufacturing as a “capability” rather than just a sector. He criticised the narrow focus on production and highlighted the need for innovation, design, and advanced manufacturing processes. Goennemann pointed to Australia’s declining position on the Harvard Economic Complexity Index and the lack of mid-sized, high-capability firms, advocating for long-term industry-led strategies that prioritise complexity and scalability.

Simon Terry, CEO of Dux Hot Water, shared his company’s experience of operating in a high-cost, highpressure environment. Despite rising energy and labour costs, Terry stressed that innovation is Australia’s competitive edge, citing Dux’s investment in Australiandesigned green technologies. He called for reforms in energy pricing, industrial relations, and quality controls for imported products to level the playing field for local manufacturers.

Finally, John Titchen, Director of Goldwind Australia, proposed a solution to increase local content in the wind energy sector. Titchen suggested a Local Tower Production Certificate scheme to incentivise developers to source a percentage of wind towers locally. This mechanism would balance cost-efficiency with the growth of local manufacturing capabilities in renewable energy projects.

In Session Two of the Summit, experts explored how global trends are reshaping industrial policy and what Australia can learn from international approaches to manufacturing resilience.

Jim Stanford, Industry Professor of Economics at McMaster University, Canada, provided a compelling overview of global trade challenges, particularly under the second Trump presidency.

He highlighted that while Australia’s trade exposure to the US is small, it’s vulnerable to global instability triggered by erratic US policies. Stanford debunked myths around tariffs, arguing they harm US manufacturers and that Australia’s risk lies in the breakdown of global trade rules. His advice for Australia: diversify trade, invest in technology-rich industries, and adopt a more strategic, coordinated approach to industrial policy.

Doug Luciani, President of CWB Group, presented a strong case for a national welder certification framework in Australia, modelled after Canada’s system. Luciani explained that Canada’s mandatory certification for welders, supervisors, and procedures ensures safety, quality, and protection against offshore competition.

With over 8,000 companies and 12,000 individuals certified globally, Luciani argued that Australia could benefit from a similar system to safeguard its fabrication industry and compete in a globalised market. He warned that without such systemic change, Australia’s manufacturing sector, contributing only 6% to GDP, could decline further.

Together, these experts underscored the need for Australia to embrace international lessons to build a resilient, competitive, and sustainable manufacturing sector.

Session Three of the Summit focused on building Australia’s industrial and energy capacity for a sustainable and competitive future.

Tim Buckley, Founder and Director of Climate Energy Finance, delivered a stark warning about the future of Australia’s industrial and energy sectors. He noted China’s rapid renewable energy expansion—13% annual growth in wind, 27% in solar, and 84% in batteries over recent years—posing a significant threat to Australia’s fossil fuel exports. Buckley argued that Australia must urgently embrace electrification, low-emission industries, and a price on carbon to avoid falling behind. The opportunity lies in realising low-cost zeroemissions energy at scale and promoting low-emission trade across Asia.

David Shankey, CEO of the Net Zero Economy Authority, explored Australia’s transition to a lowemissions economy, emphasising the need for regional communities to play a key role. While acknowledging challenges like rising energy costs and maintaining investor confidence, Shankey was optimistic about the country’s progress. With net-zero targets looming and investments flowing, his message was clear: Australia must act quickly to build sustainable markets that support manufacturing and ensure long-term prosperity.

Phil Toner, Senior Research Fellow at the University of Sydney, highlighted the importance of Verdoorn’s Law, which links productivity growth in manufacturing to increased output. Toner explained that demanddriven growth stimulates productivity, specialisation, R&D, and export potential. He warned that Australia’s declining manufacturing sector has dampened overall productivity and called for a more strategic, coordinated industrial policy that focuses on investment in science, technology, workforce development, and infrastructure to unlock further growth.

Session Four of the Summit focused on the critical need for a capable, future-ready workforce to drive sustainable growth in Australia’s manufacturing sector. The session explored innovative training pathways, education reform, and inclusive workforce development strategies to ensure no one is left behind.

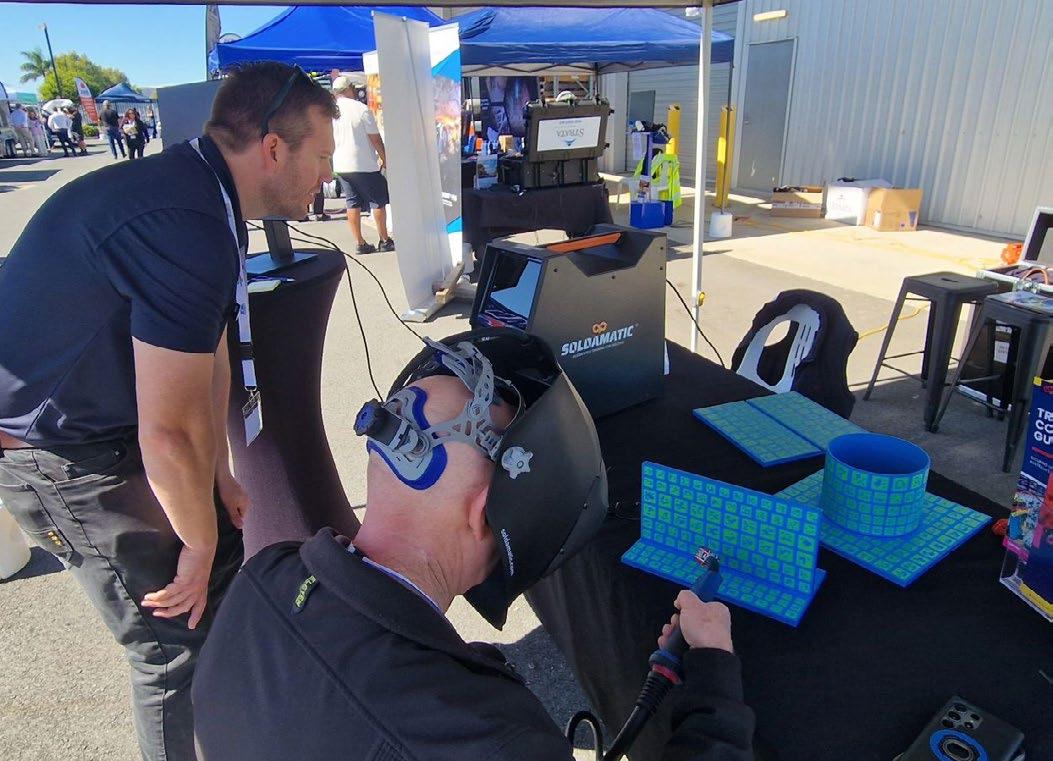

Amanda Sonntag, VET Curriculum Advisor at the NSW Department of Education, showcased how New South Wales public schools are using augmented reality (AR) welding simulators to revolutionise vocational education.

Since 2020, the technology has been integrated across 16 schools, providing students with immersive, hands-on welding experience in a safe environment. The initiative has increased engineering enrolments by 45%, with notable participation from female and Aboriginal students, traditionally underrepresented in trade training. By aligning simulations with local industry needs and creating stronger school-to-work pathways, this program is preparing students for careers in manufacturing.

Justin Spedding, Senior Project Officer at Corrections Victoria, presented a compelling example of how vocational education can change lives. Since 2022, the VET Centre of Excellence model has been expanded within correctional facilities, offering Fusion Welding training aligned with ISO 9606 certification. This program, combining augmented reality with practical training, is preparing incarcerated individuals for employment upon release.

With Australia facing a critical skills shortage, this initiative could provide up to 500 highly trained workers to the manufacturing sector. Spedding highlighted the exceptional outcomes, with employers reporting high reliability, motivation, and retention from participants.

WANT TO DISCOVER HOW WELD AUSTRALIA CAN SUPPORT YOU THROUGH MEMBERSHIP?

Questions? Queries? Wondering how Weld Australia can help support your business, staff or career progression?

Contact David Choudry (Membership Manager, Weld Australia) on d.choudry@ weldaustralia.com.au to set up a 20 minute Zoom chat. David will take you through the ways that Weld Australia can help.

If you’re not sure if you have renewed for this year, or you want to renew now, log into the Member Portal or contact us on membership@weldaustralia.com.au

Weld Australia would like to welcome all our new Members who have joined in the last month.

CORPORATE MEMBERS

• All Star Welding: https://aswelding.net

• Roddy Engineering: https://roddyeng.com.au

• Pipe Lining & Coating: https://pipelining.com.au

INDIVIDUAL MEMBERS

• Raymond Perry

• Enda Flannelly

• Joshua Pulo

• Cameron Bates

• Gopi Krishnan Bahuleyan

• Shannon Phillips

• Simon Ni

• Clay Svenson

• Matthew Douglas

• Chris Ross

• Wonseok Choi

Weld Australia is calling on the Federal and State Governments to take immediate and decisive action to protect Australian manufacturers, following the release of new research from The Australia Institute showing that east coast gas exports have caused wholesale gas prices to more than triple and electricity prices to double since 2015.

According to the Australia Institute’s report, average wholesale gas prices rose from $3.33 per gigajoule before exports began to $9.67 per gigajoule today—an increase of 190%. Electricity prices, closely tied to gas prices due to the National Electricity Market’s pricing mechanism, have surged by 73% over the same period.

The decision to allow unrestricted gas exports from the Australian east coast gas market has led to a tripling of domestic wholesale gas and electricity prices. It has left Australians exposed to not only higher world energy prices, but also the wild fluctuations that events like the Ukraine war cause.

Geoff Crittenden, CEO of Weld Australia, warned that Australian manufacturers are bearing the brunt of these price hikes. “Gas exports have exposed Australian manufacturers to international price volatility and cost blowouts that are decimating their competitiveness. Our industry is already under intense pressure from subsidised imports. Rising energy costs are a double blow many can’t survive,” said Crittenden.

“It beggars belief that, for over a decade, governments have allowed LNG producers to export surplus uncontracted gas while Australian manufacturers struggle to secure affordable supply. The system is broken, and it needs to be fixed now.”

The Australia Institute’s research highlights how these price increases are no accident. Gas companies were explicit in their intention to raise domestic prices to match export markets. In 2014, Santos even told investors its Gladstone export terminal was “as much about raising the domestic gas price as it was about exports.”

The price impacts are not limited to gas alone. As gaspowered generators often set the wholesale electricity price, manufacturers are being hit with inflated power bills due to the same export-driven dynamics.

2CC Radio Canberra: Live on-air interview with Geoff Crittenden on 6 August at 6.35am

FiveAA Radio Adelaide: Live on-air interview with Geoff Crittenden on 5 August at 9.15am

2ST Radio South Coast: Live on-air interview with Geoff Crittenden on 5 August at 10.15am

Australia Urged to Rein In Gas Exports as Supply Crunch Looms published by Bloomberg

Australia Urged to Rein In Gas Exports as Supply Crunch Looms, published by Financial Post

Manufacturers under pressure as gas prices soar, Weld Australia warns, published by Australian Manufacturing

Stop prioritising profits for foreign-owned gas giants over Australian jobs: Weld Australia, published by AuManufacturing

Australian manufacturers suffer from soaring energy costs, published by Petroleum Australia

Australia Urged to Rein In Gas Exports as Supply Crunch Looms, published by Energy Connects

Weld Australia calls for expansion of welding program, published by Manufacturers Monthly

Vocational training program seen as key to closing the gap, says Weld Australia, published by Australian Manufacturing

Weld Australian launches new reciprocal membership program, published by Manufacturers Monthly

Help shape the future of Australian industry, published by Manufacturers Monthly

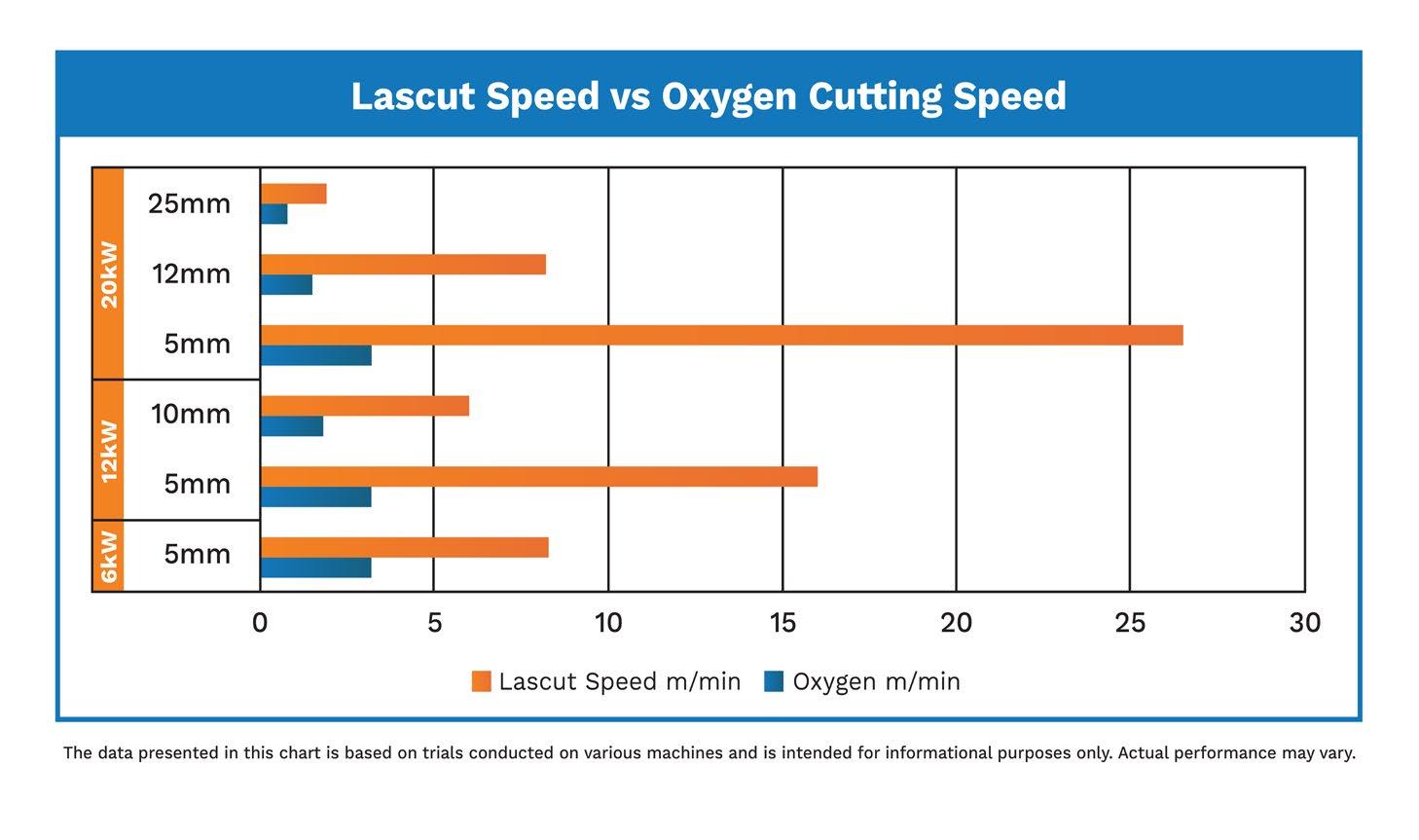

For over 50 years, Coregas has been at the forefront of supplying industrial, medical, and specialty gases to sectors such as welding, cutting, heating, and additive metal manufacturing in Australia. Our latest innovation, Lascut Speed, represents a leap forward for fibre laser cutting technology, particularly for carbon steel applications.

Lascut Speed is a ready-to-use gas mix designed to maximise both cutting speed and edge quality on carbon steel with a fibre laser. With a specially designed blend of gases, the resulting solution overcomes common limitations associated with traditional assist gases. While oxygen on its own can restrict production due to slower cut speeds, and pure nitrogen may compromise cut quality on carbon steel materials, Lascut Speed enables manufacturers to achieve rapid, clean cuts without sacrificing productivity or quality.

Modern high-powered fibre lasers are driving demand for faster parts per hour processing. Lascut Speed supports this by enabling carbon steel to typically be cut 250–500% faster than with oxygen assist gas. The gas blend maintains low dross levels similar to oxygen cutting, while substantially reducing edge oxide formation, delivering cuts that often require little or no post-processing. This directly benefits downstream operations, allowing immediate welding or painting after cutting.

Developed to unleash the potential of your cutting equipment. Lascut Speed works seamlessly with various fibre laser systems in its optimal machine power range of 6kW and above, and its pre-mixed packaging eliminates the need for additional equipment or complex setup. Smaller operations benefit from the convenient ready to use 12-pack container, while larger gas users can access tailored bulk onsite mixing solutions.

Notably, many original equipment manufacturers (OEMs) for fibre laser cutting machines now feature dedicated inlet ports and tech table settings for mixed-gas applications, further streamlining integration.

Customer feedback using Lascut Speed reported increased productivity and quality, with minimal post cut finishing requirements. Lascut Speed demonstrates Coregas’ role as a leader of innovation across Australia and New Zealand, supported by a robust distribution network. Lascut Speed is available nationwide.

To learn more or arrange a demonstration, visit www.coregas.com.au/contact, and follow Coregas on social media for ongoing updates.

Join the Weld Australia South Australia State Committee for a hands-on event that brings you face-to-face with the latest in welding technology

See live demonstrations of cutting-edge digital waveform processes and learn how these innovations can boost productivity, quality and efficiency in your workshop.

Find out how to harness Industry 4 0 capabilities, improve connectivity, and manage big data in real-world fabrication environments Whether you ' re a welder or workshop owner, this session will deliver practical insights to help you stay competitive and future-ready.

Welders and Workshop Supervisors keen to improve skills and stay up to date with the latest tools and techniques.

Fabrication Business Owners and Managers looking to boost productivity, quality, and competitiveness through new tech

Welding Engineers and Technical Specialists exploring advanced waveform processes and Industry 4 0 integration

Training, QA, and Safety Professionals focused on improving workforce capability, weld quality, and on-site safety.

Discover and engage with the latest technologies and products in the welding industry

Interact with top subject matter experts during high-energy, interactive sessions

Enjoy a fun and dynamic evening with hands-on opportunities to test new tools and techniques

Date: Thursday 4 September 2025 Time: 5:30pm to 8:00pm

Cost: FREE

Venue: W E S S

Address: 107 Cormack Road Wingfield, SA 5013

There will be beer, wine, soft drinks and a sausage sizzle after the event

Weld Australia’s Excellence Awards are one of the most prestigious events on the welding industry calendar. The 2025 Welding Excellence Awards are a fantastic opportunity for welders, fabricators and educators across Australia to showcase their people and their operations. Winners will be awarded in each state for each of the award categories below. Award entries close on 5 September 2025. If you’re not a Weld Australia member and would like to enter, simply contact David Choudry (Membership Manager, Weld Australia) on d.choudry@weldaustralia.com.au for further information.

The Company of the Year Award recognises superior performance across a comprehensive range of business metrics including: innovation, quality assurance, market success, corporate social responsibility, health and safety, sustainability, and training and development of employees. There are three sub-categories:

• Company of the Year – Fabrication Award Criteria | Enter Now

• Company of the Year – Supplier Award Criteria | Enter Now

• Indigenous Company of the Year Award Criteria | Enter Now

This Award recognises professionals who are making a valuable contribution to the Australian welding and fabrication industry. The individual should demonstrate a high level of skill, knowledge or craftsmanship, be dedicated to their profession, and have professional development plans in place. There are three sub-categories:

• Welding Professional of the Year – Welding Coordinator Award Criteria | Enter Now

• Welding Professional of the Year – Welding Supervisor Award Criteria | Enter Now

• Welding Professional of the Year – Welding Inspector Award Criteria | Enter Now

Entries must be submitted via the specific online form for each category by 5 September 2025. These forms can be found via the Weld Australia website, by clicking on the relevant red button.

Entry forms can be saved. However, before starting your entry, it is recommended that you download the Award Criteria (also available via the Weld Australia website). You will need the information outlined in the Award Criteria on hand to complete your online entry form.

Award Criteria | Enter Now

The Project of the Year Award recognises excellence in welding and fabrication projects, with a focus on exceptional craftsmanship, a commitment to Australian and International Standards, environmental sustainability and innovation. Projects must have been completed in the 12 months preceding 1 August 2024.

Award Criteria | Enter Now

The Health and Safety in Welding Award recognises organisations that are leading the way in encouraging and promoting health and safety throughout the Australian welding industry, and ensuring the health and safety of their own team. Organisations will be judged on criteria such as design and implementation of innovative programs or initiatives, the outcomes of these programs, and the health and safety of their team.

Trades Person of the Year

This Award recognises tradespeople who are making a valuable contribution to the welding and fabrication industry. The individual should demonstrate a high level of skill, knowledge or craftsmanship, be dedicated to their profession, and have professional development plans in place. There are three sub-categories:

• Young Trades Person of the Year Award Criteria | Enter Now

• Young Indigenous Trades Person of the Year Award Criteria | Enter Now

• Trades Person of the Year Award Criteria | Enter Now

Training and Education Award – Organisation Award Criteria | Enter Now

The Training and Education Award recognises the outstanding achievements of a STEM or VET provider or program. Entrants may include secondary education and tertiary education providers. Criteria include delivery of quality, innovative training programs, involvement with industry, recruitment and retention of students, and corporate social responsibility.

Training and Education Award – Individual Teacher Award Criteria | Enter Now

This Award recognises the outstanding achievements of a STEM or VET teacher. Entrants will be judged on criteria such as delivery of quality, innovative training programs, high level of knowledge or craftsmanship, strong links with students, and dedication.

VET in Schools Student of the Year Award Criteria | Enter Now

This Award recognises a student currently enrolled in a Vocational Education and Training (VET) in Schools welding or metal fabrication program who demonstrates outstanding promise in the field. The nominee should exhibit a high level of enthusiasm, a strong commitment to developing their technical skills, and a proactive attitude towards learning and growth in the welding and fabrication industry.

The awards will be presented at events held across the country from October to December:

• Queensland & NT: Thursday 9 October at Victoria Park, Herston Road, Herston

• NSW & ACT: Thursday 23 October at Strathfield Golf Club, 52 Weeroona Road, Strathfield

• Victoria & Tasmania: Wednesday 12 November at RACV Club, 501 Bourke Street, Melbourne

• Western Australia: Thursday 27 November at DoubleTree by Hilton Perth Waterfront, 1 Barrack Square, Perth

• South Australia: Thursday 4 December at Adelaide Pavillion, Veale Gardens, Corner South Terrace & Peacock Road, Adelaide

Ken Trevena Award – South Australia Only Award Criteria | Enter Now

This Award recognises someone who has demonstrated an outstanding welding expertise on a particular project, attained meritorious skill in a Weld Australia Course, made a contribution to the art and science of welding, or developed a welding principle, technique or process.

Mick Cudmore Award – Western Australia Only Award Criteria | Enter Now

This Award recognises someone who has demonstrated an outstanding welding expertise on a particular project, attained meritorious skill in a Weld Australia Course, made a contribution to the art and science of welding, or developed a welding principle, technique or process.

WITH THANKS TO OUR NATIONAL AWARDS SPONSORS

WITH THANKS TO OUR STATE AWARDS SPONSORS

Weld Australia is proud to announce its support for the transformative Buddy Up Program, developed by Future Shapers (Committee for Ballarat’s leadership program) and HM Prison Langi Kal Kal. The program is designed to break down barriers to education by improving literacy among people in prison through peer-led learning - and now, Weld Australia is calling on more organisations to get involved.

The Buddy Up Program was born out of an empathy mapping session conducted at HM Prison Langi Kal Kal, a minimum-security men’s prison in Victoria’s Grampians region. The session revealed that many people in prison can struggle with basic literacy skills. Offering a variety of educational programs in prison is critical to upskilling and leads to potential employment pathways and real job opportunities.

The empathy mapping session was part of the Future Shapers initiative facilitated by the Committee of Ballarat. Future Shapers draws together a cohort of emerging leaders from all sectors across Ballarat and the region, to think, question, build connections, broaden understanding of community leadership and effect positive change.

The Buddy Up Program pairs learners with peer coaches and uses the Toe-by-Toe structured literacy model to provide individualised support in a judgment-free, peerdriven environment. Ten people in prison successfully completed the pilot program in 2024, with more participants enrolled in 2025.

“This is about more than just learning to read. It’s about restoring dignity, confidence, and hope,” said Ben Mitchell, Director of Strategic Partnerships at Weld Australia.

Mitchell recently visited Langi Kal Kal to meet participants and witness the program in action. “It was incredibly moving to see first-hand the impact Buddy Up is having,” said Mitchell. “You can see the change in the way participants carry themselves. It’s giving them not just a new skill, but a belief in themselves and their future. By supporting Buddy Up, we’re helping to remove a fundamental barrier to rehabilitation. Literacy is a critical enabler of education, employment and reintegration.”

Weld Australia provided funding for the learning resources used in the program. Now, the organisation is seeking more partners to help expand Buddy Up and ensure its long-term success. Organisations interested in supporting inmate literacy and rehabilitation - whether through funding, promotion or collaboration - are encouraged to contact Ben Mitchell directly.

“Literacy is the foundation for education, employment and reintegration,” said Mitchell. “We’re calling on other organisations to get involved. With more support, we can expand Buddy Up to other facilities and give more people in prison the opportunity to turn their lives around.”

“Weld Australia has a long history of advocating for training, skills development and opportunityespecially in marginalised communities,” said Mitchell. “The prison system must be more than a place of punishment - it must also be a place of growth. Programs like Buddy Up prove that with the right support, change is possible.”

Participant feedback from the 2024 cohort has been overwhelmingly positive, with many expressing increased confidence and a renewed sense of purpose. One participant noted, “I feel so much more confident in reading and writing. This is not the end of my literacy journey, but has reinforced my pathway to literacy freedom.”

Weld Australia’s involvement in Buddy Up builds on its broader commitment to social impact. In 2022, the organisation partnered with Corrections Victoria and Federation University to support the Vocational and Educational Training (VET) Centre of Excellence at Langi Kal Kal. This program gives people in prison the opportunity to train to ISO 9606 international welding standards using augmented reality technology and practical workshop projects, linking participants with employers and support services post-release.

To learn more or get involved in the Buddy Up program, contact Ben Mitchell at Weld Australia via b.mitchell@weldaustralia.com.au

Weld Australia, with support from the Australian Cobotics Centre, BOC, and Diverseco, is launching a free microcredential: Fundamentals of Cobotic Welding. This program is proudly funded and supported by the Queensland Government.

This course will equip Australian fabricators with the skills to integrate automation and maintain global competitiveness in mining, structural fabrication, defence, rail, pressure, and pipeline industries. This microcredential is ideal for:

• TAFE apprentices and entry-level welders expanding their skill set

• Tradespeople and manufacturers exploring cobot welding

• Industry professionals and educators looking to upskill

What you’ll learn:

• Fundamentals of cobot welding and industry applications

• Preparing workplaces for cobot welding (safety, setup, skills)

• Business case for cobot adoption and long-term workforce impact

• If you’re an individual looking to upskill or an organisation keen to train your team, please register now.

If you would like any further information, please contact Dr Cornelis Van Niekerk, Manager of Advanced Manufacturing, Weld Australia on c.vanniekerk@weldaustralia.com.au

HAND-HELD LASER BEAM WELDING BEST PRACTICE GUIDE NOW AVAILABLE

Hand-held laser welding (HLBW) is an exciting and promising process that is relatively new for the welding and joining community.

This free guide, published by the International Institute of Welding (IIW), was borne out of necessity to ensure that this process is performed in a safe manner overall. In addition, several other considerations are presented which include education, qualification, and metallurgical considerations.

This document should be used as a guideline for using HLBW in a safe manner with a variety of weld joints and materials. Further information on laser safety is available in Weld Australia’s Technical Guidance Note TGN-SW02 Laser safety

If you would like any further information, please contact Bruce Cannon (Principal Welding Engineer, Weld Australia) on b.cannon@weldaustralia.com.au

Weld Australia’s NSW State Committee recently hosted an informative and hands-on event focused on Welding Fume Mitigation and Control. The session offered invaluable insights into protecting welders from hazardous fumes generated during the fabrication and manufacturing processes.

Bruce Cannon (Principal Welding Engineer, Weld Australia) led a presentation on welding fume mitigation and control. He discussed recent changes to the workplace exposure standards for welding fumes, which have now been reduced from an 8-hour timeweighted average (TWA) of 5 mg/m³ to 1 mg/m³. This key update is crucial for welders, employers, and safety professionals looking to ensure compliance and safeguard their workforce.

The event featured live demonstrations of cutting-edge equipment designed to enhance fume control. Attendees had the chance to interact with on-gun fume extraction systems, hooded capture extraction units, nextgeneration welding helmets with powered air-purifying respirators, portable fume extraction units, and low fume-generating welding gases.

Industry leaders showcased their latest innovations, with exhibitions and product demonstrations by top suppliers including: APEX Welding Safety (AWS), South Pacific Welding (SPW/BOC), Smenco, Kemppi, Welding Industries Australia (WIA), Lincoln Electric, Weldclass and Fantech.

Weld Australia was pleased to see such active engagement from both members and non-members alike, with many attendees leaving the event with new insights and ideas to enhance their welding operations. Thank you to all who attended, and a special thank you to the speakers and exhibitors who made this event such a success.

Weld Australia recently exhibited at the Queensland Innovation and Resources Expo in Mackay. The event is the premier platform for showcasing cutting-edge technologies, fostering industry collaboration, and driving sustainable advancements in the resources sector.

With the backing of principal sponsor Queensland Resources Council (QRC) and major sponsors Mackay Regional Council and Local Buying Foundation, the event brought together industry leaders, technology innovators, policymakers, investors and anyone interested to explore solutions that enhance efficiency, safety, and environmental responsibility.

Daniel Middleton (Senior Welding Technologist) and Lucas Bendo-Watson (Business Development Manager) were on-hand to showcase Weld Australia’s augmented reality welding simulator, sparking great conversations with local industry leaders, educators, and innovators about skills development, training, and workforce readiness in the region.

It’s always positive to see the enthusiasm and commitment to innovation and capability-building in Queensland’s resources sector.

WELDING FUME MITIGATION AND CONTROL EVENT IN VICTORIA

7 October 2025 | 5:30pm to 7:30pm Chisholm TAFE Dandenong

Join us for an informative evening focused on Fume Control and Minimising Exposure to Welding Fumes. The event will begin with a brief introduction and discussion on current best practices, followed by live demonstrations from leading equipment manufacturers showcasing the latest advancements in fume control technology.

This event is designed to educate attendees on new and emerging technologies that support welders and fabricators in effectively reducing welding fumes and minimising personal exposure.

Attendees will gain practical insights into how modern equipment can enhance workplace safety and ensure compliance with updated exposure regulations. This event is open to both members and non-members of Weld Australia.

South Australian manufacturers can now apply for matched funding of up to $50,000 to help adopt cutting-edge technologies through round two of the Manufacturing Technology Adoption Program (MTAP).

Announced by the Department of State Development, MTAP supports small and medium-sized manufacturers with upfront costs associated with integrating new technologies aimed at improving productivity and competitiveness.

Supported technologies include artificial intelligence, machine learning, data analytics, blockchain, augmented and virtual reality, additive manufacturing, the Industrial Internet of Things, and photonics.

Eligible projects should lead to the development of new or enhanced products, expansion into new markets, and improvements in productivity by allowing workers to focus on more creative and value-adding tasks.

MTAP is funded through the department’s Research and Innovation Fund and aligns with South Australia’s Advanced Manufacturing Strategy. Applications close on 29 September 2025 for South Australian manufacturers.

Australia’s manufacturing sector has taken a leap forward with the release of a new national workforce plan, aimed at driving innovation, sustainability and global competitiveness across the industry. Launched by the Manufacturing Industry Skills Alliance and formally unveiled by Minister for Skills and Training Andrew Giles, the 2025 Workforce Plan – Pathways to Transformation identifies five strategic priorities to modernise training, close skills gaps and attract future talent.

“In 2025, manufacturing will contribute more than $100 billion to the Australian economy and employ nearly one million workers across a diverse range of industries,” said Sharon Robertson, CEO of the Manufacturing Industry Skills Alliance.

“Australia’s manufacturing sector is evolving rapidly. This plan – along with the united efforts of government, industry, unions and training providers – ensures the workforce keeps pace with change and has the skills to drive future growth.”

The plan aligns with national goals including the Future Made in Australia agenda, the net zero emissions target and the push to strengthen sovereign capability across sectors like defence, clean energy and food production.

The South East Melbourne Manufacturers Alliance (SEMMA) recently launched their Australian Manufacturing BLUEPRINT

“This is a document designed to start a conversation with our policy makers about the legislative changes needed to ensure SME manufacturers receive the focus that as an industry, has underwritten Australia’s economy for decades. This document uses five pillars of growth to invigorate industry: Economic – Energy –Expand – Educate – Evolve,” said SEMMA CEO Honi Walker.

“SEMMA’s overarching policy objective is to enable economic growth in manufacturing from 5.9% (currently) to 10% GDP by 2030,” said Ms Walker.

Under each pillar, SEMMA has focused on areas that represent opportunities of growth in manufacturing policy across Australia.

“Our Economic pillar calls for a Set and Cap Tax Rate of 15% for SME Manufacturers. Reducing the business tax rate to 15% could save businesses $200k (on average) per year, potentially supporting a 3% annual wage increase,” said Walker.

SEMMA would also like to see No or Low Interest SME Business Loans. “Reducing business loan rates to below 2% could boost capital investment and drive GDP growth. Sweden has a GDP of $584,96B and a loan rate of 1.75%. Manufacturing accounted for 14.19% of GDP in 2023, according to the World Bank,” said Walker.

SEMMA says reducing the Golden Tax Exit to 10% from family businesses (with fewer than 100 staff and $25m turnover) on sales to encourage IP transfer and business consolidation, improving productivity, efficiency and our GDP. Introducing a Capital Allowance scheme instead of tax cuts would also encourage value-added work, productivity and automation. Selling machine time at reduced rates could increase equipment utility by 40%, meeting key industry needs in defence, rail and construction. This shift from asset focus to net and reinvestment focus would support wage growth.

The Energy pillar calls for a stable, sustainable and affordable energy supply with a Cap system for larger users. SEMMA’s Expand pillar encourages SME growth and innovation through R&D, 4.0 and Automation. Educate is SEMMA’s fourth policy pillar and ensures our workforce is skilled and trained in this business transformation.

SEMMA’s fifth policy pillar is Evolve. This policy ensures the regulatory framework is sized accordingly and does not inhibit growth – a one size fits all approach has not worked for SME’s who face different challenges from large manufacturers.

FEDERAL COVERNMENT APPROVES AUSTAL STRATEGIC SHIPBUILDING AGREEMENT

Austal Limited has secured a landmark agreement with the Australian Government to become the strategic shipbuilder for Tier 2 surface combatants at Henderson, Western Australia.

The Commonwealth has formally approved the Strategic Shipbuilding Agreement (SSA) with Austal’s newly created subsidiary, Austal Defence Shipbuilding Australia (Austal Defence Australia). The SSA finalises terms that appoint Austal Defence Australia as the prime contractor for key naval vessel programs, marking a significant step in Australia’s sovereign shipbuilding capability.

Austal CEO Paddy Gregg described the government approval as a “defining moment” for the company.

“It will establish Austal Defence Australia as the Commonwealth’s strategic shipbuilder for Tier 2 vessels in Western Australia and reflects both Austal’s excellent defence shipbuilding record and the capabilities that Austal possesses to help the Australian Government to achieve its defence objectives,” he said.

The SSA will govern the delivery of the Landing Craft Medium (LCM) and Landing Craft Heavy (LCH) programs, expected to produce 18 LCMs and 8 LCH vessels. Contracts for these pilot programs are in discussion, with formal announcements expected following finalisation.

“The Commonwealth seeks to ensure Australia’s defence procurement possesses sovereignty and greater certainty and resilience across the naval ship supply chain,” Gregg said. “Through the SSA, Austal is committed to helping the Commonwealth meet these objectives while establishing Austal Defence Australia as the shipbuilder of choice in WA.”

Secure up to $20,000 to support AS/NZS ISO 3834 + AS/NZS 5131 certification

Western Australian welding and fabrication businesses can now apply for funding through the Western Australia Government’s Local Capability Fund: Standards Compliance Round to help cover the costs of certification to AS/NZS ISO 3834 and AS/NZS 5131.

Delivered by Weld Australia, our combined certification service is eligible under the grant, giving you the opportunity to improve quality, meet compliance requirements, and strengthen your market position with funding support of up to 50% of eligible costs (to a maximum of $20,000).

But don’t wait. Applications close 3pm AWST on 4 September 2025 or when funding is fully allocated.

To apply for the Local Capability Fund, your business must:

• Be based in Western Australia

• Be an SME (under 200 employees)

• Have been operating in WA for at least 3 years

• Be registered for GST and have an ABN

• Supply goods or services to other businesses or government

• Be undertaking initial implementation and first-year certification audits (not surveillance or recertification)

For further information, visit the WA Government website.

Position your company as the premium choice for Australia’s most demanding projects. The combined IIW MCS ISO 3834 and AS/NZS 5131 certification isn’t just compliance. It’s your competitive weapon.

Our combined certification saves time, cuts costs, and enhances operational effectiveness, ensuring Australian fabricators meet stringent welding quality and structural steel requirements.

Cut costs while boosting quality. Companies with dual certification experience:

• Reduced welding defects and costly rework

• Fewer non-conformances that derail project timelines

• Enhanced personnel competency that delivers consistent results

• Superior risk management that protects your reputation

• Leverage the internationally trusted IIW MCS framework while maintaining complete relevance in Australian markets. This dual approach gives you unmatched credibility with both domestic clients and international partners—opening doors that singlestandard competitors simply cannot access.

Need to use ASME Section IX?

Learn how to minimise cost and maximise qualification usefulness.

BRISBANE OR LIVE

The ASME code is the American Society of Mechanical Engineers (ASME) standard that regulates the design, development and construction of boilers and pressure vessels ASME Section IX specifies the requirements for the qualification of welders and the welding procedure specifications This three day course will give participants a working knowledge of ASME Section IX, including how to comply with its requirements.

The course will be facilitated by Walter J. Sperko, P.E., President of Sperko Engineering Services, a consulting firm specialising in metal fabrication technology, including material selection, welding, heat treating, inspection, quality assurance and failure analysis. He has particular experience in piping and pressure vessel fabrication, installation, maintenance and repair.

Previously, he was Quality Control Manager for RECO North Carolina, and he provided technical support in welding, metallurgy and fabrication for the parent company, Richmond Engineering Company. He was also employed by ITT Grinnell Industrial Piping, where he was responsible for technical interface between piping system designers and the fabrication shop, including all aspects of welding, fabrication and Code interpretation He also worked for EBASCO Services in the Materials Engineering and Quality Compliance Department

7 TO 9 OCTOBER 2025

A review of the welding processes and variables, and basic steel welding metallurgy will be conducted to provide all participants with sufficient background in welding technology to interpret and understand Section IX The mechanics of using Section IX and how to address its requirements will be explained in a simple, straightforward manner Emphasis will be placed on writing welding procedures so that they contribute positively to the manufacturing process and on qualifying procedures in a cost-effective manner.

In-person:

Members: $3,610 inc GST

Non Members: $3,810 inc GST

Live webinar:

Members: $3410 inc GST

Non Members: $3610 inc GST

Date: 7 to 9 October 2025

Time: 8.30am registration on day one; 9am to 5pm

Venue: Amora Hotel, Brisbane

Venue: The Sebel Brisbane, 95 Charlotte Street

For further details, contact: Danielle Pennington on 0493 024 505 or d pennington@weldaustralia com au

Weld Australia now offers an innovative combined certification service for AS/NZS ISO 3834 and AS/NZS 5131. This new offering streamlines the certification process for fabricators and structural steel manufacturers, reducing time, cost, and administrative burden while ensuring compliance with both critical standards.

This service is only available to businesses already certified to AS/NZS ISO 3834, or those completing a dual certification. AS/NZS 5131 certification is provided as an additional component—not as a stand-alone certification.

By integrating the audits for AS/NZS ISO 3834 and AS/NZS 5131, Weld Australia eliminates redundant certification processes, providing a simplified, efficient, and cost-effective solution. Companies seeking AS/NZS ISO 3834 certification can now opt to include AS/NZS 5131 as part of a single, comprehensive audit, ensuring compliance with welding quality and structural steel requirements in one streamlined step.

Our combined certification offering removes unnecessary duplication, making compliance easier and more accessible for businesses of all sizes. By consolidating audits into a single, integrated process, companies will experience significant cost savings, as they no longer need to undergo separate assessments. Additionally, the time and effort saved by avoiding multiple audits will allow businesses to focus on operational efficiency and quality outcomes rather than administrative burdens.

Reduce costs, save time, and ensure your business meets industry standards with one simplified certification process. Simply email: engineering@weldaustralia.com.au

Achieving combined certification with Weld Australia delivers significant benefits for fabricators and purchasing organisations alike:

For JS Metal Engineering, achieving dual certification to AS/NZS ISO 3834 and AS/NZS 5131 wasn’t just about compliance. It was a strategic move to unlock new opportunities in Australia’s infrastructure pipeline.

As Majid Saleem (Quality Manager and Responsible Welding Coordinator at JS Metal Engineering) explained, the decision was driven by real-world project requirements. “We’ve been working on government contracts for the last three or four years,” said Saleem. “The Victorian Government now requires AS/NZS 5131 CC3 for new contracts. We needed that certification in place to proceed.”

With tight timelines and major projects waiting, JS Metal Engineering turned to Weld Australia, and never looked back.

“It was a very easy process for us. Weld Australia was very helpful. They gave us the right feedback at the right time to achieve certification quickly. It was a very smooth process.”

JS Metal had initially begun the AS/NZS 5131 only certification journey with another provider, but delays meant that the process had been dragging on for months. “We are still waiting on the other provider’s document review, even now,” said Saleem.

“I was already a member of Weld Australia, and when I received an email about the combined AS/NZS ISO 3834 and AS/NZS 5131 certification, I convinced the

owner of JS Metal Engineering, Xavier, that we should switch certification bodies.”

Despite having already invested in the previous provider, the decision paid off quickly. “Weld Australia was very efficient. It only took one extra week to complete both certifications together in the same audit. It was a great opportunity to get everything done at the same time.”

The impact was immediate. “One of our big jobs was on hold,” Saleem explained. “We couldn’t start without CC3. It’s now progressing as planned. Plus, since achieving certification, we’re quoting more and more jobs. We’re very busy now.”

The streamlined process and tangible benefits have made Saleem a strong advocate. “One of my friends is also looking for AS/NZS ISO 3834 and AS/ NZS 5131 certification. I’ve already recommended Weld Australia. It’s great for welding and fabrication companies. You don’t have to go through multiple audits, and it’s much more cost effective.”

For JS Metal Engineering, dual certification wasn’t just about meeting a requirement. It was about building credibility, reducing overheads, and securing the future of their fabrication business. With Weld Australia’s support, they’ve turned a challenge into a competitive edge.

Weld Australia continues to help welding businesses maintain the highest industry standards through rigorous certification audits. Recently, we have successfully completed several AS/NZS ISO 3834 surveillance audits, providing welding companies across Australia with the opportunity to verify their compliance with internationally recognised quality standards.

These audits play a crucial role in ensuring that companies meet the stringent requirements for welding quality management systems, contributing to enhanced safety, efficiency, and overall project success. Here’s a look at some of the most recent audits Weld Australia has carried out across the nation.

For nearly a century, Jayben Group has been a cornerstone of Australian manufacturing, transforming from a small machining business into a powerhouse of innovation. Specialising in powertrain products and bespoke industrial solutions, Jayben’s commitment to quality, cutting-edge technology, and a can-do attitude sets them apart. The audit reaffirmed Jayben Group’s commitment to maintaining top-notch welding standards, allowing them to continue delivering quality products to their clients with confidence.

Established in 1969, Hofmann Engineering has long been an industry leader in specialist engineering. With a dedicated research and development team, Hofman promises an innovative approach to meeting their

customers’ needs and continued improvement of their technology. Hofman services industries such as mining, defence, transport, manufacturing and agriculture on a global scale with facilities in Australia, Chile, Peru, North America, India and China.

Bendworx was founded in 2005 as a direct response to the lack of customer-focused steel processing providers in the market. That keen insight proved exactly right, and the company had to expand to a much larger facility in 2007 to cope with growing demand. Continued growth and success saw BendWorx merge with their direct competitor, Steelpro, in 2015, to become Bendworx-Steelpro. Today, Bendworx provides specialist brake pressing, plate rolling, section rolling and bending, steel processing, and pipe and steel casing services to Australian and international clients of all sizes.

First established in 1969, INGAL EPS is Australia’s leading manufacturer of quality light poles, columns, and structures. As part of Valmont Industries, INGAL EPS has access to a large network of trained specialists who can offer custom solutions for any structural pole design requirement. With staff and offices located in every state of Australia, the main INGAL EPS manufacturing plant is located in Brisbane. This facility is home to an expert in-house

Reduce costs, save time, and ensure your business meets industry standards. Simply email: certification@weldaustralia.com.au

design team that can provide engineering and drafting services, as well as bespoke concepts. INGAL EPS manufactures poles to suit every conceivable requirement for minor and major roads including poles for standard use, frangible poles in the form of impact absorbing and slip base, and an extensive range of decorative poles. Their floodlighting poles are installed at some of Australia’s most wellknown sporting grounds.

Certification audits like these are essential for businesses looking to ensure compliance with the AS/NZS ISO 3834 and AS/NZS 5131 standards. They offer welding companies a clear pathway to demonstrate their commitment to quality, safety, and continuous improvement. For companies like Jayben Group, Hofmann Engineering, Bendworx, and Ingal EPS, these audits provide assurance that their welding processes are of the highest standard, minimising risks and ensuring they meet the expectations of their clients and regulatory bodies.

For Weld Australia, these audits are an opportunity to help companies strengthen their operations and align with the global best practices in welding. As a recognised leader in welding certification and auditing, Weld Australia is committed to supporting Australian businesses in maintaining excellence across the welding industry.