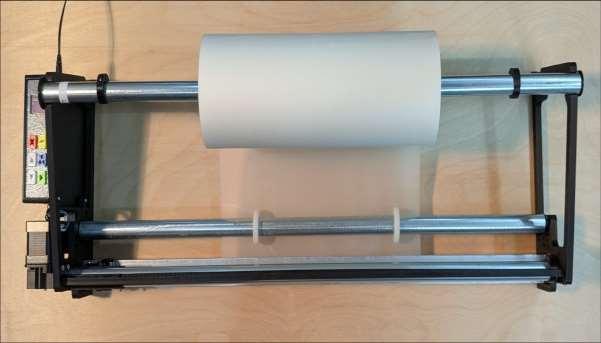

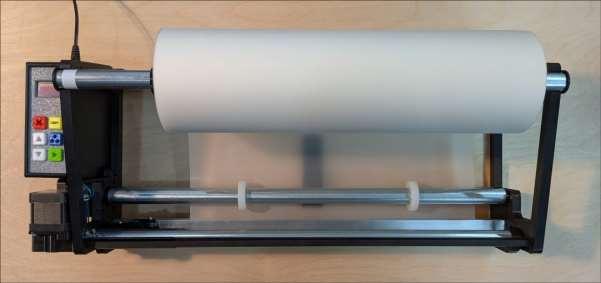

When it comes to manufacturing or processing materials, the precision and efficiency of the equipment you use are critical. One of the most vital machines in industries that work with flexible materials, such as film, is the film roll cutting machine. Whether you’re dealing with DFT film, medical-grade films, plastic films, or reflective materials for tinting applications, choosing the right cutting machine can significantly enhance your production quality and efficiency.

Film roll cutting machines are designed to convert large rolls of material into smaller, manageable sheets of specific sizes. These machines support various types of film rolls, including DFT films, PET, BOPP, PE, and PVC films. They ensure clean cuts and precise measurements for further processing or use in industries such as automotive, medical, window tinting, and packaging.

In this guide, we’ll explore the different types of film roll cutting machines, their features, and how to select the perfect one for your business.

1. Type of Film Roll to Be Processed

The first step in selecting the right film roll cutting machine is understanding the types of materials you’ll be working with. Different machines are suited for different materials, so it’s important to choose a machine that can handle the specific films required for your business.

For instance, if you work with DFT film, sublimation film, or medical and laboratory films, it’s crucial to choose a machine that provides a clean, smooth cut without damaging the material. Similarly, if you deal with reflective films for window tinting or solar applications, a specialized film roll cutter designed for such materials is essential.

2. Precision and Accuracy

A film roll cutting machine should provide high accuracy to ensure the desired sheet size. For industries requiring precise dimensions, CNC-controlled systems offer the highest level of precision. These systems can be programmed to handle various material thicknesses and lengths, which improves production efficiency and reduces waste.

If you want to improve production speeds and reduce manual labor, choosing a CNC film roll cutter is highly beneficial. These automated systems can handle high-volume cutting with minimal human intervention. The automation reduces the risk of human error and ensures uniformity in every cut. Additionally, the machine can easily switch between different materials and sizes, which makes it ideal for businesses with fluctuating demands.

Versatility is another important consideration when selecting a film roll cutting machine. A high-quality machine should be adaptable to various film types and be able to produce different sheet sizes. Whether you need to cut thin PET films or thicker BOPP films, the machine should provide consistent results.

For businesses that work with multiple types of films, a multi-functional film roll to sheet cutting machine is ideal. These machines allow you to adjust settings and switch materials without requiring significant downtime or adjustments.

If you specialize in window tinting or solar films, you will require a machine that is optimized for cutting these specialized materials. A window film cutter is designed to handle tinted films, solar films, and other reflective materials with precision. The cutting technology used ensures that the material remains undamaged during the cutting process and delivers a clean, accurate finish.

For industries that handle various types of films, from medical and laboratory films to more conventional materials like PET and PVC, choosing a versatile cutting machine is crucial. A machine that supports various film rolls provides flexibility and allows your business to handle a broad range of applications with ease.

Machines that support various film types reduce the need to purchase multiple specialized cutters, saving your business time and money in the long term.

Modern film roll cutting machines often integrate advanced technology to enhance performance. For example, CNC-controlled film cutters provide enhanced automation and precision, while sensors and software can optimize cutting patterns and reduce material wastage.

These advanced systems also enable users to program cutting parameters such as sheet size, material type, and cutting speed, ensuring optimal efficiency in production.

When selecting a film roll cutting machine, one of the primary decisions to make is whether to go for a manual, semi-automatic, or fully automatic system.

Manual Systems: These are the simplest type of film roll cutters, often used in small-scale operations. While they are less expensive, manual machines require more labor and can lead to inconsistent results.

Semi-Automatic Systems: These systems combine some automated functions with manual intervention. They offer improved efficiency over manual systems but still require some hands-on work.

Fully Automatic Systems: CNC-controlled systems are fully automated, which makes them the best choice for businesses looking to maximize productivity while minimizing human error. They allow for high-volume cutting and precise results, making them ideal for large-scale operations.

Another important consideration when selecting a film roll cutting machine is the machine's maintenance needs and durability. Look for machines built with high-quality materials that are designed to last for years. Regular maintenance is necessary to keep the machine running smoothly, but choosing a well-built machine will reduce the frequency and cost of repairs.

Look for machines that come with comprehensive warranties and after-sales support. This ensures that you have access to assistance if any issues arise during the machine's lifetime.

While cost is an important factor in purchasing a film roll cutting machine, it’s essential to focus on the long-term value the machine offers rather than just its initial price. A higher-quality machine may have a higher upfront cost, but its efficiency, durability, and versatility can result in significant savings over time.

What is the difference between a manual and CNC-controlled film roll cutting machine?

A manual film roll cutting machine requires human intervention for each cut, which can lead to inconsistent results. A CNC-controlled machine, on the other hand, automates the cutting process, offering high precision and reducing human error.

Can a film roll cutting machine handle various materials?

Yes, many modern film roll cutting machines are designed to handle different materials, including DFT film, PET, BOPP, PVC, and reflective films. It’s important to choose a machine that supports the specific materials you work with.

How do I know which film roll cutting machine is right for my business?

Consider the types of films you work with, the required sheet sizes, the volume of production, and whether you need automation. Machines that offer CNC control, adaptability, and precision will be ideal for high-volume or specialized industries.

What are the benefits of using a CNC film roll cutter?

A CNC film roll cutter offers increased precision, automation, and versatility. It reduces human error, increases efficiency, and ensures consistent results, making it ideal for businesses that require high-quality cuts.

How can I ensure my film roll cutting machine lasts longer?

To extend the life of your film roll cutting machine, ensure regular maintenance and cleaning, follow the manufacturer's guidelines for proper use, and invest in a durable, high-quality machine that can withstand frequent use.

In conclusion, selecting the right film roll cutting machine for your business is crucial for enhancing production efficiency and maintaining high-quality standards. By understanding your material requirements, machine features, and the level of automation you need, you can make an informed decision that will benefit your operations for years to come. Whether you’re cutting film for medical, industrial, or automotive applications, the right machine can significantly improve your business performance.

Connect With Us: 551-600-1400

Contact Email: staff@krexil.com

Public