How to Maintain Your CNC Backstop for Long-Term Performance

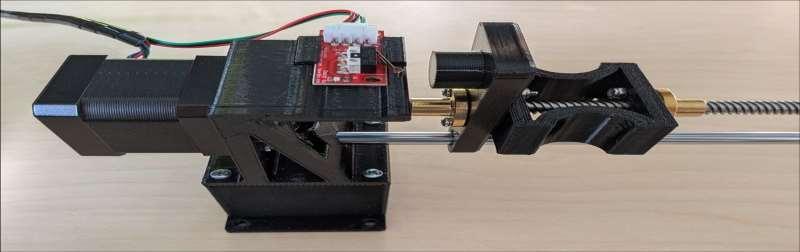

A CNC backstop is one of the most valuable positioning tools in workshops that depend on steady, repeatable cutting accuracy. Whether used with a chop saw, band saw, miter saw, or within a fully automated production setup, its purpose remains the same: ensure each cut lands at the exact measurement required. When the backstop is properly maintained, operators gain dependable performance that supports smooth workflow, safer operation, and improved material quality.

This component is widely used in manyapplications, from cutting EMT conduit and PVC pipe to trimming lumber, plastic rods, steel rods, aluminium tube, and materials used in plumbing tasks. Its versatility makes it an essential part of operations for cabinet makers, machine shops, production lines, lean manufacturing setups, and environments where quick changeovers are part of the daily routine. Achieving long-term reliability requires practical maintenance habits that support accuracy and prevent mechanical deterioration. Understanding those habits helps extend the system’s lifespan and ensures optimal operation for years

Table of Contents

Why Proper Maintenance Matters

A CNC backstop plays a crucial role in measurement precision. Even minor wear can lead to alignment drift, which compromises the consistency of cuts. When cutting materials such as steel rods or PVC pipe, small inconsistencies can lead to gaps, fitting issues, or poor material utilization. Over time, this adds unnecessary waste and lowers productivity.

Regular care prevents components from grinding, binding, or shifting out of position. It also helps counter the natural build-up of dust, shavings, and metal particles, which can reduce smooth motion and interferewith themechanisms thatkeepthebackstop movingfreely.Proper maintenance protects both the equipment and the overall workflow.

Cleaning to Protect Accuracy

A clean backstop is a reliable backstop. Every cutting task produces debris, whether it is sawdust from lumber, shavings from aluminium tube, or micro-particles generated while trimmingplasticrodsandconduit.Whentheseparticlesaccumulate,theyaffectsensors,sliding surfaces, mechanical stops, and alignment pins.

Routine cleaning prevents build-up from reaching a level where the internal components struggle to move. Wiping surfaces with a soft cloth helps maintain cleanliness without introducing abrasive scratches. Ensuring the guide rails remain free of contaminants is equally important because they affect the smoothness of the backstop’s travel. Cleanliness also helps maintain calibration and reduces the strain on supporting parts.

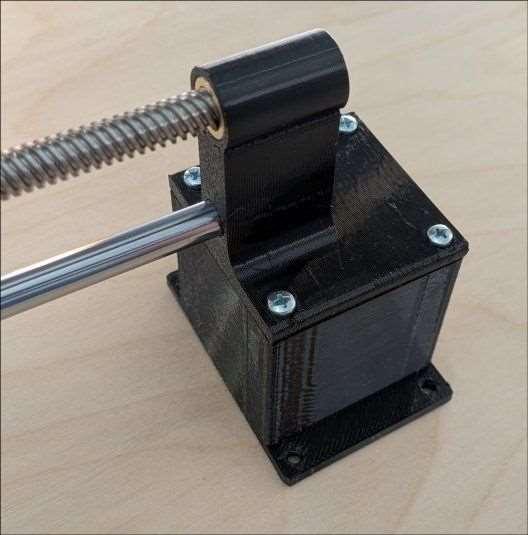

Lubricating Moving Components

Lubrication is essential for protecting motion systems from excessive wear. Smooth, gliding movement ensures the CNC backstop performs accurately, even when used repeatedly throughout the day. Friction, when ignored, begins to wear down surfaces and increases the chances of sticking, dragging, or stuttering movement. Proper lubrication helps avoid these issues by creating a thin barrier that allows mechanical components to operate freely.

It is important to use the manufacturer’s recommended lubricant to avoid compatibility problems that could cause residue build-up. Light, precision-grade lubricants often work best because they spread evenly and resist attracting excessive dust. After applying, any excess should be removed to prevent accumulation over time. This simple step helps the backstop remain responsive and consistent.

Inspecting Mechanical Parts

Just as important as cleaningand lubricationis acarefulvisual inspection.Overtime,mounting brackets, clamps, screws, and alignment features experience stress from daily use. Inspecting these components ensures the backstop remains stable and capable of maintaining its intended position.

Signs ofwear,such as loosescrewsorshallowscoringmarks along guidesurfaces, canindicate misalignment or mechanical stress. Identifying these issues early helps prevent more serious complications. If the operator notices resistance when moving the backstop or detects unusual vibration during operation, the system may require adjustment or tightening. Addressing these issues promptly helps preserve long-term reliability. A high-performance CNC backstop is not limited to one machine type. Cutting stations differ across industries, yet most share the same fundamental tools. This compatibility makes modernizing the workflow more practical and cost-effective.

Ensuring Alignment and Calibration

Alignment is the foundation of precision work. A misaligned backstop creates measurement inconsistencies and introduces errors into everycut. This can cause challenges in environments like cabinet making, where measurements must be exact, or in machine shops and production lines, where high-volume tasks require repeatable accuracy.

Calibration should be checked at regular intervals, especially when the backstop is used frequently. Ensuring that the stop point matches the digital readout or scale marking prevents cumulative errors. A properly aligned and calibrated backstop supports dependable cutting in lean manufacturing environments, where consistent output and reduced waste are essential.

Supporting the Surrounding Equipment

The performance of a CNC backstop depends heavily on the machine it is paired with. For example, when connected to a chop saw or miter saw, the accuracy of the saw’s table surface contributes directly to the stability of the backstop. Any vibration, worn bearings, or uneven surfaces affect how well the backstop can hold its position.

Keeping the saw or cutting machine in good operating condition contributes to the backstop’s stabilityandprecision.Thisincludesensuringthemachineissecuredtoaproperbase,checking saw blade condition, and confirming that the machine itself is level. When both systems work in harmony, cutting accuracy is maximized.

Extending the Life of Your Backstop Through Consistent Use Habits

Operator habits play a significant role in long-term performance. Placing materials gently against the stop, rather than slamming them forward, helps avoid stress on brackets and stops. Guiding materials smoothly along the surface prevents scratches and dents that could affect material orientation.

Understanding the limitations of the system is also crucial. Even though a CNC backstop is designed for repetitive cutting, overloading it with excessive force or weight can wear down mechanical parts much faster. Proper use ensures a longer lifespan and consistent cutting reliability over time.

When to Consider Professional Servicing

Despite careful maintenance, there may come a time when performance begins to decline. If the backstop struggles to hold alignment, drifts during use, or shows signs of weakened structural components, professional servicing may be necessary. Technicians can diagnose internal wear, recalibrate sensors, replace worn components, and restore the precision the system originally offered.

Scheduling periodic professional checks, depending on usage frequency, helps confirm that the system remains in optimal condition. Catching issues early reduces downtime and keeps production flowing efficiently.

Applications That Depend on Backstop Reliability

Backstops are vital in workplaces that cut a wide range of materials. Whether handling EMT conduit, PVC pipe, aluminium tube, lumber, steel rods, or plastic rods, the need for precise and repeatable cuts never changes. The ability to maintain consistent lengths supports better material usage, enhances overall quality, and improves workflow efficiency.

Industries such as cabinet making, machineshops, lean manufacturingenvironments, andhighvolume production lines all rely on dependable cutting setups. A properly maintained backstop reinforces the entire cutting process and contributes to smoother, more efficient operations. A CNC backstop integrates easily with chop saws, band saws, and miter saws, allowing teams to upgrade accuracy without replacing existing machinery.

FAQs

What materials can a CNC backstop help cut?

It supports accurate cutting for EMT conduit, PVC pipe, plastic rods, lumber, aluminium tube, steel rods, and materials used in plumbing or fabrication tasks.

How often should a CNC backstop be cleaned?

Cleaning should be part of a regular routine, especially when cutting materials that create dust or metal particles, as build-up affects smoothness and alignment.

Why is alignment important for long-term performance?

Alignment ensures repeatable accuracy, allowing each cut to match the required measurement. Without proper alignment, precision declines over time.

What are the signs my backstop needs maintenance?

Resistance during movement, unusual vibration, inconsistent measurements, or visible wear are indicators that maintenance is needed.

Can a CNC backstop work with different types of saws?

Yes, it can be used with chop saws, miter saws, band saws, and various equipment setups that depend on precise material positioning.