What is Industrial Marking?

It refers to the process of applying identifying labels, symbols, text, or codes to parts, components, or equipment to help with traceability, safety, and maintenance. These can be applied in various ways, such as engraving, printing, or etching, and they are designed to withstand harsh conditions such as heat, moisture, abrasion, and chemicals

From simple labels to complex identification systems, industrial marking products come in various forms to suit different needs, offering customizable solutions that meet the specific demands of each industry.

The most common types include:

Engraved nameplates

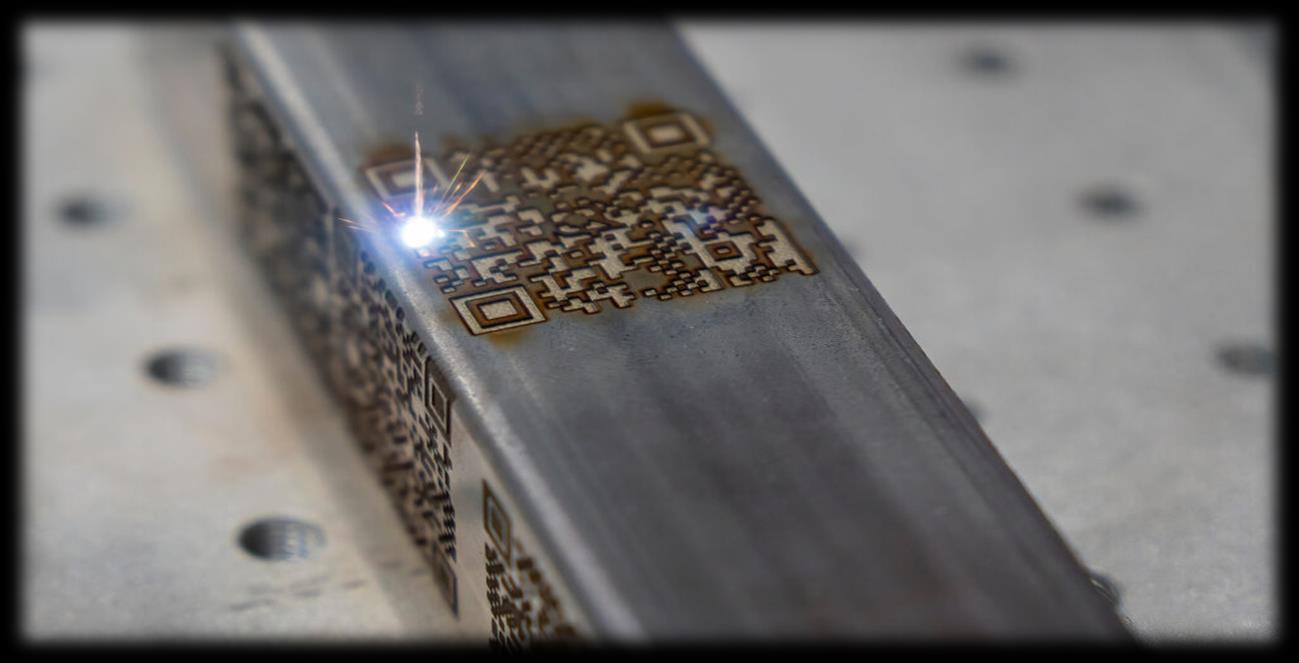

Barcodes and QR codes

Stamped metal markings

Chemical-resistant labels

Laser-etched markings

These techniques play a vital role in ensuring that parts and equipment are properly identified, tracked, and maintained

Part Marking Methods

There are several methods used in industrial environments, each offering distinct advantages depending on the material, and the required durability. These methods can range from simple to advanced, and all part markings play a vital role in industrial identification, ensuring effective identification and traceability.

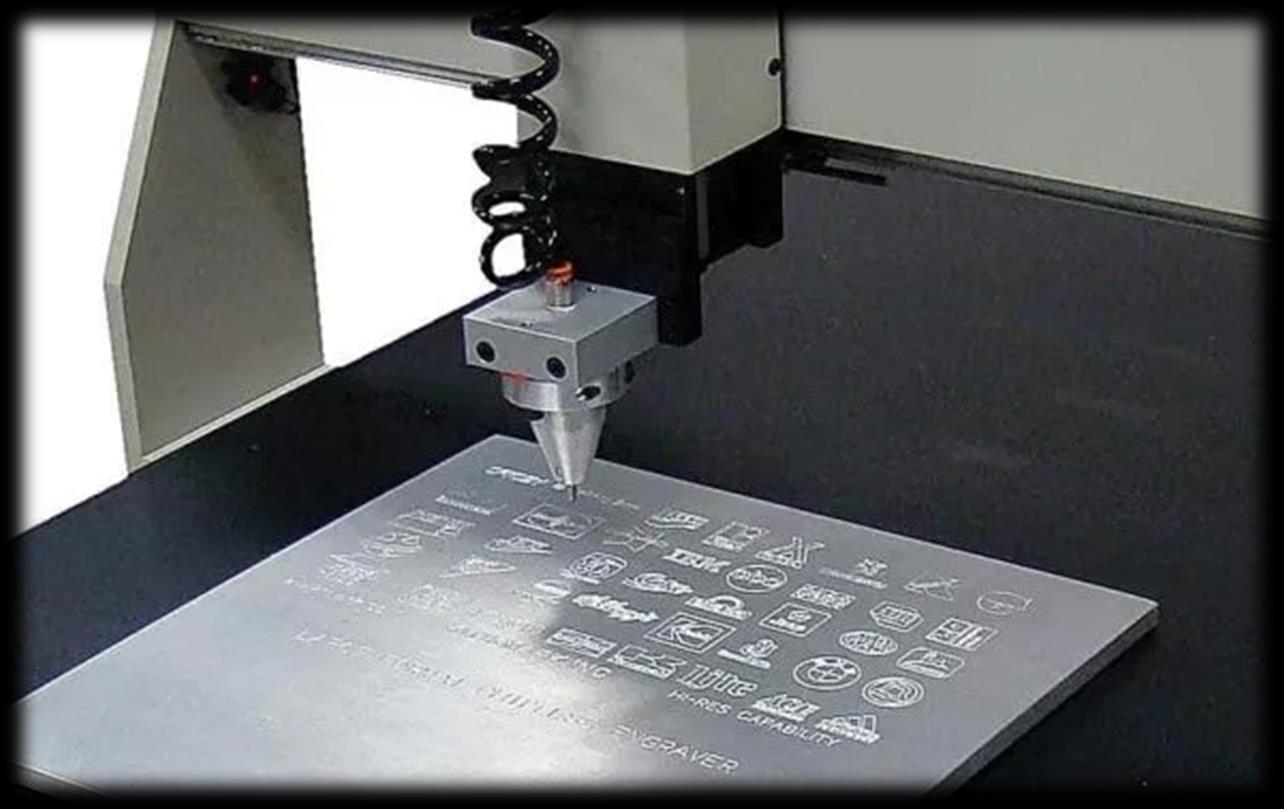

Laser Marking

It is one of the most advanced part marking methods, offering precision, speed, and versatility. A laser beam is used to create permanent markings on parts, such as text, logos, or serial numbers. This technique is widely used in industries such as aerospace, automotive, and electronics, where precision and permanence are critical.

Advantages of laser marking:

High precision and clarity

No need for ink or chemicals

Can mark a wide range of materials, including metals and plastics

Resistant to fading, abrasion, and corrosion

Stamping and Etching

Stamping and etching are traditional marking methods that involve physically applying marks to the surface of a part. Stamping involves pressing a die onto the material, while etching uses a chemical process to create markings. These methods are ideal for parts that need to withstand heavy wear and harsh environments.

Advantages of stamping and etching:

Provides deep, permanent marks

Can be used on a wide variety of materials, including metals

Cost-effective for large production runs

Types of Industrial Marking Products

Industrial marking products vary greatly depending on the needs of the industry. These products are designed to offer durability, visibility, and readability in environments where labels are exposed to wear and tear.

Engraved Nameplates

One of the reliable part marking options is engraved nameplates, providing long-lasting and clear identification. Constructed from materials such as stainless steel and aluminum, they offer

resistance to harsh conditions like heat, chemicals, and abrasion, making them ideal for industrial applications

Applications of engraved nameplates:

Equipment labeling

Machine identification

Safety signs

Control panels

Benefits of engraved nameplates:

Highly durable

Customizable in terms of design and text

Resistant to environmental factors

Barcodes and QR Codes

Barcodes and QR codes are increasingly used in industries that require real-time tracking and inventory management. These types of industrial marking products enable businesses to scan and identify parts quickly and efficiently. Barcodes and QR codes can be applied using labels, engraved markings, or directly on parts themselves

Advantages of using barcodes and QR codes:

Easy to scan for quick part identification

Ideal for inventory management and tracking

Can store a large amount of data in a small space

Industrial Labels

Industrial labels are versatile and can be used for a wide range of applications, including product identification, safety warnings, and compliance labels. They are made from materials that are resistant to heat, moisture, chemicals, and abrasion.

Benefits of industrial labels:

Can be printed with custom text, images, and barcodes

Ideal for use in harsh environments

Available in various sizes and materials

Choosing the Right Industrial Marking Product

Selecting the right industrial marking product depends on several factors, including the type of material, the environment in which the marking will be applied, and the required durability. Here are some key considerations when choosing an industrial marking solution:

Material Compatibility

Not all marking products are suitable for every material. For example, laser marking works well on metals, plastics, and ceramics, while stamped markings are ideal for hard metals. It's essential to select the appropriate marking method based on the material of the part or equipment.

Durability Requirements

In some industries, such as aerospace or oil and gas, parts may be exposed to extreme temperatures, chemicals, or physical wear. In these cases, it's important to choose a marking product that can withstand these harsh conditions.

Environmental Factors

Consider whether the marking will be exposed to UV light, moisture, or high temperatures. Products such as nameplates or laser etching are better suited for high-durability needs, while industrial labels are ideal for less demanding environments.

Industrial Marking and Safety

The industrial marking plays a crucial role in enhancing workplace safety. Whether it's labeling hazardous materials, identifying machinery, or providing instructions for operating equipment, proper part marking ensures that employees can quickly and accurately identify parts and equipment. This reduces the likelihood of accidents and enhances operational efficiency.

For example, products like safety labels and warning signs help ensure compliance with safety standards and regulations. These provide vital information about potential hazards, helping to protect workers from injury.

Final Thoughts

By utilizing the right industrial marking products, businesses can improve operational efficiency, ensure safety, and maintain accurate inventory records. Whether you are using engraved nameplates or advanced barcode systems, selecting the right marking solution is key to optimizing identification and traceability. For businesses looking for reliable and customizable marking solutions, Industrial Nameplates offers a range of high-quality products tailored to meet specific needs.

Frequently Asked Questions

What is part marking in industrial applications?

It involves applying identification marks, like serial numbers or barcodes, to parts for traceability and inventory management

How do I choose the right industrial marking product for my business?

Consider material compatibility, durability, and environmental factors. Choose between permanent options like engraving or flexible solutions like labels or barcodes.

Are engraved nameplates suitable for outdoor use?

Yes, they are durable and resistant to moisture, heat, and chemicals, making them ideal for outdoor applications.

What are the benefits of using barcodes for part marking?

Barcodes offer quick, efficient identification and tracking, making them perfect for inventory management

Can industrial labels withstand harsh environments?

Yes, industrial labels are designed to endure harsh conditions, including moisture, chemicals, and abrasion.

Contact: +1 403-930-5543

E-mail: sales@industrialnameplates.ca