Fluorescent Agates

Inside a Glacier:

Switzerland’s Ice Palace

LIZZADRO’S

Micro World

Lordsburg

Azurite & Malachite

Scrap Jewelry & It’s Worth

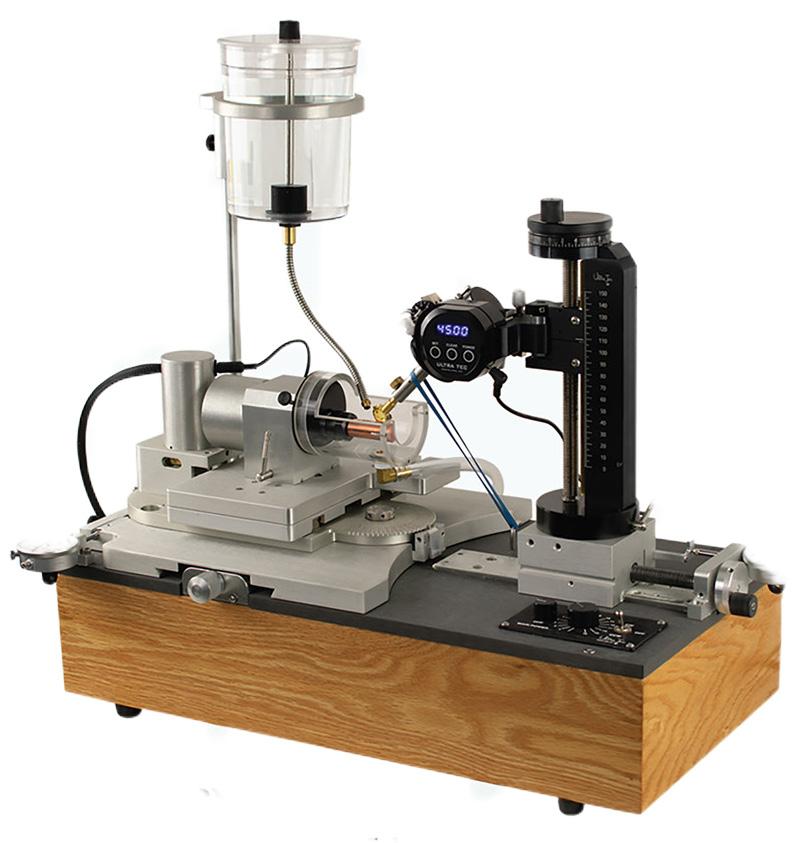

V5 Classic

Proven award-winning design

High speed positioning

Assured precision and repeatability

VL Classic

New design with classic features

Affordable

Sturdy and responsive

Shown with V5 Mast

Unlimited potential for the creative faceter

Produces concave and fantasy cuts

Machines That Shape the

Gemcutters’ World

BY AMY GRISAK

Alucky few find their life’s passion in a bucket of gravel. This was the case for Tom Mitchell, owner of Mitchell Jewelry Studio, who tried his hand at looking for gemstones as a way to enjoy the outdoors in his new home.

Moving from California to Florida, Tom and his wife were looking for ways to spend time outdoors, so they traveled to a rockhounding business in northern Georgia that provided material for screening.

Collection of stones from Tom Mitchell. Mitchell Jewelry Studio

Jenny Roseboom with the ULTRA TEC she won at the USFG Symposium.

Jenny Roseboom1

FROM PEBBLES TO BUSINESS

Sorting through the pebbles, he found rubies, sapphires and amethysts. He also found a new direction. After the success of his first bucket of gravel, he ordered another.

Tom says his wife told him, “You’re having too much fun.” She joined the activity and discovered an emerald the size of his thumb, which he had fashioned into a pair of earrings and a 15.1-carat pendant.

While the initial expenditure of gravel didn’t seem extravagant, Tom chuckles, “I neglected to mention to my wife how much it cost to have them facet these stones.”

Yet, when he calculated the cost of the rockhounding along with what it took to facet the gems, he realized it was a good investment. With the 28 stones he had appraised, 24 of them were worth twice as

much as what he paid to dig and facet them. An amethyst he found was worth five times its value, and the emerald pendant was worth over 2,700 times more than what it cost to dig the stone and have it faceted.

“That’s when I realized I need to learn to do this myself,” he says. “The thing that really fascinates me is taking a rock and turning it into a treasure.”

LAPIDARY FUNDAMENTALS

A month later, he attended the William Holland School of Lapidary Arts and Sciences, a seat of creativity and education for over 40 years, located in the lush mountain landscape of northern Georgia, where he learned the fundamentals of gem cutting.

“After that first week, I was absolutely hooked,” he says. Tom asked his instructor for a recommendation on the best machine to buy. Without missing a beat, his response: “The best machine is the ULTRA TEC.”

Immersing himself in the lapidary world, Tom proved to be a quick student. While taking a Faceting 2 course the following year at William Holland, he assisted the instructor who experienced communication limitations due to a medical condition. Already comfortable with explaining techniques and answering questions, he notes, “The following year, I was teaching up there.”

Putting focused effort into all he does, Tom decided to write his own book, “Faceting 1: Learn the Fine Art of Gem Faceting, It’s Easy!” to assist his students and anyone who is starting this enduring hobby. For the past six years, he has instructed over 600 students, providing them with the basic knowledge, tools and a healthy dose of encouragement that they need to continue the process.

HELENITE: A FIRST SPECIMEN

Tom keeps it simple to reduce the intimidation factor that many students experience when cutting their first specimens. “The first stone (they work on) is helenite. It’s a glass made from the ash of Mount St. Helen,” he says.

While all stones have interesting origins, helenite is a manmade stone that was acci-

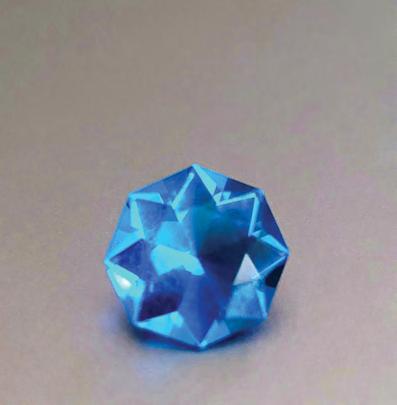

Right & Below: Dazzling finished examples of stones faceted by Tom Mitchell using ULTRA TEC machines. Mitchell Jewelry Studio

dentally discovered when timber workers at Weyerhaeuser Timber Company were using acetylene torches to salvage ash-covered equipment after the 1980 eruption. The heat from the torch on the ash turned some of the particles green, sparking an interest in the chemistry behind the phenomenon. Primarily composed of silicone dioxide, experts identified small amounts of copper and chromium, among over 30 other trace elements, in the green-colored helenite. They were then able to add other coloring agents to expand the options, including the pink and green watermelon specimens.

“About 85% of the ash creates a green stone, 14% a sky blue, and 1% makes a red, like a ruby,” Tom notes. He likes using it because of its beauty and consistency, particularly when it comes to teaching new students.

FINDING ENJOYMENT IN STUDENT GROWTH

“I enjoy teaching because it keeps me active and keeps me constantly thinking,” Tom says. “I’m able to identify what the problem is and how to fix it.”

Another aspect he appreciates is watching his students grow into their own careers, whether it’s as a lapidary, a jeweler in their own right, or a gem appraiser. The educational foundation he provides opens multiple doors in the gem world.

USING THE BEST EQUIPMENT

As for the equipment, Tom notes that one in five of his students will buy their own machine, and just as he was guided toward ULTRA TEC, he offers the same advice to his students.

“The thing about ULTRA TEC that I like so much is they listen to suggestions,” he says.

For example, Tom shares that years ago, he told Robert Mendoza, lead designer and technician at ULTRA TEC, that he had an issue that they might be able to make something to help with.

“When we’re cutting, we need to handle the stone,” he says. To remedy the situation,

Left & Below: Tom working a stone on the ULTRA TEC. Mitchell Jewelry Studio

Robert created a transfer fixture with a short handle to give cutters better control.

“I needed a transfer fixture that allows me to cut larger stones.” In response, ULTRA TEC utilized the Facetron transfer fixture, giving the gem cutter a higher degree of precision to accurately create the desired angles. Then, Tom says, “I needed a transfer fixture that allows me to cut larger stones.” In response, ULTRA TEC designed the Sliding Transfer Fixture.

“I enjoy every time I speak with them (at ULTRA TEC),” says Tom, and he appreciates their longevity. “They create a machine that is not intended to break down.”

ULTRA TEC’S DEEP ROOTS

Producing a machine that is the gold standard of faceting equipment, along with renowned durability, is why ULTRA TEC has been an integral part of the faceting community worldwide since 1965. Throughout these decades, interest in gem cutting has peaked and waned and peaked again. They continue to develop and improve their line, including the popular ULTRA TEC V5 Classic and VL Classic, along with the Fantasy machine for those looking to create intricate designs, and the Glass Tec machine geared to cut and polish this popular material.

Art, like faceting, has had a kind of renaissance, and it was always a crucial part of what we did. That’s why we’ve been here for 60 years and are stronger than ever,” explains Tim Hazeldine, ULTRA TEC vice president of sales and marketing. Their strength is firmly rooted in their history, as Howard Stanley, ULTRA TEC’s founder, who had an aerospace background and a keen interest in faceting, patented a design for his first faceting machine. Seven years later, aerospace engineer Joe Rubin acquired the company and developed products for high-tech industrial markets, as well as lapidary equipment, which is why they’ve always weathered economic changes and are on the cutting edge of technological improvements.

Another reason ULTRA TEC machines

Right & Below: Tom Mitchell cutting a stone on an ULTRA TEC. Mitchell Jewelry Studio

remain the preferred choice of the faceting community worldwide is that they maintain control over every aspect of their machines to meet the needs of their users.

Everything starts with one idea when a gem cutter says, “I wish I could have this,” says Robert. “Before we know it, we’re talking about the design. That gives us the ability to work with the design under our roof. The concept goes from virtual geometry to physical geometry in one place.”

“I’m very proud to say in the course of my 40 years (working for ULTRA TEC), I’ve been involved in many different areas to make it happen,” says Robert. He points out that they handle everything from designing the machine to engineering the projects, and then finally realizing the end product through the manufacturing process.

“Every component of the machine has to be treated with the right attention,” Robert notes. “We make sure the protocol is going according to the quality control standards we have here.”

Tim adds, “We’re a fully configured factory for designing, manufacturing, assembling, testing, and shipping. We are an integrated company accomplishing all of these tasks.”

ALWAYS IMPROVING

To expand their position of excellence, ULTRA TEC is always improving their manufacturing processes. A major historical change involved shifting from manually operated Bridgeport milling machines to a fleet of automated CNC milling machines, much better suited for a substantial increase in the volume of work and improved accuracy.

“Modern CNCs give us the ability to manufacture every single component with greater precision,” says Robert.

Robert and the ULTRA TEC team are deeply familiar with the needs of lapidary artists because they understand the gem cutting process and work closely with those who make it their life’s work.

Robert says that helping those who cut gems, whether as a hobby or a business,

achieve their goals has been a joy. He has witnessed many people who have barely touched a stone turn out to be exceptional artists. While he believes many new gem cutters think the process is very complex to learn, he holds that it is not.

“Obviously, you need an ULTRA TEC machine,” he chuckles, yet other than that, knowing how to read and understand the instructions, along with having a healthy dose of patience, is all that is required. “If you have those three things, everything else is in the details.”

Blue gem from Tom Mitchell. Mitchell Jewelry Studio

Tom Mitchell cutting a gem on the ULTRA TEC. Mitchell Jewelry Studio

THE PROCESS OF GEM CUTTING

Part of those details includes finding efficient means to bring life to the stones.

“There are three processes in gem cutting,” says Robert.

He points out that the grinding laps are used to remove the bulk of the material and give the stone its shape. “But there are still a lot of scratches,” he says. Faceters can use progressively finer grits, such as a 600 grade, then 1200, then 3000, to give life to the gem.

The next step is the pre-polish, where you still have scratches, but you use a polishing disk, such as the Darkside disk, a popular polymer-coated composite lap that is a champion at giving stones, including quartz, that sought-after polish. Because it’s so soft, use different abrasives, such as pastes or sprays of either diamond or an oxide polish, on top of the lap to provide friction.

“You have very tiny particles,” he says. While this smooths many of the scratches, the stone still doesn’t have the final dazzle. The final polish using a second Darkside, this time without aggressive abrasives, brings brilliant life into the stone.

LAPIDARY ARTIST IN PROGRESS: JENNY ROSEBOOM

One of the enthusiastic new gem cutters is Jenny Roseboom of North Carolina, who is a Spanish teacher by day, a wedding DJ on weekends, and now a quick-learning lapidary artist.

As a teacher with more time available in the summers, Jenny says, “I’ve been mining out in Franklin. I started accruing quite a little collection.” But her boyfriend pointed out, “They’re just rocks unless you do something with them.”

Jenny says she thought about it for a while, then decided to explore the possibilities. She felt she could learn the basics of cabbing from YouTube, but faceting looked more challenging, so she decided to expand her skills with the Faceting 1 class at William Holland.

It just so happens that Tom Mitchell was her teacher. When Jenny arrived at his class, she didn’t understand the technical language of lapidary or how to achieve the desired results, but when she left, she knew this was what she wanted to do.

“I just loved it,” she says. “Mr. Mitchell has the patience of a saint. (During the week), every time that door was open, I was there.” Taking advantage of every moment set her on a course she never expected, which also started with a bucket of gravel during her rockhounding adventures.

Jenny learned about a U.S. Faceters Guild (USFG) symposium in Franklin, NC, where Tom was teaching a two-day course. The only problem was that students were required to bring their own machine. Jenny had already calculated how many weddings she’d need to DJ to buy an ULTRA TEC machine, but it was a little while before she’d have enough. In the interim, Tom brought up one of his for her to use.

Jenny initially had no idea of the symposium’s extent but quickly took advantage of every moment of class time, also jotting down copious notes when attending the lineup of knowledgeable speakers throughout the weekend. She says that every time a person attended a workshop or listened

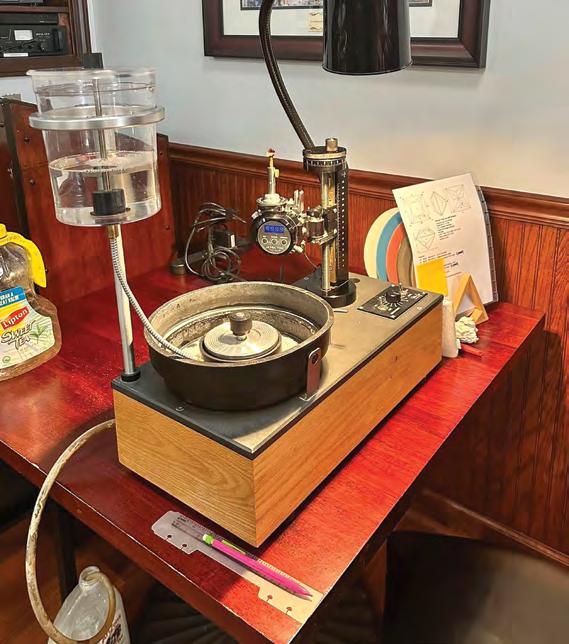

Jenny Roseboom’s ULTRA TEC at home.

Jenny Roseboom

to a speaker, they received a raffle ticket. She earned so many that she won a box of synthetic stones from Tom’s Box of Rocks, providing her with plenty of materials to increase her cutting experience.

During the event, she also learned there was a drawing for an ULTRA TEC V5, her dream machine. She bought 10 tickets, the maximum allowed, and hoped beyond hope for her chance to win it.

Jenny says it was a surreal moment as the numbers in her hand were called out one by one. “I still just sat there and waited for him to say it again. I thought I would be jumping up for joy, but I was terrified it wasn’t real.”

“I couldn’t think of anyone more deserving,” says Tom, who was sitting in the front row. “She was on the verge of tears. I was on the verge of tears! She’s a sweet lady.”

Jenny says. “It means so much to me. I feel so blessed. I wouldn’t have been here except for (Tom’s) patience and confidence in letting me borrow that machine. I want to do it justice.”

Jenny appreciates the fact that she can turn to Tom with any questions, as well as the members of the USFG, who she says are a wealth of information; everyone is also more than willing to share their experiences and offer advice.

In the meantime, she continues to practice her craft with her shiny new ULTRA TEC.

“So far, my most successful pieces come from quartz,” she says, although she faceted a couple of helenite stones.

LAPIDARY FOR THE LONG HAUL

As for long-term goals, Jenny intends to take additional classes at William Holland, including more advanced faceting courses, along with delving into metalwork to showcase her gemstones.

Plus, she has a long-term plan for this budding avocation because, as she closes in on her 20th year of teaching, retirement is on the horizon. She is putting in the time now, so the world of faceting gems and making jewelry awaits her when she steps out of the classroom.

Jenny also has her eyes set on the USFG

el. The guild decides on the design for each level. Each person in that skill level submits the same design cut and parameters.”

To prepare, she’s pulling designs from previous years to work on her technique. “Even if you don’t win, they still critique your work and give you feedback,” she says, which she considers a victory in and of itself.

Lapidary art means many things to different people. For some, it’s the ability to transform rock specimens into timeless pieces worthy of being passed down to future generations. For Jenny, who is embarking on her faceting journey, it’s a transition from discovering fascinating specimens to unlocking the entire world of gemstones and all the opportunities that lie within it.

For Tom, who immerses himself in creating beautiful pieces of jewelry as well as teaching others to do the same, he explains, “It’s a meditative thing. It keeps me focused on the here and now.”

Whatever the inspiration behind it, the process may have begun with shining gems found in a bucket of gravel. But by using any of the ULTRA TEC machines, these artists are able to transform a rough stone into a glimmering work of art.

selenite specimen in progress during faceting by Jenny Roseboom. Jenny Roseboom