DOCUMENT CONTROL

Version Date Author Description of Change

V2-12.25 1.12.2025 AE, EZ and Various SMT Contributions

Complete review and update of previous H&S policy documents

DEFINITIONS

Defined terms are capitalised throughout this policy for clarity.

ACOP: Approved Code of Practice.

AED: Automated External Defibrillator.

AI: Accidents and Incidents.

AIR: Accident and Incident Reporting.

Appointed Person: Will be a Competent Person(s) who can carry out the required duties, they do not need to be a first aid trained Team Member.

Apprentice: Not a Team Member, a person aged 16 or over contracted for a set period and may combine working with studying to gain skills and knowledge in a specific job.

AMP: Asbestos Management Plan.

AMS: Asbestos Management Survey.

Board of Directors: The collective term for the Board of Directors of such named company as outlined under a Business Unit.

Business Unit(s): Collective or individual term for Tingdene Residential Parks, Tingdene Holiday Parks, or Tingdene Marinas, Tingdene Boat Sales and Waterfront Living.

Business Unit Director(s): Collective or individual term to refer to the operational Directors for each Business Unit.

CCTV: Closed Circuit Television.

CDM: Construction, Design and Management.

Contractor(s): External companies who are contracted to provide agreed services to Tingdene Group.

Competent Person: An individual who has the skills, knowledge and experience that allows them to complete an assigned task.

COSHH: Control of Substances Hazardous to Health Regulations.

DB: Decibel.

DSE: Display Screen Equipment.

DSEAR: Dangerous Substances Explosive Atmosphere Regulations.

Designated Manager/Team Member: An individual who is authorised by a person specifically to act on their behalf.

EAV: Exposure Action Values.

EET: Electrical Equipment Testing (formerly PAT).

EICR: Electrical Installation Condition Report.

ELV: Exposure Limit Values.

FANA: First Aid Needs Assessment.

FFE: Fire Fighting Equipment.

FRA: Fire Risk Assessment.

GEF: Gas, Electricity and Fuel.

GMD: Tingdene Group Managing Director.

HAV: Hand-Arm Vibration.

H&S: Health & Safety.

Health & Safety Co-ordinator(s): Collective or individual term to refer to the responsible person regarding H&S for each Business Unit(s).

Group Health & Safety Manager: Individual term to refer to the responsible person regarding H&S for Tingdene Group.

HSE: The Health and Safety and Executive.

Health & Safety External Advisors: The Health and Safety Risk Management company employed by Tingdene Group.

Line Manager/Management/Supervisor/Designated Team Member: The person a Team Member will normally report to.

LOLER: Lifting Operations and Lifting Equipment Regulations.

Manager(s): Collective term used for those Team Members assigned a position with a level of responsibility for on-site Management and will have a reporting line to a Senior Manager or alternative.

MSDS or SDS: Material Safety Data Sheets.

MSLA: Minimum School Leaving Age.

Operative(s): The Team Member(s) who will carry out the specific work task/activity.

Park Executive: Collective term used for those Team Members assigned a position with a level of responsibility for on-site Management and will have a reporting line to a Manager.

PEEP: Personal Emergency Evacuation Plans.

PPE: Personal Protective Equipment.

PSP: Peak Sound Pressure.

PUWER: Provision and Use of Work Equipment Regulations.

PWEIL: Plant and Work Equipment Inventory List.

RAMS: Risk Assessments and Method Statements.

RIDDOR: Reporting of Injuries, Diseases and Dangerous Occurrences Regulations.

Sales Viewings: Collective term for visits by potential purchasers of homes, holiday homes, boats, moorings, etc.

Senior Manager(s): Collective term used for those Team Members assigned a Management position with a greater level of responsibility and will have a direct reporting line to an Associate Director or Director.

Site(s): Collective or individual term for any work locations and/or premises for Residential Parks, Holiday Parks, Marinas & Boat Sales, Waterfront Living and Tingdene Group Head Offices.

Site Manager(s): The Manager(s) or Park Executive(s) assigned the responsibility for the day-to-day operation of a specific Site.

SSOW: Safe Systems of Work.

Supervisor: A Team Member who has been assigned the responsibility to supervise a person(s) work activity.

Sub-Contractor(s): External companies contracted by Tingdene Group’s assigned Contractors.

Team(s): Collective term referring to a group(s) of Team Members assigned with a designated task(s).

Team Member(s): A term or collective term for an employee within Tingdene Group or an employee of a Business Unit.

Temporary Worker: A category of Worker who is engaged by the employer for a temporary period of time.

Third Party Operator(s): Collective term for Contractors, tenants, concessions, events companies etc.

Tingdene Group: For the purpose of this document, the reference Tingdene Group refers to and includes all business units and Sites under Tingdene ownership and operation including: Tingdene Parks Ltd, Tingdene Marinas Ltd, Tingdene Holiday Parks Ltd, Tingdene Boat Sales Ltd, Waterfront Living Ltd and any other subsidiary, connected or associated companies.

VAIR: Vehicle Accident Incident Report.

Visitor(s): Collective term to cover any non-Tingdene Group person on-site: such as owners, residents, holiday guests, berth holders, the public, delivery persons etc.

WBV: Whole-Body Vibration.

WEL: Workplace Exposure Limits.

Worker(s): Collective term for Team Members and individuals working under contract for Tingdene Group which may include Temporary Workers, Apprentices and Contractors.

APPENDICES

All appendices in this document, including those shown on this page, are interactive. Click any appendix link to access its content.

A1 Risk Assessment Register – Template

A2 Group Risk Assessment – Template

B1 First Aid Needs Assessment – Template

B2 Accident Incident Report Paper Form – Template (backup only)

B3 Accident Incident Response Guide

B4 Accident Incident Response Flow Guide

B5 Accident Incident Reporting Guide

B6 Accident Investigation Report

C1 Approved Contractor Application Form

C2 Approval Letter and Contractor Information

D1 Asbestos Warning Label

D2 Asbestos Emergency Plan – Flow Chart

D3 Asbestos Register – Template

E1 COSHH Assessment Register

E2 COSHH Assessment – Template

F1 DSE Workstation Assessment Form, Set Up & Exercise Guide

F2 DSE Assessors Guidance Notes

G1 DSEAR Risk Assessment (Generic RA)

H1 Night Worker Health Assessment Questionnaire

I1 LITE Assessment Poster

I2 Lifting Guide

J1 New & Expectant Mothers – Risk Assessment (Generic RA)

K1 HSE Talking Tool Kit-Work Related Stress

L1 Initial Legionella Risk Assessment Internal – Template

L2 Legionella Written Scheme of Control – Template

M1 Product Purchasing Policy Statement

M2 Plant & Work Equipment Inventory List – Template

N1 Health Surveillance Self-Assessment Questionnaire

N2 HSE – HAV – Exposure Points System and Ready Reckoner

O1 Hot Works Permit

O2 Permit to Dig – Excavate

O3 Confined Space Work Permit

O4 Working at Height Permit

O5 Electrical-Isolation Work Permit

O6 Permit to Dive

P1 SSOW-Working at Height (Ladders & Stepladders)

P2 Ladder Inspection Record – Template

INTRODUCTION

This Health and Safety Policy is published for the information of all Tingdene Group employees, Team Members, Contractors, Sub-Contractors or other interested persons or organisations in the pursuance of the duty imposed by the Health and Safety at Work Act 1974.

Tingdene Group is conscious of its legal and moral duties to provide and maintain a healthy and safe working environment and requires all employees to assist in the provision of such. Tingdene Group Directors are responsible for all matters involved in providing an effective Health and Safety system. This system will be maintained and updated as required and will be drawn to the attention of all employees.

Tingdene Group’s H&S Policy Statement will be available on all Sites.

THE LAW

Health and Safety at Work Act 1974.

There are two sections of the Health and Safety at Work Act 1974 relevant to this context:

Section 2 (1) “It shall be the duty of every employer to ensure, so far as is reasonably practicable, the health, safety, and welfare at work of all employees”. This is supported by specific reference to maintaining the workplace in a condition such that it is safe and does not put employees at risk.

Section 3 (1) “It shall be the duty of every employer to conduct undertakings in such a way so as to ensure, so far as reasonably practicable, that persons not in his employment who may be affected thereby, are not thereby exposed to risks to their health or safety”. This can be interpreted to mean any non-employees who visit any Sites such as Contractors, suppliers, Visitors, owners etc.

The Management of Health and Safety at Work Regulations in general terms puts the requirement on employers to:

• Assess the risk of Health and Safety of all employees and to anyone who may be affected as a result of work undertaken.

• Endeavour to provide comprehensive information, instruction, training, and supervision with the aim of ensuring, so far as is reasonably practicable, the Health and Safety at work of every employee or person so affected.

• Undertake risk assessments of all work-related activities.

Other policies within this document will refer to other specific regulations and any approved codes of practice.

HEALTH, SAFETY, WELFARE AND ENVIRONMENT POLICY STATEMENT

The following policy is produced in pursuance of Tingdene Group obligations under Section 2(3) of the Health and Safety (H&S) at Work Act 1974. Tingdene Group has commitment to this health, safety, welfare and environmental policy statement and the following objectives outlined, ensuring Tingdene Group has put in place an effective, practical, and achievable means to provide for the health, safety and welfare of Team Members and any other persons who may be affected by our undertakings and for the protection of the environment.

As Tingdene Group Managing Director (GMD), I will take all reasonable and practicable steps to ensure that the Health, Safety and Environmental considerations affecting Team Members, the public and any other persons who may be affected by its activities are controlled. To that end, Tingdene Group as far as reasonably practicable will:

1. Comply with all applicable legislation, codes of practice and industry standards.

2. Employ at all levels a competent and trained workforce through appropriate recruitment, selection, performance assessment, training and, when necessary, re-training.

3. Systematically identify hazards in the workplace and implement controls to minimise the risk to Team Members and the environment.

4. Provide an effective system of communication throughout Tingdene Group to minimise the risk to Team Members, Temporary Workers and Apprentices and encourage co-operation and participation for higher standards of H&S.

5. Maintain standards and procedures and work instructions sufficient to avoid injury to Team Members and others.

6. Provide properly engineered welfare facilities, plant and equipment and maintain them in a safe condition.

7. Ensure through a systematic approach, the integrity of all projects from conception to post commissioning. Selecting and utilising wherever possible materials, products, equipment, and processes with a reduced impact on the environment.

8. Only utilise approved Contractors who demonstrate a level of commitment to and comply with Health, Safety and Environmental standards commensurate with those of Tingdene Group.

9. Through investigation, follow up and undertake analysis of incident reports, strive to eliminate incidents with the potential to result in injury to Team Members and others, damage to plant and equipment, and harm to the environment.

10. Have in place audit and review systems to monitor the performance standards of Tingdene Group H&S Management system and provide for on-going improvements.

11. On an annual basis, unless a legal statute alters otherwise, review and amend Tingdene Group’s policy statement and bring such alterations to the attention of Team Members.

12. Consult with Team Members at the workplace on health, safety, welfare and environmental issues and relay requirements via safe methods of work procedures, in particular safe use, storage and transport of materials.

13. Provide reasonable resources, both monetary and physical, to meet the needs of H&S for both employees and others, e.g. the public.

14. When required use the services of an approved H&S provider for advice as required by Regulation 7 of the Management of H&S Regulations.

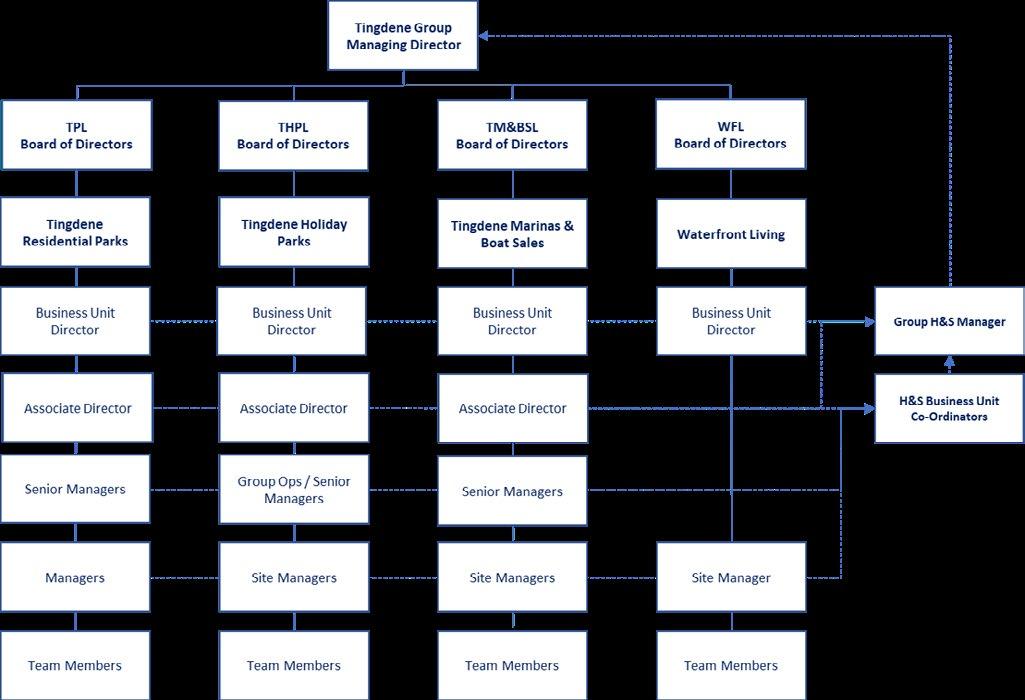

TINGDENE GROUP ORGANISATION

Tingdene Group comprises the operation of 5 business units supported by Head Office functions. Those operations include:

• Tingdene Parks Limited.

• Tingdene Holiday Parks Limited.

• Tingdene Marinas Limited.

• Tingdene Boat Sales Limited.

• Waterfront Living Limited.

Tingdene Group comprises additional entities not named above however it should be noted that their parent company is listed above.

Each entity has a Board of Directors responsible for the overall H&S governance and those Directors report to the Managing Director of Tingdene Group.

TINGDENE GROUP H&S REPORTING STRUCTURE

RESPONSIBILITIES

1. INTRODUCTION

Tingdene Group firmly believes that a good record in health, safety and environmental protection is not only an efficient Management system but also makes sound economic sense for our future well-being. In recognition of this, the following designated responsibilities have been introduced to ensure we attain and enjoy high standards of Health and Safety Management and awareness.

2. BOARD OF DIRECTORS

Tingdene Group Board of Directors have the main duty of care to ensure the health, safety, and welfare of all its employees. The Managing Director as head of the Tingdene Group will be responsible for ensuring that Tingdene Group policies are executed in such a manner as to ensure, as far as is reasonably practicable, the health, safety and welfare of all employees and others who may be affected by its operations. It should be noted under the regulations in addition to the employer’s responsibilities, all employees have a responsibility to look after the health, safety and welfare of themselves, their colleagues and of others they come into contact with while carrying out their workplace activities.

The following outlines some of the key responsibilities placed upon Tingdene Group employees in regard to Health and Safety:

3. GROUP MANAGING DIRECTOR (GMD)

• To ensure there is an up-to-date Tingdene Group policy for Health and Safety and that all employees, Temporary Workers, Apprentices and Contractors are made aware of their individual responsibility.

• Appoint Competent Persons to direct the day-to-day operations to ensure that Tingdene Group’s responsibility as an employer under the Health and Safety at Work Act 1974 and any relevant Acts of Parliament and Statutory Instruments are met.

• Ensure the Board of Directors and Senior Managers understand and fulfil their responsibilities with regard to H&S.

• Provide adequate funds and resources to meet the requirements of Tingdene Group’s policies and legislation.

• Make provisions for adequate and appropriate training to be given to all employees.

• Ensure systems for the notification and reporting procedures to the relevant statutory authorities are in place and carried out.

• Set a personal example on all Health and Safety matters.

4. BUSINESS UNIT BOARD OF DIRECTORS

• Ensure Tingdene Group H&S Policies are readily available to all Team Members on each Site.

• Bring to the attention of the GMD any amendment or new working practices and procedures relevant to the business undertaking.

• To update the Group H&S Manager of any pending changes, projects or planned works that may require a review of current H&S systems.

• Budget for adequate resources to be available, including financial, to implement and maintain H&S systems of work in line with current policies for the Business Unit under their control.

• Assign competent Senior Managers to oversee the day to day running of each Site, providing them with sufficient information, training, and resources to carry out their H&S responsibilities towards the Team Members they are responsible for.

• Ensure adequate communication lines are available for Senior Managers to discuss and review any H&S issues with their Site Managers or Team Members.

• Plan any projects and subsequent works in accordance with legislative requirements ensuring it is regularly reviewed to establish if appropriate improvements or additions should be made.

• Purchase or hire plant and equipment in line with the product purchasing policy statement (see appendix M1). Selecting and purchasing equipment that is not just best for the job but provides the lowest risk factors to the Team Member and where reasonably practical to the environment.

• Periodically review the Business Units work procedures, processes, policies to ensure they continue to meet Tingdene Group H&S policy standards. Informing the Group H&S Manager of any changes required.

• To be a champion for the H&S Management while on-site visits, by identifying and reporting any H&S issues, adhering to policies, when required wearing appropriate work wear such as Personal Protective Equipment (PPE) and promoting safe working practices as and when required.

• Where reasonably practicable act in a timely manner to address any H&S issues raised.

• In accordance with the employee handbook, provide a fair process for disciplinary whereby a Team Member has failed to discharge his or her individual H&S responsibilities satisfactorily.

• Ensure appropriate corrective action is taken to rectify any hazardous Site issues brought to their attention by the H&S Manager, Senior Managers, Site Manager, or external inspectorates.

• Ensure any audit, inspection or other H&S report actions are signed off within agreed time scales.

• Evaluate the competence level of a Contractor and/or Sub-Contractor who tender for work on projects and ensure there is a commitment on their part to implement and maintain all aspects of their own and others health, safety, and welfare.

• Ensure all Contractors and Sub-Contractors are informed of the relevant H&S policies and procedures that will affect them and any works they carry out on Tingdene Group Sites (refer to the Approved Contractors Policy for further details)

• Ensure that any incidents that occurs on any Site are investigated and remedial actions instigated. Where reportable, fully liaise with the Group H&S Manager or external safety advisor and assist the H&S Executive (HSE) if required.

• Work with Tingdene Group’s H&S Manager and/or Site Managers to identify trends, regarding accidents and incidents and any actions to be taken to rectify areas of concern within their Business Unit.

5. GROUP H&S MANAGER

Tingdene Group’s H&S Manager will be the central point of contact and support for all H&S matters. As far as reasonably practical the Group H&S Manager will:

• Ensure H&S policy is available, reviewed and updated regularly.

• Monitor and maintain a safety Management system.

• Be the main point of contact to provide advice on H&S matters.

• Advise Board of Directors and Senior Managers on H&S training requirements for Team Members, especially new starters ensuring a system of competency training is freely available for all Team Members.

• Monitor the Tingdene Group H&S status by regular inspections and auditing Sites and ensuring our compliance with current legislation, policy and standards.

• Report any H&S deficiencies and non-conforming issues to relevant Business Unit Directors and Senior Managers for review and resolution.

• When required to do so, investigate and report on any reportable accident and incidents as appropriate, recommend any means of preventing a recurrence of the incident.

• Follow up on any internal or external audit report action points to final resolution.

• Ensure each Business Unit is maintaining a system of documented risk assessment and control.

• Develop, maintain, and implement where required internal H&S training programs.

• Maintain their own H&S related qualifications up to date in relation to the role.

• Keep their own knowledge of relevant H&S legislation up to date and impart any new requirements to the GMD and relevant Business Unit Directors.

• Provide budget forecasts, assisting to provide efficient cost Management for Tingdene Group spend on H&S matters.

• When necessary, seek specialist advice from an approved H&S practitioner.

6. BUSINESS UNIT H&S COORDINATORS

Each Business Unit will appoint a H&S Co-ordinator(s) to assist with H&S matters regarding individual Business Units. The responsibility of a H&S Co-ordinator is to include:

• Promote and communicate effectively Tingdene Group’s H&S policies and any individual Business Unit operational procedures.

• Familiarise and keep themselves up to date with Tingdene Group’s H&S policies and procedures.

• Be a central point of contact and support for the Business Unit in matters of H&S.

• Refer any reported issues or concerns to a Business Unit Director, Senior Manager and/or the Group H&S Manager.

• Correlate and review all H&S reporting in line with Business Unit requirements including weekly, monthly, or annual H&S checks, inspections, etc.

• Correlate the monthly accident and incidents reporting statistics for Business Unit Directors and Senior Managers.

• Organise and when required participate in any H&S training.

• Liaise and support the Group H&S Manager on H&S matters, such as but not limited to audit follow ups, Tingdene Group projects and any H&S related issues raised.

• Bring to the attention of the Group H&S Manager any new or changes to processes within their Business Unit that may require H&S policy review and update.

• When required and undertaking interim Site inspections, following up on any actions raised to satisfactory conclusion.

7. SENIOR MANAGERS, MANAGERS AND PARK EXECUTIVES

Whether you have responsibility to manage Team Members or any other workers or not, all designated Senior Managers, Managers and Park Executives are required to familiarise and keep themselves up to date with Tingdene Group’s H&S policies and any specific safety procedures for the areas of the business under their control. They will:

• Be the responsible person for the day-to-day operations in regard to implementing and enforcing the H&S policy, and any additional safety procedures by making them available and providing instruction and training to all Team Members within their immediate responsibility.

• Ensure all new Team Members, Temporary Workers and Apprentices are given Site/department induction training highlighting Site hazards, emergency procedures, safe systems of work and any other relevant safety precautions necessary (refer to the induction checklist for further details).

• Ensure there is an ongoing program in place to ensure every Worker receives a level of competency training to carry out their duties ensuring work activities are carried out to the required standard, with the minimum of risk to Team Members or others.

• Carry out and document risk assessments on work processes, activities, areas, equipment, and any substances (including hazardous substances). Ensuring identified hazards are adequately controlled.

• Keep an up-to-date risk assessment register and review on a regular basis.

• Keep appropriate up to date H&S documents and records as outlined in the various H&S policies and procedures.

• Keep an archive of records for a minimum of 3 years or longer where stipulated in the Data Retention policy.

• Follow Tingdene Group’s product purchasing policy statement for purchasing or hiring of plant and work equipment (see appendix M1). Selecting and purchasing equipment that is not just best for the job but provides the lowest risk factors to Team Members and where reasonably practical to the environment. Ensuring any plant and equipment is maintained and fit for use. A plant and work equipment inventory is to be completed and kept up to date (refer to the Provision of Work Equipment policy)

• Bring to the attention of the Business Unit Director and/or the Group H&S Manager any H&S issues, new methods of work or potentially hazardous operations that may require a review of current safety systems.

• Ensure accidents and incidents are reported, reviewed, and investigated within the required time frame for the areas under their control. Providing and reviewing statistical trend data with a view to taking action to prevent re-occurrence.

• Ensure any actions raised from any reports are rectified and closed within an agreed time-scale. Such reports may include: H&S audits, inspections, internal compliance checks or incident investigations.

• With agreement and in line with budget controls, cost, arrange, purchase and issue to relevant Team Members appropriate PPE, as per the PPE Policy and any risk assessment.

• Monitoring the correct use of PPE, and maintaining up to date records of issue and replacement.

• Site Managers will act as the responsible person to ensure a safe Management system is in place that includes but not limited to:

– Fire safety.

– Accident incident reporting and investigation.

– The provision of welfare and first aid facilities, and these are sufficient and maintained.

Managers will ensure their Team Members are informed and aware of the provisions available.

• Where required ensure a program of health surveillance is available for applicable Team Members.

• Ensure only Contractors are contracted from the ‘approved Contractors process’ and their works are monitored while on-site to ensure they comply with the relevant H&S policies, safety procedures and their own risk assessment method statements. Taking the appropriate steps to rectify any non-compliance.

8. ALL TEAM MEMBERS

All Team Members share responsibility to look after their own H&S and to maintain the safety standards as set out in Tingdene Group’s H&S Policy. To do this, Team Members must:

• Familiarise themselves, as a minimum requirement, with elements of the H&S policies relevant to their job role and any additional Business Unit policies and procedures issued in paper form or made available to view via the online portal.

• Carry out all works in accordance with these requirements.

• Be responsible for their own H&S and that of others, observing applicable safety rules and follow any safe systems of work or instructions for the safe use of equipment.

• Attend and participate in any training program provided by Tingdene Group.

• Complete any mandatory or optional training assigned within the time-scales provided.

• Ensure any specific qualifications required for their job role are kept up to date.

• Make themselves aware and keep up to date with any emergency procedures and their responsibilities.

• Make themselves aware of the latest risk assessment requirements for the work activity or process they are assigned to. This may include the use of appropriate PPE as designated by any risk assessment or Control of Substances Hazardous to Health Regulations (COSHH) assessment.

• Ensure that only the correct tools, equipment, plant, and vehicles are used pertaining to each work activity, and these are checked prior to use and maintained in good condition.

• Report any H&S concerns immediately to their Line Manager, such as but not limited to any defects to vehicles, plant, tools, equipment, facilities or safety concerns with current processes.

• Report in the first instance, to their Line Manager or responsible person of all accidents and incidents including near miss incidents at work, however minor, ensuring a record is made by the current means available.

• Inform their Line Manager or the Human Resources Department in confidence as soon as possible of any changes to their health both physical and mental that may affect their capability to perform their job role, in order that Management may make reasonable adjustments to their working arrangements.

ARRANGEMENTS RISK ASSESSMENT

1. INTRODUCTION

Regulation 3 of the Management of Health and Safety at Work Regulations 1999 requires every employer to make a suitable and sufficient assessment of any significant risks to health and safety. Account must also be taken of the risks to the health and well-being of new and expectant mothers, to young people at work and to those with disabilities.

Failure to implement a policy on the assessment of H&S risks would render Tingdene Group vulnerable in terms of civil and criminal liability.

Risk assessments are to be undertaken by a Competent Person and must cover those foreseeable risks which apply not only to Tingdene Group Team Members but also anyone else who may be exposed to hazards or harm from Tingdene Group’s activities. This includes Visitors and Contractors working on any of Tingdene Group’s premises. The law does not expect organisations to eliminate all risk, but Tingdene Group is required to protect people as far as is “reasonably practicable” from foreseeable risk.

2. ARRANGEMENTS

A system of documented risk assessment will be utilised across the entirety of Tingdene Group to identify where reasonably practicable all potential, foreseeable significant hazards, and risk levels. Implement sufficient controls to eliminate or reduce any risk to its lowest level. The risk assessment will cover all foreseeable significant hazards of any Tingdene Group owned premises, work activities, work equipment, environment, processes and procedures.

• Completed risk assessments must be entered on the risk assessment register by the assessor and kept on file (see appendix A1).

• Each Team Member should be issued with the relevant risk assessments pertaining to their job role or work activity and confirmation received from a Line Manager that the contents have been reviewed and understood.

• Periodic reviews will be completed of each risk assessment on file by a Competent Person (refer to the ‘Review’ section below).

A generic risk assessment template (see appendix A2) will be used by all Tingdene Group Team Members to complete any local Site risk assessments.

3. THE ASSESSOR

Any designated Competent Person who carries out a risk assessment on behalf of Tingdene Group will be the assessor. Assessors will be trained to a level of competency to be able to carry out and document a risk assessment.

KEY DEFINITIONS:

• Risk Assessment: A systematic examination of what could cause harm (identify hazards) and whether sufficient measures (identify controls) have been put in place to mitigate these risks.

• Hazard: Anything with the potential to cause harm, e.g., a physical object, process, or procedure.

• Risk: The likelihood of the hazard causing harm and the severity of that harm.

• Control Measure: An item or action to remove a hazard or reduce the risk to an acceptable level.

4. PROCESS

Risk assessments will follow these recognised steps:

1. Identify the hazard.

2. Identify who might be harmed.

3. Identify the risks.

4. Identify current control measures.

5. Identify any additional control measures if required to further reduce risk to its lowest level.

6. Record findings and implement any actions.

7. Review assessment and update when required.

Any control measures to be implemented will be decided by considering the 5-step hierarchy of controls:

Tingdene Group wherever reasonably possible will endeavour to use Step 1 as the main control. Where this is not possible, one of, or a combination of Steps 2-4 will be implemented. Step 5 is considered the least effective and will only be used in combination with any of Steps 2-4.

5. REVIEW

Where a risk assessment does not exist, a new risk assessment should be completed for any new premises, work activity, use of equipment or process or change in process.

All risk assessments will be reviewed by a Competent Person in line with the designated review date or if there have been some significant changes to the Site, equipment, work processes, any concerns raised by a Team Member and/or after any relevant accident or incident.

Accident and incident statistics will be periodically reviewed as the findings may require risk assessments to be updated (please refer to the accident and incident reporting policy).

All risk assessments once reviewed will be updated when required to do so and signed off in the risk assessment register.

Reviewed and updated risk assessments will be issued and communicated to all relevant Team Members at least annually. Documented evidence must be kept on file to confirm the Team Member has acknowledged their understanding of the risk assessment. As an example, by digitally signing and dating the risk assessment register or by signing and dating each relevant risk assessment reviewed by the Team Member.

SPECIFIC RESPONSIBILITIES:

Business Unit Directors:

• Ensure to communicate any significant changes to the business activities or premises that will require risk assessment review.

Group H&S Manager:

• Shall provide support to Tingdene Group by providing generic risk assessments where possible.

• Will monitor adherence to Tingdene Group risk assessment policy via an audit process.

• Will ensure sufficient training resources are available for designated Team Members to carry out competent based risk assessment.

• Ensure the risk assessment policy is reviewed, updated when required, and communicated to Tingdene Group Team Members.

Senior Managers/Management:

• To ensure documented risk assessments are completed and on file for all potential foreseeable significant hazards for their Site.

• Ensure specific risk assessments are made for Team Members in a higher risk category such as but not limited to, new and expectant mothers, young person, vulnerable person and any pre-advised medical condition or disability.

• Ensure Team Members are competent to fulfil their roles by communicating and making available any risk assessments relevant to their work activity.

• Will review all risk assessments within the designated review date or if there have been significant changes to work processes or activity, or after any relevant accidents or incidents. Keeping the risk assessment register up to date.

Team Members:

• Responsible to ensure they make themselves aware of and abide by any risk assessment:

1. Prior to any work activity;

2. Relative to their work environment;

3. Prior to the use of specific equipment and plant.

• Will raise with their Line Manager any concerns with the controls put in place or lack of any risk assessment.

ARRANGEMENTS TRAINING & INFORMATION

1. INTRODUCTION

The Health & Safety at Work Act 1974 requires employers to provide information, instruction, training, and supervision as is necessary to ensure, so far as is reasonably practicable, the H&S at work of its Team Members, Temporary Workers or Apprentices. This is expanded by the Management of Health & Safety at Work Regulations 1999, which identify situations where H&S training is particularly important, e.g. when people start work, on exposure to new or increased risks and where existing skills may be in need of updating.

2. ARRANGEMENTS

Tingdene Group as far as reasonably practicable will ensure that all Team Members are adequately trained for the job role and/or work activity assigned to them.

• Every Team Member will receive all necessary training and information to ensure they have an adequate understanding of H&S at work.

• Any training provided by a previous employer will not be accepted as evidence of the Team Members competency until verified by the production of a valid training certificate. A competency assessment may be conducted with the Team Member for the work activity assigned, regardless of any previous training verification.

• Tingdene Group will provide adequate resources and budgetary means to ensure appropriate and required training can be provided for all Team Members.

• Training will be given by qualified, competent and/or experienced persons either by internal Team Members or external approved H&S training providers.

• Training requirements will be ongoing, reviewed and monitored to ensure Team Members are up to date with any required qualifications.

• All Team Members are required to co-operate and make themselves available for training, which is to be provided to them in the interests of H&S.

• All training will be recorded and kept on file as evidence of an individual competency to fulfil the roles and work activity assigned to them.

• Any relevant information on H&S will be discussed and made available to all Team Members, this will include the results of any risk assessment or health surveillance relevant to the individual Team Member.

• Where a Team Member makes a request for any H&S information regarding their work activity, then that information will be provided at the earliest possible time.

3. SCOPE

Any H&S at work training must meet the needs of the individual Team Member to ensure they have an adequate understanding of H&S at their place of work.

Tingdene Group training will include as a minimum:

3.1 INDUCTION TRAINING:

New Team Members (including work experience, agency temps, casual or seasonal labour etc.) will receive an initial induction within the first 24 hours of their start date (until such time they shall be supervised by a competent experienced Team Member).

Any induction will include all relevant H&S awareness information for the new starter, their work location and work activity, including but not limited to:

• The location and a brief explanation of Tingdene Group’s H&S Policy;

• A walk through of the Site, its buildings and facilities;

• Details of the Site’s safety procedure (including fire evacuation plans);

• The accident reporting procedure;

• Any specific personal protective equipment requirements;

• Any specific risks to H&S arising out of a work activity and the precautions to be taken, including the findings of risk assessments.

The new Team Member will sign for the induction training provided as acknowledgement they fully understand their responsibilities regarding H&S matters.

3.2 GENERAL H&S AWARENESS TRAINING:

In addition to any induction training, more in depth general H&S awareness will be given as initial, ongoing and/or refresher training to provide the Team Member with the current relevant H&S requirements for the business and their role. To include but not limited to:

• H&S legislation.

• Site emergency plans.

• Risk assessments.

• Requirements of the appropriate regulations.

• Details of the health hazards associated with the subject and their effects.

• An explanation of the risks.

• The precautions which must be taken.

• The correct use, storage and maintenance of machinery or personal protective equipment supplied.

3.3 WORK SPECIFIC (ACTIVITY OR EQUIPMENT):

Team Members will be given instruction on how to safely use specific work equipment and safety procedures for any work activity including location safety. Work specific training may include but is not limited to:

• Specific power tools use.

• Heavy plant & equipment use.

• Lifting and handling equipment.

• Work boats and other boat handling.

• Working at height.

• Noise and vibration at work.

• Manual handling.

• Work activity risk assessments.

• PPE requirements for specific work activity.

4. INFORMATION

Tingdene Group will ensure measures are in place for any H&S information to be freely available to its Team Members. Each Business Unit will ensure regular formal H&S meetings are held at Management level and documented. Management has the responsibility to ensure regular discussions are held with Team Member groups on relevant H&S matters pertaining to both Tingdene Group and their specific roles.

5. RECORDS

• A training plan will be kept by each Business Unit, identifying each Team Members H&S training history and their annual training needs.

• Each Team Member will have a personnel file that will include a record of attending H&S training, any courses and copies of any professional qualification, certificates and licences.

• Line Managers are to ensure any new training certificates or professional licences for their Team Members are uploaded to the personnel files via the HR Hub.

• Training records will be kept for a minimum of three years after the termination of employment or in line with Tingdene Group’s retention policy.

6. SPECIFIC RESPONSIBILITIES

6.1 BUSINESS UNIT DIRECTORS:

• Will ensure their Managers, Senior Managers and Health & Safety Co-ordinators are trained to a level of competency to oversee the operations assigned to them.

• Provide Managers with adequate resources, facilities, and funding to provide appropriate information and training for themselves and any Team Member they are responsible for.

6.2 GROUP HEALTH & SAFETY MANAGER:

• Will ensure a program of H&S training information is freely available to all Team Members via various outlets.

• Create and deliver relevant internal H&S training presentations as and when required.

• Assign, budget, monitor and review any approved external H&S training providers.

6.3 SENIOR MANAGERS & MANAGERS:

• Will ensure new Team Member, Temporary Workers and Apprentices receive training and information, in line with the latest 24 hour and E-learning Induction program.

• Will identify the training requirements in creating an annual training plan for themselves and the Team Members they are responsible for.

• Ensure all Team Members are trained to a level of competency for their job role, work activity or work equipment that has been assigned to them.

• Ensure any Team Member certifications and/or licences required for their specific role are up to date, ensuring refresher training is carried out before expiry or within one month of expiry of any regulatory certification and/or licence.

• Keep a historical record of any Team Members work related training.

• Managers will impart H&S information to Team Members and monitor competencies for carrying out the duties of their respective roles.

• Managers will not assign or will remove a Team Member from an assigned work activity should it be seen the Team Member is not suitably qualified or competent to carry out the task.

• Report on and rectify where possible any H&S issues or dangerous activity committed by workers, including Contractors on-site.

6.4 TEAM MEMBERS, TEMPORARY WORKERS AND APPRENTICES:

• All Team Members will ensure that they co-operate and make themselves available for all assigned H&S training provided.

• All Team Members are responsible to communicate to their Line Manager or Supervisor if they have not received sufficient training or do not feel competent to complete any work task assigned.

• All Team Members are responsible to notify immediately to their Line Manager or Supervisor about any changes to their regulatory licences/certificates that may prohibit them from being legally qualified to use company vehicles, plant and equipment. (E.g. expiry of driving or crane/hoist operator licences) (Please also refer to the employee handbook: Driving on Company Business Policy).

ARRANGEMENTS MONITORING & REVIEW

1. INTRODUCTION

Tingdene Group’s H&S Policy and any supporting documents are to be made available to all Team Members. Directors, Senior Managers and Site Managers are expected to review policies, ensuring that their Team Members have also reviewed the relevant policies pertaining to the individual’s role within their Business Unit. A controlled copy of this document will be held online on the TingTeam Portal for all to view.

2. MONITORING

Ongoing monitoring of Tingdene Group’s H&S Management systems will be undertaken and is the responsibility of the individuals listed in the table within the review section below.

It will take the form of but not limited to:

• Periodic reviews of policy and procedure;

• Auditing of individual operational Sites and facilities;

• Internal inspections of work activities, equipment, plant and locations;

• Periodic & statuary servicing of vehicles, plant and equipment;

• Periodic visual inspections of Contractor work activities;

• Periodic external H&S practitioners audits;

• Periodic Directors, Senior Managers and Site Managers H&S meetings;

• Team Member training;

• Discussions within the annual Team Member appraisal reviews.

3. REVIEW

A process of review will be ongoing for all areas of the H&S Management systems. All Tingdene Group Team Members have a responsibility to constantly review their work activities and processes to ensure they comply with Tingdene Group requirements. Where applicable, Team Members should raise any issues with their Line Managers.

A formal review process of the main H&S documents is listed but not limited to the following:

Process or Document Review

Tingdene Group H&S Policy

Tingdene Group Health, Safety & Welfare policy statement

Fire Risk Assessment (FRA)

Time frame

Annually or any significant business or legislative changes

Annually

Annually

Responsibility

GMD

Business Unit Directors

Group H&S Manager

GMD

Group H&S Manager

Senior Managers

Managers

H&S Co-ordinators

Process or Document Review

Risk & COSHH Assessments

Time-frame Responsibility

By the designated review date or any significant business or legislative changes or following any relevant accident/ incident. No later than two years

List of Approved Contractors, Concessions and Tenants. Annually

Senior Managers Managers

H&S Co-ordinators

Business Unit Directors

Senior Managers Managers

H&S Co-ordinators

Tingdene Group accident & incidents statistics

Group H&S Manager Business

Senior Managers Managers

H&S Co-ordinators

All controlled documents should be identified by title, version number and date (e.g. Tingdene Group H&S policy v1-03.21).

Any safety Management documents once reviewed may have to be updated to take account of the most recent legislation. Minor revisions that do not affect legal requirements or work practices will be communicated to those Team Members that are affected.

Major revisions, such as new legislation or regulation will be communicated to all relevant Tingdene Group Team Members by the most appropriate means available.

ACCIDENT-INCIDENT REPORTING AND FIRST AID PROVISION

1. INTRODUCTION

In addition to the Health & Safety at Work Act, Tingdene Group has a legal duty under the Health & Safety (First Aid) Regulation 1981 to provide adequate first aid provisions and record and investigate all work-related accidents, incidents, near misses, ill health, and incidents of zero tolerance (such as violent and discriminating behaviour).

Under the Reporting of Injuries, Diseases and Dangerous Occurrences Regulations (RIDDOR) 2013, Tingdene Group are required to report work-related fatalities, and record certain specified work-related injuries, occupational diseases and dangerous occurrences to the Health and Safety Executive (HSE.gov.uk).

2. POLICY SCOPE

For this policy, the term work-related refers only to:

• Any accidents or incidents that may occur to a Team Member while at work on behalf of the Tingdene Group (including Temporary Workers, Apprentices or Contractors); and

• Any non-workers (such as Visitors, members of the public) who sustain any injuries due to accidents that occur involving work equipment and/or work processes at a Tingdene Group location (this may include a Site, development, facilities or premises owned by the Tingdene Group).

The term reporting of accidents and incidents, covers all accidents causing injuries or property damage, incidents such as near misses, dangerous occurrences, occupational diseases, acts of violence and incidents involving discriminating or threatening behaviour.

3. RESPONSIBILITIES

Each Tingdene Group Site will designate a Competent Person(s) to act as the ‘Appointed Person(s)’ with regards to being the central point of contact for accidents or incidents and first aid requirements. The ‘Appointed Person(s)’ will be a Competent Person(s) who can carry out the required duties, they do not need to be a first aid trained Team Member.

The ‘Appointed Person(s)’ will be responsible for:

• Completing an initial First Aid Needs Assessment (FANA) (see appendix B1) for a Site to establish what level of first aid cover is required, based on work activities, and associated risks and will then make adequate arrangements.

• The assessment should be reviewed when there are any significant changes. Otherwise, the assessment should be reviewed, at least every 3 years.

• Cost and make arrangements (with Senior Manager sign off) for resources to be available to ensure that first aid measures and equipment are always provided while people are at work.

• Ensure the latest procedures are available, implemented and adhered to.

• Ensure that an accident & incident report is raised and completed correctly for all reported accidents and incidents that occur for their Site within 72 hours once notified.

• Any RIDDOR reportable accidents or occurrences are referred directly to the appropriate Senior Manager and Group H&S Manager for them to review, to enable reporting to the correct authorities within the designated time scales (see RIDDOR reporting section).

• The Appointed Person for the Site or a Designated Team Member will be responsible for maintaining the central accident and incident report filing system. The Appointed Person should ensure GDPR is adhered to regarding limiting the access to personal data to those authorised on a need-to-know basis. In some cases, this may be centrally controlled at the Business Units’ operations level by a Designated Team Member.

• The Appointed Person(s) or a designated first aider will be responsible for ensuring that first aid equipment is inspected at least once per month and re-stocked when used. A record should be kept of checks made.

Where a Site has only one Team Member (such as TPL Sites), that Team Member will be responsible for the Site(s) first aid requirements and ensuring any accident or incident is reported to their Line Manager.

Any lone working Team Member will in the first instance verbally inform an accident or incident to the ‘Appointed Person’ or if different, their Line Manager as soon as possible. Secondly at an appropriate short time after the event (within 72 hours) ensure they communicate full factual details of the incident to the Designated Team Member if not themselves for a written report to be submitted via Tingdene Group’s accident and incident reporting system.

All Team Members must familiarise themselves and comply with the current Site procedures for first aid provision and the reporting of accidents and incidents.

4. FIRST AIDERS

Based on the result of the FANA, each Site will appoint sufficient trained first aiders, the identity and normal location of which must be made known to all Team Members by appropriate means (such as on the Team notice board).

Certified first aid training and any refresher training will be provided by an approved first aid training provider, subject to the requirements of the risks involved.

Team Members who volunteer to be selected for first aid training must be approved by Senior Management, considering their suitability for the role and availability during operational hours.

5. FIRST AID EQUIPMENT

First aid equipment will be provided appropriate to the hazards identified by the first aid needs assessment. The equipment must be in a prominent position, visible or signed, with easy access and be kept clean and fully stocked.

First aiders or Appointed Persons will be responsible to ensure first aid equipment is checked at least each month, that it is fully stocked and replenished when used and always available.

All first aid equipment provided will conform to HSE Guidelines, any equipment not specified will not be used. Medication will not be stored with the first aid equipment or administered.

Where an Automated External Defibrillator (AED) is located on a Site, and is the responsibility of Tingdene Group, these should be checked regularly to ensure it is available and fit for use.

6. ACCIDENT AND INCIDENT REPORTING (AIR)

All Team Members must report all work-related accidents and incidents regardless of the severity. In the first instance verbally reporting the event immediately to the ‘Appointed Person(s)’ and/or if different their Line Manager.

If available, the ‘Appointed Person’, First Aider or a Designated Manager will be responsible for recording the event via Tingdene Group’s online reporting systems. The initial report should be submitted within 72 hours of being notified of the accident or incident.

If online reporting is not immediately available, the approved Tingdene Group accident, incident or zero tolerance report form (see appendix B2) should be used and then updated on the online system when available. Remembering to verbally inform the relevant Management of the event first.

The purpose of the AIR will be to ensure that all accidents and incidents are recorded and investigated correctly. Once completed, reports will be held in the Site or Business Units central file for a minimum of three years or if the accident or incident is COSHH related, indefinitely.

Any accident and incident report must be filed so they are easily identifiable starting with the forms reference number.

Copies of all information associated with the report, such as witness statements or photographs, video etc., must be filed with the report, each document being identifiable with the original accidents and incidents reference number.

Only designated Team Members will be able to view the full detailed report in the Sites or Business Units central accidents and incidents file.

The Group H&S Manager will need to receive an email notification of all work-related fatalities and any RIDDOR reportable accidents or occurrences.

Where the backup paper form has been completed it is the responsibility of the person completing the report to ensure the relevant Director(s) and Senior Management have been informed immediately.

The GMD, applicable Operations Directors and Group H&S Manager must verbally be informed immediately of all fatalities (work-related or not). The GMD will be responsible to inform the remaining Board of Directors.

Tingdene Group insurers will be informed of all relevant accidents and incidents that require their investigation.

7. GDPR

It is a legal requirement to gather personal data of individuals involved in any accident or incident and thus the gathering and holding of such data does not come under GDPR. However, it is the responsibility of those holding such personal data to limit the access on a need-to-know basis and hold in a central restricted file.

Where a paper accident and incident report has been raised and subsequently transferred to an electronic copy on file (scanned or re submitted via the online reporting system), the original must be destroyed.

Any request for copies to be distributed of an accident and incident report detailing personal data must be vetted and authorised by Senior Management for release to ensure there will be no breach of GDPR.

It is a legal requirement to keep accident and incident reports for a minimum of 3 years (if COSHH related indefinitely). Any accident and incident reports with personal data kept after this period the reports must be anonymised (personal data has been removed). Accident and incident reports may be kept longer than 3 years for statistical and insurance purposes.

8. REVIEW

Managers will review each accident and incident report for their Sites with a view to ensuring there are sufficient preventative measures in place to prevent re-occurrence.

Analysis of all accident and incident reporting must be undertaken each month by each Site to be reviewed by Management and Directors. Any trends should be addressed

9. ACCIDENT & INCIDENT RESPONSE

If requested to attend the scene of an accident or incident the attending ‘Appointed Person(s)’ or first person on the scene will need to approach the scene in a controlled structured manner. Please refer to appendix B3 Accident Incident Response Guide

10. REPORTING AN ACCIDENT OR INCIDENT (ONLINE OR FORM REPORTING)

Refer to the quick flow chart and guide for reporting of accidents and incidents for procedure details (see appendices B4 & B5).

11. RIDDOR REPORTING

In accordance with RIDDOR, each Business Unit in conjunction with the Group H&S Manager will file a report to the H&S Executive via its online system as soon as possible within 10 days of the work related accident or incident. This is varied to within 15 days should a Team Member’s work-related injury keep them away from work or normal duties for more than seven consecutive days (not counting the day of the accident). The HSE 24 hour online reporting system is as follows: www.HSE.gov.uk/RIDDOR/report.htm

All RIDDOR related incidents can be reported online, but a telephone service is also provided for reporting fatal/specified incidents only - call the Incident Contact Centre on 0345 300 9923 (Monday-Friday 8.30 am to 5 pm).

11.1 HSE REPORTING OUT OF NORMAL WORKING HOURS:

The types of circumstances where HSE may need to respond out of hours are:

• Following a work-related death,

• Following a serious incident where there have been multiple casualties,

• Following an incident which has caused major disruption such as evacuation of people, closure of roads, large numbers of people going to hospital etc.

If your incident fits these descriptions ring the duty officer on 0151 922 9235 RIDDOR reportable types as outlined by the regulations:

11.2 DEATH/FATALITIES (includes acts of physical violence, but not suicides)

11.3 SPECIFIED INJURIES:

• Fracture other than to fingers, thumbs or toes.

• Amputation.

• Permanent loss of sight or reduction of sight in one or both eyes.

• Crush injuries leading to internal organ damage.

• Serious burns including scalding (covering 10% of the body, or damaging the eyes, respiratory systems, or vital organs).

• Scalping (requiring hospital treatment).

• Unconsciousness caused by head injury or asphyxia.

• Any other injury arising from working in enclosed space which leads to hypothermia, heat induced illness or requires resuscitation or admittance to hospital for more than 24 hours.

11.4 REPORTABLE DANGEROUS OCCURRENCES: work-related near miss incidents that have the potential to cause death or serious injury but did not, such as explosions, fire, the release of hazardous substances, gases etc. There are 27 categories outlined in schedule 2 of RIDDOR for full list see www.HSE.gov.uk/RIDDOR/dangerous-occurences.htm.

11.5 REPORTABLE OCCUPATIONAL DISEASES:

• Carpal Tunnel Syndrome: where the person’s work involves regular use of percussive or vibrating tools.

• Cramp of the hand or forearm: where the person’s work involves prolonged periods of repetitive movement of the fingers, hand, or arm.

• Occupational dermatitis: where the person’s work involves significant or regular exposure to a known skin sensitiser or irritant.

• Hand Arm Vibration Syndrome: where the person’s work involves regular use of percussive or vibrating tools, or holding materials subject to percussive processes, or processes causing vibration.

• Occupational asthma: where the person’s work involves significant or regular exposure to a known respiratory sensitiser.

• Tendonitis or tenosynovitis: in the hand or forearm, where the person’s work is physically demanding and involves frequent, repetitive movements.

11.6 OVER SEVEN-DAY INJURIES TO WORKERS: (not counting the day of accident) - report within 15 days

11.7 INJURIES TO NON-WORKERS: work-related accidents involving the public or people not at work if the person is taken from the scene to the hospital and receives treatment for an injury arising from an accident involving work (equipment, processes, location).

12. ACCIDENT – INCIDENT INVESTIGATION

All Accidents or Incidents will be investigated and reviewed with the view to improving safety and ensuring the event does not re-occur and not to apportion blame. Not all investigations will need a formal written report.

All accidents/incidents reportable under RIDDOR will be investigated by the Sites ‘Appointed Person’ or a Designated Manager as soon as possible within 10 days of the accident/incident occurring. The investigation must have regard for the cause of the accident/incident and actions to be taken to prevent a re-occurrence. All possible RIDDOR accident/incidents will be reviewed by the Group H&S Manager and Senior Management prior to submission to the HSE.

Depending on the severity a written investigation report (see appendix B6) must be prepared, a copy of which will be held with the original accident and incident report in the central file. All relevant authorised parties must be advised on completion and the location to view the details.

A review of the report’s findings must be completed a soon as possible within 7 days of the completion of the report. Any remedial actions resulting from the investigation must be actioned within a set risk priority time frame as agreed at the time of the review.

The lead investigator (Appointed Person, Manager) will close all actions on completion, a copy of the document will be kept with the original accident and incident report in the central file for future reference.

APPROVED CONTRACTORS POLICY

POLICY SCOPE: This policy refers primarily to contractors that are to be contracted on behalf of Tingdene Group to complete works on any Tingdene Group site. Each contractor must go through the Approved Contractor process as outlined in this policy before commencing any works.

This policy may also be adapted for use if any Tingdene Group Business Unit has a local requirement to verify any ‘owner contractors’ who are directly contracted by an owner to complete works on their behalf, such as a holiday home or boat owner. In all cases a comprehensive list will be made of all contractors that attain approval through the process outlined in this policy.

POLICY: The management of those appointed to undertake contracted works for Tingdene Group are integrated into the company’s safe systems of operation.

Approved contractors are expected to abide by our policies and ensure best practice is applied at all times.

Tingdene Group acknowledge that many contractors provide skills and services which often require those undertaking the works to have gained competency qualifications. Tingdene Group has a duty to ensure that those contracted are competent and capable of undertaking the work schedule that has been issued.

Those appointed as a contractor, via their own policies, have a duty of care to ensure that their employees or those appointed as sub-contractors follow safe systems of works and are competent and qualified to undertake the tasks they are set.

To ensure that Tingdene Group meets its commitment to only utilise contractors that demonstrate a level of commitment to and comply with Health, Safety and Environmental Standards, it operates a policy that requires contractors to be approved by each Business Unit on an annual basis prior to any works being undertaken.

Each contractor is required to complete an Approved Contractor Application Form (Appendix C1) and submit it to Tingdene Group. Works may only commence once the contractor has become approved.

The Approved Contractor Application process ensures that Tingdene Group are in possession of and are able to ascertain the competency levels of the contractor prior to works being undertaken.

The Application process is separated into the following categories:

• Contact Details and General Information

• Specialisation / Trade

• Trade Qualifications / Competence

• Health & Safety

• Payments

• Connected Person(s), affiliates and associates

• Declaration

The Application process ensures that Tingdene Group capture important data and documentation such as Public Liability Insurance, Specific Trade Qualifications and all other relevant Health & Safety Documentation.

Once an application has been approved, a standard approval letter and Contractor Information (Appendix C2) will be sent to the contractor confirming the company’s acceptance and ongoing requirements.

Tingdene Group remain committed to implementing and reviewing its Approved Contractors management process.

ASBESTOS MANAGEMENT POLICY

1. INTRODUCTION

In line with the Control of Asbestos Regulations 2012, Tingdene Group will ensure as far as reasonably practicable the well-being of Team Members, Contractors and Visitors from the possible exposure to asbestos contaminated materials.

2. ARRANGEMENTS

Tingdene Group will ensure an Asbestos Management Survey (AMS) is undertaken where:

• It is suspected asbestos may be contained in any of their premises, particularly if the buildings age dates before the year 2000; and

• If asbestos is suspected during the construction or de-construction phase of any project works.

If asbestos containing materials are confirmed as being present in any premises, an Asbestos Management Plan (AMP) will be introduced to ensure the condition of asbestos containing materials are maintained in a safe condition by regular inspection and upkeep of records.

3. PROCESS

The process will include but not be limited to:

• An appropriate approved specialist company will be commissioned to carry out an asbestos survey for any existing or new Site acquisition built prior to the year 2000 where any materials are suspected of containing asbestos, unless in cases where a survey is produced by the vendors on acquisition of a particular Site.

• One of two types of asbestos surveys may be undertaken;

1. A management survey (product sampling): this will enable effective controls to be established over any general maintenance activity, which may be required and for relevant information to be provided to ensure the identified Team Members are not exposed to the inhalation of asbestos fibres which may have been disturbed.

2. A refurbishment and demolition survey (fully invasive): this is an intrusive survey and must be undertaken prior to any major refurbishment, renovation, or demolition of structures. Information regarding any asbestos containing materials present will be provided to all Contractors prior to arrival on-site to ensure they are fully aware of the type, whereabouts and condition.

4. CONTROL MEASURES

Where advised in the asbestos survey, affected areas will be labelled accordingly (see appendix D1).

All relevant affected Team Members will be informed if they are working in an area or structure with confirmed asbestos materials, including any exposure emergency procedures (see appendix D2).

Any on-site third-party operators or tenants will be informed prior to occupying or leasing any building, location, and risks of asbestos contaminated areas.

All Contractors and Sub-Contractors will be briefed prior to any works being carried out on contaminated areas.

Any briefing will include any emergency procedures in the event of finding or being contaminated by suspected asbestos containing materials during construction works.

Any work on, or removal of, asbestos-containing materials must comply with the general requirements in the Control of Asbestos Regulations. All work will be controlled to ensure that adequate precautions are taken to prevent the release of asbestos fibres.

5. MONITORING AND REVIEW

A Competent Person for the relevant Site will be appointed with the responsibility to implement an AMP, communicate, monitor and review its relevant policies and procedures to all Team Members for the Site.

The AMP will include a register of record (see appendix D3) detailing location, type, controls, ongoing inspection results and any history of removal dates of asbestos fibres.

CONSTRUCTION (DESIGN AND MANAGEMENT) POLICY

1. INTRODUCTION

The aim of this policy is to ensure Tingdene Group effectively manages the health, safety, and welfare of construction projects, by complying with the relevant parts of the Construction, Design and Management 2015 (CDM) regulations.

CDM 2015 regulations apply to all construction projects, whether or not the related work is short, small, large, or long. If it involves one person or one hundred people, if it’s classed as construction work, CDM applies.

“Construction work” is defined in the regulations to include:

• The construction, alteration, conversion, fitting out, commissioning, renovation, repair, upkeep, redecoration, or other maintenance (including cleaning which involves the use of water or an abrasive at high pressure or the use of corrosive or toxic substances), decommissioning, demolition or dismantling of a structure.

• The preparation for an intended structure including Site clearance, exploration, investigation, excavation and the clearance or preparation of the Site or structure for use or occupation at its conclusion.

• The installation, commissioning, maintenance, repair, or removal of mechanical, electrical, gas, compressed air, hydraulic, telecommunications, computer or similar services which are normally fixed within or to a structure.

A few activities are excluded from the definition as construction work including surveying, maintenance of fixed plant as part of a maintenance programme and erection or removal of marquees. CDM 2015 is applicable to almost all maintenance work.

2. RESPONSIBILITIES

CDM places clear responsibility on Clients, Designers, Principal Designers, Principal Contractors, and Contractors (for further information refer to the Duty Holders responsibilities).

Business Unit Directors or Senior Managers will identify at tender stage whether any proposed work will fall under the scope of CDM.

Where the works fall under CDM, the individual Business Units for Tingdene Group commissioning the works will act as the Client for all construction projects and will be responsible to assign a competent project Manager and/or project Team to manage the project in line with CDM requirements.

In some cases, the Business Unit as the Client may also be responsible for the design element for the project and in this case will comply with the CDM requirements for the designer.

The Principal Contractor shall be required to assist with any Health and Safety file by submitting their own proposals to overcome potential high-risk areas.

Specific advice may be called on from Tingdene Group’s H&S External Advisors as and when required.

During the contract and upon its final completion a “H&S File” shall be made available to relevant parties to aid with the safe running, maintenance, repair, and renovation of the project.

3. DUTY HOLDERS RESPONSIBILITIES

In addition to the brief outline in the table below, see also the CITB CDM Industry guidance for CDM duty holders.

CDM Duty holders

Clients are organisations or individuals for whom a construction project is carried out.

Summary of Role/Main Duties

Make suitable arrangements for managing a project. This includes making sure:

• Other duty holders are appointed.

• Sufficient time and resources are allocated. Make sure:

• Relevant information is prepared and provided to other duty holders.

• The Principal Designer and Principal Contractor carry out their duties.

• Welfare facilities are provided.

Domestic Clients are people who have construction work carried out on their own home, or the home of a family member that is not done as part of a business, whether for profit or not.

Domestic clients are in scope of CDM, but their duties as a client are normally transferred to:

• The Contractor, on a single Contractor project; or

• The Principal Contractor, on a project involving more than one Contractor.

However, the domestic client can choose to have a written agreement with the Principal Designer to carry out the client duties.

Designers are those, who as part of a business, prepare or modify designs for a building, product or system relating to construction work.

Principal Designers are designers appointed by the Client in projects involving more than one Contractor. They can be an organisation or an individual with sufficient knowledge, experience, and ability to carry out the role.

When preparing or modifying designs, to eliminate, reduce or control foreseeable risks that may arise during:

• Construction; and

• The maintenance and use of a building once it is built. Provide information to other members of the project Team to help them fulfil their duties.

Plan, manage, monitor and co-ordinate H&S in the pre-construction phase of a project.

This includes:

• Identifying, eliminating, or controlling foreseeable risks.

• Ensuring designers carry out their duties.

Prepare and provide relevant information to other duty holders. Provide relevant information to the Principal Contractor to help them plan, manage, monitor, and coordinate H&S in the construction phase.

Principal Contractors are Contractors appointed by the Client to co-ordinate the construction phase of a project where it involves more than one Contractor.

Plan, manage, monitor and co-ordinate health and safety in the construction phase of a project. This includes:

• Liaising with the Client and Principal Designer.

• Preparing the construction phase plan.

• Organising co-operation between Contractors and coordinating their work.

Ensure:

• Suitable Site inductions are provided.

• Reasonable steps are taken to prevent unauthorised access.

• Workers are consulted and engaged in securing their health and safety; and

• Welfare facilities are provided.

Contractors are those who do the actual construction work and can be either an individual or a company.

Plan, manage and monitor construction work under their control so that it is carried out without risk to health and safety.

For projects involving more than one Contractor, co-ordinate their activities with others in the project Team – in particular, comply with directions given to them by the Principal Designer or Principal Contractor.

For single Contractor projects, prepare a construction phase plan

CDM Duty holders

Workers are the people who work for or under the control of Contractors on a construction Site.

NOTE:

Summary of Role/Main Duties

They must:

• Be consulted about matters which affect their health, safety, and welfare.

• Take care of their own health and safety and others who may be affected by their actions.

• Report anything they see which is likely to endanger either their own or others’ health and safety.

• Cooperate with their employer, fellow workers, Contractors, and other duty holders.

*Organisations or individuals can carry out the role of more than one duty holder provided they have the skills, knowledge, experience and (if an organisation) the organisational capability to carry out those roles in a way that secures H&S.

Other Contractors’ duties under the CDM Regulations are essentially in support of those of the Principal Contractor. As well as these duties, Contractors still have responsibility for H&S of their own employees and others affected by their work under existing H&S legislation, e.g., H&S at Work Act, MHSW Regulations and regulations dealing specifically with construction H&S.

4. KEY ELEMENTS OF CDM

4.1

CLIENTS BRIEF:

The requirements and elements of any construction project will be set out and made clear to the Principal Designer and Principal Contractor via the ‘Clients Brief,’ developed by the Client and can be completed with the assistance of the ‘Principal Designer.’

The brief should:

• Describe the main function and operational requirements of the finished building or structure.

• Outline your motivation for initiating the project.

• Give your expectations during the project including how H&S risks should be managed.

• Explain the design direction you have in mind.

• Establish a single point of contact for any client queries or discussions during the project.

• Set a realistic time frame and budget.

4.2

F10 PROJECT NOTIFICATION TO HSE:

Where a project is expected:

• To last longer than 30 working days with more than 20 workers working simultaneously on the project at any one time; or