James Devonshire jdevonshire@nineteengroup.com

I'm very excited to be introducing you to our second issue of 2025 and, as always, this one’s a cracker!

But before I get to this edition’s content, I want to share the fantastic news that we've been shortlisted for the Association of Online Publishers (AOP) Digital Publishing Awards and not just once but twice.

Myself and the rest of The Manufacturer editorial team – Tom St John, Molly Cooper and Joe Bush – are up for Editorial Team of the Year: B2B. Meanwhile, the wider team has been recognised for Best Research/Insight Project for our 2025 Manufacturing Momentum Report.

Now, back to this edition of The Manufacturer, where we kick off with a look into Nestlé’s sustainability drive, as Editor Joe Bush sits down with the food giant’s UK Head of Sustainability to learn more about the proactive steps the business is taking to be net zero by 2050 – no mean feat when you consider the effects climate change is having on agriculture and the ongoing supply chain disruption caused by global geopolitical events.

There’s also a preview of this year’s Smart Manufacturing Week (SMW), which takes place on 4-5 June at the NEC in Birmingham. With four major exhibitions, a stellar lineup of speakers from across industry and academia, and an impressive educational agenda, SMW 2025 is shaping up to be yet another cracking instalment of the greatest

manufacturing event on the planet.

Let’s also not forget the Manufacturing Digitalisation Summit at SMW, where many of the UK’s top 250 manufacturers will converge to discuss the key challenges and opportunities facing the industry.

Meanwhile, The Manufacturer Top 100 for 2025 will be announced, celebrating and recognising the heroes of UK manufacturing across a range of categories.

I’ll be traveling the 6,791 miles from my home in the Philippines to be at SMW, so I don’t want to hear any excuses about people not being able to attend because of travel logistics.

Plus, Tom St John gets a tour of Michelin’s retread facility in Stoke to discover how the tyre manufacturer breathes new life into old rubber. Molly Cooper visits AB InBev’s Magor Brewery in Newport for an exclusive tour, showcasing the manufacturer’s sustainability efforts in action. And I speak with the Managing Director of an SME manufacturer to discover how heritage, innovation and sustainability underpin the company’s long-term success.

There’s all that and much more to look forward to in this latest edition of The Manufacturer.

I’m now off to consider my decision to fly out of Heathrow early on the morning after the AOP Awards. Schoolboy error James, schoolboy error…

@TheManufacturer www.themanufacturer.com

Jonny Williamson INDUSTRY ANALYST

Henry Anson DIRECTOR

Ashley Oulton

Stuart Biddle

STRATEGIC ACCOUNTS

Grace Gilling

MANAGING DIRECTOR

DIRECTOR & HEAD OF SALES

70 SME FOCUS Stamp of approval

From grain to glass with AB InBev

36 Empowering women in manufacturing Paving the way for inclusive leadership and industry growth

42 Hitting the right notes How tech is helping the evolution of guitar manufacturing

46 What will EPR mean for the food and beverage sector? The Food & Drink Federation discuss the potential impact of pending regulations

Focus

52 Chairman of the boards Manufacturer of timber products is thriving amid challenges

56 Waste not, want broth How one food manufacturer is achieving rapid growth

62 From garage to globe The remarkable Ryse of 3D printing manufacturer

66 Hitting the sweet spot UK expansion for India’s biggest snack brand

“Investing in sustainability is not only good for reducing emissions and supporting nature, but also to drive resilience in your business

Emma Keller, Head of Sustainability for UK and Ireland, Nestlé

be designed for recycling and we’ll be sourcing 50% of our ingredients from regenerative sources by 2030.

Of course, we can’t get complacent. We know that there is now a big drive to 2030. The low-hanging fruit has been picked, so we've got to look at how we drive the bigger step changes in emissions reductions, particularly in agriculture.

How are global events changing the strategy?

In recent years the only constant has been change, and we are continually adapting and evolving our strategy as we go. In many cases, it's strengthened our resolve for many of the commitments we've made.

For example, the climate impacts currently hitting Western Africa are affecting the yields of cocoa plants, seeing them hit a record price high; more than we've seen in over six decades. That is obviously very challenging for businesses but when we look closely and what's driving the price surge, among the factors at play is climate change linked weather conditions. This supports the case for the work we've been doing to drive regenerative agriculture in cocoa producing regions and ensure more resilience into the future.

Similarly, conflicts around the world have created supply chain challenges in terms of the availability of particular ingredients. Knowing we can work with trusted suppliers elsewhere in the world ensures we can get hold of the right ingredients to

“

We do a huge amount of work to make sure that we're communicating in a way that is honest, credible, evidence-based and transparent

Emma Keller, Head of Sustainability for UK and Ireland, Nestlé

get food on shelves and have a resilient business model.

Challenges are continuing, and there will likely be more climate shocks. We're yet to see the impact of the really wet summer we had last year on UK yields of wheat and other commodities.

Conversely, farmers haven't had much rainfall in the first quarter of 2025. Every

year is uncertain, but it only serves to demonstrate why investing in sustainability is not only good for reducing emissions and supporting nature, but also to drive resilience in your business.

How are consumer demands changing the way Nestlé manufactures?

Every year we see an increase in the number of eco-actives - consumers who are saying they actively want to make purchasing decisions based on sustainability criteria. However, at the same time we know there are other factors impacting consumers, often leading to a say-do gap. What we do know is consumers still have a greater expectation on businesses than they do policy makers in terms of action. So, there's a real role for us as a manufacturing sector to step up, act and drive change.

Consumers also have far greater access to data than they've ever had before, whether that be shopper assist apps which can be used to understand a company's credentials, or external sustainability ratings. So it's up to us to provide transparency.

At the same time, we know consumers are really savvy, engaged and are looking out for incidents of greenwashing. Therefore, we do a huge amount of work to make sure we're communicating in a way that

LEFT: Climate change has impacted the yield of crops such as cocoa and coffee - crops that are integral to Nestlé products RIGHT: Nestlé manufactures a range of products including coffee, confectionery and pet food

is honest, credible and evidence-based because we want to take consumers on the journey with us.

How is the business navigating supply chain challenges?

It's important we consult the best available science and projects to help us understand and plan for what might face us. Through our Task Force for Climate-related Financial Disclosure (TCFD) report we look globally at the risks and opportunities from both physical events e.g. changing weather patterns, and transitional events such as changes in policy.

So, what do we do about it? The first thing to note is that when you’re working in this sector, there isn't a one-size-fits-all solution. The approach we take to support a more resilient cocoa supply chain in West Africa is completely different to that required for coffee grown in Vietnam or fresh milk produced in Scotland.

Therefore, we've got a broad range of activities and programmes in place to tackle this. In the UK, for example, we’ve worked with First Milk, a regenerative farming cooperative, for over 20 years and they supply all our fresh milk for our confectionery and frothy coffee products.

Over those two decades we have created a partnership of trust and an ability to truly engage and try new things. As such we were able to reduce our carbon footprint by 30% by the end of 2024 and by working with partners such as First Milk, it enables us to better navigate challenges and cost fluctuations in the market.

How is the company working with growers/ farmers to enhance ecology and the environment?

We depend on nature and a balanced ecosystem so our partnerships within the supply chain are absolutely essential. Biodiversity and nature are metrics that are just as important to us as carbon. However, tracking the impact on nature is much more nascent and a common methodology doesn't yet exist.

But by adopting holistic regenerative agricultural practices on farms and at landscape level, we are able to see the impacts for ourselves. And, it's often the topic that farmers get most excited about.

They're proud to share with us and with each other pictures of bird species that may have returned or what's going on underneath the hedgerows they've planted.

The government have biodiversity and nature commitments to uphold to help protect 30% of the UK’s land and sea by 2030 and so we know nature is going to rise on the political agenda too.

So, that ecology piece is really important, and it's only going to become more so as policy makers start to commit to nature restoration and we begin to see the real impacts that can come about if we don't look after the environment.

How is your supply chain resilience linked to sustainability?

Sustainability, by its very definition, is about meeting the needs of a future planet without compromising the needs of today.

As well as trying to have as positive an impact as possible, we have a role to play in ensuring the business exists into the future. We want to ensure we can source the ingredients at the quality and quantity we need to produce the products we all know and love.

Being able to demonstrate how sustainability drives business resilience is really valuable to help channel more effort and resource to do more. It might be showing how a regenerative farmer is better able to withstand weather shocks or how a factory is less at risk of flooding or heat stress. Showing how resilience shows up in real terms is when you know you've hit a sweet spot in sustainability action.

Showing resilience within the business also creates those true light bulb moments; the real opportunities that help us get more investment into our different activities. That can be as simple as showing a farmer what we’ve been doing with regenerative agriculture practices, such as cover crops that will enable the farm to better withstand climate shocks.

That demonstrates what resilience looks like in real terms; where we can continue to get products on shelves because we can source ingredients at the quality and availability we need them.

How is technology influencing Nestlé’s sustainability strategy?

Technology is playing a role in everything we do; it’s helping us collect, analyse and synthesise data so that we can better streamline our reporting processes and disclosure. We operate in over 186 countries globally, so we have programmes all over the world collecting data. Being able to use it to report on our global emissions reductions pathway is incredibly complex, so the role of technology is key.

We're also seeing the role it can play through the supply chain; whether it be providing new tools to different suppliers to help them understand their impact and how we can better collaborate, to the impact it can make on farms. We're now in the era of digital farming, so we can use remote sensing to track how soil carbon is changing in real time, for example.

Part of our role is leveraging the power of tech to get people on board and make sure it's right for the application. We don't want to add burdens to already busy farmers. But by using technology, we can make their lives easier, collect more data and make better decisions to achieve better outcomes.

We're still getting our heads around where AI could really support more actionable sustainability, but I have no doubt it will. So, I’m excited about how we can leverage the power of AI to go further and faster together on our sustainability objectives.

With climate change inextricably linked to agriculture, what does the future of production look like at Nestle?

The immediate future means doubling down on what we’ve been doing already. We have a number of projects and programmes that are starting to really deliver, so we’ve been given the business confidence that this is the right track.

We’ll be leaning in to those existing projects and looking to scale them wherever possible. We've been in a phase of test and learn - which we'll still be doing a lot of going forward, particularity as new solutions and science comes to light.

We also need to continue to strengthen and build new partnerships and collaborations. No one company can do any of this alone. So, we need to work together, particularly in a challenging business context. Farmers need us and we need them, so it's really important we

support this vitalistic system together.

It’s also worth highlighting that while things are tough in the current business environment, sustainability isn’t a topic that can be parked. Results take a long time to come to fruition, so we need to be designing and implementing now, to see the impacts down the line.

I feel fortunate that sustainability has become part of Nestle's DNA. That's not to say we have all the answers but we're making good progress and I'm confident that with continued energy, action and collaboration we can deliver on our commitments and ultimately deliver for people and planet.

We need to continue on that train; knowing that projects we start today might not deliver any benefits until 2028/2029. Everything we do today is really important for the commitments we've set in the future. l

• Nestlé hit its 2025 emissions reduction commitment a year early

• 70% of the company’s carbon footprint is in the supply chain with agriculture and farming

• Advancing regenerative food systems is key to the company’s sustainability strategy

• The company will be sourcing 50% of ingredients from regenerative sources by 2030

• While some sustainability strategies take time to yield results Nestlé has learned so much by taking action

• An uncertain future means that sustainability is not only good for reducing emissions, but also to drive business resilience

“

Speakers from across industry and academia will share the ideas and strategies shaping manufacturing today and preparing it for what comes next

Impressive educational agenda

Smart Manufacturing Week’s educational programme has been carefully curated using in-depth research by The Manufacturer to highlight the topics that those working in manufacturing really want to hear about.

Across seven themed theatres, visitors will find sessions that explore Digital Transformation, Industrial Data and AI, IIoT and Connectivity, Design and Innovation, Automation and Robotics, Leadership and

Strategy, and Maintenance. One session not to miss will be presented by Professor Henrik von Scheel, also known as the ‘Godfather of Industry 4.0’. He will take the stage in the Design & Innovation Theatre on the morning of 4 June to present on The Future of Manufacturing: Megatrends that Shape the Next Decade.

In this session, he will examine the megatrends that he believes will dominate the manufacturing landscape in the years ahead. His insights offer a valuable look at the forces that will transform the sector, making this a mustattend for those looking to stay ahead.

Another standout session comes from Daniel Simkiss, Industry 4.0 Programme Lead at British Sugar. In his talk, Data Analytics and Insights for Decision-Making, he will cover how businesses can use data to optimise operations and make smarter decisions, while emphasising the importance of equipping employees with data-driven decision-making skills. This session will be particularly valuable for manufacturers seeking to upskill their workforce to meet the demands of an increasingly datadriven industry.

This year’s programme also places greater emphasis on discussion and debate. The panel session, The Innovation Imperative: Staying Competitive in a Rapidly Changing Manufacturing

Landscape, will explore how manufacturers can stay competitive by embedding a culture of continuous improvement.

Led by Nick Kemp, Head of DesignX50 at Brompton Bicycles, the session will consider how to respond to shifting market expectations and successfully integrate new technologies. The topic is particularly pertinent given the current climate shaped by Brexit, the aftermath of the pandemic and ongoing changes to global trade and tariffs.

According to Grace Gilling, Event Director, balancing technical depth and leadership insight has been a key focus for the educational programme. “We’ve put a huge focus on curation, ensuring that manufacturing end-user keynotes are scheduled so they don’t compete with one another, and that there’s the right balance of leadership insights and technical deep dives.”

Expert-led insights

At Smart Manufacturing Week 2025, the Institute for Manufacturing (IfM) will play a key role, hosting a series of masterclasses designed to address some of the most pressing challenges in the manufacturing sector. As the Knowledge Partner of the event, IfM will deliver expert-led sessions at the IfM Theatre, offering a unique, free-of-charge opportunity to gain valuable insights and practical solutions in areas such as sustainability, digital transformation, industrial safety, and diversity and inclusion.

The masterclasses will cover several critical topics such as navigating the journey to net zero, enhancing industrial safety, developing digital skills in SMEs and fostering inclusive leadership. These sessions are crafted to provide actionable strategies and frameworks, equipping attendees with the tools needed to tackle

Running alongside the exhibition, the Manufacturing Digitalisation Summit returns with a bold focus for 2025: AI-Driven Solutions for Smarter Industry. Over two days, senior leaders will explore realworld applications of AI across production, supply chains and strategic decision-making—driving transformation at the heart of UK industry.

This is not a talk-shop. With a 60% interactive agenda and 40% focused plenaries, attendees will engage in five dynamic discussion rounds, hosted by manufacturers and tech experts. Sessions are tailored across two streams—for large enterprises and scaling businesses—ensuring relevance and actionable value.

From predictive maintenance and AI-powered quality control to real-time visibility and autonomous decision-making, the summit unpacks the technologies reshaping manufacturing. Expect insights from leading sectors including defence, aerospace, and automotive, as well as proven strategies for competitive edge and operational agility. A separate ticket is required for this event. Visit: manufacturingdigitalisation.com to register. A full preview of the summit can be found on page 12.

these complex issues head-on. Notably, IfM’s masterclasses will be interactive, with participants working through challenges together in a collaborative environment guided by experienced industrial practitioners.

IfM will also be highlighting the Global Industry Safety Manifesto, calling for a collective industry effort to enhance worker safety through technology and best practices and Professor Tim Minshall, Head of IfM, will discuss insights from his new book Your Life is Manufactured, with an aim to inspire manufacturers to tackle challenges and seize opportunities in innovation and sustainability. “The book has received excellent reviews, with The Times describing it as fascinating”, said David Lott, Chief Executive Officer at IfM Engage, the knowledge transfer arm of the IfM, “Tim is a fantastic speaker, so we expect the talk to be busy.”

Places at IfM Masterclasses are limited, and pre-booking is required. These freeto-attend sessions are an invaluable opportunity for anyone looking to enhance their understanding of the latest trends and best practices in manufacturing.

Spotlighting tomorrow’s talent

Smart Manufacturing Week is once again putting the spotlight on the next generation of engineers and manufacturers. This year, the ‘Manufacturers and Engineers of the Future’ initiative has been expanded to welcome school-age students, offering them the opportunity to engage directly with people working in the sector across a myriad of roles.

Through hands-on demonstrations and real-world insights, students and apprentices will get the chance to take a closer look at the advanced technologies

driving modern manufacturing, which can help to spark their interest in STEM careers and broaden their understanding of the sector’s opportunities.

Beyond encouraging new talent into the sector, the event is committed to making manufacturing more inclusive. It continues to partner with organisations such as WISE (Women into Science and Engineering) and WES (Women’s Engineering Society) to drive gender diversity. Their work is crucial in breaking down barriers and ensuring that manufacturing roles are accessible to a broader talent pool. Both organisations contribute to discussions on attracting and retaining diverse talent, creating inclusive workplaces and ensuring that women and underrepresented groups are supported, and will be on hand to have these important conversations with visitors.

Further reinforcing its commitment to expanding the industry’s talent pipeline, Smart Manufacturing Week has partnered with New Futures Network to explore recruitment strategies that tap into previously overlooked sources. Attendees interested in innovative approaches to workforce development should also visit exhibitor LISI Aerospace, which will be featured in the Best of British Showcase and are excited to talk about the company’s approach to people and skills.

In addition, on the afternoon of Thursday 5 June, and following on from the Manufacturing Digitalisation Summit, Unloc, The Manufacturer, Verizon Business and Juniper Networks will be hosting the Changemaker Moments: Smart Manufacturing Event.

This interactive session will bring together around 50 business leaders and 50 tech native young people from the local area, to foster open discussions, share intergenerational perspectives, and develop actionable solutions.

Some of the world’s biggest manufacturers will be joining the session to help answer the question - what culture and skills do we need to attract the future workforce in manufacturing?

The organisers of Smart Manufacturing Week acknowledge that its primary role is to create business connections, but they also make it a vibrant, energising experience that blends the latest innovation with a lively atmosphere. Live music will set the tone from the moment visitors arrive, with performances throughout the event, including a Baby Grand

Piano busking spot. The Guitar Legends competition also returns, giving attendees the chance to show off their musical talent and to win a custom 3D-printed guitar. Capping off day one, The Shadow Monkeys will take the stage at the evening visitor party, bringing high-energy hits to keep the fun going.

Just announced and new for this year, ‘Smart Tank’ offers a dynamic platform for entrepreneurial talent to pitch ideas and products to a panel of industry experts in the hope of gaining funding and feedback. The businesses venturing into ‘the Tank’ are comprised of some of the most innovative exhibiting within Innovation Alley which is a mix of cutting-edge start-ups and university spin-outs, so expect huge amounts of passion and creative thinking.

The event also plays host to the FANUC WorldSkills UK Industrial Robotics Competition qualifier, giving visitors a front-row seat to the next generation of automation talent. Alongside this, the Best of British Showcase will shine a light on outstanding achievements in UK manufacturing, from bold design to global success stories. Previous years have featured projects from ThrustWSH, Airbus and Aston Martin.

While the event moves at pace, there are also opportunities to recharge. Visitors can take advantage of Workspace Hubs with seating, charging points and private phone booths. The dedicated Wellness Area offers a space to pause and reset, with professionals on hand to provide revitalising treatments. These moments of downtime are designed to help visitors stay refreshed and focused, ensuring they make the most of their time at the event.

A spotlight on exhibitors

Smart Manufacturing Week 2025 will host over 450 exhibitors, offering visitors the chance to explore the latest innovations, product launches and transformative solutions across the manufacturing ecosystem. Among the standout participants are this year’s Platinum Partners, who will be key stops on the show floor.

In Smart Factory names including Biffa, Epicor, FANUC and ifm Electronic will be showing off their smart solutions. Visitors can also discover how Ericsson (Stand: 5-C130) is helping manufacturers drive smarter operations by connecting people, data and things through robust, limitless connectivity.

At Maintec, Platinum Partners Fluke

and IFS Ultimo will be displaying their maintenance solutions. IFS Ultimo (Stand: 5-J20) will showcase its innovative approach to enterprise asset management (EAM), while Fluke will display its wide range of portable test instruments, including the ii900Sonic Industrial Imager, which enables maintenance teams to quickly and accurately locate air, steam, gas and vacuum leaks in compressed air systems.

In the Drives & Controls area you’ll find exhibitors including binder and Charter Controls and in Design & Engineering Expo you can expect to see 3M highlight its range of industrial adhesives and tapes designed to optimise assembly processes and improve cost-efficiency.

Visitors can also expect to see Schneider Electric, Hoffmann Group, HP Additive Manufacturing Solutions, Cembre and IFS.

Every minute counts

With so much to see across the exhibition floor, a little planning will help visitors get the most out of Smart Manufacturing Week. The event is organised into clearly defined zones, each focused on a specific area of manufacturing. Reviewing the exhibitor list and programme in advance makes it easier to pinpoint the sessions and stands that align with your priorities, ensuring time on-site is spent where it matters most.

A brand-new addition for 2025, the Smart Manufacturing Week event app is a must-have tool for attendees. It provides an interactive schedule, an exhibitor directory and other useful features to help plan and navigate the event seamlessly.

To help navigate the exhibition, curated Visitor Trails offer guided routes tailored to key themes such as Digital Transformation, Innovation and Smart Technologies and Workforce Development and Upskilling. These structured paths lead attendees to the most relevant presentations,

The evening of 4 June will see the announcement of The Manufacturer Top 100 2025. The awards programme scours the length and breadth of the nation to find the 100 most dynamic leaders and innovators in manufacturing, nominated by The Manufacturer’s audience, the industrial community and judged by a panel of industry leaders, academics and manufacturing associations.

The Manufacturer Top 100 celebrates the heroes of UK manufacturing and recognises their contribution to Net Zero, Digital Transformation, Innovation and Leadership. We shine a spotlight on Unsung Heroes, Sector Activists and the Young Pioneers making an impact in the industry. themanufacturertop100.com

technologies and suppliers, making it easier to focus on what matters most to their business.

With all this under one roof, Smart Manufacturing Week is a time-efficient way to tick off so many of the ‘to-do’ list actions all in an enjoyable, upbeat environment.

Smart Manufacturing Week 2025 takes place on 4-5 June at the NEC in Birmingham. Other exhibitions relevant for the manufacturing and engineering sector are taking place at the NEC at the same time, and these include Automechanika, Med-Tech Innovation Expo, TCT 3Sixty and Subcon. One visitor badge provides access to all events. l

This coming 4–5 June, the NEC Birmingham will once again become the centre of industrial innovation as The Manufacturer hosts its fifth annual Manufacturing Digitalisation Summit, colocated with Smart Manufacturing Week. This year’s event promises to be the most ambitious yet, tackling the most urgent challenges and most exciting opportunities facing manufacturers today

With the pace of change accelerating across every sector, the summit provides a crucial platform for manufacturing leaders to come together, exchange ideas and explore practical solutions for digital transformation. From scaling smart factory initiatives to integrating AI and building agile supply chains, the summit’s keynote sessions and interactive roundtables will provide insight, inspiration and actionable strategies.

Addressing the real challenges facing UK manufacturers

The manufacturing sector is undergoing a seismic shift. Technology is no longer a bolt-on, it’s the backbone of future competitiveness. But with this opportunity comes complexity. Many of the themes explored at this year’s summit reflect the very real challenges manufacturers are facing on their digital journeys.

Artificial Intelligence (AI) will have a major focus. While the potential of AI to optimise quality control, automate key processes and enhance supply chain planning is widely recognised, many manufacturers still struggle to move from pilot projects to production-scale deployment. A dedicated roundtable will examine how to use AI for predictive maintenance, reduce waste and streamline operations - without losing the vital human expertise that drives innovation.

Data, ERP and the pursuit of smart operations

Despite the wealth of data generated by modern manufacturing environments, many businesses are not yet leveraging it

to full effect. At the summit, a roundtable on data-driven decision-making will explore how to break down siloes, connect insights across the business and embed a culture of data into day-to-day operations.

No digitalisation strategy is complete without tackling ERP modernisation. While ERP is often seen as a back-end system, when aligned with broader transformation goals, it can become a key enabler of agility and growth. This year’s summit will host a roundtable on avoiding the common pitfalls of ERP projects, aligning them with AI and MES rollouts, and driving true businesswide engagement.

Another standout theme will be the shift from Industry 4.0 to smart operations. It’s not just about digital connectivity anymore - it's about transforming how operational decisions are made in real-time using AI agents, automation and intelligent workflows. This evolution demands new thinking about roles, responsibilities and the nature of frontline empowerment. Sessions will explore how to make digital tools genuinely useful for the people using them - and how to ensure adoption takes root at every level of the organisation.

With connectivity now critical to digital transformation, several sessions will explore the rise of private 5G networks and how they can underpin secure, scalable and agile manufacturing. The focus will be on building infrastructure that supports dataintensive operations, AI applications and real-time analysis - without compromising reliability or security.

Process mining and intelligent workflows will also feature prominently. Process mining software is now helping manufacturers map what actually happens on the factory floor, uncover inefficiencies and drive automation in weeks rather than months. Similarly, intelligent workflows are redefining the relationship between people, machines and data - enabling agile responses, sharper decisions and more engaged teams.

One of the biggest hurdles that still remains is cyber security. Despite growing threats, cyber security is still too often viewed as an IT problem rather than a business-critical priority. A key session will focus on how manufacturers can overcome internal resistance, secure executive buyin and foster a proactive, security-first culture across the business. The discussion will explore how to make cybersecurity a shared responsibility and a source of competitive advantage.

Real dialogue, real insight

Unlike traditional conferences, the Manufacturing Digitalisation Summit is built around interactive, off-the-record roundtables designed to encourage open discussion and honest insight. Delegates will have the opportunity to choose from a range of discussion topics across both days, covering everything from quality modernisation and frontline transformation to supply chain resilience and scaling smart factory initiatives.

This peer-to-peer format is what sets the summit apart. Whether you're just starting your digital journey or leading enterprisewide change, the summit is a space to challenge ideas, test strategies, and share lessons with fellow manufacturers facing the same pressures and ambitions. l

As the UK manufacturing sector navigates an era of change, the need for strategic clarity, cross-functional collaboration, and shared learning has never been more important. The 5th annual Manufacturing Digitalisation Summit offers exactly that: a chance to step back from the day-to-day, engage with leading thinkers, and shape the digital future of your business. Find out more: manufacturing-digitalisation.com

Richard Lloyd Leadership and Manufacturing Consultant

Scott Foxall Group IT & Business Systems Manager, Sertec

Carl Milbourne Head of SASB Operations, Sertec

Robert Baker Director, Operations IT –Engineering, Astra Zeneca

Amelia Kallman Futurist and Author

Edward Markey Manufacturing Intelligence & Visualisation Team Lead, Rolls-Royce

Dan Middleton Head of Innovation, Atlas Copco

Louis Gill Production Manager, LISI Aerospace

David Forrest Manager, AMIEO Digital Manufacturing, Nissan

Nasar Jockey Manufacturing Engineering Specialist, Rolls-Royce

Stephen Mason Advanced Digital Technologies Manager - Global Industrial Operations, JLR

Christopher Morris ME Digital Systems Methods Engineer, Airbus Defence & Space

Lauren Orszt Programme Director, Leonardo

Stefan Clements Information Technology Manager, Worldwide Fruit

Anna Kimber-Tarbuck Operations Systems Developer, Smurfit Westrock

Shona Munro General Manager, Sanmina

Aitana Ucles Design Business Coordinator, General Motors

Razvan Popescu AI Strategy Lead, Johnson Matthey

Claire Umney Managing Director, Alwayse

Jennifer Fenner Co Founder & Managing Director, DefProc Engineering

Ben Richards IT Manager, Dynex Semiconductor

In March, AB InBev welcomed journalists, local government representatives and the British Beer & Pub Association to its Magor Brewery in Newport, South Wales, for an exclusive tour that showcased its sustainability efforts in action. The Manufacturer’s Molly Cooper joined them

When the editorial team got invited to a brewery for a tour and tasting, who better to send than Molly Cooper - the only team member who can’t indulge due to a gluten intolerance? Questionable choice? Maybe. But there was no way we could pass up the chance to visit one of the world’s largest brewing brands.

The day was titled ‘Cheers to Nature’, but why? Well, AB InBev’s beer is made from 100% natural ingredients, and the brewing industry relies on the natural world around them to make manufacturing possible. “Being sustainable is not only the right thing to do, but it’s in our long-term interest to be great stewards of natural resources,” said Brian Perkins, President, West Europe & CEO, Budweiser Brewing Group, part of AB InBev.

THE MAGOR BREWERY SITE TIMELINE

Evolution of business

In 1979, the greenfield site in Magor was purchased and the company at the time, Whitbread (sold to AB InBev in 2001), built a brewery as part of its decision to move from many smaller scale breweries into several large-scale sites.

Originally, the site only kegged beer, but due to the market change, in the 1980s it introduced canning and then in the 2000s, bottling. Due to this packaging evolution, the site now has two canning and four bottling lines as well as kegging

LEFT: Some of the brands that are brewed at Magor Brewery, Newport RIGHT: Brian Perkins, President, West Europe & CEO, Budweiser Brewing Group, part of AB InBev

facilities and more recently, producing the PerfectDraft kegs.

Magor Brewery is responsible for brewing many of the world’s most loved brands including Stella, Budweiser, Corona, Bud Light and more recently Camen Hells.

The location of the site was chosen due to the abundance of water that flows through the area. In 1879, a large volume of water, later dubbed the ‘Great Spring’, flooded the works during construction of the nearby Severn Tunnel. The spring originated from the Welsh side which means the water can be pumped in and used at the brewery.

“This is great source of good quality water. It produces around 15 million litres every single day,” explained Lloyd Manship, Brewery Manager at Budweiser Brewing Group UK&I.

The brewery currently has over 500 employees. “We have found it very easy in South Wales to recruit highly skilled people and retain them. We have people working in the brewery who have been here for over 40 years, but we also have young people just starting out on their careers,” said Lloyd.

The business has invested in the apprenticeship team, which has been critical. As a former apprentice himself, Lloyd sees the importance of working with the next generation of brewers.

Not only this, but the brewery is located on the M4 corridor meaning the business has good transport links which also creates easy access to the rest of the European market.

Sustainable initiatives

Every investment Magor Brewery receives is all in a bid to make it more sustainable. The local Welsh government has been of great

support both financially and with policy, and the brewery has received several grants over the years to grow the business.

Throughout that time, it has also developed more sustainability goals and environmental impact initiatives. “We’ve removed all plastic from our packaging. This includes the plastic rings from our cans and the plastic wrap which went around the packs. This ensures that we're plastic-free,” explained Lloyd.

Magor is also committed to delivering its Budweiser with 100% renewable energy. To achieve this, the company has installed one of the largest wind turbines in the UK and it also uses 100% UK barely within its Budweiser brewing at the site.

The brewery strives to invest in optimisation of the plant, its output and energy savings. To achieve this there has been a variety of new technology introduced at Magor including the world's biggest wort cooler, which can chill three million pints of beer each day. With a surface area the size of a football field, the new cooler is four times the size of a standard version which would be used in a similar scale brewery. It can also reheat the water as well.

Sustainability is not only the right thing to do but it’s also in our long-term interest to be great stewards of natural resources

Brian Perkins, President, West Europe & CEO, Budweiser Brewing Group, part of AB InBev.

Time to invest

“For us, our stewardship of natural resources is critical if we plan to continue brewing for the next 300 years,” urged Lloyd.

He also explained that looking back ten years, the brewery wouldn’t have been a good choice for investment. Magor found itself inefficient and underperforming. “We

2012 Began brewing Becks

Began brewing Bud Light

2023 Facilities installed for PerfectDraft 2025 Began brewing San Miguel

Consistency is key

Water from the Great Spring is piped directly into the brewery where it’s treated to make sure it is perfect for the brewing process. Over time the pipes which feed the brewery are at risk of degrading. If the brewery notices a change in the flow, it could suggest a breakage in the pipe meaning that inferior quality water could be pulled through into the brewery. “When this happens, we must re-clean and restart our systems, which is a problem. However, the quality of the natural spring water is stable and is the same as it always has been; it’s perfect for our beer,” said Llyod.

Right now, it takes 2.99 pints of water to make one pint of beer. Although this has been significantly reduced from 3.62, the Magor site is aiming to halve this number again, reducing it to 1.65. Lloyd certainly believes this to be possible as it is being done in other breweries around the world.

“Our target for this year is 2.8, which is an ambitious goal,” he said.

Magor brewery runs on 100% renewable energy which it purchases from solar farms. Lloyd continued: “For us, we want to work on our own green energy. We discussed a range of options including changing our power plants, installing more solar panels and wind turbines to provide more electricity. The wind turbine here provides us with 20% of our power directly on an annual basis.”

One option the company is exploring still further is hydrogen. As battery technology improves and the batteries themselves become smaller, the feasibility of having electric boilers versus hydrogen boilers becomes more of a viable option. For Magor, it’s about finding the most sustainable method.

One project the site is looking at is refillable bottles for its brewed drinks. It is working alongside the local Welsh government and a consortium of beverage producers across soft drinks, spirits and beer to discuss the idea further.

“Can we imagine a future where bottles are returnable and refillable in the UK? This idea is both sustainable and good for business. But it requires significant investment and the creation of an industry-wide bottle washing and sorting facility,” said Brian.

The cost of investment is partly a response to the UK's extremely high packaging taxes, which are among the steepest globally. “With the upcoming regulations, the UK will have the highest Extended Producer Responsibility (EPR) costs in Europe, nearly double that of the next country. While these policies are well-intentioned, their financial burden can discourage companies like ours from investing,” he added. This incentive would need to be industry-wide and could not only apply to one brand or company. As such, AB InBev has created a consortium of competitors as it is not a problem that the business could realistically or practically solve on its own.

“The project has the potential to materialise, but it would require a bottle sorting and washing facility plus a return loop. The industry would have to consider standardised containers for the products to make the lines work efficiently and it would need to be simpler for the consumer when they are returning bottles,” explained Brian.

The scheme is in its early stages and discussion has been ongoing for a few years. The next stage is putting together a pilot in Wales. “We have a huge opportunity to reframe and reposition this idea to consumers and beer drinkers as a better and more sustainable choice. This has not been the narrative for the last 20 years,” Brain added. l

• Magor Brewery, part of AB InBev, has made significant strides in reducing its environmental impact. From eliminating plastic packaging to using 100% renewable energy and UK-sourced barley

• The brewery has achieved a 60% reduction in water loss over five years, improving from nearly ten per cent to 3.51% as of 2024. It treats water from The Great Spring and uses technologies like the Simmer and Strip process and water recycling to further cut water usage

• Magor has undergone major upgrades including expanding packaging capabilities, adding new fermenters and installing advanced equipment. These moves have improved efficiency and allowed the site to produce over 1.1 billion pints annually

• Located in South Wales with access to high quality water and strategic transport links, Magor Brewery employs over 500 people. Its apprenticeship programme supports workforce development and has created long-term career paths for the local population

• AB InBev is collaborating with the Welsh government and industry peers to explore refillable bottle schemes. This initiative aims to reshape the consumer packaging experience for long-term environmental benefit

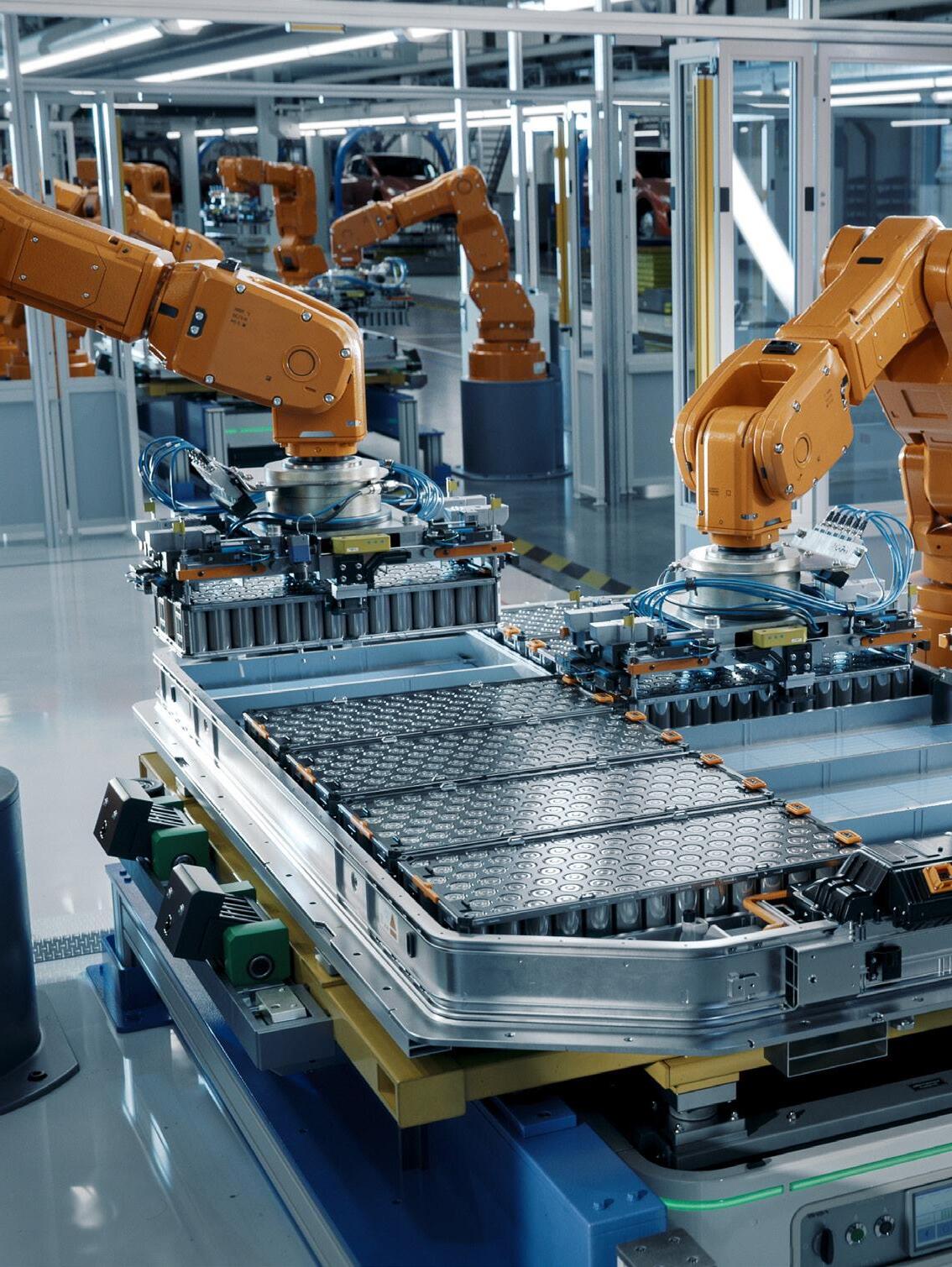

After a bruising decade, the automotive industry faces another set of formidable challenges. However, industry leaders remain adamant that the UK’s strengths in advanced engineering, local supply chains and clean-tech investment still offer a competitive edge. Jonny Williamson reports

Following Brexit upheaval, pandemic shutdowns and supply chain chaos, automotive bosses had hoped for a smoother road ahead. It wasn’t to be. Vehicle output has fallen to near seven-decade lows, global

trade tensions are rattling boardrooms, and the transition to electric vehicles is testing the readiness of both industry and consumers. The result is a sector caught between long-standing strengths and mounting structural pressures.

“There’s no denying the current situation is extremely challenging,” said Mike Hawes, Chief Executive of the Society of Motor Manufacturers and Traders (SMMT). “Our production data shows demand for Britishbuilt cars rose in March, up for the first time

government support is also essential. Yes, it will be led by the Department for Business and Trade, but the issues cut across energy, education, transport and the treasury. All must be aligned behind a shared goal of driving economic growth. That’s how we give investors the confidence to back UK manufacturing for the long-term.”

The pivot to electric

The shift to electrification is where longterm commitment is needed most. In April, the government adjusted the Zero Emission Vehicle (ZEV) mandate to give carmakers more leeway. While the core 2030 target remains – ending the sale of new petrol and diesel cars – manufacturers now have greater flexibility in how and when they meet emissions targets in the run-up. Key revisions include extended allowances for hybrid vehicle sales, now permitted until 2035. But the pressure to invest and adapt hasn’t gone away.

That urgency is visible in production trends. Electrified vehicles now account for almost half of all UK car output. EV sales hit a record high in March, with growth across all categories – hybrid electric vehicles (HEVs), plug-in hybrids (PHEVs) and battery electric vehicles (BEVs). It’s a welcome sign, but one driven more by looming tax deadlines than true consumer confidence.

From April, electric cars became subject to the ‘luxury car tax’ – the Vehicle Excise Duty (VED) supplement applied to cars costing more than £40,000 new. The change has drivers paying several thousand pounds over the first six years of ownership, compared with zero previously.

Combined with ambitious targets, like 28% of new car sales and 16% of vans

• £93bn turnover and £22bn value added to the economy

• The sector employs employs 813,000 people, with wages 13% higher than the average

• It invests invests around £4bn each year in R&D

• 25+ manufacturers build 70+ vehicle models, supported by 2,500 component providers

• Eight out of ten UK-built cars are exported to 140 different markets

needing to be zero emission this year, it’s hard to ignore that government policy and industry investment seem to be moving in different directions. “There’s little to no fiscal incentive for private buyers right now,” Mike said. “If anything, recent policy changes have made it harder.”

“Manufacturers are doing their part,” he continued. “They spent an estimated £4.5bn on EV discounting last year alone. They’ve also invested in product development, with more than 130 models now available across every size category. And pushed the average driving range to 290 miles, more than double the typical weekly mileage. But relying on industry discounting isn’t sustainable. We need long-term growth, not short-term bubbles.”

While fewer than one in four new car buyers plan to go electric by 2028, two in five EV sceptics say the right incentives and infrastructure development could change their mind. A clear opportunity if government and industry can align.

Suppliers, meanwhile, are feeling the squeeze. Many are grappling with high interest rates, volatile demand and rising employment costs. Mike suggests simple, short-term relief measures, such as flexible payment terms from HMRC, could provide vital breathing room. “It’s not about avoiding tax,” he said. “It’s about helping small businesses manage cash flow during a turbulent time.”

The road ahead

Despite the headwinds, there’s no shortage of ambition within UK automotive. It has the highly skilled workforce, dense network of globally regarded brands and

TOP TO BOTTOM: March was the best month ever for new EV registrations, but the tenfold increase since 2020 has only been possible thanks to unsustainable subsidies by car makers

The number of vehicles on British roads reached its highest ever level in 2024, rising by 1.4% to just under 42 million, with plug-in vehicles now accounting for one in 20

Germany is the largest source of cars on UK roads, accounting for 29.5%, followed by the UK (14.1%) and Spain (10.3%). China has risen to become the 12th largest

Switching to zero emission commercial vehicles would shrink the UK’s carbon footprint by 35.7 megatonnes, more than the total emissions of Sweden

All slides courtesy of

EV uptake is still being heavily and unsustainably subsidised by the industry

Protectionism isn’t good for industry, for economies or consumers

Mike Hawes, Chief Exec, SMMT

proven capacity for innovation needed to thrive. But realising that potential depends on clarity from government, confidence from investors and closer collaboration across the supply chain.

Above all, the Industrial Strategy must be delivered as promised this summer. That strategy must go beyond broad ambition and include clear, accountable delivery plans that give businesses the certainty to invest.

“There’s a tremendous prize to be won if we can navigate the choppy waters,” Mike concluded. “The UK has the capability, the reputation and the global standing to lead, but we can’t take it for granted. We need to build on it. New brands are entering the market here and in Europe, and are looking to manufacture locally. That’s just one example of the huge opportunities available to drive value in the UK supply chain.”

Through its Vision 2035 report, SMMT outlines a three-pronged plan to secure the future of UK automotive: shore up exports through urgent trade diplomacy, accelerate domestic EV production with clear industrial policy, and support the supply chain and workforce through long overdue investment. Whether this proves enough to reverse the slide may depend on the speed and clarity of government action in the weeks ahead. l

*All quoted figures courtesy of SMMT

Once a tyre’s tread wears thin, you may assume its life is over. But in Stoke-onTrent, Michelin is breathing new life into truck and bus tyres through a sophisticated, high quality remanufacturing process. Retreading is a sustainable, longer-lasting alternative to the wasteful single-use tyres that are making their way into the UK. The Manufacturer’s Tom St John went inside Michelin’s retread facility to learn more

Michelin is a household name, and a titan of the tyre industry.

Those who work in one of its 121 production facilities across the world, proudly associate the name with performance and durability. And those on the outside will no doubt think of the little, smiling, chubby fella made out of tyres. (more on him further down the page)

Group Michelin is over 130 years old. By 1927, it had established itself in the UK, and made Stoke-on-Trent its home. Which of course, is a city with its own industrial heritage — kilns, clay and craftsmanship. And just like the potteries, the Michelin plant has its own artisanal touch, albeit one focused on rubber and tread rather than porcelain and glaze.

Over the years, the Stoke plant has manufactured tyres for cars, two wheel vehicles, buses and trucks. And, just over 40 years on from arriving in Stoke, a retreading facility was built on the site.

Today, the site is solely focused on giving tyres a second life through retreading. It no longer produces brand-new tyres, which makes it the company’s only retreading facility in the UK.

Remarkably, as early as 1923, Michelin began to offer retread truck tyres, setting a precedent for its focus on sustainability.

The modern day retread process fuses cutting-edge technology with hands-on inspections by skilled operators.

This site wants to spread the message and unite other tyre manufacturers in the

fight against cheaper, single-use tyres that are flooding the UK market from overseas. Michelin is desperately trying to convey to its customers that this alternative, while more costly, results in a significantly higher quality and more environmentally friendly product. This plant in Stoke-on-Trent is loudly leading a retread revolution, one tyre at a time.

Tread carefully I arrived in Stoke knowing that retread certainly doesn’t mean patched-up or second-rate tyres. We visited Bridgestone in Lincolnshire last year. A competitor of Michelin, yes, but united in the retread ethos.

As Andrew French, B2B Sales Director at Michelin, explained, this is a process steeped in sustainability and circular thinking.

“Over the years that we’ve been based in Stoke, we’ve given a second life to over ten million tyres,” he said. “That’s a huge sustainability win – and something the group has been committed to for over a century."

It’s easy to underestimate the significance of that number. Each retread tyre means raw materials haven’t been extracted, emissions haven’t been released, and waste hasn’t gone to landfill.

To be more specific, the retread process doubles the lifespan of truck tyre casings. Five tonnes of raw materials are saved and more than six tonnes of CO2 are prevented from entering the atmosphere for every 100 Remix tyres remanufactured.

LEFT: The black crumb from detreaded tyres is used in a variety of other applications

In a world where manufacturers are focussing on sustainability as environmental regulations tighten, those numbers aren’t just impressive, they’re essential. And yet, there’s a trend in the market that’s completely at odds with this approach.

“Over the last six to eight years, there’s been a big influx of budget, tier-three tyres entering the market,” explained Andrew. “These tyres are designed for single use only. They’re not built for longevity or a second life. Environmentally, it’s a huge concern.”

He continued: “That’s why we believe the multi-life offer that Michelin provides, supported by retreading, is an absolute game-changer."

For companies like Michelin, there are several problems with the continuing influx of these tyres, many of which come from China. Two concerns are particularly key; the cost difference and the quality disparities.

Both undermine the retread market, and are damaging for its long-term future. As far as retreaders like Michelin are concerned, the problem is that good quality and environmentally sound retreads are being priced out of the market.

As we’re about to find out, there is no comparison in terms of quality here. It’s cheap, short-lived tyres versus premium products designed to live again. One

feeds a throwaway culture, the other a sustainable future.

The plant in Stoke receives and examines used Michelin and competitor truck tyres. Once these arrive in the warehouse, they’re assessed to see whether they can be rebuilt as Remix or Encore, the two brands of Michelin retreads.

The Remix line has been in place since 1968, and uses Michelin truck tyres. The Encore line, which uses worn Remix casings or competitor tyres, came in during the year 2000. The plant has the capacity to produce 315,000 tyres per year.

The retread process is a thorough and complex one, as Chrissy Peloquin, Stoke Factory Manager, explained: “There are really four major stages: casing inspection, detreading, retreading and final quality examination."

It all starts with inspection. Tyre casings, the body of the tyre after the tread has worn down, arrive from across the UK and overseas. Each is painstakingly examined by skilled operators, both manually and using high-tech scanning equipment like X-rays and shearography machines, which can detect internal flaws invisible to the human eye.

MAIN PIC: The tyre goes through a series of checks before and after it gets retreaded

“

Once people see the amount of checks and testing one of our tyres goes through, we feel able to ask the question, ‘why consider the alternative?’

Chrissy Peloquin, Factory Manager, Michelin

“The inspection process is still very manual,” Chrissy explained. “We’re actually piloting automation in Europe right now, to make inspection better from an ergonomics and safety perspective.”

Once the casings are thoroughly examined, only the ones in a suitable condition are allowed to continue to the next stage, which is detreading.

This is where the worn tread is ground away, producing a storm of black rubber

As Andrew put it: “We’re committed to minimising impact and maximising the use of materials while they’re in service. Extending the life of tyres is crucial for reducing CO2 emissions, lowering resource consumption and improving the green credentials of both Michelin and our customers.”

As we’ve touched on, every saved casing means less raw rubber, and fewer tyres piling up in waste streams. It's all pretty logical, and intuitively sensible. The wider challenge is getting the whole industry on board.

And it’s a challenge for which Andrew has a clear vision: “There's a lot of pressure from cheap imports, especially tier-three Chinese tyres. These are single-use, low-longevity products. It’s a real environmental setback.

“That’s why we’re working with other companies, even our competitors like Bridgestone, to push for stronger regulations and to benchmark best practices across the industry. We’re all in this together."

Chrissy added: “Over the last three to five years there has been a greater willingness to benchmark other companies. In the past, companies weren’t interested in that, especially larger companies. We didn't want to share necessarily.

“However, sharing best practices is the way forward, particularly when it comes to battling the tier-three Chinese market. That's an area where we have to stick together.”

This is another good example of the increased collaboration that is occurring in manufacturing. Rather than a cutthroat competition culture that may have existed in previous years.

There is a problem in the tyre market that needs to be answered. But, walking through the Stoke-on-Trent plant, there’s a welcomed feeling of optimism in overcoming that challenge.

And actually, when you drill into the numbers, the UK is quite receptive to retreads - 25,000 busses are fitted with retread tyres, as well as an impressive 70% of supermarket delivery lorries.

There are also considerably less supply chain emissions when you opt for retreads; 95% of truck tyre retreads in the UK are made in the UK. Emissions are greater, and lead times are longer if you buy from China.

Eight-five per cent of the worn out tyre is reused in a retread. And as mentioned

already, the discarded black crumb can be used in other applications.

The only metric where imported tyres win out is cost. But as manufacturers like Michelin are pointing out, it’s also an inferior product that doesn’t have the same longevity as a Michelin retread. This means that over the whole lifetime of the product, the increase in cost is balanced out. The challenge is making customers realise this bottom line impact.

Like any sustainable product or project, while you pay more upfront, your benefits are longer-lasting.

In the last issue of the magazine, we brought you the exploits of The Royal Mint’s e-waste processing – using the extracted precious metals for jewellery and sending other elements out into manufacturing supply chains.

Retreading tyres might not conjure the same romance of striking gold, but the outcome is just as precious, and it’s evidence of another one of the UK’s manufacturers answering a deeply urgent problem.

One-hundred years of retreading at Michelin is proof that sometimes, the most revolutionary ideas aren't new. They’re simply old ideas done better, at scale and for the right reasons.

It’s a key differentiator. While some might associate retread tyres with a compromise in quality, Michelin’s relentless focus on inspection and verification ensures that every tyre leaving Stoke-on-Trent is as safe, reliable and durable as a brand-new product.

One of the final inspections involves a pressure check. The tyre is placed inside an enclosed, controlled area, just in case it goes bang. I was told this makes quite a sound, one that can be heard right across the site.

As someone who doesn’t do well with sudden, loud noises, I was relieved that the tyre we were watching passed this test, and remained intact.

I asked Chrissy if customers get taken on this factory tour. “Absolutely,” she replied. “It usually seals the deal. Once people see the amount of checks and testing that one of our tyres goes through, we feel able to ask the question, ‘why consider the alternative?’”

The alternative being single-use tyres that wear out quickly and end up discarded. It’s clear which path is more environmentally responsible. To say nothing of the fact that the customer is also getting a high-quality product. l

• Extending the life of over ten million tyres goes a long way to reducing raw material use and CO2 emissions

• Quality and safety are central to Michelin’s retread process

• The influx of low-cost, singleuse tyres pose a significant environmental and industry-wide challenge

• There is strong advocation for industry collaboration, with competitors like Bridgestone, and regulatory reform to answer this challenge

Wendy Graham is the first woman Plant Manager in the 97 years of Ford’s iconic Dagenham site, coming 57 years after its women factory workers famously went on strike in a demand for equal pay. The Manufacturer’s Molly Cooper went to the site to speak with her about being a woman in a traditionally male dominated field and what the new role means

I’ve never had a woman as my manager, so it was difficult to envisage myself in a leadership position

Wendy Graham, Plant Manager, Ford Dagenham

Visiting the Ford Dagenham site was of both personal and professional interest to me.

I was excited to speak with Wendy but also, my dad has worked at the site for over 29 yearsthat’s longer than I’ve been alive. Until now, I had never seen where he worked. Over the years, he’s held various roles across the plant, from the shopfloor to, more recently, the union office. Seeing the site in person provided a greater appreciation of the history and scale of the manufacturing operations that take place there.

The Dagenham site manufactures diesel engines and machined components for the global market, predominantly for commercial vehicle products such as the popular Ford Transit Van and Ford Ranger. Currently it produces over 2,100 engines per day, equaling 480,000 per year. To date, the plant has produced and shipped over 49 million engines worldwide.

“I have just recently been appointed the Plant Manager, which is overall operations manager for the site. Before that, I was the Assistant Plant Manager, and was mainly in charge of day-to-day operations and production scheduling. The expanded role means that I have full control over engineering, manufacturing, logistics and the interactions with the external partners, such as our local councils and Thames Freeport,” explained Wendy.

The right path

As a young child, Wendy was always curious about how things worked. “Growing up on a farm in Northern Ireland, we had a variety of different machinery that needed regular repairs.” At school, Wendy saw herself as an all-rounder and even though she enjoyed learning languages, the logic of maths and science appealed more.

Yet, it was a work experience week when she was 16 that was a turning point on her path. “I worked at a drinks bottling and canning factory and seeing the entire process from raw material through to a product that we see on the shelves in the

supermarket, sparked something in me,” Wendy continued.

From there, she realised that engineering was all about solving real-world problems and making the world a better place. “It combined my love of problem-solving with an opportunity to make a real impact. Engineering felt like a natural fit for me, aligning with my interests and abilities.”

Wendy first joined Ford Dagenham in Vehicle Operations, a large part of the business on the shopfloor. The sheer scale of the operation was overwhelming to a new apprentice. “The speed of vehicles flying past every 90 seconds, the complexity of the operations and the amount of equipment was complete sensory overload,” she explained.

Wendy quickly realised that automotive manufacturing was high pressured, dynamic and was consistently changing its priorities. “Decisions needed to be made quickly. I joined towards the end of a new product launch, so everyone in the plant was getting used to how it all worked so it was a steep learning curve. I spent a lot of time listening, asking questions and learning how things got done.” She also discovered the importance of teamwork, collaboration and how the success of an entire operation depends on how the team work together.

For those also feeling overwhelmed after joining the automotive industry, Wendy believes the best advice is to find a trusted colleague; an unofficial mentor who can help grow your understanding and how you can be more valuable to the organisation. “I was most likely out of my comfort zone 95% of the time, but I adapted to survive,” Wendy said.

Being a woman in a traditionally male dominated industry, Wendy admits that there have been some challenges. “Early in my career, I felt that I had to work harder than everyone else to be taken seriously. Looking back, there were certainly instances of unconscious bias, where ideas were overlooked and contributions weren't fully recognised as my own due to my age and gender.”

Wendy added that one of the biggest hurdles she faced was not having any other female role models to look up to. When joining Ford, there weren't any women in leadership positions and it wasn’t until her second decade of working at the company before there was a woman leader in the manufacturing organisation. “I’ve never had

ABOVE: Wendy Graham, Plant Manager, Ford Dagenham BELOW: The Ford Dagenham Diesel Centre at night

a woman as my manager, so it was difficult to envisage myself in a leadership position.”

However, when it came to being a leader, Wendy wanted to be true to herself when it came to her management style. “Initially, I tried the ‘macho’ leader style, making sure that when I spoke, it was with facts. I didn’t want to leave room to be corrected. But that wasn’t me, and as time went on, I became more confident in my own knowledge and began expressing my first thoughts, without having to research everything beforehand,” she said.

Wendy also found support in seeking out allies - both male and female - across the business and recognised that change takes time. “Twenty years ago, it was rare to see any women in a manufacturing leadership position. Now I can confidently say that every manufacturing position across Ford Europe has been occupied by a woman at one time, which is real progress. Now, by being visible and successful I’m helping to pave the way for future generations.”

There have also been other challenges that come with working in a manufacturing environment that Wendy has faced. She added: “When you have major equipment failure, and particularly when you work with older equipment, it can cause significant disruption to production.”

Ford Dagenham’s operations are not just local, and the company has global

27 customers, so if a major breakdown does occur, it can cause huge setbacks. “I can stop vehicle operations in Thailand, Argentina and South Africa. The pressure and stress associated with that is high as I've become more experienced and more senior in the company and in my position,” explained Wendy.

Once, she was the engineer who needed to find a solution to fix the issue, before becoming the Production Manager who had to report the numbers. “Now I am the plant manager and its taught me the importance of trusting the expertise of the team, remaining calm under pressure, making quick decisions and sticking with them, but flexing if you need to.”

With lows, comes highs and Wendy recalls a significant success being a paint engineering project where she was leading as Chief Engineer in Europe. “I was implementing a new paint material for emissions regulations purposes. However, the change meant that while introducing a new material, we also had to introduce industry first application equipment as well.”

The primary goal was to meet emissions legislation in the future and allow Ford Motor Company to introduce cost efficiencies in its paint application process and reduce energy consumption.

Wendy added: “For me, the project was pivotal. I worked on the base programme which was launched in one plant. After its success I moved roles, but it continued to be rolled out in other plants. In the decade since the initial project, it was replicated across six other plants globally. I was responsible for setting that in motion and it was my first experience of leading a global team.”

• Wendy’s journey from a farm in Northern Ireland to the top of Ford Dagenham was fuelled by a love of problem-solving and a determination to make an impact in engineering and manufacturing

• Navigating a male-dominated industry, Wendy overcame unconscious bias and the absence of female role models to carve out a leadership style that’s both authentic and inclusive

• She has led high stakes, globally implemented projects such as introducing new, environmentally friendly paint materials and worked across continents to drive innovation and collaboration

• Wendy is steering the Dagenham plant toward a more sustainable, technologically advanced and inclusive future, while fostering a culture of continuous learning and adaptability among the workforces

Back in November 2024, Wendy was appointed Plant Manager at the Dagenham site. Starting her career at the same site 30 years ago, Wendy could never have imagined herself in this position. “It’s a tremendous responsibility to be given. Dagenham has a rich history and a legacy that goes back nearly 100 years.”

Dagenham still stands as one of the largest industrial sites in London and to be the first woman to lead the plant after so many years provides Wendy with a sense of pride. “This isn’t just for me but for all the women who have worked at this site before. Women in Dagenham changed the course of history as the strikes triggered the passing of the Equal Pay Act in 1970.”

Wendy hopes that her newest appointment will send a message that anything is possible regardless of gender. “It is now my responsibility in this role to make sure that I lead Dagenham with integrity, innovation and build a diverse and inclusive workforce where everyone can thrive, regardless of gender for future generations. That’s my mission.”

Wendy has worked in different roles and regions, broadening her knowledge and providing her with a deeper understanding of the complexities of the automotive industry.

“My time in global manufacturing engineering exposed me to different cultures. I had teams working across Russia, South America, China and Europe. Learning the importance of cultural sensitivity and ensuring that our workforce were able to work effectively with people from different backgrounds was key to successful production,” she added.

The next generation Encouraging the next generation into manufacturing requires a multipronged approach and Wendy believes it starts with changing the perception of what manufacturing is.

“We need to start showcasing the different roles and opportunities that exist within industry, from manufacturing, engineering, design, operations and management. It’s important to reach children early and expose them to STEM in a fun, engaging way.”

Ford UK are involved in school outreach projects and hands-on activities in the local and wider community to get young people involved in the sector. “Mentoring and shadowing are so important. It was a work experience week that sparked my interest for the sector so as a personal mission, I’ve ensured that we have restarted work experience placements for students at Dagenham.”

Another issue pertinent within modern manufacturing is the landscape of the workplace. People

Lance Owide, General Manager of B2B at BigCommerce, recently spoke with The Manufacturer about the role of AI in manufacturing and B2B ecommerce. In this article, Lance shares how manufacturers are already applying AI to drive efficiency, improve margins and streamline operations. He also outlines the essential foundations for getting started

Artificial intelligence is rapidly reshaping industries across the board, but few sectors stand to benefit as comprehensively as manufacturing. From sales and logistics to forecasting and inventory management, AI is proving its worth in driving efficiency, improving margins and creating more dynamic customer experiences.

Lance believes the manufacturing sector is particularly well-positioned to capitalise on AI’s potential. In a wideranging conversation, he outlined why AI is gaining momentum, what real-world applications are delivering results today, and how manufacturers can begin their AI journeys effectively.

Why AI has captured manufacturers’ attention

The manufacturing sector’s interest in AI is no passing trend. For Lance, it’s the promise of end-to-end optimisation that’s capturing attention - extending far beyond front-end sales automation to core processes like production planning, supply chain management and post-sale servicing.

“AI’s real draw is in its ability to boost revenue while driving efficiency and margin improvement,” he explained. “It’s not just the flashy stuff like chatbots. It’s about optimising how products are built, where they’re sent and how they’re supported after the sale. That has huge implications for the entire product lifecycle.”

Start small. Test and learn. Build internal advocacy. That’s how real transformation happens

Lance Owide, General Manager of B2B, BigCommerce

ABOVE: AI-powered product recommendations are incorporated into many ecommerce platforms

While elements of AI – such as demand forecasting models - have existed in manufacturing for some time, what’s new is the ability to feed those systems with real-time data. Inputs such as changing customer behaviours, seasonal patterns or even weather data, can now update predictive models dynamically, improving accuracy and responsiveness.

Real-world efficiency gains

Lance shared several practical examples where manufacturers are already seeing measurable returns from AI. In one case, a BigCommerce customer - a children’s product manufacturer - implemented AI-powered product recommendations on its ecommerce platform. The result? A more than 50% increase in product purchasing among users who interacted with these tools.

“This was about suggesting complementary products that distributors frequently purchased together,” Lance said. “It drove conversion and helped both the manufacturer and their buyers sell more effectively.”

Another standout use case involved automated quoting. One BigCommerce client, a manufacturer of mobile device accessories, developed an AI-based system that allows distributors to request and negotiate quotes directly on the website. The AI uses live pricing data, customer lifetime value and purchasing history to make dynamic offers - removing the salesperson from the initial quoting process entirely.

“The bot can negotiate within guardrails, and if it can’t reach an agreement, the process then gets passed to a human,” said Lance. “It’s a smart way to automate while still maintaining control.”

Strengthening the supply chain AI’s impact extends deeply into logistics and supply chain strategy. With dynamic pricing and predictive analytics, manufacturers can optimise everything from warehouse placement to shipping routes in real time.

“Think about placing inventory closer to where it’s being purchased,” Lance noted. “Manufacturers have long done this in a static way. AI now enables those decisions to be updated in real time, helping to reduce overheads and speed up sell-through.”

AI also plays a critical role in helping manufacturers manage disruptionsomething that’s become all too common in recent years. Whether it's navigating tariffs, pandemics or supplier shortages, AI can detect risk factors, run scenario planning models and suggest proactive mitigation strategies.

The promise of AI is in driving revenue, improving margins and creating efficiency across the entire product lifecycle

Lance Owide, General Manager of B2B, BigCommerce

BELOW: The manufacturing sector is particularly well-positioned to capitalise on AI’s potential