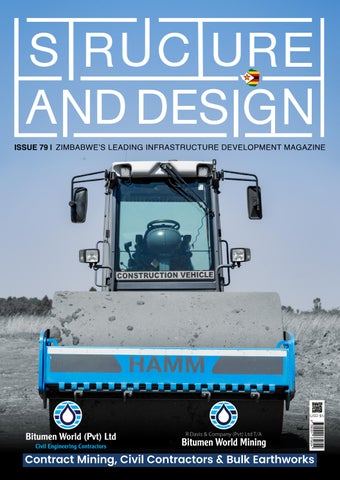

At Bitumen World, we deliver top-tier civil engineering solutions that stand the test of time. From roads and bridges to large-scale infrastructure projects, our expertise ensures quality, durability, and innovation in every build. Partner with us for a future engineered for success.

We are expanding beyond Zimbabwe, delivering high-impact projects in Mozambique and Zambia. We are driving growth, innovation, and operational excellence across borders.

HARARE OFFICE:

30 George Avenue, Msasa, Harare

Tel: +263 24 2447 231-3

Email: enquiries@bitumenworld.net

Website: www.bitumenworld.net

Civil Engineering Contractors

Bitumen World-Zimbabwe’s sporting infrastructure is getting a huge boost with the construction of an international-standard astroturf field at Hellenic Academy. Bitumen World is undertaking the four-month project, which began on August 1st and is set for completion on December 5th. The site, initially waterlogged, required extensive drainage work, including trial holes and a cutoff trench. After managing water levels, crews removed swampy soil and replaced it with a rock fill, creating a stable base. The field’s construction includes a 150mm G7 pavement layer, a 150mm sub-base layer, and a base layer using crushed stone from Pomona Stone Quarries. The final surface will be a 35mm-thick layer of asphalt applied in two passes, with subsoil drains installed around the perimeter. Bitumen World’s work culminates with the asphalt layer. Expert subcontractors from South Africa will then lay the astroturf, ensuring all specifications are met. The project also includes paved walkways, concrete curbing, and future fencing and lighting, promising a comprehensive, world-class facility.

Halsted Builders Express - has opened its 13th branch at the Honeydew Lifestyle Centre in Greendale, offering over 14,000 product lines. The new store’s design was a collaborative effort, with Architexture Spatial Design creating the plans, and Bruce Rowlands and Martyn Roberts providing conceptual and detailed drawings. Significant earthworks by Echo Earthworks were necessary to level the steeply sloping site, with retaining walls to ensure stability. Insor Aluminium Zimbabwe supplied the extensive glazing, while The Steel Building company, in conjunction with Emmanuel Consulting Engineers, provided and fitted the roof structure and steel girders. Scribante Concrete delivered the concrete for the polished floor slab, which was finished by Scope Contractors. Cool Runnings installed air-conditioning, and Da Souza Shopfitters supplied the dry walling and aluminum. Project manager Geoff van der Ruit from Skilfish Enterprises ensured a smooth construction process, with Kilsud Builders as the main contractor.

Windcatcher Construction - is setting a new standard for luxury and sustainable living with a new residential estate at 29 Steppes Road in Borrowdale. The development, slated for completion by mid-2026, will feature 20 four-bedroom, four-bathroom homes, each on a generous 1,250 sqm plot. The project’s design tackles the site’s challenges, including poor water supply and a difficult slope. To address these issues, developers have implemented a unique, closed-loop water and waste management system. This includes a bio-digestion plant from Danish company Kaackai to treat all sewage. The project also has a comprehensive rainwater harvesting plan, with an anticipated collection of up to 4 million litres annually, to be stored and filtered for use. The challenging slope has allowed for unique, individual home designs. Inarch Design and civil engineer Harvey Rapson have ensured robust structural and water engineering. The steel trusses, deliberately oversized by Brown Engineering, have been transformed into a prominent architectural feature.

While every effort has been made to ensure the accuracy of its content, neither editor nor publisher can be held responsible for any omissions or errors: or for any misfortune, injury, or damages which may arise there-of.

All rights reserved. Copyright 2025

No Part of this magazine may be reproduced or transmitted in any form or by any means electric or mechanical, including photocopying or recording.

SCAN QR CODE

OUR PROJECTS

CROCO MOTORS V-FALLS

REVO SERVICE STATION

ZUVA SERVICE STATION

SIMBISA BRANDS BALMAIN/NORICH (N RICHARD STORES)

ATTICUS INVESTMENT KHAYA CEMENT

GAFUNKEL RESTAURANT

Mautric Electrical Pvt LTD set its foot as an electrical supply and equipment trading and services company. Over the years, the company has earned a reputation for excellence and professionalism for continuously striving to meet - and even exceed - standards which set the climate for a sustainable business relationship with its clients.

As an electrical solution specialist, we offer electrical power products ranging from transformers, switch gears, breakers, XLPE cables, panel boards, power meters, and switches. The company also offers control products such as variable frequency drive, soft starters, UPS, AVR, batteries, motors and even lighting fixtures.

Our team is composed of technically skilled and highly dedicated personnel working cohesively to promote value-added solutions with a competitive pricing structure to suit your needs.

We also engage in electrical product installations, testing and commissioning, preventive maintenance, automation, and energy saving solutions.

PUBLISHER

Caast Media Group

MARKETING

Tinashe Mafiko

Newton Musara +263 781 421 866 +263 781 512 568 +263 78 953 2918

DESIGN, LAYOUT & VIDEOGRAPHY WEBSITE & SOCIAL MEDIA

Saul Chidakwa

Zimiso Geoffrey Nyamande

Olga Gertrude Dzingo

Princess Kuvengurwa

Tinaani Francis Garikayi

Albert Chitumba

JOURNALISTS

Martin Chemhere

Michael Nott

DISTRIBUTION

Itai Kanyemba Gift Sepi

PHOTOGRAPHY CAAST MEDIA GROUP

EMAIL marketing1@caastmedia.org markerting@structureanddesign.co.zw

FIND US AT 31 Alexander Rd, Highlands, Harare

In recent years, the Zimbabwean sporting infrastructure has had a huge boost, putting the country into the international spotlight. Currently, Bitumen World is constructing an international standard astroturf field at a new site between Newlands and Borrowdale, for Hellenic Academy.

The project, valued at just under US$1 million, is a four-month undertaking that began on August 1st and is slated for completion on December 5th. This new facility, which will span under 8,000 square meters, promises to elevate the standards of sports in the country, with its construction adhering to international specifications.

FOR VIDEO

Nathanael Khanye, the project's site engineer, provided a detailed look into the technical aspects of the construction. The site initially presented a significant challenge: it was waterlogged and close to swampy areas. The first week of the project was dedicated to mitigating this issue. The team carried out several trial holes and dug a cutoff trench to continuously manage water levels. This meticulous approach was crucial before proceeding with the main earthworks.

Once the drainage was under control, the crew began the topsoil removal and a series of cut-to-waste operations. A particularly swampy section required the removal of 300 millimetres of black cotton soil, which was then replaced with a 300-millimeter-thick rock fill. This foundational work ensured a stable and well-drained base for the subsequent layers.

The project's layering process is a critical part of achieving an international standard playing surface. The first pavement layer applied was a G7 layer, 150 millimetres thick, which has already been completed. This was followed by the sub-base layer, also 150 millimetres thick. The next phase involved laying the base layer, which will utilize crushed stone from Pomona Stone Quarries.

Upon completion of the base layer, the field will be surfaced with a 35-millimeter-thick layer of asphalt. This will be applied in two passes: a 20-millimeter layer followed by a 15-millimeter top layer. To further address potential water issues, subsoil drains will be installed around the entire field, spanning the northern, eastern, and southern sides.

"The levels are the most critical aspect of this project," said Khanye. "We need to make sure that the levels are within the specifications to produce a valuable product." The Bitumen World team works closely with the design engineer, Consolve Engineering Solutions, and performs its own checks to ensure the surface is perfectly flat and meets all required standards.

Bitumen World's scope of work extends up to the final asphalt layer. The official astroturf will then be laid by expert subcontractors who are based in South Africa. These specialists will verify that Bitumen World's work meets the required acceptance criteria before proceeding with the final turf installation.

The project also includes the construction of paved walkways and concrete curbing to provide easy access for pedestrians. Other aspects of the project, such as fencing and lighting, will be handled by different subcontractors brought in by the client, ensuring a comprehensive and complete facility.

With approximately 65% of the project completed, Nathanael Khanye confirmed that the team is on track and potentially ahead of schedule. "We're very much excited to be doing these turfs," he said, highlighting that this isn't their first such project, with a recent successful completion at Falcon College.

Bitumen World's initiative to partner with schools like Hellenic is part of a broader mission to improve the sports industry in Zimbabwe. The renowned firm is constructing facilities that meet international standards, and aims to ensure that hockey players have access to the same quality of playing surfaces as their counterparts in countries like the United Kingdom and other first world countries.

This project demonstrates the commitment of companies like Bitumen World to invest in and uplift the nation's sporting future.

Looking for building materials and hardware all in one convenient place? Halsted Builders Express has you covered. Their brand-new store at Honeydew Lifestyle Centre in Greendale brings their network to 13 branches nationwide. Along with durable, top-quality building materials, they stock an extensive range of paints, plumbing and electrical goods, kitchen and bathroom fittings, tools, and just about everything you need for construction.

You’ll also find everyday essentials such as bulbs, mops, adhesives, garden supplies, and even decorative items - over 14,000 product lines sourced both locally and internationally. And with experienced, well-trained staff on hand to give expert advice, Halsteds makes it easy to find exactly what you need, all under one roof.

When Halsted made the decision to open a new store at Honeydew, the existing retail space was not adequate for their needs. An impressive extension was considered and subsequently constructed to meet Halsted’s requirements, while still retaining the overall feel and aesthetic of the complex.

Well-known local firm, Architexture Spatial Design, drew up the plans with Bruce Rowlands providing the

PROJECT CONSULTANTS

Plans and renders courtesy of Architexture Spatial Design

Emmanuel Consulting Engineers (ECE)

Project Manager: Skilfish Enterprises

Main Contractor: Kilsud Builders

The Steel Building company

Echo Earthworks

Scibante Concrete

Inso Aluminium Zimbabwe

Scope Contractors

Da Souza Shopfitters

Cool Runnings

conceptual design and Martyn Roberts providing detailed working drawings and architectural supervision.

The new extension fits seamlessly on to the original existing building and Rowlands has kept to the materials

palette of the surrounding structures in the complex – exposed face brick, green Chromadek roofing, some decorative exterior timber cladding and loads of aluminium and glass.

There are two entrances to the shop, one northfacing (existing), and one south-facing (new)

which looks towards Food Lover’s. Both the north and the south entrances have extensive glazing for natural light – the north façade has vertical steel and timber slats to break up direct sun, while the south entrance has a large roof overhang for shade and shelter.

Inso Aluminium Zimbabwe supplied the aluminium and glass for the extensive glazing.

Both entrances have till points for customers’ convenience, so there’s no waiting to pay.

The west façade, facing the car park, has no glazing to protect the interior from the harsh afternoon sun.

Rather than presenting a large blank wall, it has been clad

in vertical stripes of protruding brick work and timber strips. The timber was recycled from the floorboards used in the offices of the old Food Lover’s. The west wall also provides ample space for Halsted’s corporate signage and branding.

Also, on the western side a new ablution block, adjacent to Alfresco, the bakery, helps to blend the old and new structures (there are also plans to extend Alfresco into the little courtyard created by the new building). The eastern side is reserved for deliveries and dispatch. The large roller shutter door was salvaged from the original

building and re-used in a new position. Joining the existing roof to the new roof was a bit of a jigsaw puzzle as the roof ridges are set at perpendicular angles, but an ingenious solution was worked out whereby the two slopes meet neatly and efficiently.

The roof structure, the steel girders and the cladding, was supplied and fitted by The Steel Building company in conjunction with Engineer Fred Smith from Emmanuel Consulting Engineers (ECE).

Both the old and the new roofs have high translucent sky

lights for additional natural light – augmented by pendant lights when necessary. The roof in the new section appears higher as the floor slab steps down about 600mm from the existing to the new sections. The extra volume gained increases the feeling of uncluttered spaciousness.

The site slopes quite steeply from the northern side adjacent to Greendale Avenue, down towards the side facing the new Food Lovers, so fairly extensive earthworks (by Echo Earthworks) were needed to level the ground, and retaining walls were needed to stabilise the site. Apart

from the interior change in level the entrance to the south side has been built up by about a metre with wide steps up the doors. The floor slab is 160mm grade 30 concrete with 235 steel mesh with nylon fibre added to prevent surface cracks.

Premix concrete for the slab was delivered on site by Scibante Concrete and then ground, polished and sealed by Scope Contractors to an attractive and durable finish.

There are two mezzanine floors inside – one on the north side which has offices and a boardroom, while on the south side there are offices, the IT server and a small staff kitchenette. The dry walling and the aluminium were supplied by Da Souza Shopfitters. Cool Runnings supplied the air-conditioning for the vast warehouse-like space to keep the customers comfortable throughout the year.

The extension has doubled the size of the original shop allowing Halsted much more space to display their range. A small, plastered wall section on the interior melds the two buildings together to blend seamlessly. The extension was completed in just a few months, in time for the opening on 1st September, with the grand opening set for November.

Geoff van der Ruit from Skilfish Enterprises was the project manager ensuring that the construction happened smoothly, while the main contractor was Kilsud Builders who also did the plumbing and other necessary work as needed. Electrical work and the lighting were mostly done by Halsted’s in-house team. Several years ago, Architexture drew up a plan for the whole of Honeydew, although it has been adapted over time as new developments arise. Part of the masterplan includes a new double storey East Block for additional shops and offices, which will link Halsted to the main Food Lover’s complex.

Honeydew Lifestyle Centre has multiple outlets including restaurants, a pharmacy, a hairdresser, a baby shop, a clothing shop, a stationery shop and even an ATM – among many others. It really is a one-stop shopping destination and conveniently located just off Samora Machel Avenue. The history of Halsted goes back to humble beginnings in 1949, when brothers Robert and Paul Halsted opened Halsted Bros. in Bulawayo. The first branch in Harare (then Salisbury) followed in 1964, with more branches opening across the country in the years that followed. In 2014, the company rebranded to Halsted Builders Express and introduced the tagline “Serious About Quality.”

From the start, their commitment has been to build with and for Zimbabweans, providing the best products and service through continual innovation and growth. Today, they proudly live their vision of “Building Tomorrow Together,” with stores in Msasa, Workington, Borrowdale, Mazorodze, Honeydew, Willowvale, Bulawayo, Kwekwe, Masvingo, Mutare, Marondera, Victoria Falls, and Gweru. Despite phenomenal expansion, Halsteds remains a family-run business focused on customer satisfaction, employing 32 staff members at Honeydew and over 850 nationwide.

Windcatcher Construction, a Harare-based firm, is developing a new and upmarket residential estate at 29 Steppes Road, Borrowdale, a project that is setting a new standard for luxury, modern design, and sustainable living. The homes are designed with four bedrooms and four bathrooms, each a generous 302 square meters on a 1,250 square meter plot.

The target completion date is mid-2026, with an expected timeline of two years for the full complement of 20 houses. The estate is within easy reach of a number of shopping malls in Rolf Valley, Chisipite, Highlands and Borrowdale Village, all convenient and attractive for prospective home owners.

Main contractor: Windcatcher Construction

Designed by: InArc Design

Civil engineer: Harvey Rapson

Steel trusses by: Brown Engineering

Concrete premix: Pomona Stone Quarries

Eathworks by: Kobot Earth Moving

Bio-digestion plant: Kaackai

Stormwater pipes: DripTech

Images and video by Caast Media Group

Text by Martin Chemhere

All sewage and effluent from the homes will be directed into a large septic tank, where it will undergo a four-stage treatment process.

Windcatcher has made a name for itself by designing homes that redefine contemporary living. Their philosophy balances aesthetics with practicality, emphasizing environmental responsibility. The homes feature open-concept layouts, filled with natural light and cutting-edge design elements.

The use of premium materials creates an atmosphere of understated elegance and sophistication, a hallmark of Windcatcher’s developments. According to Richard Wild the director, Windcatcher Construction in collaboration with Inarc Design (PVT) Ltd, has consistently delivered innovative residential solutions.

He notes that this particular project’s commitment to sustainability is impressive, especially given the challenges of the location. The site is known for its poor water supply and a steep slope that makes connecting to the municipal sewer system prohibitively expensive. In response, the developers have created a unique, closed-loop system that manages water and waste efficiently.

The treated water, known as “blue water,” is non-potable but will be used for irrigating the common lawns and gardens through a system of G-jets. This innovative approach ensures no water is wasted and prevents the need for an external sewer connection.

Water sustainability is a top priority, and the project has a comprehensive plan for managing its water resources. With an anticipated capture area of approximately 8,000 square meters, the project could collect as much as 8 million litres of water annually from rainfall.

Even with a conservative estimate, about 4 million litres of water could be captured and stored in a large dam at the base of the property. This water will be filtered and stored in a separate 317,000-litre tank, ready for use.

The project also benefits from five on-site boreholes and a municipal water connection that provides water every few weeks. This hybrid system ensures a reliable water supply for all residents.

Borehole water will be used for in-house consumption, while captured rainwater and municipal water will be used for gardens and external needs. All wastewater from the homes will flow into the bio-digestion system, creating a self-sustaining cycle where nothing is wasted.

The site’s steep, ten-meter slope has presented a unique set of design and engineering challenges. The changing gradient has necessitated extensive terracing to prevent runoff and erosion. To manage the large volume of water that will flow down the slope during rainy periods, 400mm stormwater pipes from DripTech will be installed underground.

This will collect the water and distribute it down the property, preventing erosion and protecting the integrity of the driveways and retaining walls.

The slope has also allowed for the creation of unique, individual houses, each with its own character and design considerations. Working with teams like InArc Design and civil engineer Harvey Rapson, the developers have skilfully navigated these challenges, ensuring that the structural and water engineering is robust and reliable.

The project also features off-the-grid systems, including solar panels and inverters for electricity and gas for water heating. These solutions, combined with the on-site water and waste management systems, make the community a self-reliant ecosystem, reducing its reliance on external infrastructure.

The project is a result of a long-standing collaboration between Windcatcher Construction and Brown Engineering and a shared vision to create homes that are not only aesthetically pleasing. All their projects are harmoniously integrated with their natural environment.

Brown Engineering, the steel truss manufacturers, have deliberately oversized the steel, transforming a typically functional element into a prominent architectural feature. This approach is perfectly suited for the modern trend of open-plan living, where kitchens, dining rooms, and lounges flow seamlessly into one another, creating expansive, shared family spaces.

The design incorporates a steel ring beam that distributes the weight of the structure, allowing for the precise placement of trusses. Steel brackets, fixed within the concrete of the ring beam, enable the trusses to be welded into place with perfect accuracy, ensuring an even distribution of weight. This method provides significant advantages over traditional timber constructions, as steel eliminates the risk of sagging over long spans. The visible steelwork also contributes to the home’s contemporary aesthetic, giving it a sleek, industrial feel.

Brown Engineering has also designed an upturned purlin system using 76mm by 50mm sections, spaced every 450mm centre to centre. This allows for an impressive 1.8-meter span, a feat that would require a much shorter span in a typical timber truss design. While steel C-sections could allow for even larger spans of up to 3 meters, they would make the roof structure look visually sparse.

The project also incorporates timber elements. Instead of using speed screws, standard 75mm timber and safe top nails are used for fixing the roof sheets. This tried-and-tested method also integrates an open-ended glass gable into the truss, a sophisticated touch that maximizes natural light and ties the structure together. The steel trusses are primed and painted a neutral grey but can be customized to the homeowner’s preference.

Windcatcher Construction has once again expanded its impressive portfolio with the completion of the new residential estates, marking another significant milestone in their upmarket developments. This project is a piece of modern engineering, sustainable design, and a collaborative vision.

The new estates are a symbol of a shared commitment between Windcatcher Construction and Brown Engineering to a more sustainable and beautiful future for Harare. Together, these companies are building not only residences but also communities that embody innovation and a dedication to environmental stewardship. The project is being developed in partnership with Brown Engineering, a leading steelworks company.

Quality Crushed Products

3mm Dust • 7mm Dust

7mm Stone • 10mm Stone

13mm Surfacing Stone

19mm Surfacing Stone

20mm Stone

40mm Stone

Granite Boulders

Decomposed Filling