(Below) Sunlight permeates through the petals of a peony May 22 at Hidden Springs Peony Farm near Spring Grove. The Kubes family, who owns the farm, previously lived in the Twin Cities.

BY AMY KYLLO STAFF WRITER

SPRING GROVE —

Laura Kubes inherited peonies from her grandmother and great-grandmother.

Now, since purchasing a peony farm a few years ago, over 600 varieties of peonies shower her rural Spring Grove acreage with vibrant blooms.

The location is Hidden Springs Peony Farm, owned by Kubes and her husband, Bryan, and their daughters, Gwen, Bianca and Mira. The family purchased the flower farm — which opened in 2012 — in late 2022.

bouquet they pick or that is pre-picked, or stop by the greenhouse, where there are potted peonies, fruit trees, unusual perennials and native plants.

The farm is open every day in season, and the public is welcome to come see the flowers regardless of whether they make a purchase. The peony field is close to the driveway, making it easier for those with mobility issues to experience the flowers.

With a legacy of passing down peonies, Kubes said buying the peony farm felt right.

“Peonies can be a family heirloom,” she said. “They live for more than 100 years, and they’re just such a great and beautiful sign of spring. I think it’s something fabulous to look forward to after a long winter.”

In the spring, guest can visit the farm with its 2.5-acre peony field, buy a

“This is a peony farm,” Kubes said. “It should be shared; it should be enjoyed.”

Last fall, the farm sold peony roots to customers in 45 states, and Kubes said she estimates the farm received thousands of in-person visitors.

She said one of the most common things she visits with customers about is the peonies they remember their family having.

“I hope (our peonies) conjure memories of Grand-

ma’s garden and bring you back to that place,” she said. “I hope the peonies that people purchase become family heirlooms for their daughters and sons and future generations to come.”

The only paid flower experience at the farm is their evening picnic events. Each guest is given a lunch basket, drink and small bouquet of flowers. Guests can come when they want and stay as long as they want, all while listening to live music.

Kubes page 2

Published by Star Publications

Copyright 2025 522 Sinclair Lewis Ave. Sauk Centre, MN 56378

Phone: 320-352-6577 | Fax: 320-352-5647

NEWS STAFF

Mark Klaphake, General Manager, mark.k@dairystar.com

Amy Kyllo, Editor, amy.k@star-pub.com

Tiffany Klaphake, Writer, tiffany.k@dairystar.com

Ben Sonnek, Writer, ben.s@saukherald.com

Emily Breth, Writer, emily.b@star-pub.com

Rae Lanzrath, Writer, rae.l@star-pub.com

Sara Hoppe, Copy Editor

Publisher:

Joyce Frericks, 320-352-6577, joyce@saukherald.com

Story ideas send to: amy.k@star-pub.com

SALES STAFF

Laura Seljan, 507-350-2217, laura.s@dairystar.com

Julia Merten, 507-438-7739, julia.m@star-pub.com

Bob Leukam, 320-260-1248, bob.l@star-pub.com

PRODUCTION STAFF

Amanda Thooft, amanda@saukherald.com

Cheyenne Middendorf, cheyenne@star-pub.com

Nadiia Griepentrog, nadiia@star-pub.com

ISSN Print: 2834-6491 | Online: 2834-6505

Deadlines:

Country Acres South will be published the first Saturday of every month. Deadline for news and advertising is the Friday a week before publication.

“The peonies aren’t in bloom for a super long time, so we want as many people to enjoy them while they are at their peak as possible,” Kubes said.

area, the Kubes family operates by the same philosophy the original owners of the farm had: If the box stores sell it, they do not.

Kubes said her favorite part of the farm is watching the field develop across the season.

“(There are) so many plants in this world we can grow,” Kubes said. “We don’t all have to focus on the same thing.”

Single white peonies are Kubes’ favorite, while she said her husband enjoys the double, fragrant peonies. The three most asked-for peonies on the farm are the yellow, coral and fern varieties.

“The newspaper of today is the history of tomorrow.”

“It’s so fun just to come and walk through and see all the flowers,” she said. “There are different colors that take over at different times in the peony season. … Every one smells different; every one looks a little different. There’s always some that you see that you didn’t think a peony could look like that.”

In the greenhouse

The first peonies on the farm were planted by the previous owners in 2008. The Kubes family bought the business when these owners were

retiring. The timing was right for the Kubes family, as they had been looking to move out of the Twin Cities to a rural home and acreage where they could

grow a niche crop.

“We were … looking to get out of the rat race, slow down, live more of a small-town life,” Kubes

Kubes page 3

said.

from page 2

Kubes had been working as a meteorologist at KARE 11.

“News and weather don’t take a break,” Kubes said. “It just wasn’t a super family-friendly position, working nights, working weekends, being on call. We really just wanted more family time together, rather than passing in the night.”

They soon decided to go forward with the peony farm purchase.

“All the pieces of the puzzle were there, the timing was right, the place was right, the people were right,” Kubes said. “Without ever seeing the peonies in bloom, we bought the property and moved down here.”

Kubes began working on the farm full time, although she still tapes her gardening segments at KARE 11 once a month or so. Bryan works full time off the farm but helps when he can.

Kubes said the first peony season was stressful, as she learned how to operate the business and manage the plants.

“We felt comfortable taking over the business side of things because (the former owners) were so great in showing us their process,” Kubes said. “(They made) it as easy as possible to step into a business they had already built.”

The peonies are simple to care for, Kubes said. Their main challenge is weed control. They have not needed to irrigate or fertilize, and wildlife does not seem to bother the plants.

“(They) seem like they’d be a fussy plant because they’re so big, and they’re beautiful, and they’ve got these massive flowers,” she said. “They don’t need anything but

sun.”

The family has integrated into the community, with their children enrolled at the local public school and Kubes volunteering as president of the Spring Grove Area Chamber of Commerce.

“We were a little worried that we would be branded city slickers and not welcome, but everyone has been so welcoming,” Kubes said. “We want to be part of the local community, and we’re

happy that they want us to be (as well).”

The farm will likely encompass the rest of her career.

“We imagine ourselves at this property for years and years to come,” Kubes said. “Hopefully one day, one of (our daughters) will want to carry on the business. I’m not holding my breath because that doesn’t always happen, but that would be my goal.”

On Saturday, May 17, I boarded a Delta flight at 6 a.m. alongside my boyfriend to fly to Georgia to meet his family.

I was nervous. Ever since we met about a year ago, I had heard all about his home. As time went on, it had become abundantly clear that, since I really like this sweet Georgia boy, eventually, I wanted to meet his family.

There’s something rather intimidating about traveling well over 1,000 miles to meet someone. There’s no dropping by Georgia for supper. Beyond that, there’s all the normal nerves of hoping they like you and that you don’t accidentally say something stupid.

The night before my flight, knowing I was quite likely progressively freaking out, my sister and her husband called me to settle me down and help me to relax and enjoy the whole experience. They encouraged me to be myself and not to fall into the trap of being fake.

As everyone had told me, all the meetings went well. His family was very kind to me, and their efforts to make time to see me were really appreciated. I had met a couple of them over Zoom, but this was the first in-person meeting with any of them. Of his over 12 family members in Georgia, we managed to catch 11 while down there. His dad and mom were so sweet to me. The look of joy on his mom’s face when we arrived and as she gave her precious son a hug let me know just how much he is loved. From homemade meals to hugs, I was blessed by his family.

Of course, seeing family was the main reason for our visit, but this was also my first time in Georgia. Here are a few observations:

The traffic. As my boyfriend had warned me, the traffic in Georgia, especially in the Atlanta metro, is more intimidating than Minnesota. In the metro area, highways can be 16 lanes wide, and the abundance of cars creates veritable seas of metal. Traffic is also much swifter, with 10 mph over the speed limit the starting point for speed for most drivers.

The countryside. The biggest thing I noticed about the area I was in east of Atlanta was how much more wooded it was. I rarely saw row crop fields, so it was mostly either pastureland or woods.

Secondly, the trees seem like they grow a bit taller. I wonder if the milder climate makes it easier for them to thrive. Finally, since they do not have to worry about leaving space for snow removal, the trees are allowed to grow so much closer to the road. The ditches are minimal, and shoulders are almost nonexistent on certain roads. There were freeways with tree branches extending above the right lane, which was crazy to me.

I had to try some authentic food while visiting. My boyfriend’s sister-inlaw made us a meal with black eyed peas, collard greens, barbecued chicken, peach cobbler and sweet tea. I liked everything I tried, albeit some of the flavors were not as familiar. My boyfriend took me to one of his favorite local barbecue places, where I could try the authentic, non-sweet barbecue. The tanginess of the meat was a change from most places up here in the North, but it was really delicious. His mom also made us a meal, which was good — especially the apple turnover I enjoyed as dessert. His mom owns an athome bakery business, which means tasty baked goods are always to be found.

Besides spending time with his family, we also got to visit some sights. We traveled to Gibbs Gardens, which is a privately owned estate with hundreds of acres of woods, gardens, landscaped ponds and more. We saw roses in bloom and fields of poppies as well as a view of the distant mountains. My boyfriend enjoys photography and has a professional camera, so I got my own photo shoot. I enjoy photos of myself in aesthetic surroundings as much as the next person, so that was a fun treat.

We also explored the Georgia Aquarium in Atlanta, which is the largest aquarium in the U.S. We saw sharks, beluga whales, dolphins and so much more in their many exhibits.

I like to buy souvenirs at fun places I visit, so I came home from the trip with three wildly overpriced T-shirts. I might have to downsize my current T-shirt collection to accommodate.

More fun than anything I saw, however, was just spending a few days exploring with my boyfriend. It was a gloriously happy trip and a big reminder of the many things I appreciate about him. I feel honored that such a good man would want to show me his home and introduce me to his family. I am blessed.

“Dairy

about our

animals. We’re recyclers, we’re good to the environment. Dairy products are safe to consume and are good for us.”

Kids participated in seven activities: a presentation on dairy nutrition and the bovine rumen; a dairythemed obstacle course; a

tour of the dairy; feeding calves; experiencing the milking parlor; going on a hayride; and getting out of a dairy-themed escape trailer. Students also had a cheeseburger lunch in the farm shop.

“I hope that they can say they learned at least one thing,” Turner said. “If that one thing is even just ‘We have dairy farms in Houston County, and it’s a fun place to be,’ that would be fantastic.”

Turner was assisted by 15-20 volunteers, including all three members of Houston County’s dairy royalty, FFA students and the Welscher family.

Dairy farmer Joe Welscher led kids in their experience of the milk house and parlor. Welscher milks 300 cows alongside his two brothers, Jay and Jim, and his two sons, Kyle

Blue View Dairy page 9

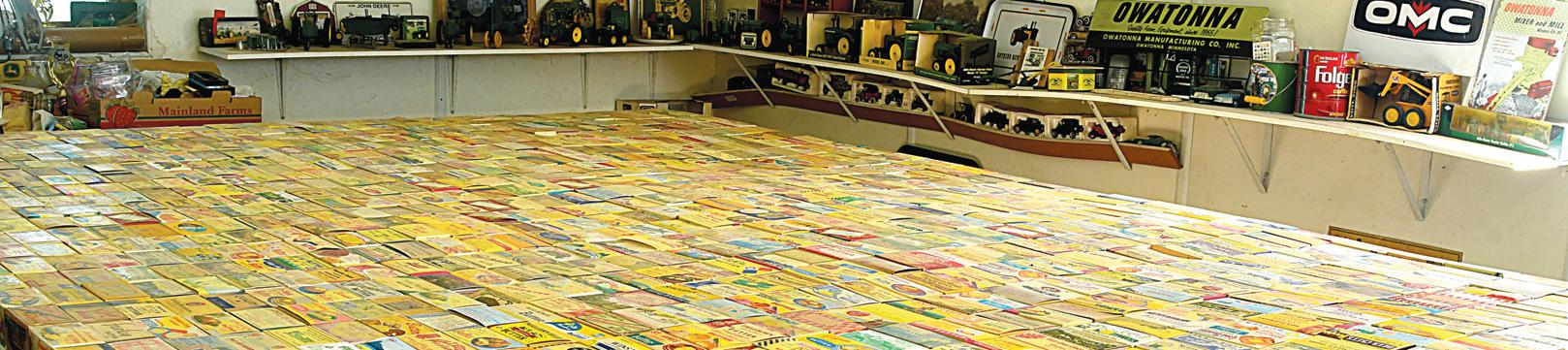

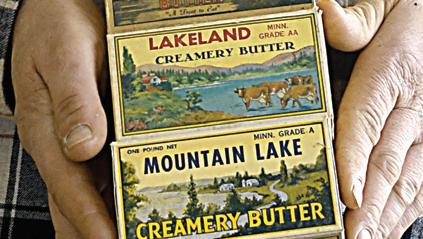

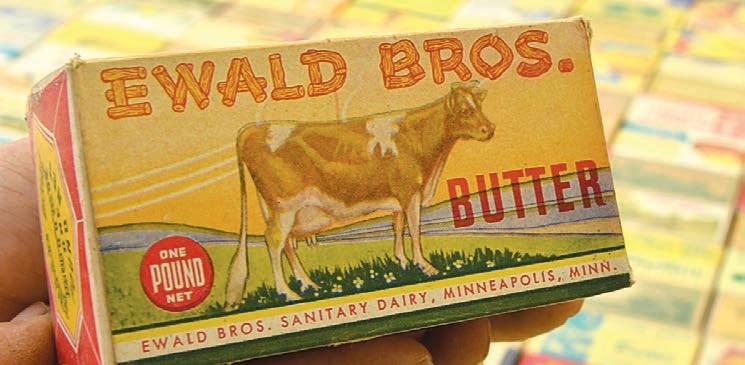

Butter boxes line an 8- by 12-foot table March 6 at the Krause family farm near

about

“It’s an addiction,” Krause said. “If I drank beer as much as I collect butter boxes, I’d be alcoholic.”

BY AMY KYLLO STAFF WRITER

OWATONNA —

Ninety-six square feet of table-top real estate holds about two-thirds of Scott Krause’s butter box collection. The 8by 12- foot table space holds about 980 boxes. And yes, these are butter boxes, the small, branded cardboard containers which hold four sticks of buttery deliciousness.

Though he has never counted his full collection, Krause believes it numbers around 1,500 boxes, of which about 1,000 are unique.

“It’s a rush when you find one that you don’t have,” Krause said.

Krause and his dad, Loren, milked around 100-120 cows until 2021. Now, Krause raises beef and dairy animals.

A collection of dairy product cartons is displayed March 6 at the Krause family farm near Owatonna. In addition to his dairy related collection, Scott Krause also collects John Deere farm toys and has about 1,500 beer cans.

His butter box collection spans about 100 years of butter boxes. His earliest boxes are from the 1920s, he said, and a few familiar boxes from the current decade also grace his collection. Most boxes are from the 1950s and 1960s.

“That was a time when a lot of those creameries (were) a center point of most little communities,” Krause said.

Krause’s collection has boxes representing creameries largely from Minnesota, Wisconsin, Iowa, South Dakota and Krause page 11

BY AMY KYLLO STAFF WRITER

ALTURA — Stetson Mumma has a passion for color. Bright, vibrant, loud color. He also has a passion for woodworking, and through his wood and epoxy art, he has blended these two enthusiasms.

Mumma is the owner of Whitewater Wood Company LLC. He creates wood pieces like charcuterie boards — which are his most popular item — game boards, jewelry boxes, memorial plaques, award

( LEFT)

plaques, counter tops, and fall and Christmas home decor with poured epoxy detailing. Mumma operates his business from rural Altura.

“Epoxy will never be the same twice,” Mumma said. “If you ask me to replicate this, I couldn’t do it. … That’s what makes it a one-ofa-kind piece.”

Mumma’s work is 90% custom. This extends to carving words and images into the pieces using a computer numerical control machine.

“Once people know that I can personalize it,

all the general stuff goes right out the window,” Mumma said.

Much of his work is commissioned gifts.

“When I got married, … there are two (gifts) that I remember, and they were personalized,” Mumma said.

“It’s personalized, and it means something.”

Mumma’s journey to being the creator he is today started in Cub Scouts in Colorado, where he enjoyed the woodworking project. Mumma took as many woodworking classes as he could in high school.

After high school, his

A fall-themed charcuterie board sits March 12 at Stetson Mumma’s shop near Altura. Charcuterie boards are Mumma’s

first big project was making several massive, heavy poker tables.

ive, his w ne-

After marrying his wife, Erin, who grew up in southeast Minnesota, his woodworking journey continued as he redid the doors and trim at their Colorado home and would work on woodcarving out in his garage.

However, it was a date night glass blowing class that launched him.

“(It) reignited my creative passion,” Mumma said.

Mumma page 15

A gameboard Minnesota detailing sits March 12 at Stetson Mumma’s shop near creates charcuterie boards, jewelry boxes, memorial plaques, award counter tops, and fall and Christmas home decor. most popular item. ) A ecorated with nnesota sit h at Stetson Altura. Mumma eates charcuteri boards, game jewelry memoria pl p aques, plaques, unter tops ristmas me deco

Stetson Mumma pours epoxy March 12 at his shop near Altura. The epoxy is expensive to work with, costing at minimum $80 a gallon.

hole a few times, and I was really drawn to the epoxy,” Mumma said.

from page 14

Mumma began helping the glass blower for free several nights a week.

“It was magical,” he said. “That’s the best way I could put it because it’s pure creation.”

“It was kind of combining my love of woodworking and glass blowing because, (with) glass, you can make so many different colors.”

Mumma began experimenting, making gifts for his mom out of epoxy and wood.

After moving to Minnesota to get more space for their family of five and lower living expenses, Mumma discovered epoxy pouring with wood.

“I went down a YouTube rabbit

“She was a good guinea pig,” Mumma said. “I would be like, ‘Hey, I made this for you for Mother’s Day, but you have to show your friends.’”

16

from page 15

As time went on, Mumma’s business began to grow with orders coming in on Facebook. Today, he is a full-time dad of three daughters, and Whitewater Wood Co. keeps him busy a bit under full time.

Mumma said he is thankful for Erin’s support of the business.

“Without her … chasing this dream of mine wouldn’t be possible,” Mumma said. “She truly is amazing and I couldn’t do this without her.”

Mumma has social media channels on Facebook, Instagram, YouTube and TikTok. He has 6,241 followers on TikTok and has begun to do brand deals

with epoxy supplies companies. His content includes short form and long form videos showing projects from start to finish as well as tips and tricks for wood working and epoxy.

Mumma has a whiteboard in his shop listing the projects he is working on and whether he has been shooting the videos for that project in horizontal or vertical mode. Choosing the orientation can be challenging, as vertical orientation performs well on short-form prioritizing platforms like Instagram and TikTok, while horizontal orientation does well on YouTube.

Mumma said he is thankful for social media because it has allowed him to grow his business, which he said he does not think would survive in a traditional brick-and-mortar store. He relies on online orders for his business.

Each project starts with Mumma selecting a piece of wood, looking for cool grain and features. He removes the bark and gets the piece to the desired thickness. Then, the wood has any custom carving done,

and the epoxy is poured.

Working with epoxy is challenging, as there are many variables such as cure rates, shop temperature and time of pour to manage, Mumma said. The two biggest enemies of epoxy, he said, are humidity and dust. Humidity can affect cure rate, and dust can settle into the drying epoxy and affect the finished look.

After the epoxy is partially thickened and dried, he adds in the swirled designs.

“It’s unique,” Mumma said. “Each piece that I create is one of one.”

Mumma colors the epoxy using a either a dye, which will create an opaque look, or mica powder, which is more translucent.

The epoxy is expensive to work with, costing at minimum $80 a gallon.

Once the epoxy has cured, he sands the piece down and finishes it.

When it comes to

getting orders, one of the challenges, Mumma said, is he is essentially trying to sell a picture on social media. Several years into his business, he invested in a light box to get better photos and saw a corresponding increase in orders. Business ebbs and flows throughout the year. Mumma starts advertising for Christmas gifts in late July or August. He said while it can be nerve wracking waiting for orders during the slower times of the year, he uses that time to hone existing skills, while also doing experimenting to keep his business fresh. He also utilizes that time to check off things on the “honey-do” list his wife has requested.

“I have this battle in my own head where I’ll be super busy and have 10 orders going and 10 on the board ready to go, and I just want to get done so I can make something I want to do,” Mumma said. “Then, you get to that place, and you’re like, ‘Where are the orders?’”

Mumma wants to continue to do the work himself and does not want to hire employees. He wants just enough work to keep him busy and happy.

“It’s just awesome making stuff that people love,” Mumma said. “I’m flattered that they put it in their home. … I love creating things, and this is a really good outlet for that.”

Tony said Joshua can cut up a pig by himself and often gets up early to get done with chores so he can work on butchering.

Tony has processed meat for his own use for his whole life, but two years ago, he became state certified for butchering.

The coronavirus pandemic launched Tony on the certification journey. During that time, he helped others learn how to butcher their own animals. This time also illuminated the lack of local processing facilities.

“When COVID hit, you couldn't get in for two years,” Tony said. “If you had animals sold, you're stuck.”

Food supply unknowns during the coronavirus pandemic also provided opportu-

nities for Golden Hawk Farms.

“It fell into the whole food security (and) where your food comes from,” Tony said. “It just fell into that whole new marketing strategy.”

The Heppners buy their beef animals as calves and then finish them. Tony spent part of his career working in beef nutrition.

“I know how to change a carcass just by changing feed,” he said. The beef animal ration is high forage, and then they are finished on

grain. Tony said feeding is important for how the meat turns out.

“You can tell the difference,” he said. “You can tell how they've been fed just by how they come in. … That's really what I enjoy.”

Tony does not use implants or other growth encouragers. He also does not push for a large size at harvest because he feels the energy required versus the size gained is inefficient.

Heppner page 20